Method for ultrasonically detecting weld quality of main loop pipeline of nuclear power plant by phased array

An ultrasonic detection and phased array technology, which is applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, can solve the problems of hidden dangers in the safe operation of nuclear power facilities, easy to miss detection, and cumbersome detection procedures, and achieve stable and reliable detection results. High-precision, highly adjustable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

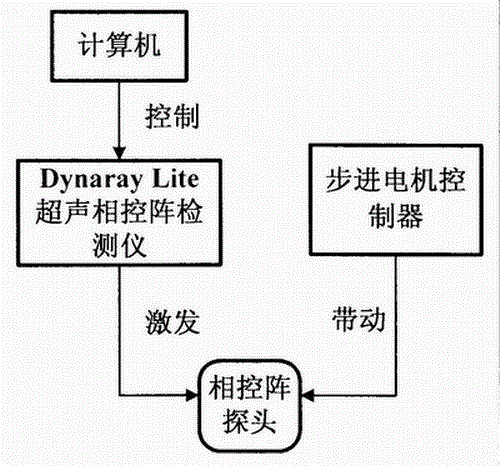

[0022] The method of phased array ultrasonic detection of weld seam quality of main circuit pipeline of nuclear power plant is composed of figure 1 The Dynaray Lite ultrasonic phased array detector shown, UltraVision3.2R9 phased array operating system, low frequency dual crystal longitudinal wave area probe, scanner and calibration test block are composed. It can detect centrifugally cast austenitic stainless steel nuclear power plant main circuit pipes with a wall thickness of 66-99mm. The detection process is as follows:

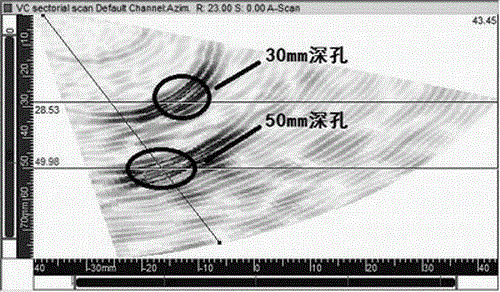

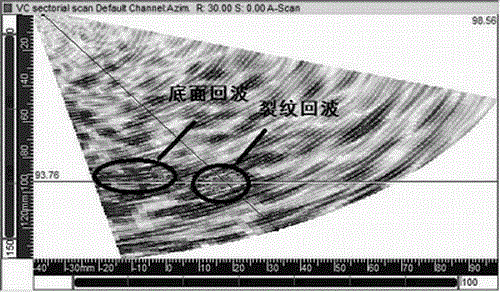

[0023] (1) For the centrifugally cast austenitic stainless steel phased array test axial test block with a thickness of 92mm, it is known that the welding method is narrow gap automatic welding, and 100% inspection must be carried out on the weld seam and the range of 10mm adjacent to the base metal. Surface treatment of the tested part: For the contact surface, remove welding spatter and any rough things that hinder the free movement of the probe or weak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com