Ultrasonic measurement and inversion method for elastic constant of coating layer with uniform substrate

A technique for measuring elastic constants and ultrasonic waves, which can be used in measuring devices, using sonic/ultrasonic/infrasonic waves to analyze solids, and using sonic/ultrasonic/infrasonic waves for material analysis, etc. The initial value has strong robustness, improves measurement accuracy, and improves the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

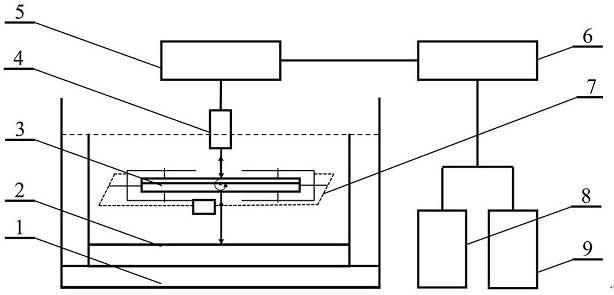

[0038] figure 1 A schematic structural diagram of an ultrasonic measurement system for the elastic constant of a uniform substrate coating layer is shown. In the figure, the ultrasonic measurement system for the elastic constant of the uniform base coating layer includes a water tank 1, a back reflector 2, a coating sample 3, an ultrasonic water immersion probe 4, an XYZ three-dimensional stepping device 5, and an ultrasonic flaw detector 6 , rotating angle measuring device 7, GHz sampling frequency oscilloscope 8 and computer 9, the back reflector 2 is located at the bottom of the tank 1, the rotating angle measuring device 7 is located directly above the back reflector 2, and the coating layer sample 3 is fixed on On the rotating angle measuring device 7, the ultrasonic water immersion probe 4 is set directly above the coating layer sample 3, the XYZ three-dimensional stepping device 5 is electrically connected to the ultrasonic water immersion probe 4 and the ultrasonic fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com