Ultrasonic nondestructive testing device and method for T-shaped composite structure and R-region detection method and device

A technology of composite structure and detection method, which is applied in the direction of measuring device, analysis of solids by using sound wave/ultrasonic wave/infrasonic wave, material analysis by using sound wave/ultrasonic wave/infrasonic wave, etc. It can solve the problems of high measurement cost, poor detection effect and poor acoustic coupling effect And other problems, to achieve the effect of improving detection accuracy, improving stability and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

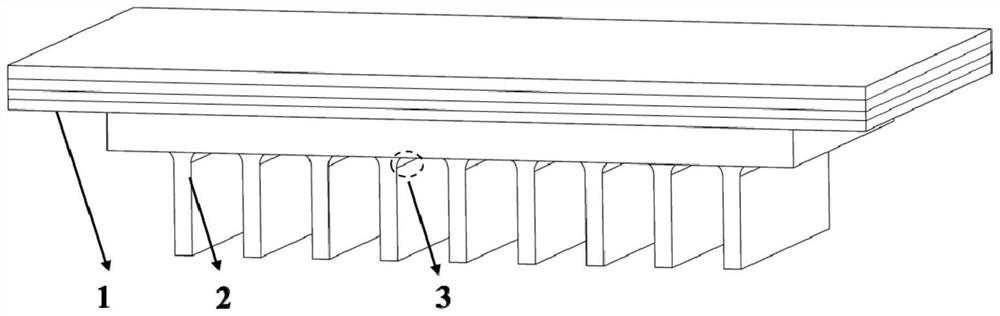

[0089] Embodiment 1. This embodiment proposes a method for detecting the back side of defects in the R region of a T-shaped composite structure, which is characterized in that the method is:

[0090] Ultrasonic signals are emitted from the back of the R zone and outside the top composite material layer, and echo signals are collected, and whether there is a defect in the R zone to be detected is obtained according to the echo signal, and the coordinates of the defect position are determined.

Embodiment approach 2

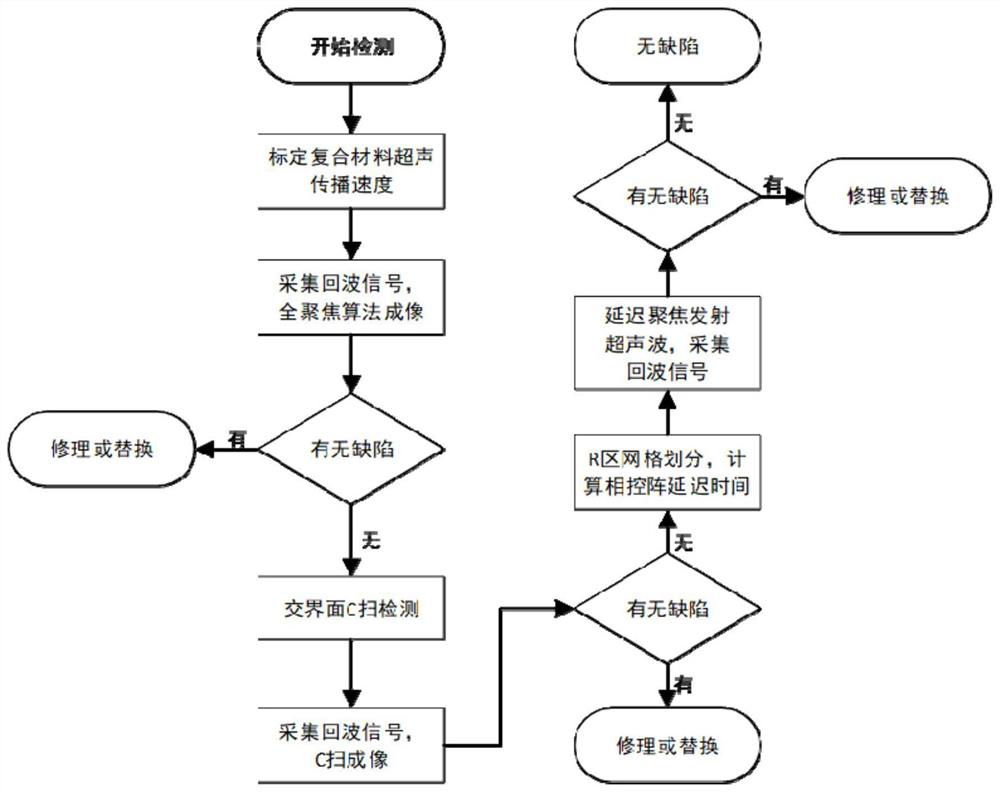

[0091] Embodiment 2. Combination figure 1 and 4 This embodiment is described. This embodiment is a further limitation of the back detection method for R-zone defects of a T-shaped composite structure proposed in Embodiment 1. The method is as follows:

[0092] Calibrate the propagation speed of ultrasonic waves in all directions inside the top composite material to be tested;

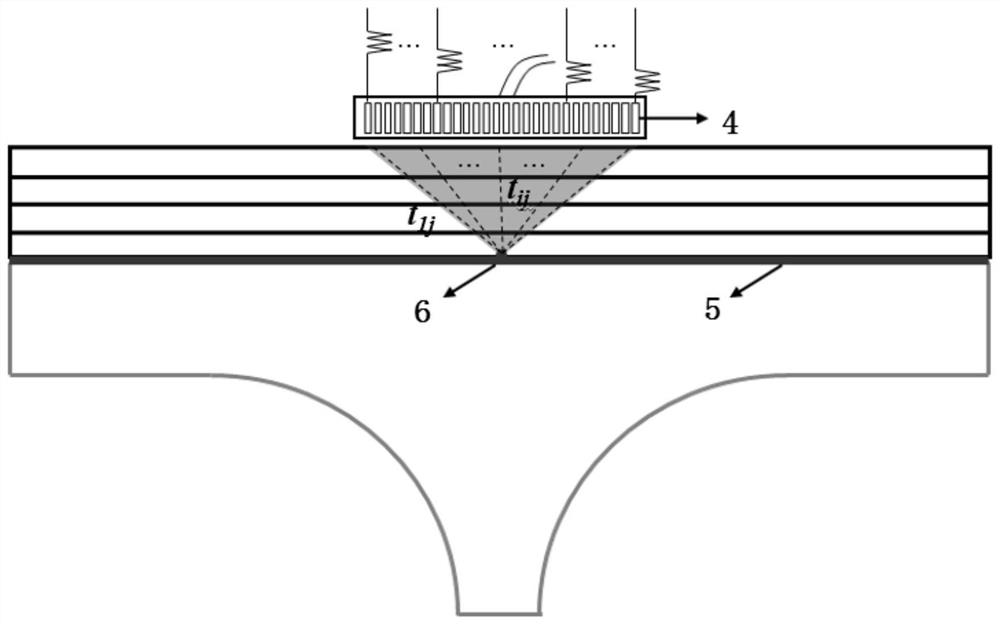

[0093] The target area to be detected is divided into grids to obtain multiple grid points, and each grid point is detected from the back of the R area one by one with an ultrasonic phased array:

[0094] For the i-th array element of the ultrasonic phased array, according to the Fermat principle, the coordinates of the ultrasonic phased array are obtained as (x i ,z i ) The i-th array element transmits the ultrasonic wave through two layers of media to the propagation time T of the focal point P i :

[0095]

[0096] Among them, c 1 Indicates the ultrasonic propagation velocity of the first l...

Embodiment approach 3

[0103] Embodiment 3. This embodiment proposes a rear ultrasonic nondestructive testing device for defects in the R zone of a T-shaped composite structure. The device includes:

[0104] propagation time T i The acquisition module is used to obtain the coordinates of the phased array according to Fermat's principle as (x i ,z i ) from the upper part of the T-shaped composite structure for the i-th array element to transmit ultrasonic waves through two layers of media to reach the focal point P with propagation time T i :

[0105]

[0106] In the formula, c 1 Indicates the ultrasonic propagation speed of the first layer of medium, c 2 Indicates the ultrasonic propagation velocity of the second layer medium, (x s ,z s ) represents the incident point coordinates of the ultrasonic wave from the first layer of medium to the second layer of medium, (x 0 ,z 0 ) represents the coordinates of the focal point of emitting ultrasonic waves, H represents the thickness of the top l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com