Distance and angle synchronously-adjustable linkage device, receiving and transmitting module and plane stress field detection device and method

A stress field and angle adjustment technology, which is applied in the direction of measuring devices, measuring force, photovoltaic power generation, etc., can solve the problem that the deflection angle of the transmitting and receiving transducers cannot be consistent.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

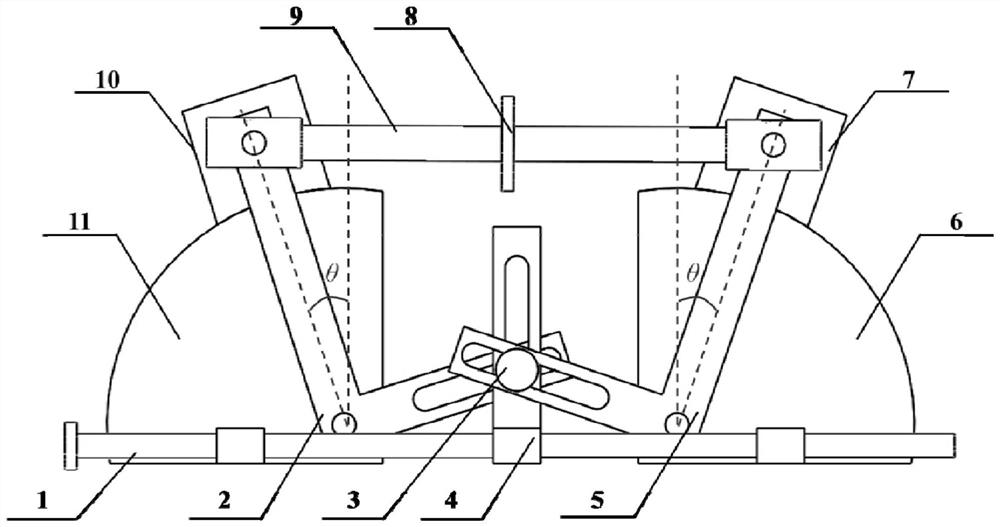

[0045] Implementation Mode 1, see figure 1 Describe this embodiment. This embodiment provides a linkage device with synchronously adjustable distance and angle. The device includes: a base, a distance adjusting screw 1, an angle adjusting screw 9, a left connecting rod 2, and a right connecting rod 5. Axle column 4 and column lock 3; the screw rod of the distance adjustment screw 1 is fixedly connected with the base, the shaft column 4 is a cuboid, the upper half has a long strip-shaped through hole, and the lower half has a circular through hole. hole, and the opening directions of the elongated through hole and the circular through hole are perpendicular to each other, and the circular through hole in the lower part of the shaft column 4 is fixed in the middle of the screw rod of the distance adjusting screw 1 position, the threads of the threaded areas of the screw located on both sides of the shaft column 4 are opposite, and the threaded areas on both sides of the screw ar...

Embodiment approach 2

[0046] Implementation mode two, see figure 1 Describe this embodiment. This embodiment is a further limitation of a synchronously adjustable distance and angle linkage device provided in Embodiment 1. The device also includes: a distance adjustment handwheel and an angle adjustment handwheel 8; The distance adjusting handwheel is used to drive the distance adjusting screw 1 to rotate; the angle adjusting handwheel 8 is used to drive the angle adjusting screw 9 to rotate.

Embodiment approach 3

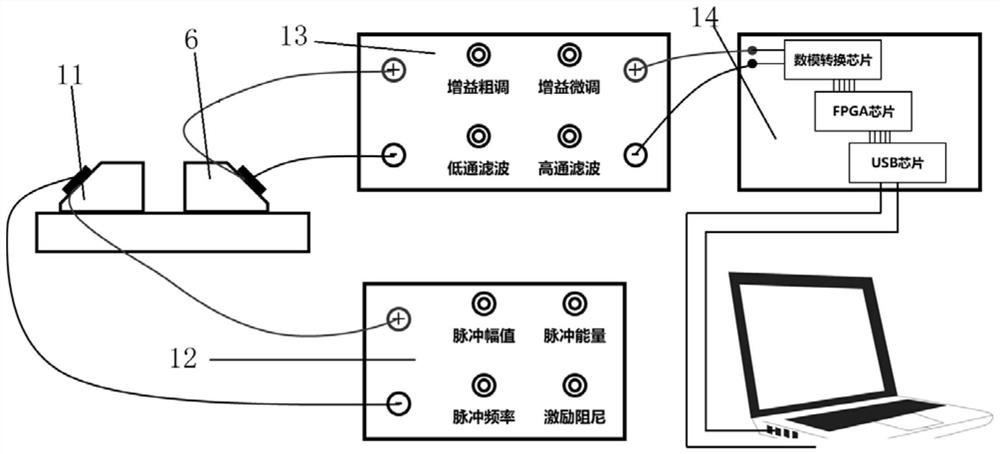

[0047] Implementation mode three, see figure 1 This embodiment is described. This embodiment provides a transceiver module of a plane stress field detection device whose distance and angle can be adjusted synchronously. The module includes: a linkage structure, a receiving end wedge 6, a receiving probe 7, and a transmitting end wedge Block 11 and transmitting probe 10; described linkage structure is a kind of distance and angle synchronously adjustable linkage device described in claim 1 or 2; described receiving end wedge 6 and transmitting end wedge 11 are mirror-symmetrically arranged on on the base, and are respectively fixedly connected with the two nuts of the distance adjusting lead screw 1, the receiving probe 7 and the transmitting probe 10 are mirror-symmetrically arranged, and are respectively located on the receiving end wedge 6 and the transmitting end wedge 11, and the receiving probe The middle part of 7 is connected with the receiving end wedge 6 through a rot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle of refraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com