Method for identifying defect ultrasonic signals in steel ingot based on support vector machine

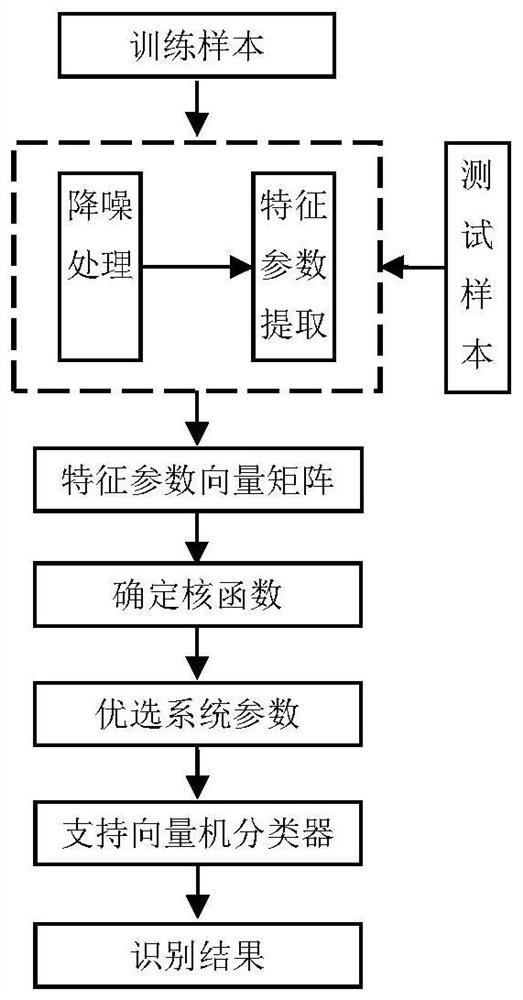

A support vector machine and identification method technology, applied in the field of ultrasonic nondestructive testing, can solve problems such as difficult identification of defect types, complex waveforms of ultrasonic detection signals, and ultrasonic signals of defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with concrete experiment the present invention will be further described:

[0028] The implementation process of this experiment includes the following steps:

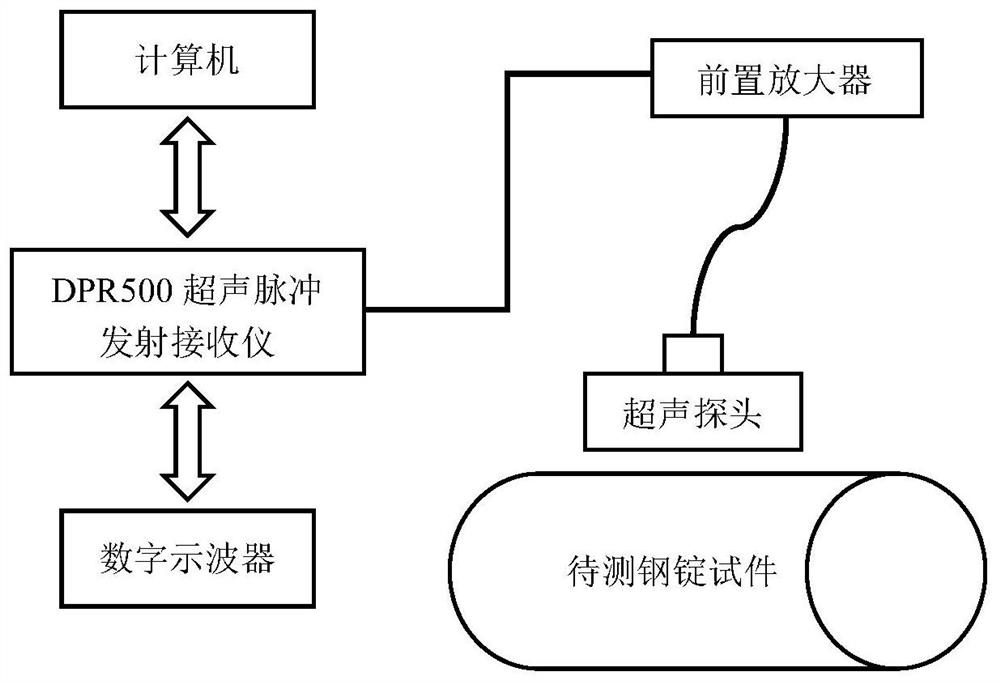

[0029] 1. Experimental system and test pieces: according to figure 2 The experimental device system diagram shown in the figure builds the experimental system, which mainly includes a computer, DPR 500 ultrasonic pulse transmitter receiver, ultrasonic probe, digital oscilloscope and preamplifier. The ultrasonic probe is Shanchao 1Z30N probe, the center frequency of the probe is 1MHz, the diameter of the probe is 30mm, the excitation signal is a negative sharp pulse, and the sampling frequency is 10MHz. The steel ingots to be tested are 4330 and 42CrMo die-cast billet steel ingots, which contain shrinkage cavity defects and porosity defects respectively. The ultrasonic probe is facing the steel ingot specimen to be tested. The ultrasonic probe is connected to the DPR 500 ultrasonic pulse t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com