Auto-collimation device for ultrasonic non-destructive testing probe based on manipulator and working method

A technology of non-destructive testing and ultrasonic probes, which is applied in the direction of manipulators, measuring devices, program-controlled manipulators, etc., and can solve problems such as inability to meet special requirements, poor flexibility and applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

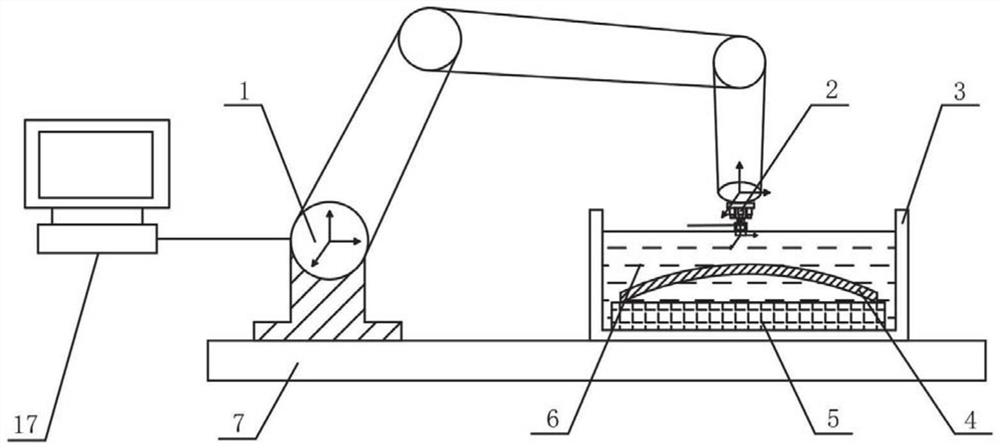

[0066] Such as figure 1 As shown, the self-collimation device of the ultrasonic non-destructive testing probe based on the manipulator of the present invention is set on the front end of the six-degree-of-freedom articulated manipulator 1 for use, the six-degree-of-freedom articulated manipulator 1 is set on the workbench 7, and the six-degree-of-freedom articulated manipulator 1. An industrial computer 17 is connected by wires. A water tank 3 is also provided on the workbench 7. A coupling agent 6 is provided in the water tank 3. A workpiece clamping device 5 is immersed in the coupling agent 6. A similar dipping device is installed above the workpiece clamping device 5. The workpiece 4 to be measured in the couplant 6; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com