Method for detecting defects of additive manufacturing part based on ultrasonic phased array

An ultrasonic phased array and additive manufacturing technology, which is applied in the use of sound waves/ultrasonic waves/infrasonic waves for material analysis, use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, and measuring devices, etc., can solve problems such as poor detection results and missed detection , to achieve the effect of improving the positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

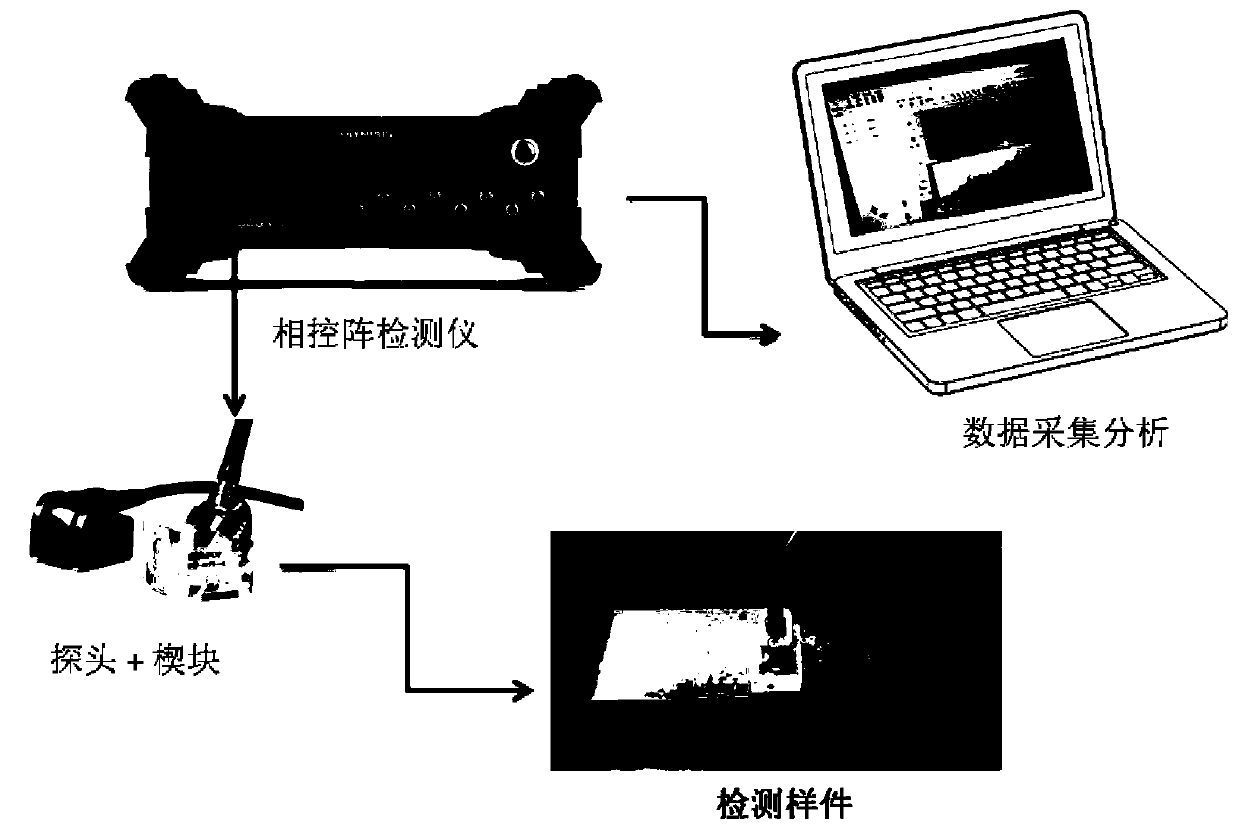

[0042] This embodiment is to detect the defects of titanium alloy parts prepared by laser additive manufacturing technology, and the comparison test block used is a titanium alloy test block prepared by the same material and process.

[0043] Explanation of terms:

[0044] Group:

[0045] In data acquisition analysis software, a group is a defined configuration of all parameters required to generate one or more ultrasonic sound velocities using a conventional or phased array probe. A group can use the same probe for pulse transmission and signal reception, or use two different probes to transmit pulses and receive signals respectively, and one probe can be used by multiple groups.

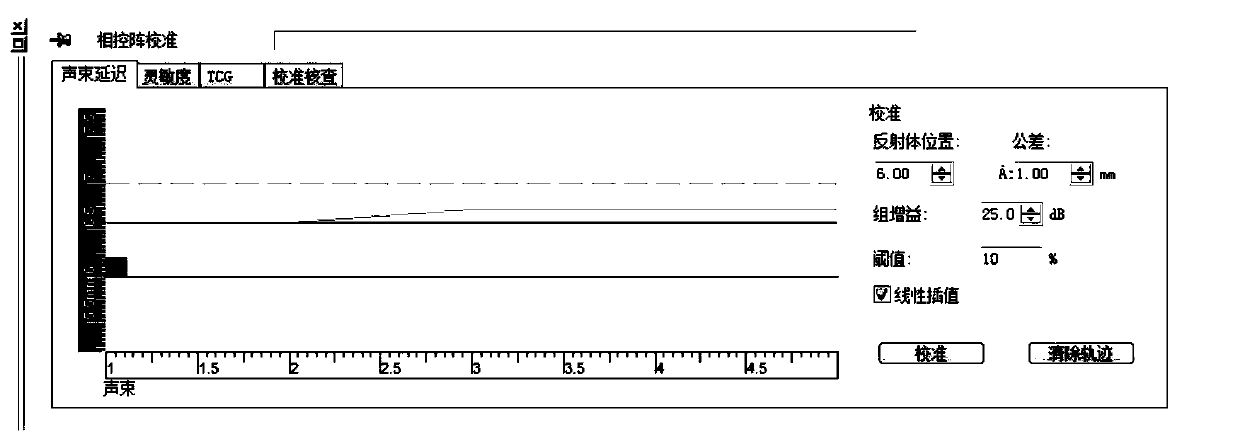

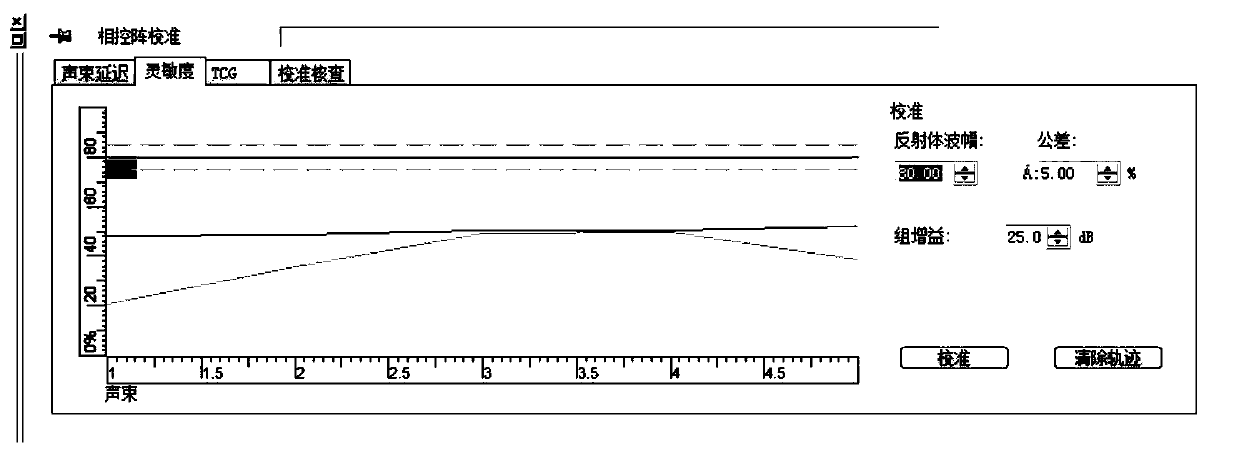

[0046] To calibrate the sound velocity delay:

[0047] The purpose of calibrating phased array sound velocity delays is to adjust the delay of each sound velocity so that all sound velocity-acquired indications of a known reflector defect appear at the correct depth. Each group must perform this...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com