Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

76 results about "Three point flexural test" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The three-point bending flexural test provides values for the modulus of elasticity in bending Ef, flexural stress σf, flexural strain εf and the flexural stress–strain response of the material. The main advantage of a three-point flexural test is the ease of the specimen preparation and testing. However, this method has also some disadvantages: the results of the testing method are sensitive to specimen and loading geometry and strain rate.

Test method for J-R resistance curve of high-toughness material

ActiveCN102353595AAvoid restrictionsMaterial strength using steady bending forcesMaterials testingLarge deformation

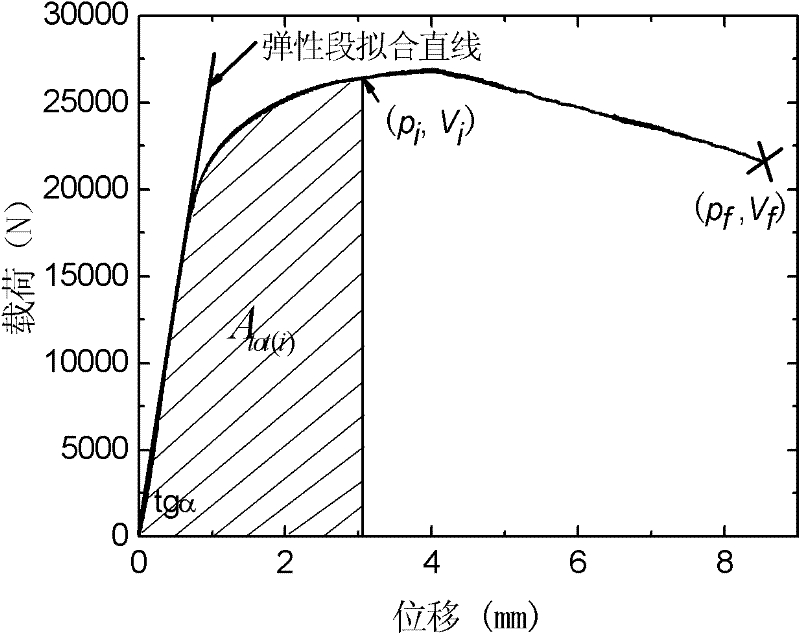

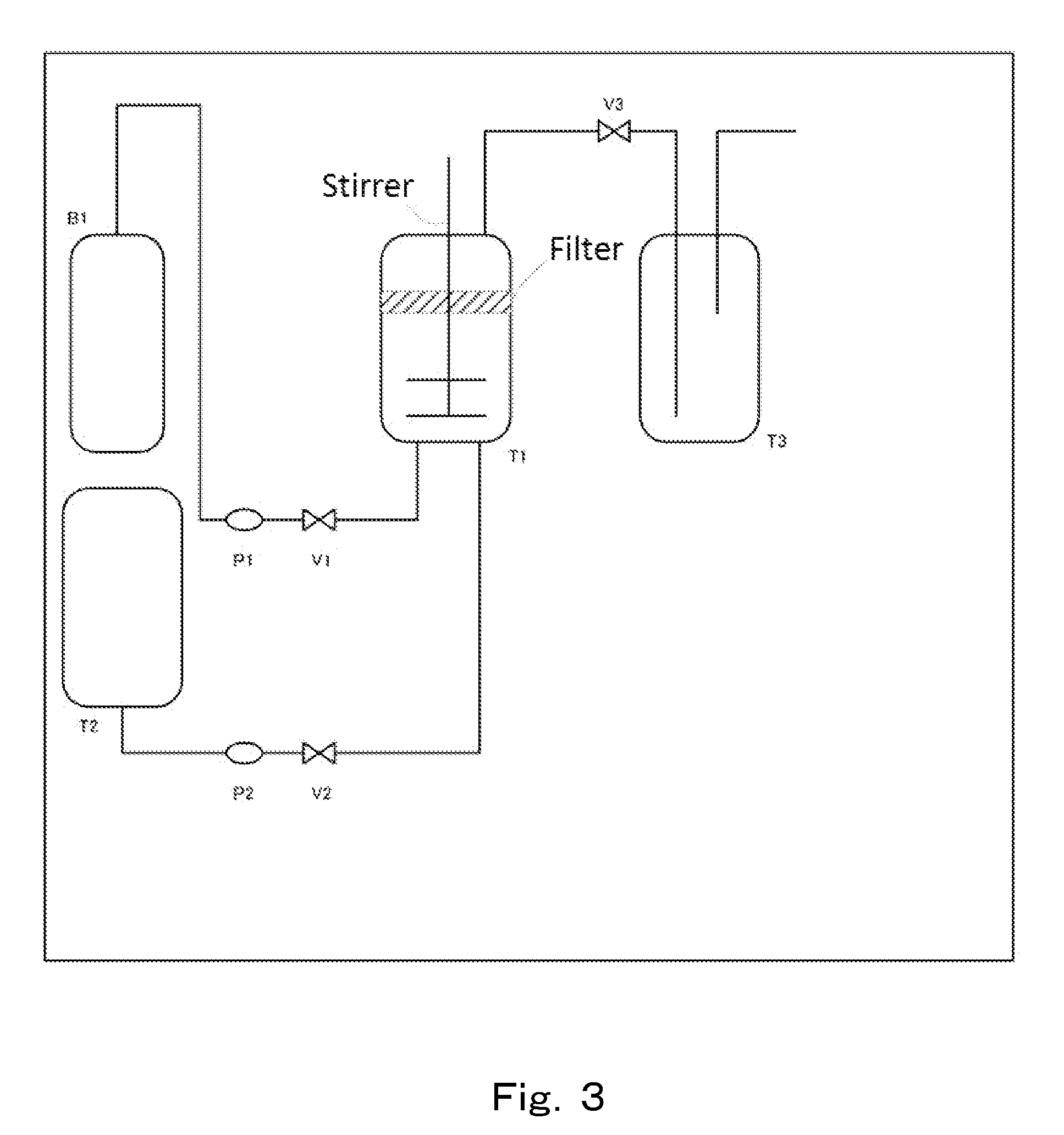

The invention relates to a test method for a J-R resistance curve of a high-toughness material. The method comprises the steps of sample processing, three point bending test, determination of crack length, calculation of J-integration at every load, establishment of a difference function, recursive calculation of crack length and p-V data pairs and construction of the J-R resistance curve. According to the invention, an extensometer is not employed for testing opening displacement and unloading flexibility of a crack mouth; instead, a testing machine is used for direct acquisition of deformation of a three point bending sample and a load-displacement curve in the whole process of fracture; then, the J-R resistance curve of the material is obtained through a series of calculation; therefore, the problem of restriction of testing apparatuses caused by large deformation of a sample in the testing of high-toughness materials is overcome, a J-R resistance curve in the situation of expandedlong size crack is measured, and the test method is applicable to measuring of J-R resistance curves of samples at different temperature and with different dimension.

Owner:EAST CHINA UNIV OF SCI & TECH

Toner

A toner has toner particles containing a binder resin that comprises a block polymer as a main component, obtained by chemically bonding a crystalline polyester resin with an amorphous polyurethane resin, wherein the binder resin has a specific content of a crystalline polyester resin component, and has a concentration of ester bonds derived from the crystalline polyester resin component of not more than 5.2 mmol / g, and The maximum value EMAX of the flexural elasticity modulus E in a three-point bending test on the toner and the strain energy u for the toner satisfy specific values.

Owner:CANON KK

Three/four-point bending performance test general clamp for material

ActiveCN103674692AImprove efficiencyEliminate replacement timeStrength propertiesTest efficiencyFour point flexural test

The invention belongs to clamps for testing material mechanical properties, and relates to a three / four-point bending performance test general clamp for a material. The three / four-point bending performance test general clamp provided by the invention helps to improve the three / four-point bending performance test efficiency, and especially helps to substantially improve the four-point bending performance test efficiency. Under the prerequisite of satisfying domestic and foreign test standards, five technical measures are employed for improving the efficiency of test preparation work, and specifically the five technical measures comprise generalizing the clamp, displaying span in digital manner, arranging scale on a bearer and performing bidirectional centering. The general clamp provided by the invention is capable of finishing three / four-point bending performance tests, so that the clamp replacing time is saved. When the three-point bending performance test is carried out, only an appropriate pressure head needs installing after two pressure-head seats of the clamp are in contact.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Experimental device for evaluating pumping oil polish rod coating for fatigue strength influence

ActiveCN101281109AFacilitates a true reflection of the effects of fatigue performanceEasy to filterMaterial strength using repeated/pulsating forcesControl systemUltimate tensile strength

The invention discloses a test device for evaluating the effect of an oil pumping polished rod coating upon a fatigue strength, including a three-point bending test machine, a tension-tension fatigue test machine and an analysis sample, the three-point bending test machine includes a pressure adding roller wheel, a pressure head clip, a three-point bending support and a support roller post, the tension-tension fatigue test machine includes an upper fixture, the pressure adding roller wheel and the pressure head clip of the three-point bending test machine which are arranged into integration in the upper fixture, wherein, the upper fixture connects with a control system through a sensor and connecting lines, the analysis sample is horizontally placed on the support roller post of the three-point bending test machine, and the pressure adding roller wheel faces a rod-like fatigue sample. Through combining the control system of the tension-tension fatigue test machine and the support and the pressure head of the three-point bending test machine, a three-point bending test can be carried out to realize the simulation of the bending fatigue process in the scope of 10 centimeters underneath the clip of the oil pumping polished rod in oil field site, when using the device of the invention, the effect of the coating upon the fatigue strength can be effectively evaluated.

Owner:ANTON OILFIELD SERVICES (GRP) LTD

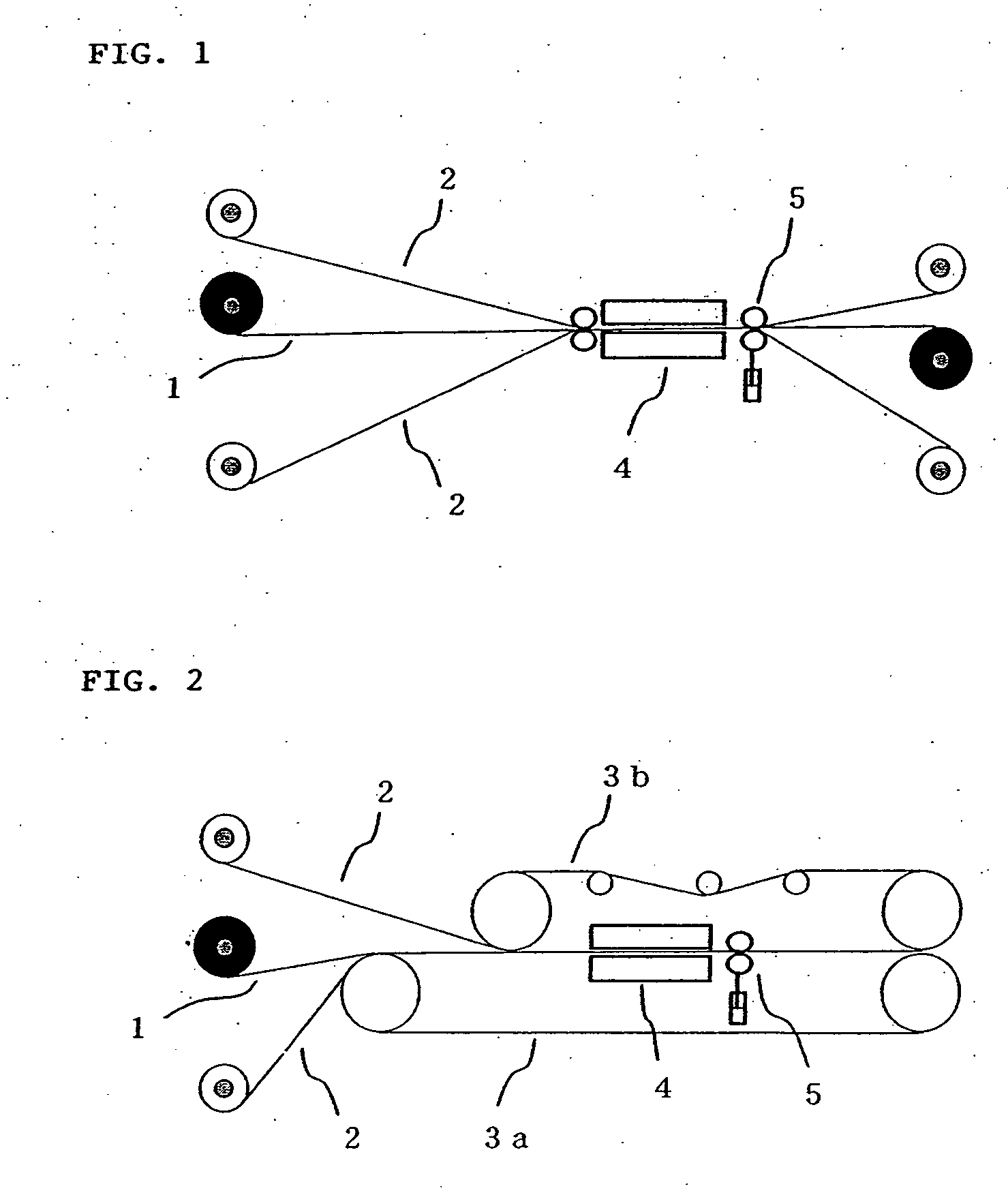

Porous carbon electrode substrate and its production method and carbon fiber paper

InactiveUS20050100498A1Improve conductivityIncrease flexibilityFinal product manufactureActive material electrodesFiberCarbon fibers

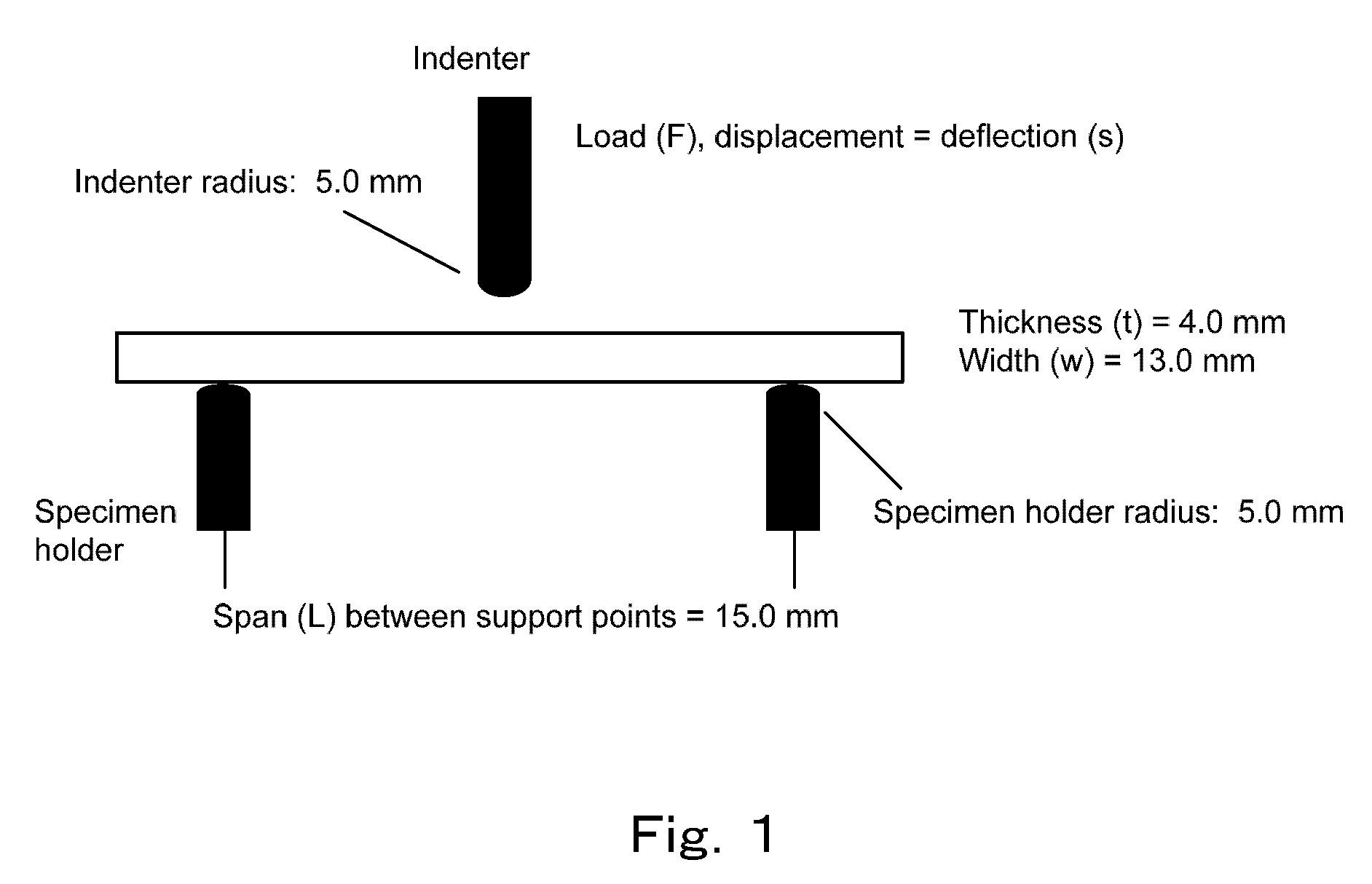

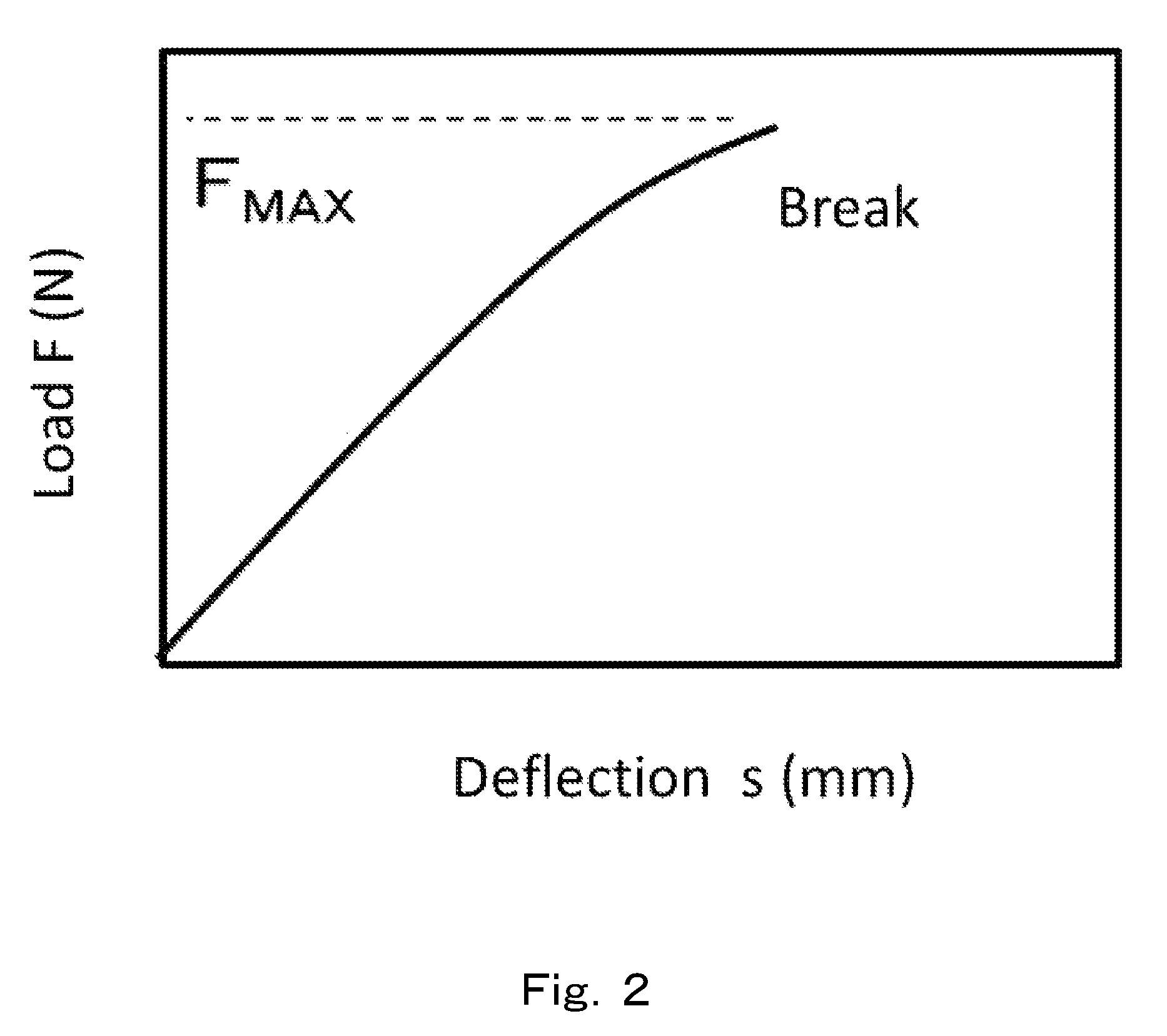

The present invention provides carbon fiber paper consisting of an organic high-molecular compound as a binder and carbon fibers, characterized in that the carbon fibers contain thin fibers with an average diameter smaller than 5 μm and an average fiber length of 3 to 10 mm; a porous carbon electrode substrate for a fuel cell having a thickness of 0.05 to 0.5 mm and a bulk density of 0.3 to 0.8 g / cm3, also having a bending strength of 10 MPa or higher and a deflection of 1.5 mm or more at the time of bending, measured by a three-point bending test in conditions of using a sample width of 1 cm, a strain rate of 10 mm / min, and a distance between supporting points of 2 cm; and a method of producing a porous carbon electrode substrate for a fuel cell by impregnating the carbon fiber paper with a thermosetting resin, curing the thermosetting resin by heating and pressing treatment, and then carbonizing the paper. The electrode substrate of the present invention is excellent in flexibility and bending strength and able to be rolled on a roll and thus has high productivity, and the carbon fiber paper of the present invention is suitable for producing the electrode substrate.

Owner:MITSUBISHI CHEM CORP

Porous carbon electrode substrate and its production method and carbon fiber paper

InactiveUS20070166524A1Improve conductivityIncrease flexibilityCell electrodesFinal product manufactureFiberCarbon fibers

Owner:MITSUBISHI RAYON CO LTD

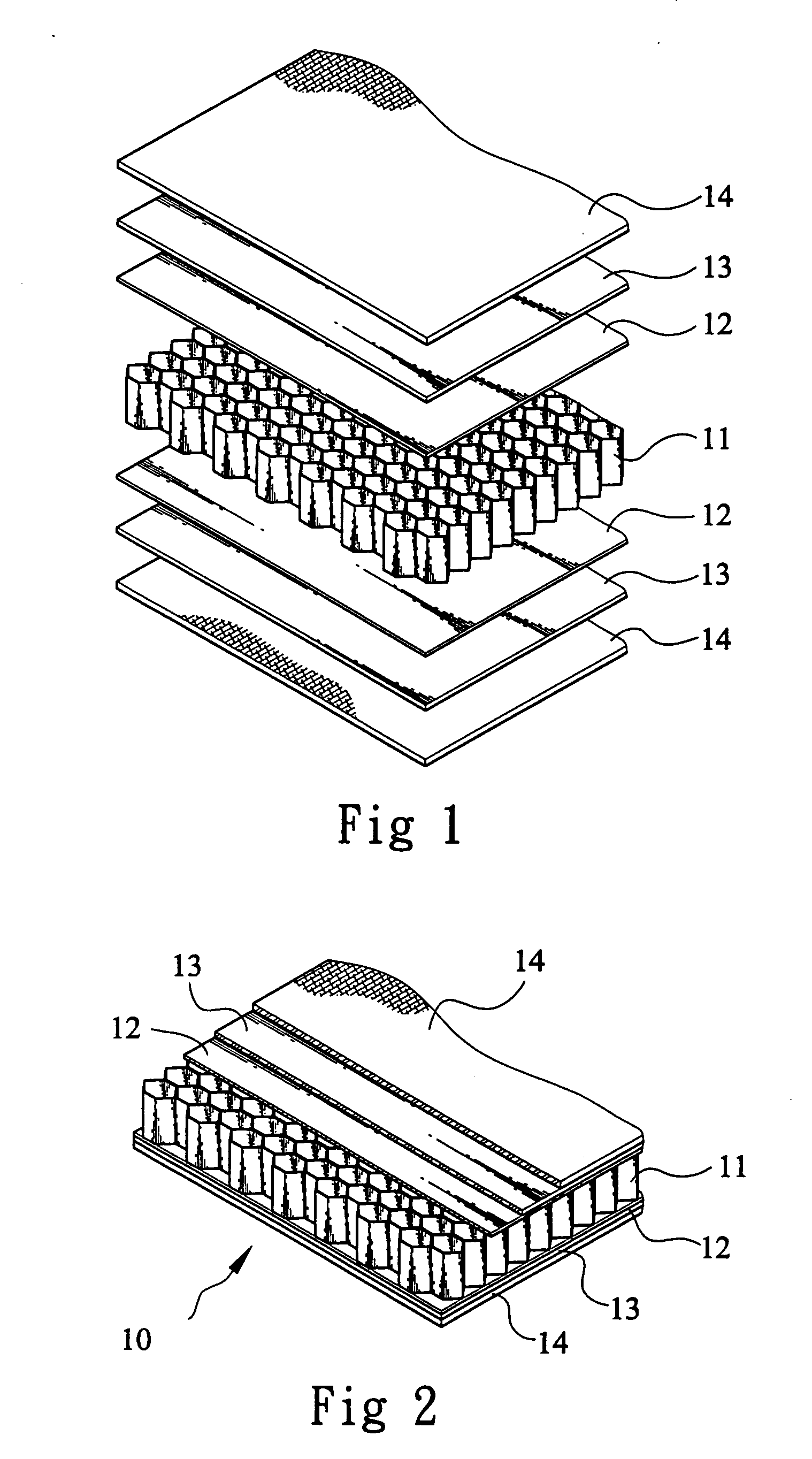

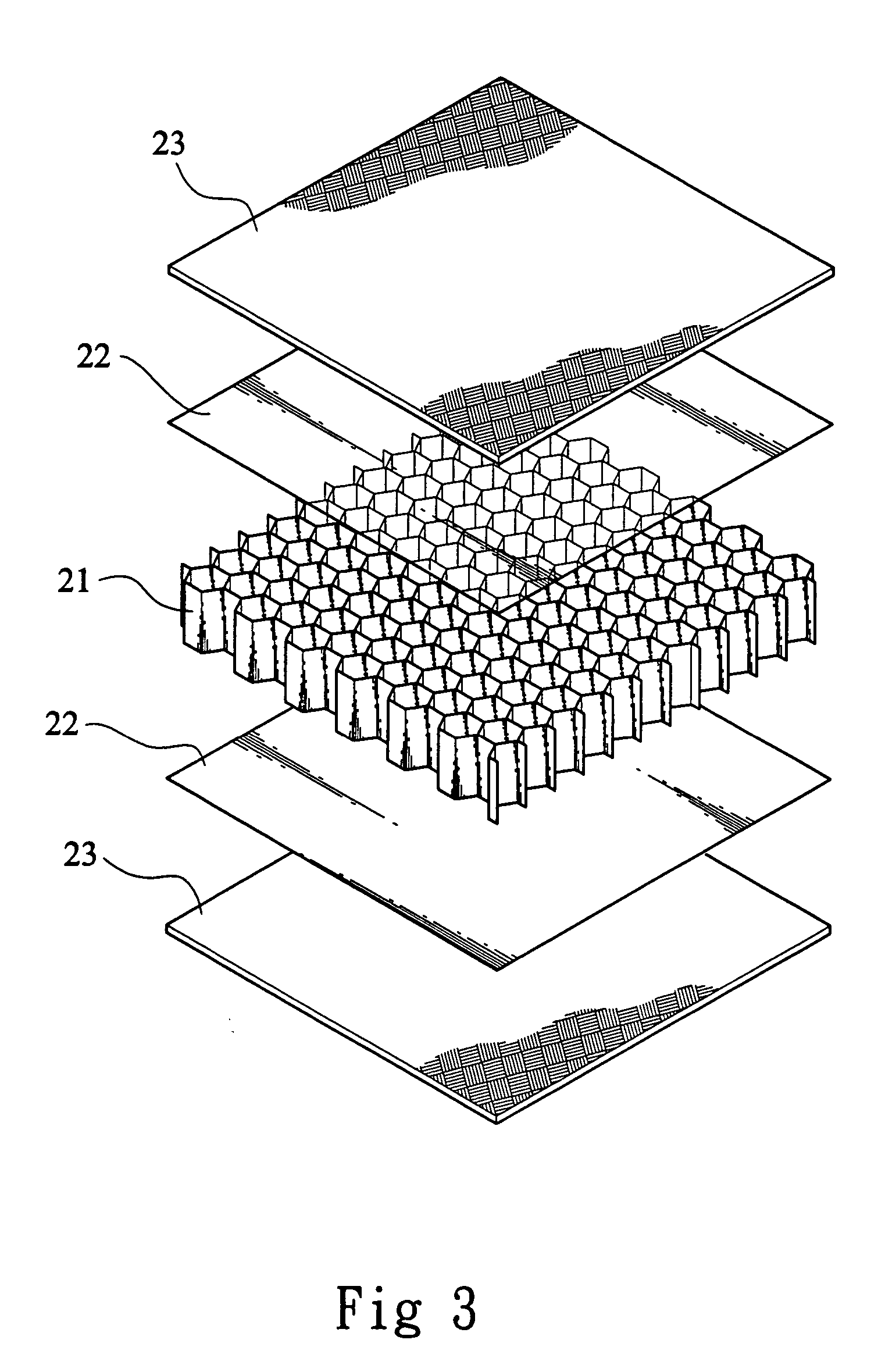

Sealing of honeycomb core and the honeycomb core assembly made with the same

InactiveUS20060008611A1Synthetic resin layered productsVehicle componentsThermoplastic polyurethaneThree point flexural test

The invention provides a new sealing process for the RTM of honeycomb structures. A thermoplastic polyurethane film is first heated and adhered on the surface of honeycomb core to seal the cells. Then the general RTM process is conducted and the honeycomb products are finished. The cells with resins filled in are less than 1%. Flatwise tension and three-point bending tests are carried out to verify the bonding between the film and honeycomb core. This honeycomb core sealing can be done in less than forty minutes and the whole RTM process can be much faster than the existing methods.

Owner:SHEN SHYAN BOB +2

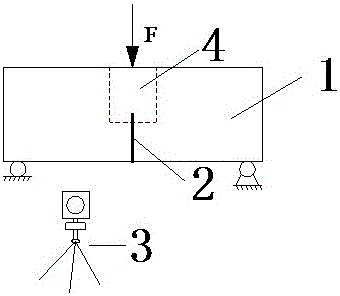

Rock type-I crack expansion whole process detection method based on three-point bending test

ActiveCN106290002AEasy to operateThe test result is accurateMaterial strength using steady bending forcesTensile strainTest sample

The invention discloses a rock type-I crack expansion whole process detection method based on three-point bending tests. The rock type-I crack expansion whole process detection method comprises the following steps: prefabricating a type-I crack in the middle part of a three-point bending test piece, performing jetting speckling treatment in an appointed analysis area of the test piece, and performing three-point bending tests on the appointed analysis area; meanwhile, performing whole process continuous imaging on the appointed analysis area, acquiring digital images, and analyzing, so as to obtain horizontal tension strain epsilon h of the whole test process of the appointed analysis area of the three-point bending test piece; coring the three-point bending test piece after the tests, manufacturing a Brazilian split disc test sample, performing sharp Brazilian split disc tests on the Brazilian split disc test sample so as to obtain ultimate tensile strain epsilon T, and comparing different values of epsilon h so as to obtain time nodes that horizontal tensile strain in different positions meets the ultimate tensile strain epsilon T in the whole type-I crack expansion process of the three-point bending test piece; according to second strength principles, acquiring crack expansion whole process information of type-I cracks of rock under the action of three-point bending. The rock type-I crack expansion whole process detection method disclosed by the invention is simple and easy to operate and precise in test result.

Owner:CHINA UNIV OF MINING & TECH

Sintered Silicon Wafer

InactiveUS20100016144A1High strengthEasy to processSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingTest sampleMetal silicide

Provided is a sintered silicon wafer, wherein the volume ratio of silicon oxide contained in the wafer is 0.01% or more and 0.2% or less, the volume ratio of silicon carbide is 0.01% or more and 0.15% or less, and the volume ratio of metal silicide is 0.006% or less. Additionally provided is a sintered silicon wafer having a diameter of 400 mm or more and having the following mechanical properties (1) to (3) measured by collecting a plurality of test samples from the sintered silicon wafers: (1) average value of the deflecting strength based on a three-point bending test is 20 kgf / mm2 or more and 50 kgf / mm2 or less; (2) average value of the tensile strength is 5 kgf / mm2 or more and 20 kgf / mm2 or less; and (3) average value of the Vickers hardness is Hv 800 or more and Hv 1200 or less. Even in the case of a large disk-shaped sintered silicon wafer, it is possible to provide a sintered compact wafer having definite strength and similar mechanical properties as single crystal silicon.

Owner:JX NIPPON MINING& METALS CORP

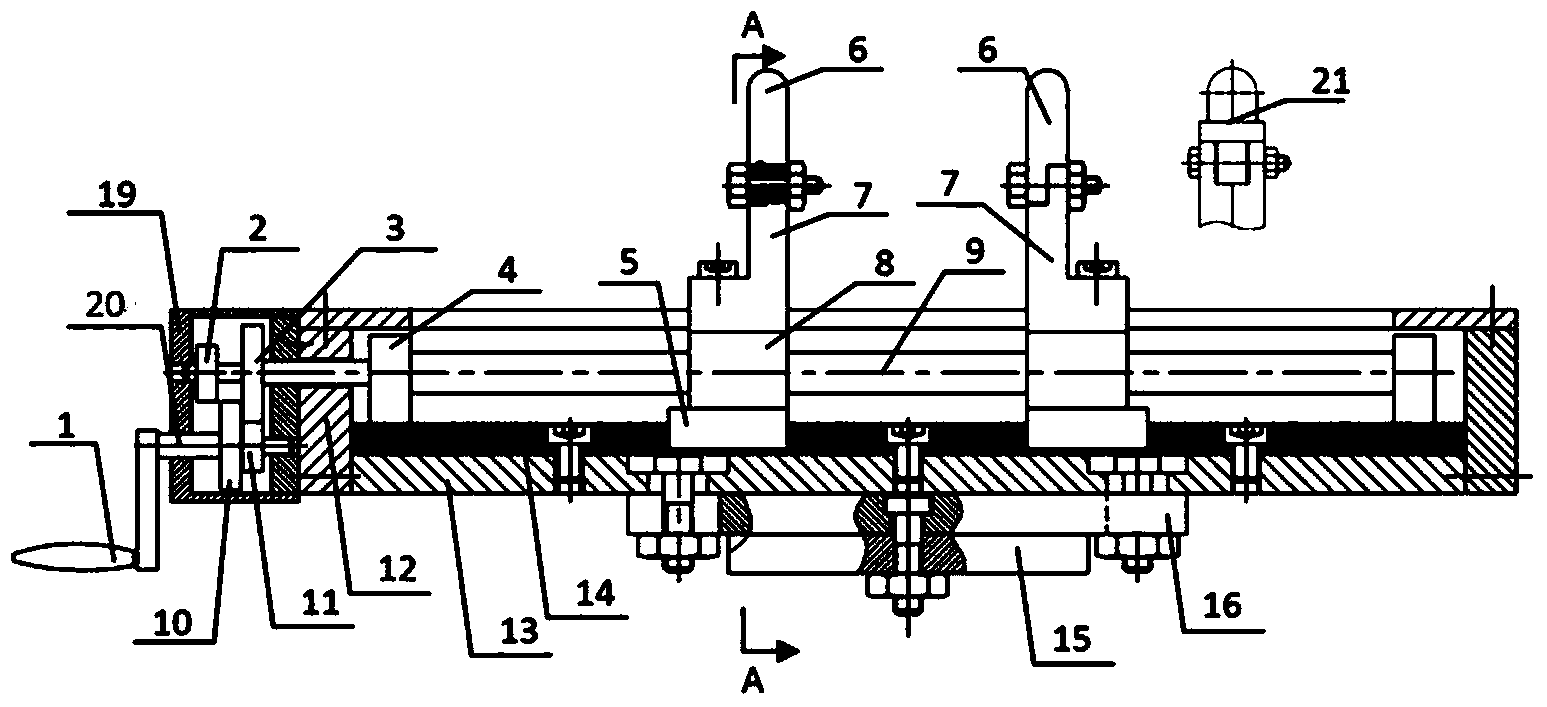

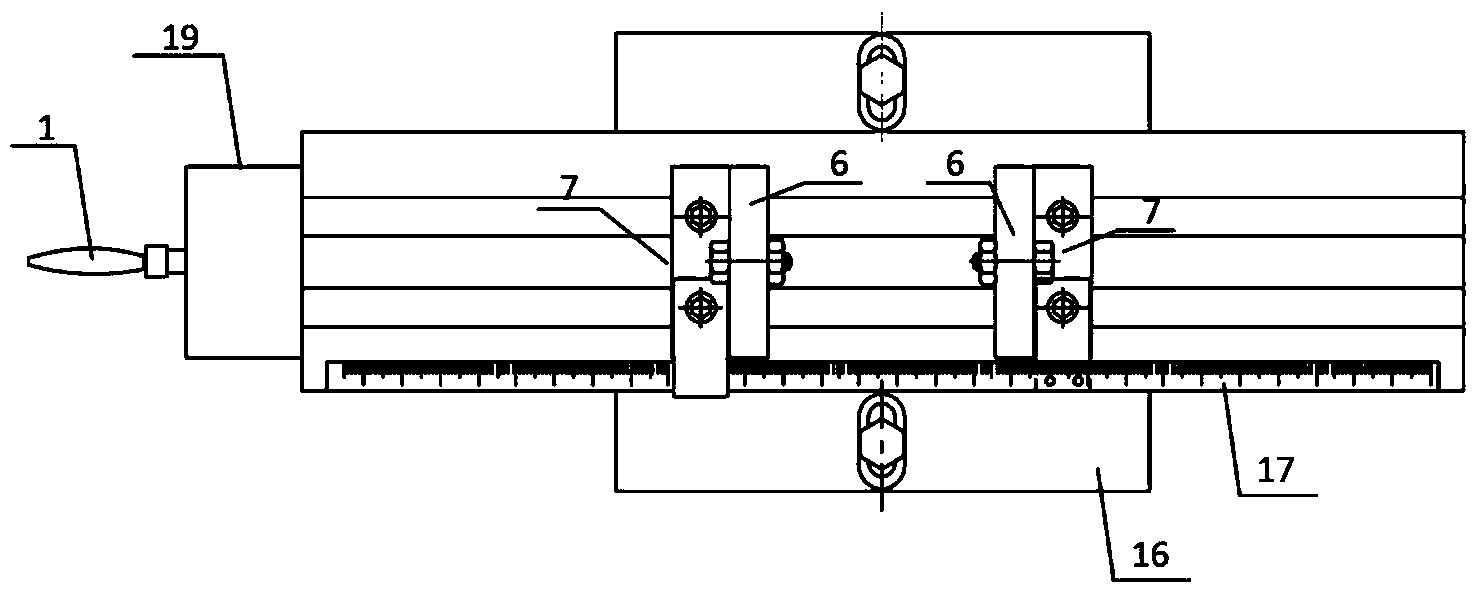

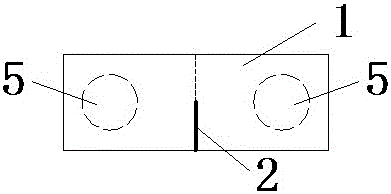

Three-point bending test device and test method for high-speed tensile test machine

ActiveCN104406863AConstant speed loadingEasy to operateMaterial strength using steady bending forcesEngineeringThree point flexural test

The invention relates to a three-point bending test device for a high-speed tensile test machine. The device comprises a base, two fixing seats which are fixedly arranged on the base and used for placement of test pieces, and a loading head for generating loading force to the test pieces, wherein the two fixing seats are symmetrically arranged on the two opposite sides of the loading head. The device is characterized in that two through holes are formed in each of the two fixing seats, a through hole is formed in the loading head, the test pieces penetrate through the through holes, and two ends of each test piece are respectively fixed in the through holes. The three-point bending test device disclosed by the invention can realize the dynamic three-point bending loading through the high-speed tensile test machine directly, and the operation is simple.

Owner:AUTOMOBILE RES INST OF TSINGHUA UNIV IN SUZHOU XIANGCHENG +1

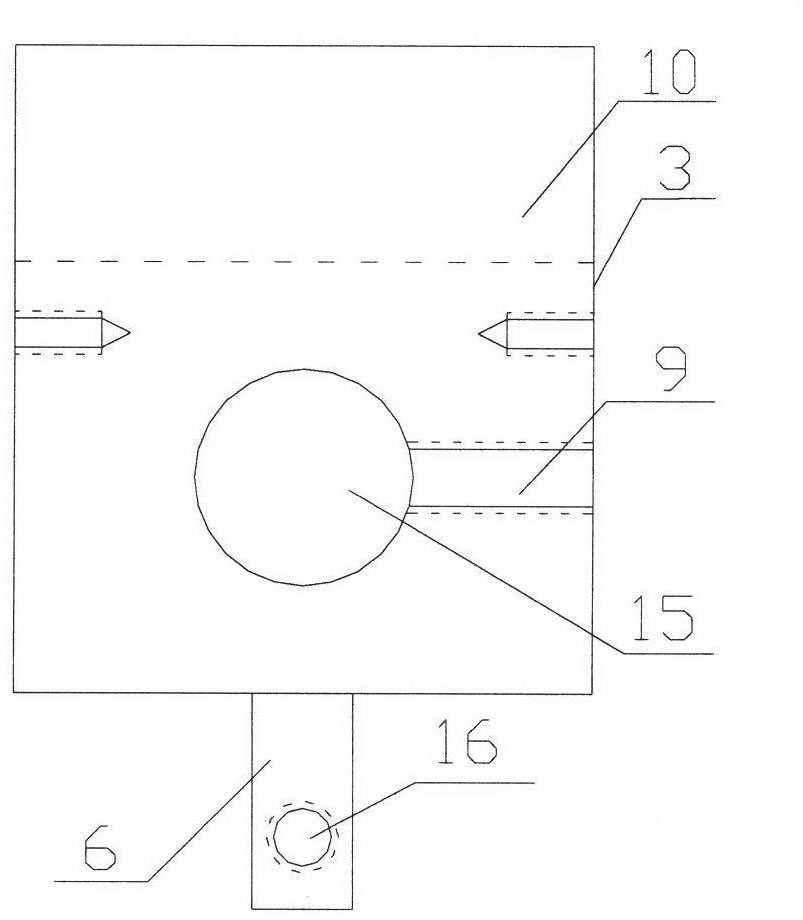

Three-point bending test apparatus for simulated deep sea high-pressure corrosion fatigue

PendingCN108414360APrecise temperature controlQuick changeMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesFatigue loadingMetallic materials

A three-point bending test apparatus for simulated deep sea high-pressure corrosion fatigue belongs to the field of metal material corrosion technology studying. The apparatus is composed of a water circulating system, a sample fixing device, a pressure head executing mechanism, a fixing rack, a temperature control box and a control main engine; and the circulating device is characterized in thatseawater in a water storage box is connected with the inlet of a booster pump through a water conveying pipeline, the outlet of the booster pump is connected with the water inlet of the kettle body through a water conveying pipeline, and a water outlet at the bottom of the kettle body of the high pressure kettle is connected with the water storage box through a water conveying pipeline. The apparatus can perform three-point bending corrosion fatigue test on a material in the simulated deep sea high-hydrostatic pressure environment, and can perform fatigue loading on a sample by adopting various waveforms (sine wave, square wave and triangular wave) through regulating the motion speed and the motion mode of a pressure head by the control main engine. The apparatus adopts a partial pressureplate to reduce the load of a bearing shaft, and the partial pressure and the high pressure kettle body are fixed to improve the reliability of the test apparatus. The apparatus has the advantages oflow cost and convenience in operation.

Owner:ARMOR ACADEMY OF CHINESE PEOPLES LIBERATION ARMY

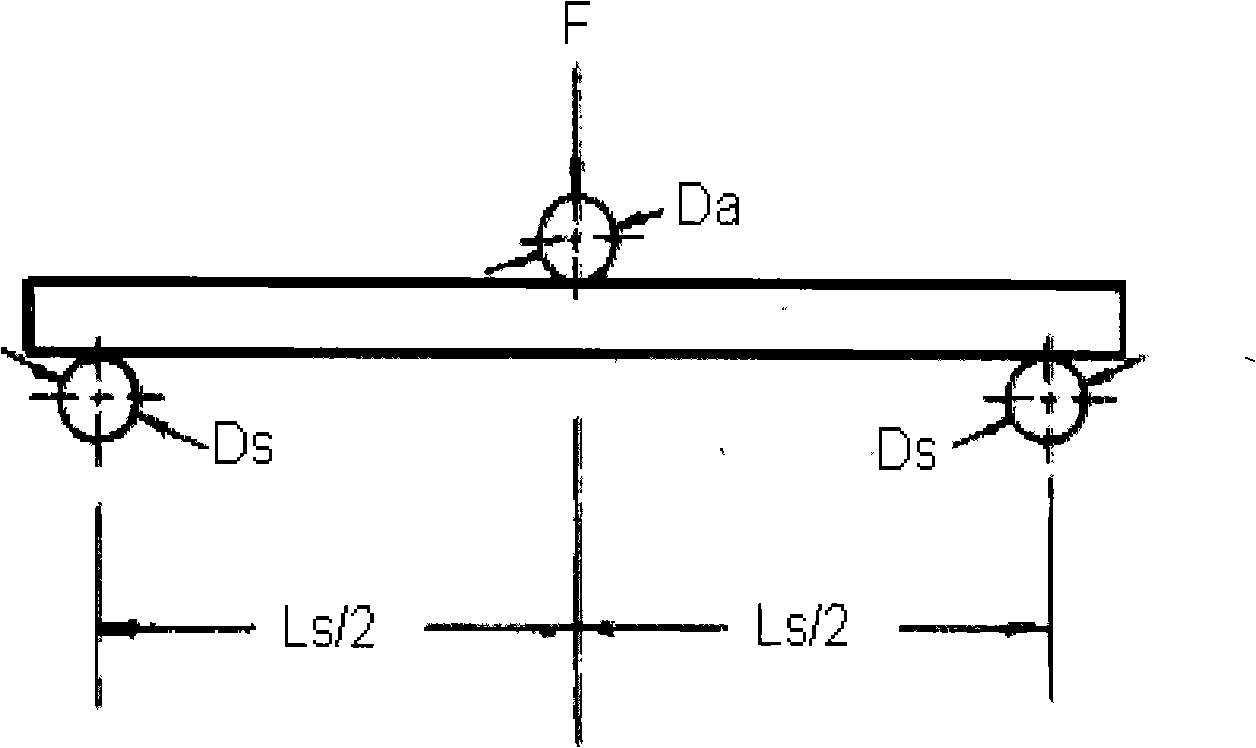

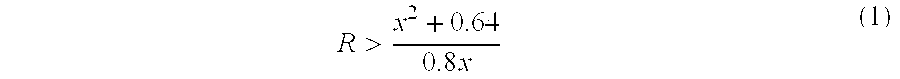

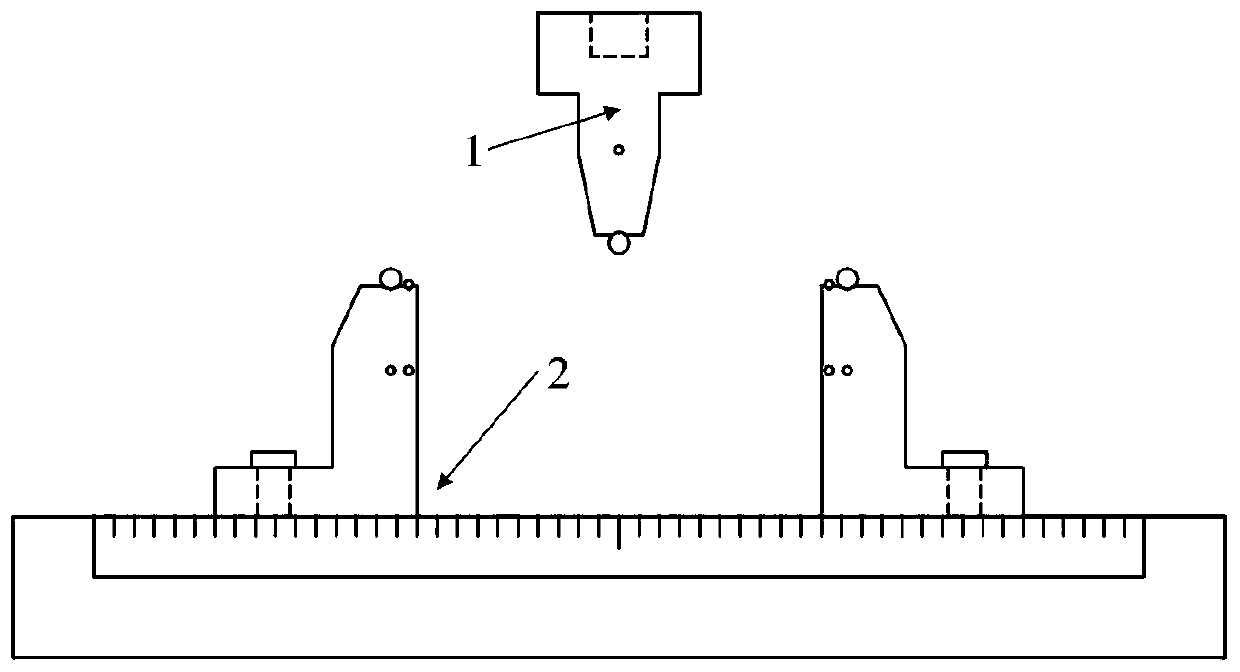

Rock three-point bending fixture for size effect tests

PendingCN109855957AMeet the three-point bending testSave materialStrength propertiesEngineeringThree point flexural test

The invention discloses a rock three-point bending fixture for size effect tests. The rock three-point bending fixture includes a pressure head section and a supporting section arranged on the lower part of the pressure head section, the pressure head part includes a pressure head body and a pressure roller, and the pressure roller is arranged at the bottom of the pressure head body; and the supporting part includes supporting rollers, moving supports, a base, and a guide rail platform, the moving supports are arranged at the two ends of the guide rail platform correspondingly, the moving supports are connected with the guide rail platform through the base, the supporting rollers are further arranged on the moving supports, and the moving supports are arranged symmetrically on the guide rail platform using the pressure head body as the center. The rock three-point bending fixture for the size effect tests can be adapted to the rock three-point bending tests with various sizes by changing the pressure roller and the supporting rollers, and the three-point bending tests of each group of test pieces with the large size change are conducted on the fixture.

Owner:SICHUAN UNIV

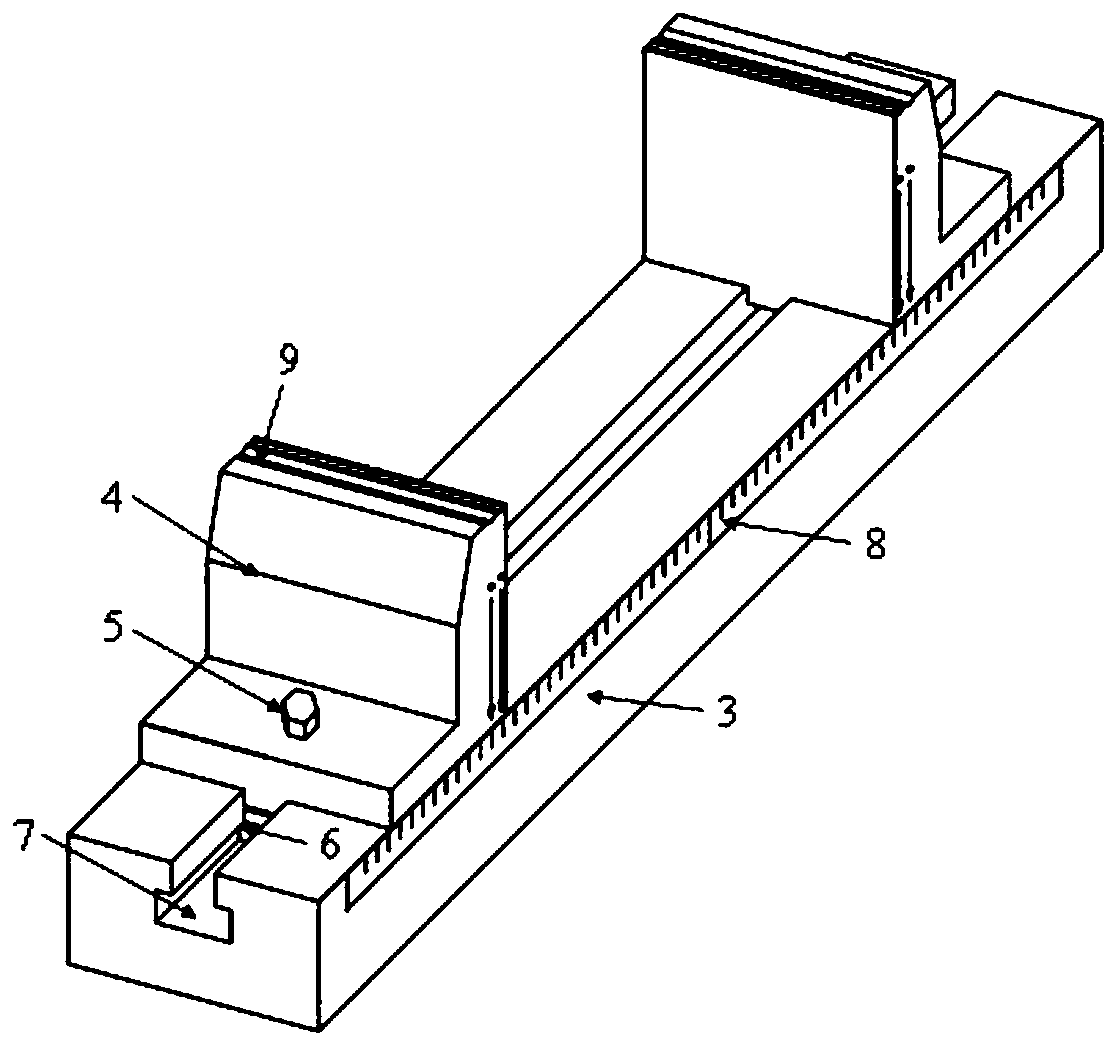

Adjustable multi-adaptive three-point bending test device

InactiveCN107132129AAccurate adjustment positionAvoid skewMaterial strength using steady bending forcesMaterial strength using steady shearing forcesEngineeringThree point flexural test

The invention provides an adjustable multi-adaptive three-point bending test device which comprises an upper pressure head, two lower pressure heads and a base. A T-shaped groove is formed in the base; two T-shaped nuts are arranged on the T-shaped groove and can slide in the T-shaped groove; threaded holes are respectively formed in the top and side faces of the T-shaped nuts; the lower pressure heads comprise vertical parts and horizontal parts; tops of the vertical parts are used for arranging test pieces; through holes are formed in the horizontal parts and are connected with threaded holes in the tops of the T-shaped nuts; two fine-grained long bolts are arranged in the T-shaped groove; heads of the two fine-grained long bolts are respectively exposed out of two ends of the T-shaped groove; screw rods of the two fine-grained long bolts are respectively matched with threaded holes in side faces of the two T-shaped nuts; and the positions of the lower pressure heads in the T-shaped groove can be adjusted by rotating the head of the fine-grained long bolts. Multiple types of three-point bending tests can be adapted by replacing the pressure heads, different testing machine fixtures can also be adapted by replacing the upper pressure head and the base support, and the device has the characteristics of high stability, simplicity in operation and the like.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

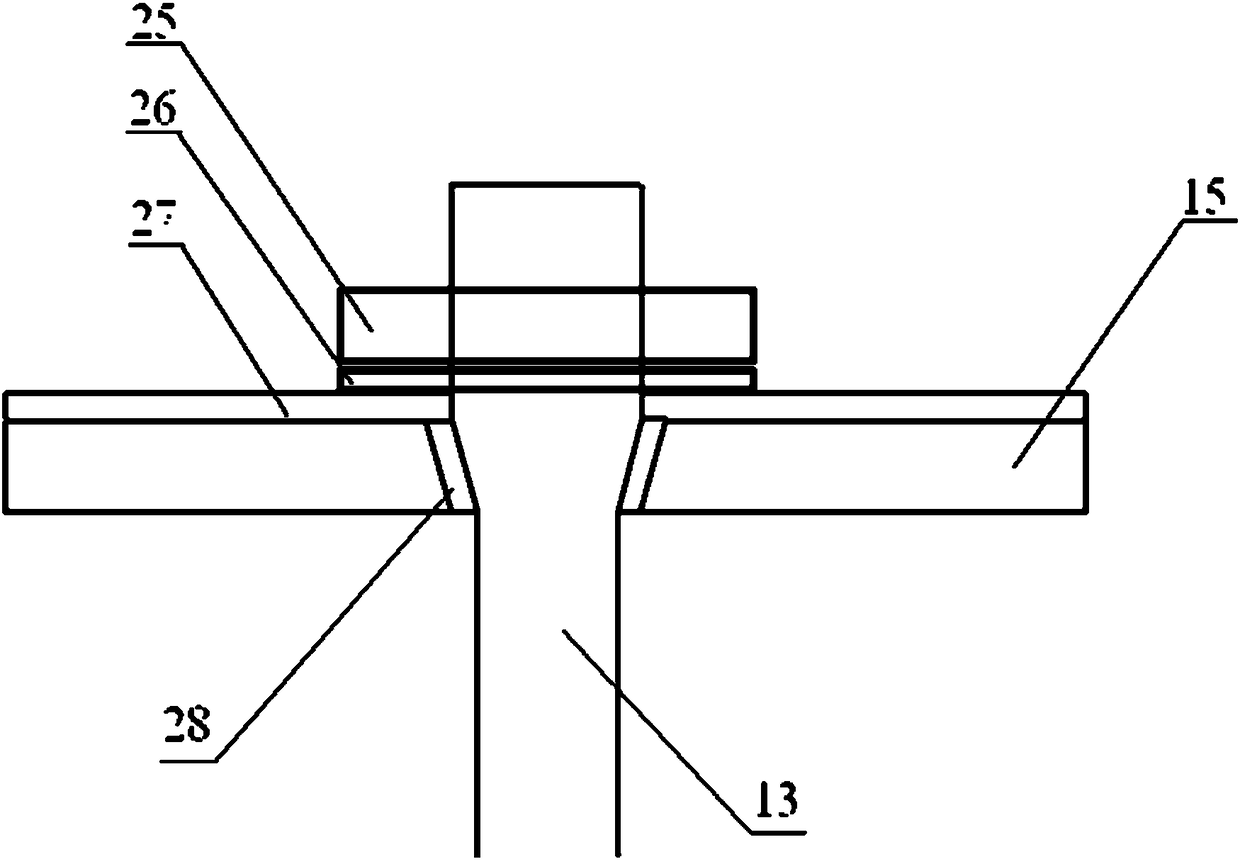

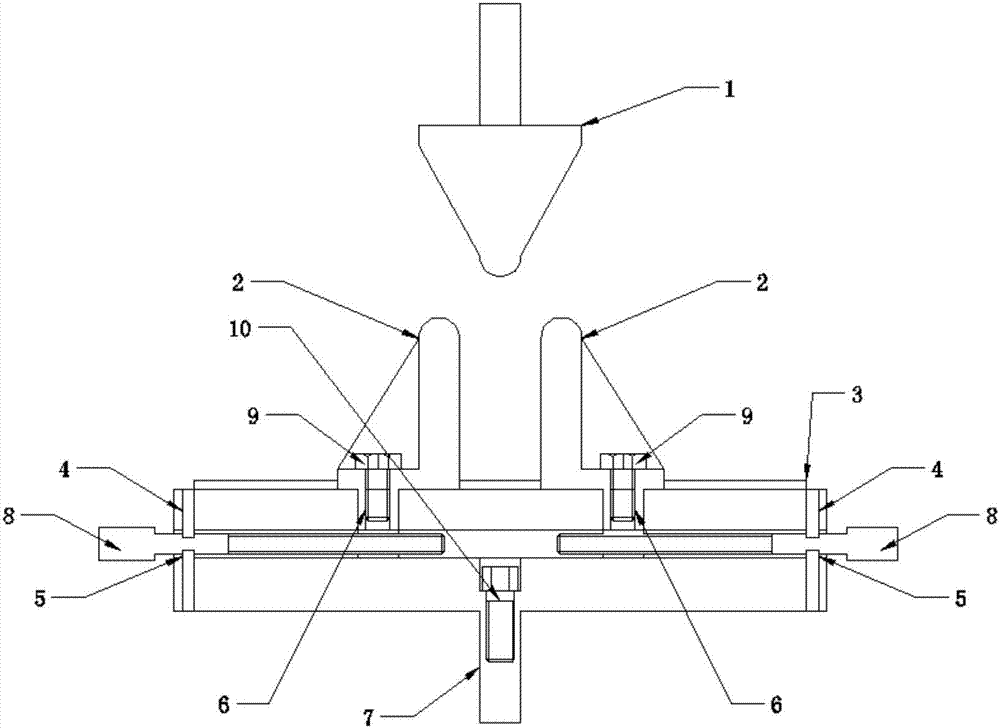

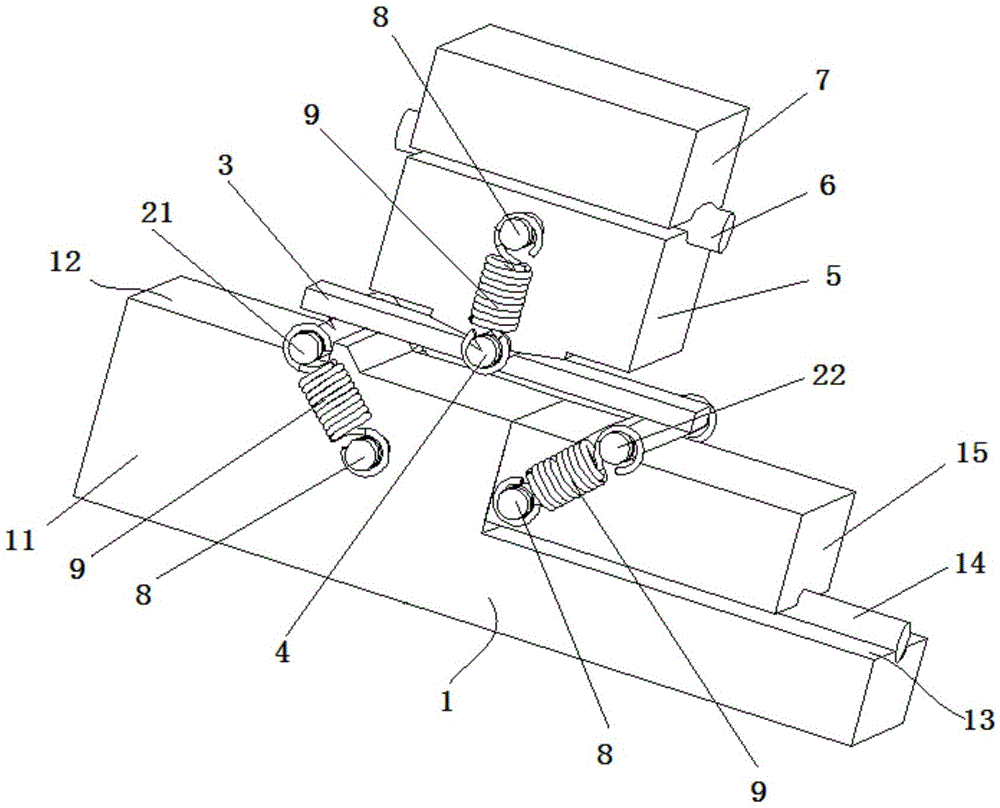

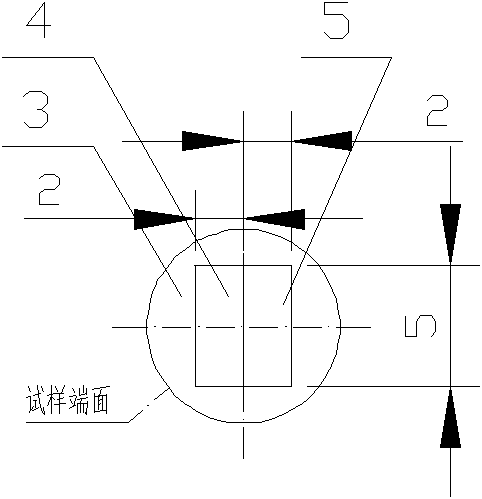

Three-point bending test device with laser centering device

ActiveCN105300810AReduce the impact onHigh centering accuracySurveying instrumentsMaterial strength using steady bending forcesLight beamEngineering

The invention discloses a three-point bending test device with a laser centering device. The three-point bending test device comprises a lower support beam, an upper pressure head, two lower supports and the laser centering device, wherein a plurality of diamond-shaped and / or isosceles-triangle-shaped centering signs of which the symmetry axes are on the same straight line are arranged on the center lines of the top surface and the side surface of the lower support beam; a plurality of diamond-shaped and / or isosceles-triangle-shaped centering signs of which the symmetry axes are on the same straight line are arranged on the center line of the side surface of the upper pressure head; each lower support comprises a stretched spring, a base and a lower support roller, and the stretched spring is connected with the base and a suspension loop on the lower support roller; the base is connected with a slider under the base via tightening bolts, and the slider can slide in a concave chute in the lower support beam; the laser centering device comprises a cross laser. The three-point bending test device realizes centering according to beams of the cross laser, so that influence on centering from artificial subjective factors is reduced, and the accuracy of testing results is guaranteed.

Owner:武汉钢铁有限公司

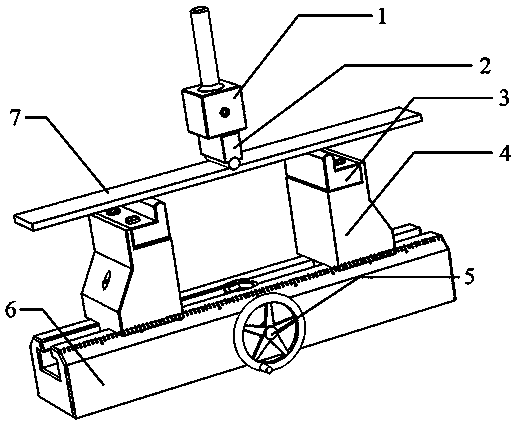

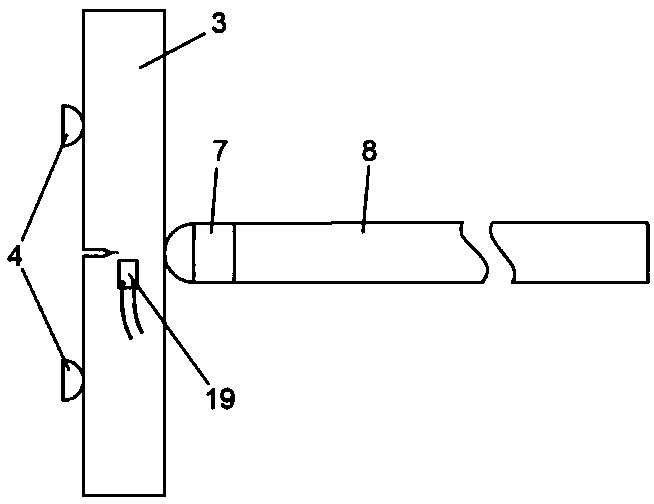

Novel three point bending test device for rock sample

InactiveCN102607964AAvoid offsetReduce frictionMaterial strength using steady bending forcesEngineeringRock sample

The invention relates to a novel three point bending test device for a rock sample, which belongs to test equipment. The test device is formed by a base, supports, rolling shafts and adjusting bolts, wherein the supports of the test device are in a rectangular shape; rolling shaft positioning grooves are arranged above the supports; the adjusting bolts are located in guide holes of the base and are arranged in bolt holes in bosses of the supports in a rotating way; a space between the supports can be adjusted through rotating the adjusting bolts, and the offset of the supports can be avoided; and meanwhile, scale marks are marked on the surface of the base, so that the supports can be positioned according to the size of the rock sample. The rolling shafts of the supports are fixedly arranged in the rolling shaft positioning grooves of the supports through springs, so that friction between the rock sample and the supports can be reduced, mutual sliding of the rock sample and the rolling shafts is prevented, and the measured value is more accurate. According to the test device, the deformation and the conversion between signals in a traditional method are changed, the real-time monitoring on a three point bending test of the rock sample is realized, the intuitiveness is strong, the structure is reasonable, the operation is flexible and simple, the effect is good, and the disassembly is convenient.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

Asphalt mortar self-repairing performance evaluation method based on shape memory properties

InactiveCN107421820APreparing sample for investigationMaterial strength using steady bending forcesFiberFine line

The invention discloses an asphalt mortar self-repairing performance evaluation method based on shape memory properties and belongs to the technical field of asphalt pavement durability. The problems that an asphalt mortar self-repairing performance testing method is absent, the fatigue test method is high in time consumption, the operation is complicated and the test result is poor in repeatability and reproducibility are solved. The method disclosed by the invention comprises the following steps: preferably selecting shape memory staple fibers and thermoplastic particles, wherein the fibers serve as a mortar reinforcing material and are endowed with the shape memory function; preparing an asphalt mortar small beam test specimen, performing a three-point bending test, stopping loading when the crack of the small beam test specimen is expanded to a fine line at 5mm on the top of the beam, and recording the maximum flexural-tensile strength Ri; and maintaining the small beam which is not completely broken in a drying oven, repeating the test on the cooled test specimen, recording the maximum flexural-tensile strength Rs, taking a ratio of the Rs to Ri as an index for evaluating the self-repairing effect, comparing the mixing amount and self-repairing effect of different staple fibers and thermoplastic particles, and determining the optimal mixing amount, so that the service life of the asphalt pavement is prolonged.

Owner:NANJING FORESTRY UNIV

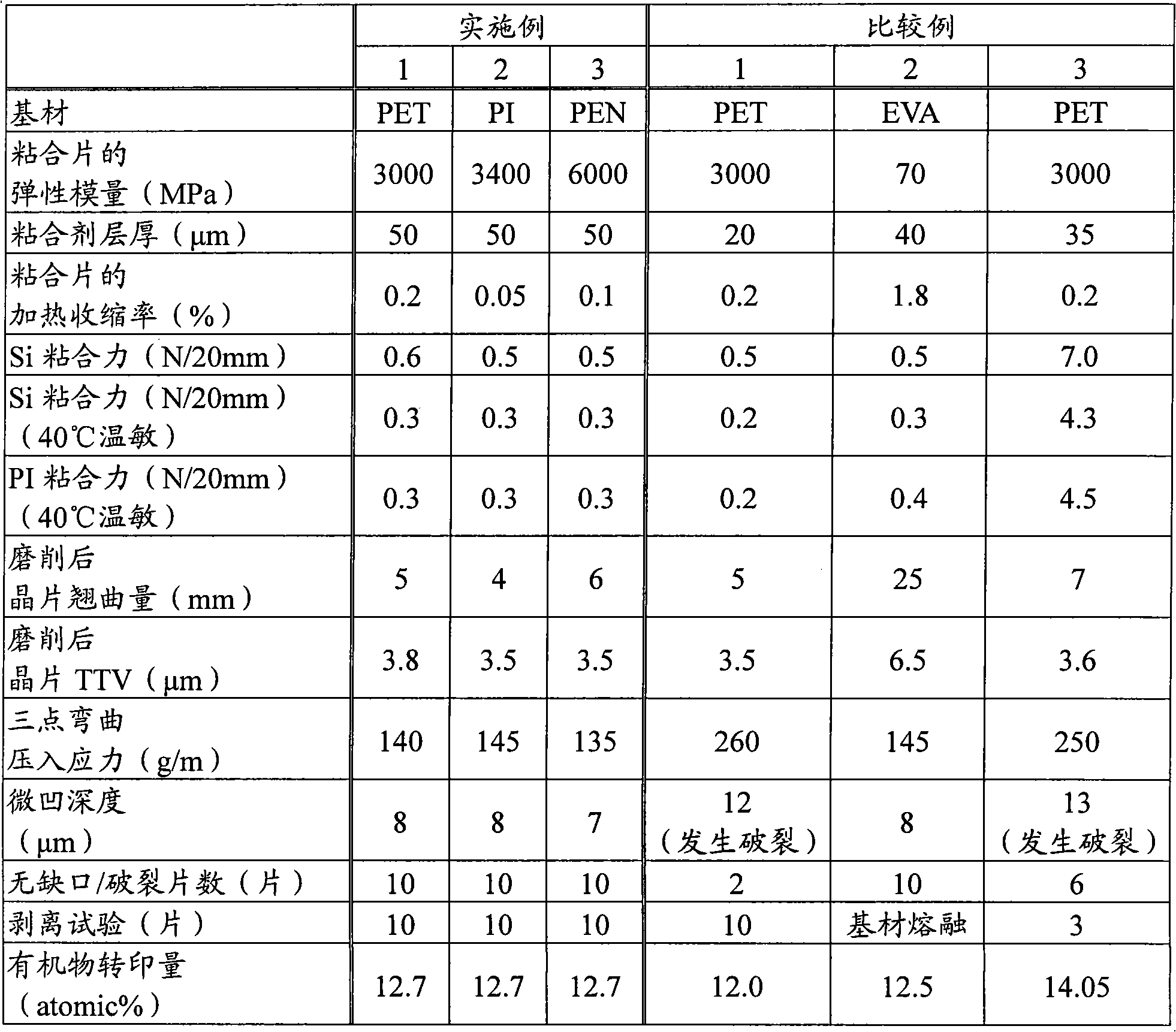

Re-peelable adhesive sheet

InactiveUS20110097576A1Reduce crackingImprove adhesionAdhesive articlesSynthetic resin layered productsEngineeringThree point flexural test

A re-peelable adhesive sheet for grinding a semiconductor wafer comprises: a base film, and an adhesive layer laminated on the base film, the re-peelable adhesive sheet has a modulus of elasticity of at least 103 MPa, and a heating shrinkage factor of 1% or less, after heating for 10 minutes to 60° C., and the adhesive layer is set to a thickness at which the maximum point stress is 200 g / cm or less, at a pressing amount of 30 μm from the adhesive layer side in a three-point bend test. The present invention can provide a re-peelable adhesive sheet that can reduce wafer warping, cracking, and edge chipping, that can improve the adhesive force in relation to temperature variations and / or reduce contamination of the adherend when re-peeling, and that can facilitate film re-peel.

Owner:NITTO DENKO CORP

Three-point bending test apparatus

ActiveCN105547828AUniform forceMaterial strength using tensile/compressive forcesStress concentrationEngineering

The invention relates to the field of material performance testing technology, and especially relates to a three-point bending test apparatus. The three-point bending test apparatus comprises the following components: a base body, whose top is provided with a first support and a second support which are parallelly arranged; a test member, which is arranged on the first support and the second support; a pressure head, which is used for extruding the test member; a rotary pressing bench, which is arranged on the pressure head; an upper rotating shaft, which is rotatably arranged on the upper surface of the rotary pressing bench around an axis of the upper rotating shaft; a cover plate, which is arranged on the upper rotating shaft, and the top surface of the cover plate is vertically connected to a pressure rod of a pressure testing device. Directions of acting forces of the three-point bending test apparatus can be automatically adjusted by the effects of the rotary pressure head and the upper rotating shaft which rotate around axes of one's own, so that acting forces which are distributed on three lines, including the test member and the pressure head, the first support and the second support are always kept uniform; when the surface of the test member is rough or the upper and the lower surfaces of the test member are not parallel, test failure caused by compression due to partial stress concentration is avoided.

Owner:上海秦耀航空试验技术有限公司

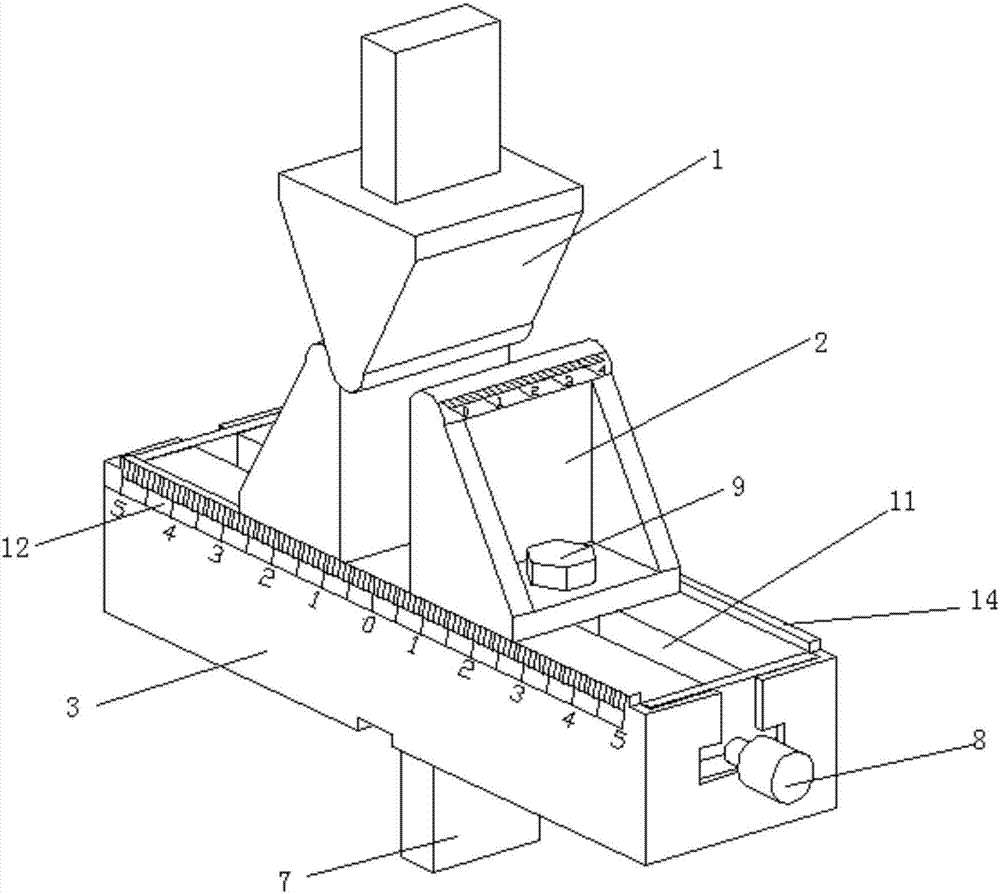

Novel three-point bending experimental device

InactiveCN109632526AEasy to calculateEasy to holdMaterial strength using steady bending forcesEngineeringThree point flexural test

The invention relates to the technical field of material performance testing, in particular to a multifunctional material bending experimental device. The experimental device comprises a base, a scaleline on the base for aligning two supports, a first support and a second support for supporting a sample, a removable and replaceable three-point bending and four-point bending indenter and a pulleyfor adjusting the positions of the two supports. The position of the support can be adjusted accurately through the pulley, and the purpose that measurement can be carried out under different bendingmoments is achieved; different grooves are opened in the top parts of the two supports, a corresponding form is adopted for a different sample, and the sample can be better fixed; a material three-point bending experiment can be carried out, and also, a four-point bending experiment can be carried out by replacing the indenter; and the device is the removable device and can be directly connected with a tensile testing machine, the operation is simple, and the application range of the experimental equipment can be greatly increased.

Owner:HARBIN UNIV OF SCI & TECH

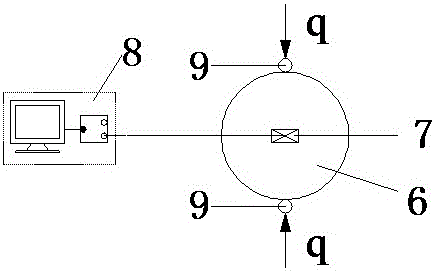

Three-point bending test device for simulating corrosion fatigue of splash zone of ocean

ActiveCN103630451AGuaranteed cleanlinessThe test results are accurate and reliableWeather/light/corrosion resistanceMaterial strength using repeated/pulsating forcesSurface oceanLine tubing

The invention relates to a three-point bending test device for simulating the corrosion fatigue of a splash zone of an ocean. The three-point bending test device comprises a three-point bending test block, a main box for fixing the three-point bending test block, an auxiliary box for keeping the test water level, a seawater spraying pipeline for simulating wave splashing, and a seawater circulating power device for providing power for seawater flowing. The three-point bending test device can not only guarantee that cracks are in impurity-free circulating seawater but also prevent seepage, is easy to operate, and integrates the functions of environmental protection, automation and intelligentization.

Owner:DALIAN UNIV OF TECH

Detection method for betel nut fiber softness

InactiveCN106323763ASolve the defect of evaluating the softening effectMaterial strength using steady bending forcesBetelEngineering

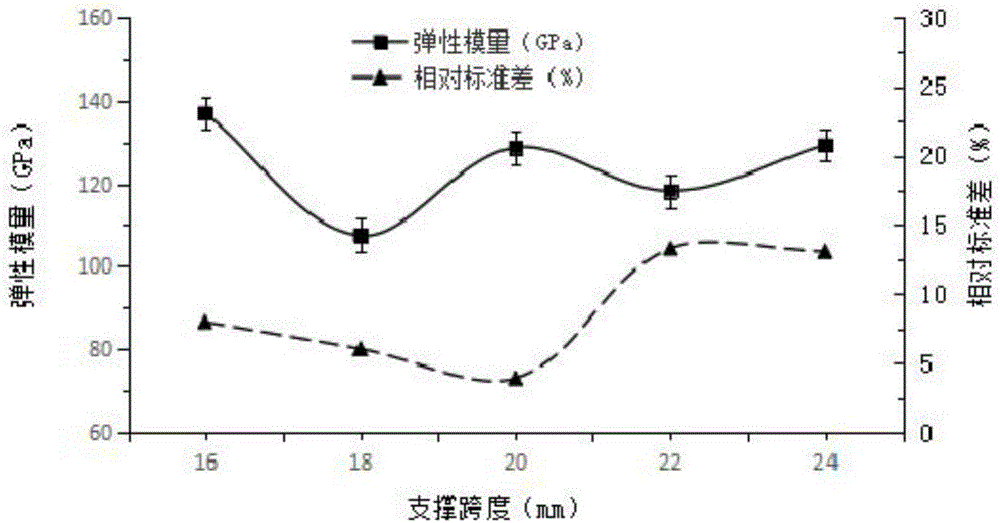

The invention belongs to the agricultural products physico-mechanic detection field, and relates to a detection method for betel nut fiber softness, slitting the areca nut into sample along with the fiber texture and based on the center axis, connecting the texture analyzer with three point bending testing apparatus, putting the betel nut between the supporting vertical walls of three point bending testing apparatus with the concave surface facing up, and adopting three point method for testing, using the formula to calculate the elasticity modulus of betel nut fiber layer, taking elasticity modulus as the measurement criteria of sample softness. The detection method for betel nut fiber softness adopts elasticity modulus as the measurement criteria of sample softness and standard three point testing method as the detection method, which solves the defect of taking the traditional mouth chewing sensory for softening effect evaluation, provides scientific qualitative detection method for betel nut production, processing and quality assessment, and lays a significant theoretical basis for the development of betel nut processing subject.

Owner:INST OF PROCESSING & DESIGN OF AROPROD OF HAINAN ACADEMY OF AGRI SCI

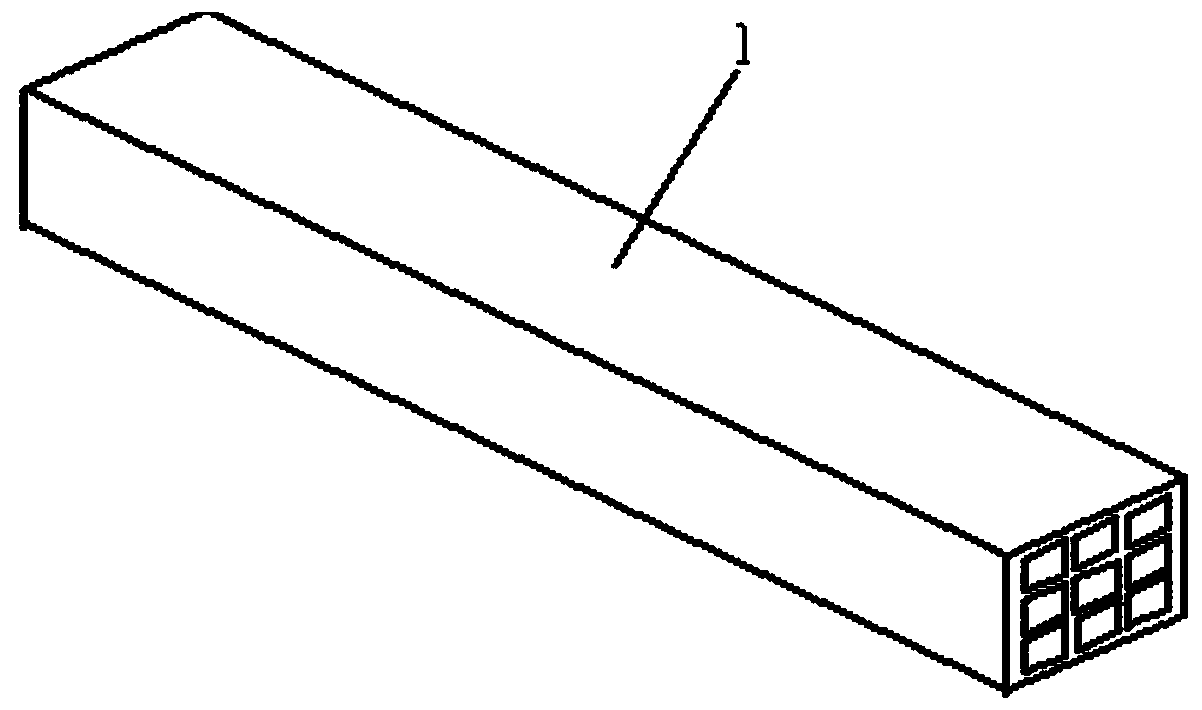

A method for establishing an equivalent model of a large steam turbine generator stator end wire rod structure

InactiveCN109948234ASolve complexitySolutionSpecial data processing applications3D modellingWire rodElement analysis

The invention discloses a method for establishing an equivalent model of a large steam turbine generator stator end wire rod structure. The method comprises the following steps that S1, actually measuring bending rigidity of a wire rod through a three-point bending test; S2, carrying out entity modeling on a wire rod result; S3, carrying out Boolean operation on the entity model to obtain a geometrical model of the wire rod; S4, researching an equivalent method of the wire rod; S5, verifying the correctness of the equivalent method, if the correctness is correct, executing the subsequent steps, and otherwise, executing the step S4; and S6, obtaining an equivalent model of the wire rod structure. According to the method, the advantages of finite element analysis are utilized to provide a reference scheme for the optimization design of the wire rod structure, and the problems that in the prior art, the wire rod modeling process is complex, and a reasonable and effective equivalent methodis lacked to simplify modeling are solved.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

Material dynamic fracture tenacity measuring device based on Hopkinson bar

InactiveCN108918299AImplement dynamic loadingReduce volumeStrength propertiesExperimental methodsEngineering

Owner:SOUTHWEST JIAOTONG UNIV

Method for evaluating welding degree of hole type defect in forge piece

InactiveCN102654439AObjective evaluation of welding effectLoose size requirementsMaterial strength using steady bending forcesButt jointEngineering

The invention belongs to field of the physical simulation technology of the material hot processing, and in particular relates to a method for evaluating the welding degree of a hole type defect in a forge piece. The method comprises the following steps of: (1) processing experimental materials into a cylinder, wherein the roughness of the end surface of a sample is Ra6.3-Ra0.4; cleaning the surface of the processed sample with acetone, carrying out the sample butt joint experiment on a thermal simulation tester according to the preset deformation temperature, the thermal preservation time and the strain; butting the end surfaces of two samples so as to butt two surfaces with closed cracks in the butt joint end surface simulation forge piece during the sample butting experiment; and (2) cutting the butted samples into bent samples after the experiment, and presenting the welding degree of a hole type defect in the forge piece by the specific value of the bending strength of the bent samples and the bending strength of the complete samples. The method disclosed by the invention is not influenced by the sample interface state, the precision of an observation apparatus, the selection position and the like, a three-point bending experiment is used to evaluate the welding effect of the butted samples. The requirements on the size of the samples are loose, and the method is convenient to sample and is easy to operate.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

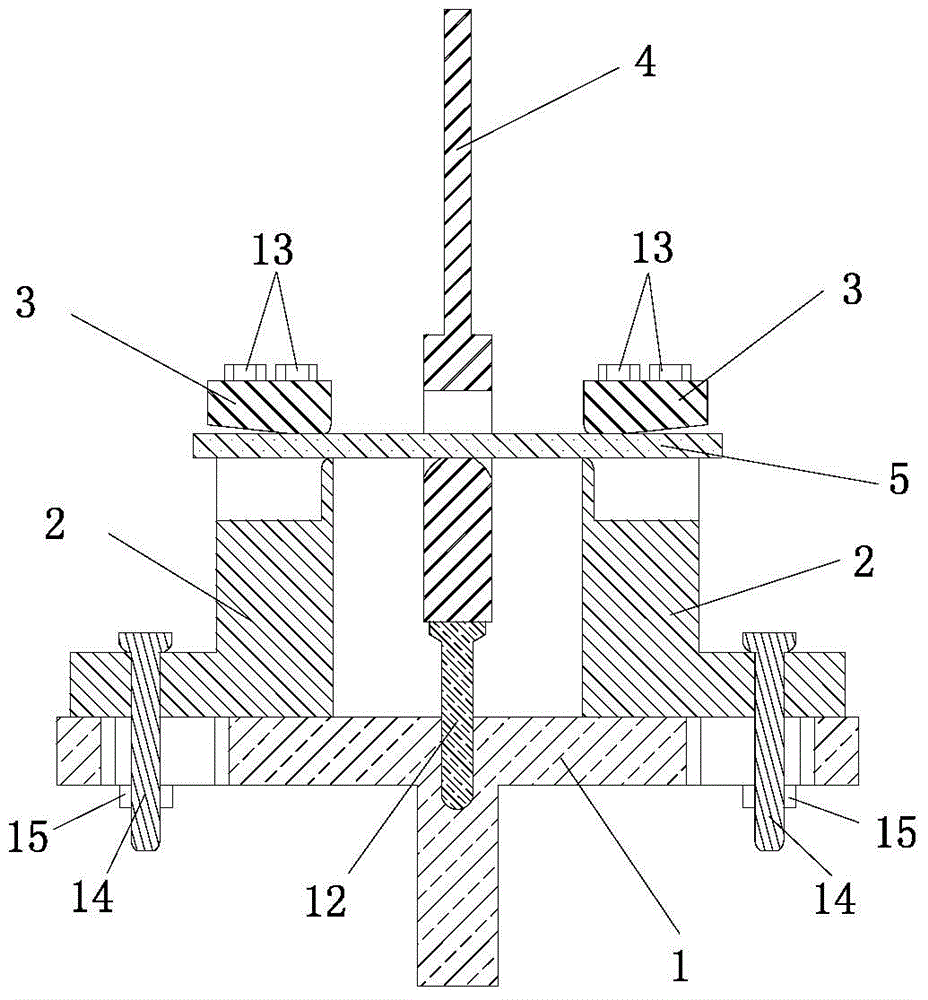

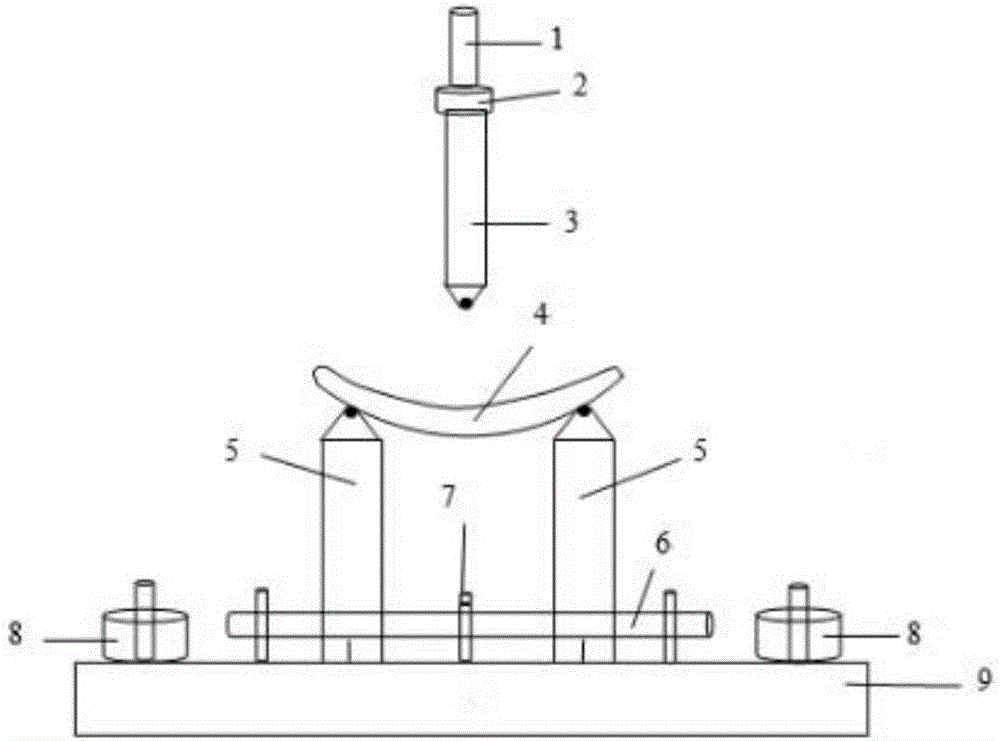

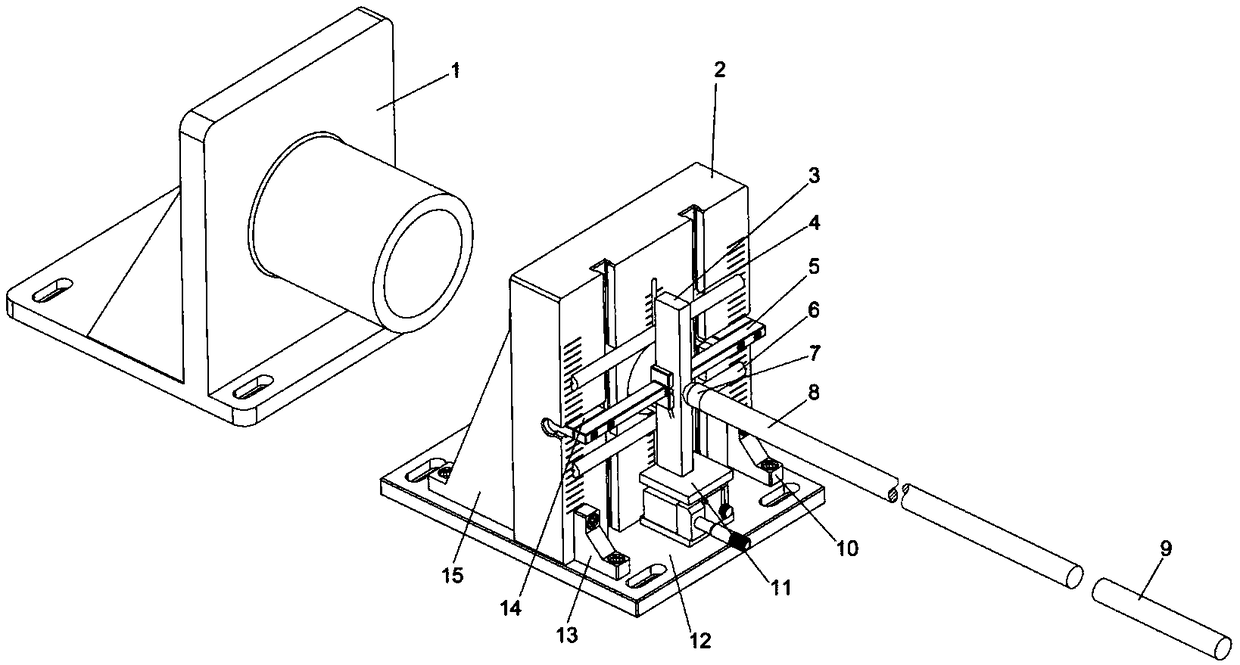

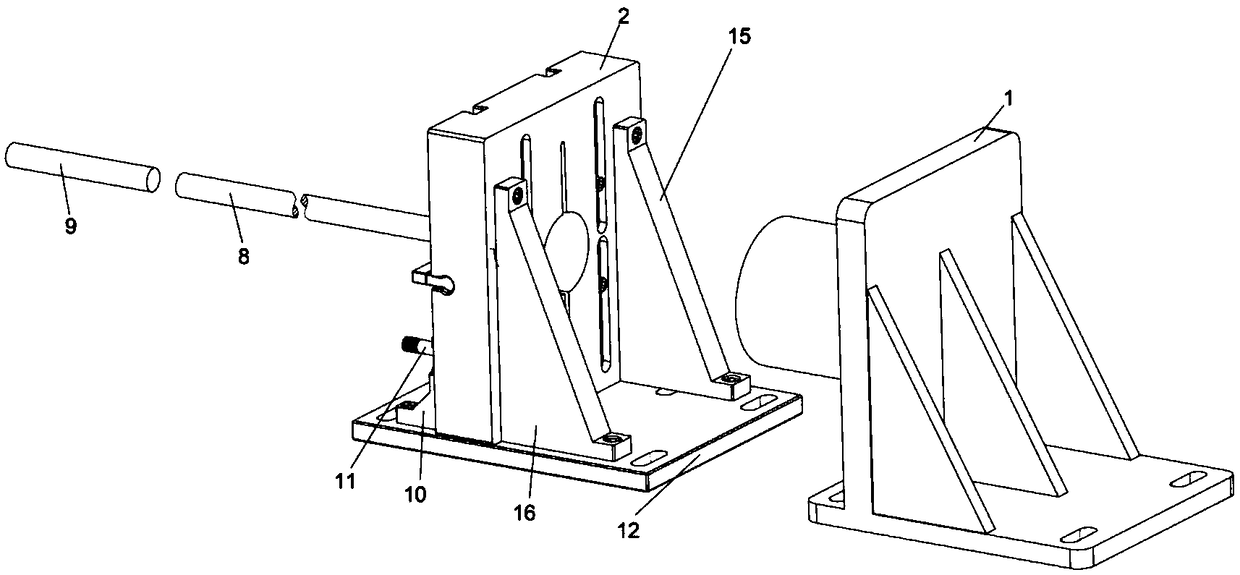

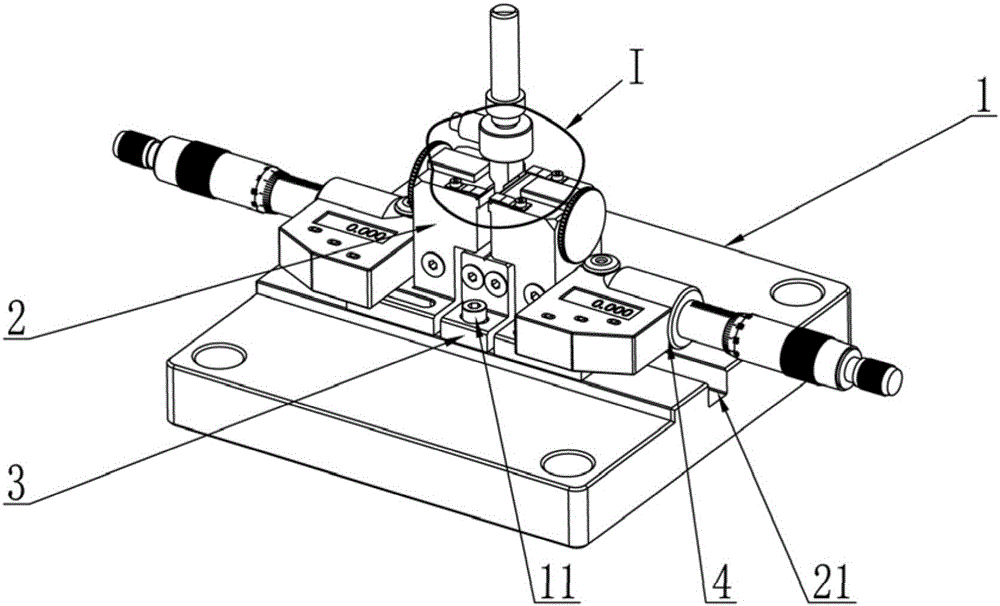

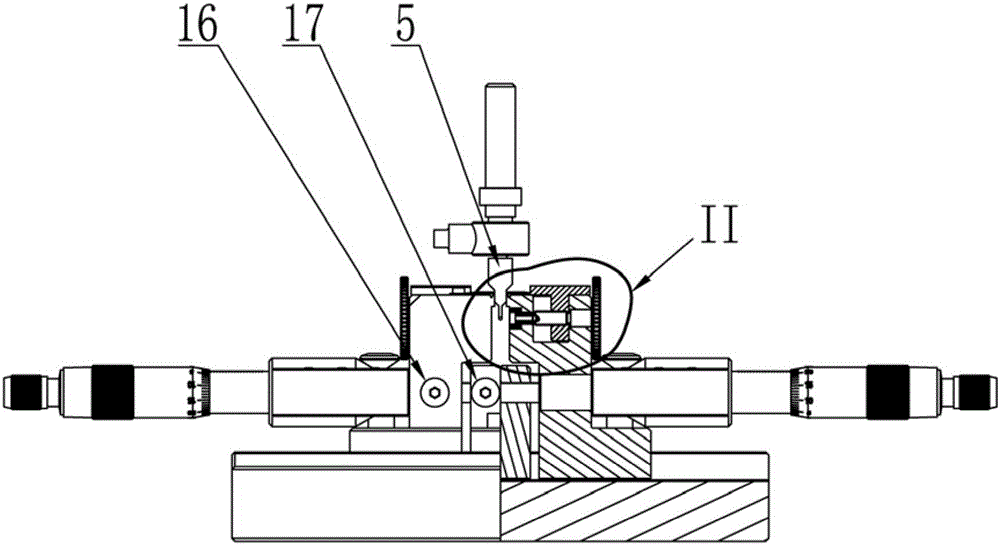

Biological bone small-dimensional sample three-point bending test device

ActiveCN105891009AEasy to placeReduce the impactMaterial strength using steady bending forcesMicrometerEngineering

The invention relates to a bone small-dimensional sample three-point bending test device, wherein a support seat guide rail groove (21) is processed in a base (1); support seats (2) and a center block (3) are arranged on the support seat guide rail groove (21); a threaded hole is processed in a lug boss arranged on the support seat guide rail groove (21) of the base (1); kidney-shaped holes used for locking and fixation are processed in the two sides of the support seats (2) and the center block (3); after the centering test on the center block (3), the center block (3) is fixed on the base (1) through tightly screwing center block fastening screws (11); the support seats (2) realize the axial line distance regulation of two rolling shafts (6) through the regulating the sliding of direct advancing type electronic micrometer heads (4) along the support seat guide rail groove (21) of the base (1). The mutual position between the support seats (2) is regulated by the direct advancing type electronic micrometer heads (4); good adaptability is realized by three-point bending tests of various kinds of small-dimension bone samples in a certain range.

Owner:NAT UNIV OF DEFENSE TECH

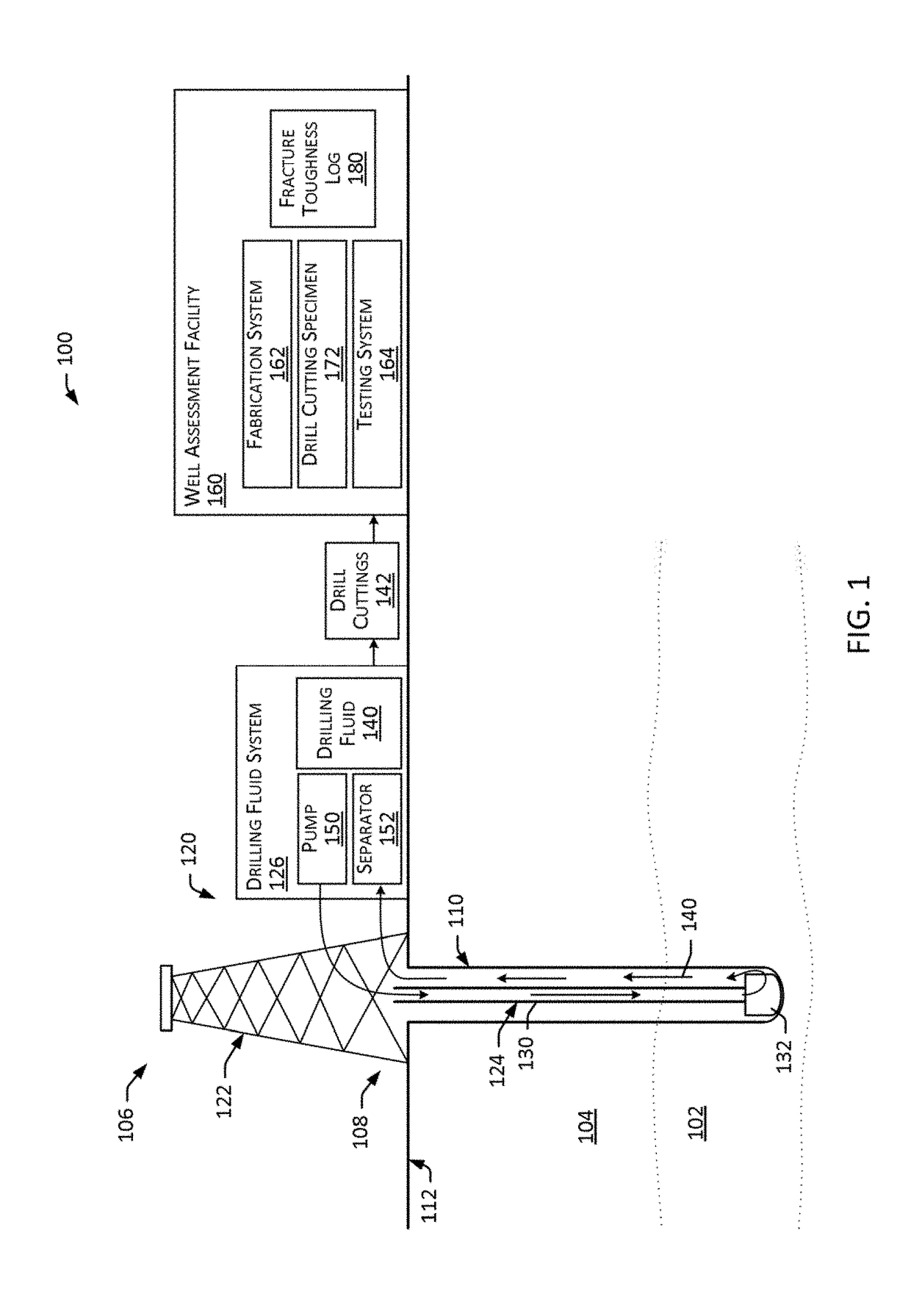

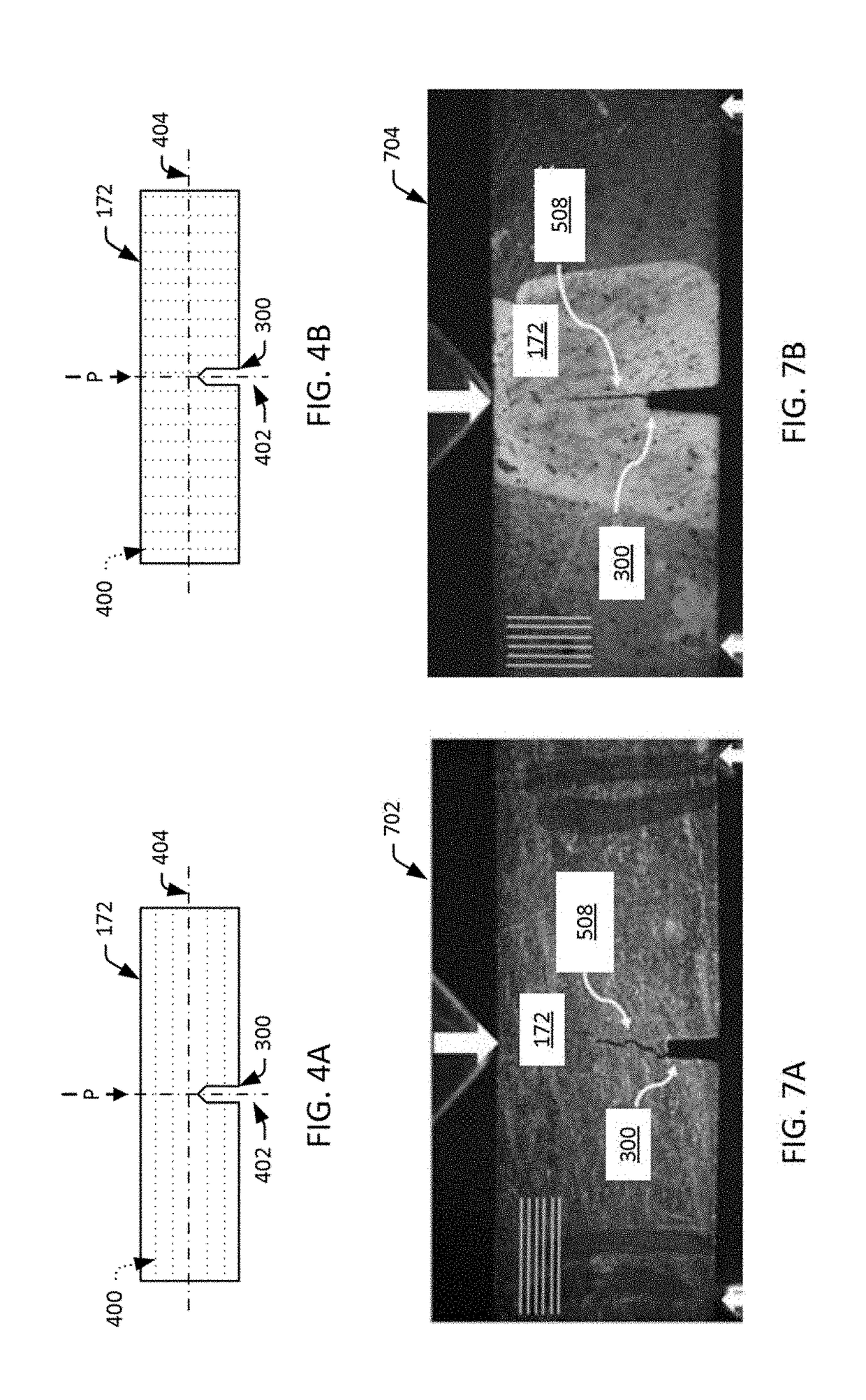

Logging Fracture Toughness Using Drill Cuttings

ActiveUS20180347355A1Accurately propertyMore compliantFluid removalDrilling machines and methodsGeomorphologyWell drilling

Provided are systems and methods for determining fracture toughness of a subsurface geologic formation. Embodiments include collecting (from drilling fluid circulated into a wellbore during a drilling operation) a drill cutting generated by a drill bit cutting into a subsurface formation, preparing (from the drill cutting) a drill cutting specimen comprising a miniature single edge notch beam (SENB) having a specified length in the range of 1 millimeter (mm) to 100 mm, conducting a three-point bend testing of the drill cutting specimen to generate load-displacement measurements for the drill cutting specimen, and determining (based on the load-displacement measurements for the drill cutting specimen) a fracture toughness of the subsurface formation.

Owner:SAUDI ARABIAN OIL CO

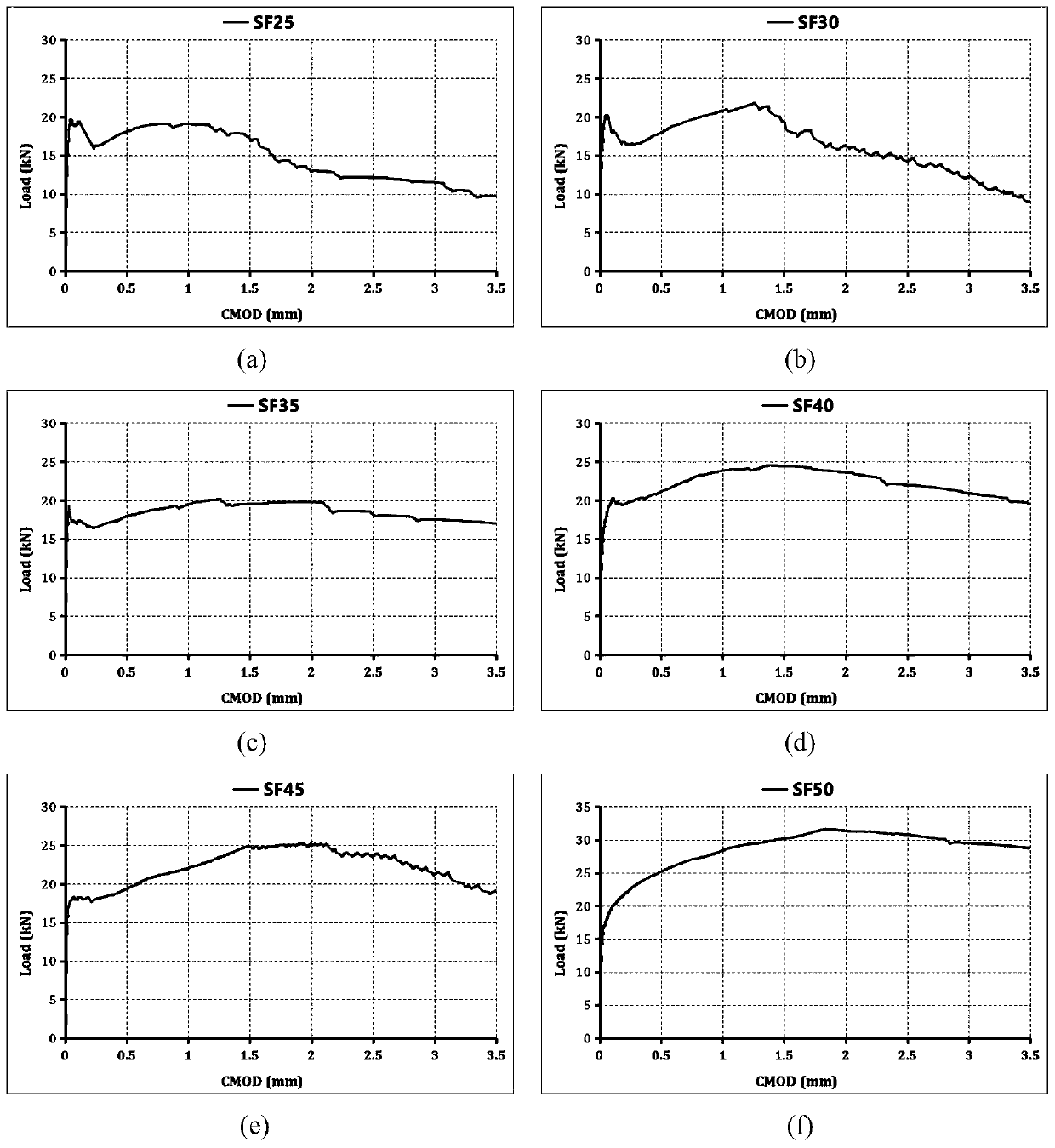

Steel bar-steel fiber concrete shield segment normal section bearing capacity and reinforcement measuring method

ActiveCN111220467AReflects the stress-strain relationshipEmbodies the strengthening and toughening mechanismMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesResidual strengthRebar

The invention discloses a steel bar-steel fiber concrete shield segment normal section bearing capacity and reinforcement measuring method, which is characterized by taking an elastic flexural-tensileresidual strength value obtained through an open beam three-point bending test as a basic parameter of a material constitutive model, converting the elastic flexural-tensile residual strength obtained by the test into axial-tensile residual strength under a constitutive model; determining the axial force and the bending moment of the steel fiber reinforced concrete on the normal section of the shield segment according to the tensile strength and the stress distribution function of the steel fiber reinforced concrete; and then, considering steel bar configuration, establishing a steel bar-steel fiber concrete shield segment normal section ultimate bearing capacity balance equation set, and determining ultimate bearing capacity or steel bar configuration on the shield segment normal section. Therefore, the method not only can be used for determining the ultimate bearing capacity, but also can be used for determining the steel bar configuration, a steel bar-steel fiber reinforced concrete structure normal section bearing capacity measuring and calculating system is further perfected, and full exertion of the advantages of the steel bar-steel fiber reinforced concrete structure and application and popularization in other fields are facilitated.

Owner:中铁科学研究院有限公司 +1

Method for measuring relationship between external load of ceramic soldering joint and metal deformation of welding line

InactiveCN102735552AFair use requestMaterial strength using steady bending forcesDigital imageSoldering

The invention discloses a method for measuring a relationship between an external load of a ceramic soldering joint and metal deformation of a welding line, relates to a method for measuring the relationship between an external load of a welding joint and metal deformation of a welding line, and aims to solve the problem that a method for measuring the external load of the ceramic soldering joint and the metal deformation of the welding line is not available. The method comprises the following steps of: selecting a piece to be detected, performing a three-point bending test, and recording deformation pictures of the welding line under different load conditions in the process of bearing the external load by adopting a metallographic microscope; and analyzing the deformation pictures through DIC software by utilizing a digital image fitting method, namely obtaining the relationship between the external load and the metal deformation of the welding line of the piece to be detected. The invention has the advantages that the constitutive relation between the metal deformation of the welding line and the joint strength is successfully disclosed by combining the three-point bending test, the metallographic microscope and the digital image fitting method. The method is mainly used for measuring the relationship between the external load of the ceramic soldering joint and the metal deformation of the welding line.

Owner:HARBIN INST OF TECH

Re-peelable adhesive sheet

ActiveCN102093827AReduce warpageReduce crackingAdhesive articlesSynthetic resin layered productsEngineeringThree point flexural test

Owner:NITTO DENKO CORP

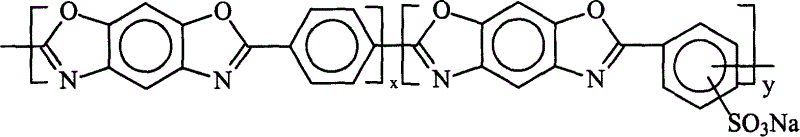

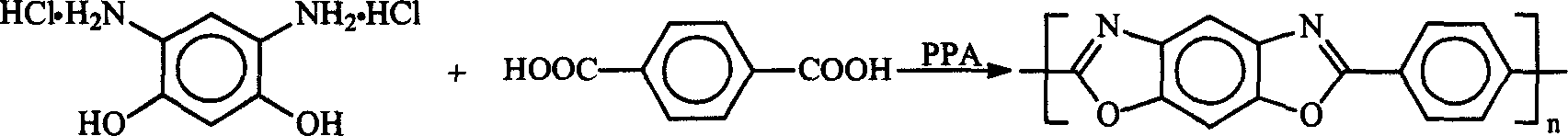

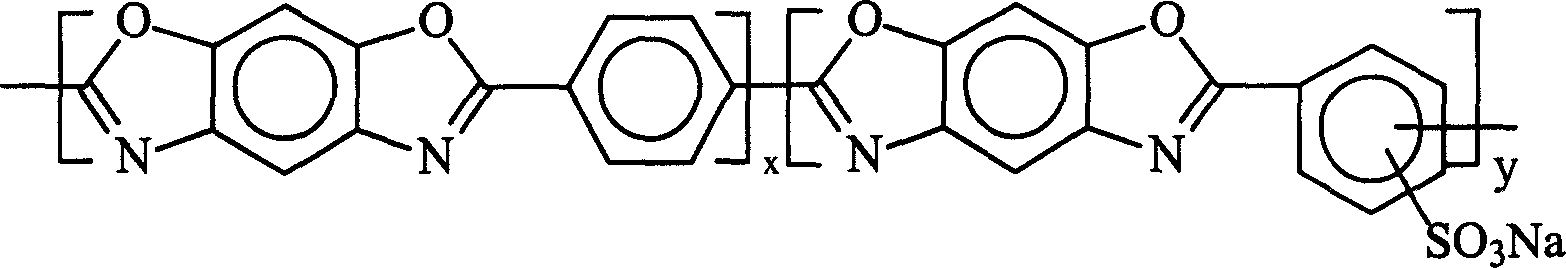

Poly-benzobisoxazole polymer containing ion group and process for preparing same

This invention discloses a polyphenylene and two- azole polymer with ionogenic group and its preparation method. The polymer solution can be dry sprayed and wet spinned to prepare high capability fiber by screw extruder, and its compression modulus can be determined by three points flexural measurement method. The polymer with strong ionic interaction between molecules is synthesized by import ionogenic group to macromolecular chain, and its interface capability can be improved. The above molecular structure is the polymer's molecular structure in this invention.

Owner:DONGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com