Detection method for betel nut fiber softness

A measurement method and technology of softness, applied in the direction of measuring device, strength characteristics, and using stable bending force to test the strength of materials, etc., can solve the problems that the softening effect cannot be formed into a unified evaluation standard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to Embodiment 7

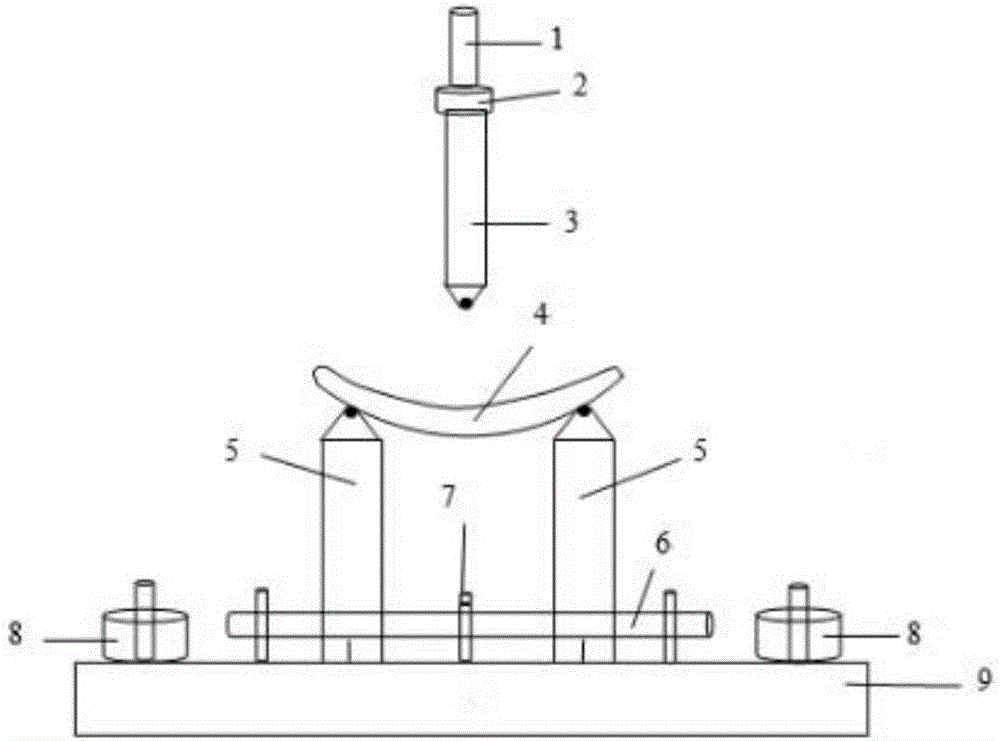

[0036] The longitudinal cutting width of dried betel nut is 5.0mm, 6.0mm, 7.0mm, 8.0mm, 9.0mm, 10.0mm and 11.0mm. The central part of the quasi-betel nut sample is pressed down, and the measurement parameters of the fiber softness are measured by the three-point bending method. The final speed is 30mm / min, and the speed during the test is 60mm / min, and the pressing distance of the probe is 4.0mm. The experiment was repeated 3 times, and the average value was taken.

[0037] Table 1 shows the elastic modulus calculated by the formula based on the maximum displacement in the elastic stage and the corresponding maximum stress.

[0038] Table 1

[0039]

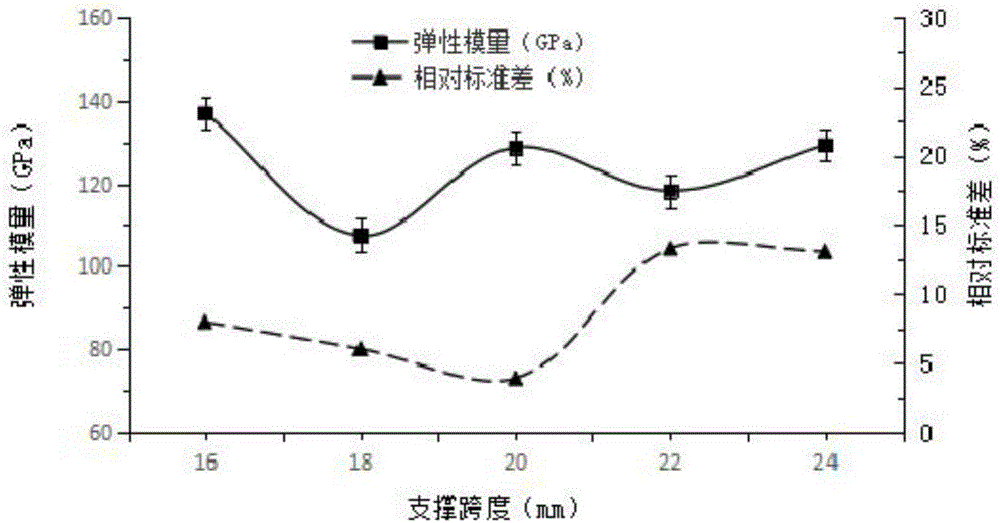

[0040] Origin8.5 was used for data analysis and figure 2 , to calculate the standard error. Significant difference analysis was performed using SPSS 19.0 software. After analyzing the elastic modulus of different sample widths by Spss software, it was found that there was no significant difference between the elastic mod...

Embodiment 13

[0048] This method can also be used for the mensuration of the softness of betel nut fresh fruit fiber. In embodiment 13, the fresh betel nut fruit with consistent maturity is selected to be longitudinally cut into a sample with a width of 9.0 mm, and the concave surface of the betel nut sample is placed on the three-point bending test. Between the supporting vertical walls of the device, the supporting span is 20.0 mm. The softness of the fiber is measured by the three-point bending method. The probe is aligned with the center of the betel nut sample and pressed down. The initial force of the probe is 1N, and the speed before and after the test is 30mm / min, test speed 60mm / min, probe pressing distance 4.0mm. The experiment corresponding to each embodiment was repeated 3 times, and the average value was obtained.

[0049] Table 3 shows the elastic modulus value calculated by the formula based on the maximum displacement in the elastic stage and the corresponding maximum stress...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com