Rock type-I crack expansion whole process detection method based on three-point bending test

A technology of three-point bending and crack propagation, which is applied in the direction of applying a stable bending force to test the strength of materials, measuring devices, instruments, etc. It can solve the problems of inability to quantitatively determine cracks, macroscopic cracks, etc., and achieve accurate test results and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and examples.

[0021] The present invention is based on the three-point bending test method for detecting the whole process of rock type I crack propagation, specifically as follows:

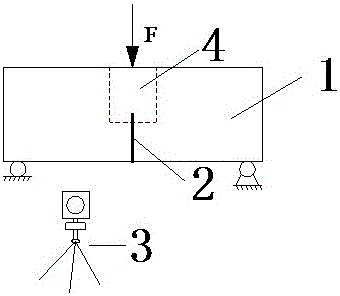

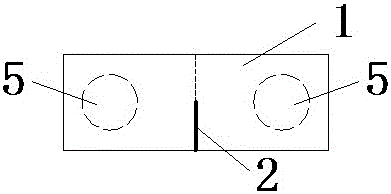

[0022] Firstly, the rock mass of the test project is sampled and made into a flat cuboid specimen 1 (three-point bending specimen), and a type I crack 2 is prefabricated in the middle. The crack surface of the type I crack is perpendicular to the long side of the test piece and located in the middle of the long side. Generally, the depth h of the type I crack of the three-point bending specimen is 0.35-0.50 times the height H of the specimen.

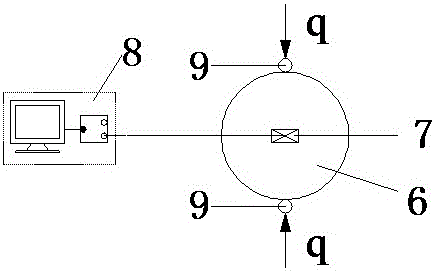

[0023] A three-point bending test was performed on the specimen (see figure 1 ). First follow figure 1 Place the three-point bending specimen in the manner shown. Place the three-point bending test piece flat on the three-point bending testin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com