A method for establishing an equivalent model of a large steam turbine generator stator end wire rod structure

A steam turbine generator and stator end technology, applied in the field of mechanics and mechanics, can solve the problems of complex wire rod modeling process, lack of reasonable and effective equivalent methods, modeling simplification, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0062] See Figure 1- Figure 9 , an embodiment of an equivalent model building method for a large turbogenerator stator end bar structure, comprising the following steps:

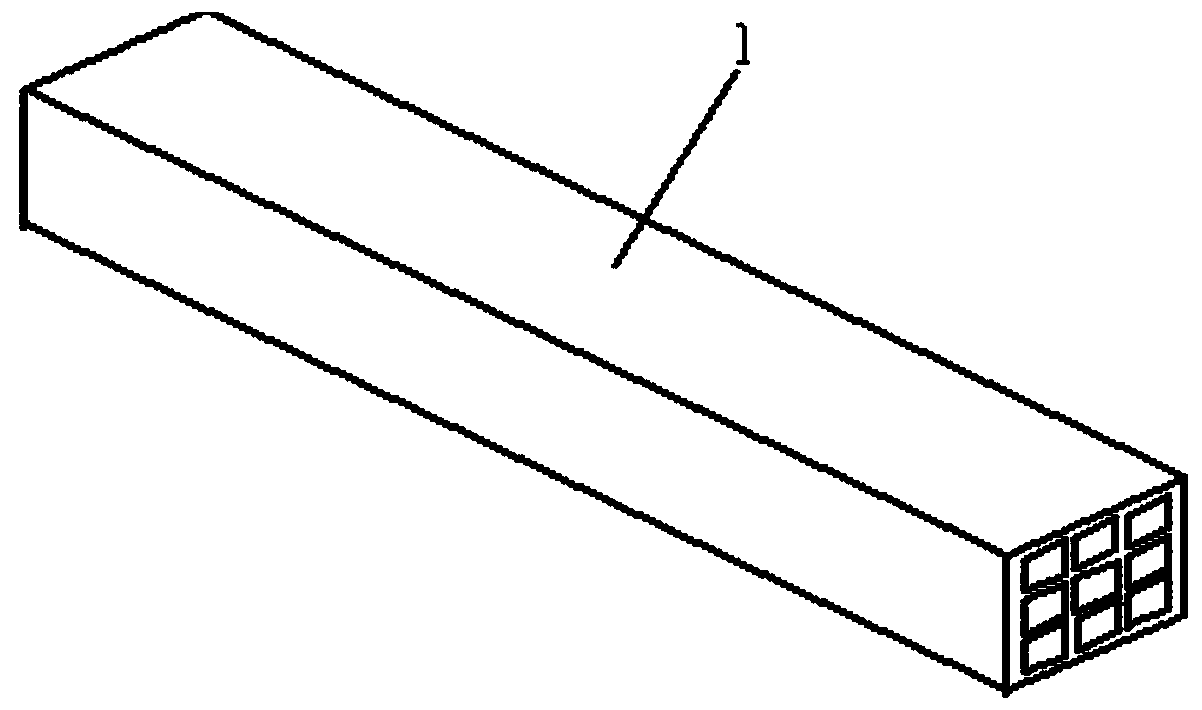

[0063] Step S1: using a three-point bending test to measure the bending stiffness of the wire rod 1;

[0064]In this embodiment, taking a 600MW two-stage three-phase synchronous turbogenerator as an example, the stator winding has two layers of wire bars, and the upper and lower layer wire bars 11, 12 have a short straight line after protruding from the stator core slot. After that, it is developed into a net-like cone shell structure in the form of an involute along the opposite direction. This design ensures the elevation of the end of the wire rod, the pitch and the equal distance between two adjacent coils to ensure equal and uniform current intensity. Reliable ventila...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com