Piezoelectric ceramic fibers having metallic cores

A metal core and piezoelectric material technology, applied in the direction of piezoelectric/electrostrictive/magnetostrictive devices, circuits, piezoelectric effect/electrostrictive or magnetostrictive motors, etc., can solve the problem that piezoelectric materials are not sufficient Applicable, aluminum-based materials are not preferred, etc., to achieve the effect of effective design versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

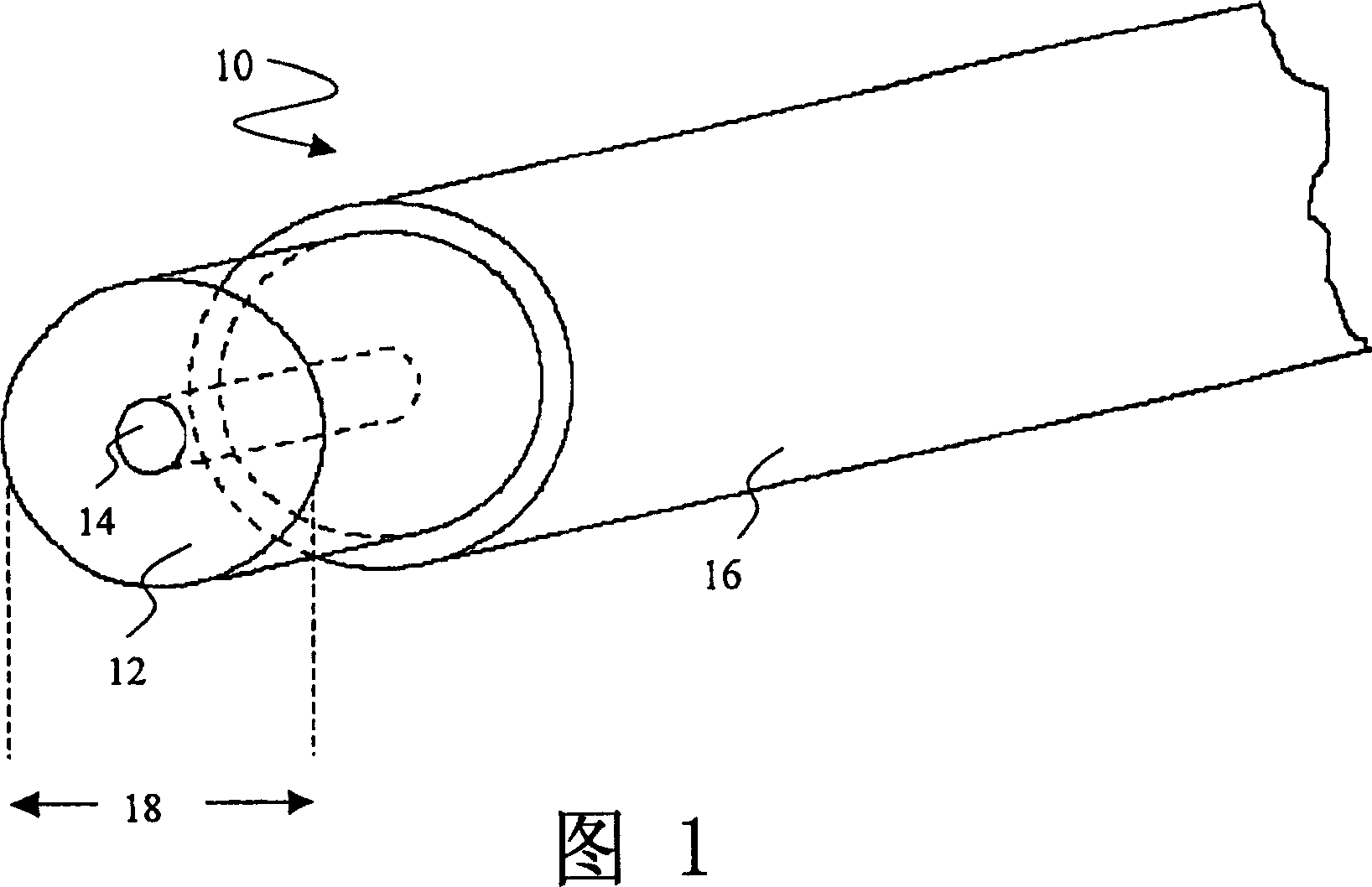

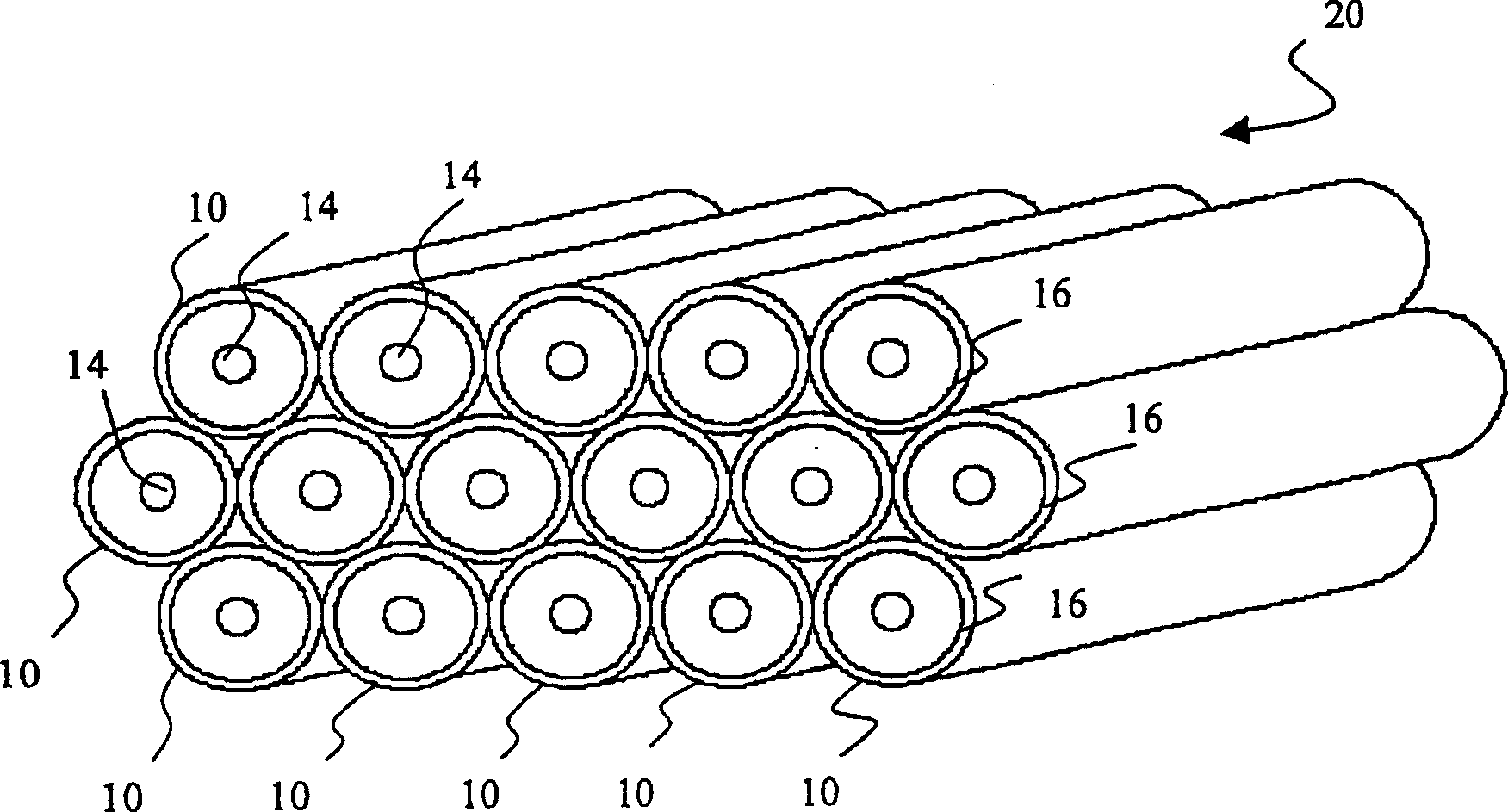

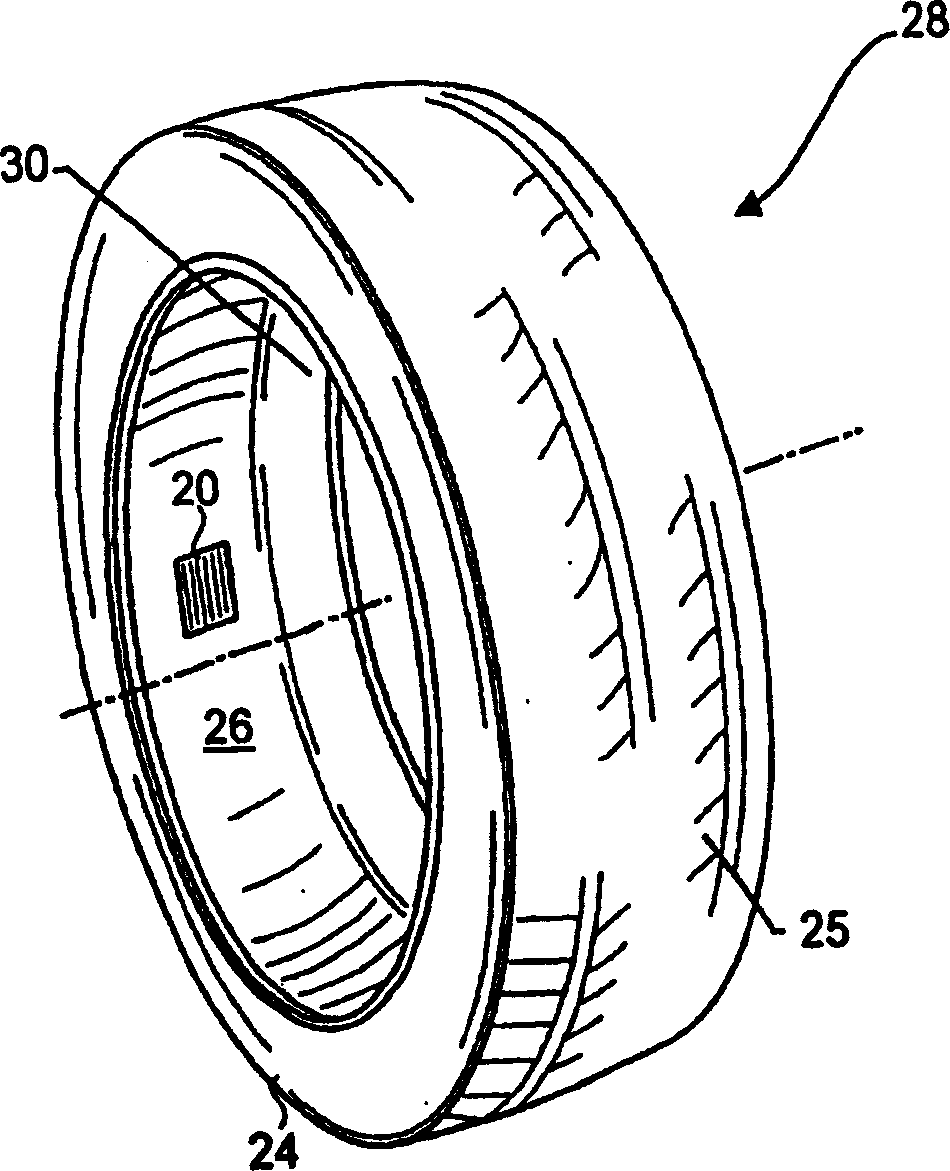

[0029] As stated in the Summary of the Invention, the present invention relates in particular to improved piezoelectric materials for use in tire and wheel assembly applications, and more particularly for use in sensors or actuators or in tire electronics Device components with improved piezoelectric materials in power generation modules. Improved piezoelectric materials include piezoceramic fibers, such as barium titanate, formed together with a metal core, aspects of which are depicted in FIGS. 1 , 2 , 4 and 5 . exist Figure 3A with 3B Such piezoelectric structures integrated with tire components are described in . When the piezoelectric module of the present invention is used in power generation applications, the module can be used in power generation systems such as Image 6 shown.

[0030] Selected combinations of the above-described aspects of the disclosed technology correspond to a number of different embodiments of the invention. It should be noted that each emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com