Experimental device for evaluating pumping oil polish rod coating for fatigue strength influence

A technology of fatigue strength and experimental device, which is applied in the direction of applying repetitive force/pulsation force to test the strength of materials, etc., can solve the problem of not reflecting the fatigue performance of the coating, and achieve the effect of reducing the accident of bending fatigue fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

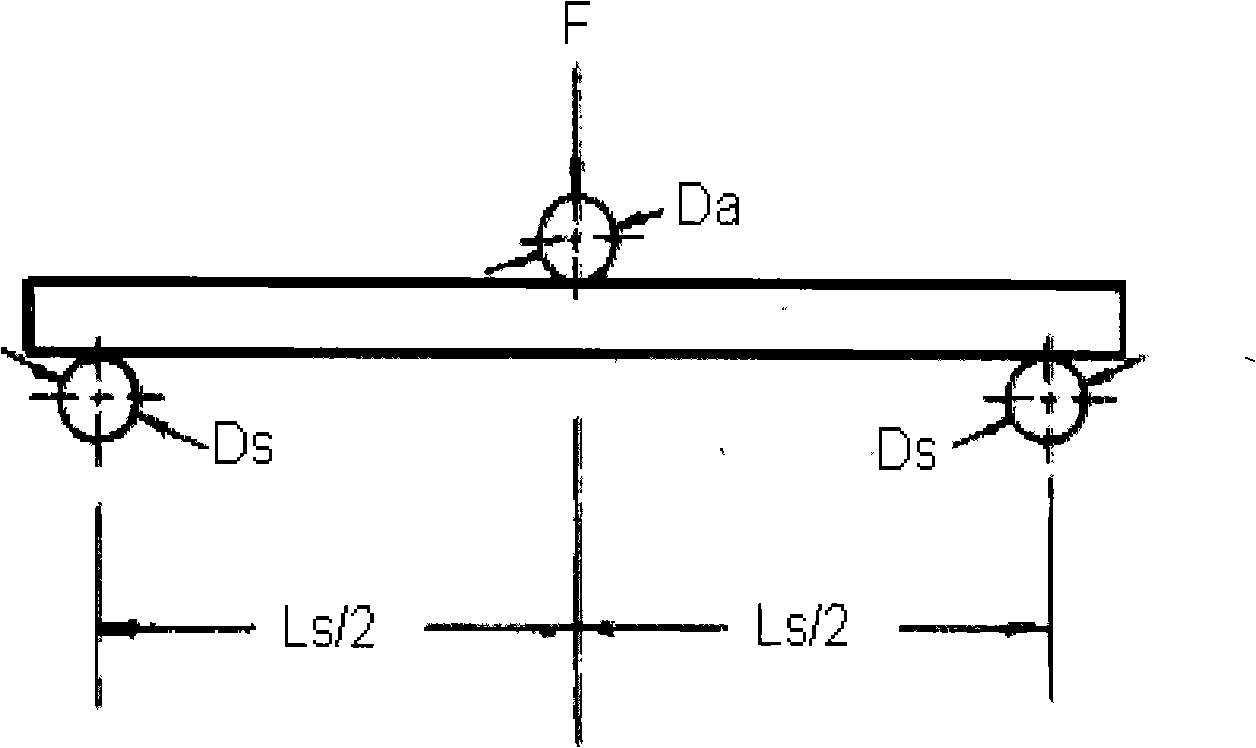

[0019] Such as figure 1 As shown, a kind of experimental device of the present invention evaluates the influence of oil pumping polished rod coating on fatigue strength, comprises three-point bending test machine, pull-pull fatigue test machine and the sample to be tested, and described three-point bend test machine includes Roller 1, indenter clip 2, three-point bending bracket 3 and supporting roller 4, the pull-pull fatigue testing machine includes an upper fixture 5, and the pressure roller and indenter clip of the three-point bending testing machine are assembled as one And be installed in the upper fixture of pull-pull fatigue testing machine, described upper fixture is connected with control system 7 through sensor and connectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com