Three-point bending test apparatus for simulated deep sea high-pressure corrosion fatigue

A three-point bending and corrosion fatigue technology, which is applied in the field of metal material corrosion technology research, can solve problems such as economic waste, casualties, national and social economic losses, and achieve the effects of improving reliability, reducing load, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

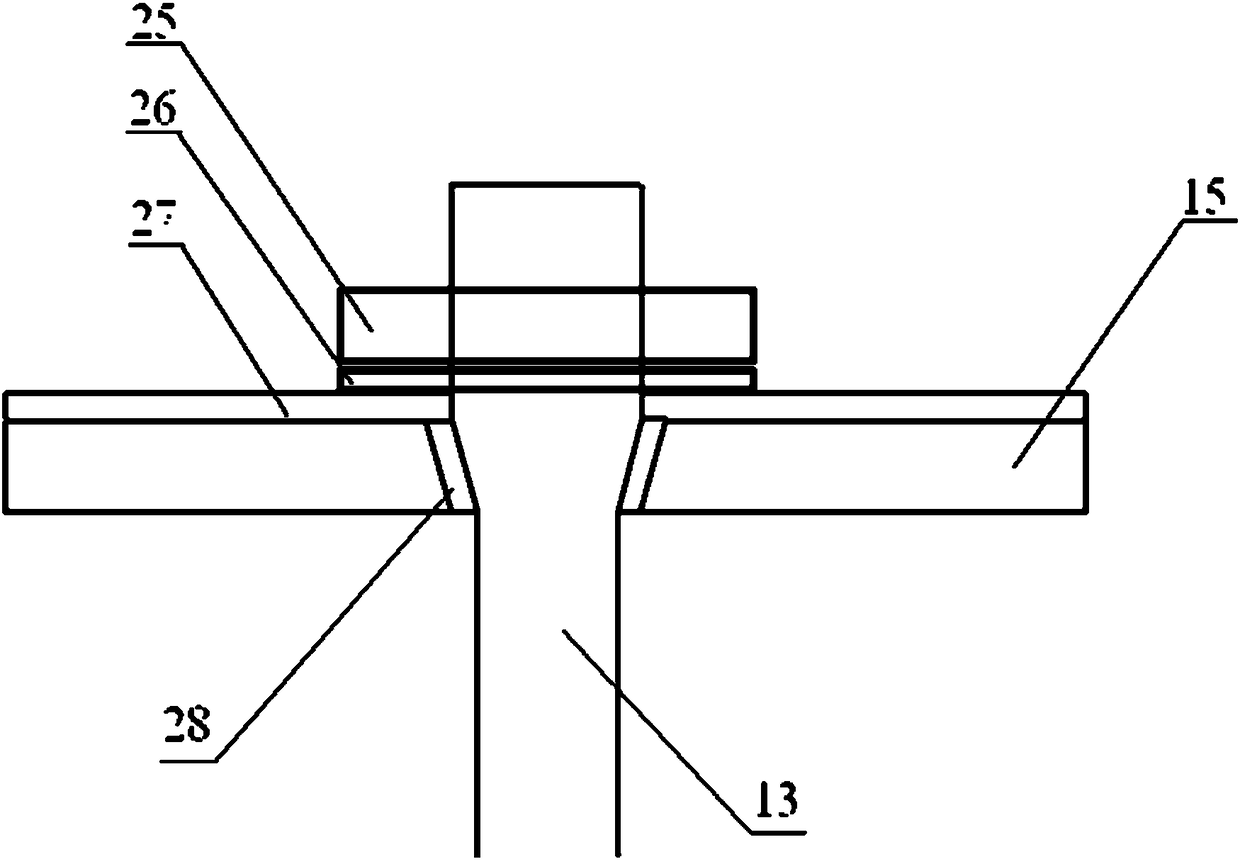

[0028] Such as figure 1 As shown, the present invention provides a three-point bending test device for simulating deep-sea high-pressure corrosion fatigue, which is composed of a water circulation system, a sample fixing device, an indenter actuator, a fixing frame, a temperature control box 24 and a control host 23;

[0029] The water circulation device is connected as follows: the seawater in the 18L water storage tank 1 flows into the autoclave body 20 through the water delivery pipeline 3 under the drive of the booster pump 21 . When the water outlet valve 22 is opened, the seawater in the autoclave can flow into the lower water storage tank 1 through the water delivery pipeline under the action of gravity, so as to realize the circulation flow of seawater in the water circulation device; when the water outlet valve 22 is closed, the seawater in the autoclave Only in and out, the hydrostatic pressure in the autoclave can be controlled by adjusting the inflow of seawater. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com