Re-peelable adhesive sheet

A releasable, adhesive sheet technology, applied in the direction of adhesive types, ester copolymer adhesives, film/sheet adhesives, etc., which can solve the adverse health effects of operators, strong odor, etc. problem, to achieve the effect of reducing warpage, reducing pollution and easy peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

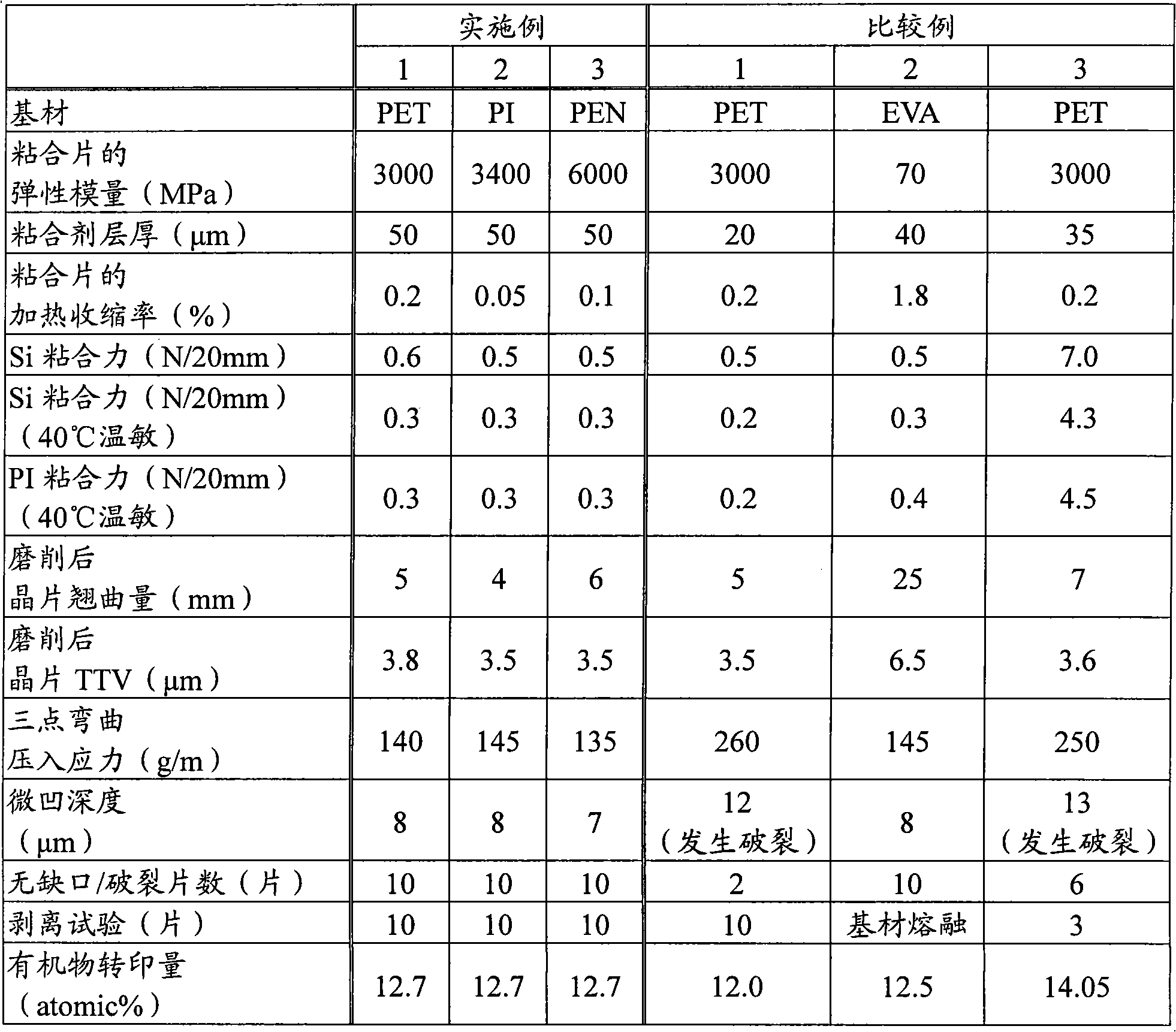

Examples

Embodiment 1

[0092] 100 parts of n-butyl acrylate, 3 parts of acrylic acid, and 0.1 part of 2,2'-azobisisobutyronitrile were mixed at 25°C so that the total volume was 200 g, and put into a flask with an inner capacity of 500 ml. The flask was stirred while introducing nitrogen gas into the flask for about 1 hour, and the inner air was replaced with nitrogen gas. Thereafter, the container was heated to raise the internal temperature to 60° C., and the state was maintained for about 6 hours to perform polymerization to obtain a polymer solution.

[0093] Add 2g polyisocyanate compound (manufactured by Nippon Polyurethane Industry Co., Ltd.: CORONATE L), 0.5g polyfunctional epoxy compound (manufactured by Mitsubishi Gas Chemical: TETRAD C) to 100 g of the obtained polymer solution, dilute with ethyl acetate, stir until uniform, A binder solution is obtained.

[0094] The resulting adhesive solution was coated on a polyester film (PET, 50 μm thick) as a substrate, and dried in a drying oven ...

Embodiment 2

[0096] A pressure-sensitive adhesive sheet was produced in the same manner as in Example 1 except that a polyimide film (PI, 50 μm thick) was used as the substrate instead of the polyester film.

Embodiment 3

[0098] A pressure-sensitive adhesive sheet was produced in the same manner as in Example 1, except that polyethylene naphthalate (PEN, 50 μm thick) was used as the substrate instead of the polyester film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com