Method for rolling and forming rectangular section aluminium alloy ring piece

A rectangular section, aluminum alloy technology, applied in metal rolling, metal rolling and other directions, can solve the problems of low geometric accuracy of rings, low material utilization rate, large machining allowance, etc., to shorten production time and improve metal structure. and performance, the effect of reducing the number of heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The method for rolling and forming a rectangular cross-section aluminum alloy ring is realized according to the following steps: 1) blanking: sawing the aluminum alloy bar into material sections, the length of the material section is L=(1~3)B, and B is the length of the blank Axial dimension.

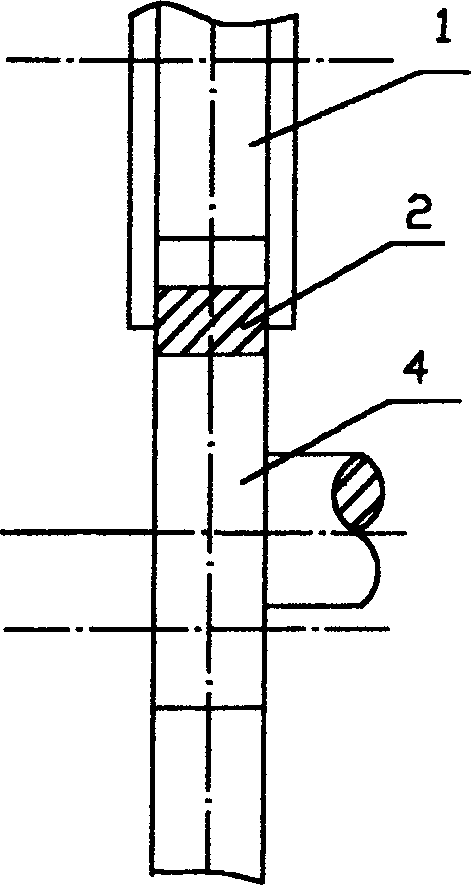

[0018] 2) Billet making: uniformly heat the material section from room temperature to a heat distortion temperature of 350°C to 550°C with high plasticity and low resistance, and upsetting, punching, and punching the hot aluminum alloy material section to make it into a specified shape Dimensions of ring blanks for rolling.

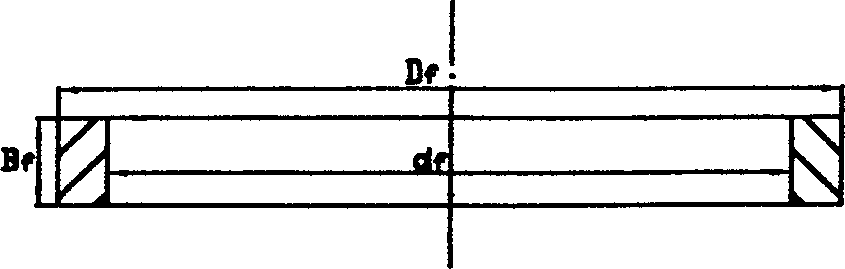

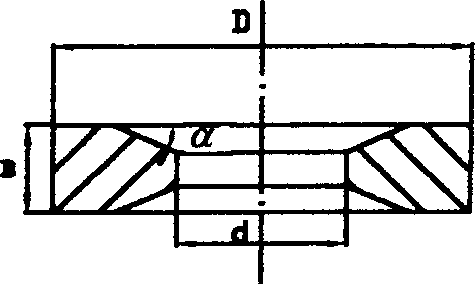

[0019] In order to reduce the burrs on the edge of the hole of the ring, a bevel angle α is designed on the edge of the inner hole of the blank, and its value is α=0°~15°. The hole diameter of the rectangular cross-section aluminum alloy ring forging is d f , the axial dimension is B f , The rolling ratio is λ, λ=2~8, then the hole diameter of the blank f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com