Double-active rubbing forming method for short cylindrical roller bearing outer ring main roll core roll of aerospace main shaft

A technology for short cylindrical rollers and outer rings of bearings, which is applied to shafts, bearings, bearing components, and threaded products, etc. It can solve the problems of uneven and sufficient plastic deformation, uneven distribution of hard phases, and large thermal flow stress of materials, etc. problems, achieve the effect of saving raw materials, shortening production time, and improving metal structure and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

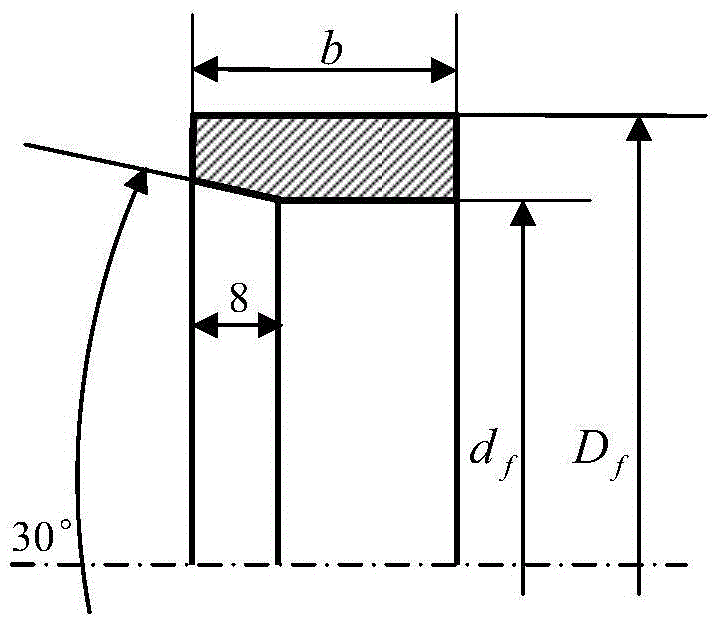

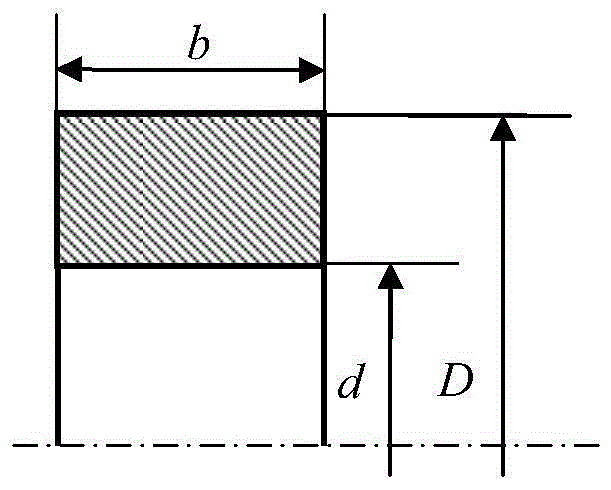

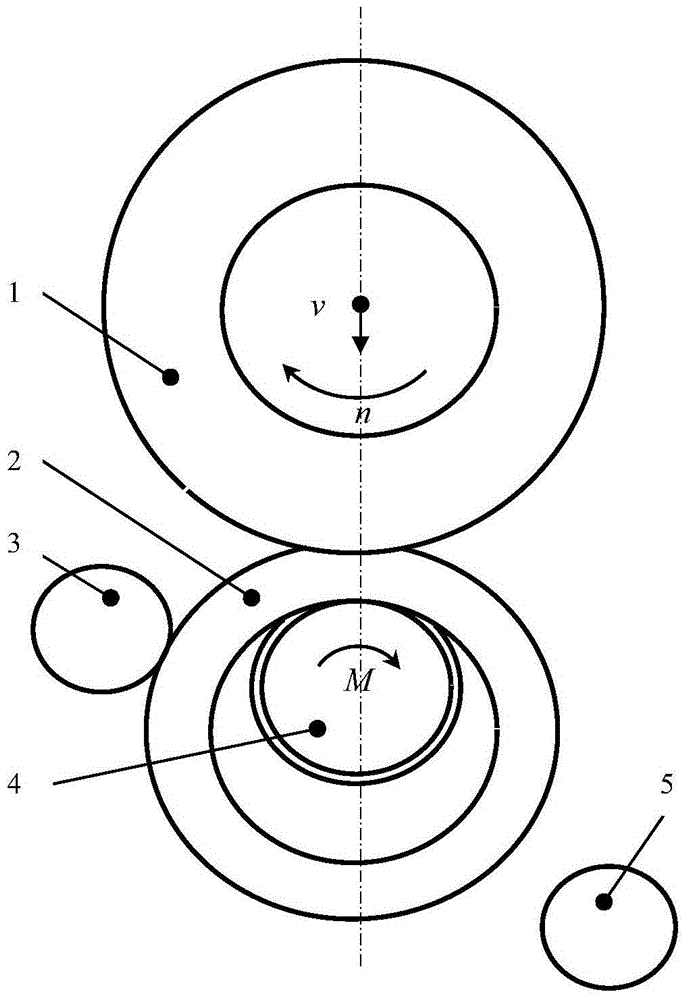

[0022] Such as Figure 1-4 Shown, a kind of method that is used for the dual-active rolling forming of main roll core roll of short cylindrical roller bearing outer ring of aviation main shaft, it comprises the following steps:

[0023] 1) Cutting: sawing the bar into sections, the length of which is L=(1~3)b, where b is the axial height of the ring forging (bearing outer ring) (also the axial dimension of the ring blank).

[0024] 2) Billet making: uniformly heat the material section from room temperature to the heat deformation temperature of high plasticity and low resistance, and then upsetting, punching, and punching the hot material section to make a ring blank for rolling.

[0025] The material section is uniformly heated from room temperature to the thermal deformation temperature of high plasticity and low resistance, and the thermal deformation temperature of the AISI-M50NiL special steel annular blank is 950°C to 1200°C (that is, the material of the annular blank is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com