Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51 results about "Mass centre" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

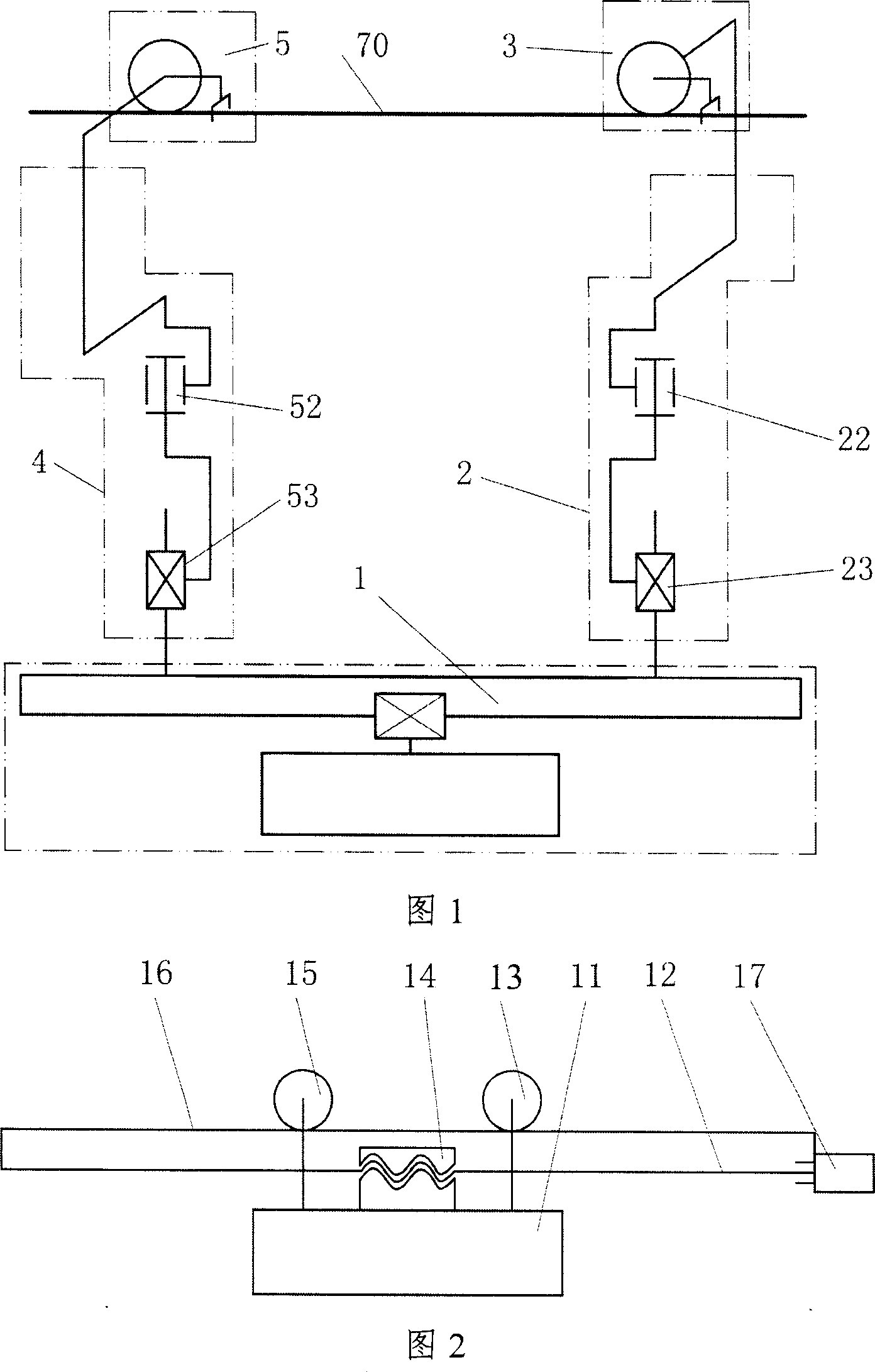

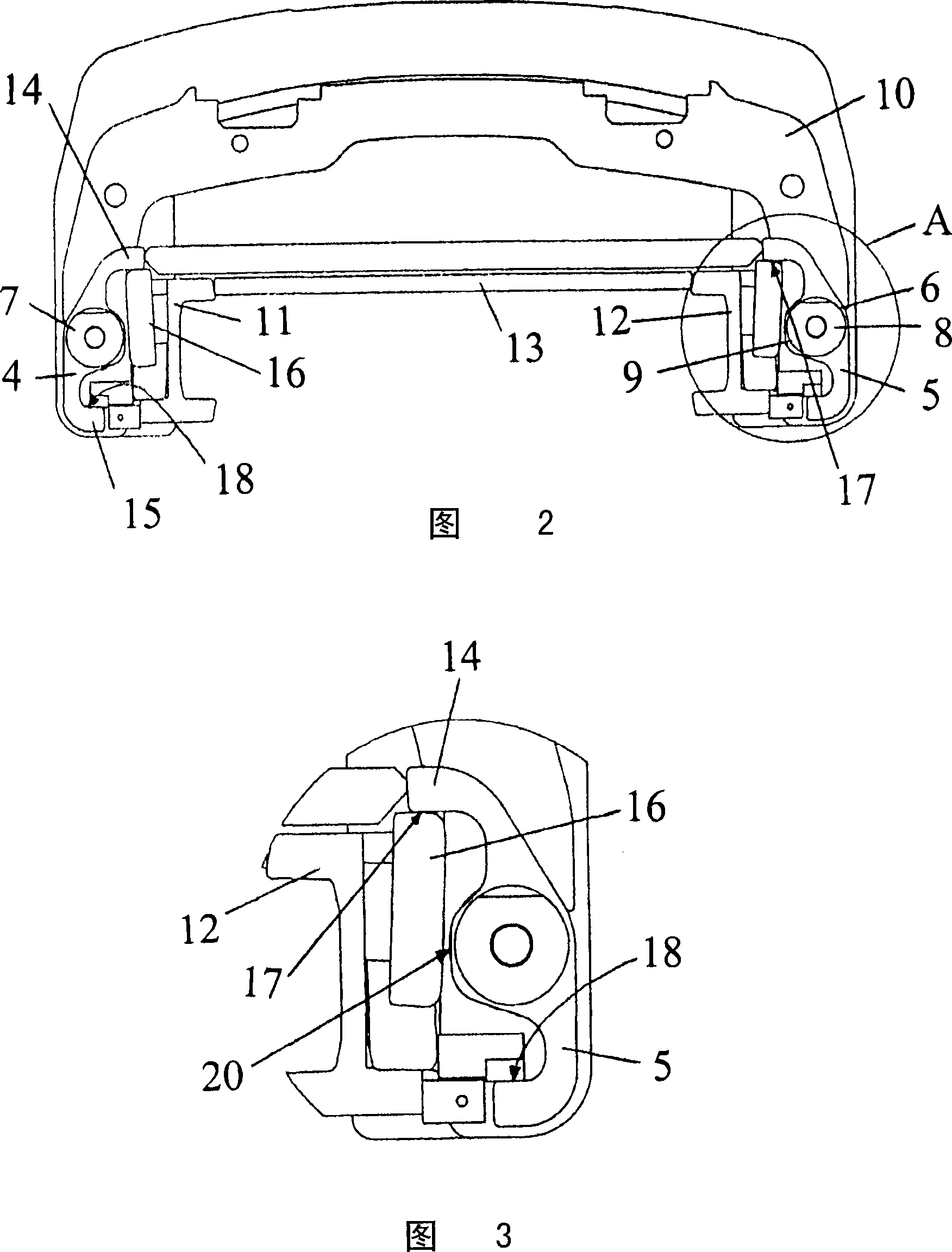

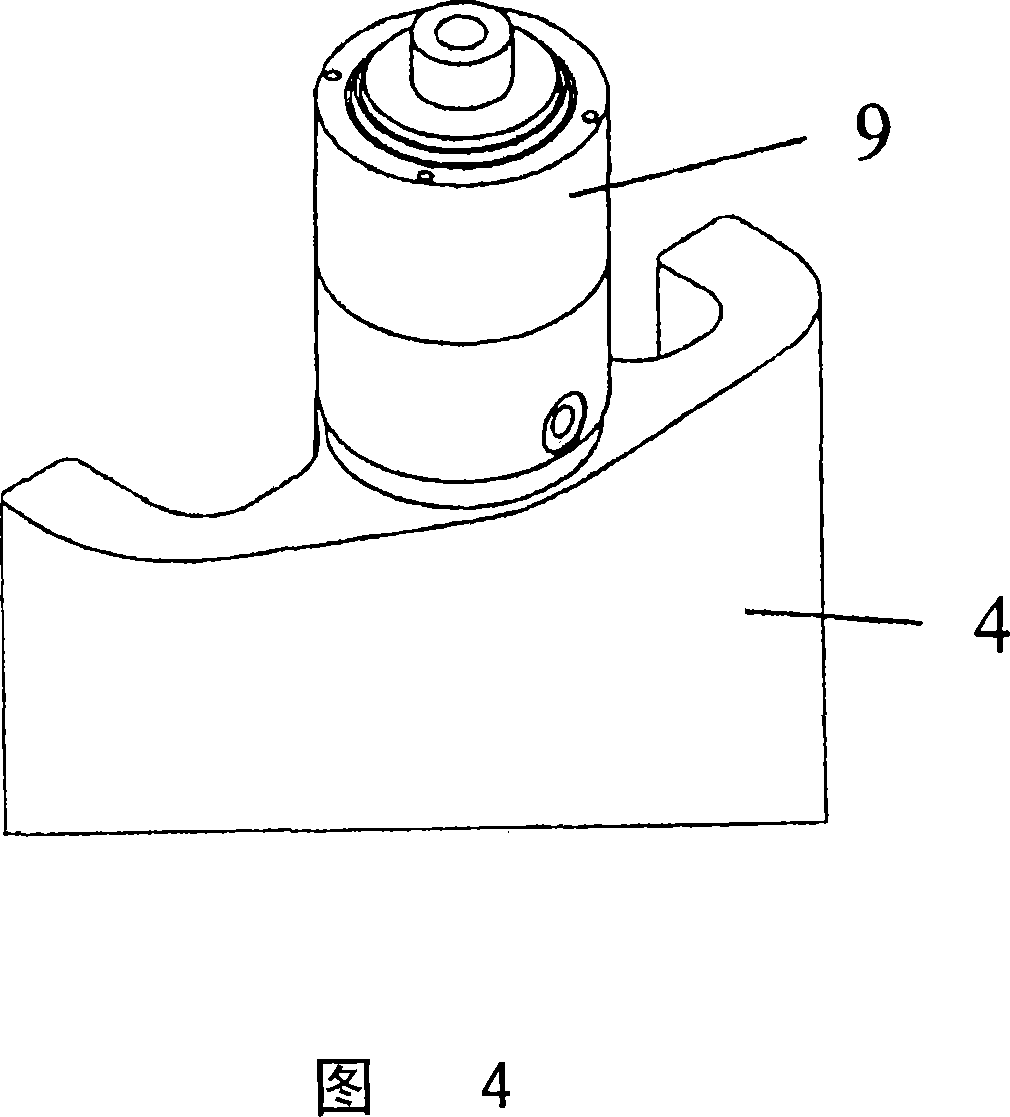

Autonomous obstacles surmounting mechanism of grip hook composite type tour inspection robot

ActiveCN100999216AEasy to walkConducive to overcoming obstaclesLocomotivesApparatus for overhead lines/cablesAgricultural engineeringTwo degrees of freedom

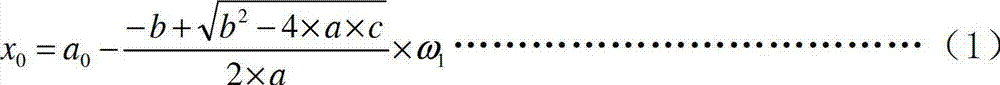

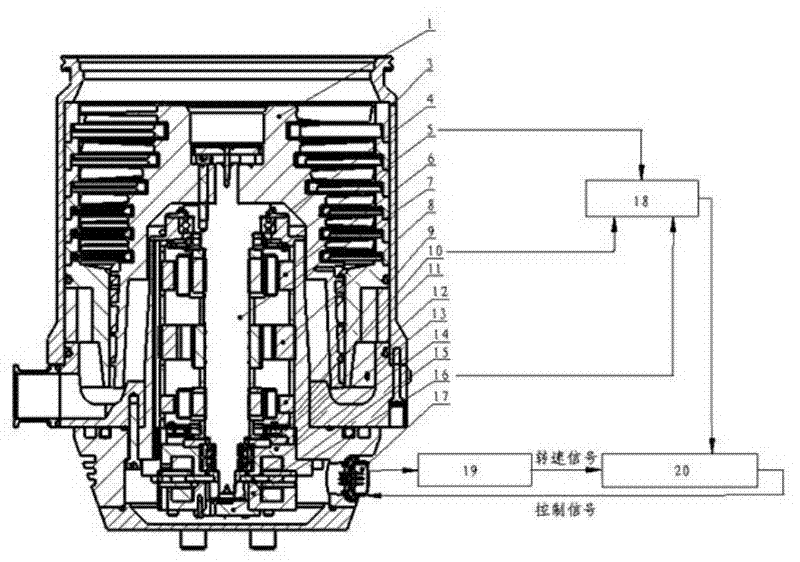

The present invention discloses an EHV transmission line patrol robot mechanism. It is formed from mass centre regulation mechanism, front arm, forwards-travelling holding mechanism, rear arm and backwards-travelling holding mechanism. Said invention also provides its working principle and its concrete operation method.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

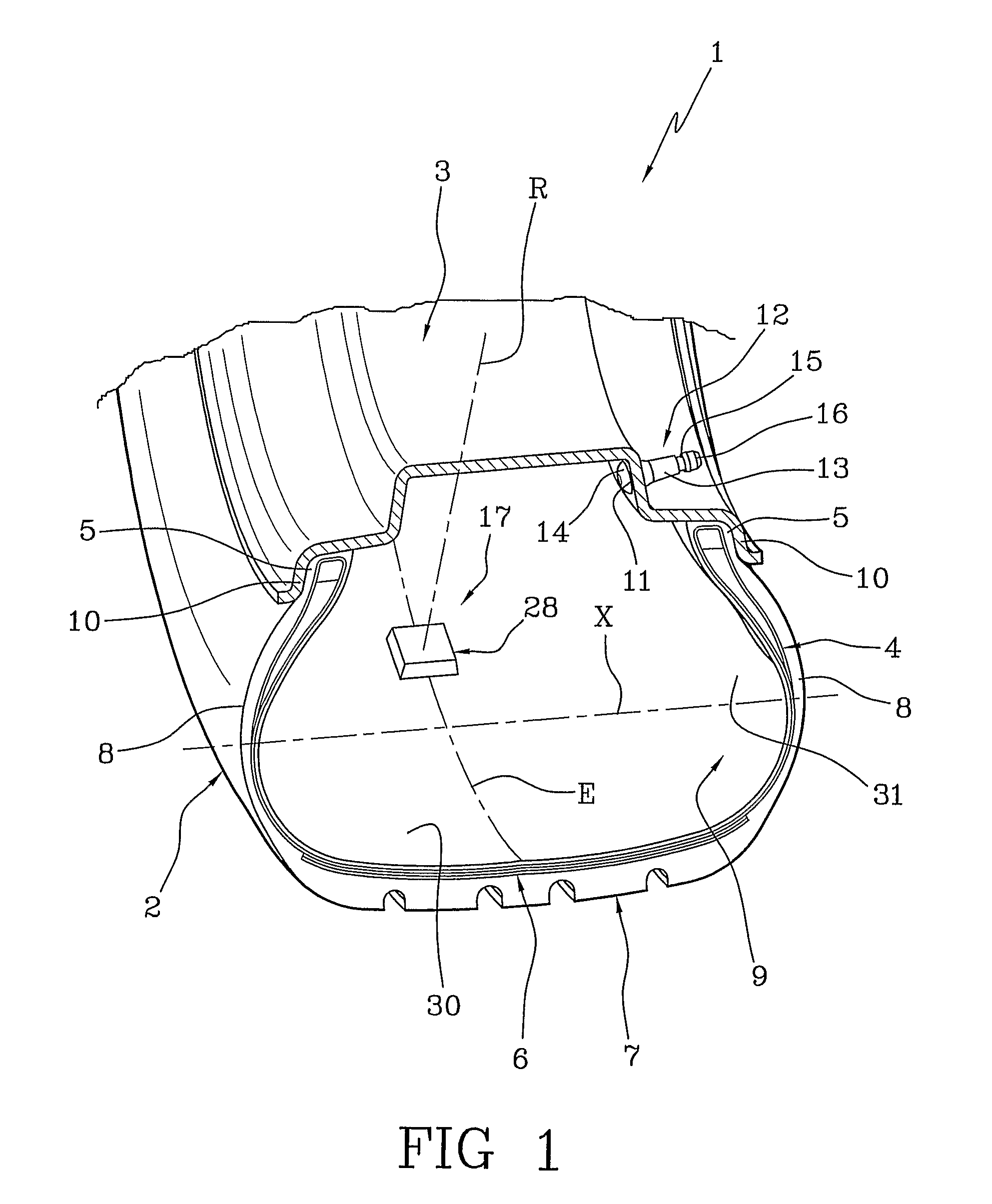

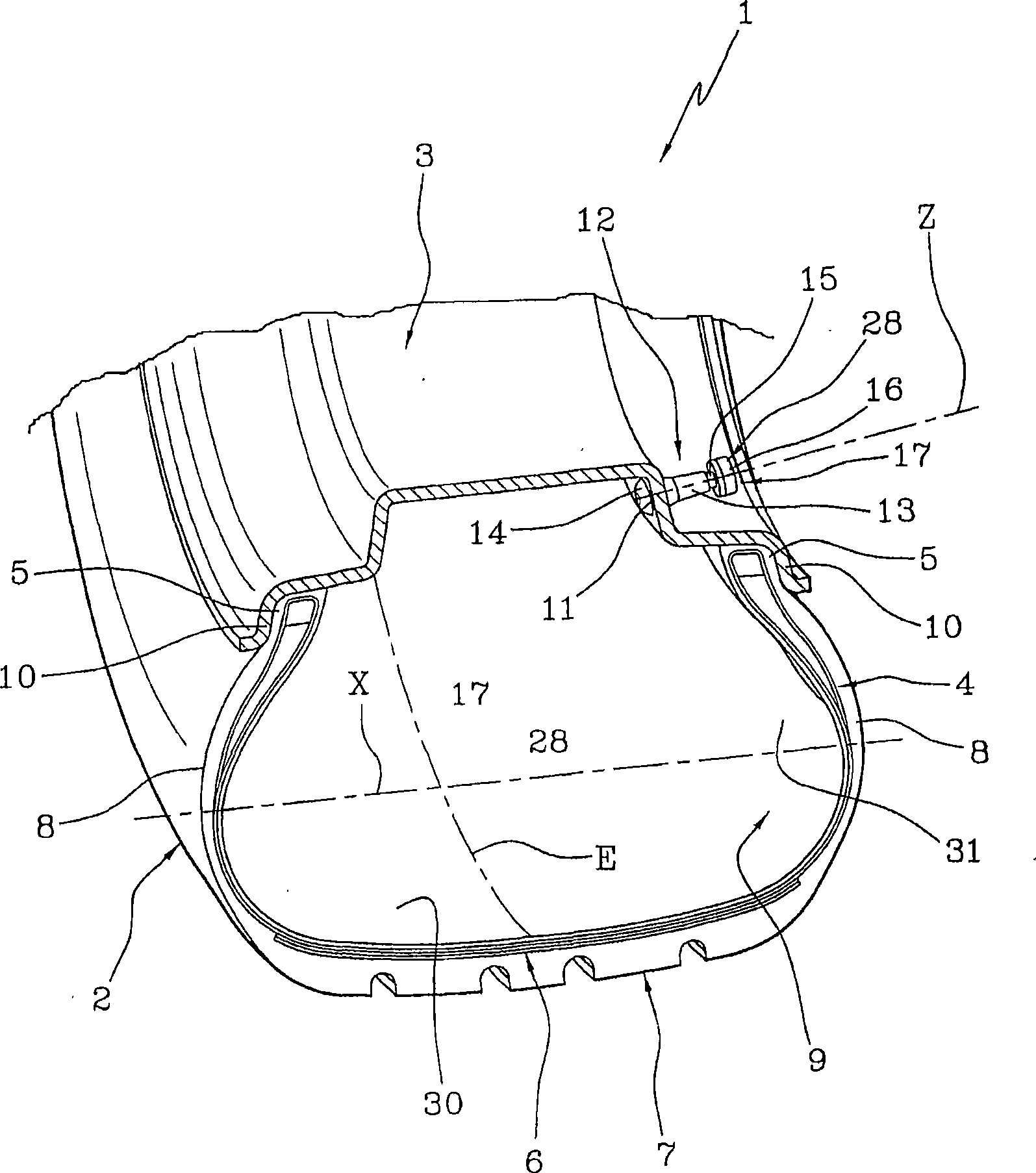

Wheel for vehicles

InactiveUS7856871B2Easy to installEasy to replaceTyre measurementsMechanical energy handlingRotational axisElectric generator

A wheel for vehicles includes a rim, a tyre mounted on the rim, and at least one device for energy generation operatively associated with the tyre. The device for energy generation includes a first element that is fixed relative to the rim or to the tyre, and a second element mounted on the first element and free to rotate relative to the first element around a predetermined rotation axis. The second element has a mass centre eccentric to the predetermined rotation axis. The device for energy generation further includes an electric generator having a stator mounted on the first element and a rotor mounted on the second element.

Owner:PIRELLI TYRE SPA

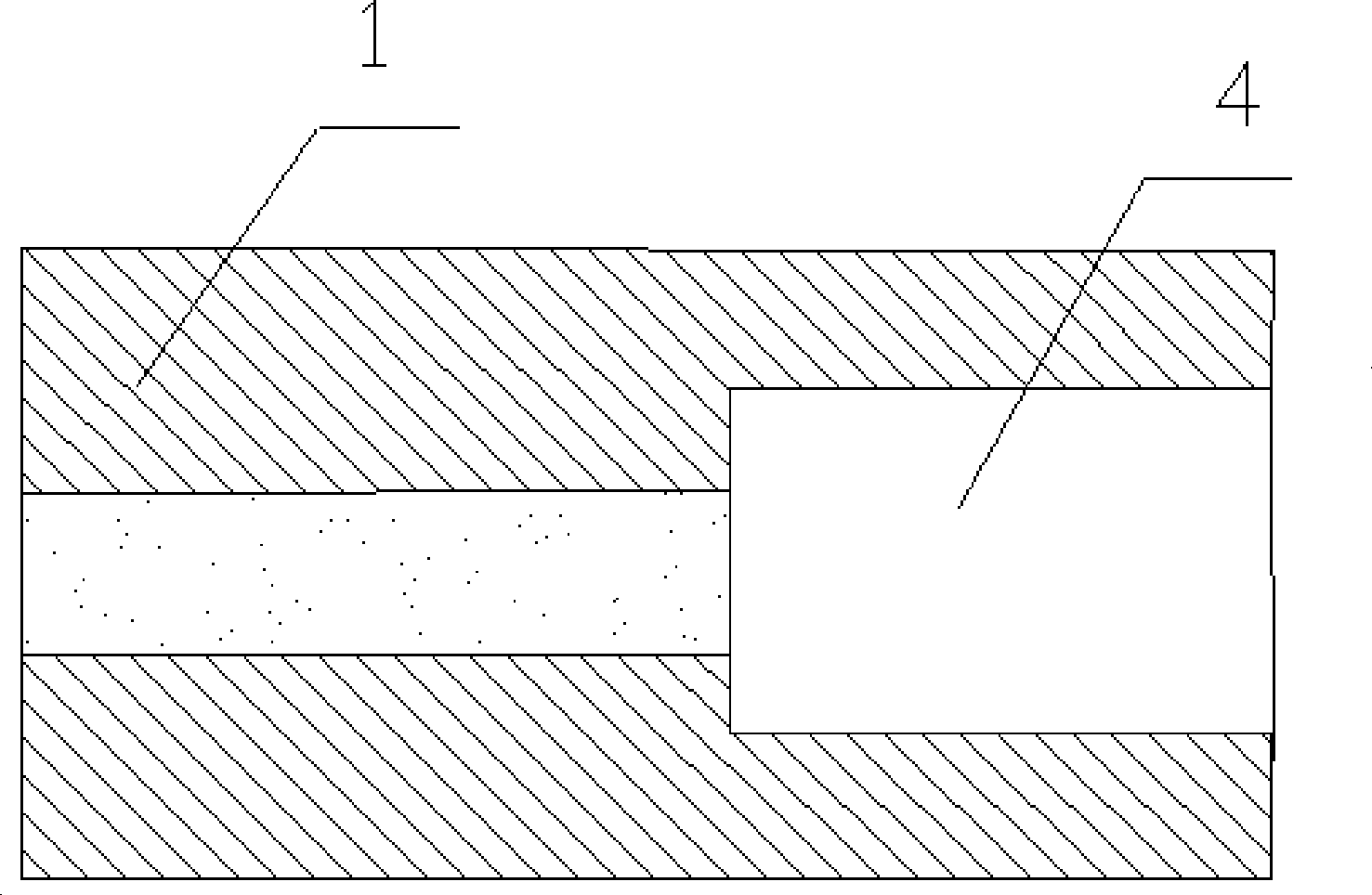

Optical fiber F-P acceleration and pressure sensor and its manufacturing method

InactiveCN101424697AChange rangeChange thicknessAcceleration measurement using interia forcesCladded optical fibreOptical reflectionFiber

The invention provides a fiber optic acceleration and pressure sensor dispensing with other structures, in particular relates to a fiber optic Fabry-perot acceleration and pressure sensor which comprises optic fibers and connected optic fibers, wherein microflutes are formed on the end faces of the optic fibers, projections are formed on the connected optic fibers, and the optic fibers and the connected optic fibers are connected through butted joint to form a fabry-perot chamber and membranes; and besides, the optical reflecting surface of the fabry-perot chamber is a plane. The sensor does not need to be matched with other structures; when the sensor senses the external accelerated speed and pressure, the length of the fabry-perot chamber can be changed, and the corresponding measurement amount can be obtained by measuring the change of the length of the chamber; and besides, as the optical reflecting surface of the sensor is a plane, the sensor has favorable optical performance. The invention can be used as the acceleration and pressure sensor, and the measurement range thereof can be changed by changing the thickness or the shape of each membrane and the length or the weight of the hard mass centre.

Owner:冉曾令

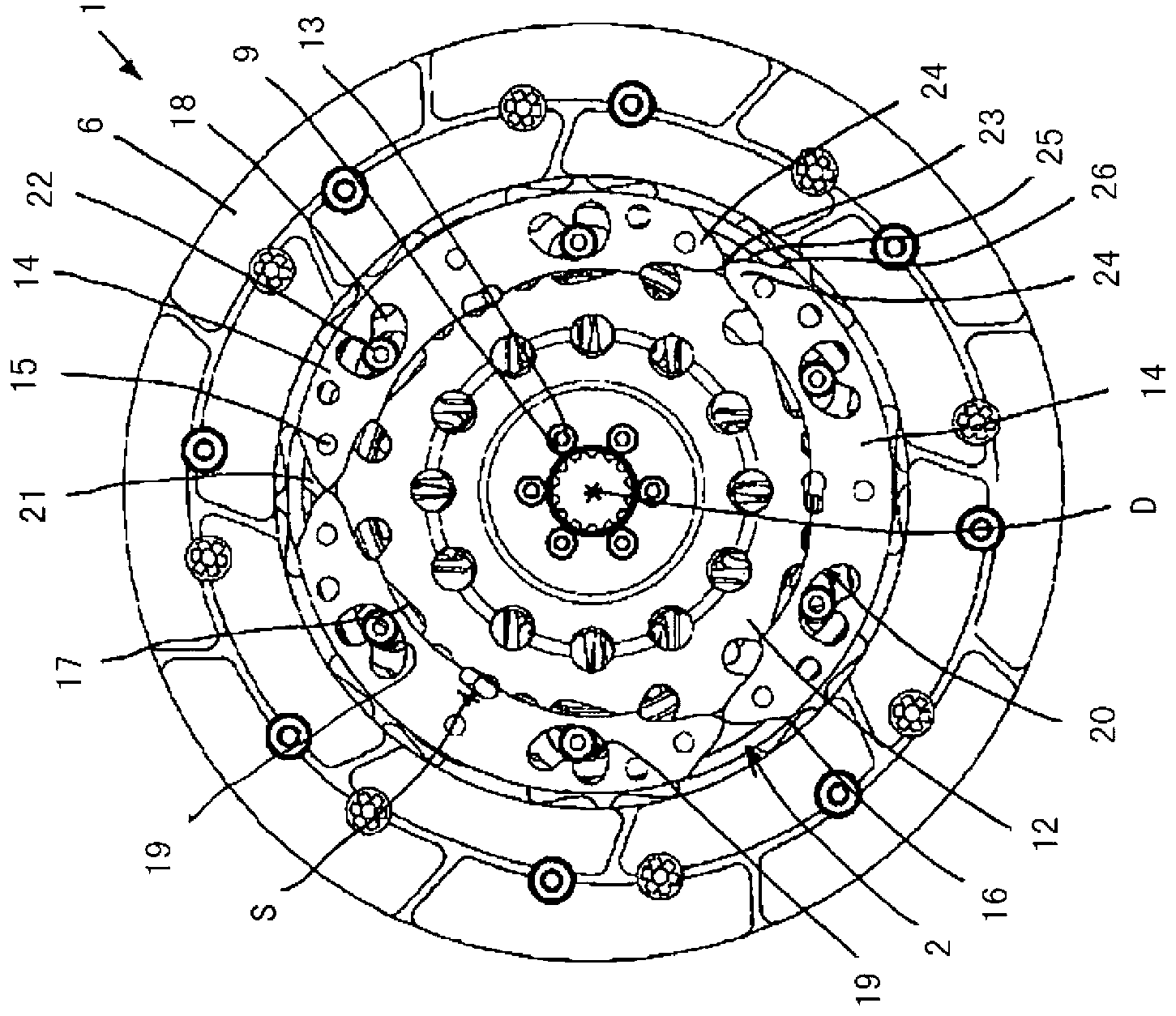

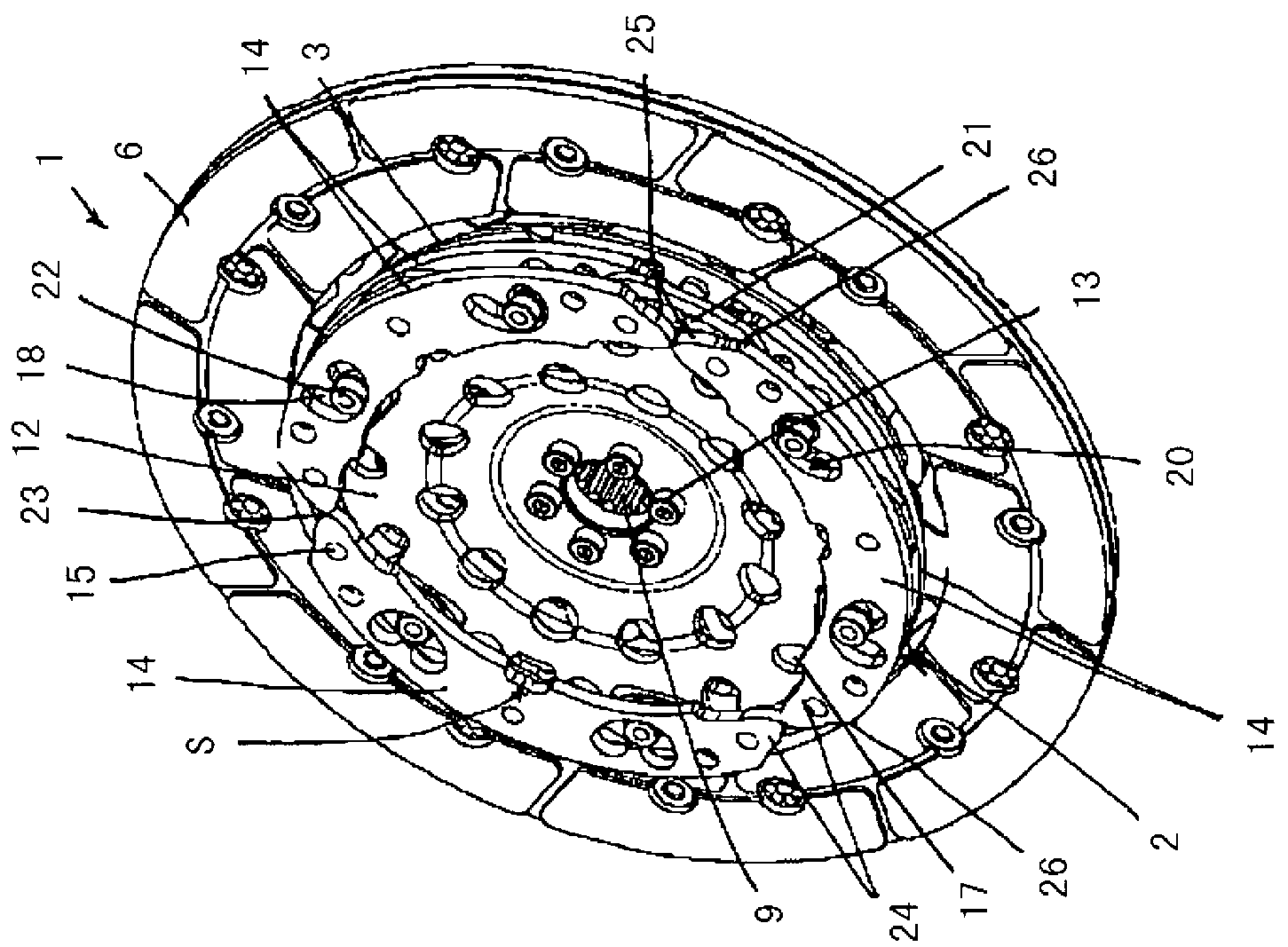

Centrifugal force pendulum and clutch disc having the same

ActiveCN103228946AReduced radial installation spaceAchieve overlapRotating vibration suppressionEngineeringCentrifugal force

The invention relates to a centrifugal force pendulum (2, 2a) having a carrier flange (12, 12a) and having at least one pendulum mass (14, 14a) which is arranged so as to be pivotable in the circumferential direction and radially to a limited extent with respect to the carrier flange by means of rolling bodies (22) which roll on raceways (49) of cutouts (17) provided in the carrier flange and in the pendulum masses, and also to a clutch disc (1) having the same. To attain improved vibration isolation of rotary vibrations in particular of a centrifugal force pendulum arranged on a small diameter of the clutch disc, the at least one pendulum mass is guided in the raceways so as to rotate about the mass centre of itself during a deflection with respect to the carrier flange.

Owner:SCHAEFFLER TECH AG & CO KG

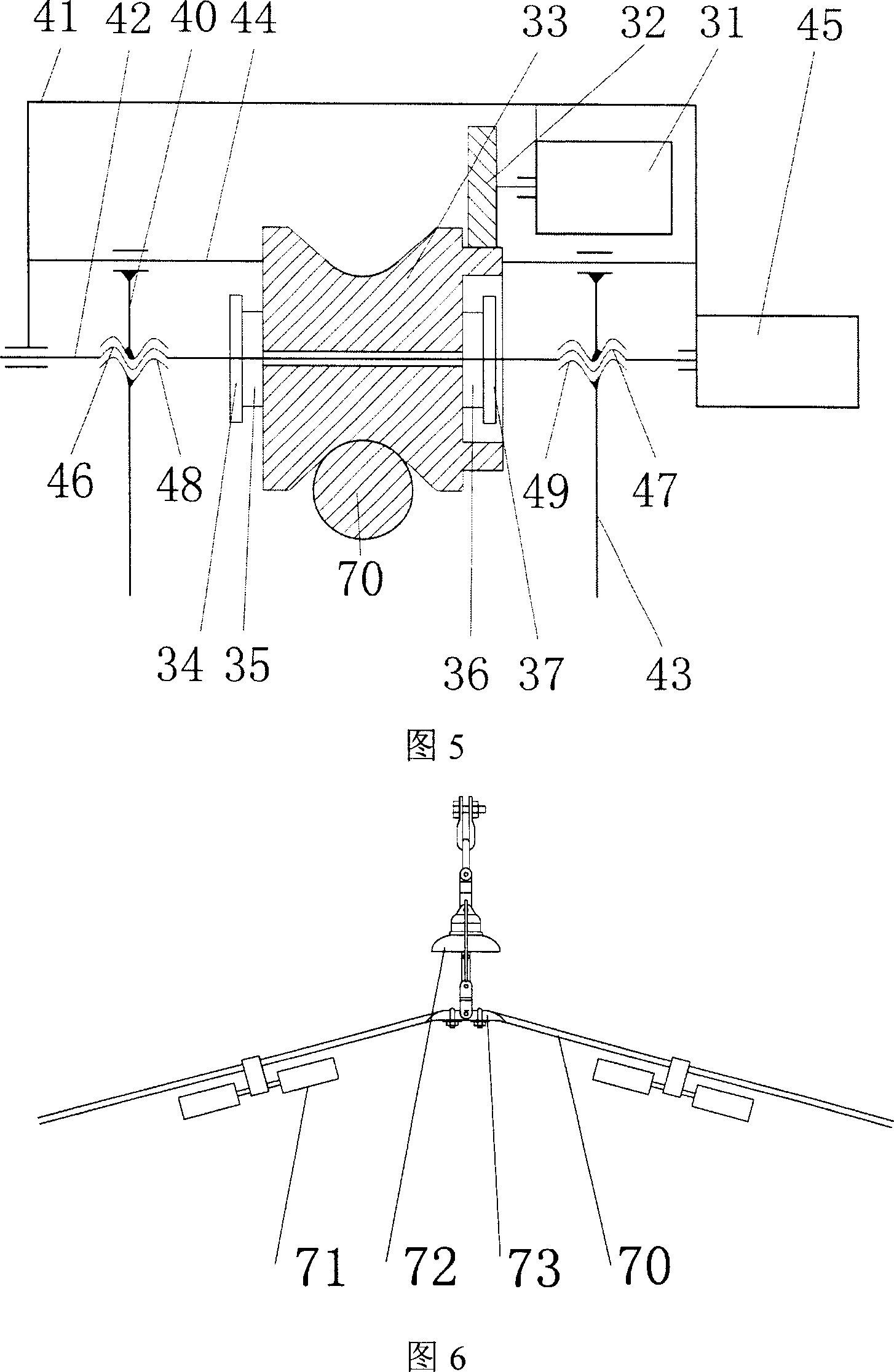

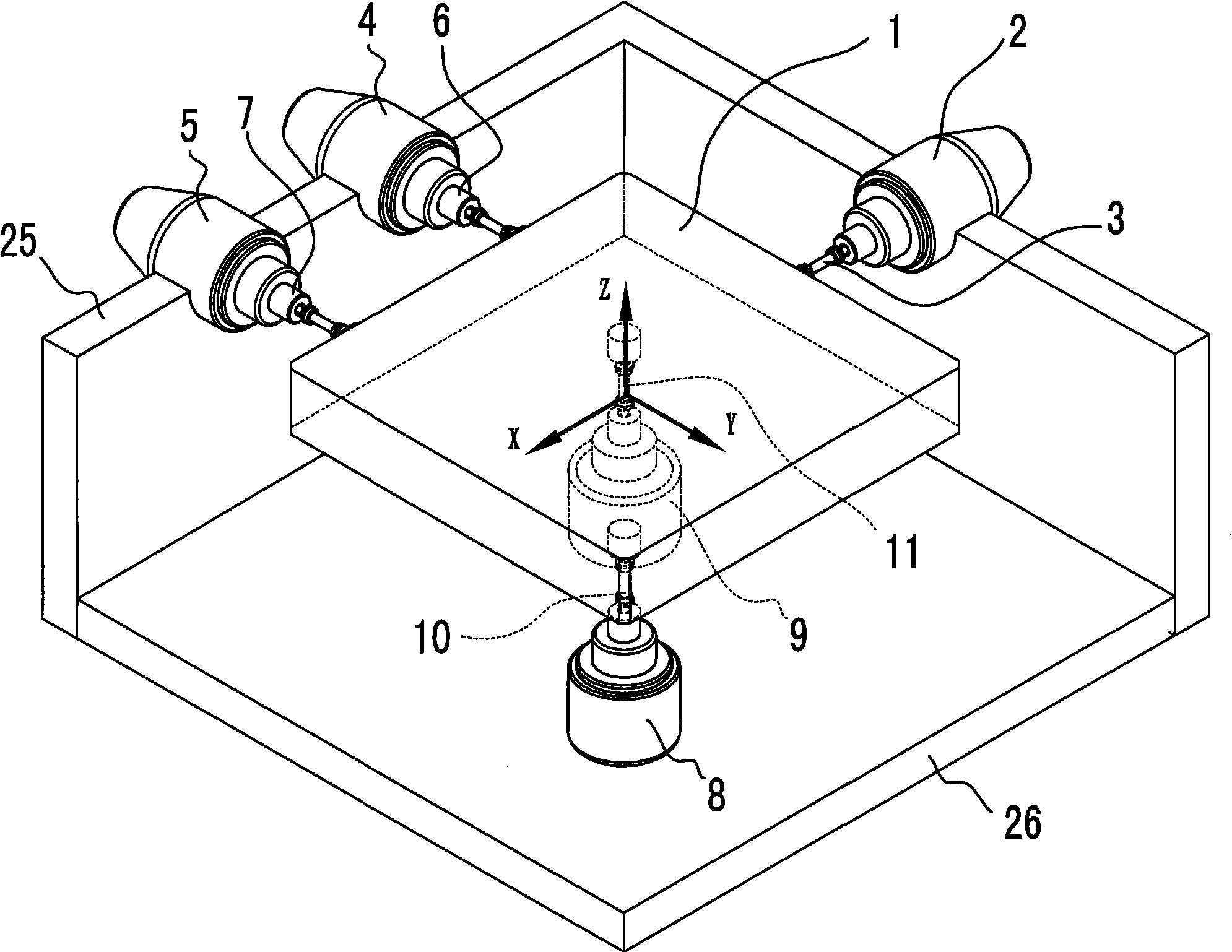

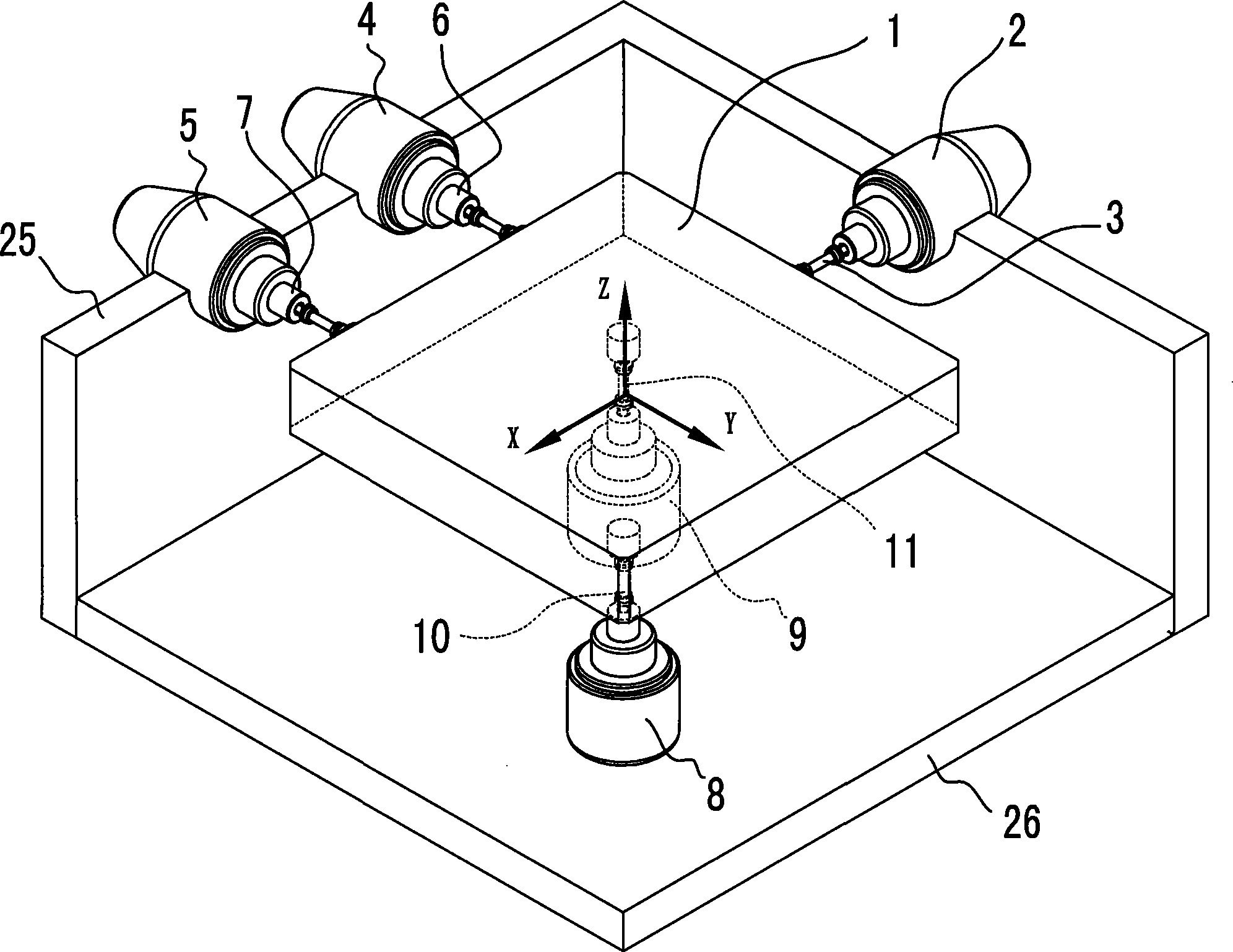

Three-axis six-freedom degree vibration test apparatus

ActiveCN101281088AQuick switchImprove Vibration Testing EfficiencyVibration testingAcousticsTest equipment

A vibration test equipment with three axis and six degrees of freedom, comprising a sample worktable, a first vibration generator arranged in the level X-axis direction with the mass centre of the sample worktable used as origin of coordinates; a second vibration generator and a third vibration generator which are arranged side by side in the level Y-axis direction with the vibration body of the second vibration generator connected with the sample worktable through a second sphericity connector and the vibration body of the third vibration generator connected with the sample worktable through a third sphericity connector; a forth vibration generator and a fifth vibration generator which are arranged side by side in the level Z-axis direction with the vibration body of the forth vibration generator connected with the bottom surface of the sample worktable through a forth sphericity connector and the vibration body of the fifth vibration generator connected with the bottom surface of the sample worktable through a fifth sphericity connector. The invention can simulate X, Y, Z triaxiality and six degrees of freedom complex vibration environment in true environment to reproduce the real working condition more accurately, largely increasing the accuracy of the vibration test result.

Owner:SUZHOU SUSHI TESTING INSTR CO LTD

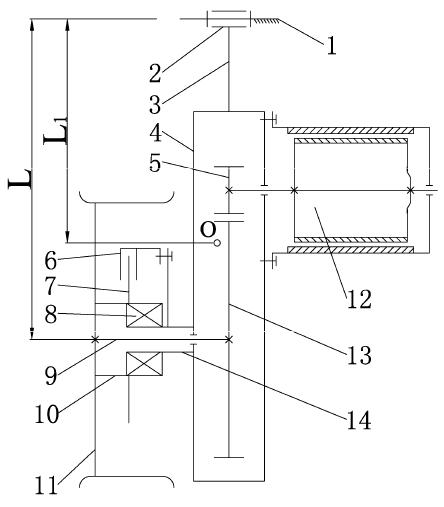

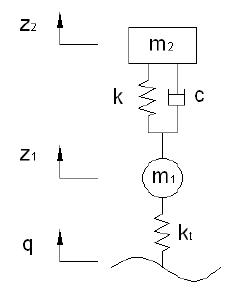

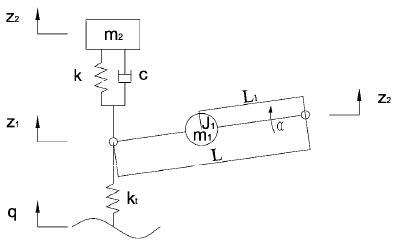

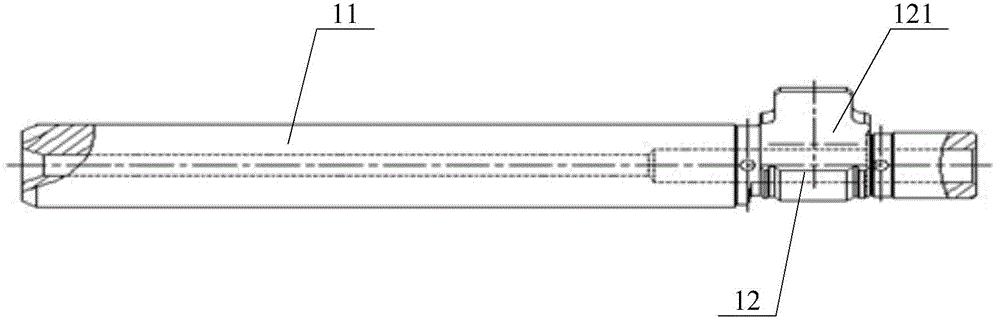

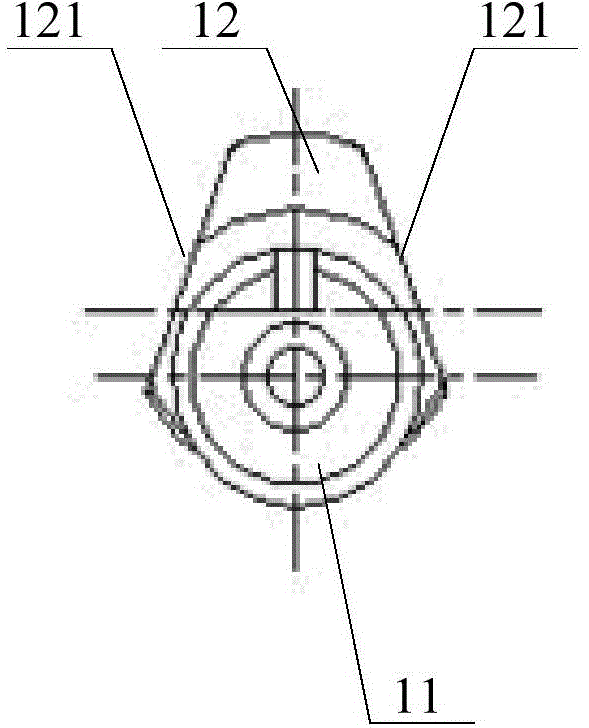

Structure and method for reducing equivalent unsprung weight of wheel-rim electrically-driven system of single trailing arm type suspension

ActiveCN102092256AHigh vibration frequencyImprove comfortResilient suspensionsControl devicesVehicle frameTrailing arm

The invention discloses a structure and method for reducing the equivalent unsprung weight of a wheel electrically-driven system of a single trailing arm type suspension, which is characterized in that an elastic rubber hinge is supported on a frame, one end of a swing arm of the single trailing arm type suspension is connected with the elastic rubber hinge, and the other end of the swing arm is connected with a reducer casing; the reducer casing is connected with a sleeve of a half axle; a motor is fixedly arranged on the reducer casing, the power output end of the motor is connected with a small gear, then the small gear is meshed with the large gear, and the large gear is connected with the sleeve of the half axle; and after the gear reducing is performed, the power is outputted to a rim by the half axle so as to drive wheels. The equivalent unsprung weight is reduced by reducing the distance between the mass centre of non-concentric parts of a wheel and a central swing axis of the single trailing arm type suspension. The structure and method disclosed by the invention have the advantages of increasing the vibration frequencies of wheels, reducing the resonance, reducing the impact and vibration from road surfaces, and improving the running smoothness of vehicles.

Owner:TONGJI UNIV

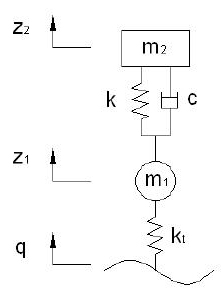

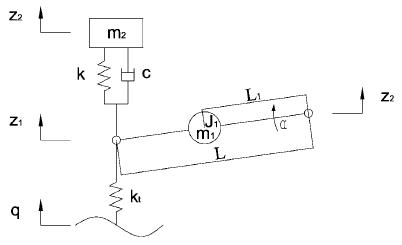

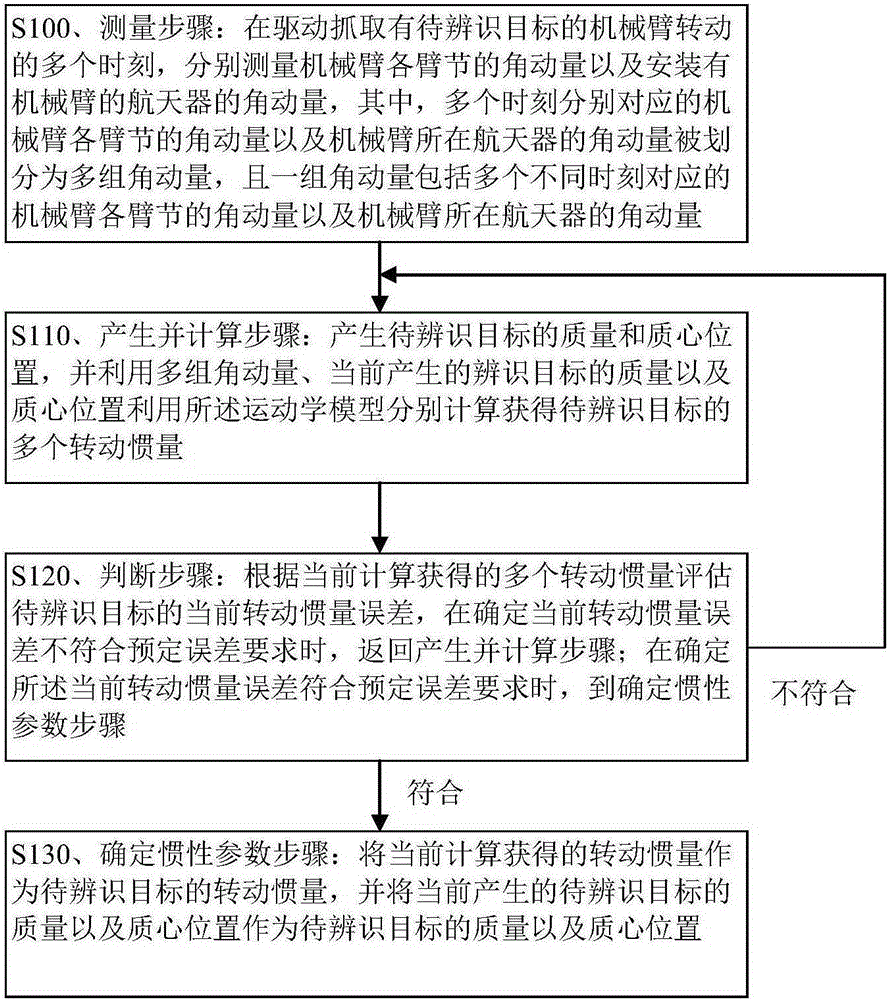

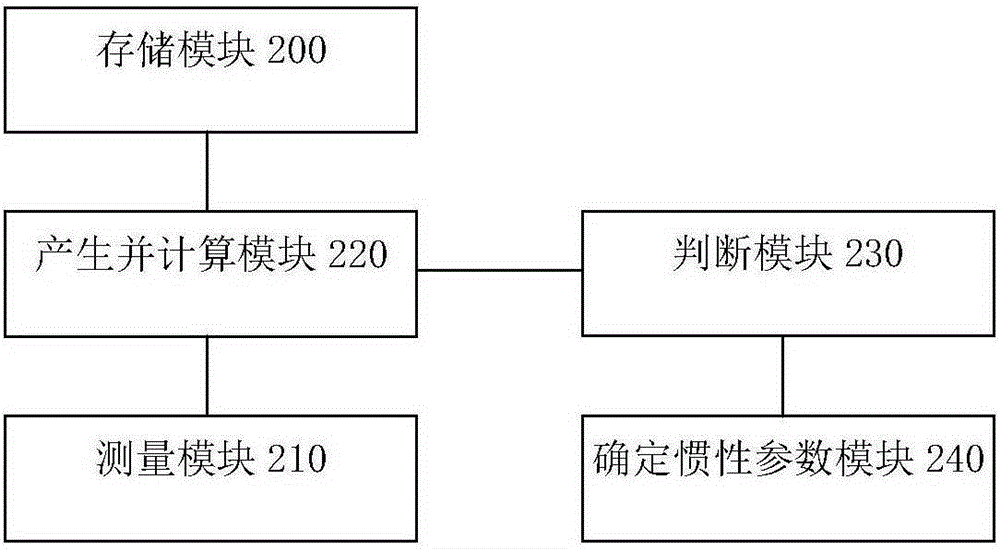

Method and apparatus for identifying inertial parameters of object to be identified

ActiveCN105259786AAccurate identificationReduce adverse effectsSimulator controlGeneral purposeMomentum

The present invention discloses a method and apparatus for identifying inertial parameters of an object to be identified. The method includes the steps as follows: measuring the angular momentum of various arm sections of a mechanical arm and the angular momentum of a spacecraft at a plurality of points in time that the mechanical arm is driven to rotate for grabbing the object to be identified; generating the mass and mass center position of the object to be identified, and calculating out a plurality of inertia moments of the object to be identified by utilizing the several groups of angular momentum and the current generated mass and mass center position of the object to be identified according to a preset kinetic model; evaluating the current inertia moment error of the object to be identified according to the current acquired inertia moments, returning to the generating and calculating processes when the error does not accord with a preset error requirement, and otherwise, employing the current calculated out inertia moment, the current generated mass and mass centre of the object to be identified as the inertia moment, the mass and mass centre position of the object to be identified. According to the invention, the valuable fuel of the spacecraft is saved, the inertial parameter identification precision of the object to be identified is improved, and the ideal general purpose is provided.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

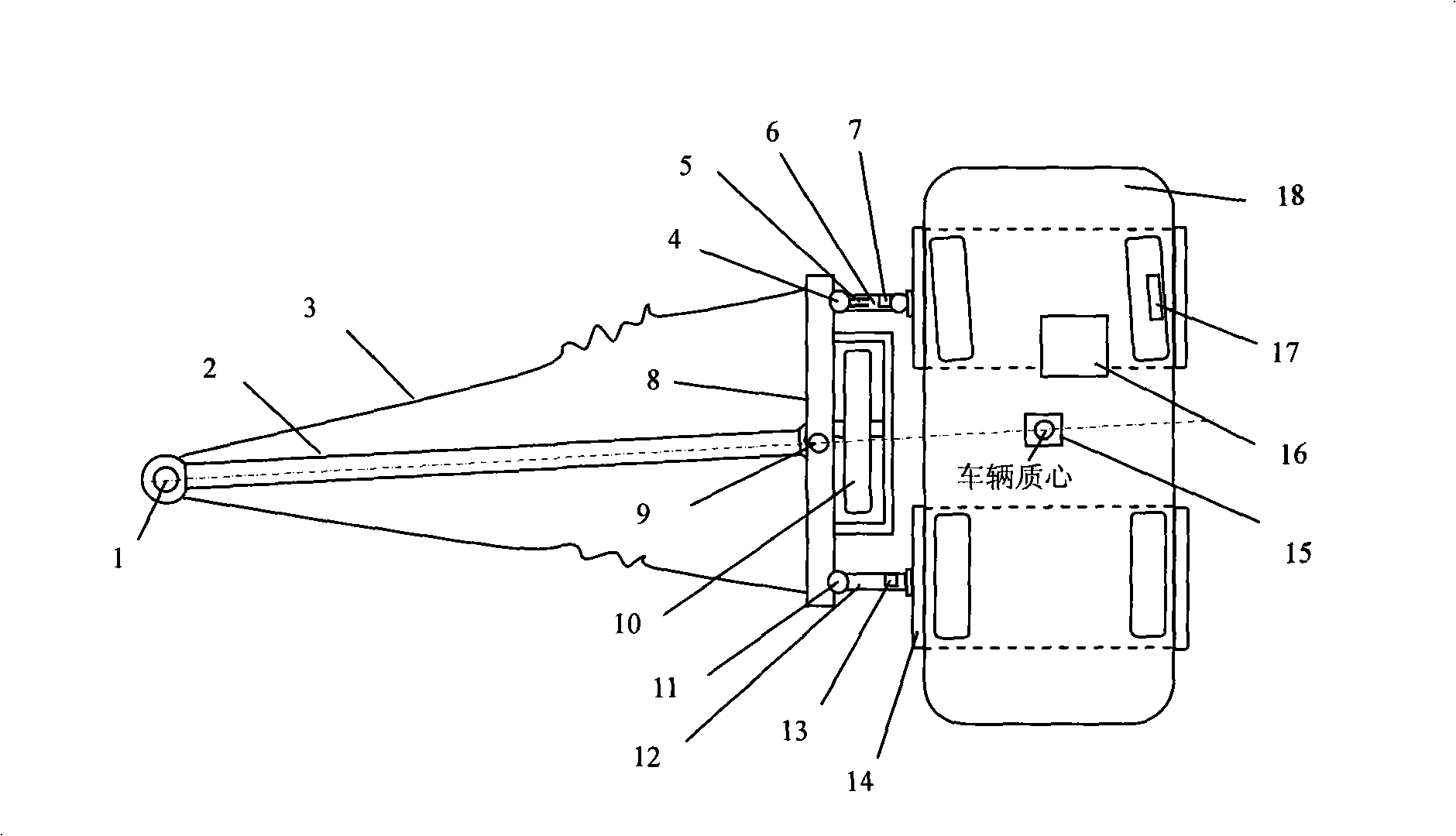

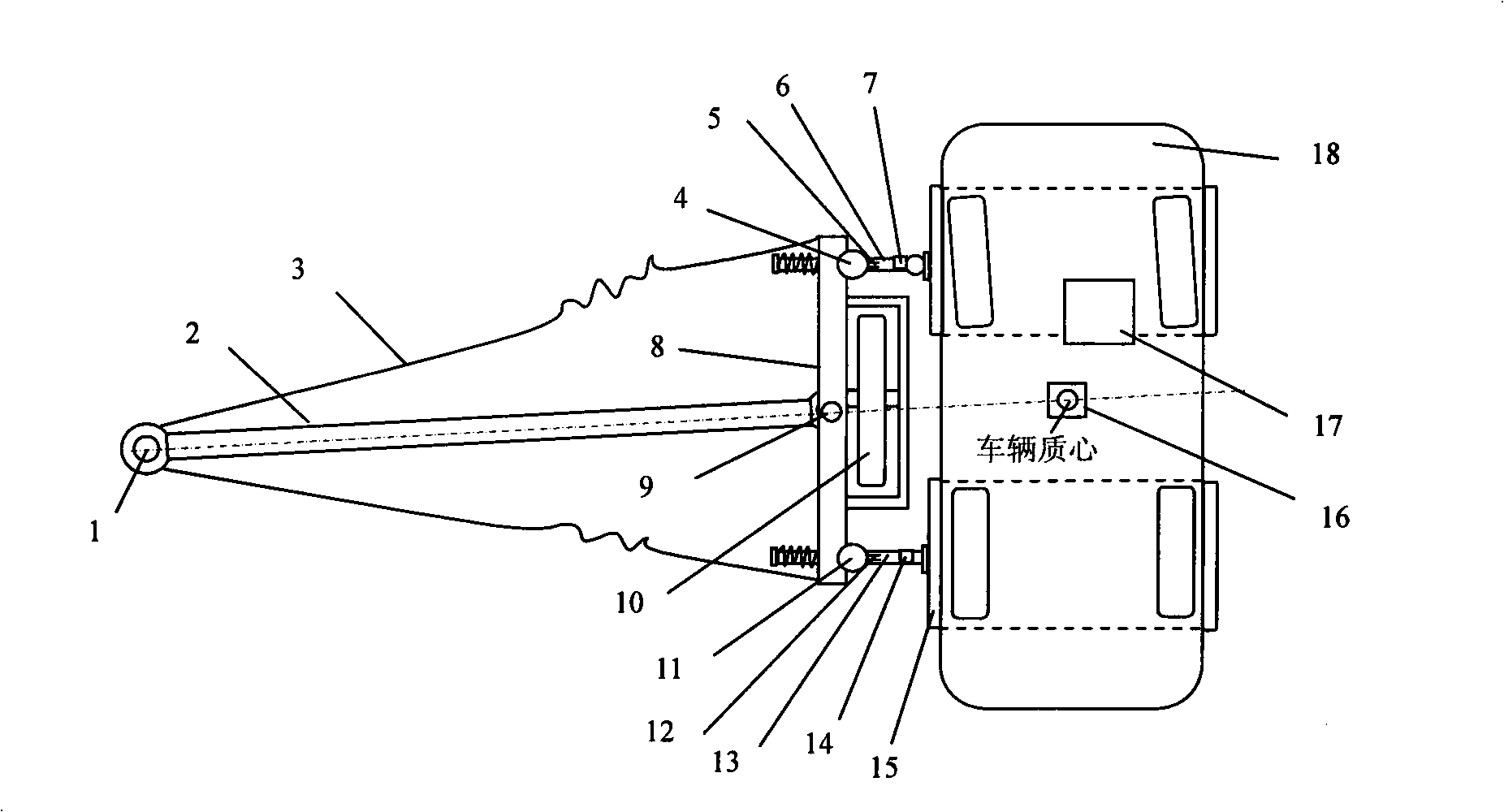

Automotive stability control real vehicle testing system

The invention discloses an automotive stability control real vehicle testing system. The testing system is composed of three parts of a traction rod component, a transverse swing link component and a vehicle component. The two ends of the traction rod are respectively connected with a fixed shaft and the transverse swing link by pin shafts, a five-wheeled instrument is mounted on the transverse swing link so as to support the transverse swing link, the tension rods of a front wheel and a rear wheel are respectively connected to the transverse swing link and a vehicle clamping device by pin shafts, and the vehicle clamping device is fixedly connected to the vehicle. The relative motion relationship among the traction rod component, the transverse swing link component and the vehicle component is determined according to the angular displacement sensors between the traction rod and the transverse swing link and among the tension rods of the front wheel and the rear wheel and the transverse swing link and by the measurement parameter of the linear displacement sensor of the tension rod of the front wheel; the mass centre of the vehicle and the slip angle of each wheel can be measured by the front wheel steering angle measured by a vehicle running stability control system; the stress relationship among the traction rod component, the transverse swing link component and the vehicle component is determined according to the measurement parameters of the tension gauges of the front and rear wheels; and the effect for controlling the whole vehicle motion can be obtained by adjusting the side force of the whole vehicle, the transverse swing link torque and the tyre ground acting force through the whole vehicle centrifugal force measured by the vehicle running stability control system. All sensors are connected to a signal collecting system for collecting and storing signals. The tyre ground acting force is adjusted by a control system.

Owner:CHINA AGRI UNIV

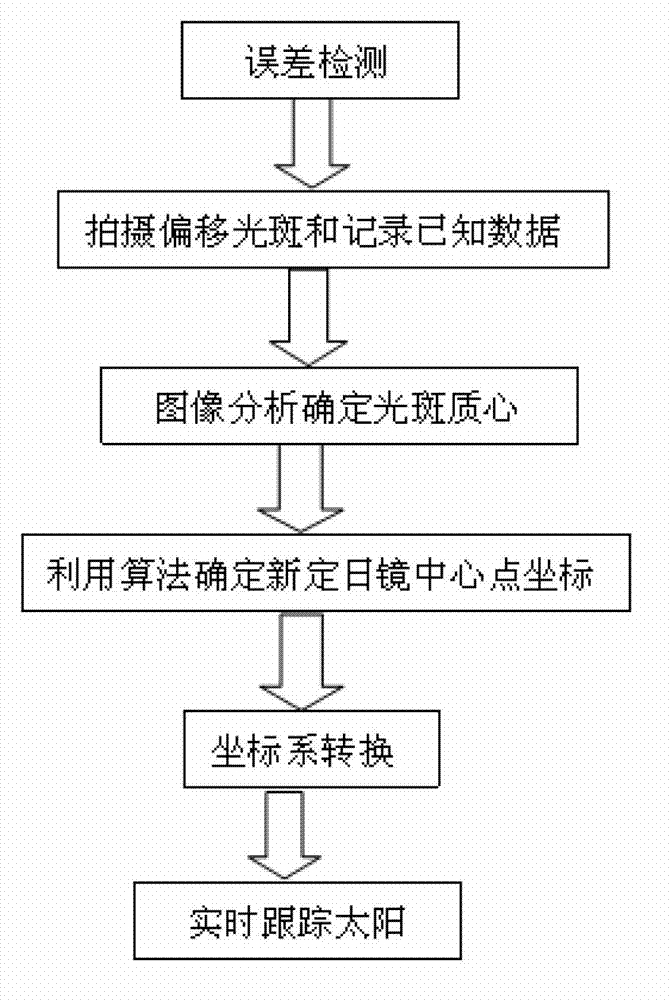

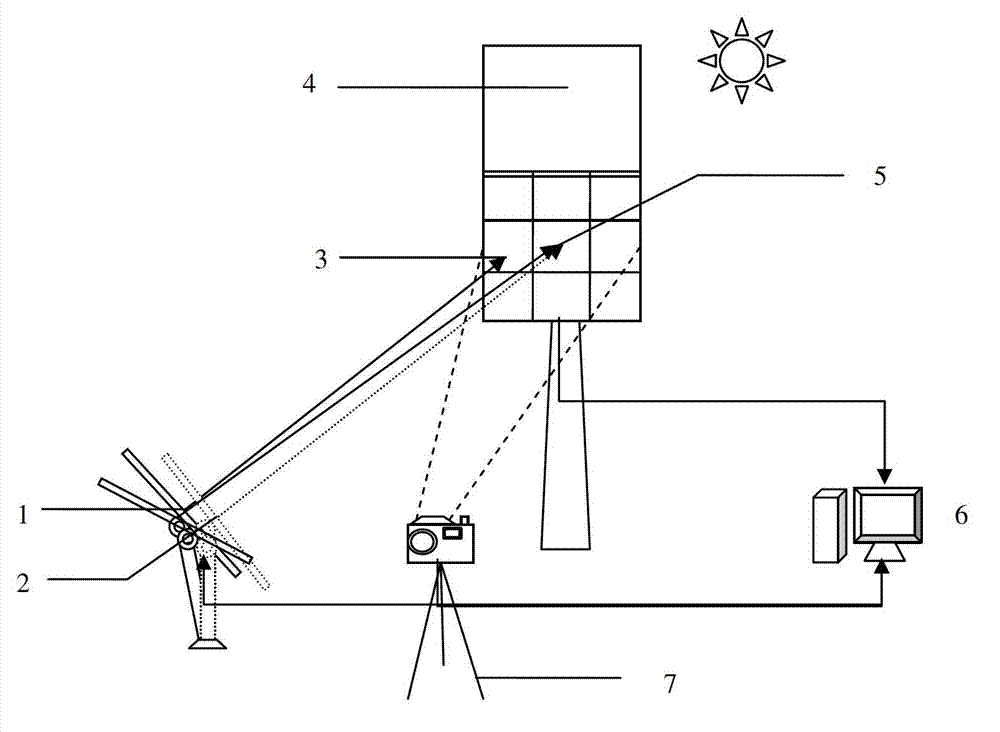

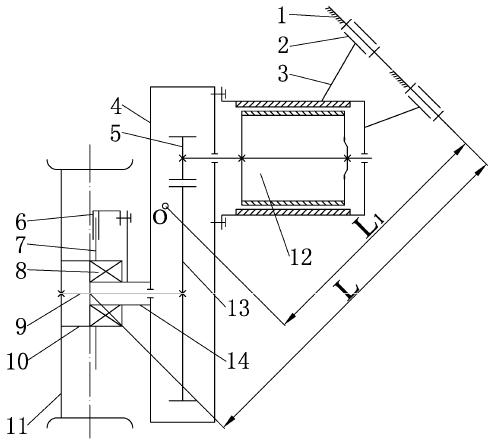

Mechanical-error calibration method for heliostat

InactiveCN102929299ACalibration Tracking ErrorImprove work efficiencySolar heating energySolar heat collector controllersElevation angleHeliostat

The invention relates to a mechanical-error calibration method for a heliostat, which is based on the application of a heliostat real-time follow-up solar device of a tower type solar energy heat-collection system. The method comprises the following steps: judging the position of a light spot on a heat collector through images shot by a camera; comparing the mass centre position of the light spot with an appointed position, if deviation occurs, showing that mechanical error of the heliostat exists, at the moment, recording the elevation angle and azimuth angle of the sun, as well as those of the heliostat when light spot deviates, the height of a heliostat bracket and position coordinates of the heliostat bracket relative to the center spot of the heliostat heat collector; calculating the coordinates of the deviated heliostat mass centre relative to the mass centre position of the original heliostat through a computation module; converting the deviation amount of the heliostat center spot into deviation amount of the mass centre point of the heat collector through a coordinate system, and building a new heliostat center spot; determining the appointed position coordinates of the heat collector under a coordinate system taking the new heliostat center spot as an origin; and taking the heliostat having the mechanical error as a criteria, re-calculating and re-sending so as to realize the tracking of the heliostat, and projecting the light spot data, thereby achieving the purposes of high-efficiency tracking and sunlight spot projection.

Owner:宁夏医深科技股份有限公司

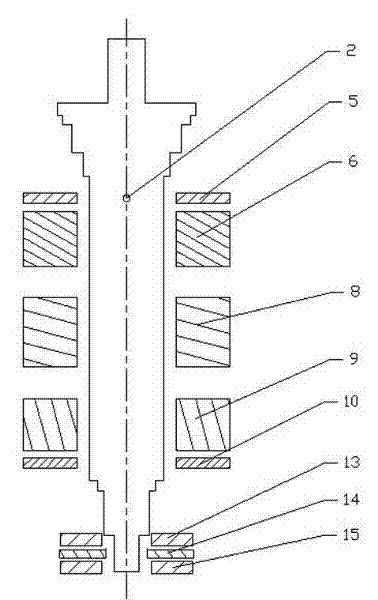

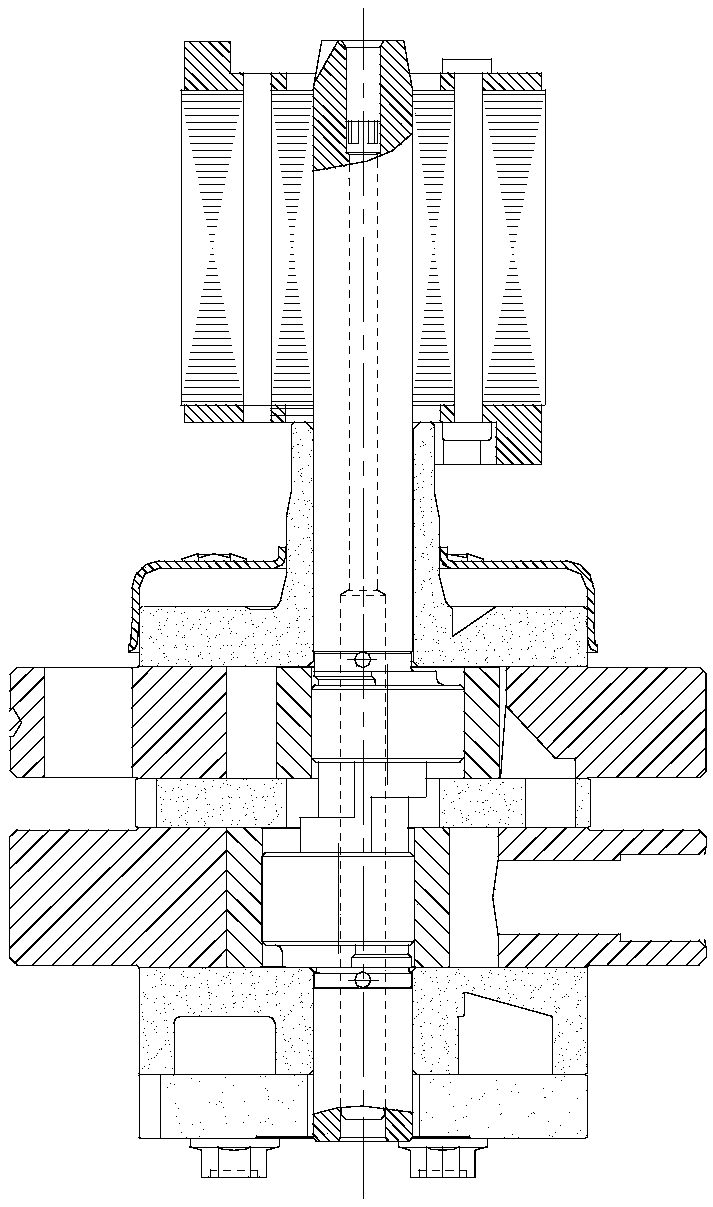

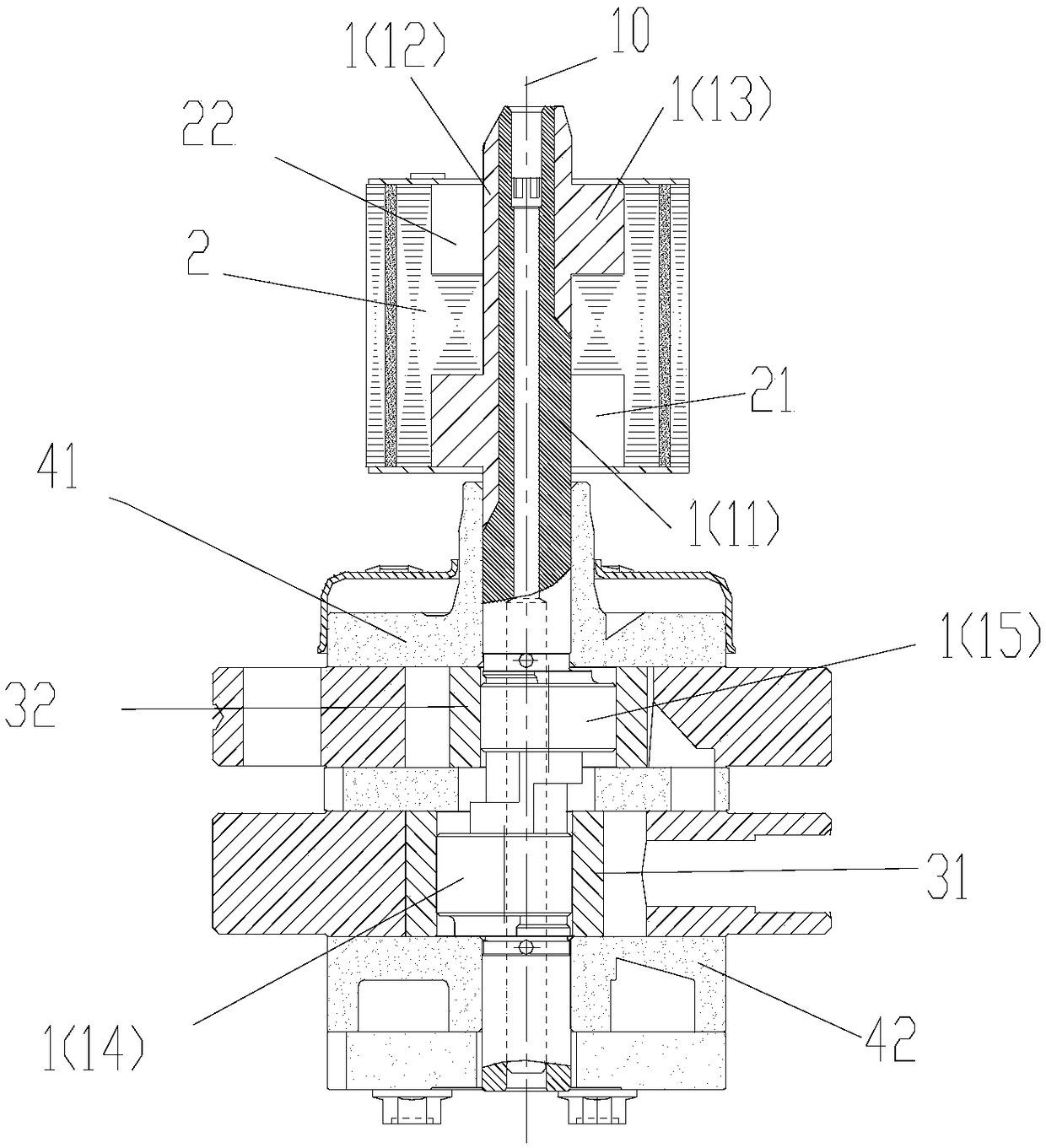

Maglev molecular pump, and control method and manufacturing method thereof

ActiveCN102242722AImprove control efficiencyImprove control stabilityPump controlAxial flow pumpsImpellerMagnetic bearing

The invention discloses a maglev molecular pump, and a control method and a manufacturing method thereof. The maglev molecular pump comprises a pump body and a rotor shaft system arranged in the pump body. The rotor shaft system comprises a rotor, a first radial magnetic bearing, a second radial magnetic bearing, a first axial magnetic bearing and a second axial magnetic bearing. The rotor comprises a rotor shaft and an impeller fixed with the rotor shaft. The first radial magnetic bearing and the second radial magnetic bearing are sequentially sleeved in the middle of the rotor shaft at intervals. Under a normal state, the mass centre of the rotor is arranged on the axis of the rotor shaft and superposed with the mass centre of a first radial sensor. According to the maglev molecular pump disclosed by the invention, the situation that two motions of translation and rotation of the rotor are mutually decoupled is realized basically; the two motions can be adjusted and controlled respectively; therefore, the control process is simplified; the control difficulty is reduced; and the control efficiency and the stability of a maglev molecular pump system are improved.

Owner:KYKY TECH +1

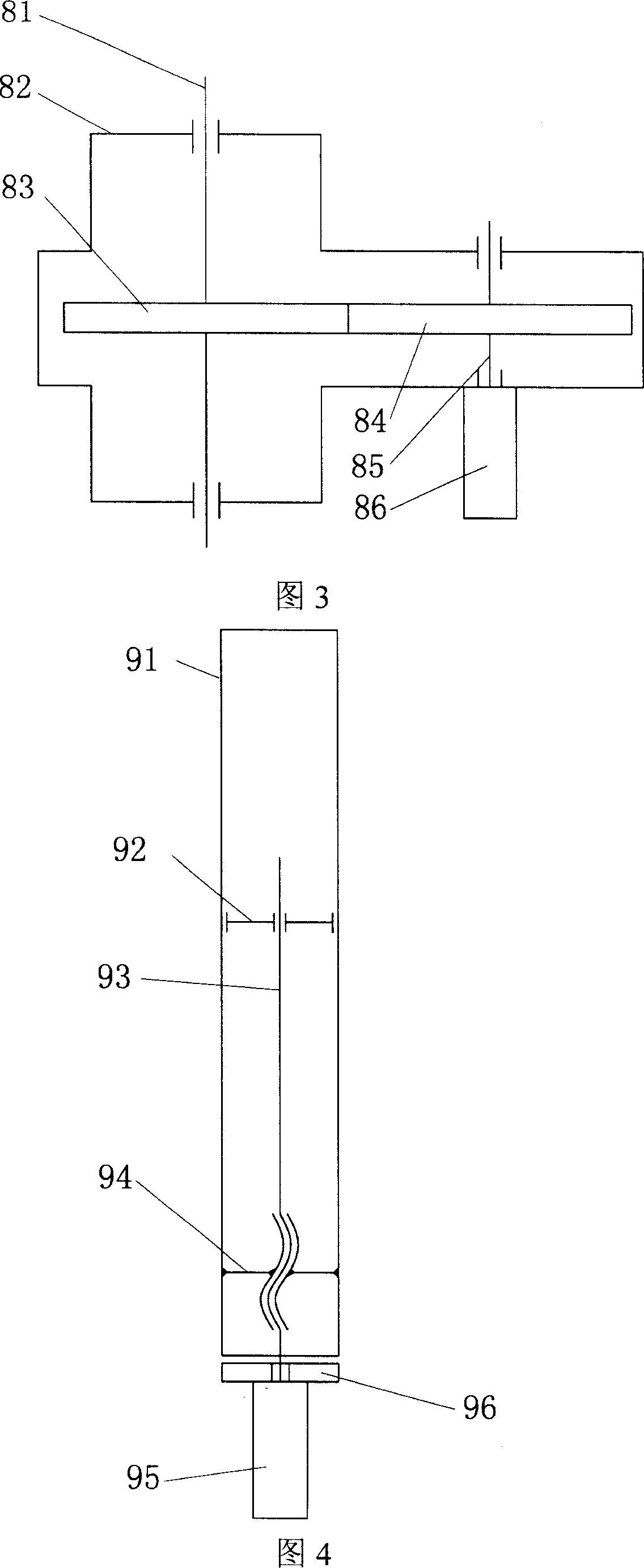

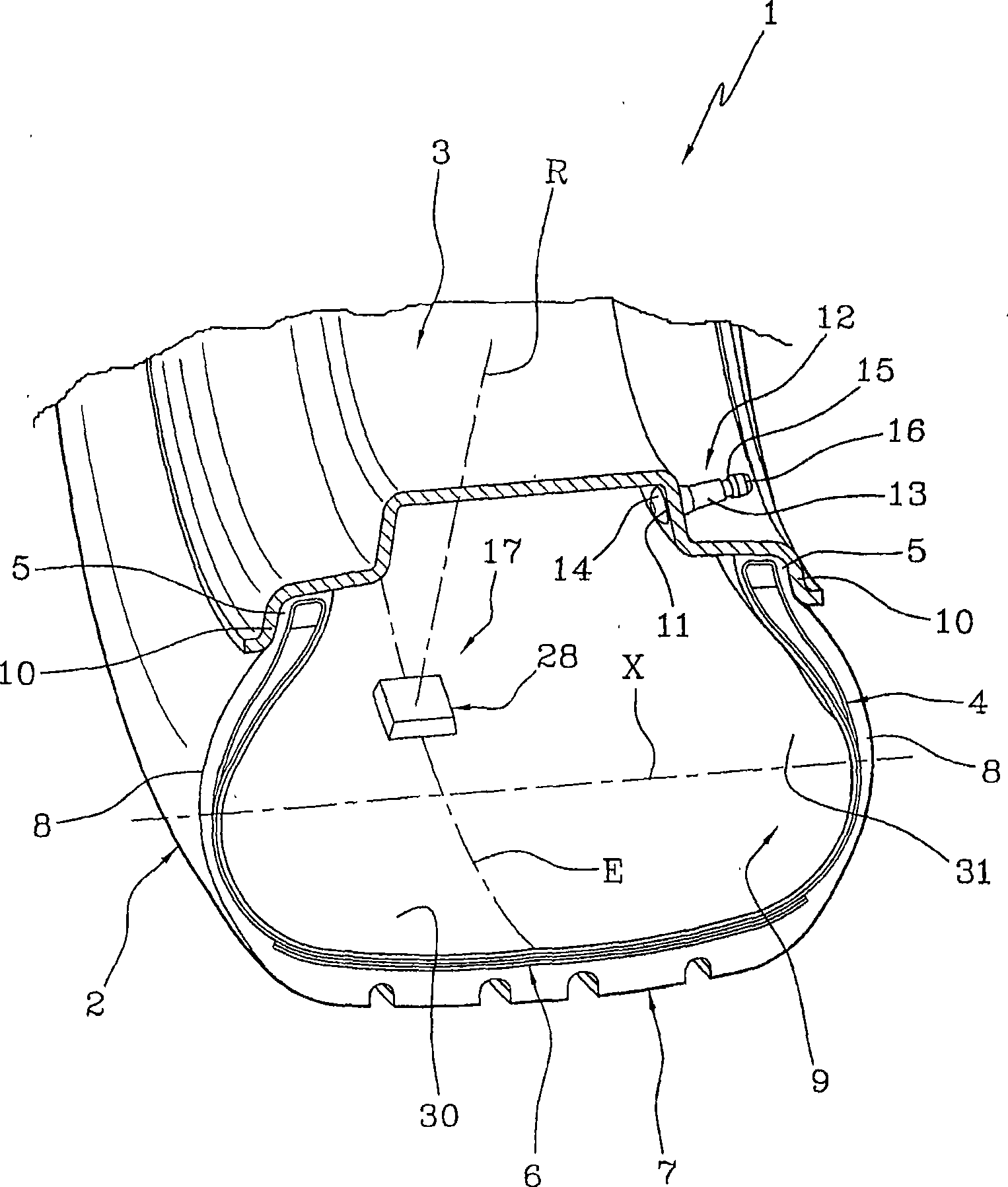

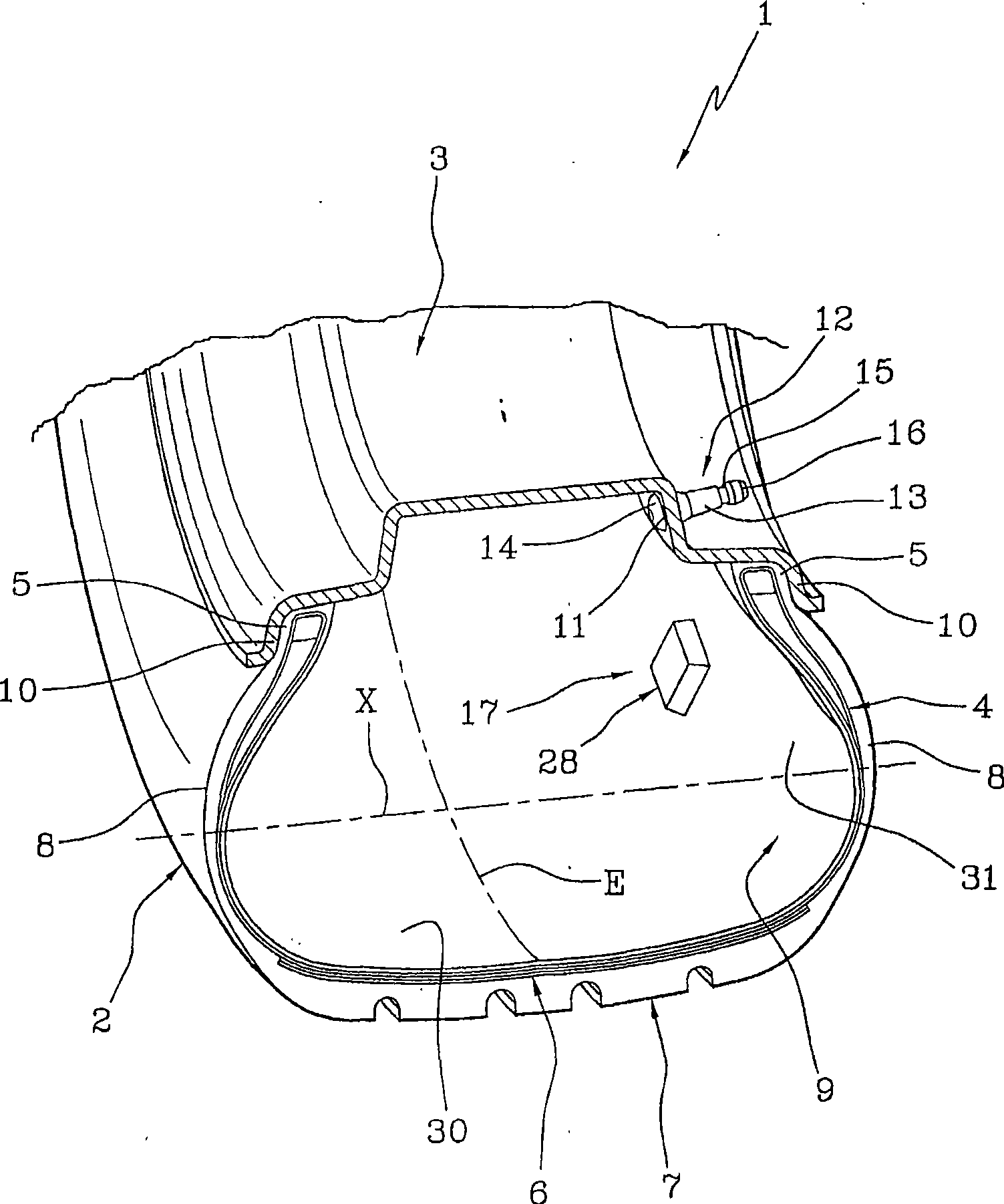

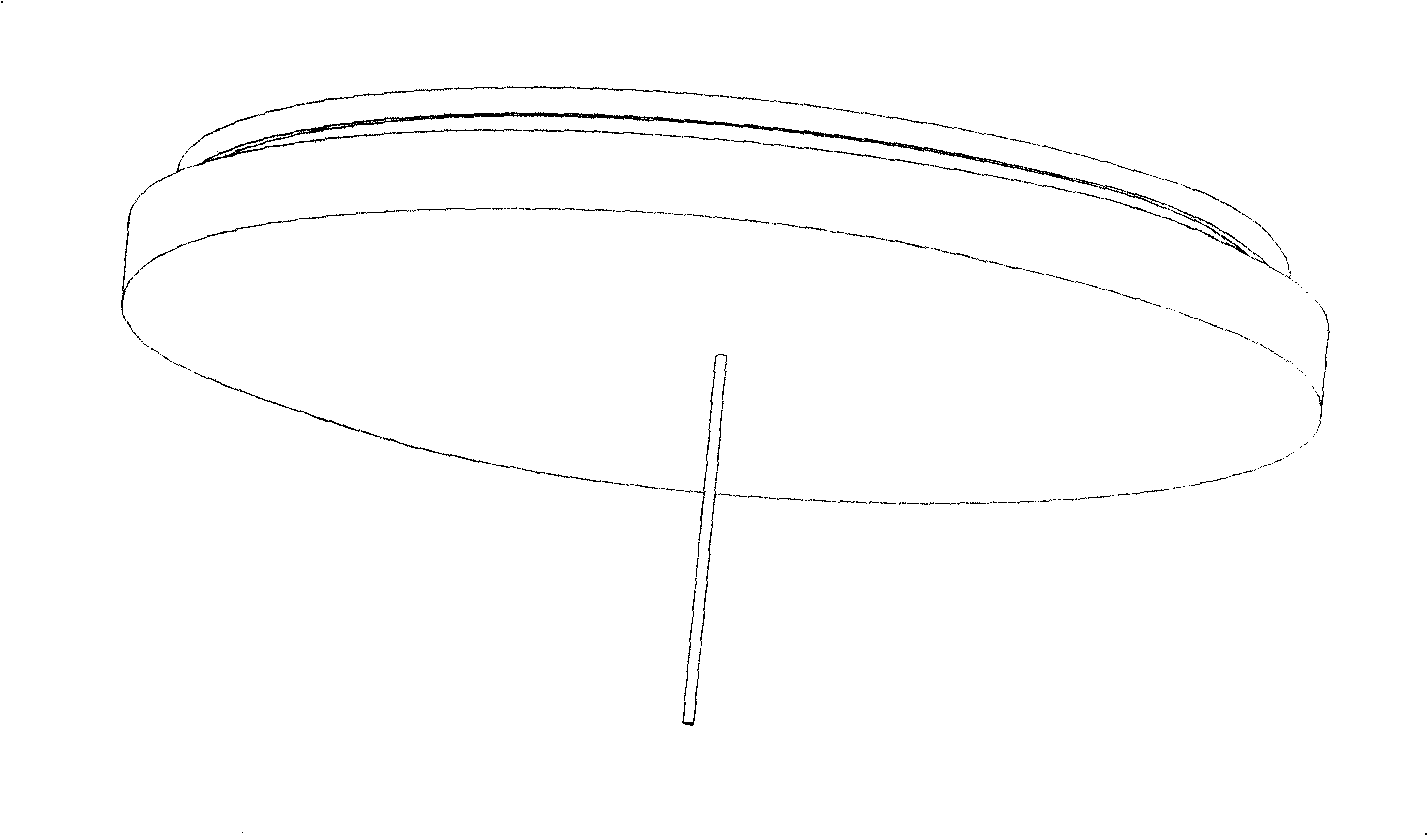

Wheels for vehicle

InactiveCN101511614AReduce manufacturing costTyre measurementsMechanical energy handlingEngineeringMass centre

A wheel for vehicles comprises a rim (3), a tyre (2) mounted on the rim (3), at least one device (17) for energy generation operatively associated with the tyre (2). The device (17) for energy generation comprises a first element (18) that is fixed relative to the rim (3) or to the tyre (2), and a second element (19) mounted on the first element (18) and free to rotate relative to said first element (18) around a predetermined rotation axis (Z). The second element (19) has a mass centre (CG) eccentric to the predetermined rotation axis (Z). The device (17) for energy generation further comprises an electric generator (25) having a stator (26) mounted on the first element (18) and a rotor (27) mounted on the second element (19).

Owner:PIRELLI TYRE SPA

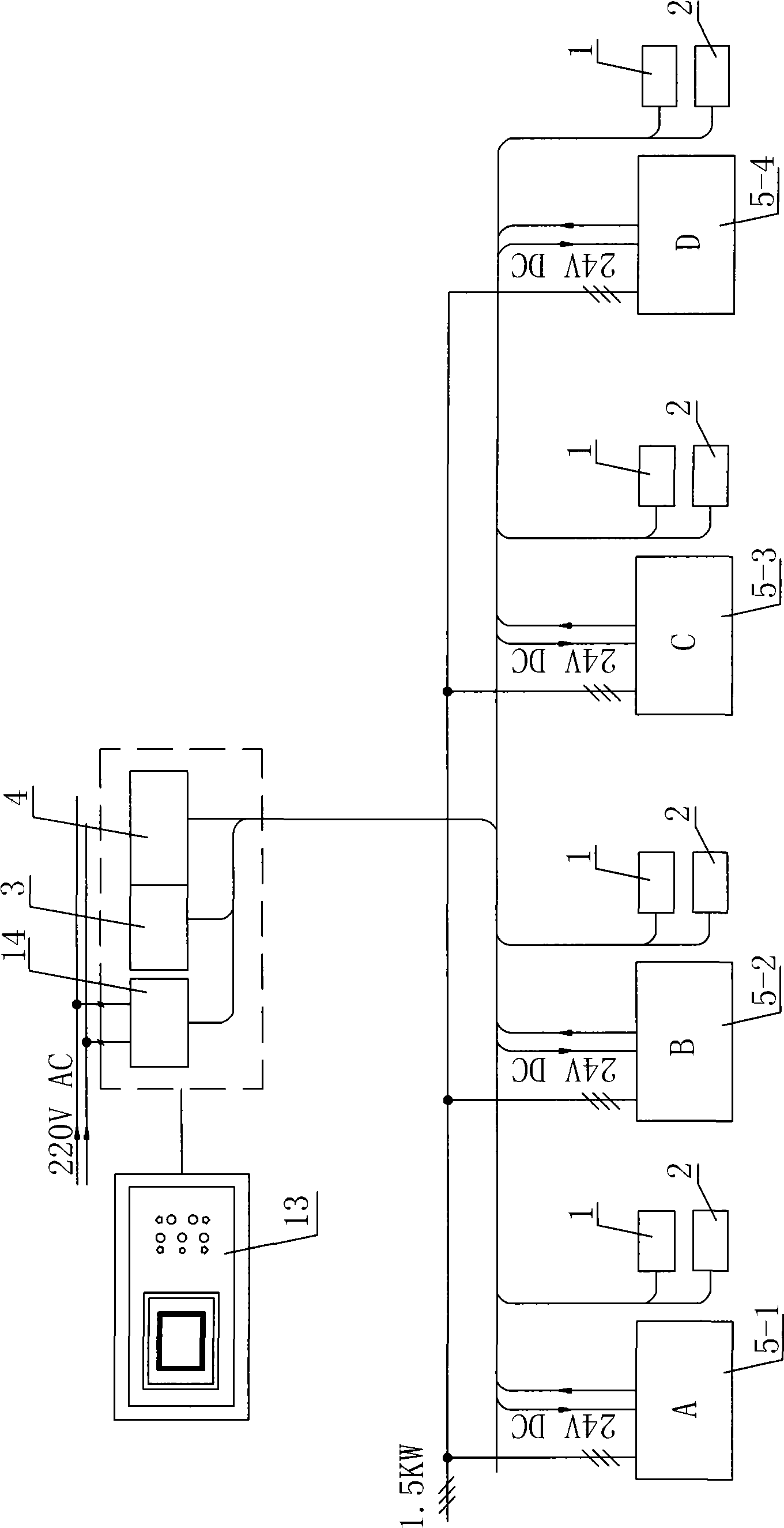

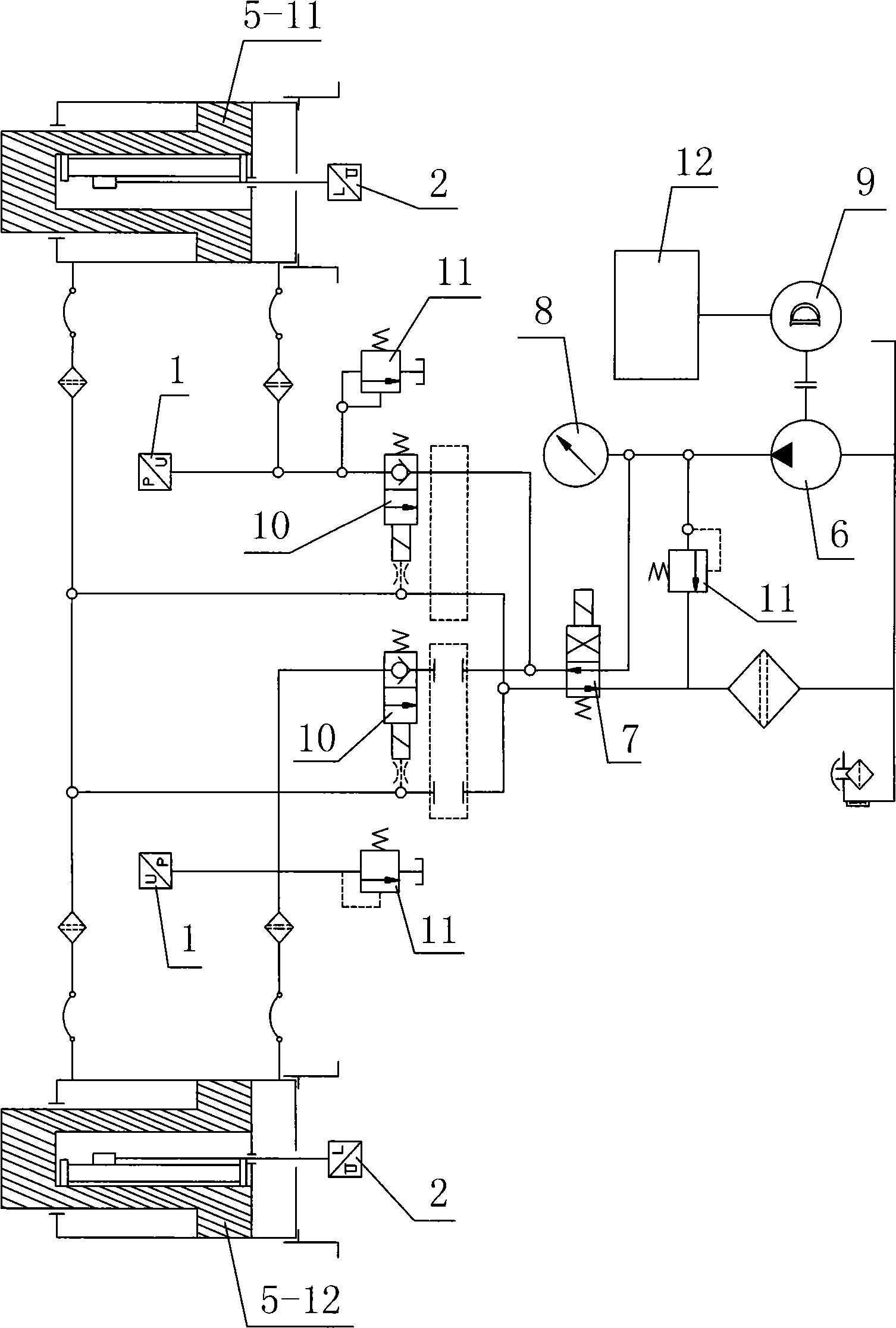

Test system and method for drill platform mass centre

ActiveCN101487755AReasonable structureSimple structureStatic/dynamic balance measurementWell drillingControl system

The invention discloses a gravity center testing system for a drilling platform and a testing method thereof. The testing system comprises a power supply source, a plurality of parallel and autonomous working hydraulic drive mechanisms for synchronously jacking and lowering a drilling platform to be tested in parallel, a plurality of pressure sensors for respectively detecting bearing pressures of a plurality of hydraulic drive mechanisms in real time, displacement sensors for respectively detecting jacking displacement or lowering displacement of a plurality of hydraulic drive mechanisms in real time, and a control system for analyzing to obtain barycentric coordinates of the drilling platform. Signals detected by the pressure sensors and the displacement sensors are sent to the control system via an A / D conversion circuit, and the control system controls dynamic mechanisms of a plurality of hydraulic drive mechanisms. The testing method comprises steps of preparing, zero setting, synchronously jacking and weighing, as well as synchronously lowering and testing the gravity center. The gravity center testing system has reasonable structure and simple testing method, is convenient to be realized with high test precision, and can effectively solve the problems in drilling platform gravity center testing.

Owner:西安信通控制系统有限责任公司

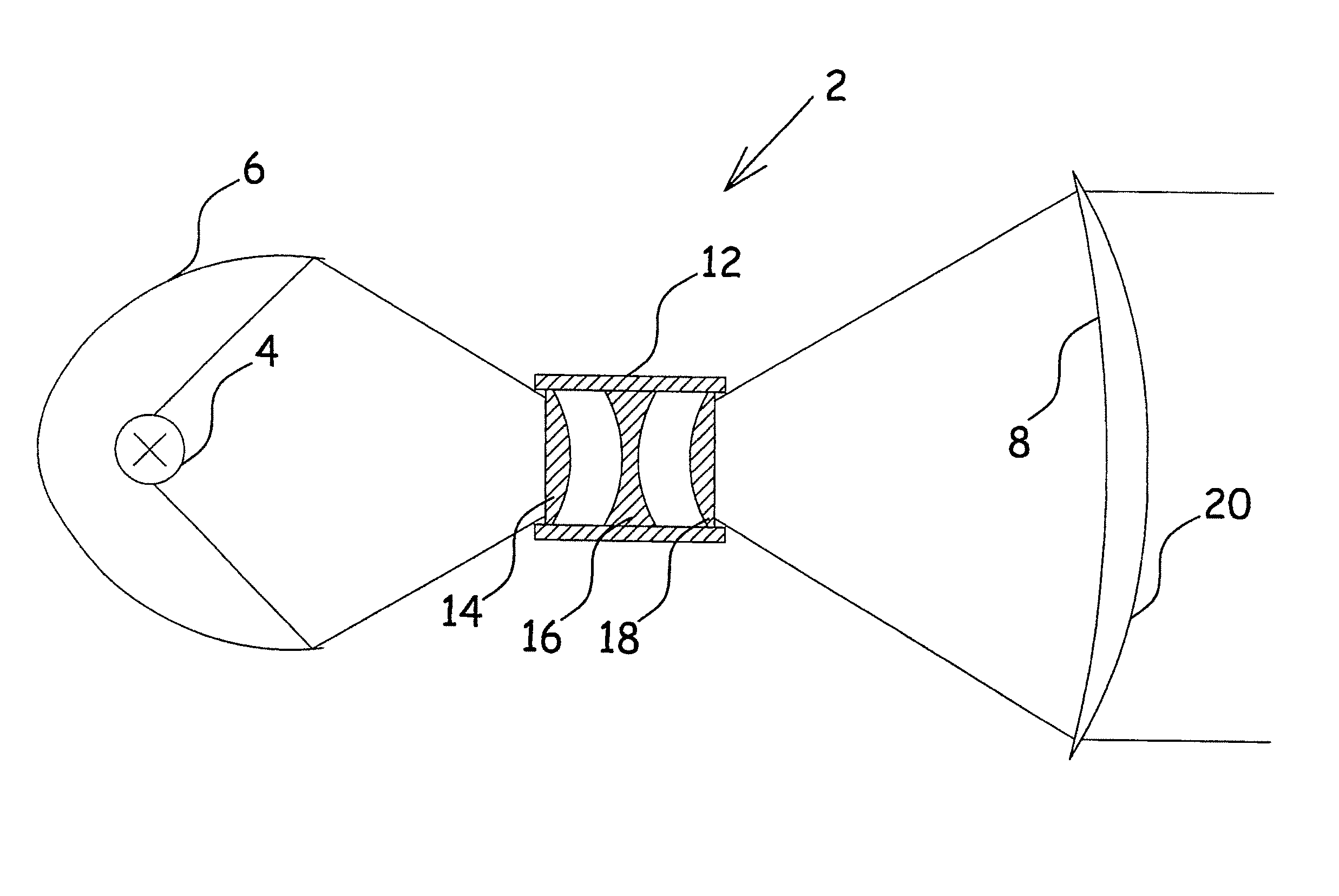

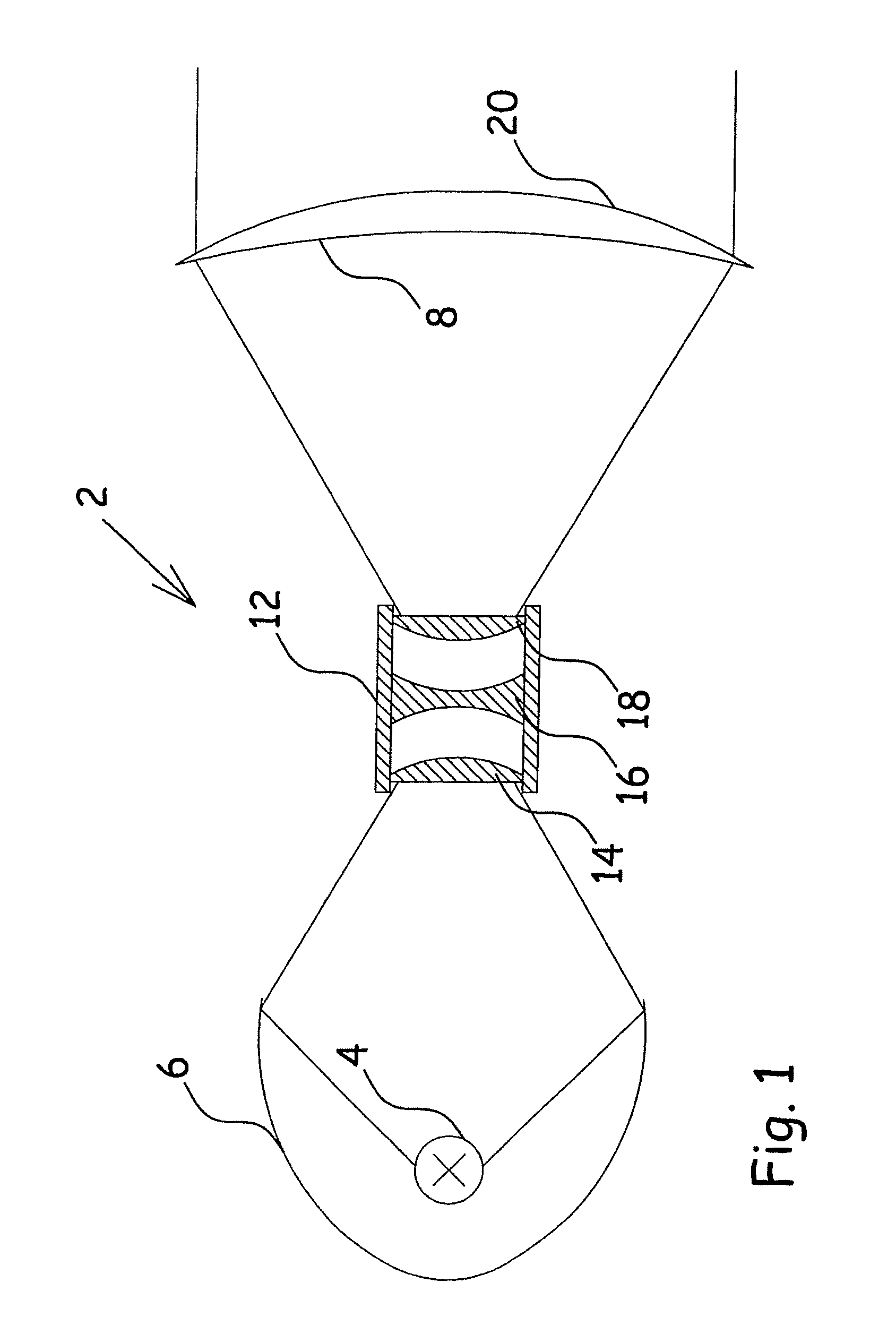

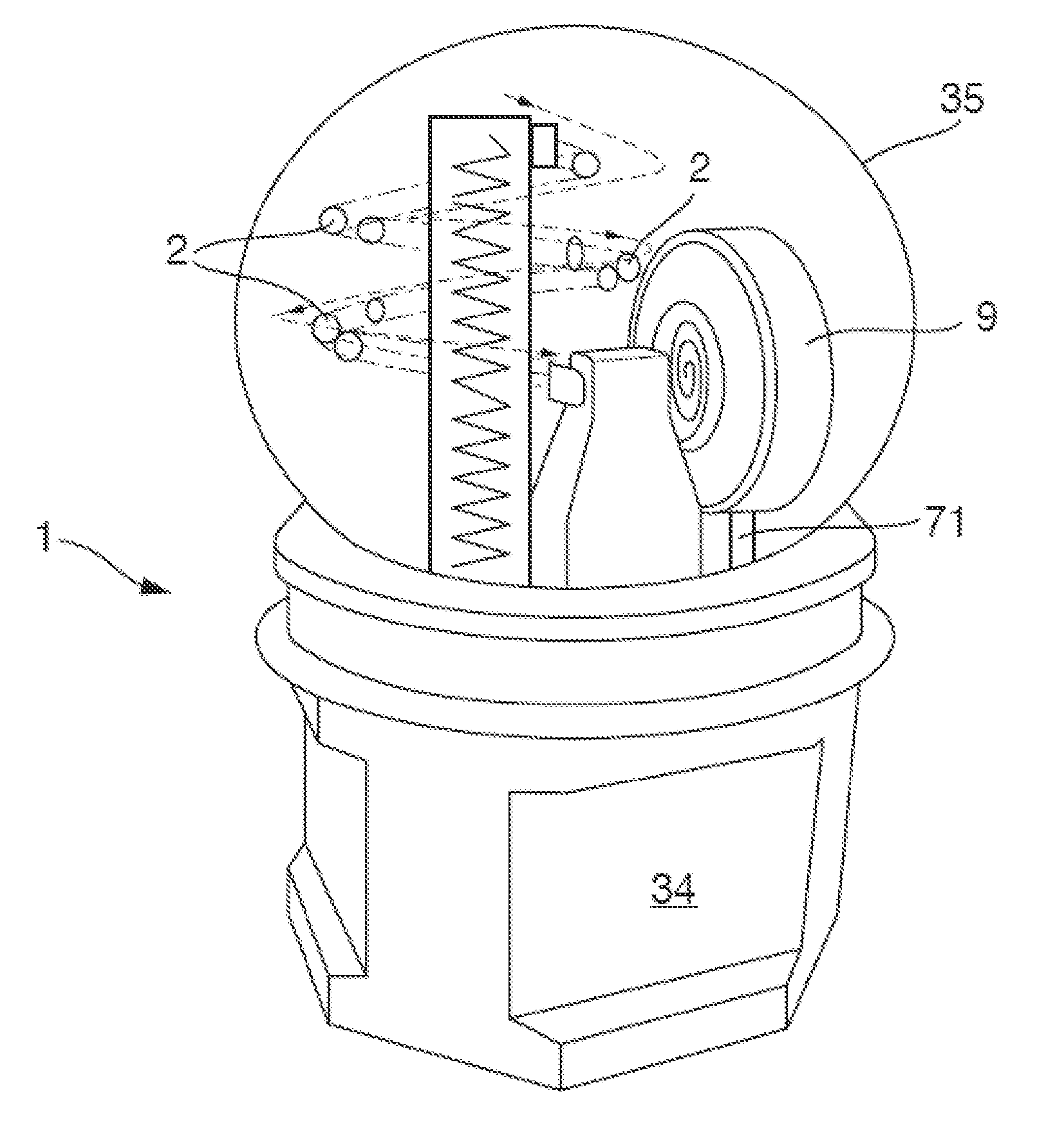

Light Assemblies

ActiveUS20080158884A1Economical to useReduce weightLighting applicationsMechanical apparatusLight beamOptoelectronics

The present invention relates to a method for forming a light beam, and to a light assembly comprising at least one light source placed in conjunction with a fixed reflector, which reflector forms a beam of light into light forming means, which light assembly comprises a front lens, where the light forming means at least comprise a light deflecting means for changing the light angle of the light beam after passing through the front lens. The object of the invention is to achieve a light assembly, where major optical components are mechanically fixed in relation to a housing for achieving a light assembly, the mass centre of which changes only slightly during operation. A further object is to achieve a closed light assembly having openings in the case only for cooling. This can be achieved, if the front lens has a central part that differs from the surrounding parts of the front lens, and where the light deflecting means in a first position concentrates the light beam into the central part of the front lens to generate a wide-angle light beam, and where the light deflecting means in a second position distributes the light beam over the entire front lens to generate a narrow-angle light beam, and where the light deflecting means is connected with a first actuator, and where the light deflecting means is movable between the first and the second position. A very efficient wash light zoom system can hereby be achieved, where the front lens has different characteristics between its centre portions and the rest of the surrounding part of the front lens. Because of the internal light deflecting means, the front lens does not have to be movable with respect to the housing. Furthermore, the reflector and the lamp are held in a fixed position. This may result in constant control of the air flowing around the optical components.

Owner:MARTIN PROFESSIONAL

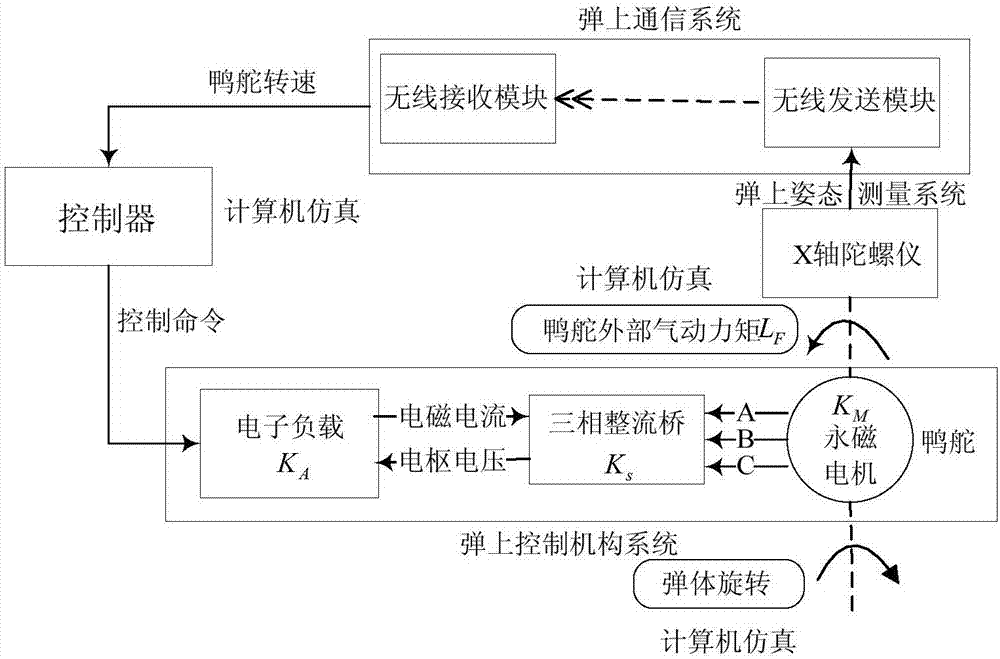

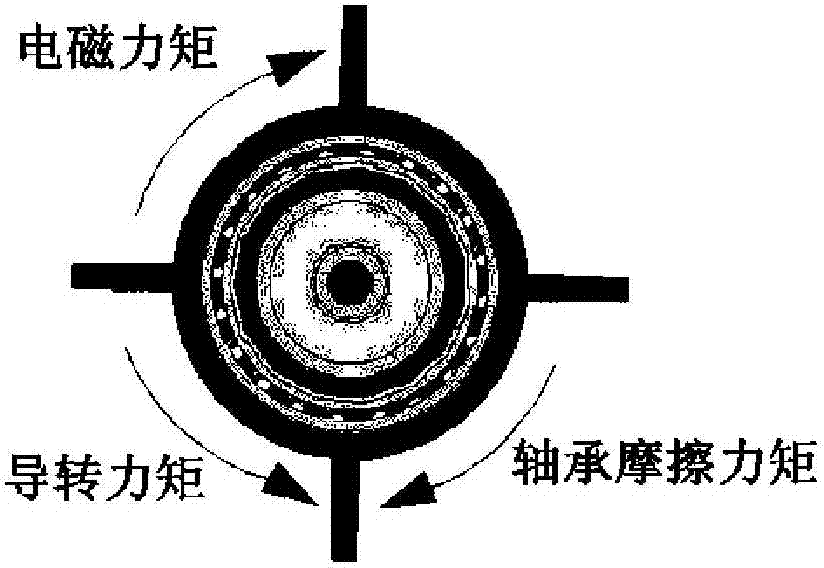

Control system used for fixed wing canard rudder

InactiveCN106871741AChange the direction of the control force vectorChange the electromagnetic torqueProjectilesElectronic loadAngular velocity

The invention discloses a control system used for a fixed wing canard rudder, and the control system replaces the head of a mortar projectile to fuze, and is mounted on the head of the mortar projectile. The control system comprises a control mechanism system, an attitude measurement system, a wireless communication system and a processor, wherein the control mechanism system comprises electronic load, a rectifying bridge and a permanent magnet motor; the attitude measurement system is used for transmitting acquired rolling angular velocity to the processor through the wireless communication system; the processor is used for controlling the electronic load according to rotation speed difference between the wing canard rudder and a projectile body; and electromagnetic torque of the permanent magnet motor is regulated through the rectifying bridge, so that rolling angular velocity of the fixed wing canard rudder is changed. According to the control system disclosed by the invention, the electromagnetic torque of the permanent magnet motor and the rolling angular velocity of the fixed wing canard rudder are changed, so that the control force vector direction of the canard rudder is changed; mass centre motion is corrected by motion around a mass center, so that fall point precision of the mortar projectile is improved; and moreover, a conventional servo mechanism is cancelled, so that the size and the cost of the control system can be greatly reduced, and therefore, the control system has the characteristic of a high cost-benefit ratio.

Owner:BEIJING AEROSPACE AUTOMATIC CONTROL RES INST

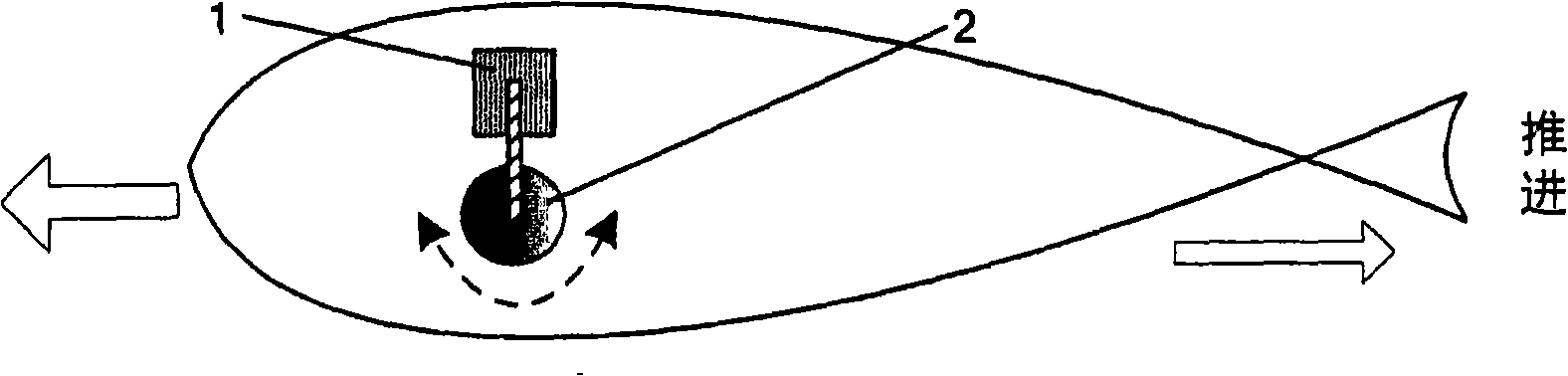

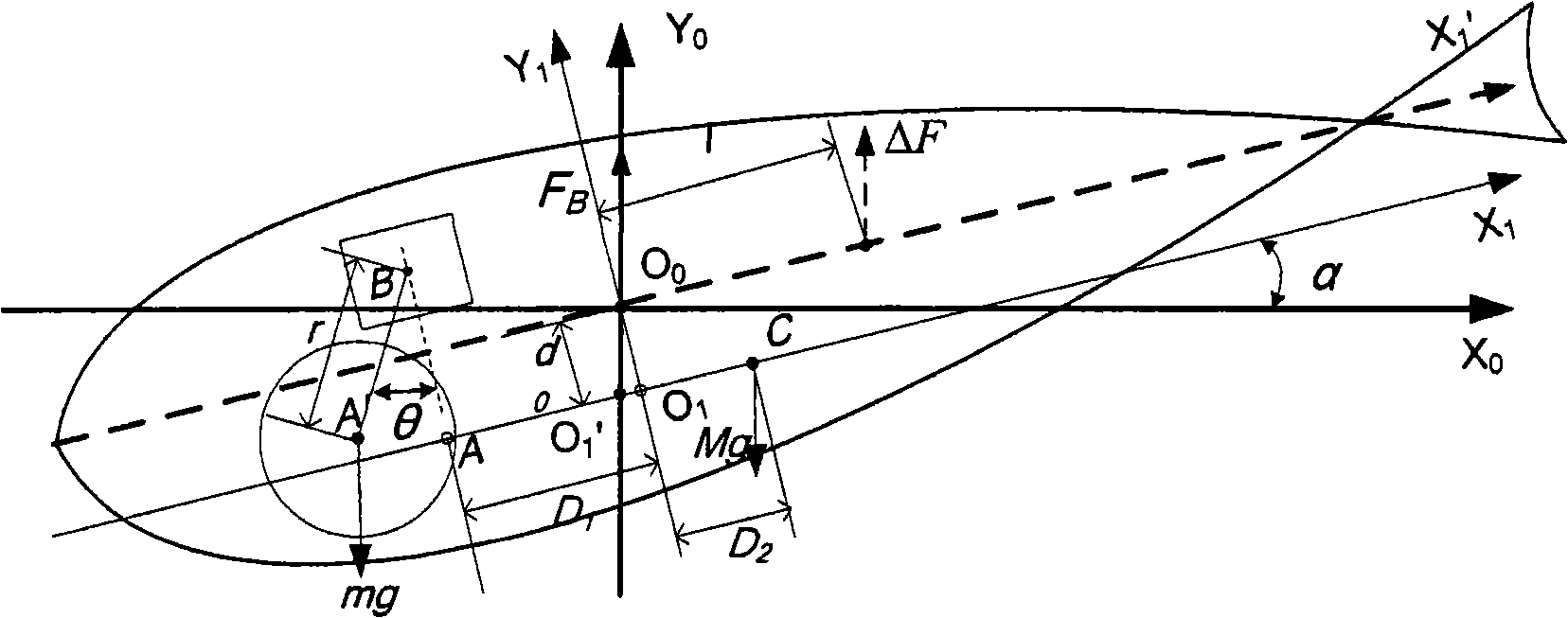

Bionic machine fish depth control method based on mass centre changing

InactiveCN101315563AAvoid influenceEasy to controlAltitude or depth controlEngineeringGravity center

The invention provides a biomimetic robot fish depth control method based on gravity-changing, relating to the biomimetic robot fish field and adopting a gravity-changing device to realize rising, diving and depth-control in a moving process in virtue of the propelling force of the biomimetic robot fish. The present depth information h is calculated according to a pressure sensor and the depth deviation e, deviation changing rate de and deviation integral ie are calculated with an appointed depth hd to get an output theta a of a PID controller, and then the output is combined with a distortion compensation-dosage sigma to get a controlled variable of gravity-changing to keep the biomimetic robot fish in a certain depth by timely regulation. The invention can effectively avoid the impact of depth on the biomimetic robot fish and can realize accurate control, thus providing technical guarantee for underwater detection, ocean territory defense, ocean resource exploitation and underwater saving, etc. for the biomimetic robot fish.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

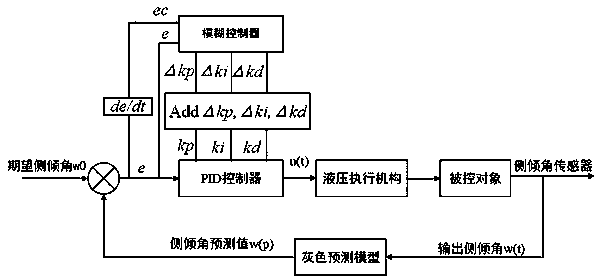

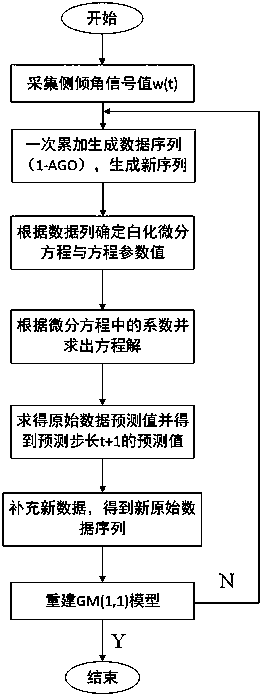

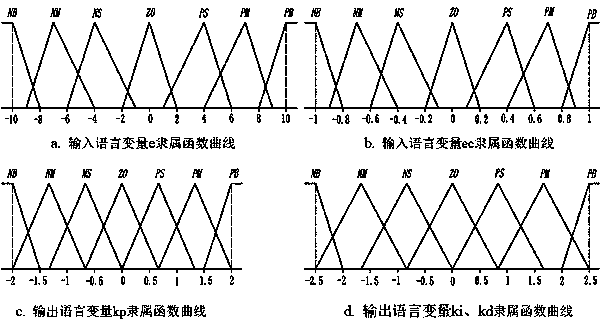

System for controlling roll stability of high-clearance vehicle based on grey prediction fuzzy PID algorithm

PendingCN109739083AImprove controller effectGood effectControllers with particular characteristicsFuzzy pid controlControl system

The invention relates to a system for controlling the roll stability of a high-clearance vehicle based on a grey prediction fuzzy PID algorithm. The invention belongs to the field of agricultural carrier operation engineering and agricultural vehicle stability control, relates to a grey prediction, fuzzy control and PID control theory, and researches and developments a method for controlling the roll stability of a high-clearance agricultural vehicle. For the characteristic that the system has the nonlinearity, the complexity and the time-varying uncertainty when the high-clearance vehicle isoperated, by utilization of the advanced control characteristic of a grey prediction model, an active torque control system for mass centre side inclination angle control of a vehicle load is established based on a fuzzy PID control algorithm; the current state value of the vehicle is measured through a sensor; after the current state value of the vehicle is sent to an electronic control unit, a corresponding control instruction is generated, so that the space attitude of the vehicle load is adjusted; the control system can be well suitable for a complex working environment; and a solid foundation is provided for developing a relatively diversified agricultural vehicle stability control system.

Owner:SHIHEZI UNIVERSITY

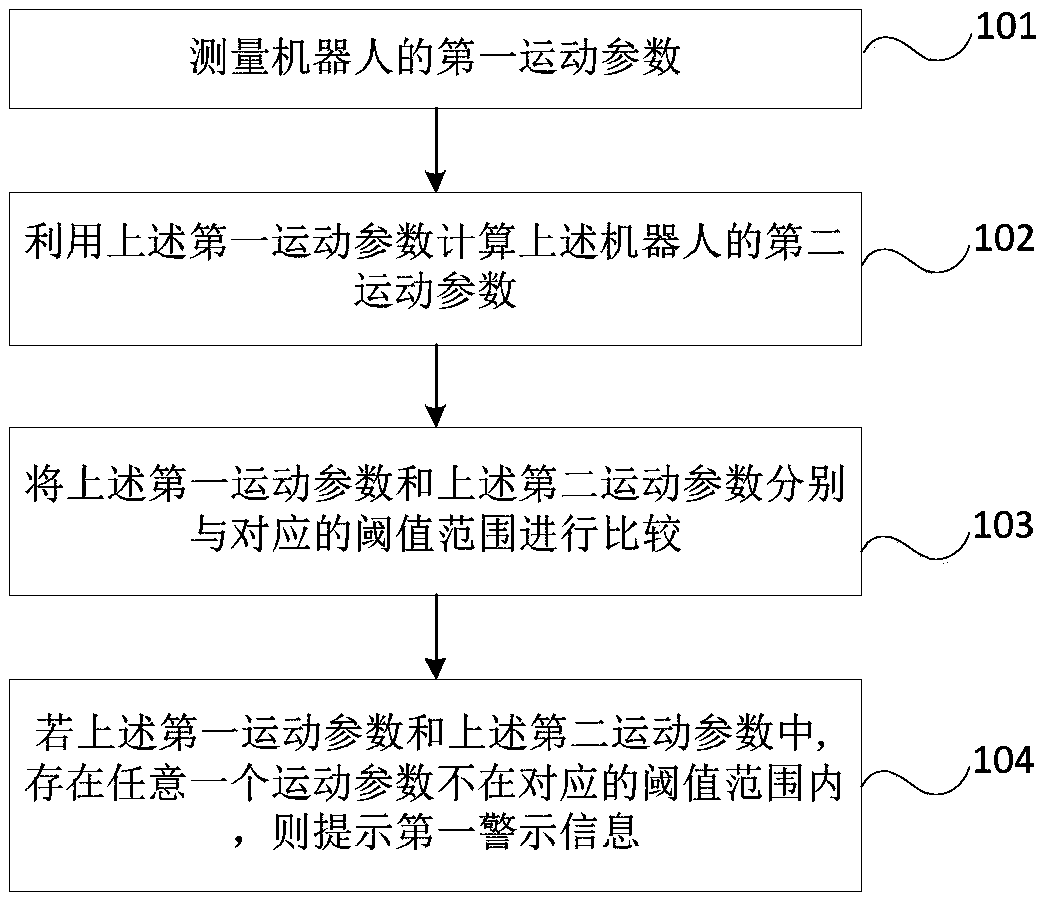

Motion detecting method, motion detecting device and computer readable storage medium

ActiveCN109623876ARealize abnormal motion monitoringImprove stabilityManipulatorMotion parameterSmart city

The invention discloses a motion detecting method, a motion detecting device and a computer readable storage medium, which are applied to the field of smart cities. The method comprises the followingsteps: measuring first motion parameters of a robot, wherein the first motion parameters comprise linear speed and angular speed, and the linear speed is linear speed of a mass centre of the robot; utilizing the first motion parameters to calculate second motion parameters of the robot, wherein the second motion parameters comprise linear speed of a left front wheel of the robot and linear speed of a right front wheel of the robot; separately comparing the first motion parameters and the second motion parameters with a corresponding threshold range; and if any one of the first motion parameters and the second motion parameters is not within the corresponding threshold range, prompting first caution information. Multiple motion parameters of the robot are obtained by direct measurement andcalculation for judging whether the robot is in an abnormal motion state or not according to a condition whether any motion parameter of the robot is within the threshold range or not.

Owner:PING AN TECH (SHENZHEN) CO LTD

Method and apparatus for identifying playing balls

ActiveUS20140029795A1Extended service lifeIncrease probabilityLottery apparatusCharacter and pattern recognitionPattern recognitionComputer graphics (images)

A method for identifying a selected playing ball from a prescribed number of playing balls, wherein each of the playing balls is provided with a different symbol, wherein: a) the selected playing ball is moved from a starting position past an image recording unit pickup, b) the mass centre of the depiction of the selected playing ball in the image is kept unaltered for a prescribed, c) the image position and size of the depiction of the playing ball is ascertained, and a check is performed to determine whether portions of the depiction of the playing ball are situated outside a lateral of the image, and d) if portions of the depiction of the playing ball are situated outside said lateral edge, the playing ball is returned to the pickup area of the image recording unit and / or is repositioned and steps b) to d) are repeated.

Owner:NOVOMATIC

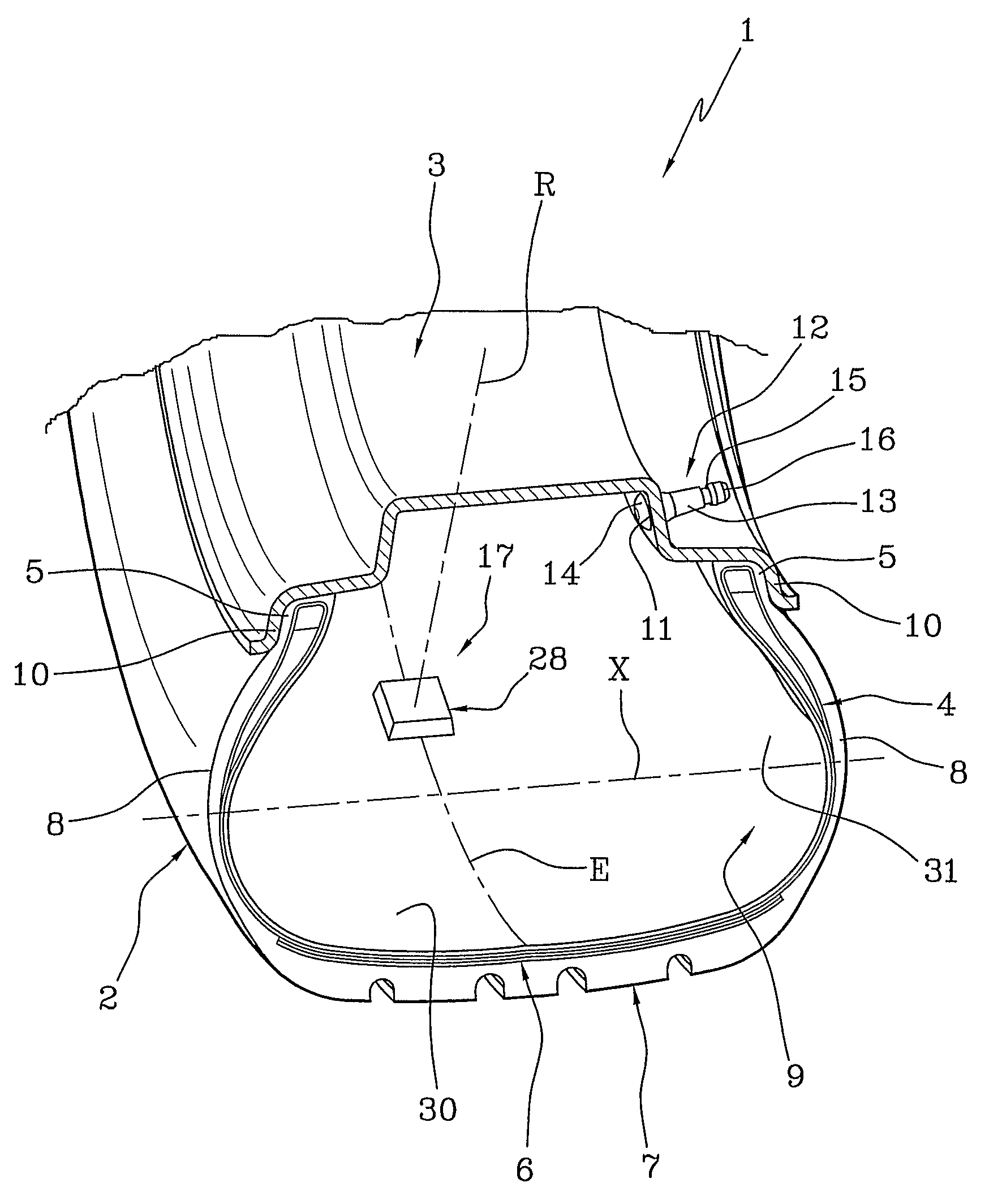

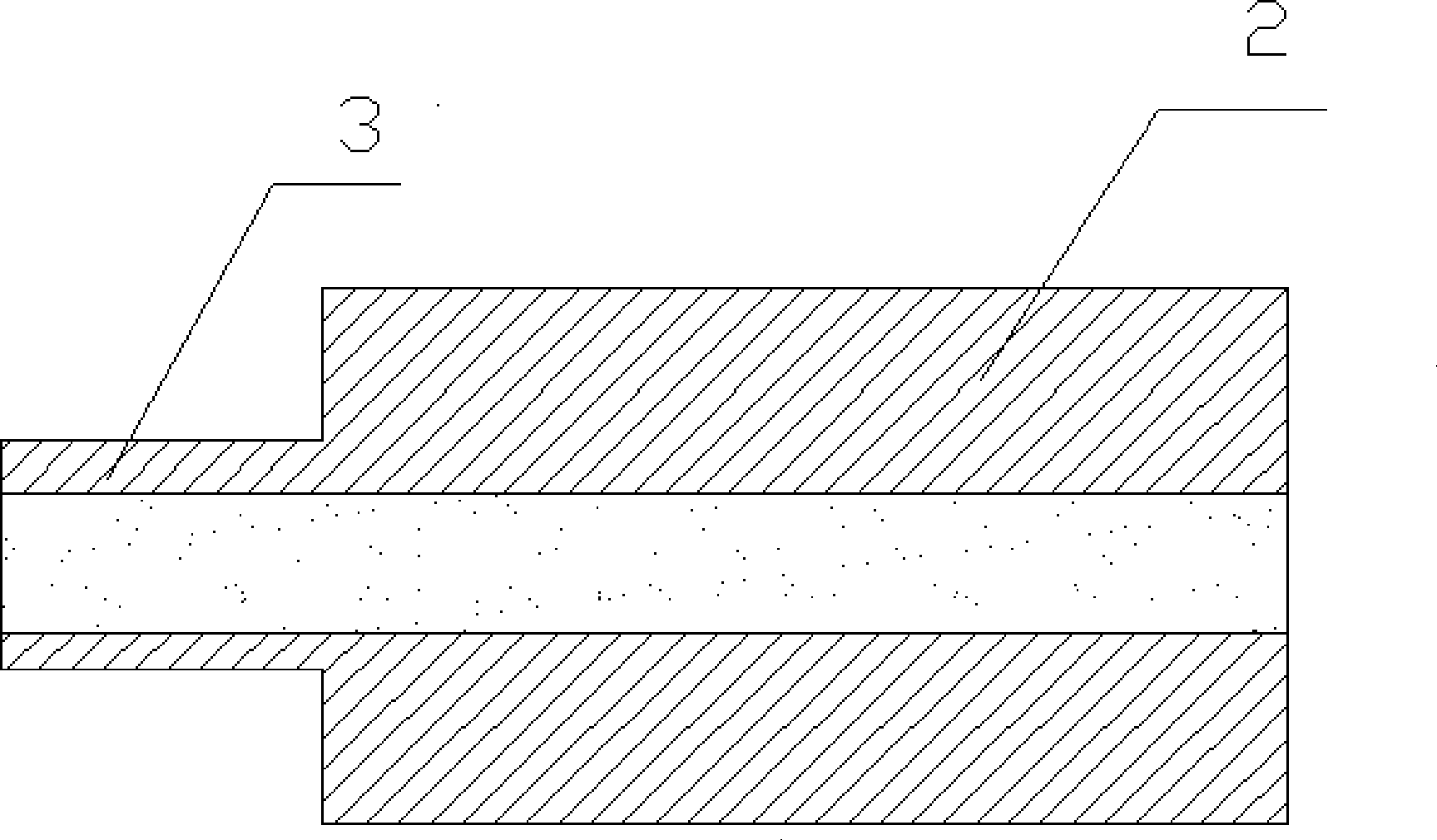

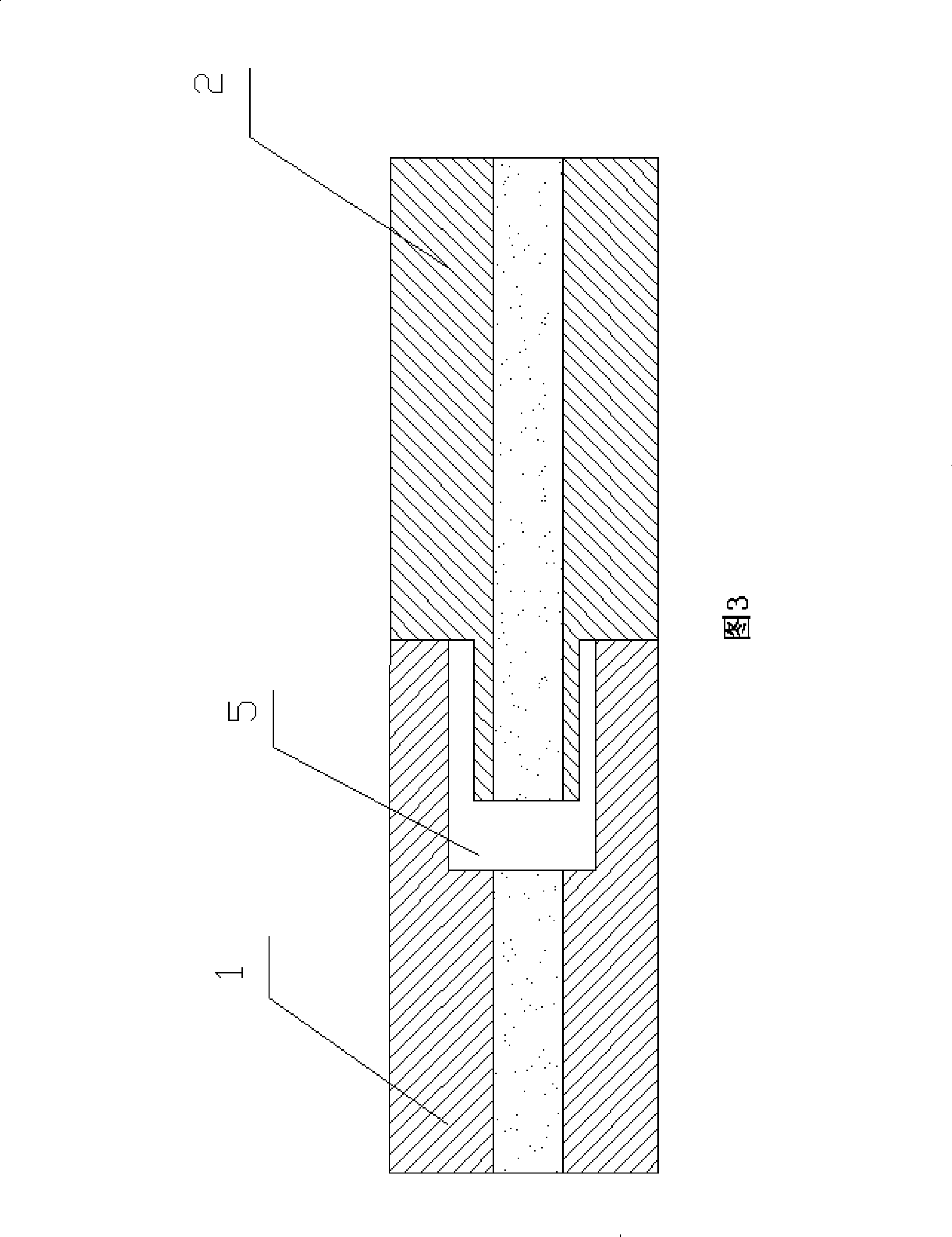

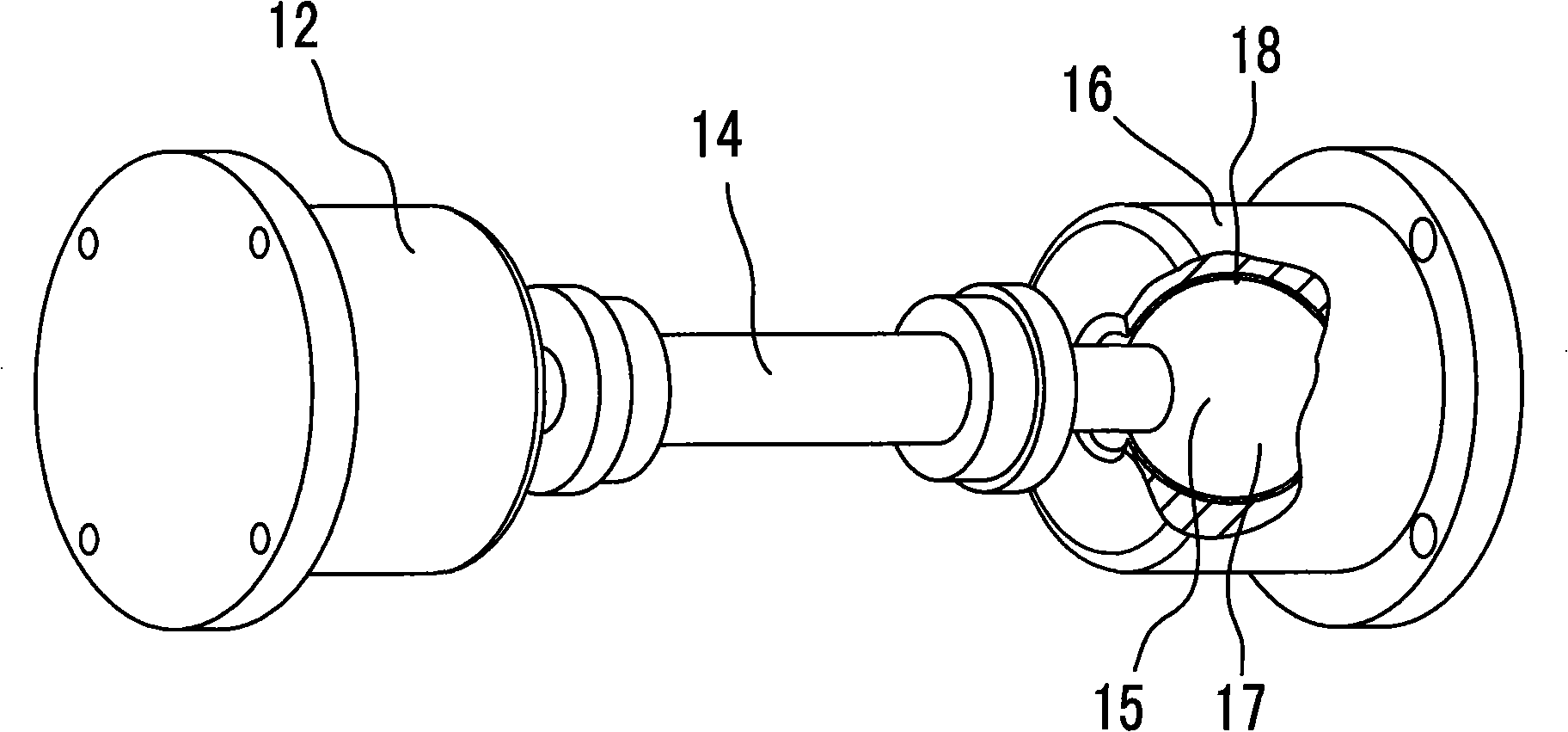

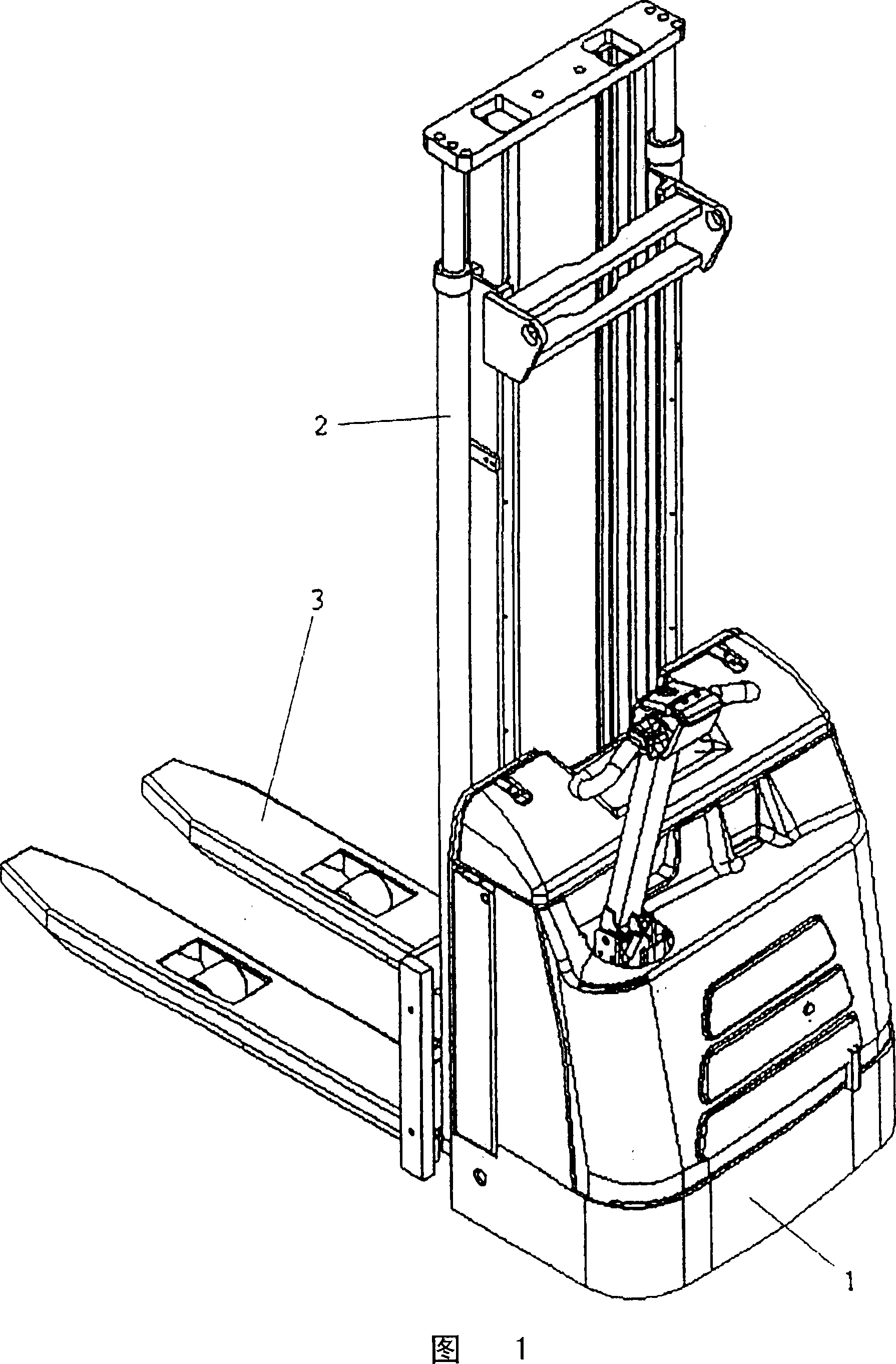

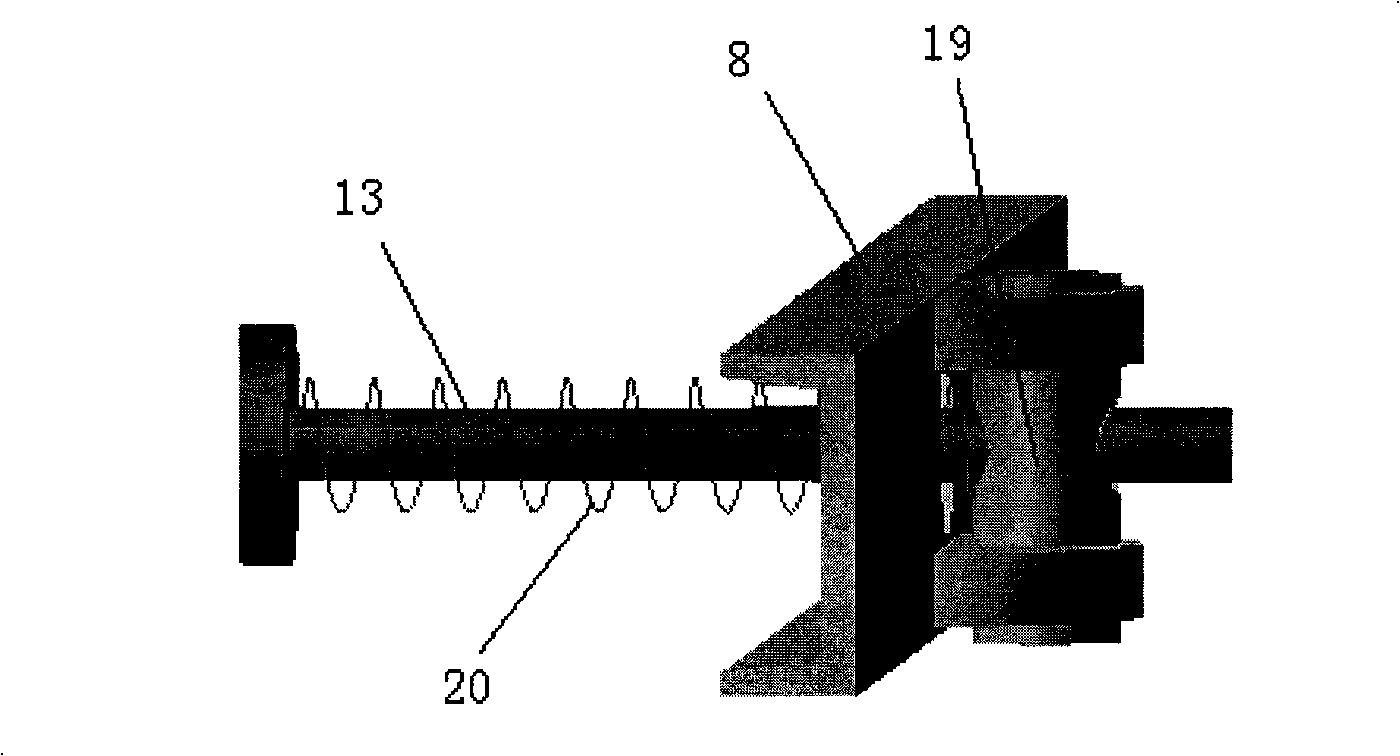

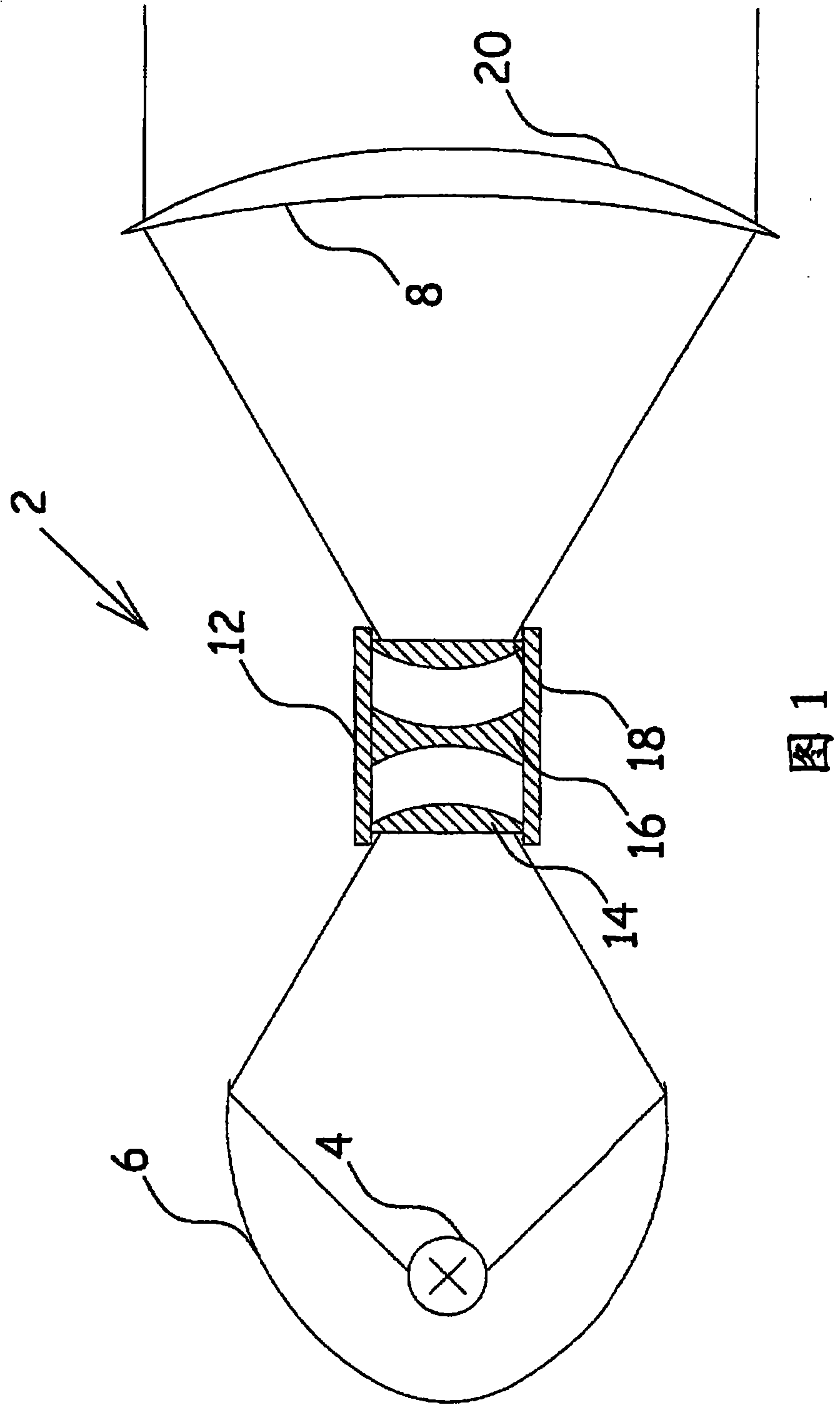

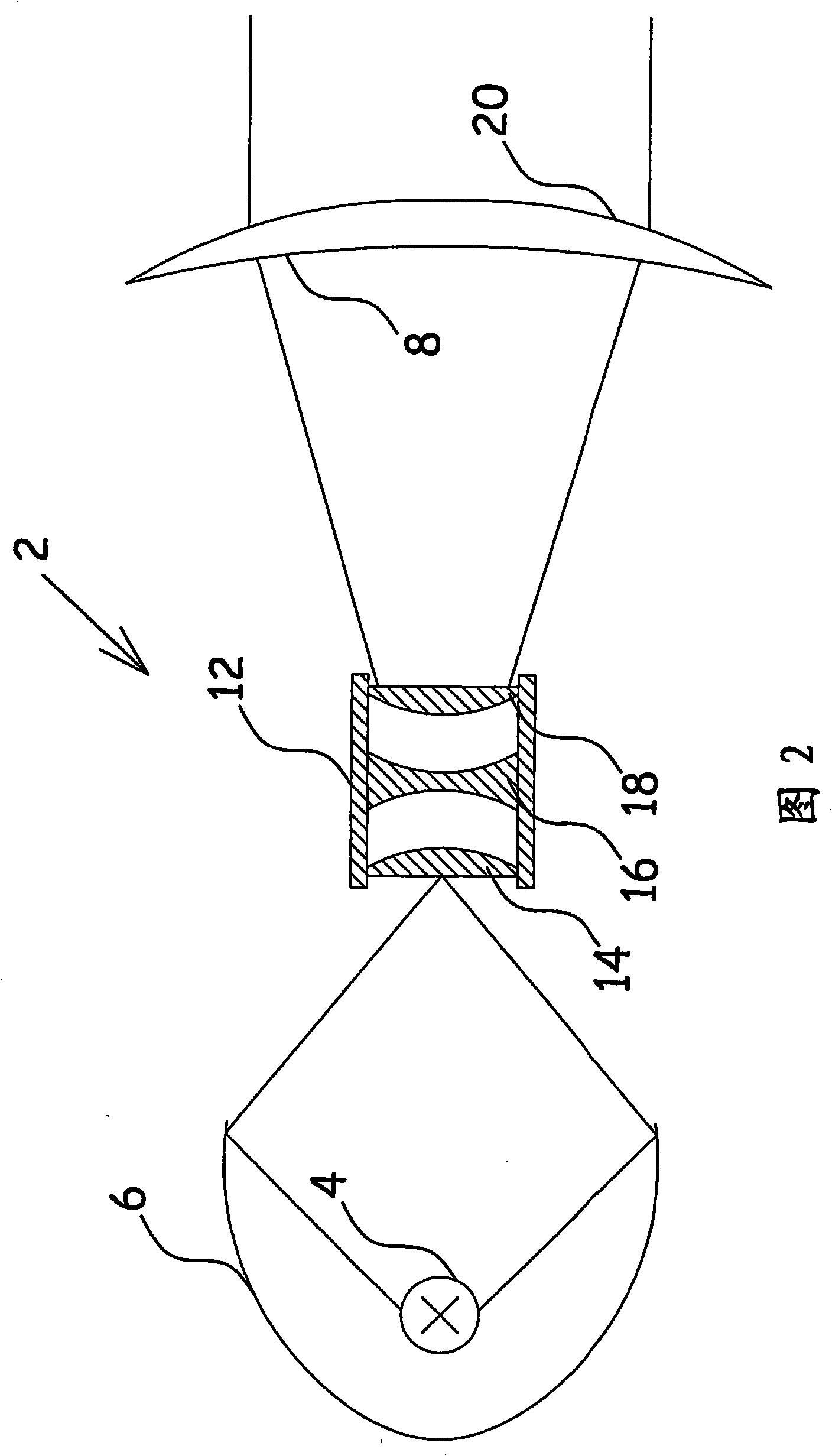

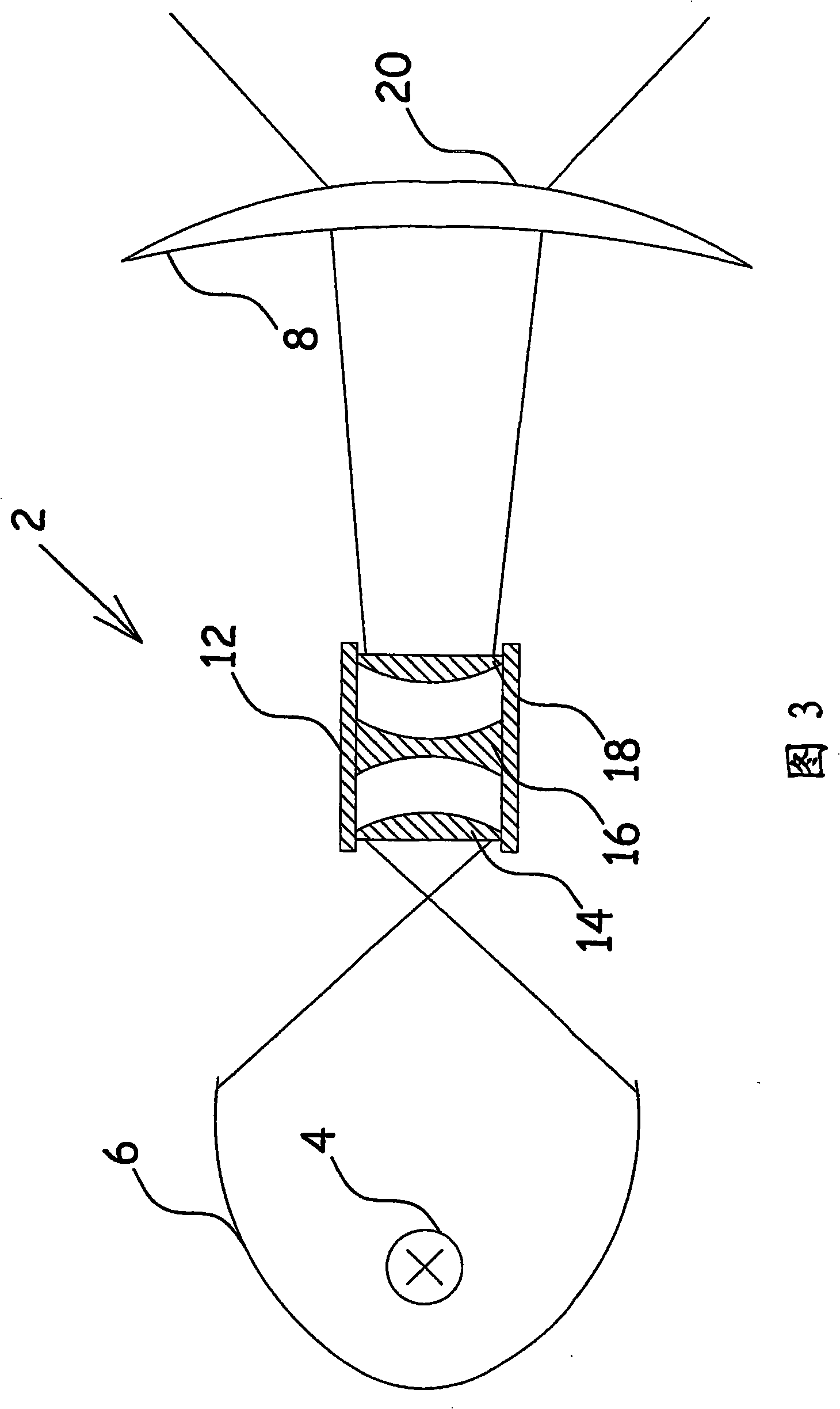

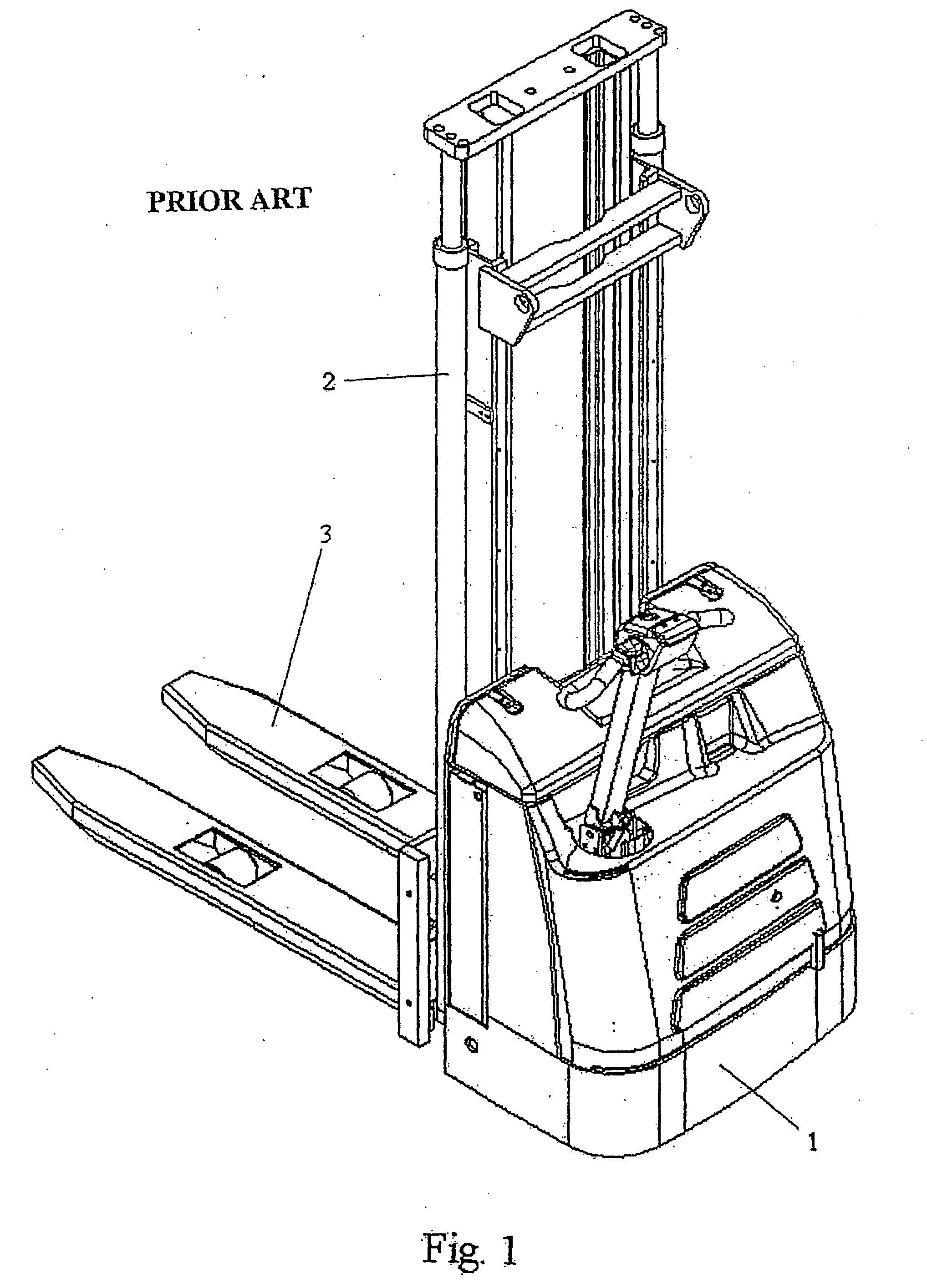

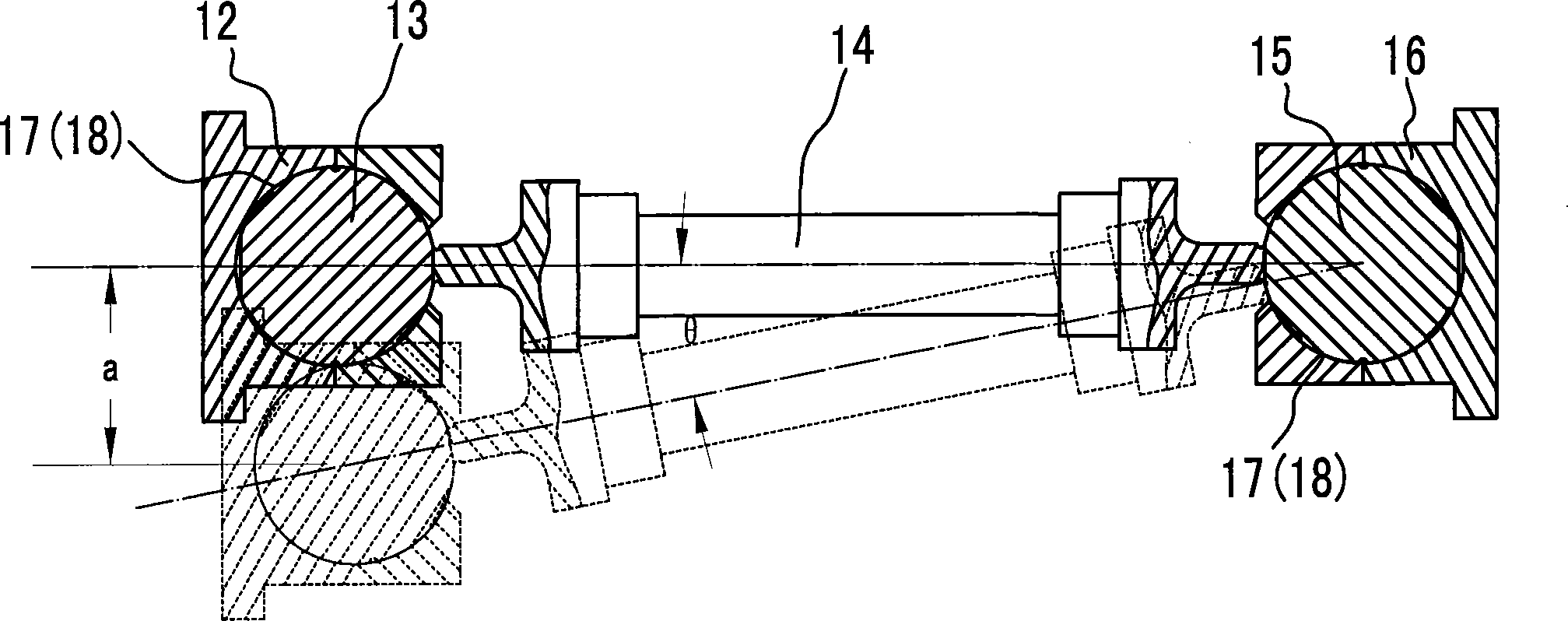

Forklift mast

InactiveCN101027243AFavorable stiffness-to-weight ratioLifting devicesHoisting equipmentsHydraulic cylinderBearing surface

The invention relates to the mast-hydraulic cylinder construction (4, 5) of a two or multiple-stage forklift mast. The substantially vertical beams (4, 5) and cylinder liners (6) of the solid mast structure form an integrated structure (4, 5), in which the cylinder liners (6) consist of ducts integrated within the beams (4, 5), with the mass centre of the cross-section of the integrated structures being at the centre of the cylinder liner (6) or in its immediate vicinity so that the integrated structure (4, 5) can be manufactured by heat extrusion or cold drawing, and in that the integrated structure (4, 5) comprises a first protrusion (14), whose surface substantially transverse to the direction of movement of the forklift and facing the cylinder liner is a bearing surface (17) for a roller bearing (16), and a second protrusion (15) for providing a mass centre at the centre of the cylinder liner (6) or in its immediate vicinity, and a support surface (18, 19) substantially transverse to the direction of movement of the forklift and disposed on the second protrusion (15) or on the outer surface of the cylinder liner facing the first protrusion (14). The invention also relates to a method for producing an integrated structure (4, 5).

Owner:ROCLA

Automotive stability control safety testing system

The invention discloses an automotive stability control safety testing system. The testing system is composed of three parts of a traction rod, a transverse swing link and a vehicle component. The two ends of the traction rod are respectively connected to a fixed shaft and the transverse swing link by pin shafts, the transverse swing link is supported by a five-wheeled instrument. The tension rods of a front wheel and a rear wheel respectively pass through the horizontal holes of vertical pin shafts connected with the transverse swing link, and a limiting spring is located among the tension rods and the vertical pin shafts for limiting the overlarge extension amount of the tension rods. The tension rods of the front and rear wheels are connected to a vehicle clamping device vertically and fixedly through the vertical pin shafts, and the vehicle clamping device is fixedly connected to the vehicle. The relative motion relationship and the stress relationship among the traction rod, the transverse swing link and the vehicle component are determined according to an angular displacement sensor, a linear displacement sensor, and the measurement parameters of the tension gauges of the front and rear wheels among the traction rod, the transverse swing link and the vehicle component. The mass centre of the vehicle and the slip angle of each wheel can be measured by the front wheel steering angle, and the effect for controlling the whole vehicle motion can be obtained by adjusting the side force of the whole vehicle, the transverse swing link torque and the tyre ground acting force through the whole vehicle centrifugal force.

Owner:CHINA AGRI UNIV

Improvements in or relating to light assemblies

The present invention relates to a method for forming a light beam, and to a light assembly comprising at least one light source placed in conjunction with a fixed reflector, which reflector forms a beam of light into light forming means, which light assembly comprises a front lens, where the light forming means at least comprise a light deflecting means for changing the light angle of the light beam after passing through the front lens. The object of the invention is to achieve a light assembly, where major optical components are mechanically fixed in relation to a housing for achieving a light assembly, the mass centre of which changes only slightly during operation. This can be achieved, if the front lens has a central part that differs from the surrounding parts of the front lens, and where the light deflecting means in a first position concentrates the light beam into the central part of the front lens to generate a wide-angle light beam, and where the light deflecting means in a second position distributes the light beam over the entire front lens to generate a narrow-angle light beam, because of the internal light deflecting means, the front lens does not have to be movable with respect to the housing.

Owner:MARTIN PROFESSIONAL

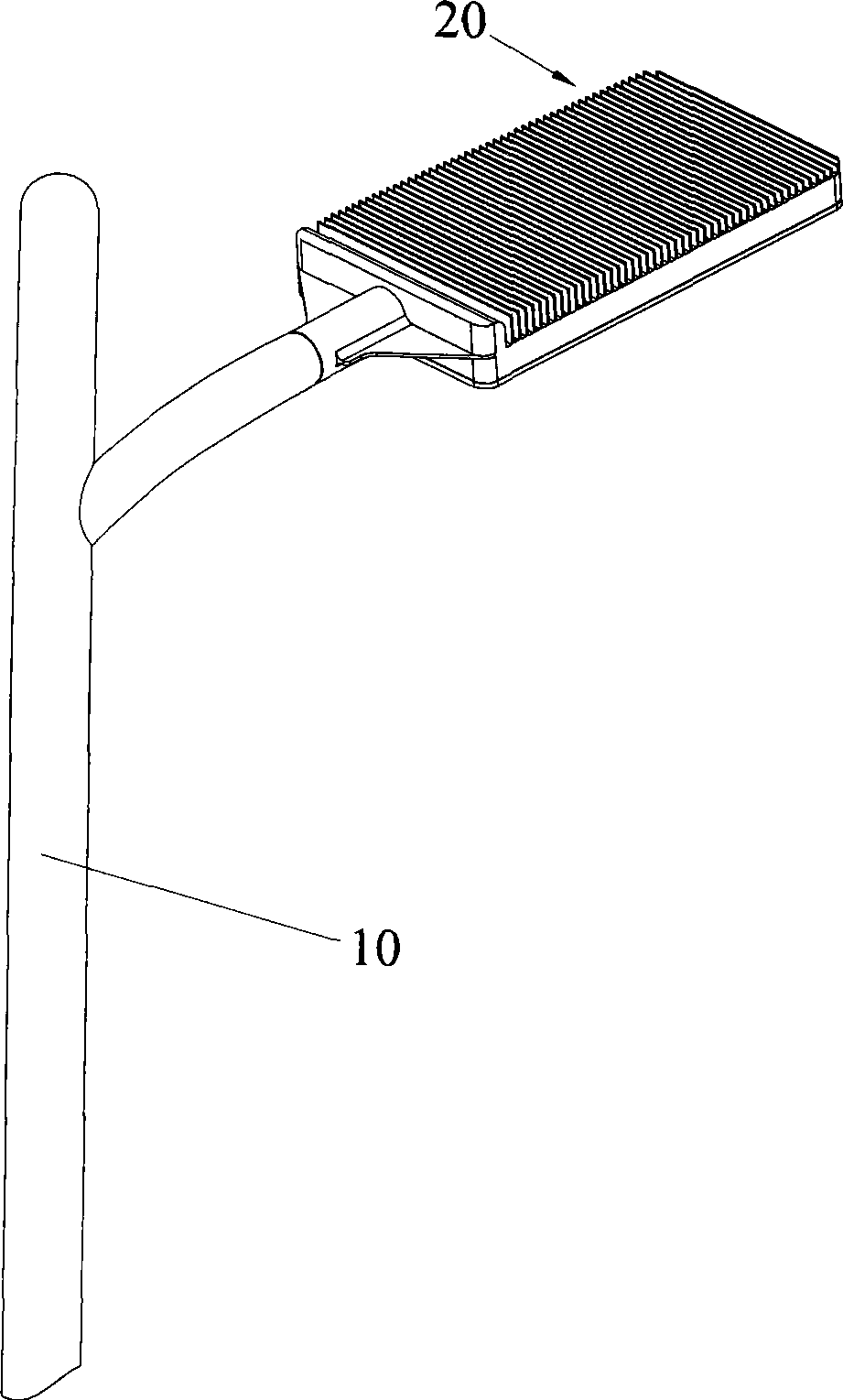

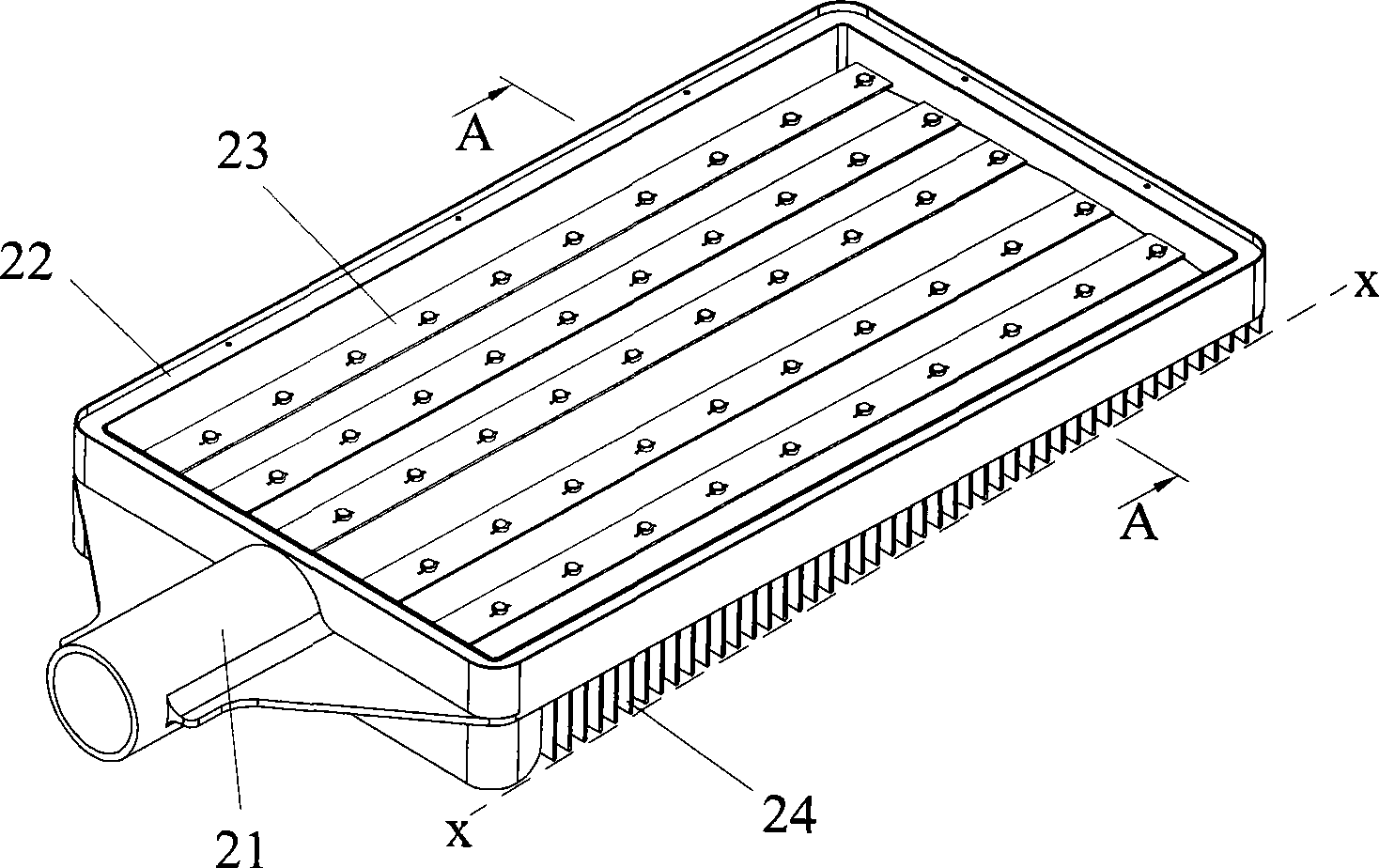

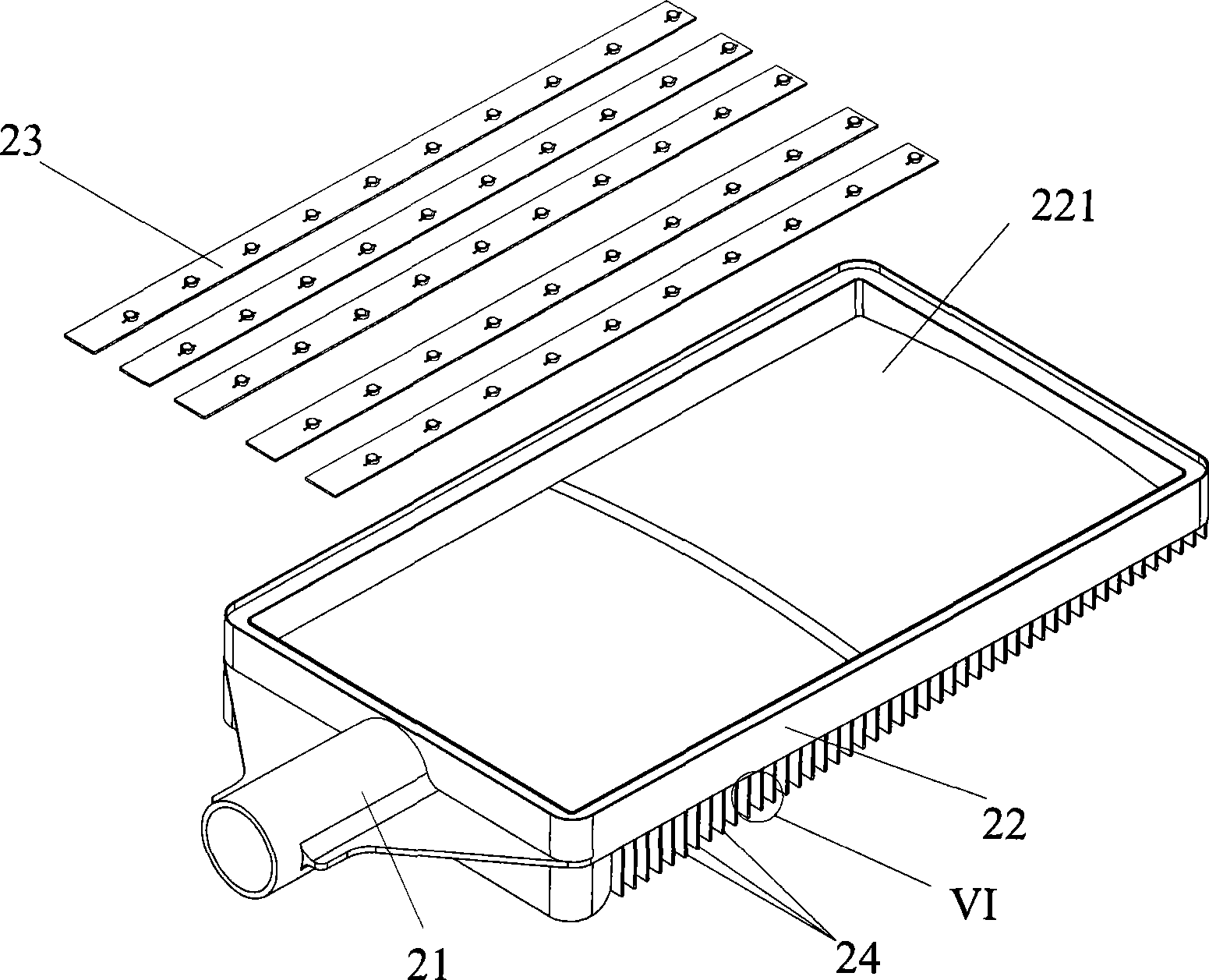

Road lamp heat radiation outer housing

InactiveCN101440952AReduce stressPoint-like light sourceLighting heating/cooling arrangementsEngineeringGravity center

A road lamp heat radiation outer casing comprises a lamp body supporting base for mounting the road lamp on the lamp post and a lamp body base for connecting the lamp body supporting base. The lower surface of the lamp body base is provided with at least one downwardly-extending radiating fin, and the distance from the resultant mass centre of all the radiating fins to a first end surface of the lamp body base is smaller than the distance from the resultant mass centre of all the radiating fins to a second end surface of the lamp body base. Adopting such design, the whole lamp body volume is less, the weight is lightened, the installation is convenient, the mass center of the lamp body moves backward, the applied force at the connection point of the lamp body supporting base and the lamp body base is reduced, and the applied force point is transferred, thereby leading the product to be more fixed.

Owner:DONGGUAN BANGCHEN PHOTOELECTRIC

Computation method of radioactive source error of centralization

InactiveCN101248999AHigh rigidity without deformationNot easy to bendSurgical instrument detailsSpecial data processing applicationsElement analysisFinite element analysis software

A method for calculating the error of centralization of a radioactive source is provided, which is based on finite element analysis software. The method is characterized in that the method comprises the following steps: A) calculating the weight and the mass centre of a treatment head, and transferring the weight and the mass center to the mount position of the treatment head according to the mechanical equivalence principle; B) designing a cover needle as a representative of the treatment head, which structurally comprises a top cover and a needle connected with the center of the top cover, wherein the top cover is positioned at the site of the treatment head and the needle tip is positioned at the center of a roller to represent the focus point of a radioactive source, the mass of the cover needle is negligible, and the deformation of the cover needle is negligible for the rigidity of the cover needle is extremely large; C) configuring parameters and limits required by finite element analysis according to the material physical parameters of the roller; and D) calculating the stress and the displacement of components of the roller by using the finite element analysis software, wherein the calculated displacement value of the needle tip of the cover needle is the error value of centralization of the radioactive source. The invention can relatively accurately calculate the error of centralization of the radioactive source during the design step, optimize the structural design, increase the design accuracy, and reduce consumption of time and cost.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

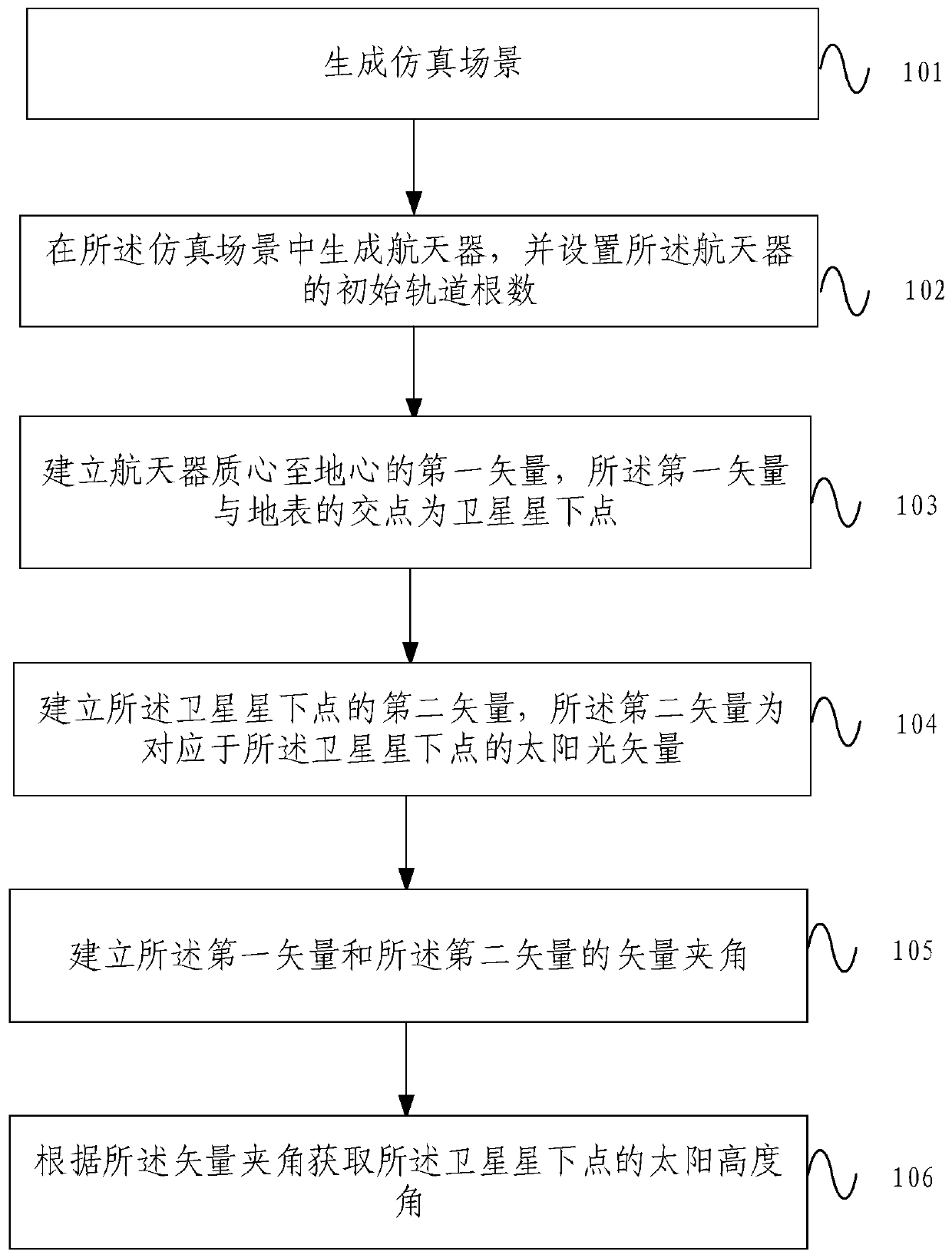

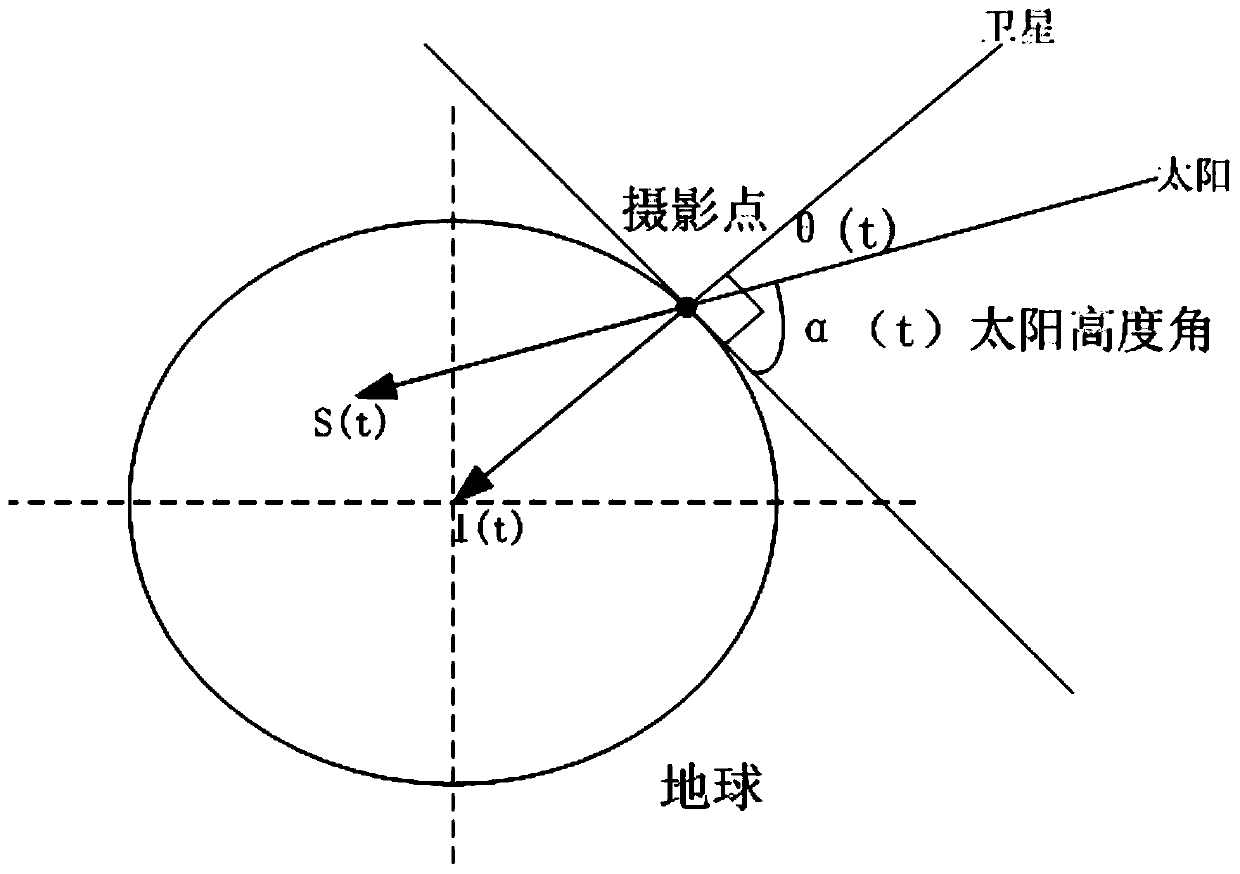

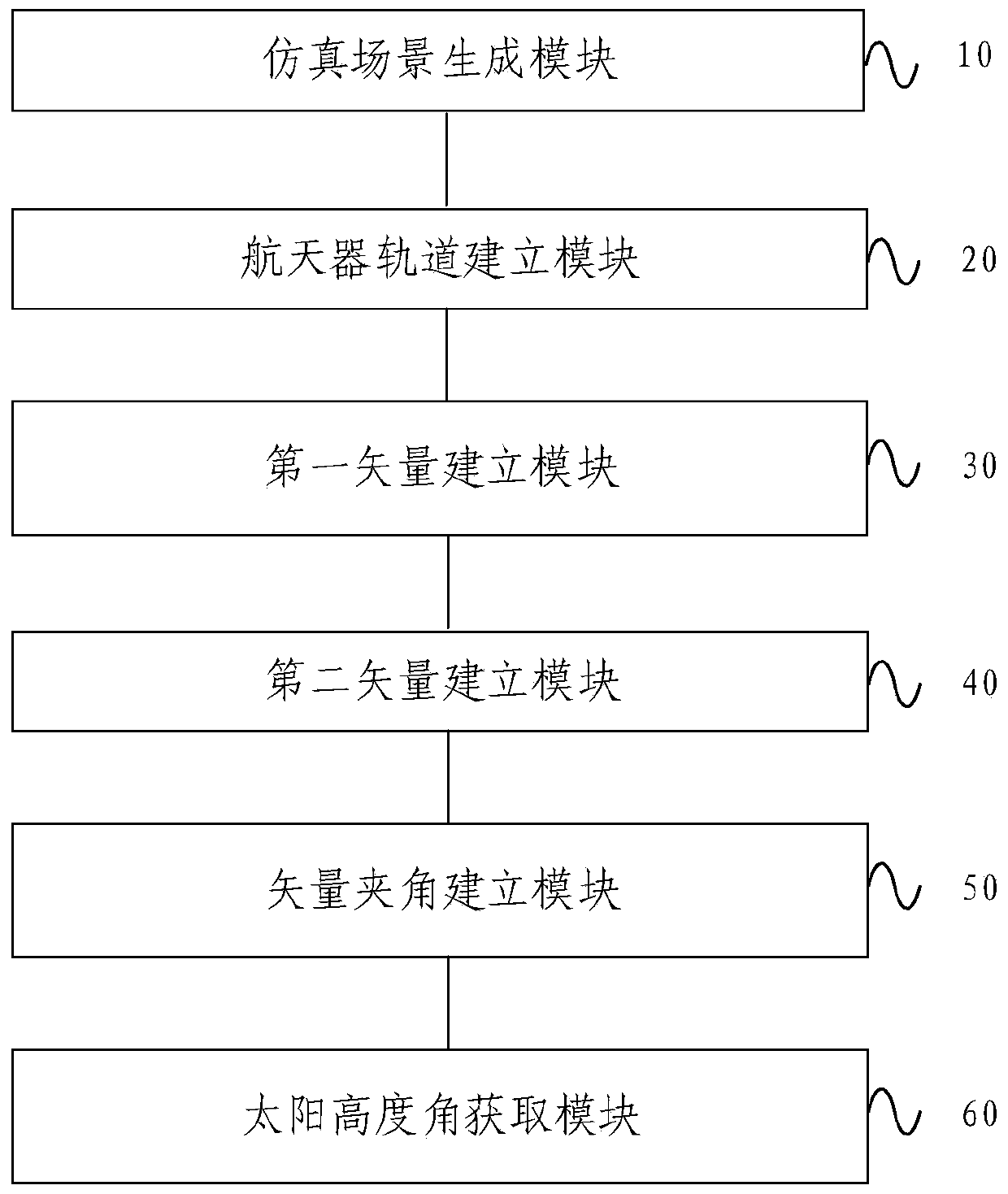

Solar altitude simulation analysis method and system of sub-satellite point

ActiveCN110220492AHigh precisionResolve changeAngle measurementIntersection of a polyhedron with a lineEarth surface

The embodiment of the invention provides a solar altitude simulation analysis method and system of a sub-satellite point. The method comprises the steps of: generating a simulation scene; generating aspacecraft in the simulation scene, and setting the initial orbit elements of the spacecraft; establishing the first vector from the mass centre of the spacecraft to the centre of the earth, whereinthe intersection point between the first vector and the earth's surface is the sub-satellite point; establishing the second vector of the sub-satellite point, wherein the second vector is the sunlightvector corresponding to the sub-satellite point; establishing the vector included angle between the first vector and the second vector; and, obtaining the solar altitude of the sub-satellite point according to the vector included angle. According to the embodiment of the invention, simulation, analysis and calculation on the solar altitude in a satellite running process can be realized; the change problem of the photography point position and the sun position running along with the satellite can be solved; the solar altitude calculation precision is increased; and thus, effective design basisis provided for parameter adjustment of a space camera in a satellite design stage and a factor test stage.

Owner:锡创索科技(苏州)有限公司

Crankshaft rotor assembly and compressor

PendingCN109139477ASolve the problem of increased noiseLight in massRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsEngineeringMechanical engineering

The invention provides a crankshaft rotor assembly and a compressor. The crankshaft rotor assembly comprises a crankshaft and a rotor; the crankshaft comprises a rotating axis, a crankshaft main bodyand a main eccentric part; the main eccentric part can be connected to the outer peripheral surface of the crankshaft main body; an eccentricity r3 exists between the mass centre of the main eccentricpart and the rotating axis in the radial direction; the rotor is provided with a central shaft hole for the crankshaft to penetrate through and comprises a main accommodating groove which is formed in the radial direction from the central shaft hole; and the position of the main accommodating groove corresponds to that of the main eccentric part, so that the main eccentric part is inserted into the main accommodating groove, and the main eccentric part is allowed to rotate in the main accommodating groove. Through the crankshaft rotor assembly, the main eccentric part which achieves a balancing effect is positioned in the rotor, so that the noises caused by shocking a main balancing block by the gas which is exhausted from exhaust holes in a silencer can be effectively reduced; the problems that the main balancing block is over-high and the increment of the noises caused by shocking the main balancing block by the gas which is exhausted from the silencer are solved; the cost can alsobe reduced; hidden danger of breakage of a balancing block is reduced; the problem about interference is solved; and the universality is improved.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

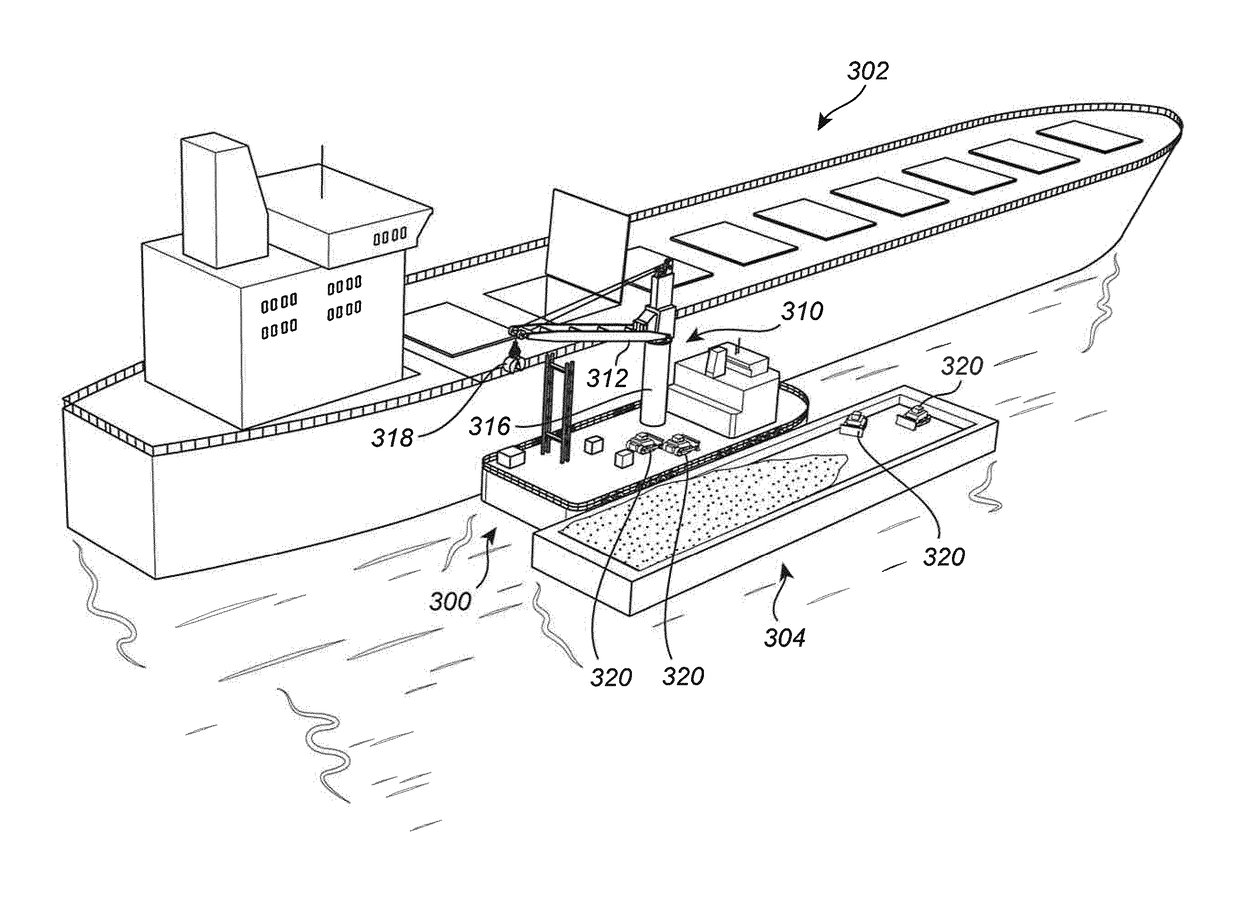

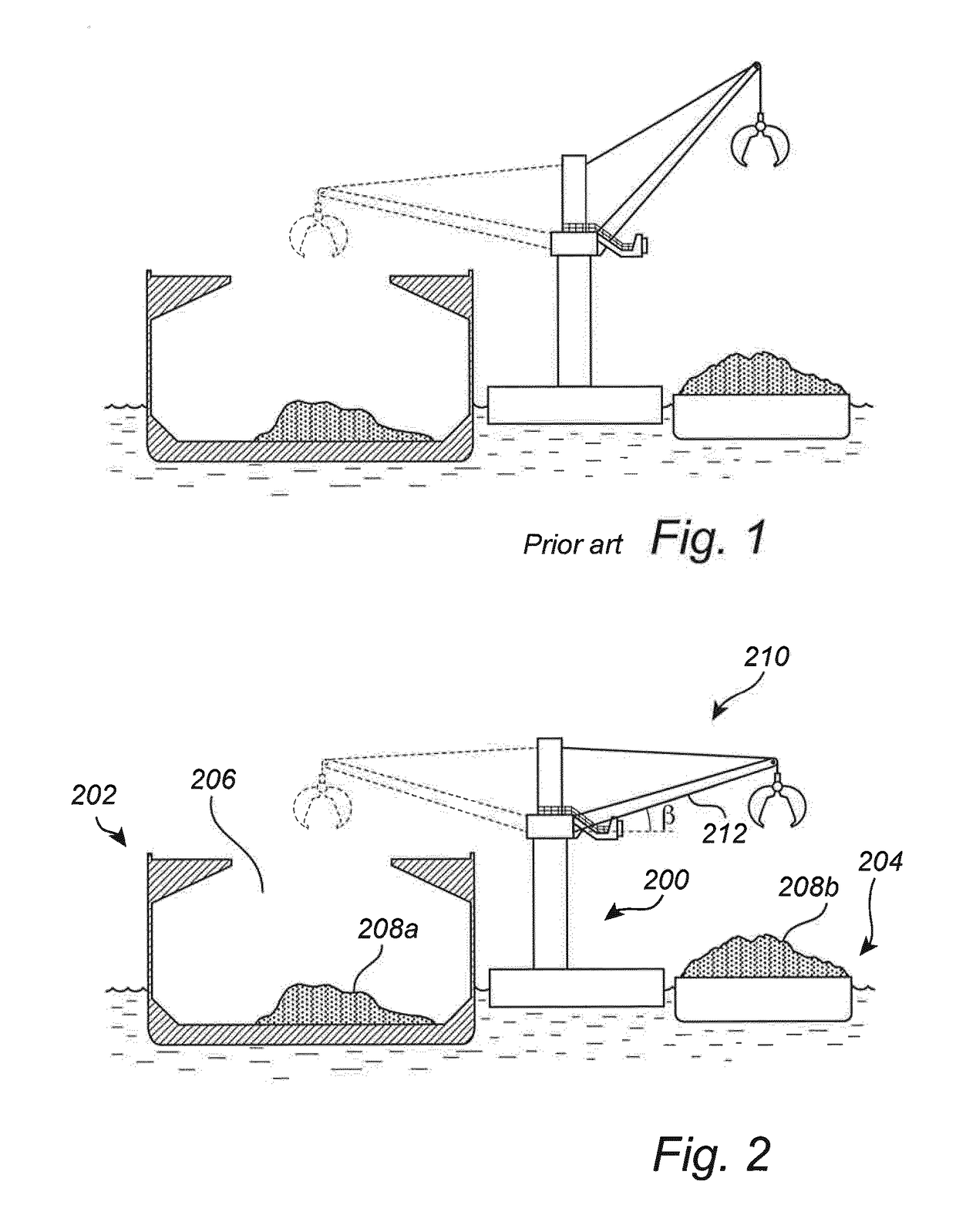

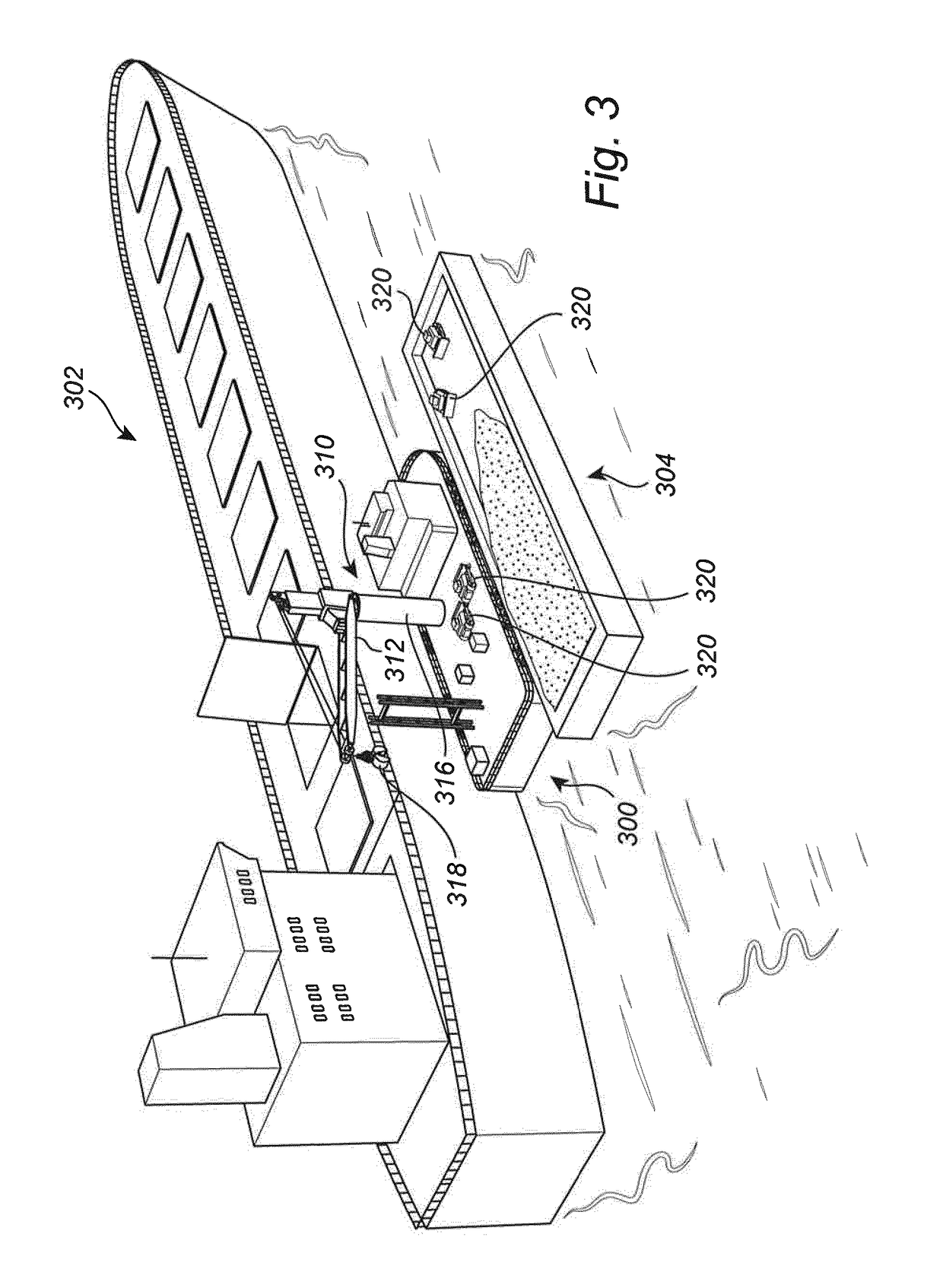

Vessel comprising cargo transloading system

ActiveUS20170120991A1Energy efficiency and reliabilityLittle riskCargo handling apparatusPassenger handling apparatusRotational axisVertical plane

The present invention relates to a vessel (200, 300, 400, 600) comprising: a cargo transloading system, comprising: a crane (210, 310, 410, 610) supporting a cargo handling device (318, 418), and a counterweight arrangement (450, 550). The cargo handling device (318, 418) being rotatable about a vertical axis of rotation arranged with a first fixed offset in a first side direction with regard to a first vertical plane coinciding with a longitudinal centre axis (CA) of the vessel (200, 300, 400, 600). The counterweight arrangement (450, 550) comprising a weight (452, 552, 652) which is movable such that the mass centre (554) of the weight (452, 552, 652) is laterally displaceable between a first end position (556, 656) in which the mass centre (554) is arranged in the vicinity of the first vertical plane and a second end position (558, 658) in which the mass centre (554) is arranged with a second offset in a second side direction opposite to the first side direction with regard to the first vertical plane. The counterweight arrangement (450, 550) being arranged to move the weight (452, 552, 652) while the cargo handling device (318, 418) is rotated about the axis of rotation as a function of the rotation angle (a). The present invention also relates to a corresponding method and a use of the vessel (200, 300, 400, 600).

Owner:MACGREGOR SWEDEN

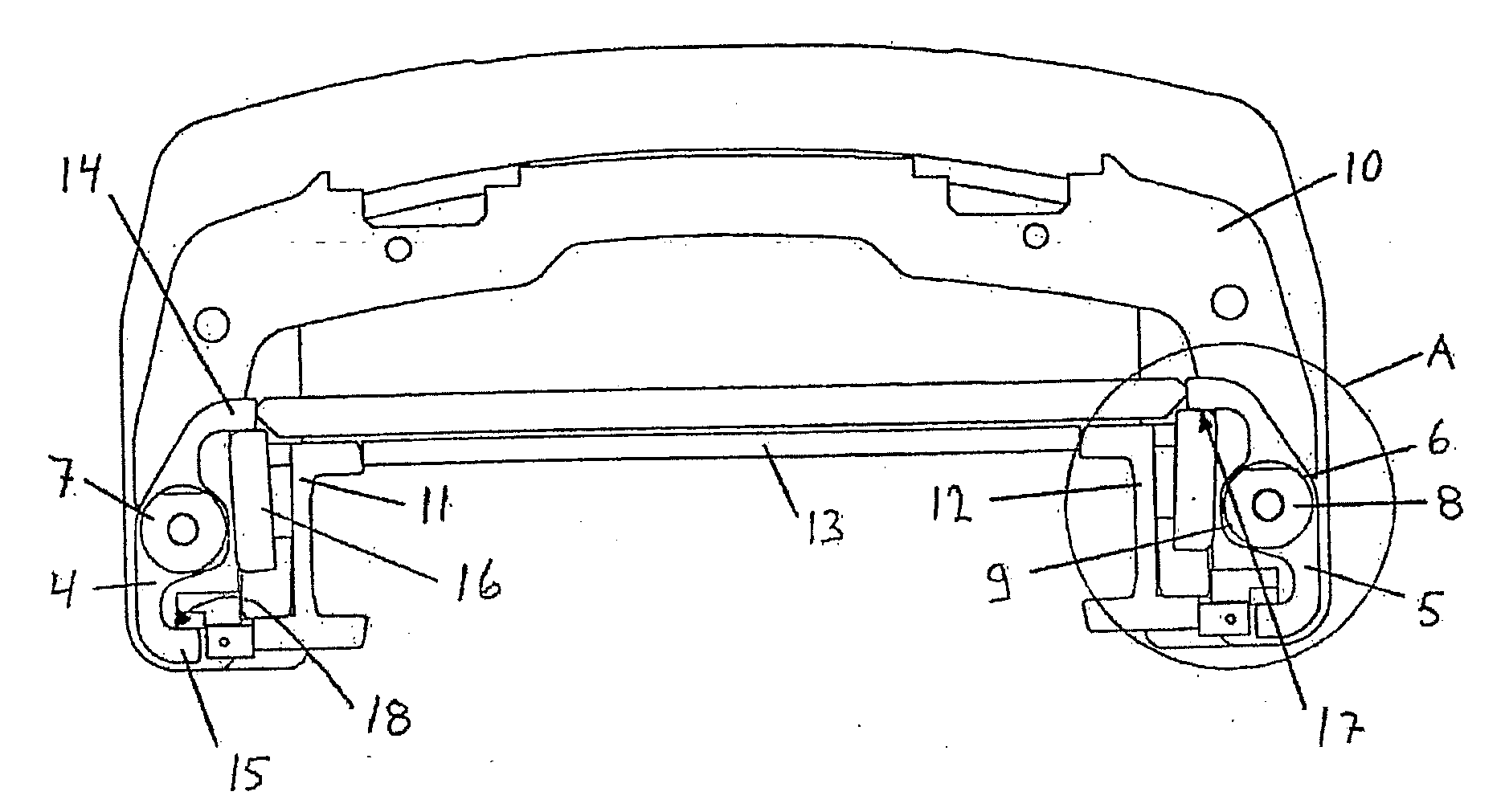

Forklift Mast

InactiveUS20090026019A1Advantageous rigidity to weight ratioMetal-working apparatusLifting devicesHydraulic cylinderBearing surface

The invention relates to the mast-hydraulic cylinder construction (4, 5) of a two or multiple-stage forklift mast. The substantially vertical beams (4, 5) and cylinder liners (6) of the solid mast structure form an integrated structure (4, 5), in which the cylinder liners (6) consist of ducts integrated within the beams (4, 5), with the mass centre of the cross-section of the integrated structures being at the centre of the cylinder liner (6) or in its immediate vicinity so that the integrated structure (4, 5) can be manufactured by heat extrusion or cold drawing, and in that the integrated structure (4, 5) comprises a first protrusion (14), whose surface is a bearing surface (17) for a roller bearing (16), and a second protrusion (15) for providing a mass centre at the centre of the cylinder liner (6), and a support surface (18, 19) substantially transverse to the direction of movement of the forklift. The invention also relates to a method for producing an integrated structure (4, 5).

Owner:ROCLA

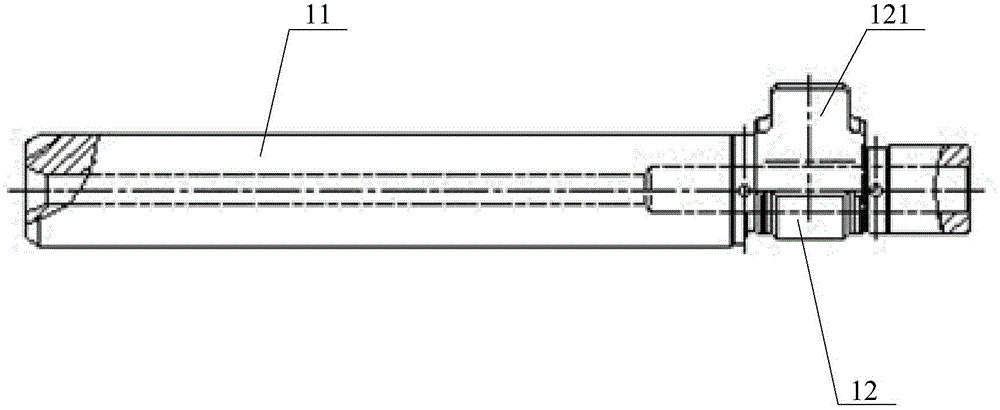

Structure and method for reducing equivalent unsprung weight of wheel-rim electrically-driven system of single oblique arm type suspension

ActiveCN102092255AHigh vibration frequencyImprove comfortResilient suspensionsControl devicesVehicle frameDrive wheel

The invention discloses a structure for reducing the equivalent unsprung weight of a wheel-rim electrically-driven system of a single oblique arm type suspension, which is characterized in that an elastic rubber hinge is supported on a frame, one end of a swing arm of the single oblique arm type suspension is connected with the elastic rubber hinge, and the other end of the swing arm is connected with a motor fixed on a reducer casing; the reducer casing is connected with a sleeve of a half axle; the power output end of the motor is connected with a small gear, then the small gear is meshed with a large gear, and the large gear is connected with the sleeve of the half axle; and after the gear reducing is performed, the power is outputted to a rim by the half axle so as to drive wheels. The equivalent unsprung weight is reduced by reducing the distance between the mass centre of non-concentric parts of a wheel and a central swing axis of the single oblique arm type suspension. The structure disclosed by the invention has the advantages of reducing the equivalent unsprung weight of the wheel-rim electrically-driven system, increasing the vibration frequency of wheels, reducing the resonance, reducing the impact and vibration from road surfaces, and improving the running smoothness of vehicles.

Owner:TONGJI UNIV

Three-axis six-freedom degree vibration test apparatus

ActiveCN101281088BQuick switchImprove Vibration Testing EfficiencyVibration testingAcousticsTest equipment

A vibration test equipment with three axis and six degrees of freedom, comprising a sample worktable, a first vibration generator arranged in the level X-axis direction with the mass centre of the sample worktable used as origin of coordinates; a second vibration generator and a third vibration generator which are arranged side by side in the level Y-axis direction with the vibration body of the second vibration generator connected with the sample worktable through a second sphericity connector and the vibration body of the third vibration generator connected with the sample worktable througha third sphericity connector; a forth vibration generator and a fifth vibration generator which are arranged side by side in the level Z-axis direction with the vibration body of the forth vibration generator connected with the bottom surface of the sample worktable through a forth sphericity connector and the vibration body of the fifth vibration generator connected with the bottom surface of the sample worktable through a fifth sphericity connector. The invention can simulate X, Y, Z triaxiality and six degrees of freedom complex vibration environment in true environment to reproduce the real working condition more accurately, largely increasing the accuracy of the vibration test result.

Owner:SUZHOU SUSHI TESTING INSTR CO LTD

Rotary compressor and crankshaft assembly thereof

ActiveCN105221428AReduce distanceLower the balance weightCrankshaftsRotary/oscillating piston pump componentsEngineeringUltimate tensile strength

The invention discloses a crankshaft assembly. The crankshaft assembly comprises a crankshaft body, wherein an eccentric part is arranged on the end part of the crankshaft body; the top edge of the axial cross section of the eccentric part is arc-shaped; balance notches are oppositely formed in the two sides of a flange of the eccentric part; the connection line between the vertex of the outer edge of the eccentric part and the rotation centre of the eccentric part, and the axis of the crankshaft body determine a plane; and the two balance notches are symmetrical by taking the plane as a reference plane. During a working process, the two balance notches which are symmetrically formed are capable of effectively shortening the distance between the mass centre of the eccentric part and the rotation centre of the eccentric part, and reducing the balance weight of a compressor, and therefore a friction contact surface between the crankshaft assembly and rollers is effectively reduced on the premise of guaranteeing the strength and the stressed area of a crankshaft structure, then the wear of the related mating parts is reduced, and correspondingly the running reliability of the rotary compressor is improved and the service life of the rotary compressor is prolonged. The invention further discloses a rotary compressor using applying the crankshaft assembly.

Owner:ZHUHAI LANDA COMPRESSOR +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com