Centrifugal force pendulum and clutch disc having the same

A centrifugal force pendulum and clutch disc technology, which can be used in spring/shock absorber, vibration suppression adjustment, mechanical equipment, etc., and can solve problems such as difficulty in buffering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

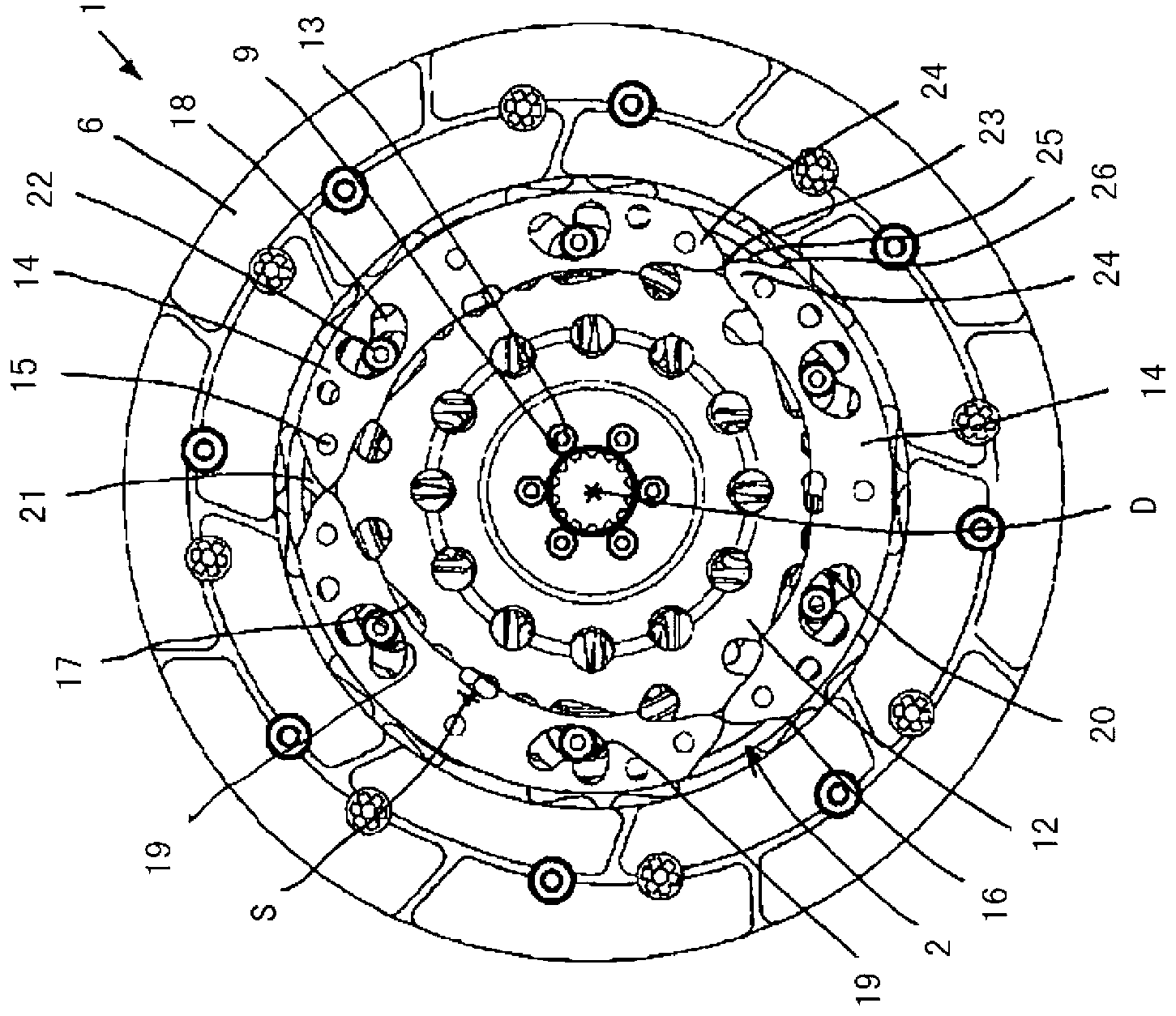

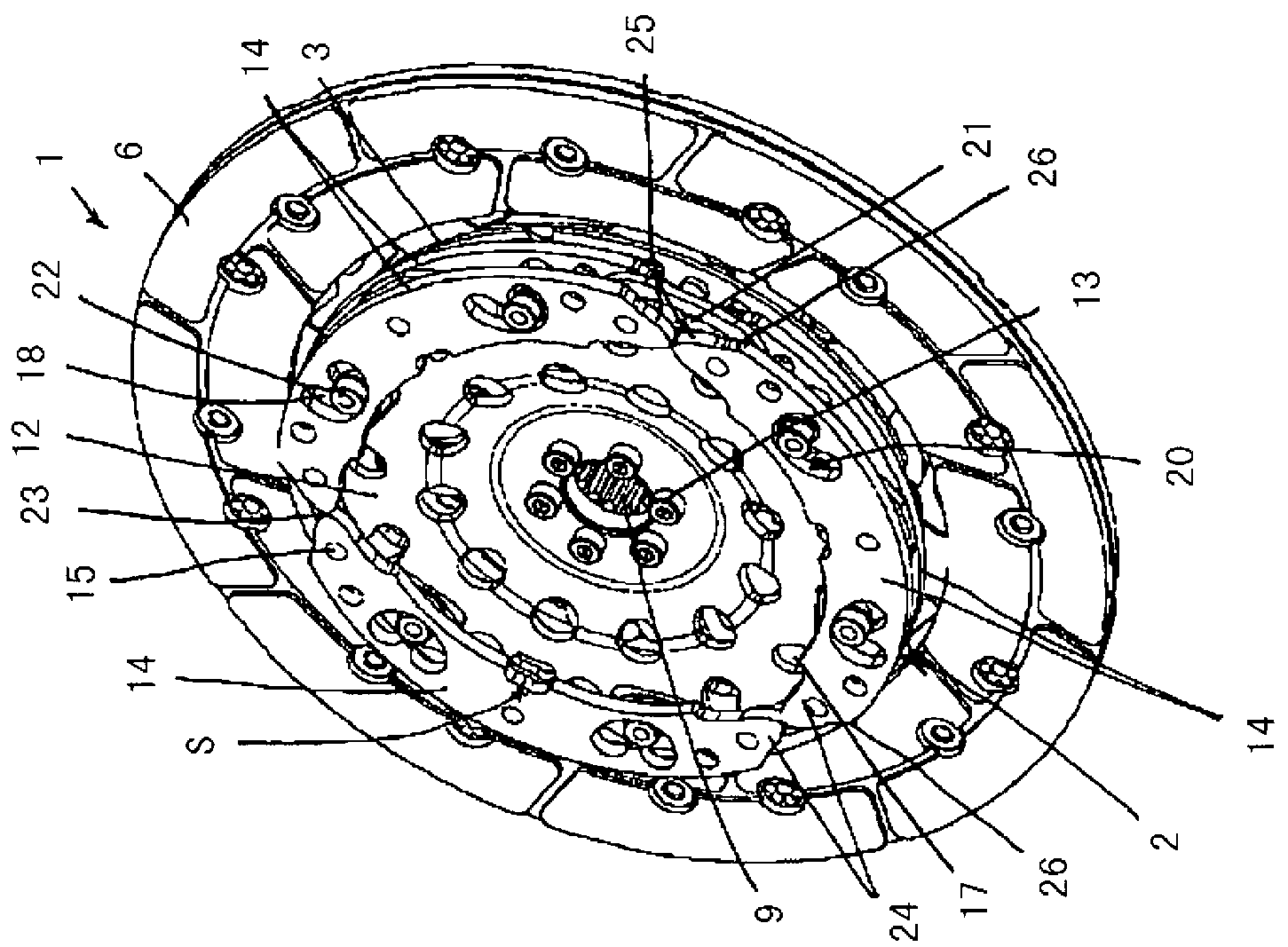

[0024] Figures 1 to 3The clutch disk 1 with the centrifugal pendulum 2 is shown in section, front view and 3D oblique view. The clutch disc comprises an input part 5 formed by flange parts 3 , 4 and an output part 8 formed by a flange part 7 , wherein the flange part 3 carries a friction lining 6 , the output part can be connected to the flange in a rotationally fixed manner. The hub 9 to which the component 7 is connected is connected in a rotationally fixed manner to the transmission input shaft. The input part 5 and the output part 8 are able to rotate in a limited manner about the axis of rotation D against the action of a spring arrangement 11 formed by a helical spring 10 and form a torsional vibration damper here.

[0025] The centrifugal pendulum 2 is assigned to the output part 8 of the clutch disk 1 . For this purpose, the support flange 12 of the centrifugal pendulum 2 is connected to the hub 9 in a rotationally fixed manner by means of screws 13 and / or abuts aga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com