Autonomous obstacles surmounting mechanism of grip hook composite type tour inspection robot

An inspection robot and composite technology, applied in locomotives, motor vehicles, overhead lines/cable equipment, etc., can solve the problems of limited obstacle surmounting ability, difficult control, complex structure, etc., and achieve strong obstacle surmounting ability and working space. The effect of large, large working range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

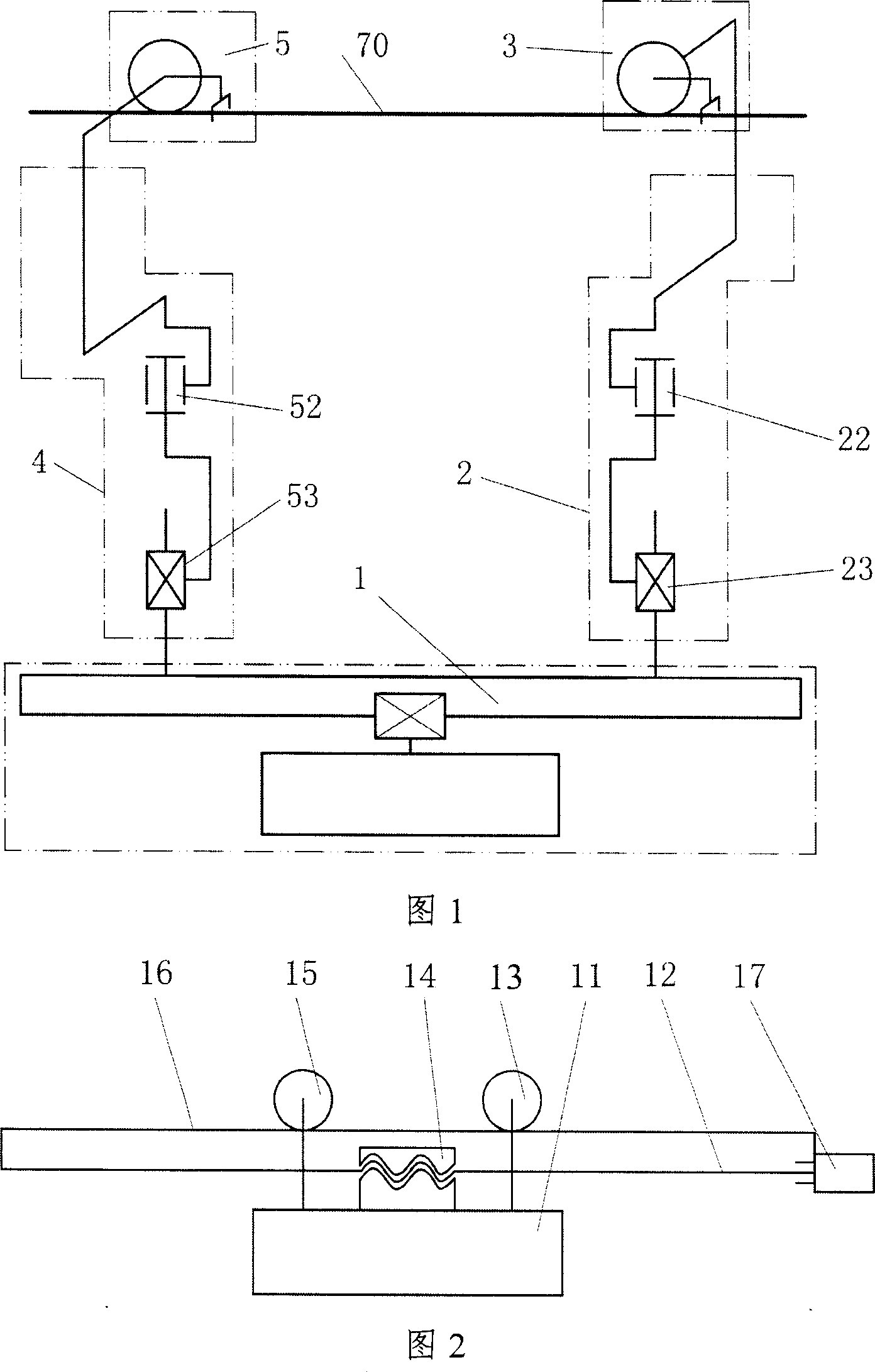

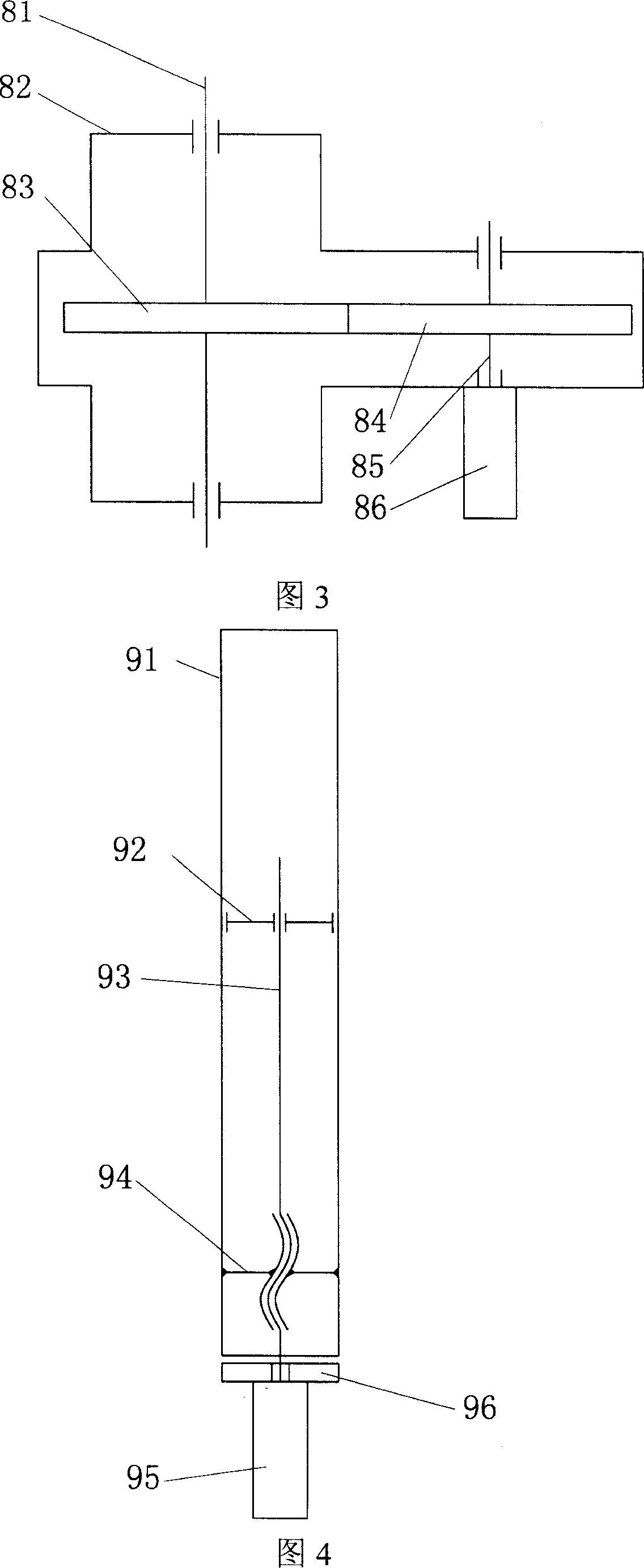

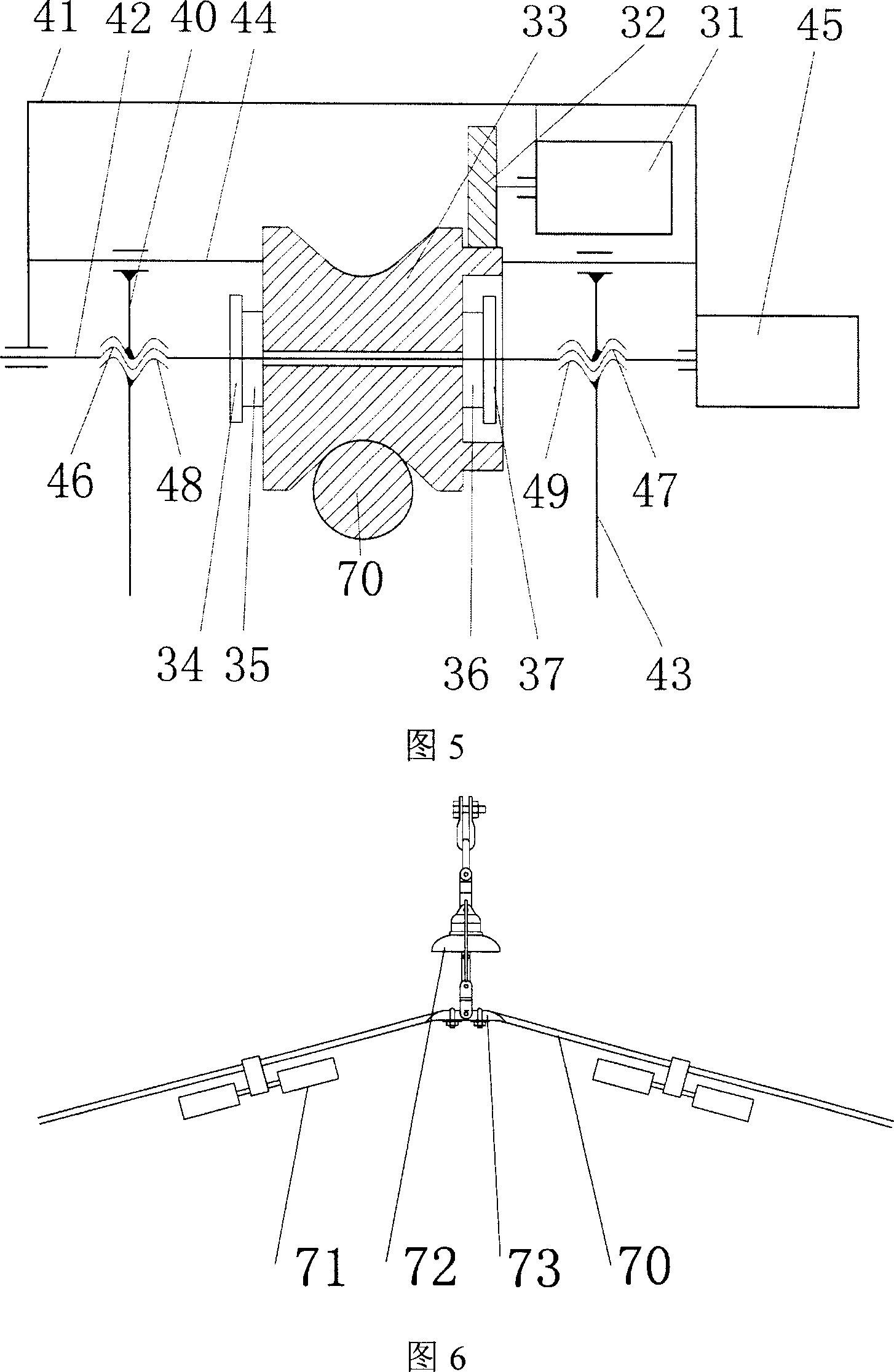

[0025] As shown in Figure 1, the mechanical structure of the present invention is made up of center of mass adjustment mechanism 1, front arm 2, front travel clamping mechanism 3, rear arm 4, rear travel clamping mechanism 5, described front and rear arms 2,4 One end is fixed on the center of mass adjustment mechanism 1 by screws; the other end is connected with the front and rear travel clamping mechanisms 3 and 5, and the arms 2 and 4 are respectively controlled by the front and rear rotary mechanisms 22 and 52, and the front and rear vertical telescopic mechanisms 23. , 53, wherein one end of the front and rear slewing mechanism 22, 52 is directly connected with the front and rear travel clamping mechanism 3, 5, and the other end is connected with the center of mass adjustment mechanism 1 after the front and rear vertical expansion mechanism 23, 53; The walking clamping mechanism is located on the overhead ground; the front and rear walking clamping mechanisms 3, 5 and the f...

Embodiment 2

[0035] The difference from Embodiment 1 is that, as shown in Figure 8, in the center of mass adjustment mechanism 1, the driving reel 12, the passive reel 13, and the cable 14 are used to replace the original screw nut mechanism, further reducing the weight. The flexible cable 14 two ends pass through the active reel 12, the passive reel 13 is connected with the electrical box 11, and the active reel 12 and the motor 17 drive the flexible cable 14 to move, thereby driving the electrical box 11 to move on the carrier plate 16.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com