Maglev molecular pump, and control method and manufacturing method thereof

A control method and molecular pump technology, applied in pump control, pump, axial flow pump, etc., can solve problems such as complex rotor motion, long adjustment time, and complicated control process, so as to improve control efficiency and stability and reduce control Difficulty, the effect of simplifying the control process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

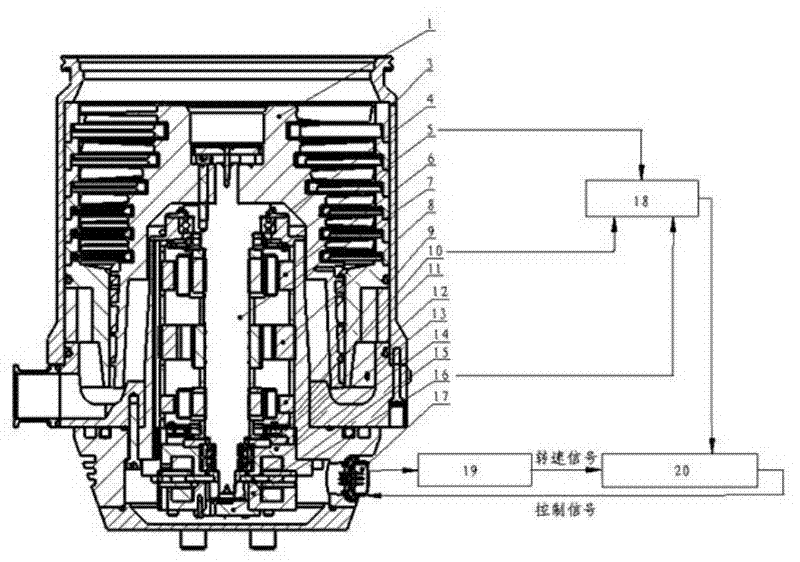

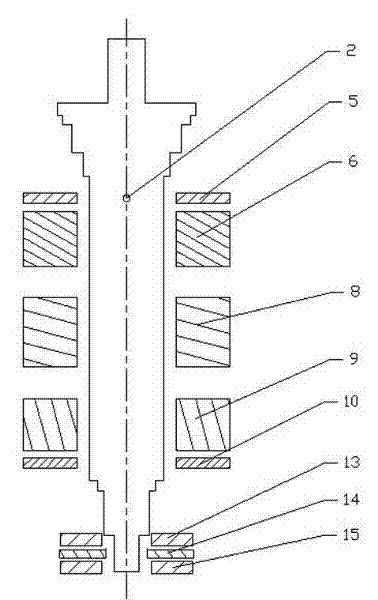

[0020] Such as figure 1 Shown is a schematic structural diagram of the magnetic levitation molecular pump involved in the present invention. In this embodiment, the magnetic levitation molecular pump is arranged vertically, and the magnetic levitation molecular pump includes a pump body 3 and a rotor shaft arranged in the pump body 3 System, and other structures that the magnetic levitation molecular pump described in the prior art should have. Since the present invention does not involve the above-mentioned other structures, it will not be repeated here.

[0021] The rotor shaft system includes a rotor, a first radial magnetic bearing 6, a second radial magnetic bearing 9, a first axial magnetic bearing 13 and a second axial magnetic bearing 15; the rotor includes a rotor shaft 7, and The impeller 1 to which the rotor shaft 7 is fixed, and the assembly parts for fixing the impeller 1, such as screws, nuts, and the like.

[0022] The axis of the rotor shaft 7 is arranged in a verti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com