Improvements in or relating to light assemblies

一种光学组件、光学部件的技术,应用在光源、电光源、点状光源等方向,能够解决减少光学效果等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

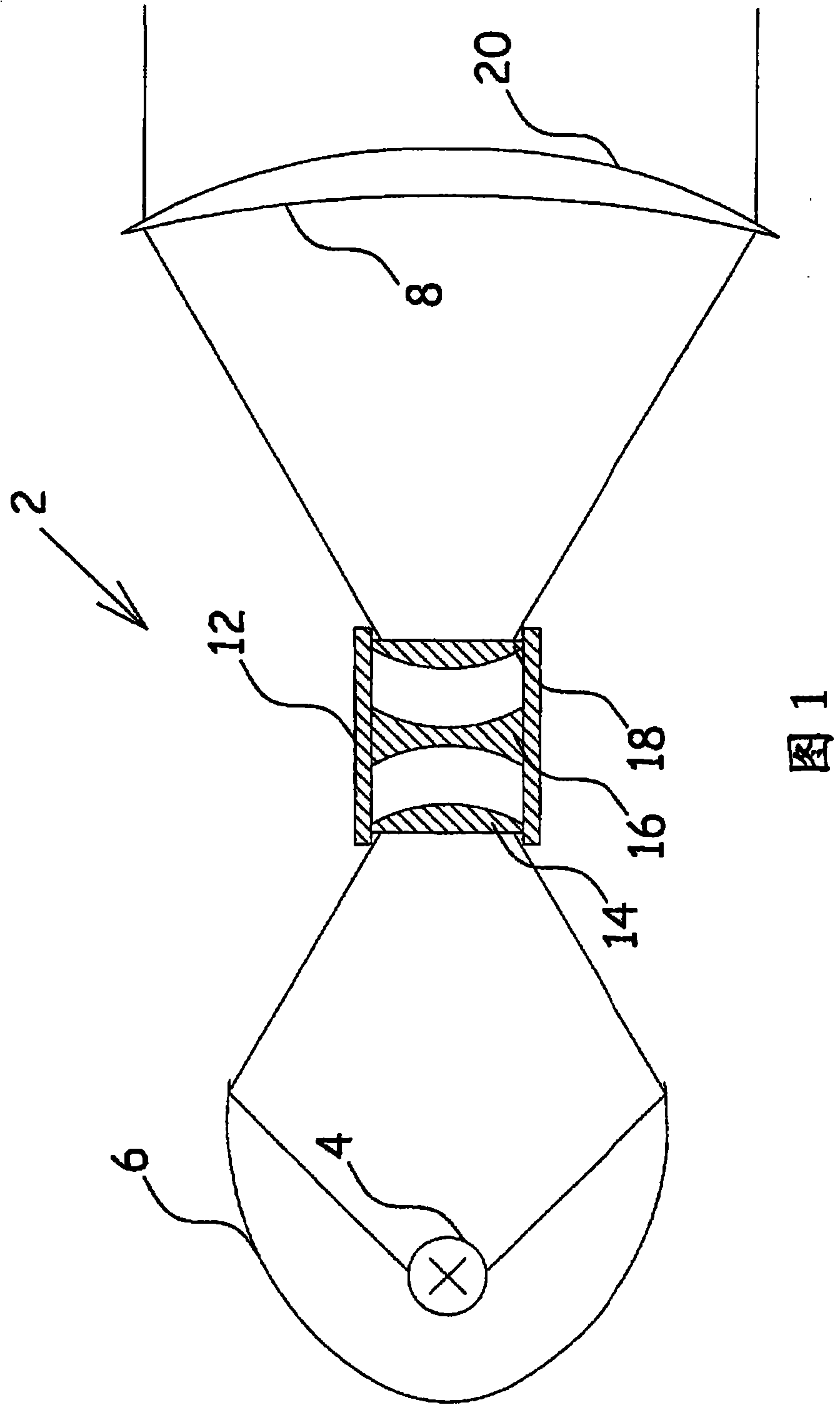

[0035]FIG. 1 shows an optical assembly 2 comprising a lamp 4 positioned relative to a reflector 6 . A front lens 8 is placed at the front end of the optical assembly 2 . Between the mirror 6 and the front lens 8 is placed a light deflecting device 12 comprising at least lenses 14 , 16 and 18 . The front lens 8 comprises a central region 20 which has different optical properties than the lens in the region surrounding the central region. In operation, the reflector 6 reflects the light emitted by the lamp 4 so that it is converged in the light deflecting means 12 . Before the light enters the light deflecting device, it may pass through a color changing device or an optical effect element. The light rays leaving the light deflecting means 12 diverge, causing substantially the entire backside of the front lens 8 to be illuminated. The front lens converges the light so that a relatively narrow beam leaves the optical assembly 2 .

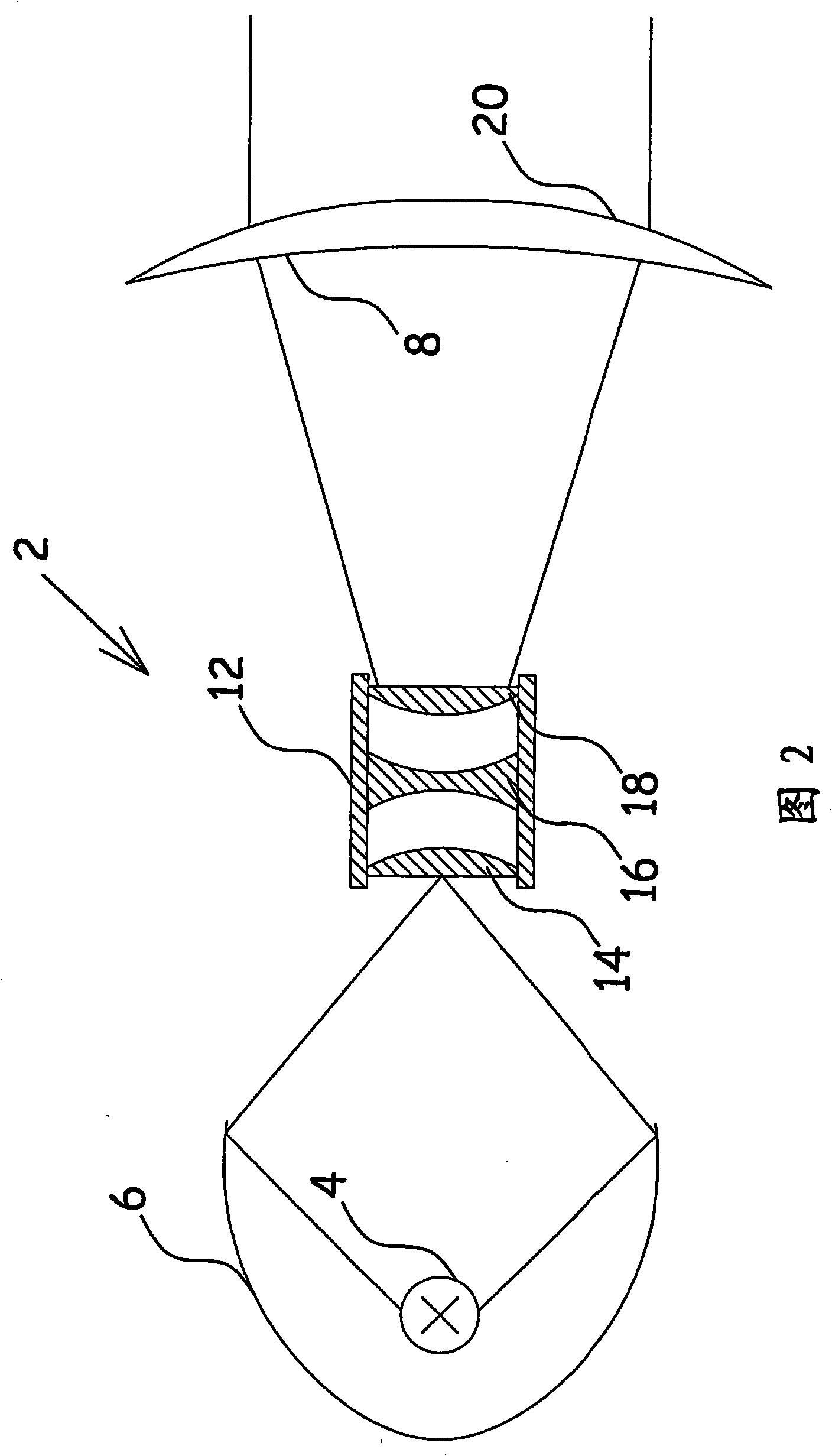

[0036] FIG. 2 shows an optical assembly as s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com