Test system and method for drill platform mass centre

A drilling platform and testing system technology, applied in static/dynamic balance testing, machine/structural components testing, measuring devices, etc., can solve problems such as difficulty in normal construction, low degree of operability, large difference, etc., to achieve Convenience, high test accuracy and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

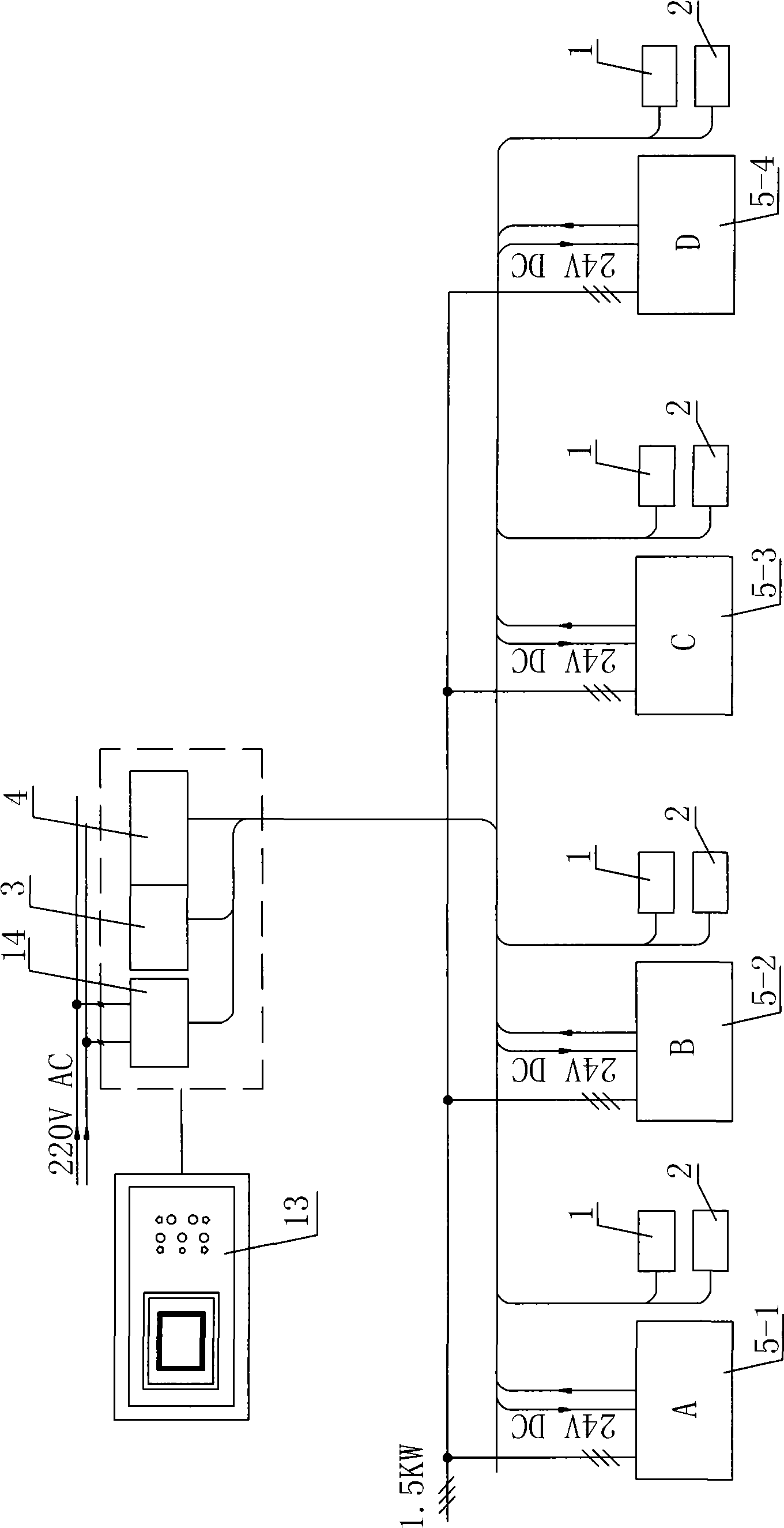

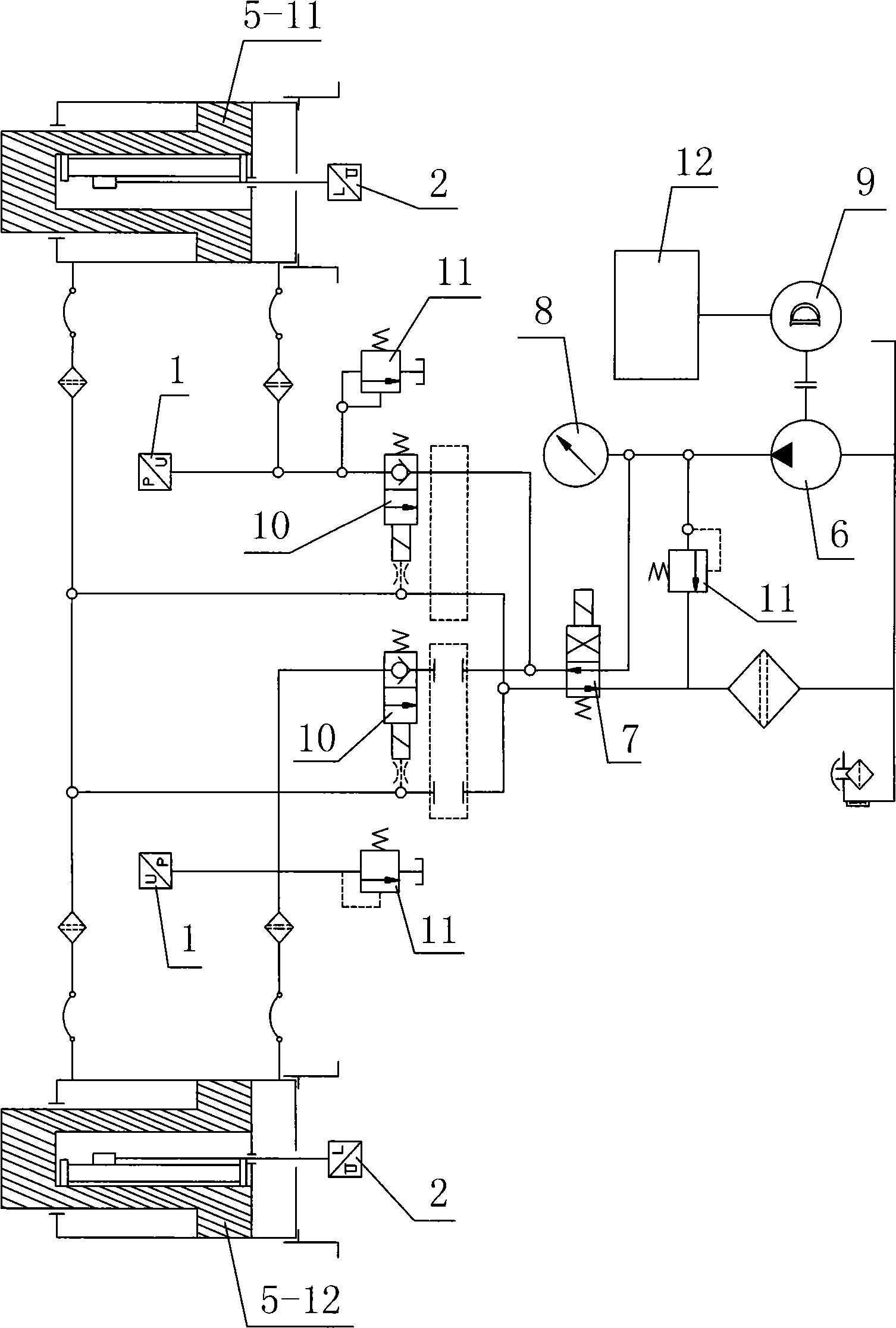

[0038] Such as figure 1 As shown, the drilling platform test system used in the present invention includes a power supply, a plurality of parallel and independently working hydraulic drive mechanisms for synchronous parallel jacking and lowering of the tested drilling platform, and a pressure test for multiple hydraulic drive mechanisms. Multiple pressure sensors 1 for real-time detection, displacement sensors for real-time detection of the lifting or lowering displacements of the multiple hydraulic drive mechanisms respectively, and corresponding analysis and processing of the detected drilling platform according to the pressure sensors 1 and displacement sensors Control system of center of gravity coordinates 3. The signals detected by the pressure sensor 1 and the displacement sensor are sent to the control system 3 after passing through the A / D conversion circuit 4 . The control system 3 controls the power mechanisms of the multiple hydraulic drive mechanisms. The contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com