Forklift mast

A technology for forklifts and masts, which is applied to lifting devices, hoisting devices, etc., can solve the problems of increased external dimensions of integral beams, large steel consumption, and bulky integral beams, and achieves the effect of favorable weight ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

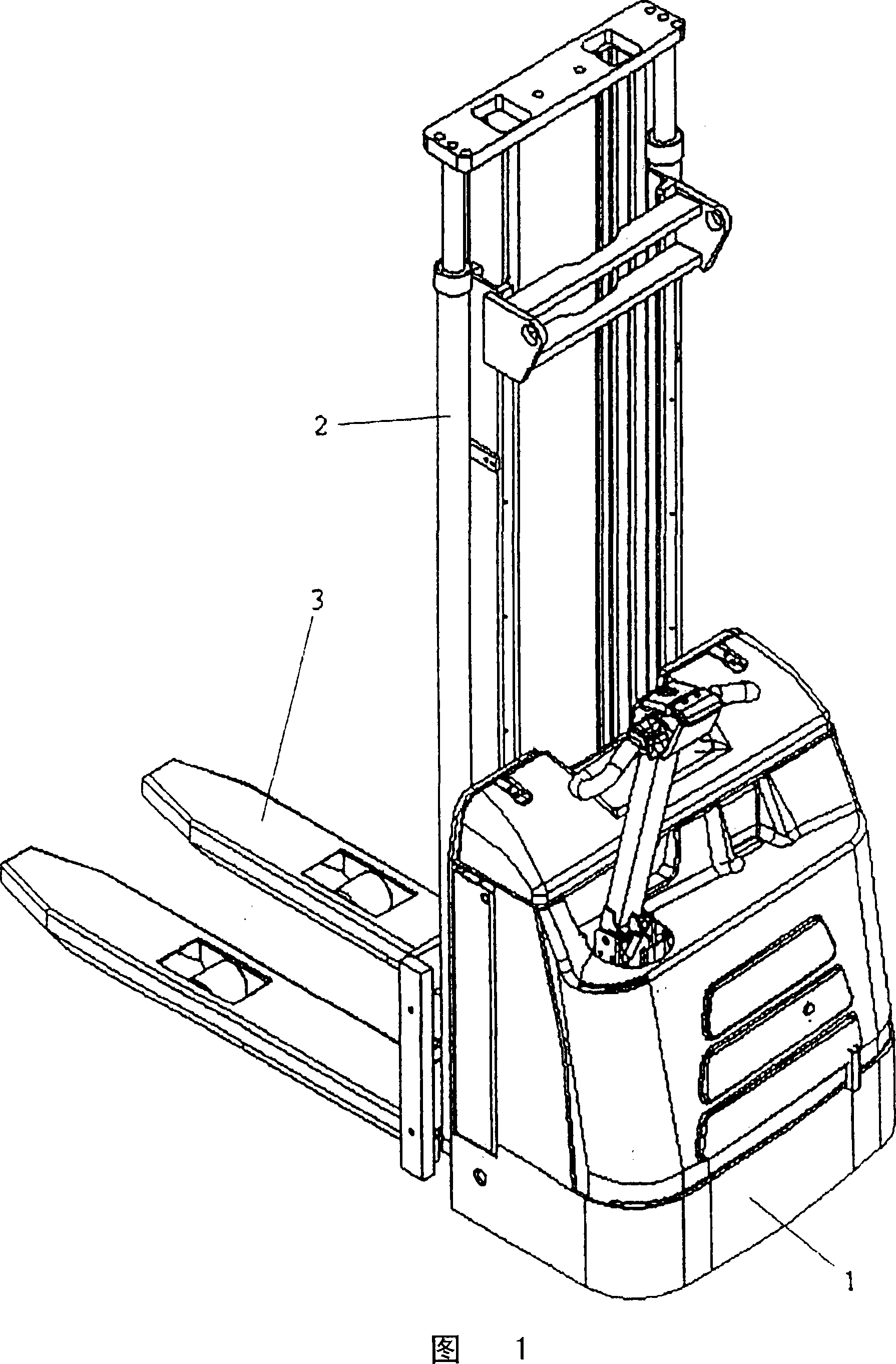

[0025] Figure 1 shows a known form of mast type forklift. The frame 1 of the mast type forklift includes an attached mast structure (or vertical column structure) and a hydraulic cylinder structure 2 through which the lifting bracket 3 can be raised. In this case, the lifting bracket 3 is a fork bracket. Depending on the mast configuration, the lifting bracket 3 is raised in two or more steps.

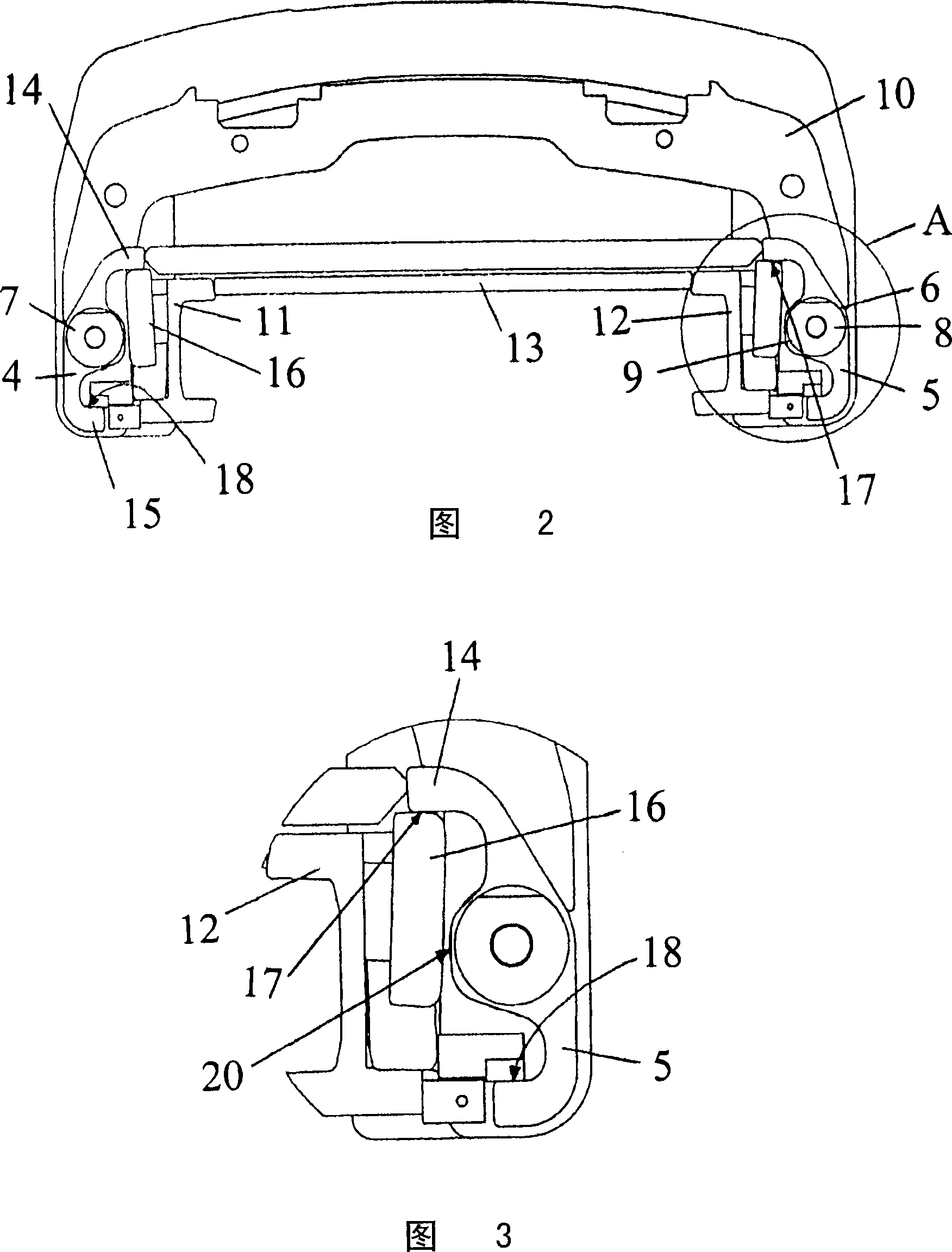

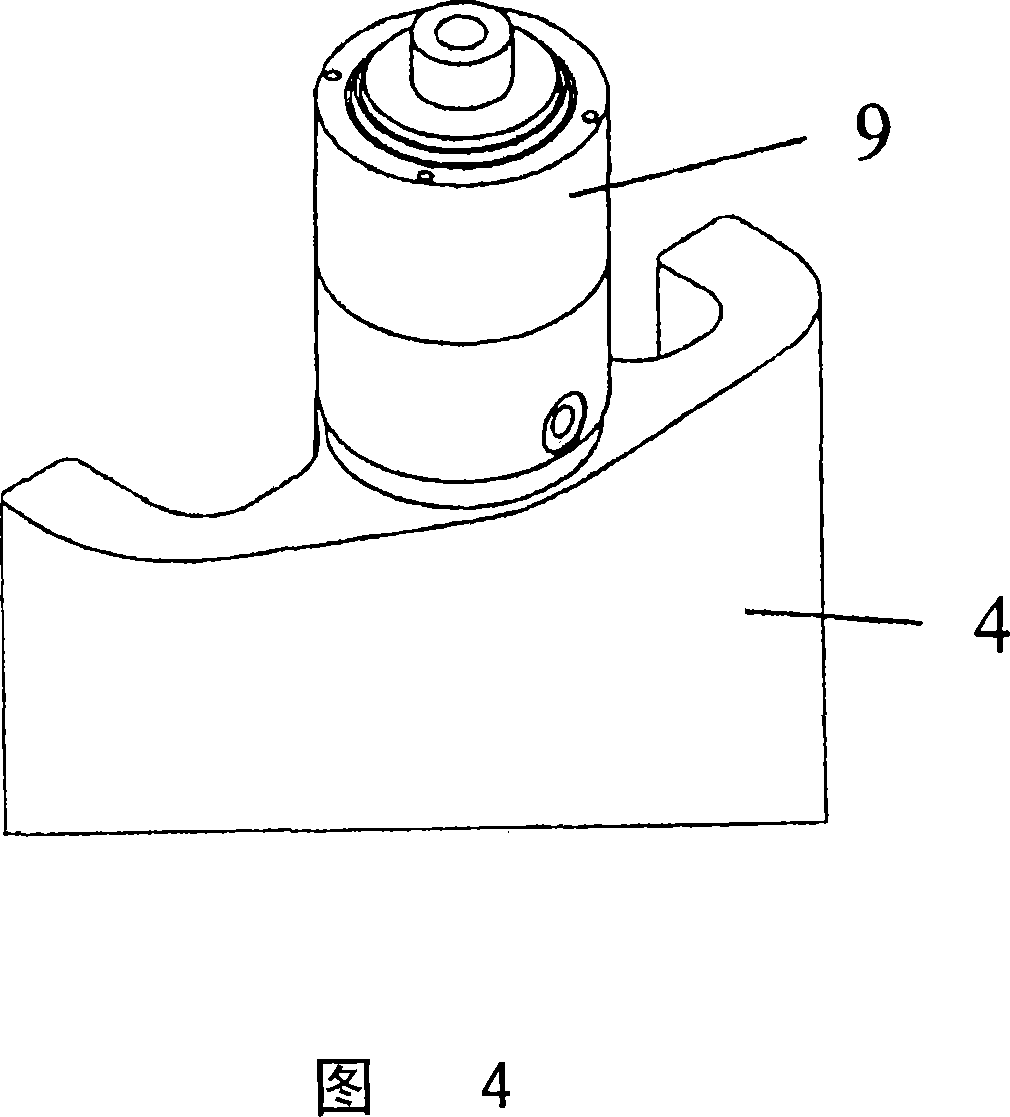

[0026] Fig. 2 is a top sectional view of the mast structure of the mast-type forklift of the present invention. The figure shows the substantially vertical (or vertical) beams 4 and 5 that are integrally constructed, and they include pistons 7 and 8的Integral cylinder liner6. The cylinder liner 6 is a hole extending longitudinally through the monolithic beams 4 and 5, the holes being sealed by pressure bushings or plugs at their lower ends, for example, and equipped with a packing box 9 at their upper ends, in order to seal and guide the pistons 7 and 8. The packaging box is installed outsi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com