Crankshaft rotor assembly and compressor

A compressor and crankshaft technology, applied in the field of compressors, can solve the problem of increased noise of the main balance block, and achieve the effects of reducing quality, saving man-hours, and increasing vertical distance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

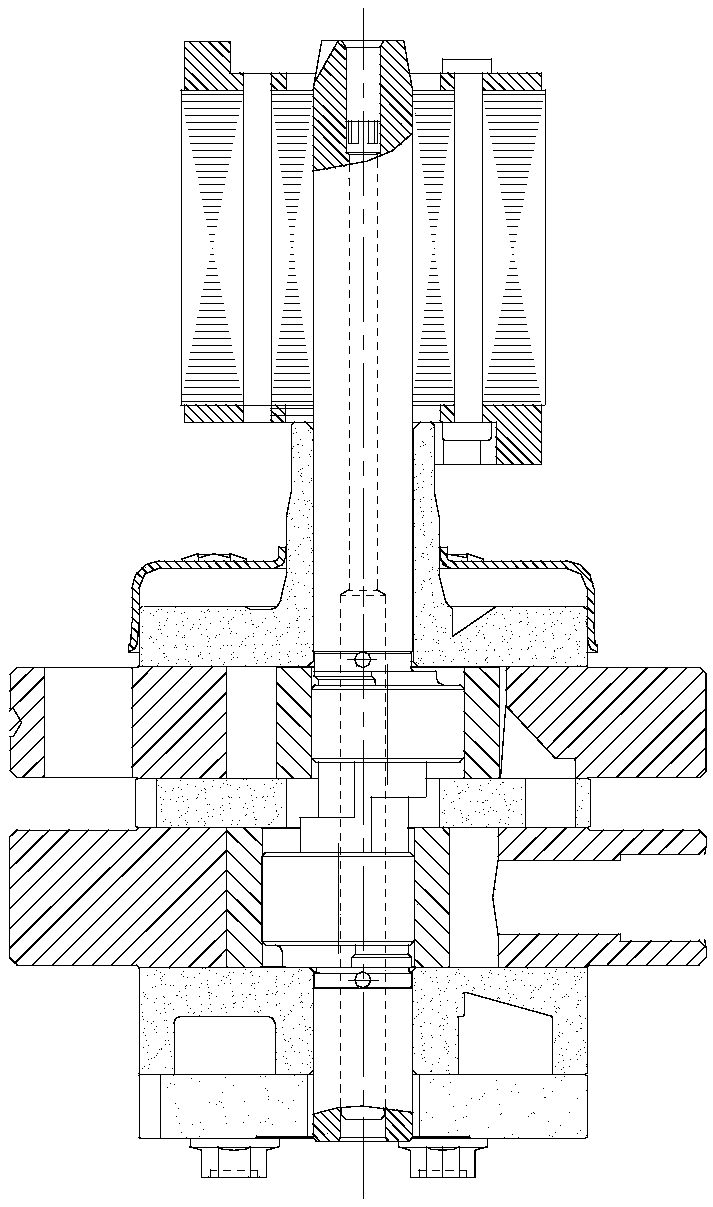

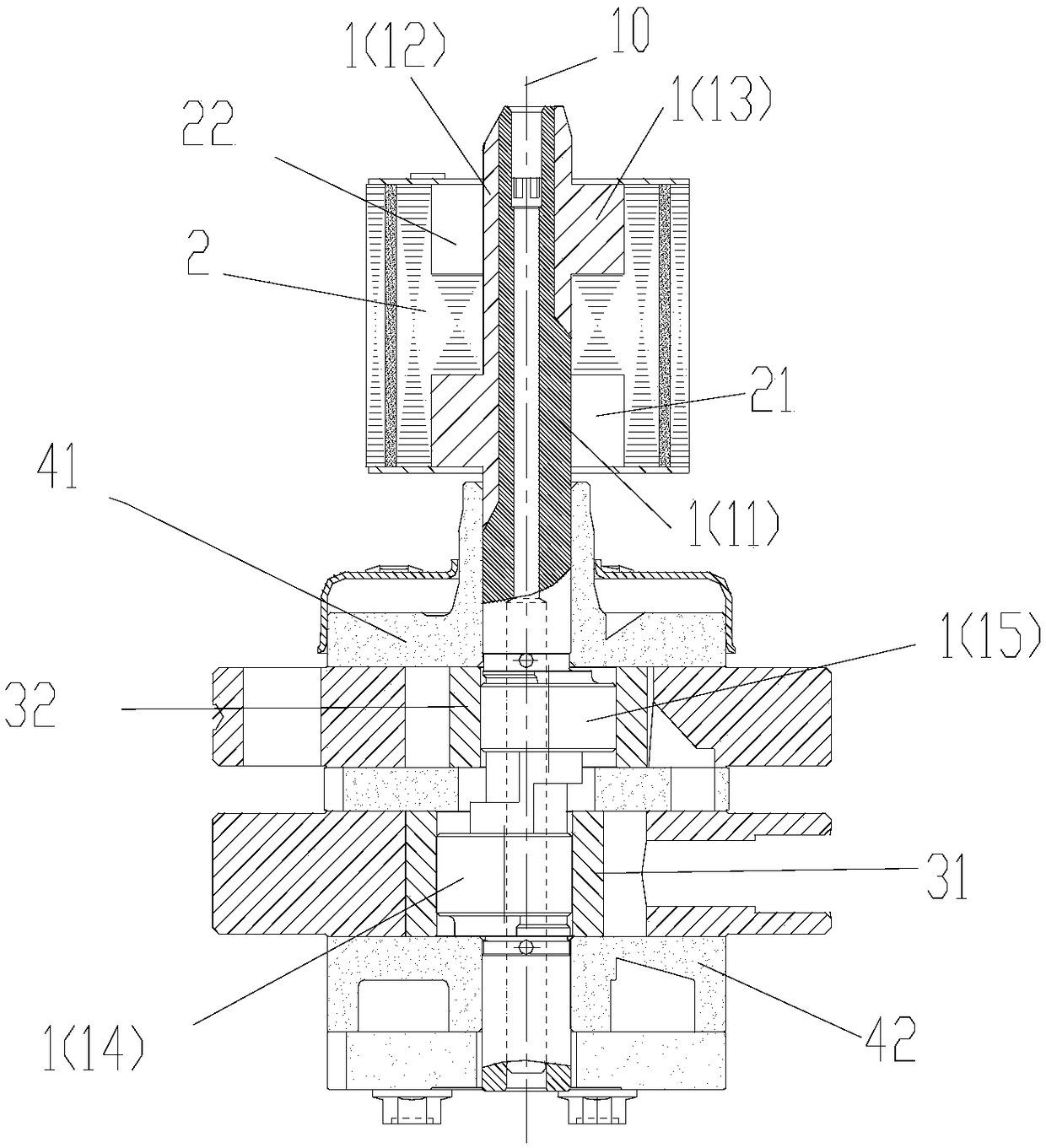

[0050] Such as Figure 2-8 As shown, the present invention provides a crankshaft rotor assembly, which includes:

[0051] The crankshaft 1 includes a rotation axis 10, a crankshaft main body 11, and a main eccentric part 12, the main eccentric part 12 can be connected to the outer peripheral surface of the crankshaft main body 11, and the center of mass of the main eccentric part 12 is connected to the rotating The axis 10 has an eccentricity r3 along the radial direction,

[0052] The rotor 2 has a central shaft hole 20 capable of accommodating the crankshaft 1 passing therethrough, and the rotor 2 also includes a main receiving groove 21 opened radially from the central shaft hole 20, and the main receiving groove 21 is connected to the The position of the main eccentric part 12 is corresponding to accommodate the insertion of the main eccentric part 12 and allow the main eccentric part 12 to be able to rotate in the main receiving groove 21 .

[0053] In the present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com