Automotive stability control safety testing system

A stability control and safety test technology, applied in vehicle testing, machine/structural component testing, measuring devices, etc., can solve problems such as high cost, high risk, and long cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

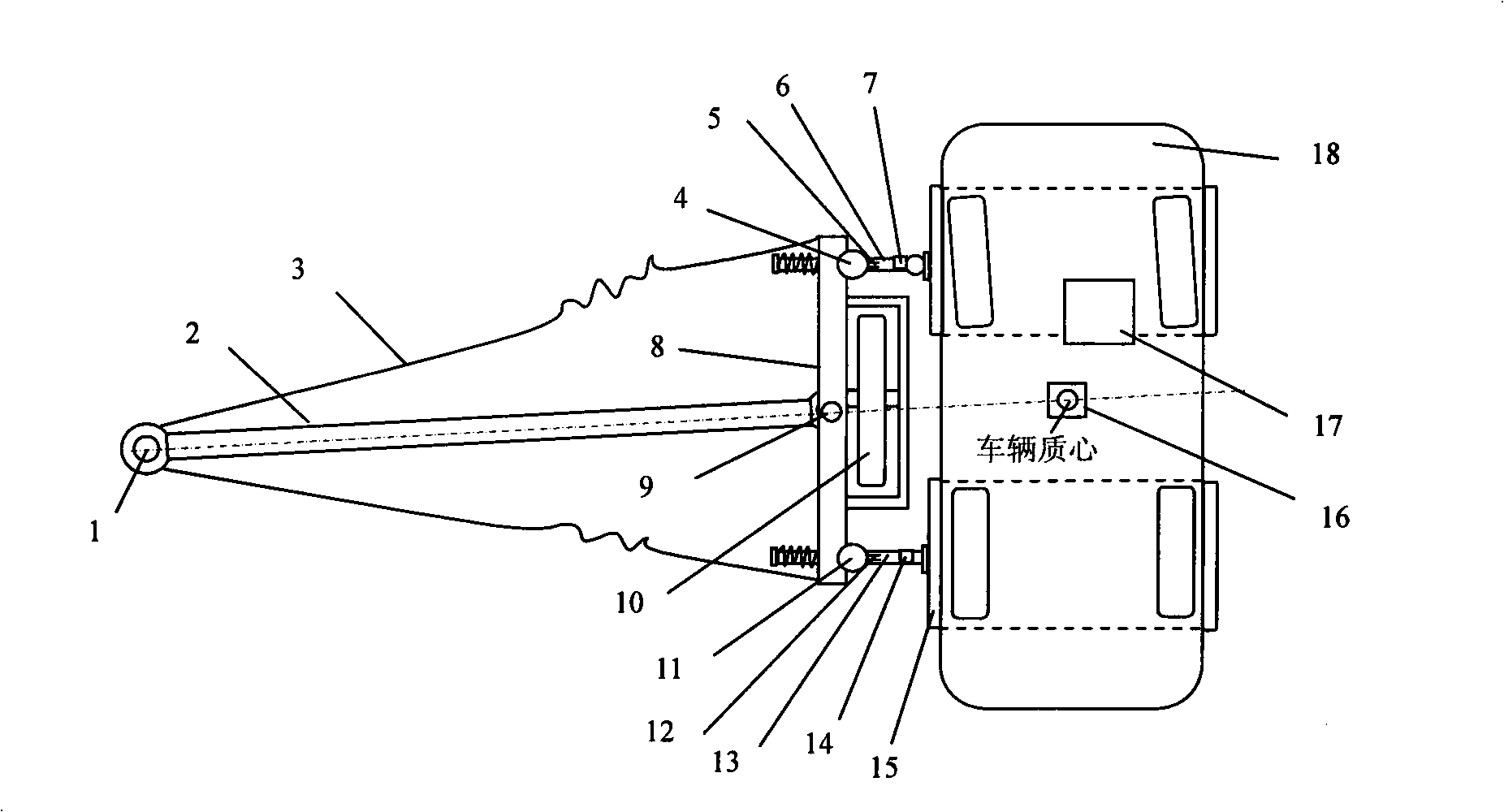

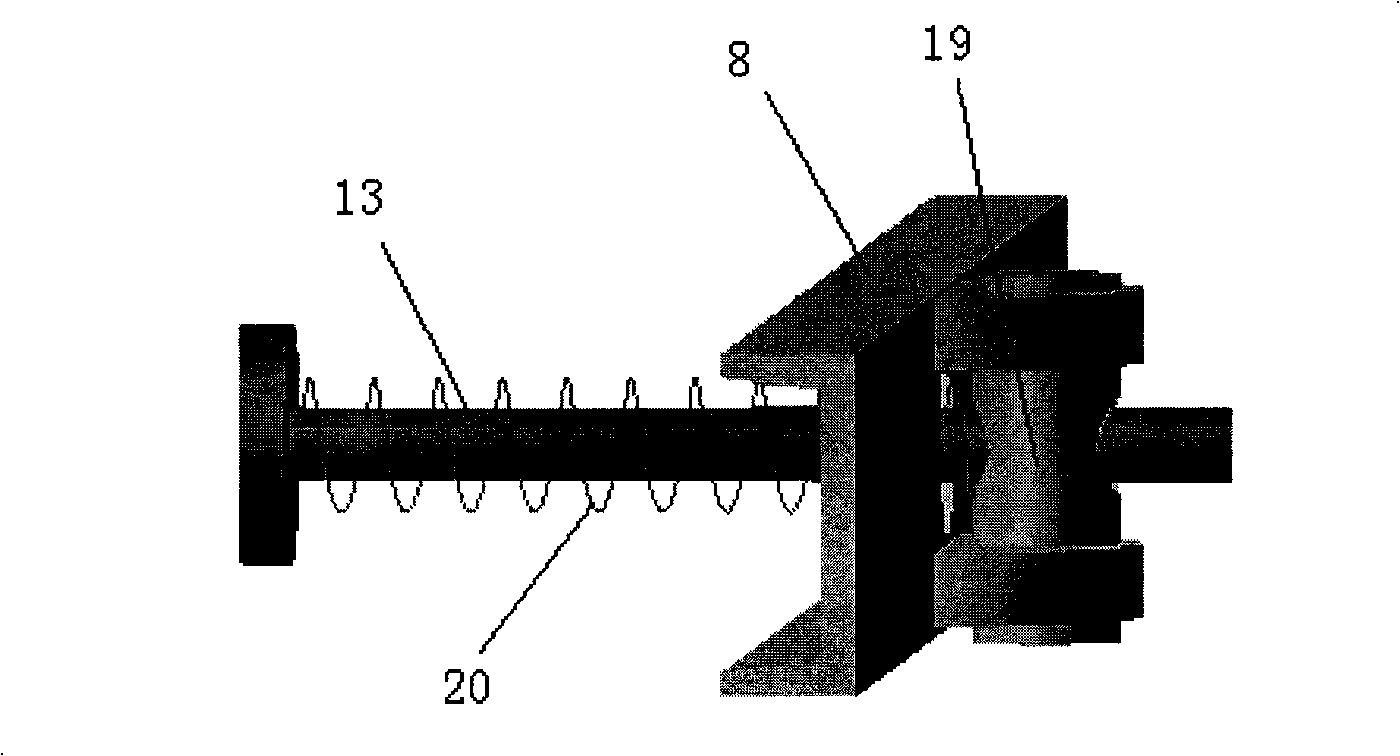

[0010] Combine below figure 1 Automobile stability control safety test system structure and figure 2 The vertical pin structure in which the tension rod is connected to the yaw rod specifies the invention.

[0011] The vehicle stability control safety test system consists of three components: traction bar components, sway bar components and vehicle components, such as figure 1 . The drawbar part is composed of fixed shaft 1, drawbar 2 and limit rope 3; the yaw bar part is composed of the angular displacement sensor 4 between the front wheel tension rod and the yaw rod, the front wheel tension rod line displacement sensor 5, the front wheel Tension bar 6, front wheel tension gauge 7, sway bar 8, angular displacement sensor 9 between draw bar and yaw bar, five-wheel instrument 10, angular displacement sensor 11 between rear wheel tension bar and yaw bar, Rear wheel tension rod line displacement sensor 12, rear wheel tension rod 13, rear wheel tension gauge 14; vehicle compon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com