Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

58 results about "Folch solution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Folch solution is a solution containing chloroform and methanol, usually in a 2:1 (vol/vol) ratio. One of its uses is in separating polar from nonpolar compounds, for example separating nonpolar lipids from polar proteins and carbohydrates in blood serum.

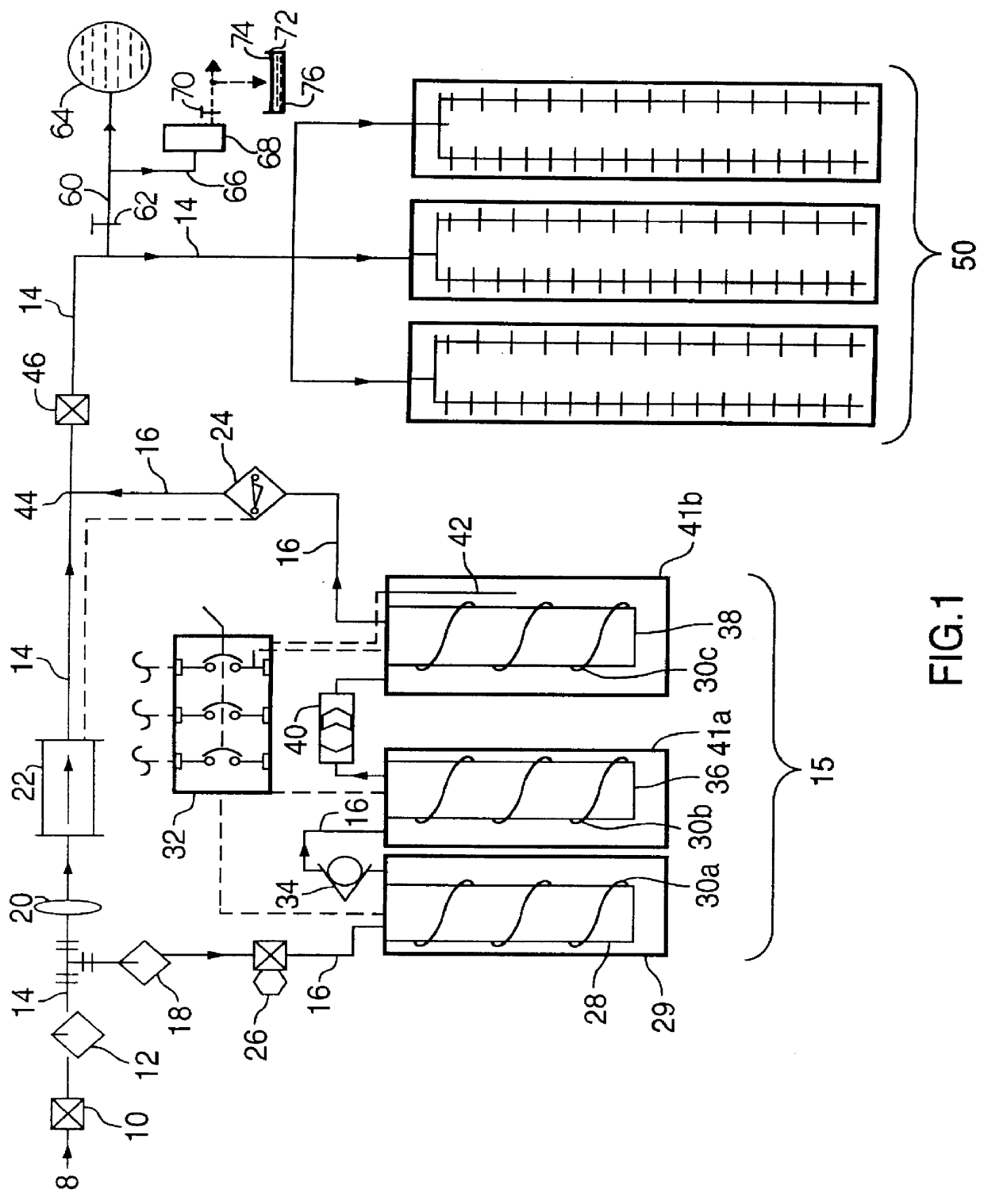

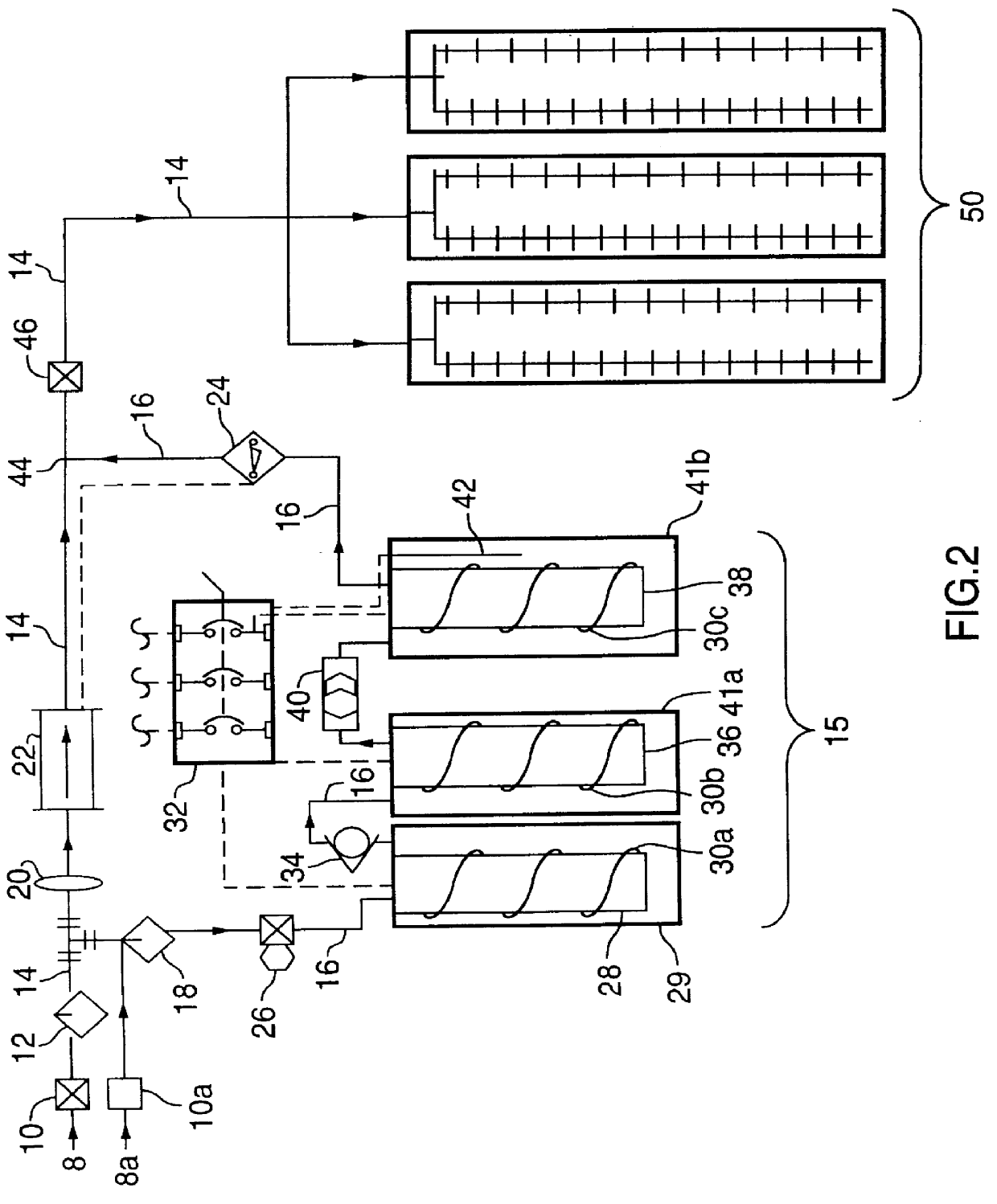

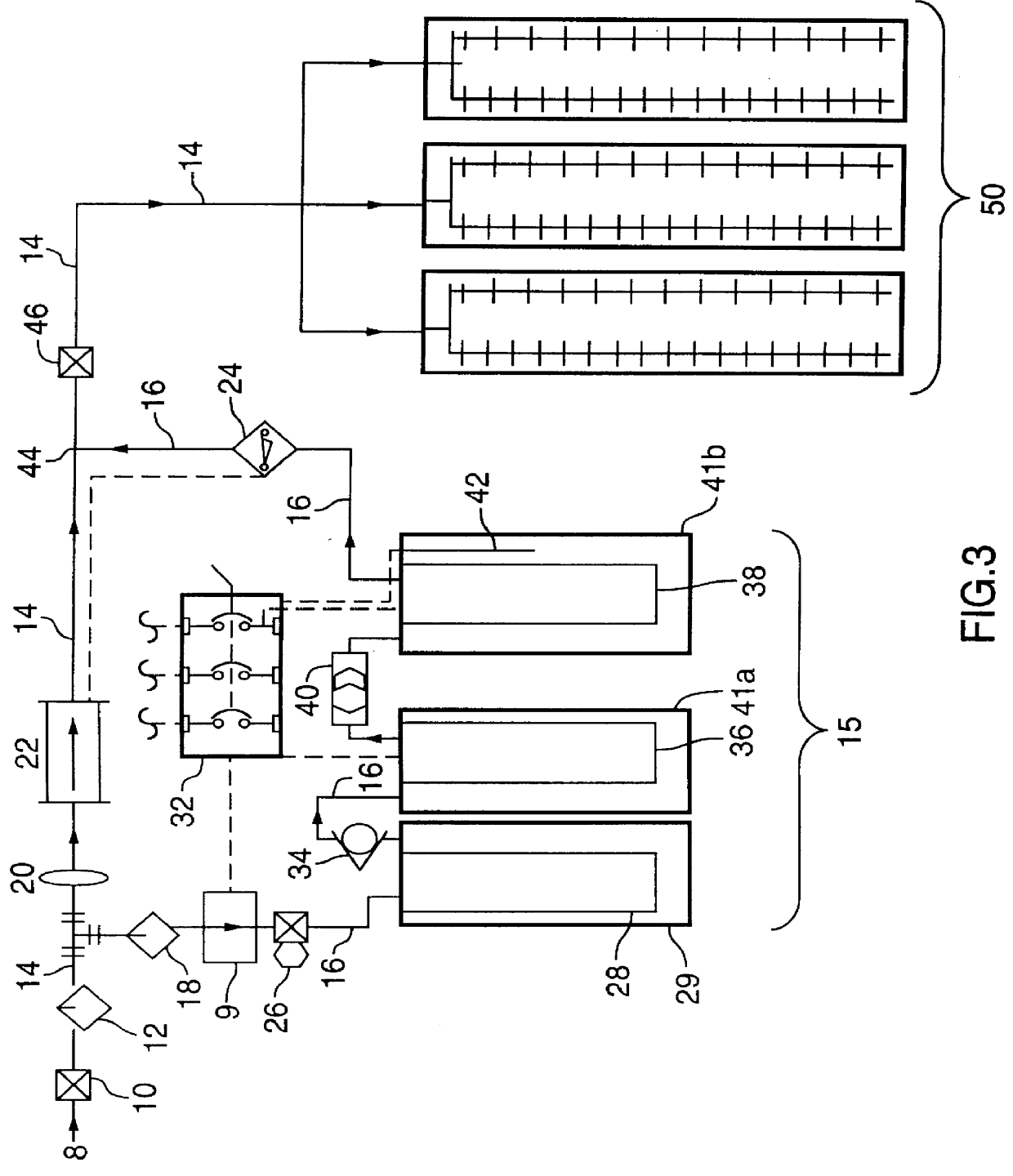

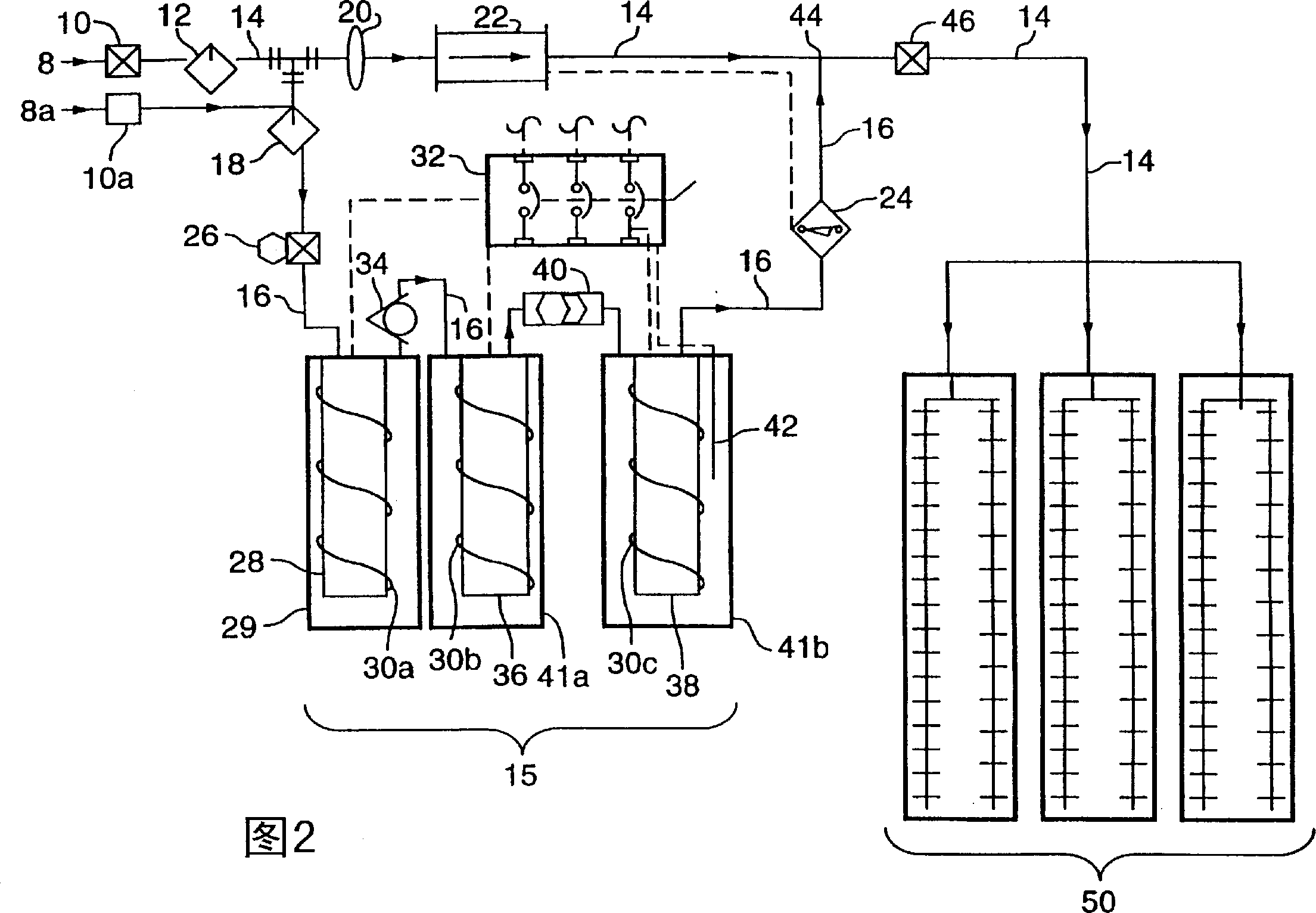

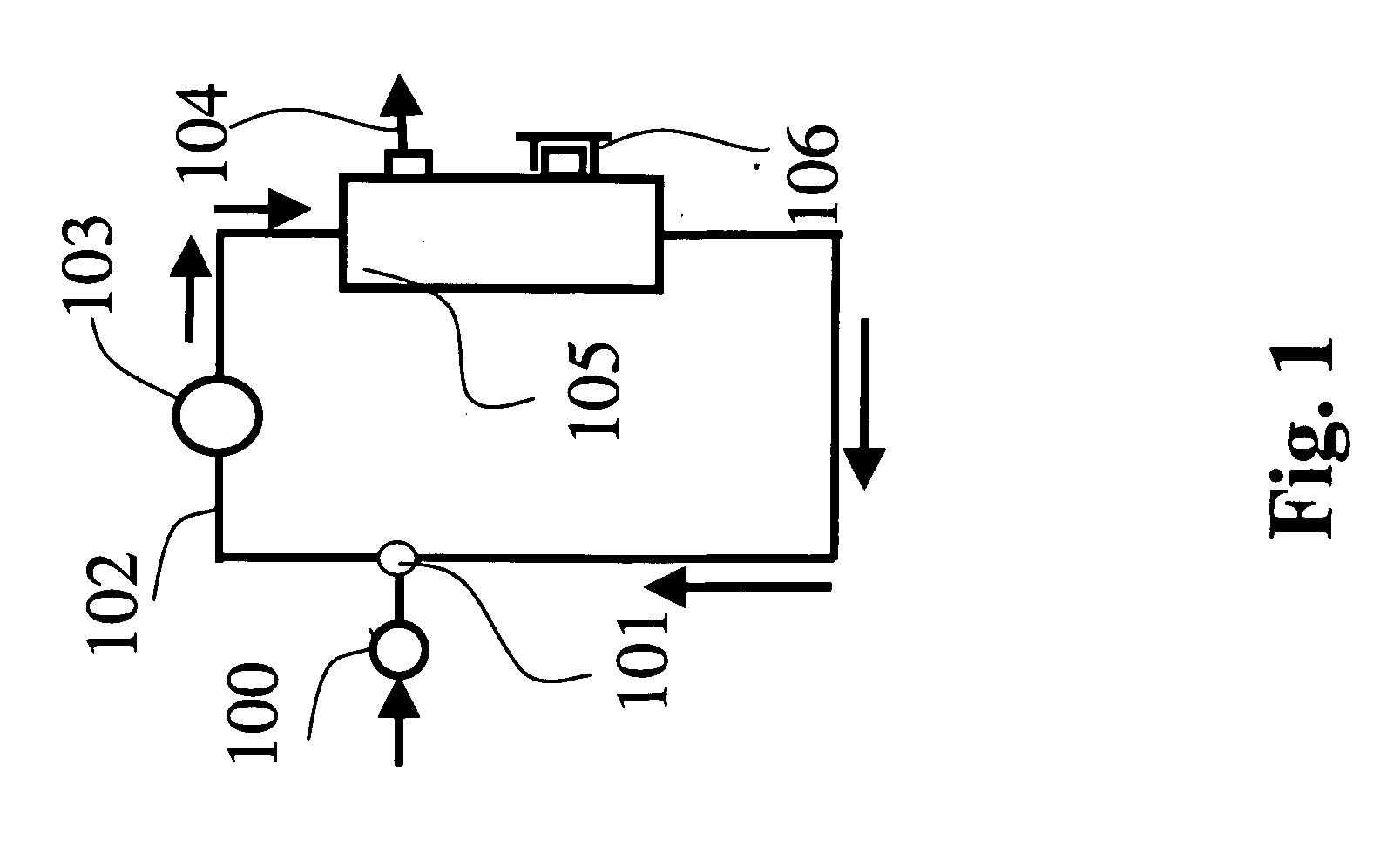

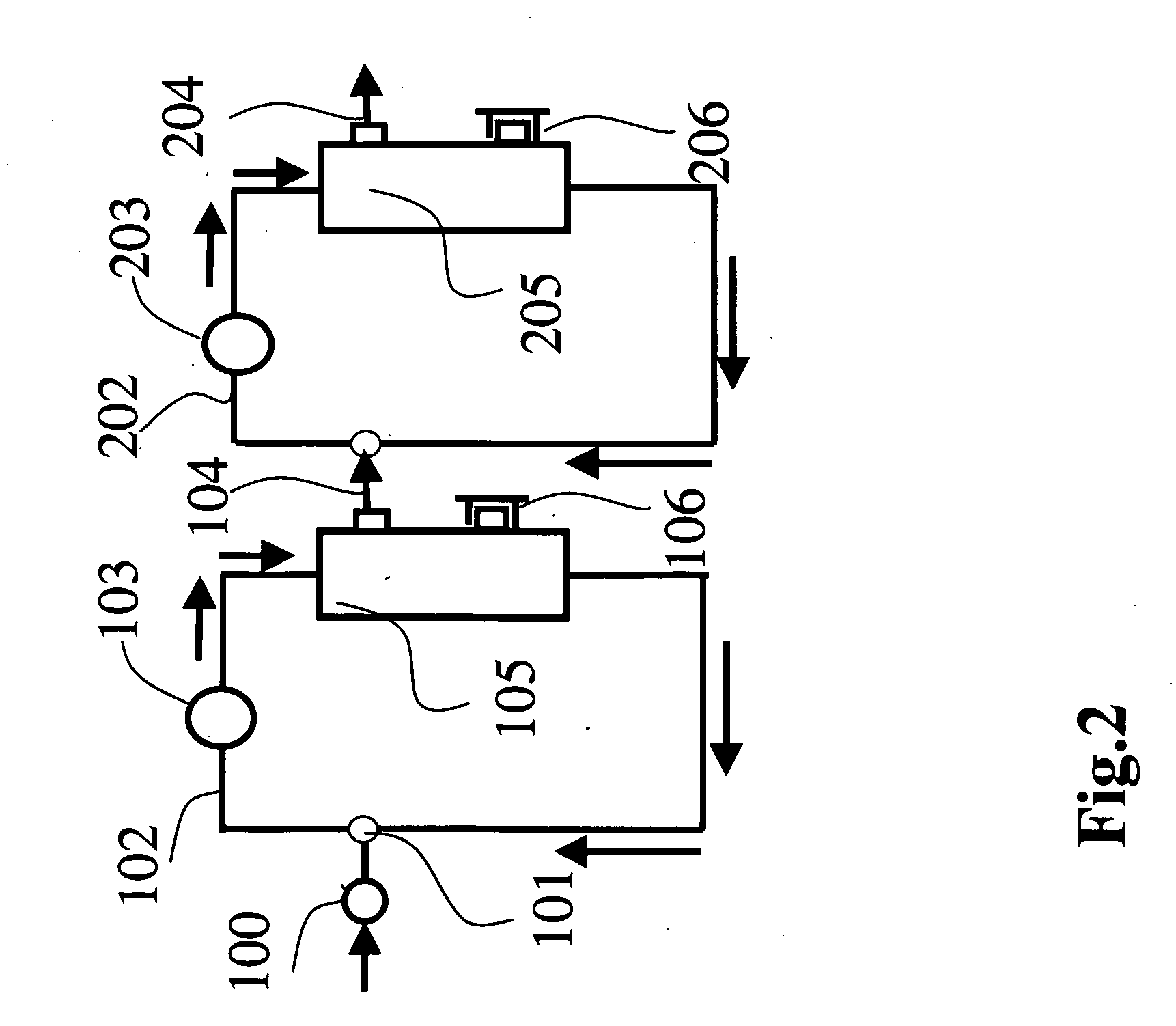

Iodinated water treatment process

InactiveUS6139731AReduce the amount requiredReduce mortalitySeparation devicesWater/sewage treatment by heatingFree iodineCooling tower

A method and apparatus for producing bacteria-free iodine-species-containing drinking water for farm animals under continuous dynamic water flow, comprising dissolving solid iodine into a first water flow to produce a saturated iodine species-containing aqueous solution at a pre-selected temperature; blending the saturated solution with a second water flow to produce a diluted iodine species bacterium-free aqueous solution; and providing the diluted solution as drinking water to the animals. Preferably, the iodine is dissolved in the first water flow to provide a saturated iodine species at a pre-selected temperature at a known concentration, which saturated solution is then blended into a mean water flow. The continuous flow of iodine species-containing water is fed to a farm animal drinking water distribution network with reduced risk of back-contamination by bacteria-containing water through the network. Other uses of the iodinated water are as a disinfectant, for example, in the food processing industry; fruit, vegetable and fish preservation; industrial, commercial cooling tower waters, sewage and waste water treatment; and as a nutrient as an iodine source for humans, livestock, fish and plants.

Owner:IOSOLUTIONS

Pharmaceutical porous particles

InactiveUS20060002995A1Enhance the imageIncrease contrastPowder deliveryGranular deliveryMedicineCompound (substance)

The present invention relates to a pharmaceutical, preferably inhalable, porous, free flowing particle to be used in therapeutical application, optionally comprising a therapeutically active compound or substance, whereby the particle consists of one or more network forming compounds, which in diluted solutions self associates to large three dimensional structures having a density of <0.5 g / cm3.

Owner:ADAGIT

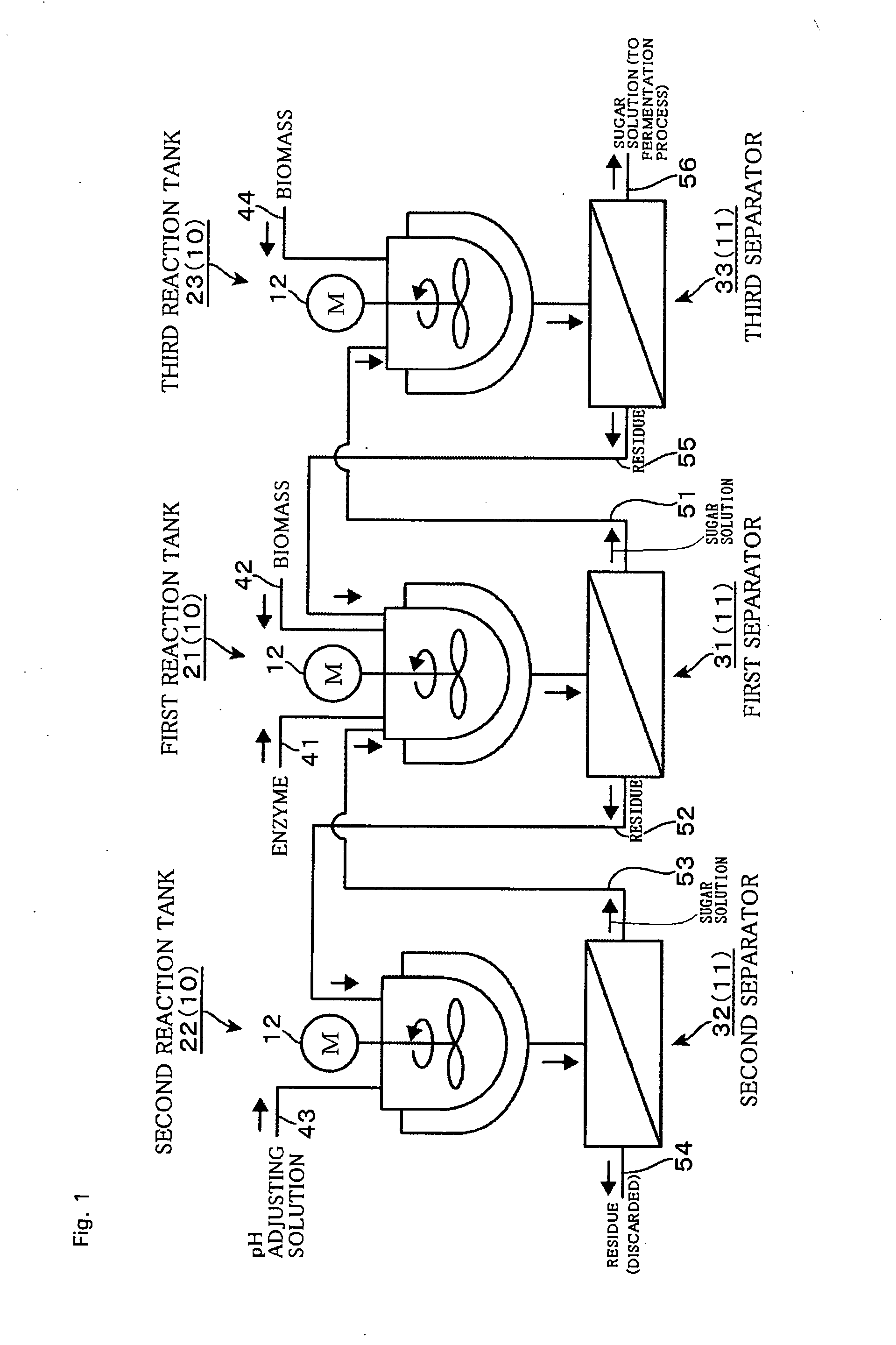

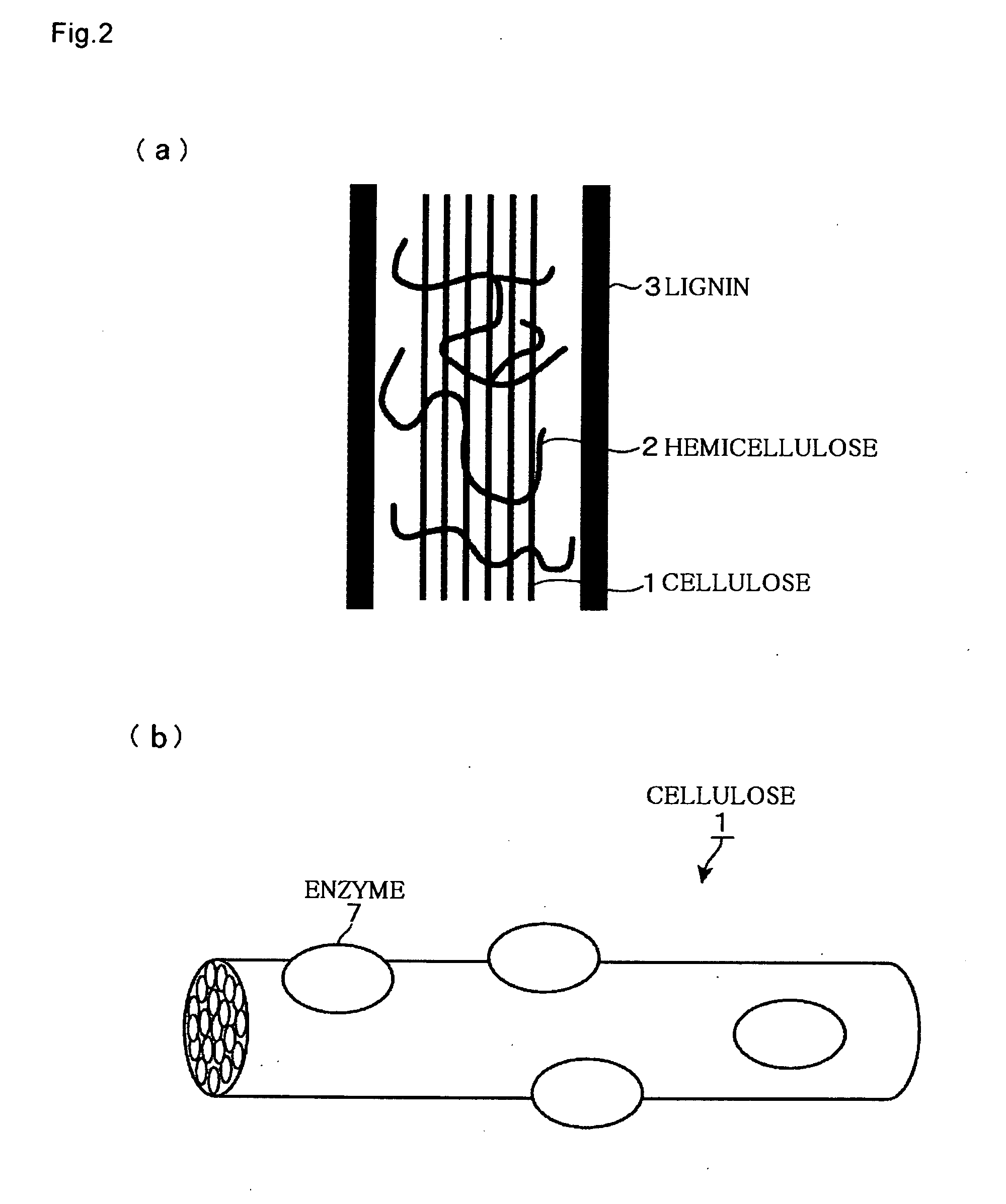

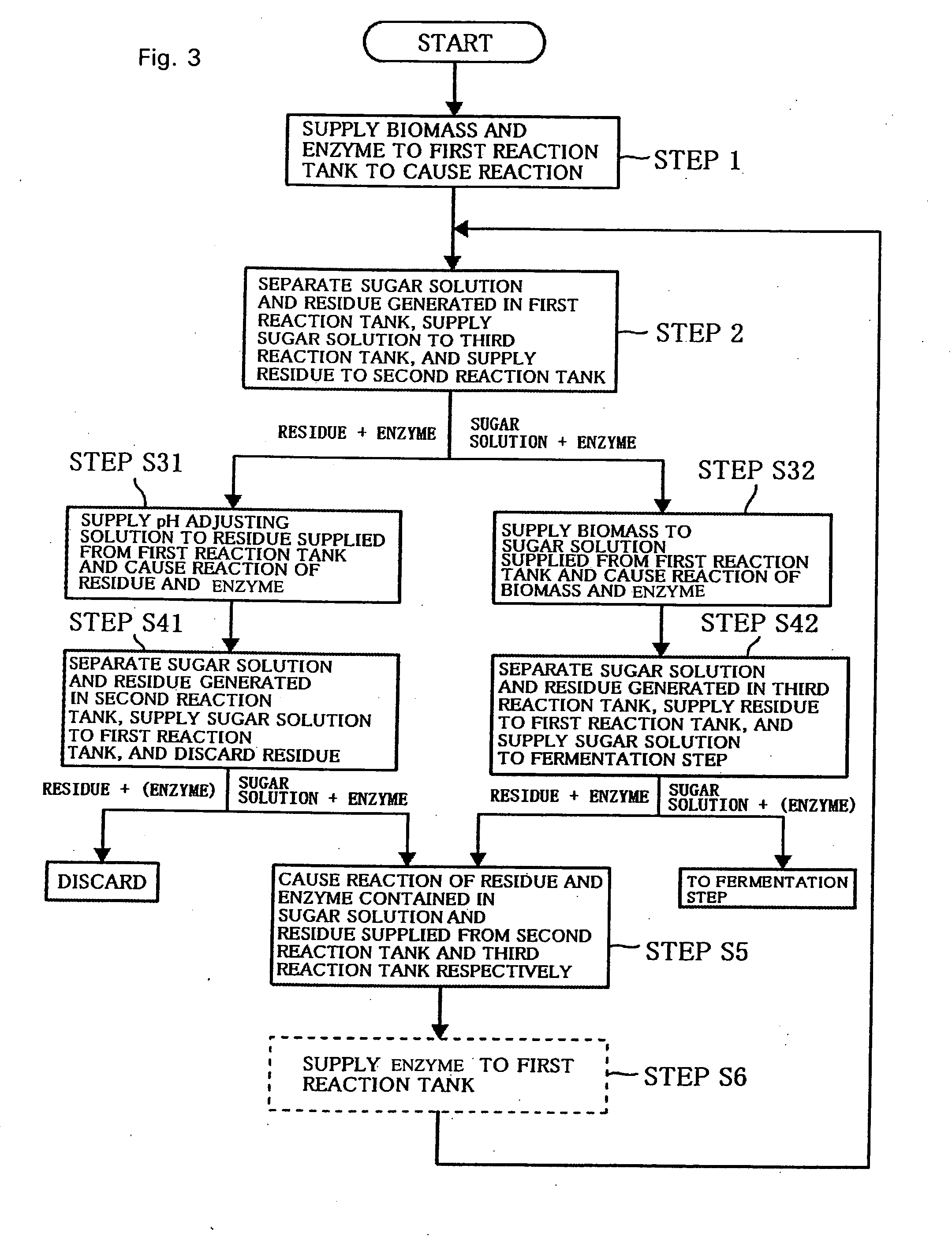

Method of producing sugar solution and saccharification device

InactiveUS20120107920A1Reduce the amount requiredLow costBioreactor/fermenter combinationsBiological substance pretreatmentsCelluloseFolch solution

To achieve efficient use of enzyme in obtaining a sugar solution through a reaction of the enzyme and biomass containing cellulose. In obtaining a sugar solution through a reaction of enzyme and biomass containing cellulose, the biomass and the enzyme are caused to react in a first reaction tank, whereby a sugar solution in which the enzyme is dispersed and a residue containing the unreached biomass adsorbing the enzyme are generated, these sugar solution and residue are next separated, a pH adjusting solution is supplied to the residue in a second reaction tank to prepare a dilute solution whose sugar concentration is lower than that of the sugar solution, and in this dilute solution, a sugar solution is generated through a reaction between the residue and the enzyme adsorbed to the residue.

Owner:JGC CORP

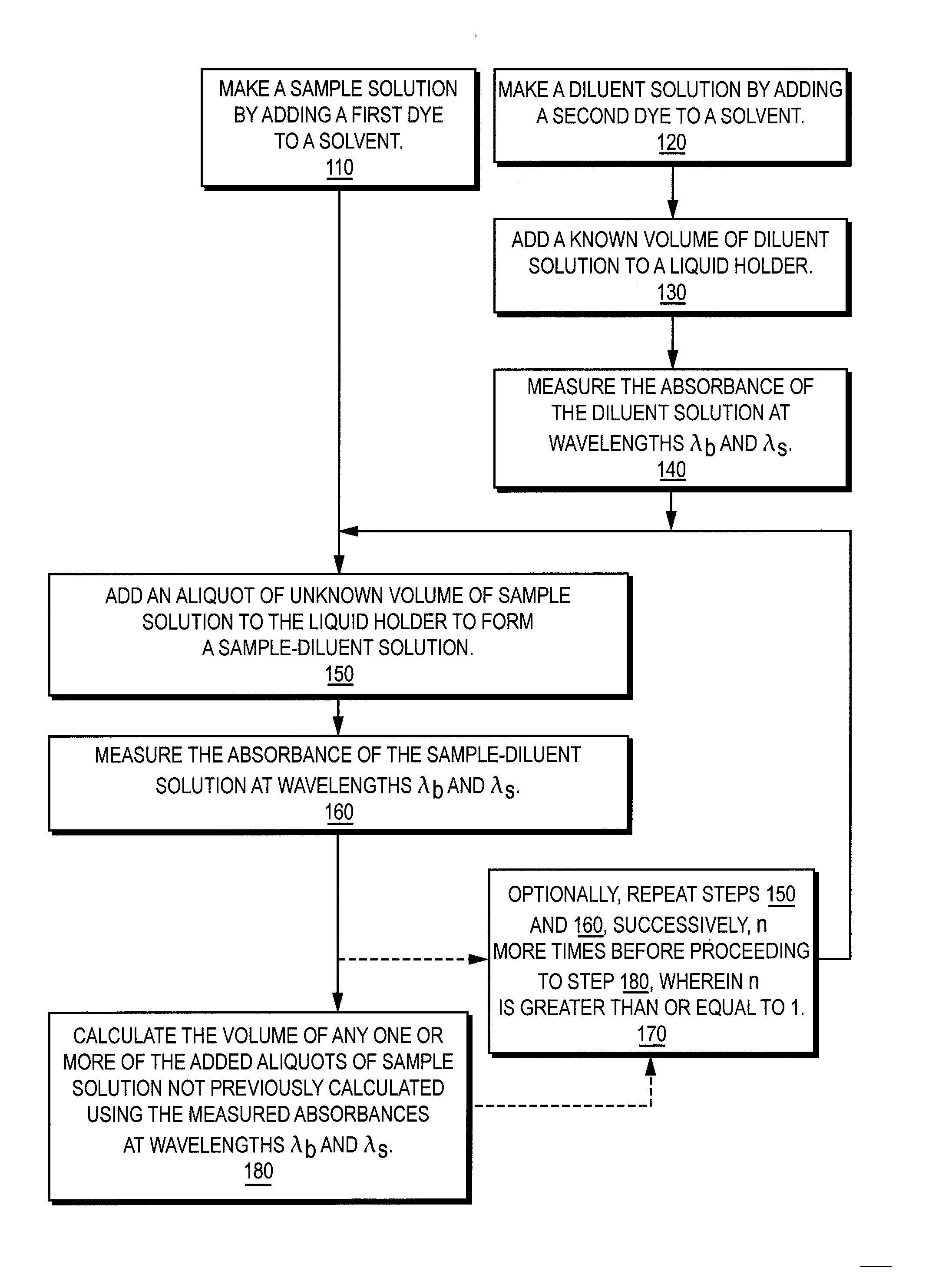

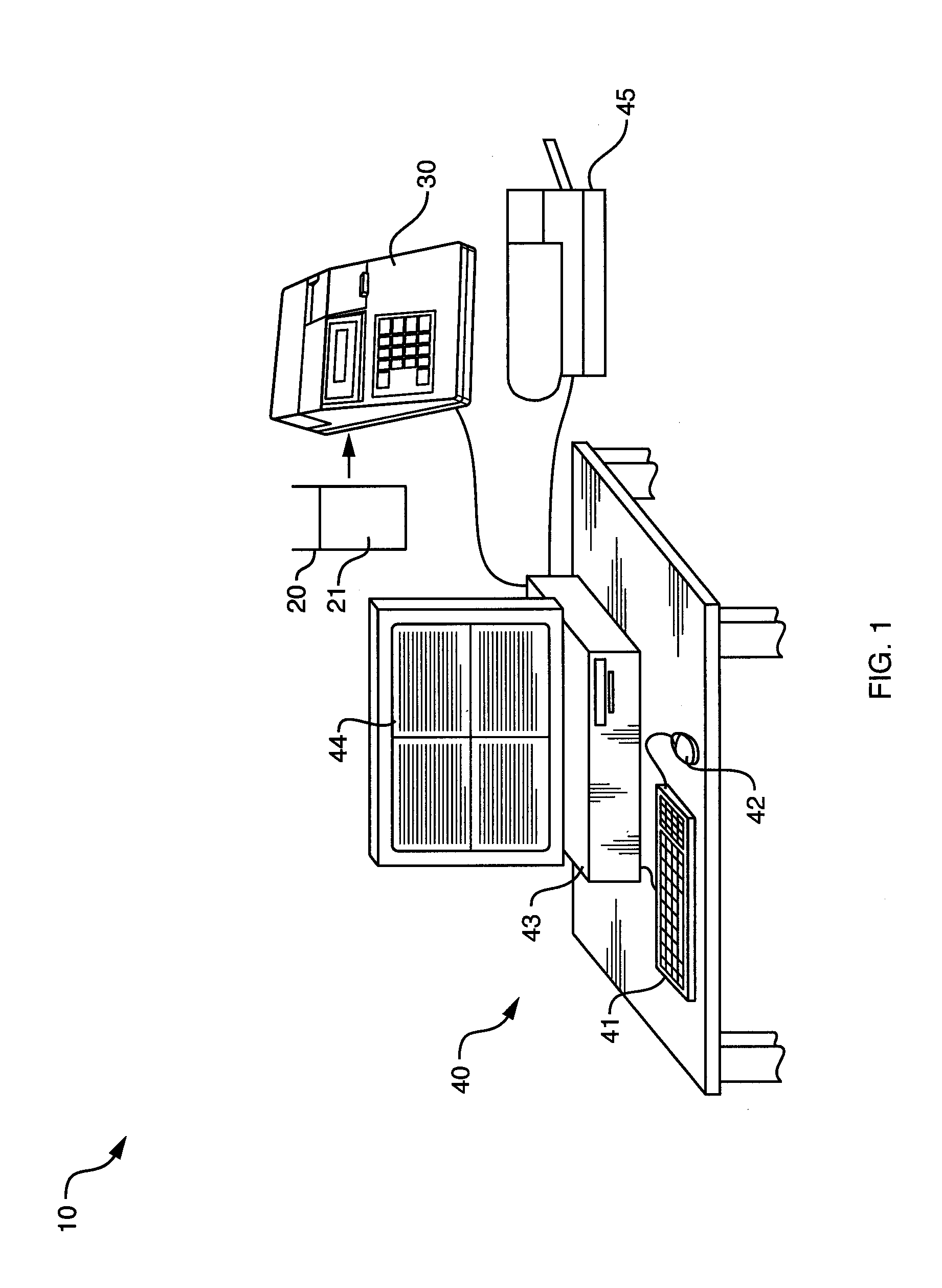

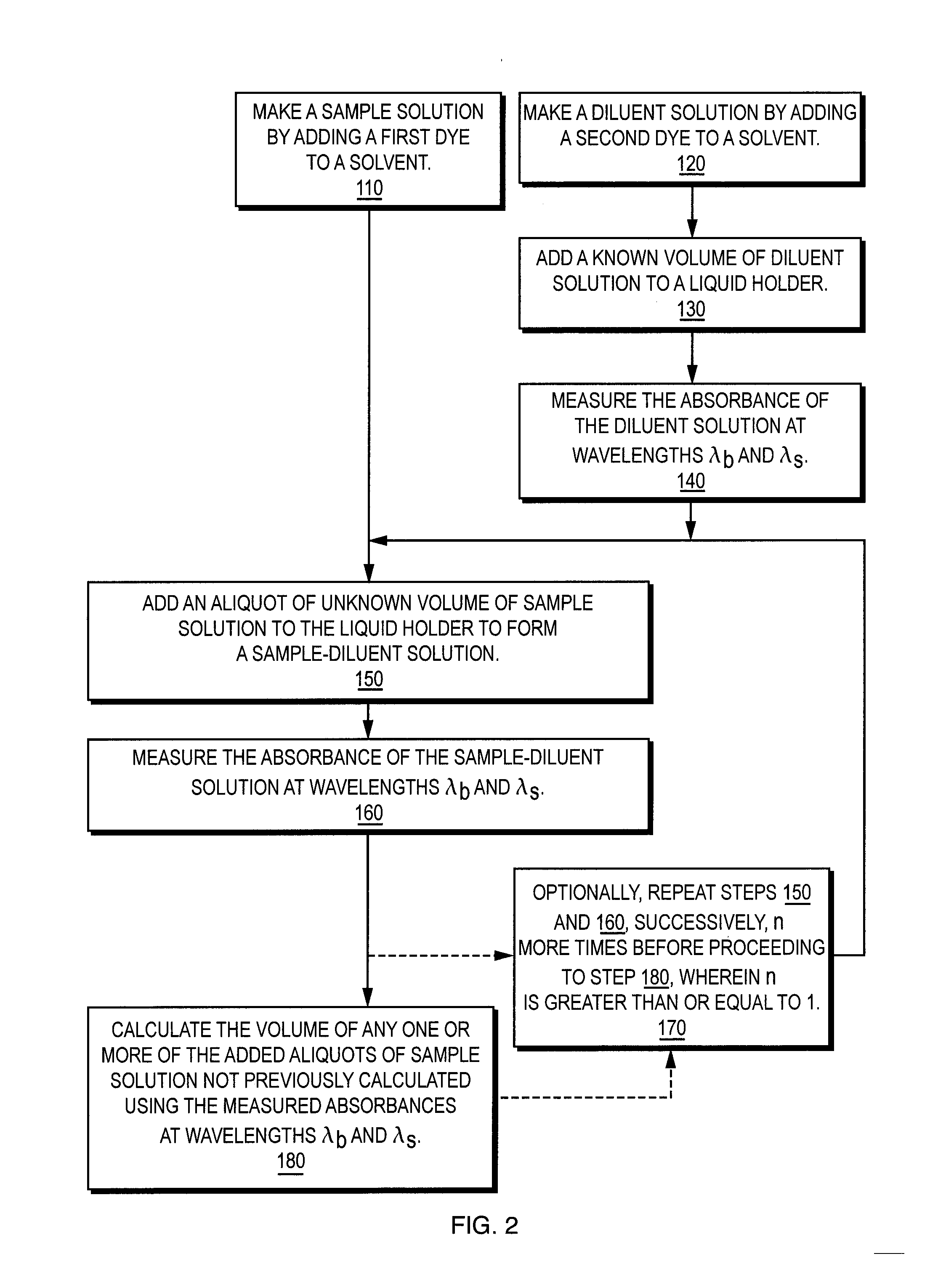

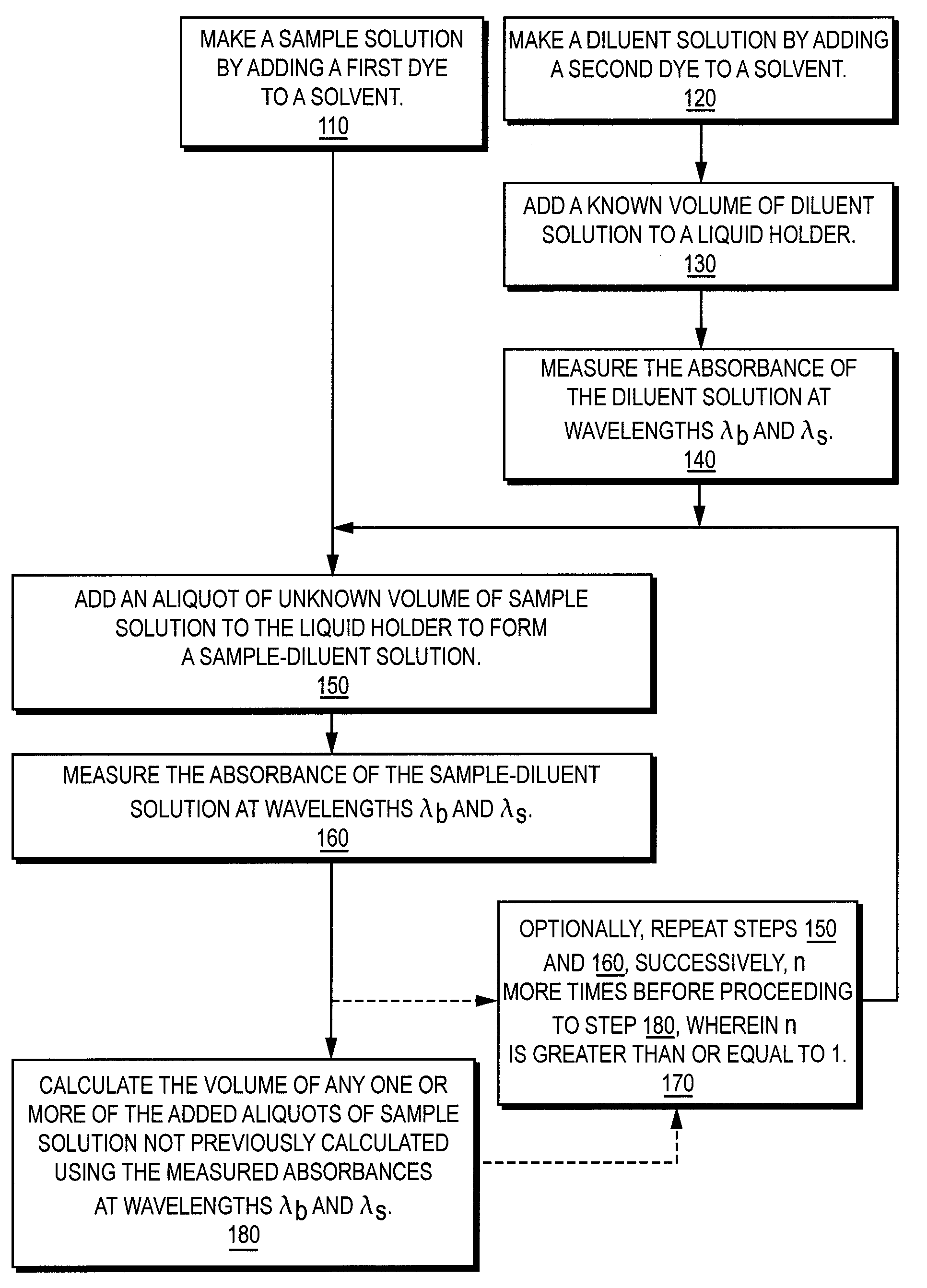

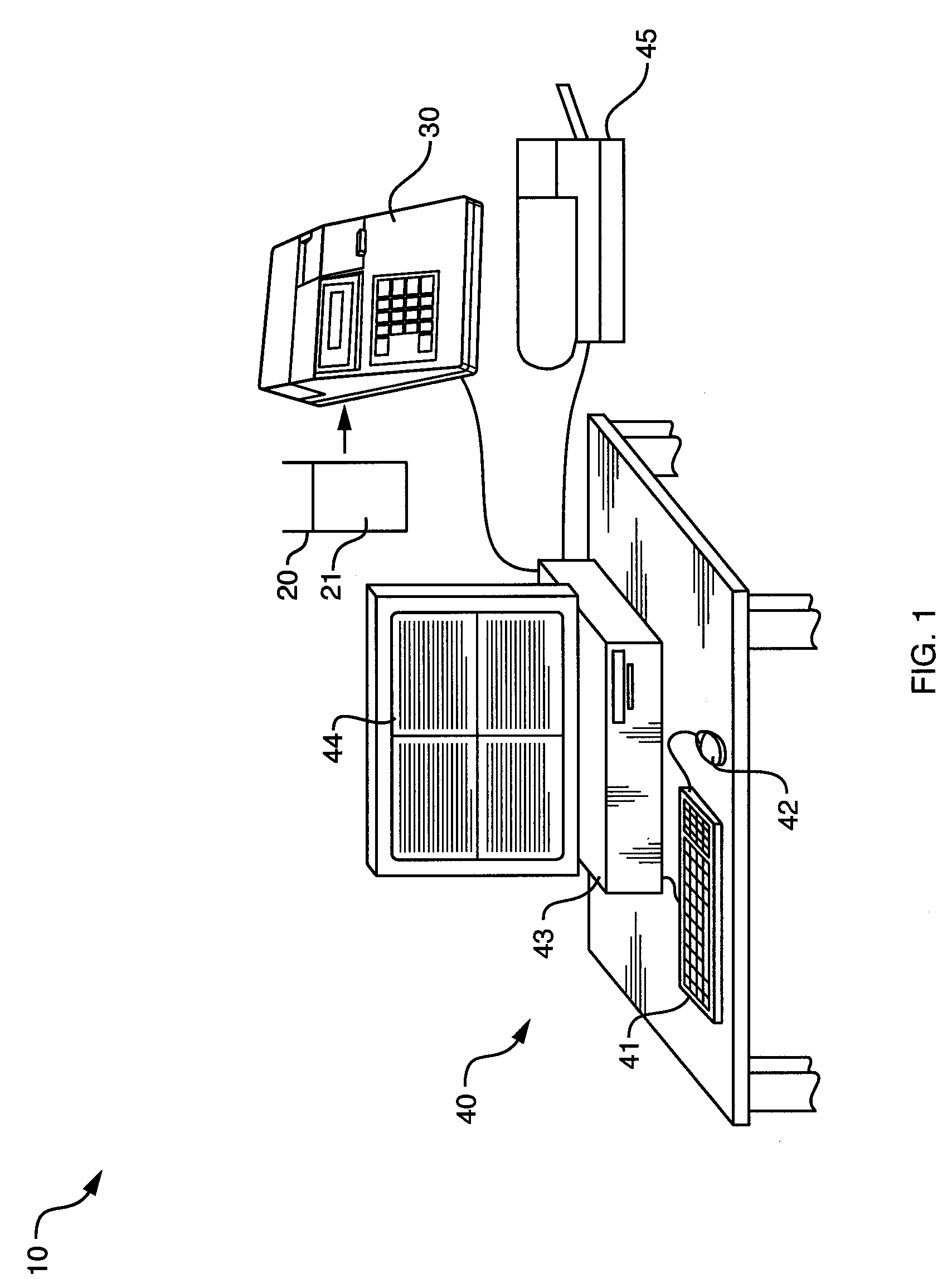

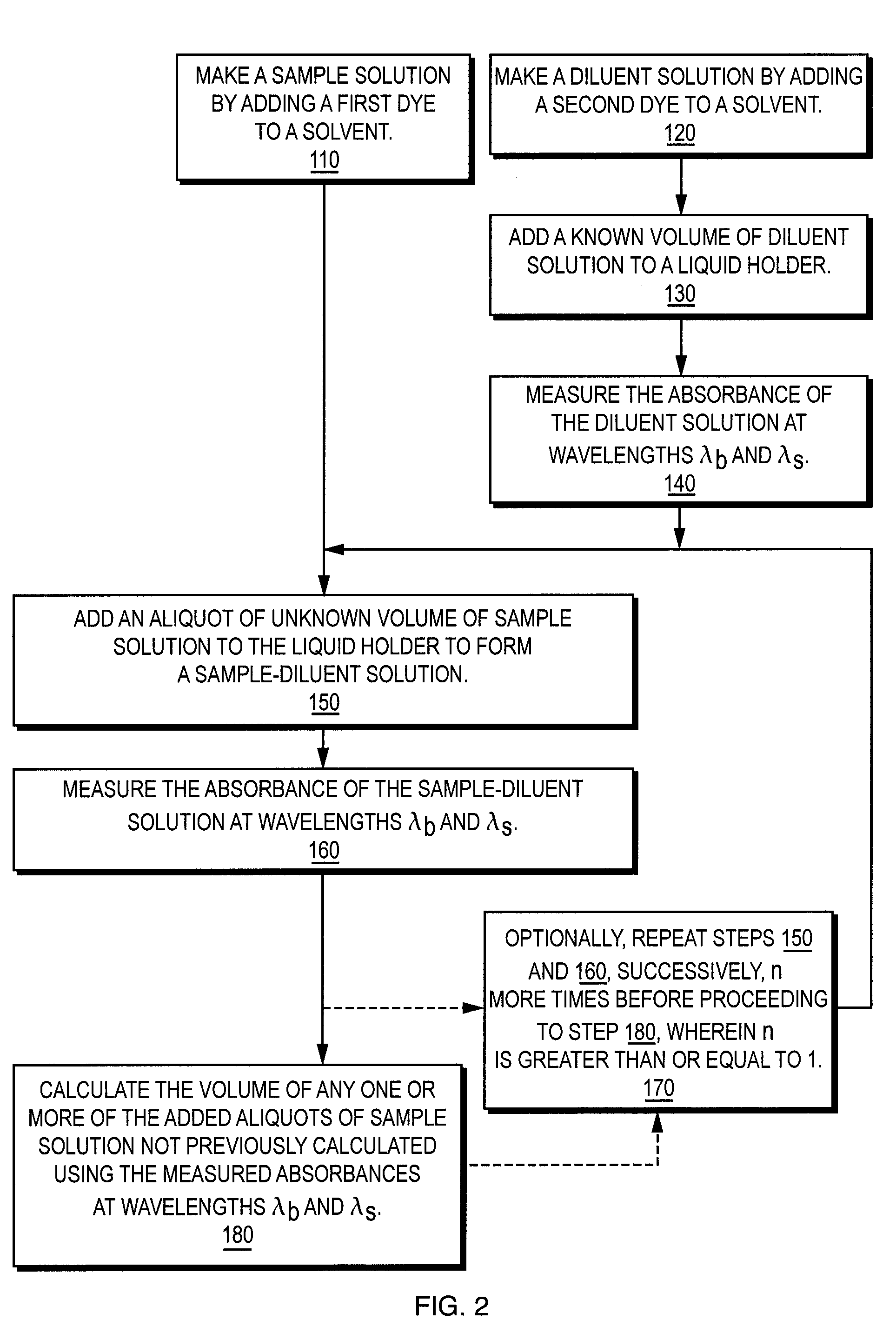

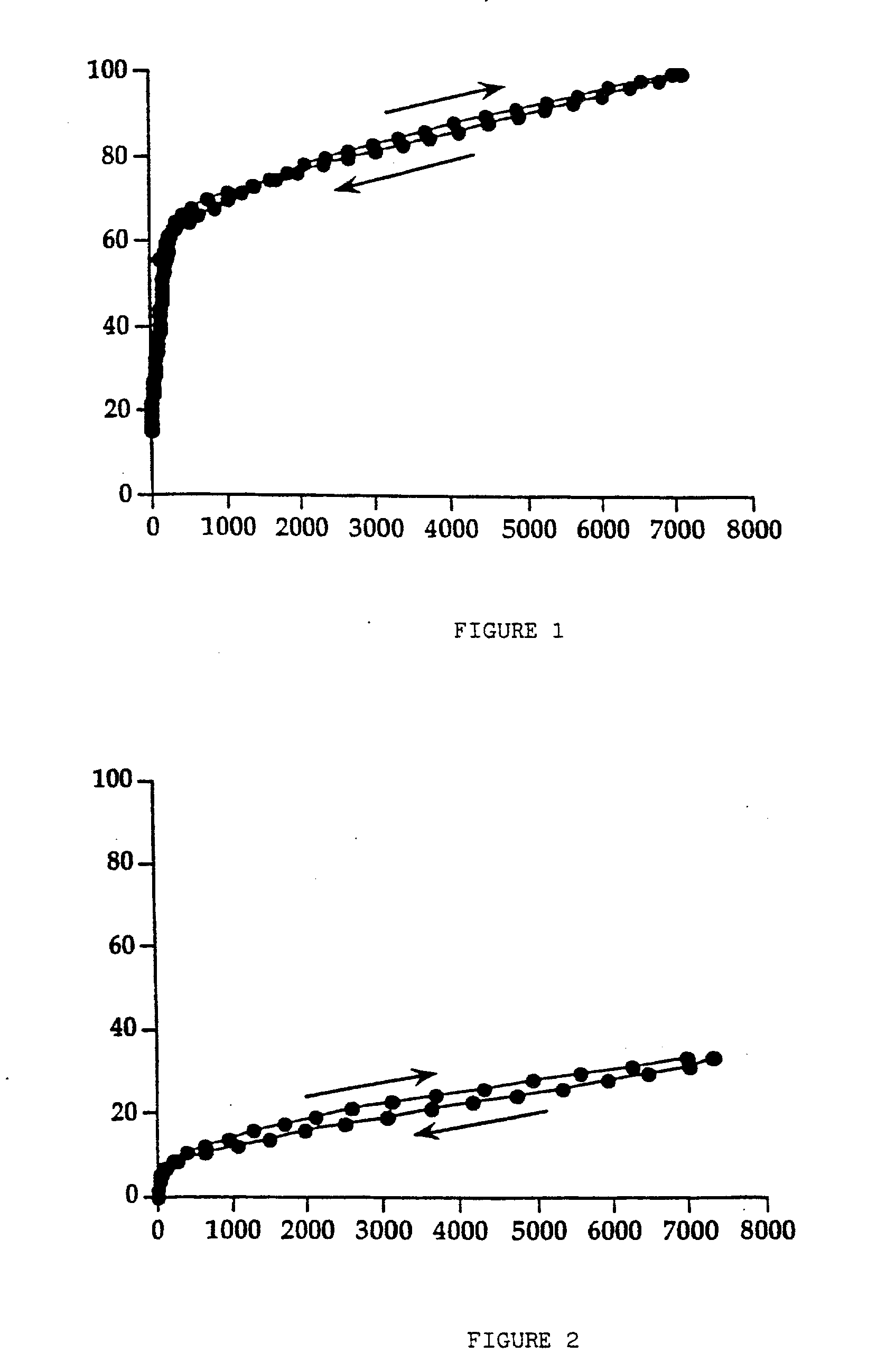

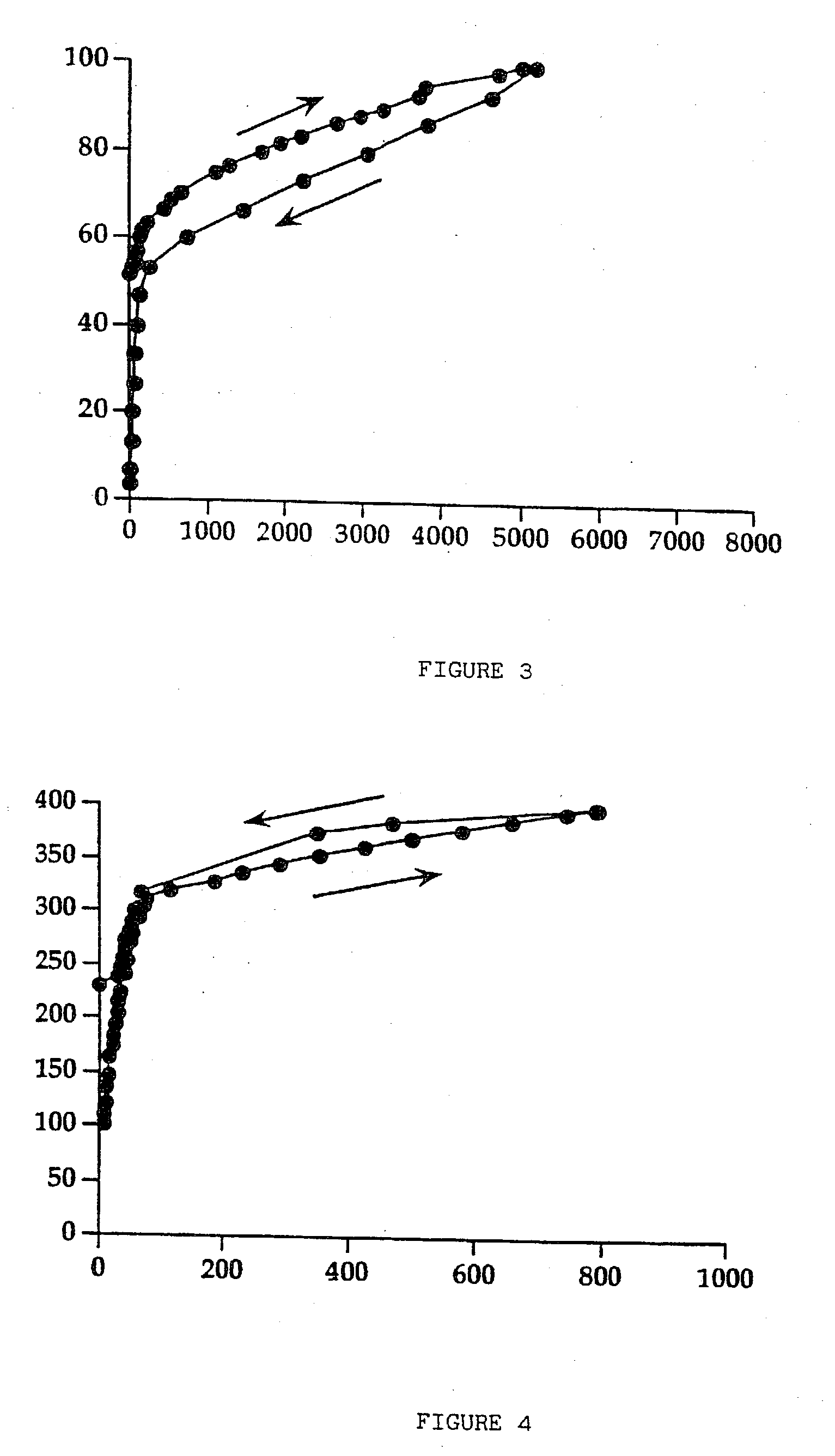

Method and apparatus for determining liquid volume

ActiveUS20070161114A1Precisely and accurately determiningAccurate measurementTesting/calibration apparatusFlow propertiesDiluentLength wave

A method, apparatus and kit for precisely and accurately determining the volume of a liquid aliquot which can be used to calibrate a liquid delivery device. Two dye-containing solutions, a sample solution and a diluent solution, are prepared such that each solution contains a different dye, with the solutions having different absorbance values at a first wavelength and at a second wavelength. The absorbance value of a known volume of diluent solution is measured at both wavelengths. Either one aliquot of sample solution is added to the diluent solution and then absorbance measurements are made at both wavelengths, or multiple aliquots of sample solution are mixed serially into the diluent solution and then absorbance measurements are made at both wavelengths after each aliquot is added. The volume of any single aliquot is calculated by using a two-step formula which is based on the Beer-Lambert law.

Owner:ARTEL

Cigarette filter tip additive capable of reducing smoke harmful effect to respiratory system

The present invention relates to a cigarette filter tip additive: It is characterized by that the raw material for preparing said additive is one kind or several kinds of 15 Chinese medicinal materials of red azalea leaf, biota leaf, loquat leaf, hemp-leaved vitex seed and lonicera flower, etc. and its effective component is fraction of medium boiling range, and is obtained from extract of raw material or volatile oil of said raw material. After the additive is diluted by using 95% ethyl alcohol, the diluted solution can be added into the cigarette filter tip. Said additive has the functions of relieving cough and asthma, reducing phlegm, relieving inflammation and relieving harmful effect of smoke to respiratory system.

Owner:CHONGQING CHINA TOBACCO IND CO LTD

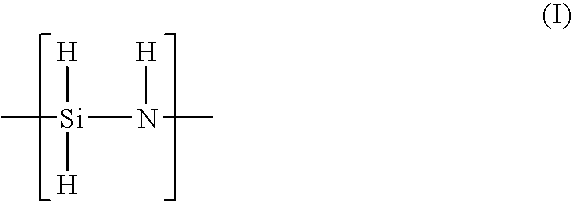

Hydrophilization-accelerating and hydrophilicity-keeping agents for polysilazane-containing coating films

InactiveUS20050119402A1Improve hydrophilicityLess of a smellOther chemical processesPretreated surfacesHydrophilizationOrganic acid

An aqueous solution is prepared comprising 5 to 25% by weight of an anionic surfactant, 0.5 to 20% by weight of an amphoteric surfactant, 4 to 6% by weight of a nonionic surfactant and, if necessary, an antiseptic and the aqueous solution is adjusted with an organic acid to pH in the range of 4.5 to 7.0, which is used as an undiluted solution of a hydrophilicity maintaining and promoting agent for a polysilazane-containing coating film. The undiluted solution is diluted with water to from 3 to 15 times and the resulting solution is used as a hydrophilicity promoting agent. While the undiluted solution is diluted with water to from 30 to 70 times and the resulting solution is used as a hydrophilicity maintaining agent. The hydrophilicity promoting agent is applied on an anti-fouling coating film which is formed by applying on a substrate a coating solution comprising polysilazane and, if necessary, silica conversion catalyst, and thereby the coating film is made hydrophilic in an extremely short time. Further the hydrophilicity maintaining agent is used for removing stains which adhere to the coating film and maintaining the hydrophilicity of the film.

Owner:MERCK PATENT GMBH

Method and apparatus for determining liquid volume

ActiveUS7772008B2Precisely and accurately determiningAccurate measurementTesting/calibration apparatusFlow propertiesDiluentLength wave

A method, apparatus and kit for precisely and accurately determining the volume of a liquid aliquot which can be used to calibrate a liquid delivery device. Two dye-containing solutions, a sample solution and a diluent solution, are prepared such that each solution contains a different dye, with the solutions having different absorbance values at a first wavelength and at a second wavelength. The absorbance value of a known volume of diluent solution is measured at both wavelengths. Either one aliquot of sample solution is added to the diluent solution and then absorbance measurements are made at both wavelengths, or multiple aliquots of sample solution are mixed serially into the diluent solution and then absorbance measurements are made at both wavelengths after each aliquot is added. The volume of any single aliquot is calculated by using a two-step formula which is based on the Beer-Lambert law.

Owner:ARTEL

Preparation method for urine monohydroxyphenyl metabolites detection reagent

InactiveCN102565055APrompt relapsePrompt transferMaterial analysis by observing effect on chemical indicatorMetaboliteBiology

A preparation method for a urine monohydroxyphenyl metabolites detection reagent comprises the steps of preparing solution A, preparing solution B, preparing solution C, uniformly mixing solution A, solution B and solution C at the volume ratio of 1:(1.5-2):(0.5-1.5), adding distilled water into the mixture, and stirring the mixture uniformly, wherein solution A is a mixture prepared through reacting 1 part by weight of metallic mercury with 2-2.2 parts by weight of nitric acid and being diluted by distilled water; solution B is a nickel nitrate solution with the concentration of 0.05g / ml-0.15g / ml; solution C is a mercuric sulfate solution with the concentration of 0.05g / ml-0.15g / ml. The process for preparing testing reagents of monohydroxyphenyl metabolites in urine has the advantages of being low in production cost, and the prepared testing reagents of monohydroxyphenyl metabolites in urine is high in stability and sensitivity, low in false positive rate and false negative rate, and suitable for mass screening and clinical examination.

Owner:宜春中奇金域生物科技股份有限公司

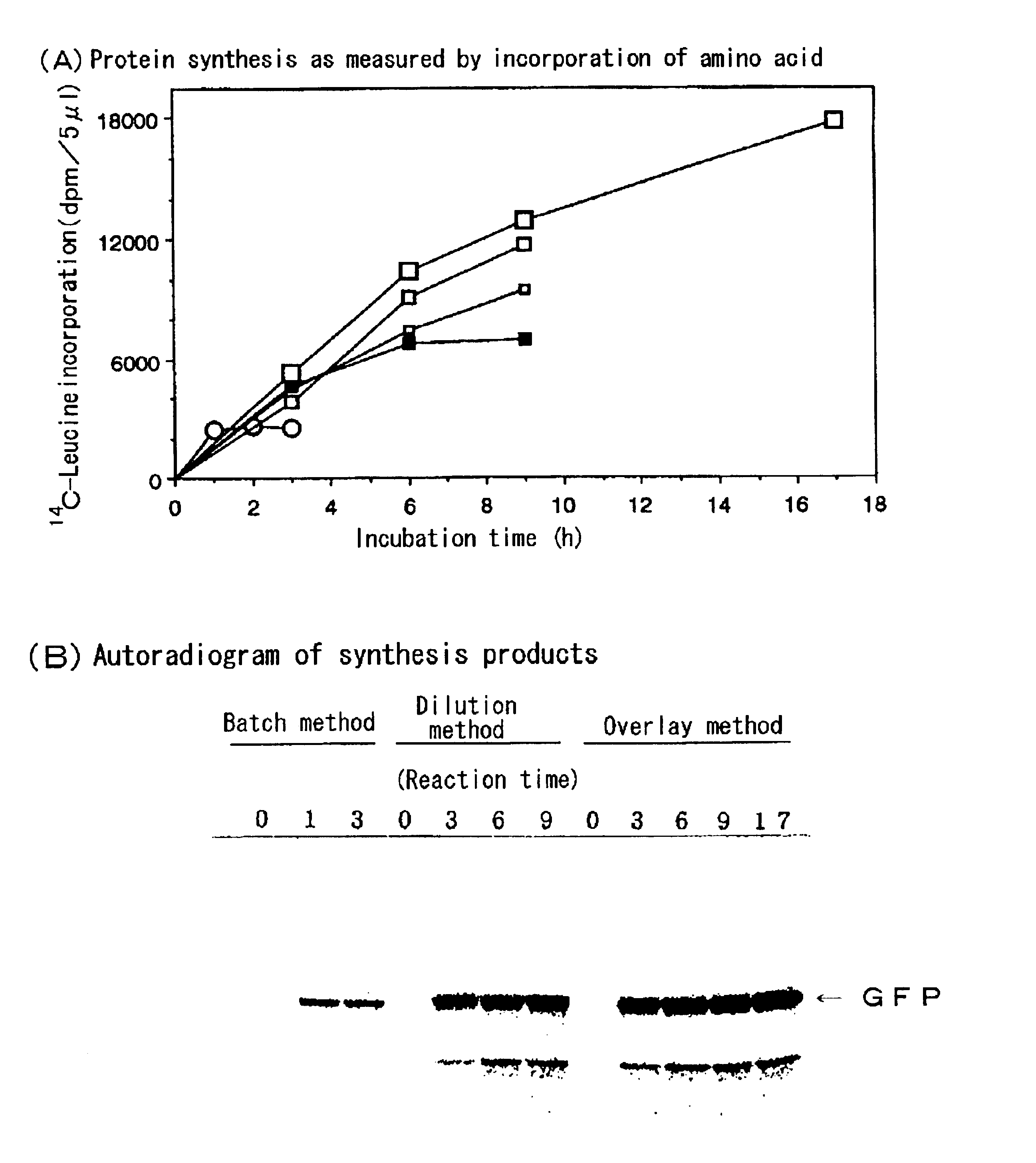

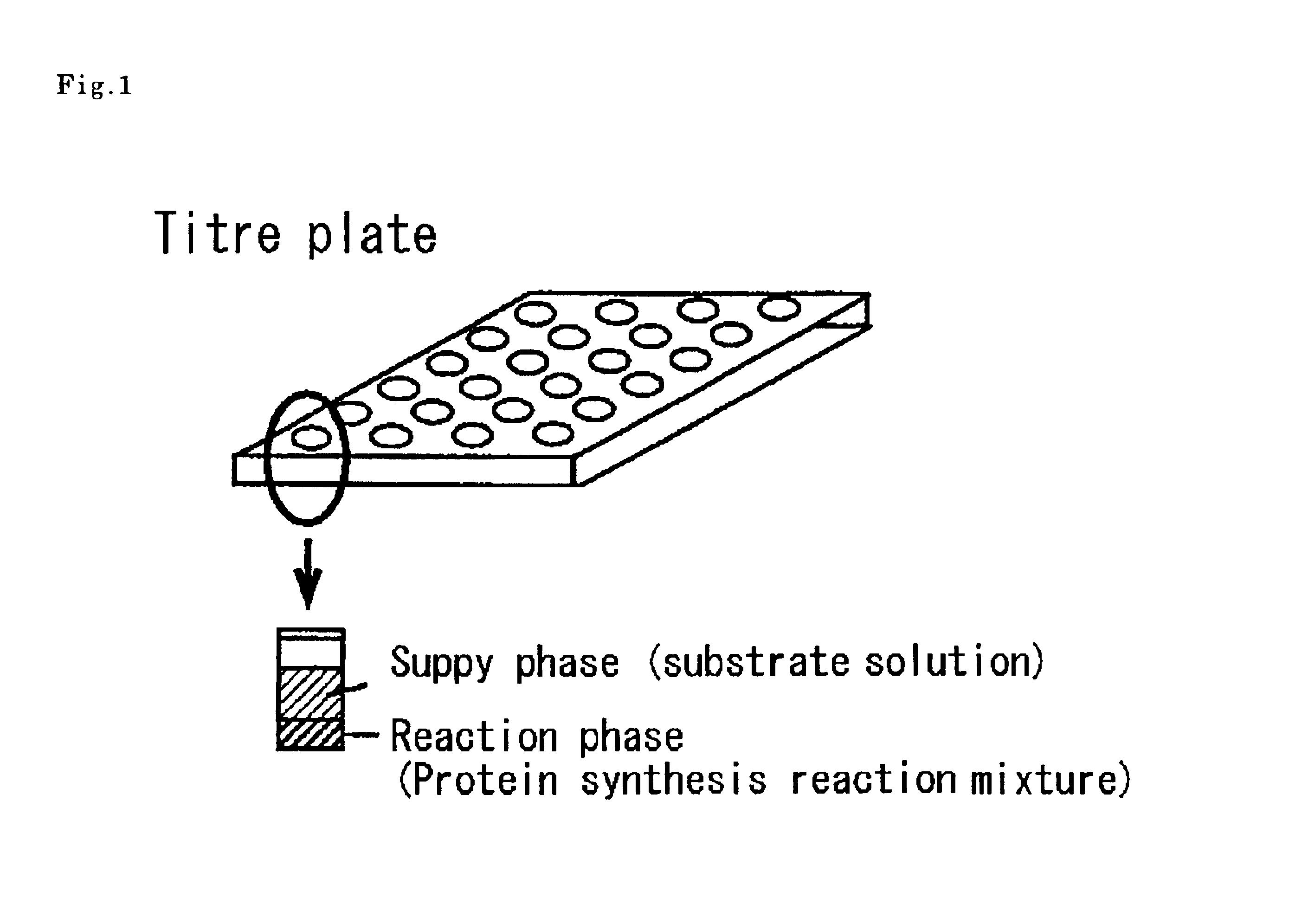

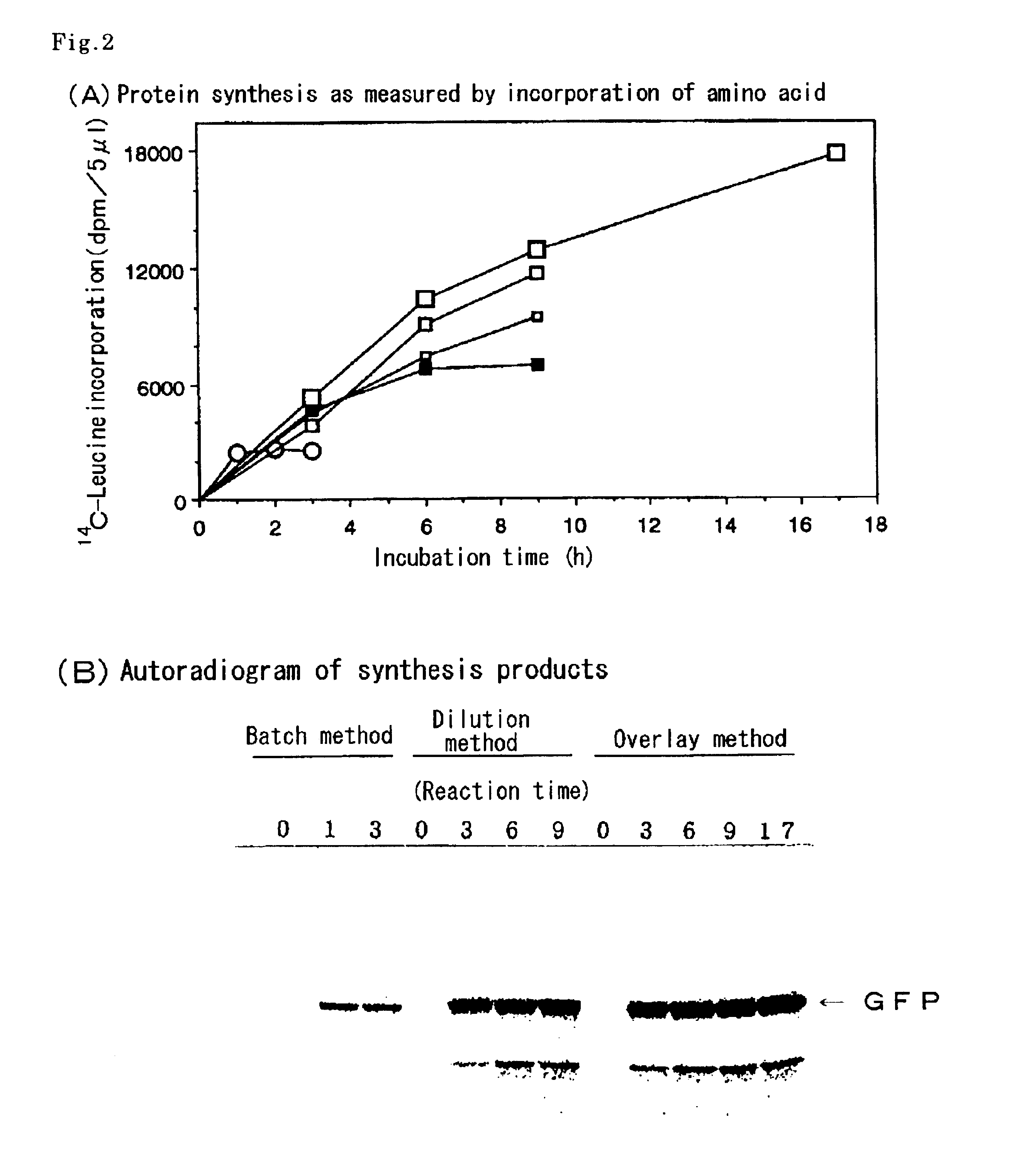

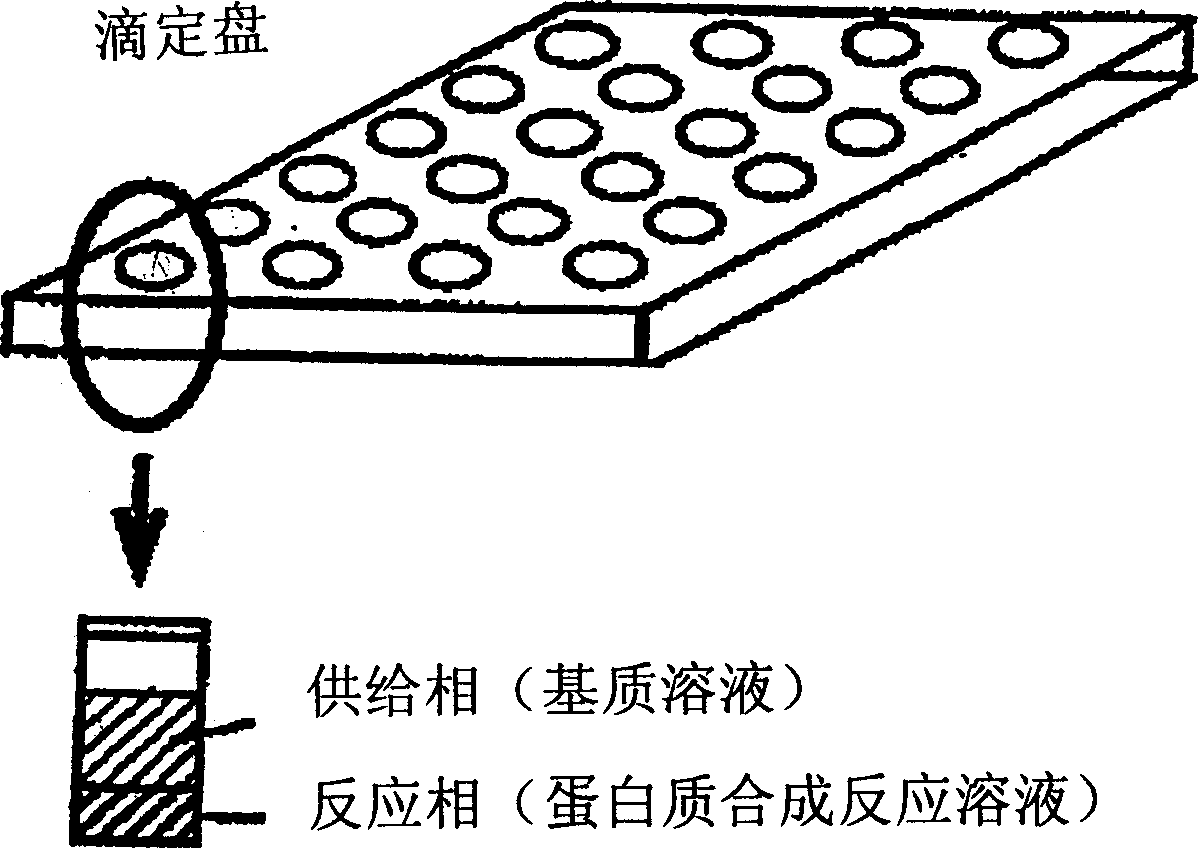

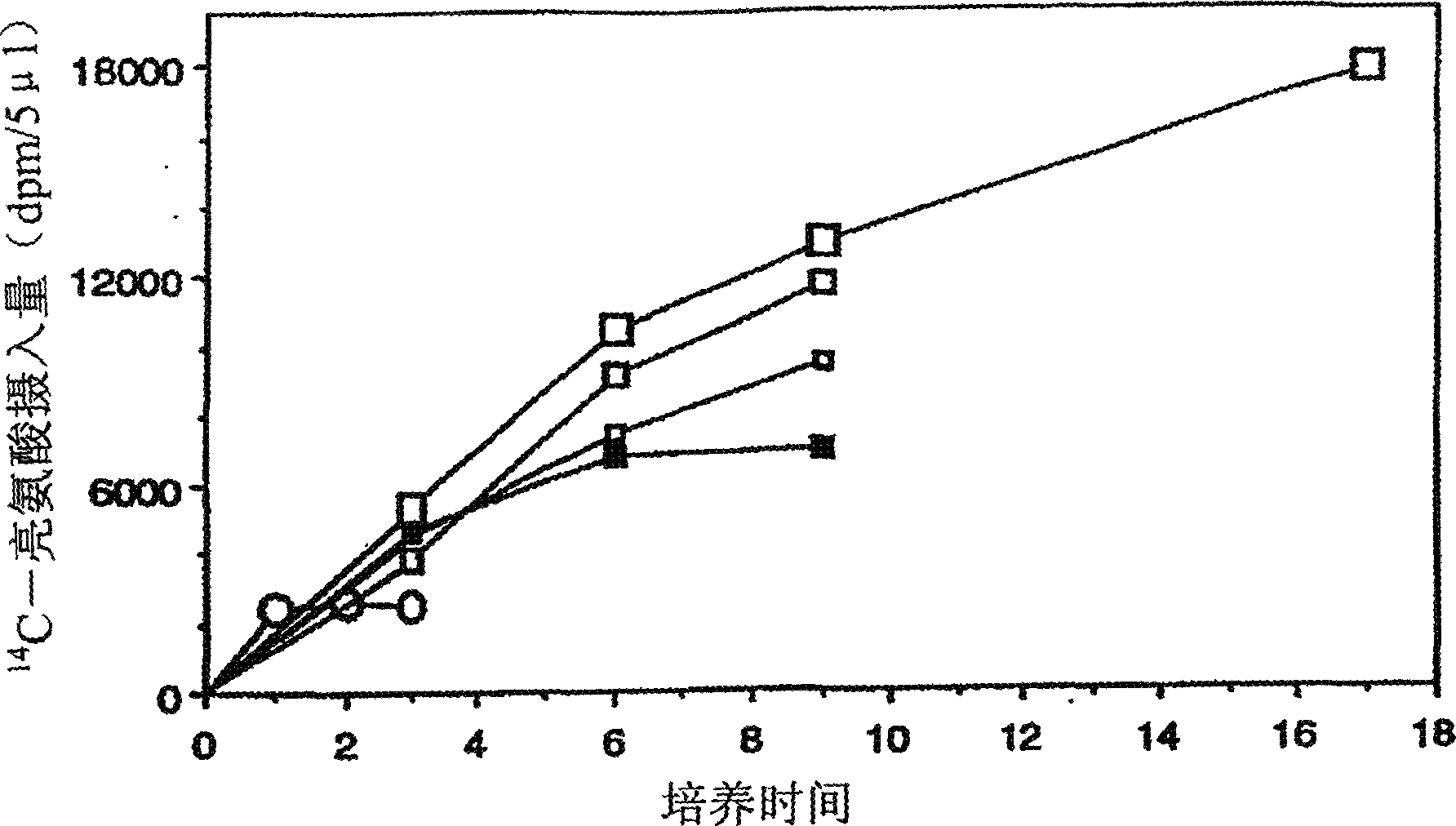

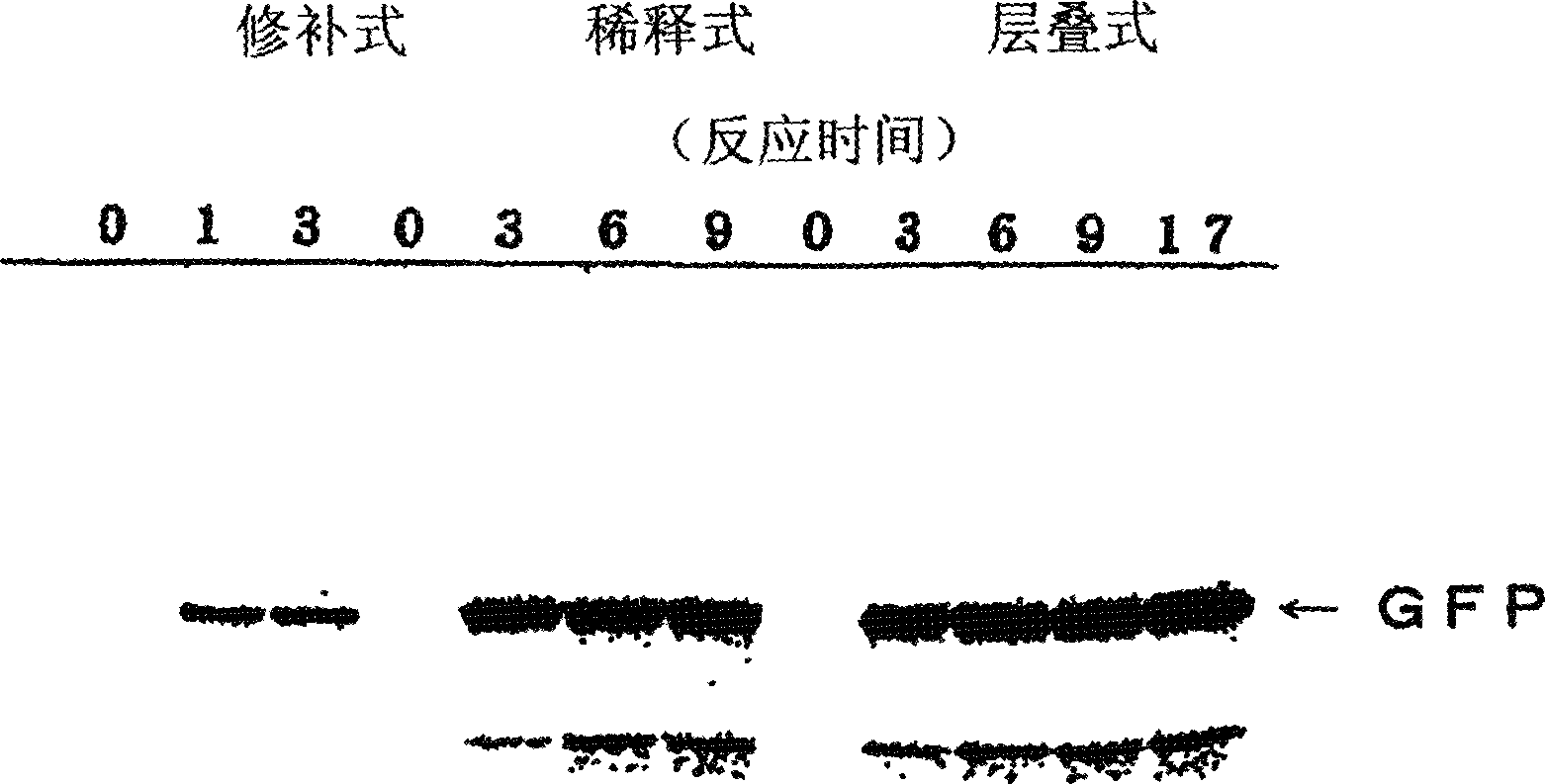

Methods of synthesizing cell-free protein

InactiveUS6869774B2Extended service lifeHigh synthesis efficiencyPeptide preparation methodsDepsipeptidesCell freeSynthesis methods

One embodiment of the present invention is a diffusion continuous batch cell-free protein-synthesis method characterized simultaneously by continuously supplying substrate and energy source molecules in the supply phase to the reaction phase by the free diffusion via interface between both phases and by transferring by-products formed in the reaction phase by enhancing the efficiency of the synthesis reaction by prolonging the reaction lifetime by directly contacting a synthesis reaction mixture (reaction phase) containing a biological extract with a substrate- and energy source-supplying solution (supply phase) without using barrier such as semi-permeable membrane or ultrafiltration membrane in a general cell-free protein-synthesis reaction means. Another embodiment of the present invention is a dilution batch cell-free protein synthesis method characterized by enhancing the efficiency of the protein synthesis by prolonging the reaction lifetime by adding a diluting solution to the reaction mixture after pre-incubating the reaction mixture in a cell-free protein-synthesis reaction means using a wheat-embryo extract. Another embodiment of the present invention is a method characterized by enhancing the efficiency of the synthesis reaction simultaneously by re-supplying substrate and energy sources necessary for the protein synthesis (e.g., amino acids, ATP, GTP, creatine phosphate) to the reaction mixture using a gel filtration column and / or semipermeable membrane and by discontinuously removing by-products formed during the reaction after the synthesis reaction stops in the batch cell-free protein synthesis method.

Owner:CELLFREE SCI

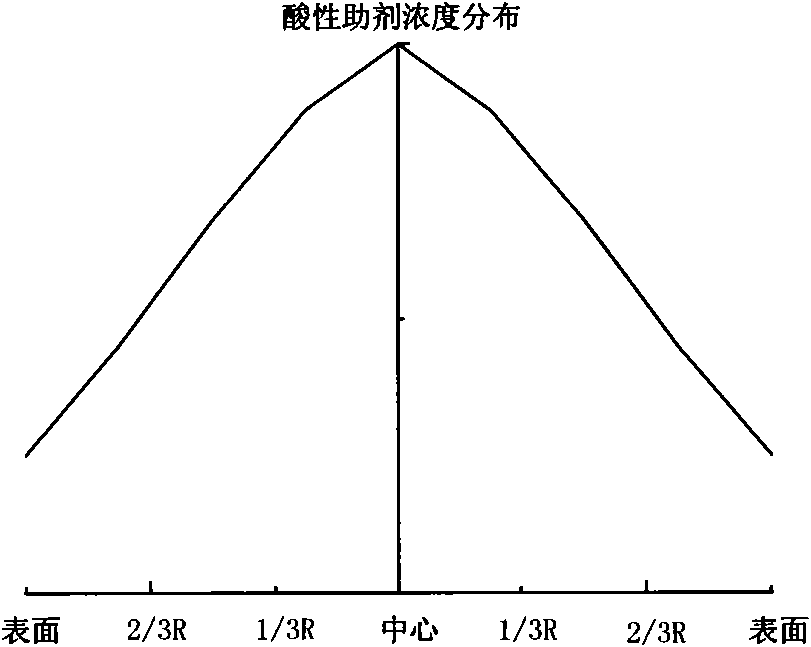

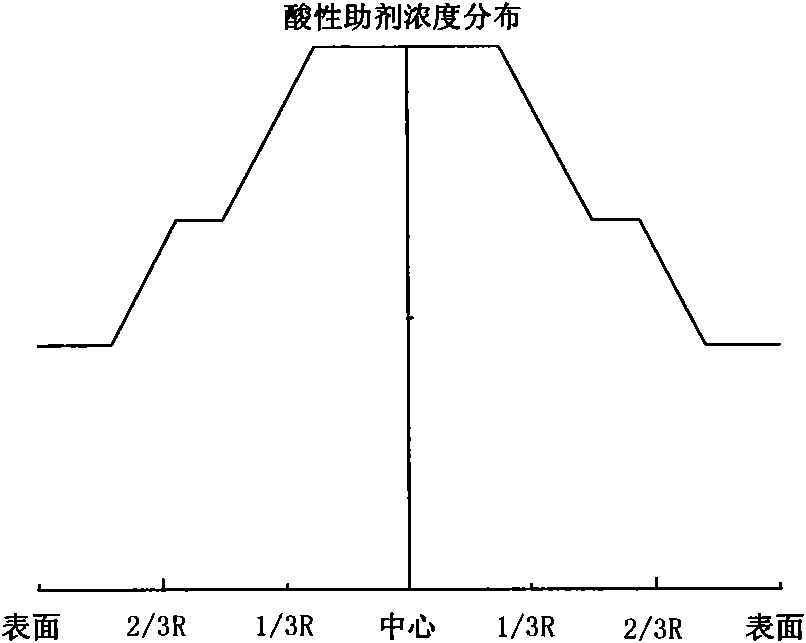

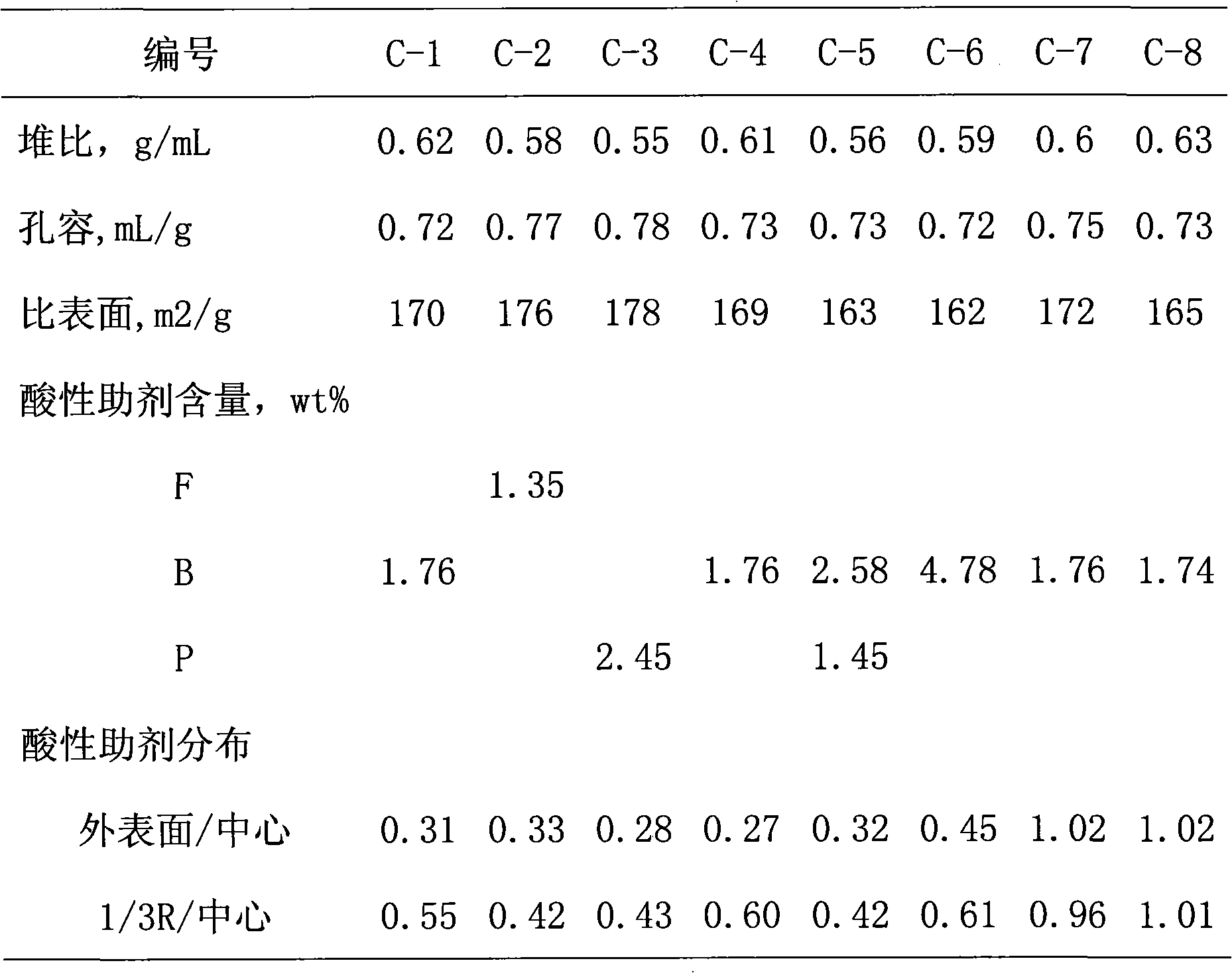

Hydrogenation catalyst carrier the concentrations of acid additives of which are distributed in gradient reducing and preparation method thereof,

ActiveCN101927192AReduce distributionEasy to makeCatalyst carriersCatalyst activation/preparationHigh concentrationActive component

The invention relates to a hydrogenation catalyst carrier the concentrations of acid additives of which are distributed in gradient reducing, and a preparation method thereof; the preparation method comprises the following steps: adopting Al2O3 or Al2O3 containing SiO2, TiO2 and ZrO2 as a carrier, preparing a solution of higher concentration of the acid additives, and saturating and spraying the carrier by gradually adding deionized water to dilute the solution in the process of soaking the carrier; or preparing at least two kinds of solutions of different concentrations of the acid additives, and then spraying the solutions on the carrier in a descending order of the concentration of the acid additives; then drying for 1-8 hours at 80-150DEG C, and then roasting for 2-6 hours in air at 300-650DEG C; the acid additives are compounds containing P, B or F; and the preparation is simple, the manufacturing cost is low, the carrier is used as a carrier for a heavy-oil hydrogenation catalyst, the preparation method is simple, the manufacturing cost is low, the acidity and pore properties of the carrier can be effectively modified, and the acidity of the catalyst can be effectively modified and / or the interaction between active components and the carrier is improved.

Owner:PETROCHINA CO LTD

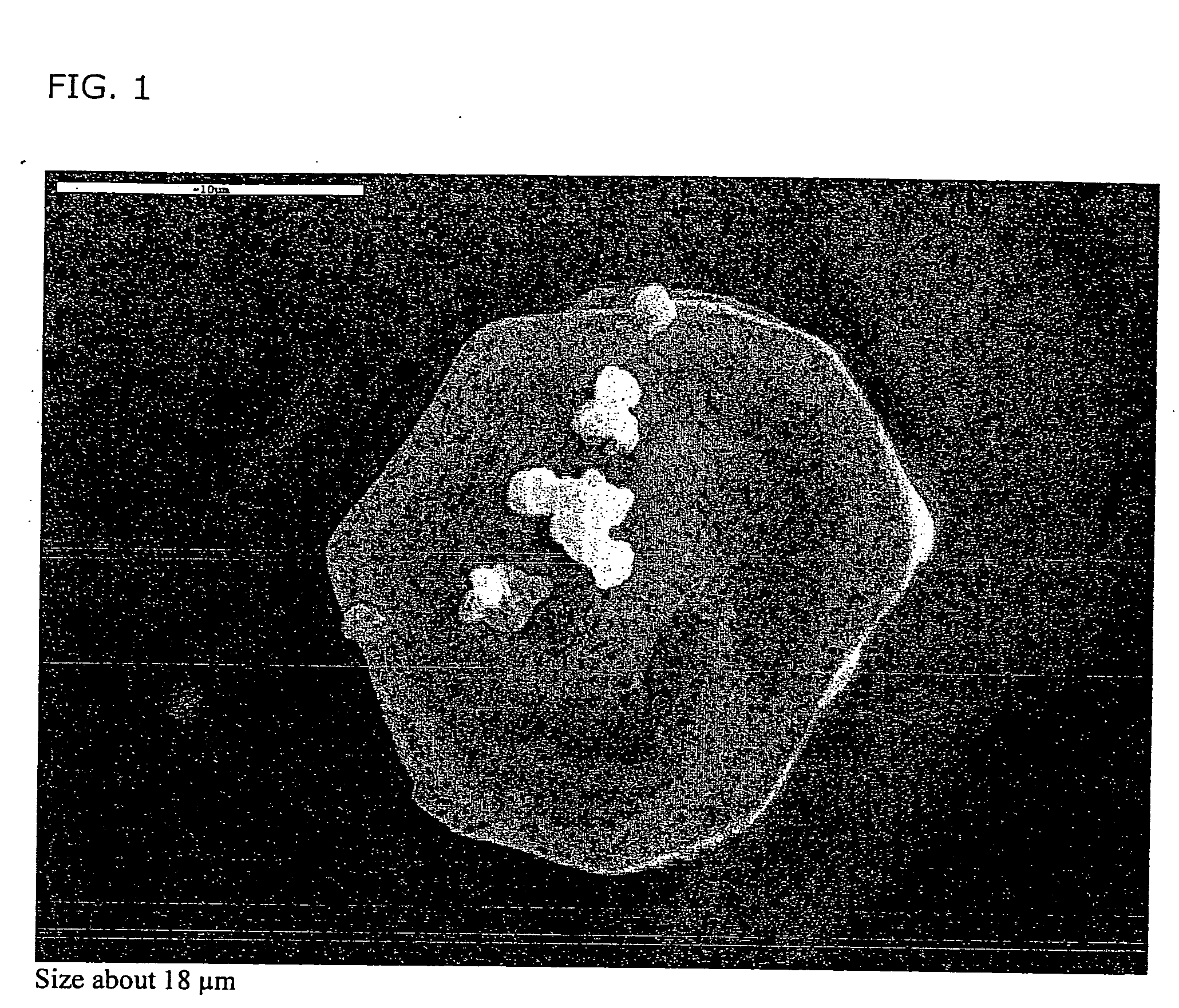

Process for (A) separating biological/ligands from dilute solutions and (B) conducting an immunochromatographic assay thereof employing superparamagnetic particles throughout

Superparamagnetic ("SPM") subunits of 1-30 nm average mean diameter (e.g. ferro fluid) subparticles are treated with a magnetically noninterfering substance capable of coating and covering them (e.g, BSA) and they spontaneously form agglomerates of about 100 nm to about 450 nm or higher average mean diameter and are then used to form complexes with target biological ligands such as viruses, contained in large volumes of liquid. The complexes are subjected to the gradient intensity of a strong magnetic field, and excess liquid is removed, where upon an immunochromatographic assay is conducted to determine the identity and / or amount of target ligand present, in which operation SPM particles that bonded to the ligand function as tags for ligand detection.

Owner:ABBOTT DIAGNOSTICS SCARBOROUGH INC

Method for preparing strong acid type ion exchange fibers by sulfonating PP-ST-DVB fibers

The invention discloses a method for preparing strong acid type ion exchange fibers by sulfonating PP-ST-DVB fibers. The method comprises the following steps: swelling the PP-ST-DVB fibers by using a swelling agent for 6-12 hours; then adding a sulfonating solution into the bottom of a reaction kettle and gradually heating to finish a sulfonating reaction; after the sulfonating reaction is finished, recycling the sulfonating solution into a solution storage tank; then, removing the swelling agent attached on the surfaces of the fibers by reduced pressure distillation; collecting and refluxing the volatile swelling agent into the solution storage tank; and after reduced pressure and distillation, obtaining PP-ST-DVB-based strong acid type ion exchange fibers and subpackaging for storage so as to avoid acid gradient washing. A certain amount of a dilution solution of chlorosulfonic acid is supplemented in the sulfonating solution and the sulfonating solution can be circularly utilized, so that the PP-ST-DVB fibers are continually sulfonated to prepare the strong acid type ion exchange fibers. The sulfonating method has the advantages that the preparation process is simple, the cost is obviously reduced, the acid solution gradient solution is not needed, no waste solutions are discharged, the sulfonating solution can be circularly utilized and the like.

Owner:河南省科学院同位素研究所有限责任公司 +1

Large-scale cytorrhyctes compound purifying technology for recombining tPA derivative

InactiveCN1613869AReduce dosageLow costPeptide preparation methodsEnzymesEscherichia coliProtein target

This invention relates to protein renaturation. It is used for large inclusion body for recombination of tPA derivative and is carried out by: dissolving inclusion body of target protein, centrifuging to obtain supernatant containing it, diluting it with first renaturation liquid containing oxidation reducing pairs, settling a period, diluting it with second renaturation liquid without oxidation reducing pairs, settling a period, filtrating and concentrating to obtain primary concentrated liquid, filtrating and diluting with buffering liquid to regulate pH value 4.0-5.5, filtrating and concentrating to obtain secondary liquid containing renatured target protein.

Owner:上海中科伍佰豪生物工程有限公司

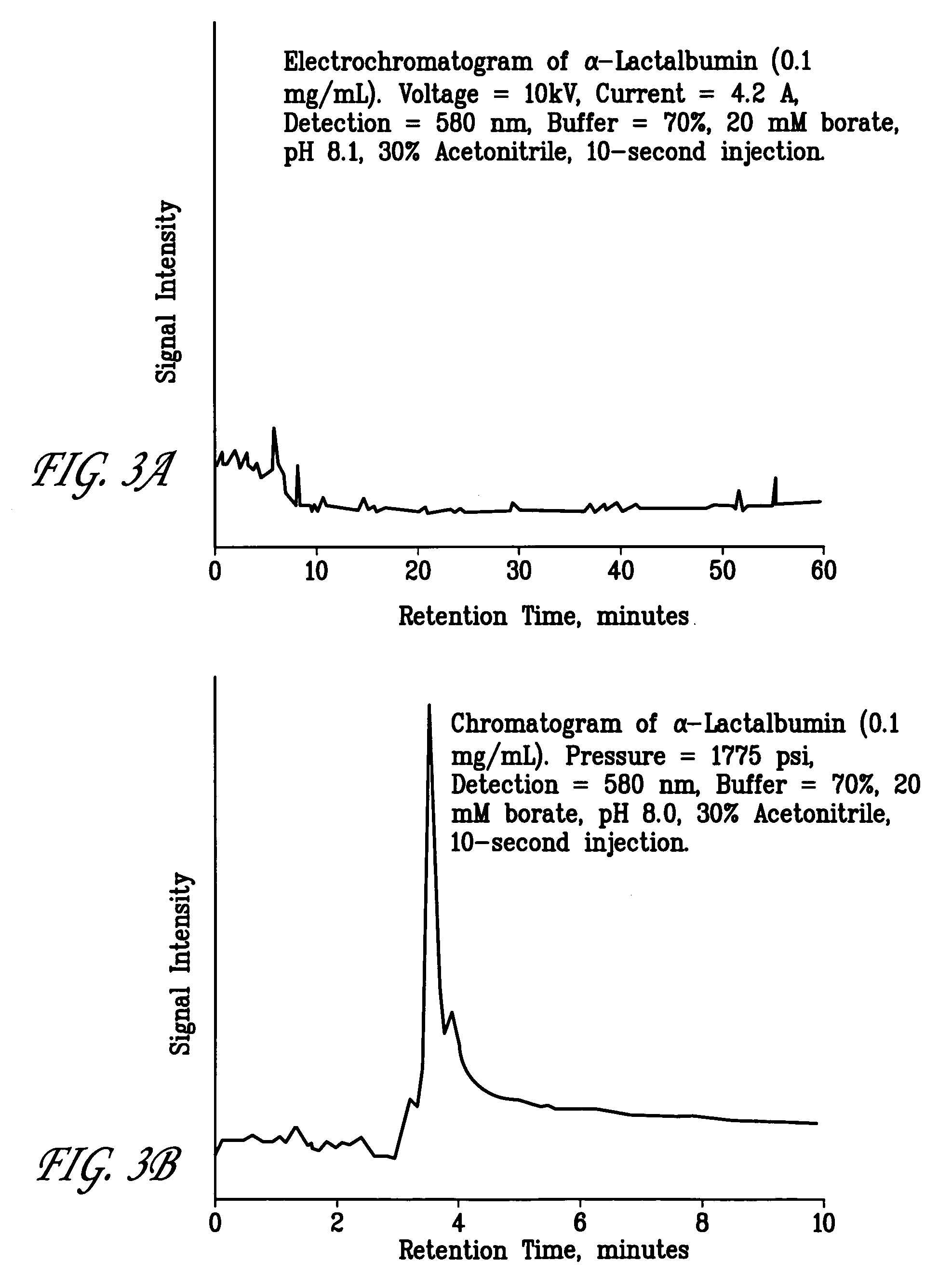

Cast-to-shape electrokinetic trapping medium

InactiveUS7052608B2Improve structural stabilityElectrolysis componentsIon-exchanger regenerationChemical physicsTrapping

A three-dimensional microporous polymer network material, or monolith, cast-to-shape in a microchannel. The polymer monolith, produced by a phase separation process, is capable of trapping and retaining charged protein species from a mixture of charged and uncharged species under the influence of an applied electric field. The retained charged protein species are released from the porous polymer monolith by a pressure driven flow in the substantial absence of the electric field. The pressure driven flow is independent of direction and thus neither means to reverse fluid flow nor a multi-directional flow field is required, a single flow through the porous polymer monolith can be employed, in contrast to prior art systems. The monolithic polymer material produced by the invention can function as a chromatographic medium. Moreover, by virtue of its ability to retain charged protein species and quantitatively release the retained species the porous polymer monolith can serve as a means for concentrating charged protein species from, for example, a dilute solution.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

Method of disinfecting water and food stuff preservation with iodine species

InactiveCN1259107AAvoid damageImprove preservationEggs preservation using chemicalsSpecific water treatment objectivesFree iodineCooling tower

A method and apparatus for producing bacteria-free iodine-species-containing drinking water for farm animals under continuous dynamic water flow, comprising dissolving solid iodine into a first water flow to produce a saturated iodine species-containing aqueous solution at a pre-selected temperature; blending the saturated solution with a second water flow to produce a diluted iodine species bacterium-free aqueous solution; and providing the diluted solution as drinking water to the animals. Preferably, the iodine is dissolved in the first water flow to provide a saturated iodine species at a pre-selected temperature at a known concentration, which saturated solution is then blended into a mean water flow. The continuous flow of iodine species-containing water is fed to a farm animal drinking water distribution network with reduced risk of back-contamination by bacteria-containing water through the network. Other uses of the iodinated water are as a disinfectant, for example, in the food processing industry; fruit, vegetable and fish preservation; industrial, commercial cooling tower waters, sewage and waste water treatment; and as a nutrient as an iodine source for humans, livestock, fish and plants.

Owner:IOSOLUTIONS

Biocidal protection system

The invention relates to a shelf stable liquid disinfectant concentrate composition containing at least 1% by weight of a quat biocide (biocidally active quaternary ammonium compounds) and capable of dilution with 20 parts of water to 1 part of concentrate to produce a diluted solution, the diluted solution exhibiting a MIC after 24 hours in the presence of up to 2% tryptone (or the protein equivalent thereof) which is less than the MIC of a simple solution of the same concentration of the same quat biocide in water in the presence of the same concentration of the protein. The biocidal efficacy of the quat biocide may be protected by an "activity protector" selected from the group consisting of "enzyme stabilisers", "enzyme stabilising systems", micelle formation modifiers and inhibitors, and combinations thereof. The invention also relates to a disinfectant working solution prepared from the concentrate, and to a method of protecting a quat biocide from deactivation.

Owner:NOVAPHARM RES AUSTRALIA

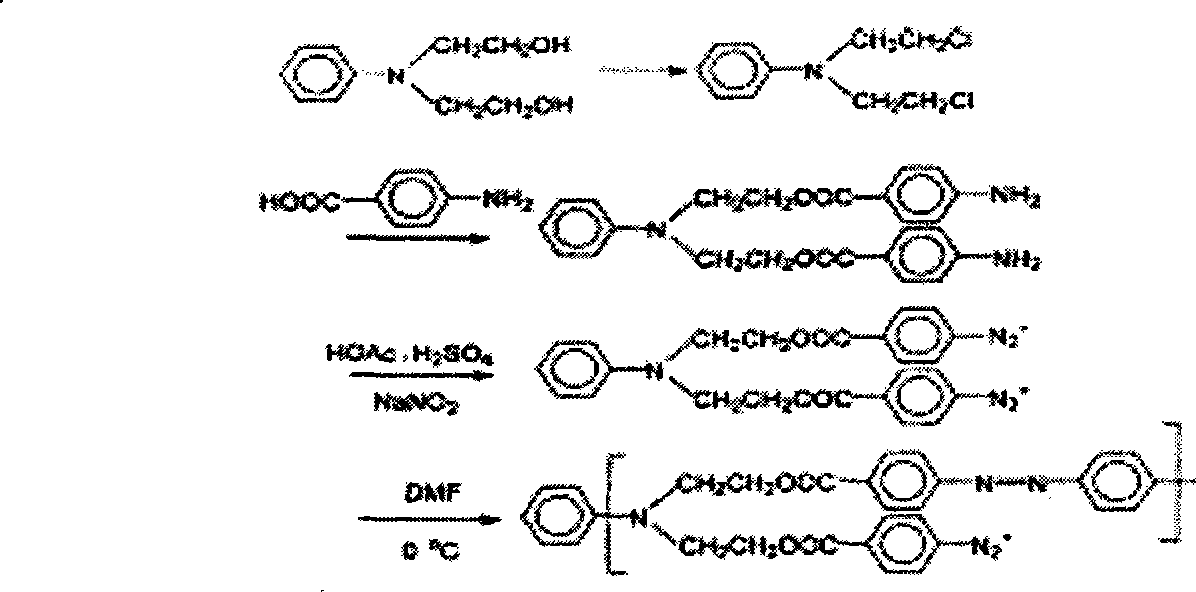

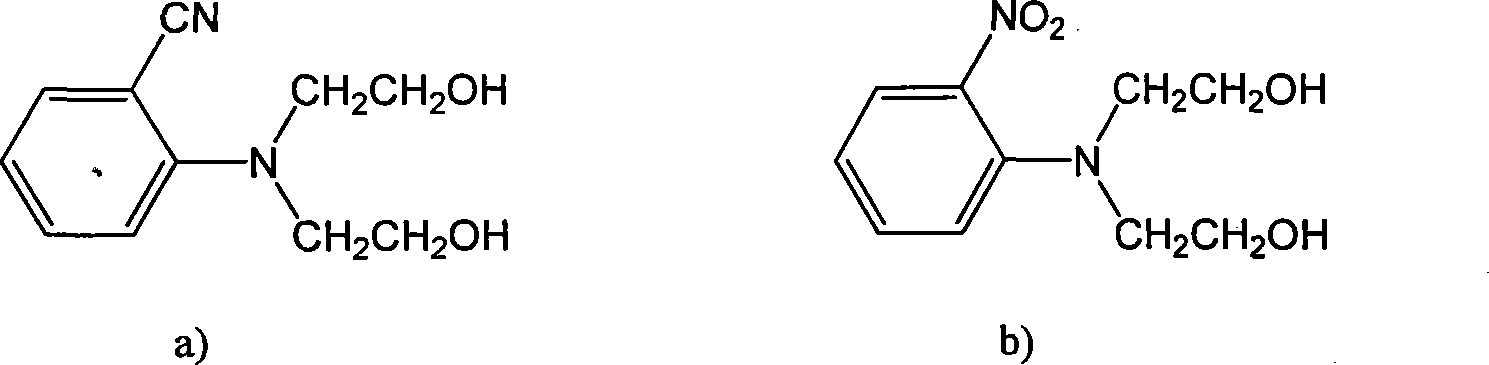

Enzyme immobilization method based on excessive expenditure polymer

InactiveCN101182510AImprove adsorption capacityCatalytic activity was not significantly affectedOn/in organic carrierPresent methodOrganic solvent

The invention relates to an enzyme immobilization method based on a hyperbranched polymer, which belongs to the technical field of bioengineering. The method comprises: in a synthetic hyperbranched polymer solution with a large number of diazonium salt groups on the periphery, or In the dilute solution of the hyperbranched polymer solution diluted with water or organic solvent N,N-dimethylformamide less than 100 times, the carrier is soaked for more than half an hour; then the carrier is taken out, washed with water, and then immersed in In the enzyme-containing buffer solution, adsorb at 4°C for more than 4 hours to achieve saturated adsorption; this method can greatly simplify the operation steps of immobilized enzymes, without the need for pre-modification of materials and enzymes, and has high universality; it can be used On a variety of enzymes and carriers, and has no obvious effect on the catalytic activity of the enzyme.

Owner:TSINGHUA UNIV

Household cleaning composition

ActiveUS20070129279A1Inorganic/elemental detergent compounding agentsOrganic detergent compounding agentsSodium bicarbonateAdditive ingredient

New cleaning compositions and methods of forming and using those compositions are provided. In a preferred embodiment, the compositions are in tablet form, with the tablets being dissolvable in water at the point-of-use for ease of storing and shipping. The compositions comprise sodium bicarbonate, citric acid, an alkali metal alkylbenzene sulfonate, an ingredient selected from the group consisting of a trialkyl glycol monoalkyl ether, limonene, and mixtures thereof, and other ingredients depending upon the embodiment. The diluted cleaner has a very low impact on the environment due to the low levels of surfactants in the diluted solution. Furthermore, the cleaning solution performs well on protein stains due to the production of CO2 and the presence of sodium perborate. The inventive composition can be used on a wide range of substrates, from hard surfaces to fabrics.

Owner:KEGEL LLC

Methods of synthesizing cell-free protein

The invention provides a synthetic method of a cell-free protein, which connects synthesis reaction solution (reaction phase) containing organism extract to substrate and energy source supplying solution (supplying phase) directly, and free diffuse substrate and energy source atoms of supplying phase by connecting surface, continuously supplying to the reaction phase; and discharge the by-products of reaction phase to the supplying phase to prolong the duration of the reaction. The invention prolongs the duration of the reaction by adding dilution solution to the solution containing wheat germ extracts. The invention re-supply amino acids, ATP, GTP and fiber phosphoric acid for protein synthesis by gel filtration column and translucent film in the solution after synthesis reaction, and discontinuously discharge the by-products of the reaction.

Owner:CELLFREE SCI

Hydrophilicity promoting and maintaining agent for polysilazane-containing coating films and method of using same

An aqueous solution is prepared comprising 5 to 25% by weight of an anionic surfactant, 0.5 to 20% by weight of an amphoteric surfactant, 4 to 6% by weight of a nonionic surfactant and, if necessary, an antiseptic and the aqueous solution is adjusted with an organic acid to pH in the range of 4.5 to 7.0, which is used as an undiluted solution of a hydrophilicity maintaining and promoting agent for a polysilazane-containing coating film. The undiluted solution is diluted with water to from 3 to 15 times and the resulting solution is used as a hydrophilicity promoting agent. While the undiluted solution is diluted with water to from 30 to 70 times and the resulting solution is used as a hydrophilicity maintaining agent. The hydrophilicity promoting agent is applied on an anti-fouling coating film which is formed by applying on a substrate a coating solution comprising polysilazane and, if necessary, silica conversion catalyst, and thereby the coating film is made hydrophilic in an extremely short time. Further the hydrophilicity maintaining agent is used for removing stains which adhere to the coating film and maintaining the hydrophilicity of the film.

Owner:MERCK PATENT GMBH

Process for the preparation of granular and porous sucralfate dry gel

InactiveUS20030206950A1Suitable for preparationConveniently preparedOrganic active ingredientsBiocideSucrose sulfateApparent density

Sucralfate gel in the dry state in porous granular form having a particle-size distribution of between 100 and 1000 mum, an apparent density of the powder bed of between 0.7 and 0.9 g / ml, a settling index of between 5 and 15%, and a residual humidity of between 5 and 15%, and the corresponding process of preparation, which comprises a treatment with microwaves of a diluted solution of powdered sucralfate gel, with a sucralfate titre of between 20 and 70 wt. %. This solid product may be advantageously used in the preparation of solid pharmaceutical compositions that contain it as single active principle, or else as coating of solid compositions that contain, as active principle, a substance that may cause lesions to the gastric mucosa.

Owner:D R DRUG RES

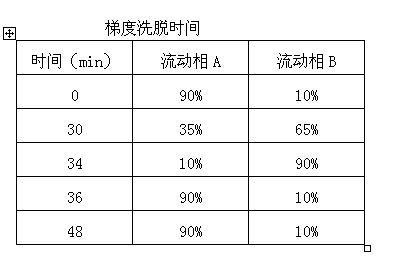

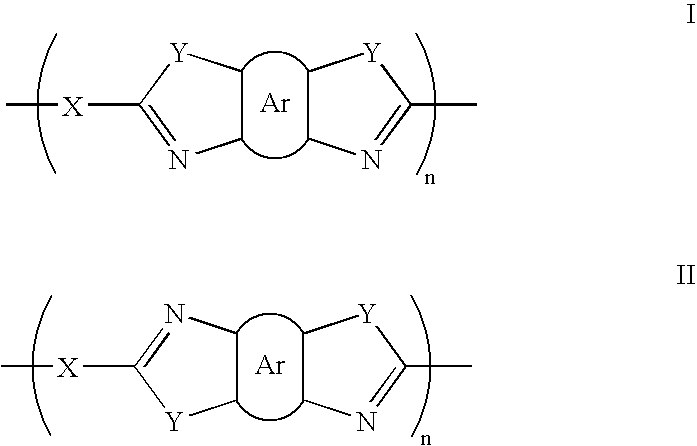

Determination method of hesperidin content

ActiveCN103091437AAccurate determination of contentImprove quality controlComponent separationVitamin CTest sample

The invention discloses a determination method of hesperidin content, which comprises the following steps of: (1) preparing a dilute solution; (2) preparing an extract solution; (3) preparing a reference solution; (4) preparing a test sample solution; (5) determining chromatographic conditions; and (6) detecting a program. The determination method of the hesperidin content disclosed by the invention is convenient, simple and fast to operate, good in specificity and repeatability, high in recovery ratio, can accurately determine the hesperidin content, and is convenient for controlling qualities of citrus bioflavonoids and vitamin C complex preparations.

Owner:JIANGSU ALAND NOURISHMENT

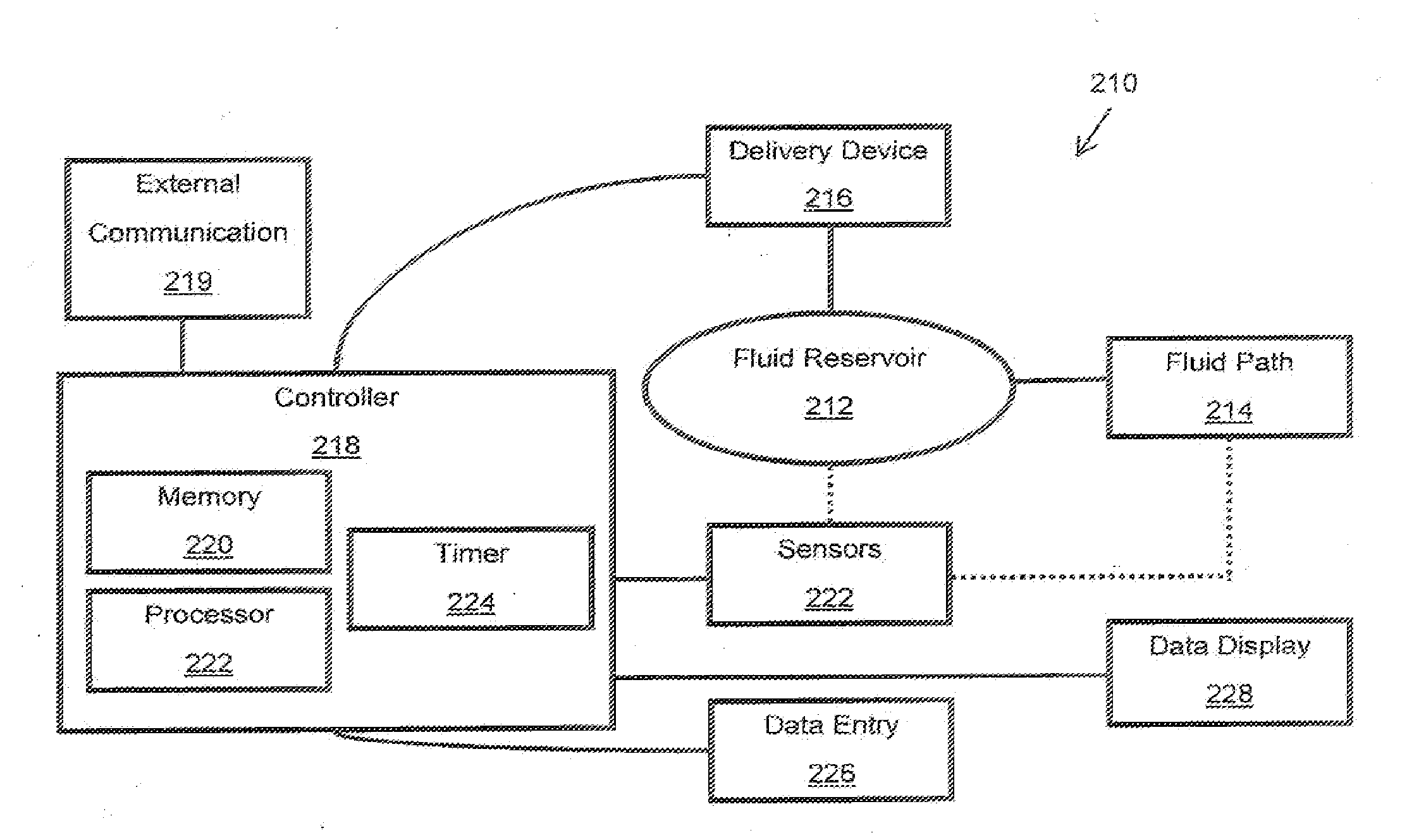

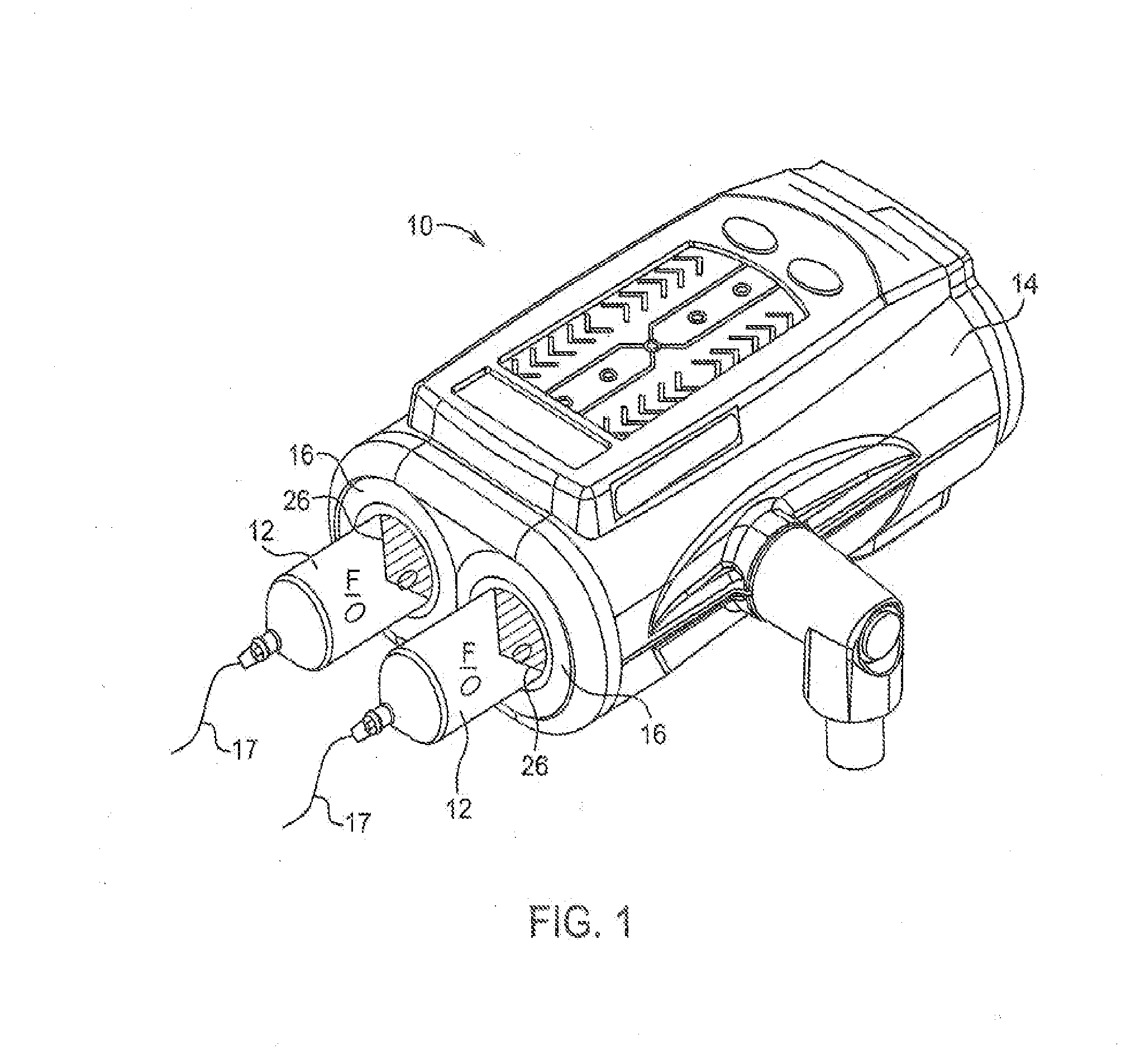

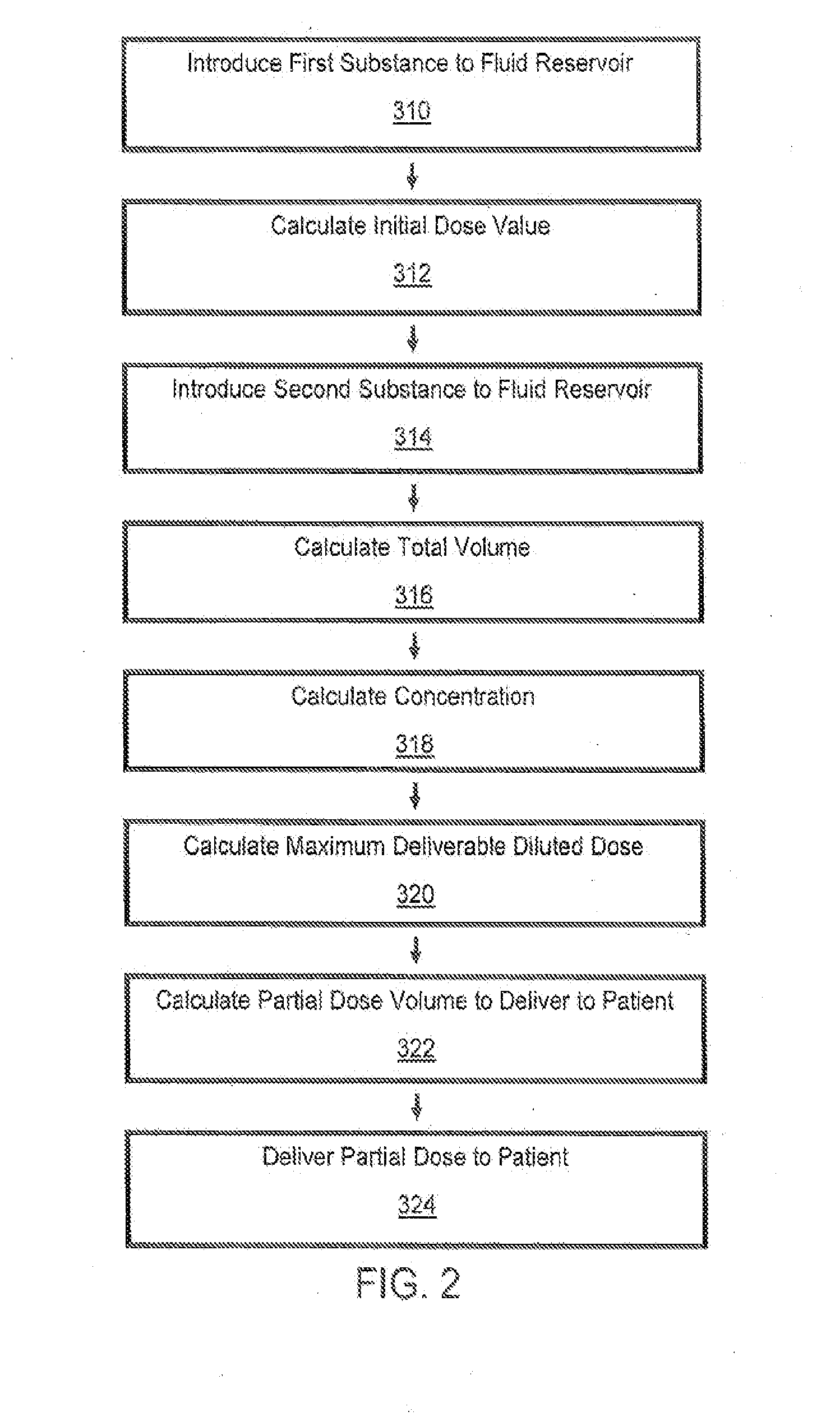

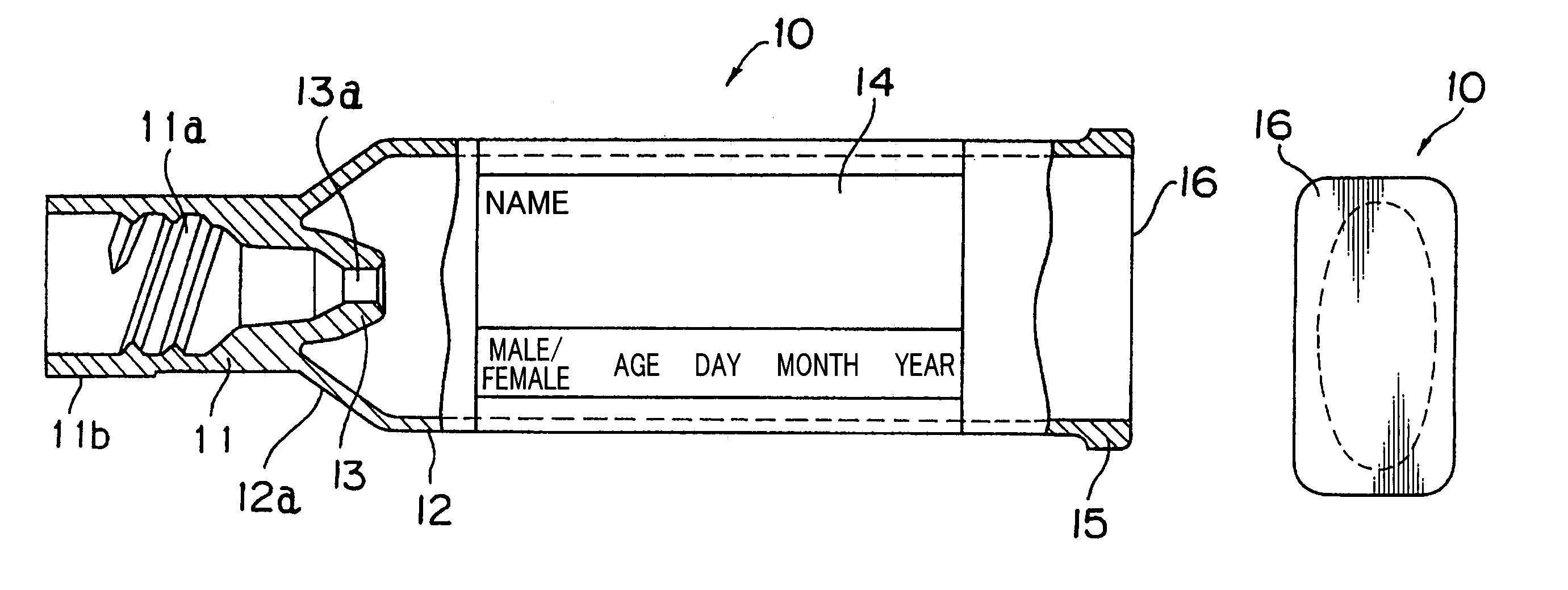

Accurately Delivering Partial Doses of a Drug Post Dilution Using an Injector

Methods and systems for diluting a dose of a substance to be delivered to a patient and for determining a maximum deliverable dose of the substance and / or a partial fluid volume to be delivered to the patient to provide a desired dose amount are provided. The method includes the step of providing a first substance within a fluid reservoir having an initial unit value. The method also includes diluting the first substance with a second substance to produce the diluted solution. Once the first substance is diluted, a total volume (VTotal) of the diluted solution is measured. A concentration of the diluted solution is then calculated based on the initial unit value and the total volume (VTotal). A fluid delivery system including a fluid reservoir and fluid delivery device, which is configured to perform the method, is also provided.

Owner:BAYER HEALTHCARE LLC

Methods for fine powder formation

InactiveUS20060191375A1Reduce environmental stressEnsure adequate heatingPowder deliveryOrganic active ingredientsCrystallographyAmbient pressure

Improved methods for forming fine particles of a material have been developed, wherein the method steps include dissolving the material in a solvent to form a dilute solution, immobilizing the dilution solution, and then removing the solvent to yield particles of the material. Methods of immobilizing the dilute solution include freezing, gelation, and chelation. In a preferred embodiment, the immobilized solvent is removed by lyophilization, i.e. reducing the ambient pressure while avoiding application of sufficient heat to power a phase transition. Essentially any material and solvent for the material can be used in the methods described herein. Proteins and peptides in an aqueous solvent are the preferred systems.

Owner:MANNKIND CORP

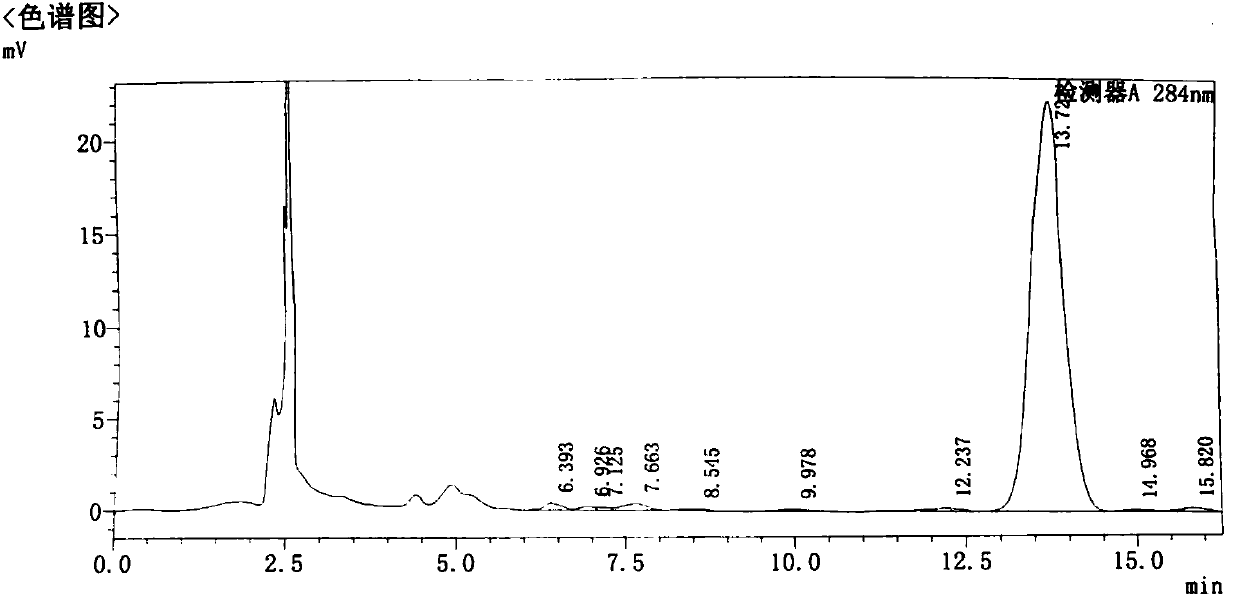

Fecal assay method and analyzer

ActiveUS7569183B2Analysis using chemical indicatorsMicrobiological testing/measurementAnimal fecesStool analysis

A fecal analyzing apparatus includes an extraction / dilution section (43) for extracting a fecal suspension from a feces sampling container (1). The fecal suspension is formed by dispersing feces in a feces-dissolving liquid in the feces sampling container (1), and mixing a diluting solution having a different concentration than the feces-dissolving liquid, with respect to a specific pigment, into the extracted fecal suspension in a predetermined amount. An optical-absorbance measurement section (61) detects the concentration of the specific pigment to be changed in response to the addition of the diluting solution, and a control device (66) determines the adequacy of the extraction amount of the fecal suspension in accordance with the detected concentration of the specific pigment. The adequacy of the extraction amount of the fecal suspension can be determined to provide an adequate assay result.

Owner:ALFRESA PHARMA CORP

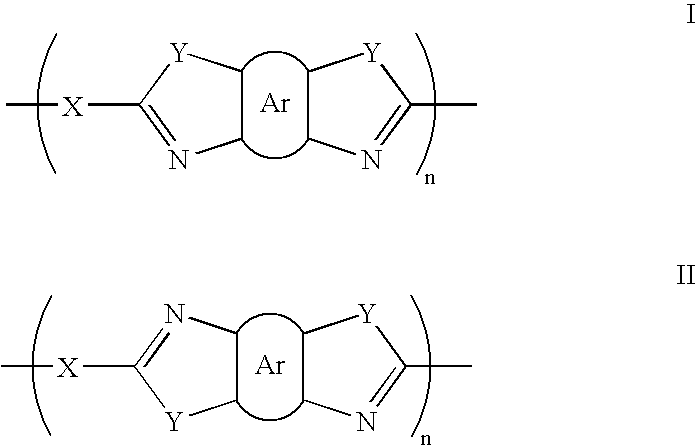

Dilute solutions of lyotropic liquid crystalline polymers, methods of making same and compositions prepared from same

The invention features dilute solutions of rigid rod or extended rod lyotropic liquid crystalline polymers prepared from high concentration polymerization mixtures. The invention also features methods of preparing such dilute solutions which utilize high mechanical shear to induce mix the high concentration solution with a diluent. The invention further provides articles of manufacture, including films and fibers, having a porous microstructure which are prepared from the dilute homogeneous solutions of the invention.

Owner:FOSTER-MILLER

Method of making high performance activated aluminum sesquichlorohydrate powders

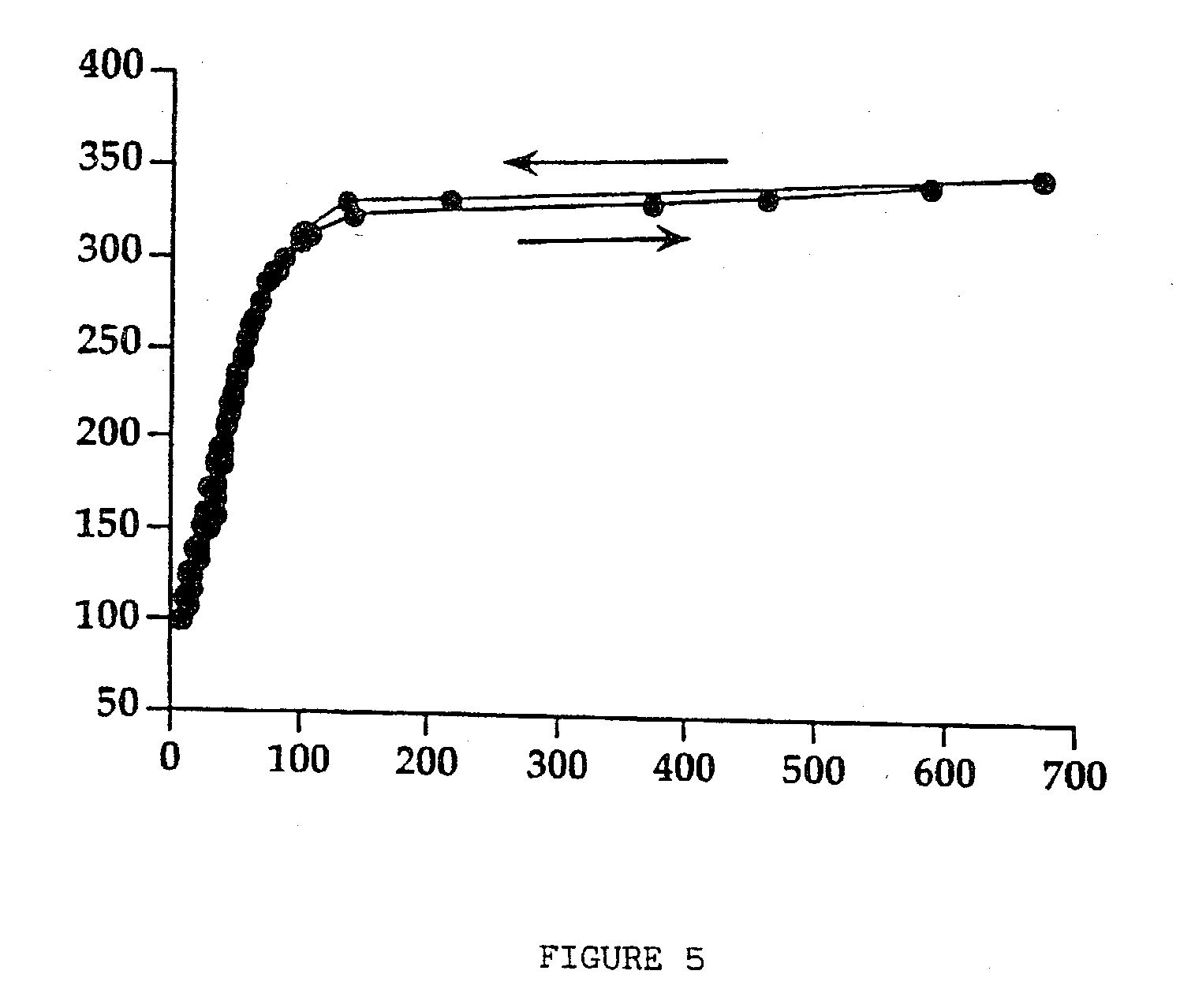

ActiveUS20170000701A1Good curative effectCosmetic preparationsAluminium compoundsPolymer scienceFolch solution

Activated aluminum sesquichlorohydrate (AASCH) powders and method of making are disclosed. The AASCH powder has Al:Cl atomic ratio of from about 1.60 to about 1.90 and Band III polymer concentration of at least about 20% and Band IV polymer concentration of at least about 15% when analyzed with Size Exclusion Chromatogram (SEC) operated by High Performance Liquid Chromatograph (HPLC). The method of making the active comprises (a) diluting the concentrated aluminum sesquichlorohydrate (ASCH) solution to from about 10% to about 25% by weight and (b) heating the diluted solution to obtain a Band III polymer concentration of at least about 20% and a Band IV polymer concentration of at least about 15%, and (c) drying the heated solution to powders having Al:Cl ratio of about 1.60 to about 1.90 and (d) optionally screen or light mill the powders to free flowing spherical particles.

Owner:NEW YORK UNIV IN ABU DHABI CORP +1

Isonaringin extraction and separation process

ActiveCN111018929AHigh product contentRaw materials are easy to getSugar derivativesSugar derivatives preparationNaringinIsonaringin

The invention provides an isonaringin extraction and separation process, which belongs to the technical field of plant extraction. The isonaringin extraction and separation process comprises the following steps: (1) carrying out reflux extraction on an extraction raw material by using an extraction agent to obtain a flavone concentrated solution; (2) adjusting the pH value of the flavone concentrated solution to 7.5-8.5 by using an inorganic acid, standing, carrying out suction filtration, and taking a mother solution, namely, a liquid containing isonaringin; (3) continuing to adjust the pH value to 5-7 with an inorganic acid, uniformly stirring, carrying out crystallizing, and carrying out suction filtration to obtain a crude isonaringin product; (4) adding the crude isonaringin product into a polar organic solvent, heating the organic solvent to dissolve the crude isonaringin product, carrying out filtering to remove insoluble impurities, carrying out concentrating and crystallizing,carrying out suction filtration, carrying out washing with water, and carrying out drying to obtain a semi-finished isonaringin product; and (5) dissolving the semi-finished isonaringin product witha polar organic solvent, stirring for dissolving, carrying out filtering to remove impurities, adding pure water to dilute the solution, stirring, standing for crystallization, carrying out suction filtration, carrying out washing with pure water to neutrality, and carrying out drying to obtain a yellow isonaringin product. Isonaringin is obtained through extraction, separation and refining, the content reaches up to 90% or above, and the purity is 95% or above.

Owner:YAAN TAISHI BIOLOGICAL SCI & TECH CO LTD

Method of preparing solution having composition of biological components

InactiveUS20070082401A1Bioreactor/fermenter combinationsBiological substance pretreatmentsElectrophoresesFluid phase

The invention provides a method of preparing a biological components-containing solution suitable for clinical proteome analysis by mass spectrometry, electrophoresis, liquid chromatography or the like and an apparatus for the method. The method of the invention is a method for combining two steps among steps of (1) adsorbing proteins having a molecular weight equal to or higher than that of albumin; (2) fractionating proteins having a molecular weight equal to or higher than that of albumin; and (3) concentrating proteins: or a method for preparing the solution by separation using a membrane separation unit having a comparative permeation ratio of 50 or higher for proteins with a molecular weight less than 15,000 and proteins with a molecular weight of 60,000 or higher; or a method for preparing the solution by introducing a biological components-containing raw solution into a separation membrane module and successively passing a diluting solution for circulating the solution and passing a portion of the solution through a separation membrane.

Owner:TORAY IND INC

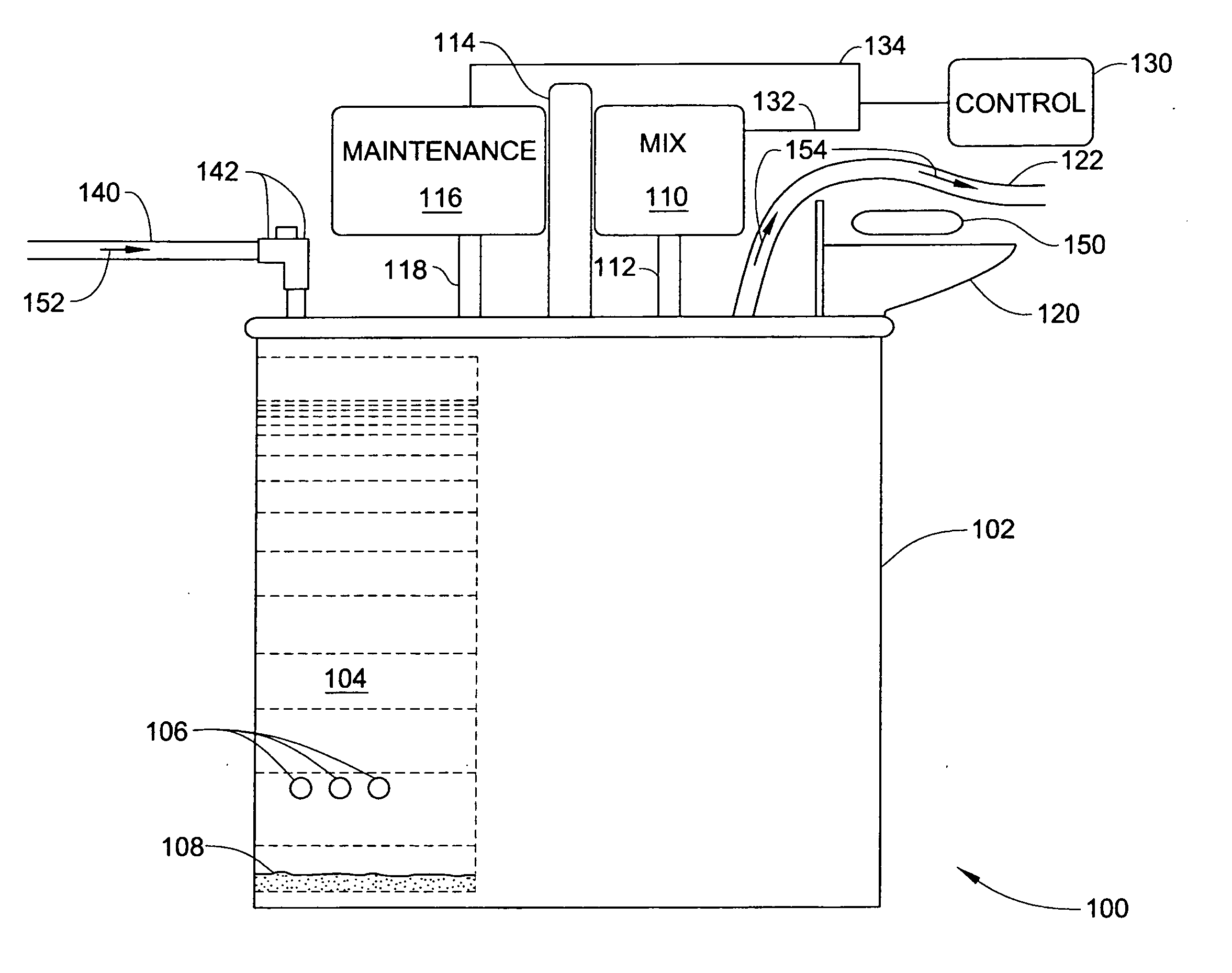

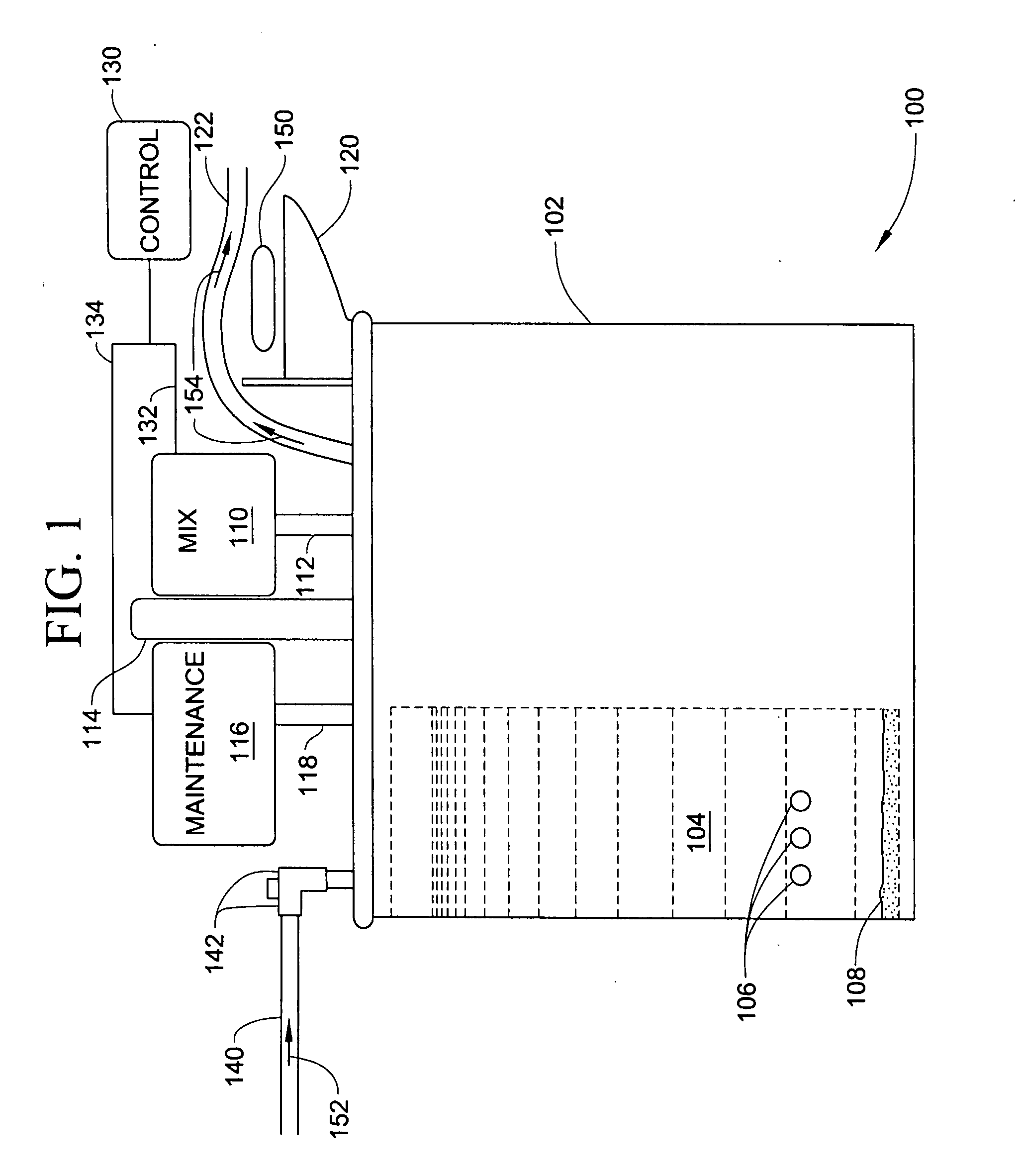

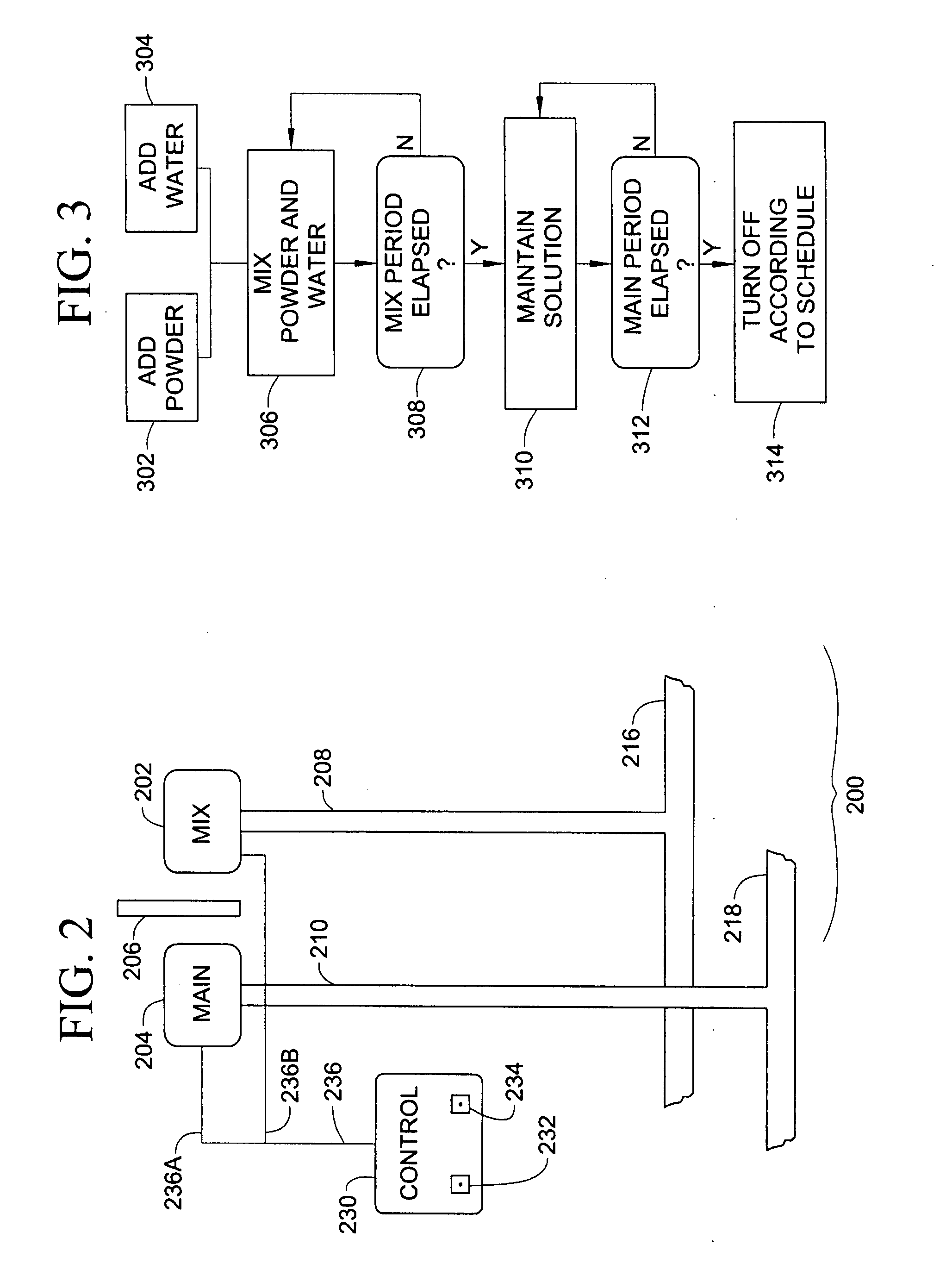

System and assembly for dissolving powders and/or diluting concentrated liquids to obtain a solution having desired concentrations of a plurality of solutes

InactiveUS20080013402A1Avoid cloggingMixing methodsTransportation and packagingEngineeringFolch solution

A system and assembly for mixing powder and liquid into a solution and maintaining the powder in the solution is disclosed. A mixing device operates an agitator to mix the powder and the liquid at a certain power level. The mixing device operates for a period of time, and then turns off. A maintenance device then operates another agitator to maintain the powder in the solution to reduce the amount of residue or sediment that settles in the container. The maintenance device operates at a lower power level than the mixing device. A dilution chamber is connected to the container to further dilute the solution for use in commercial or industrial applications.

Owner:KELLEY CARL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com