Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

175 results about "Ethenone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ethenone is the formal name for ketene, an organic compound with formula C₂H₂O or H₂C=C=O. It is the simplest member of the ketene class. It is a tautomer of the even less stable ethynol.

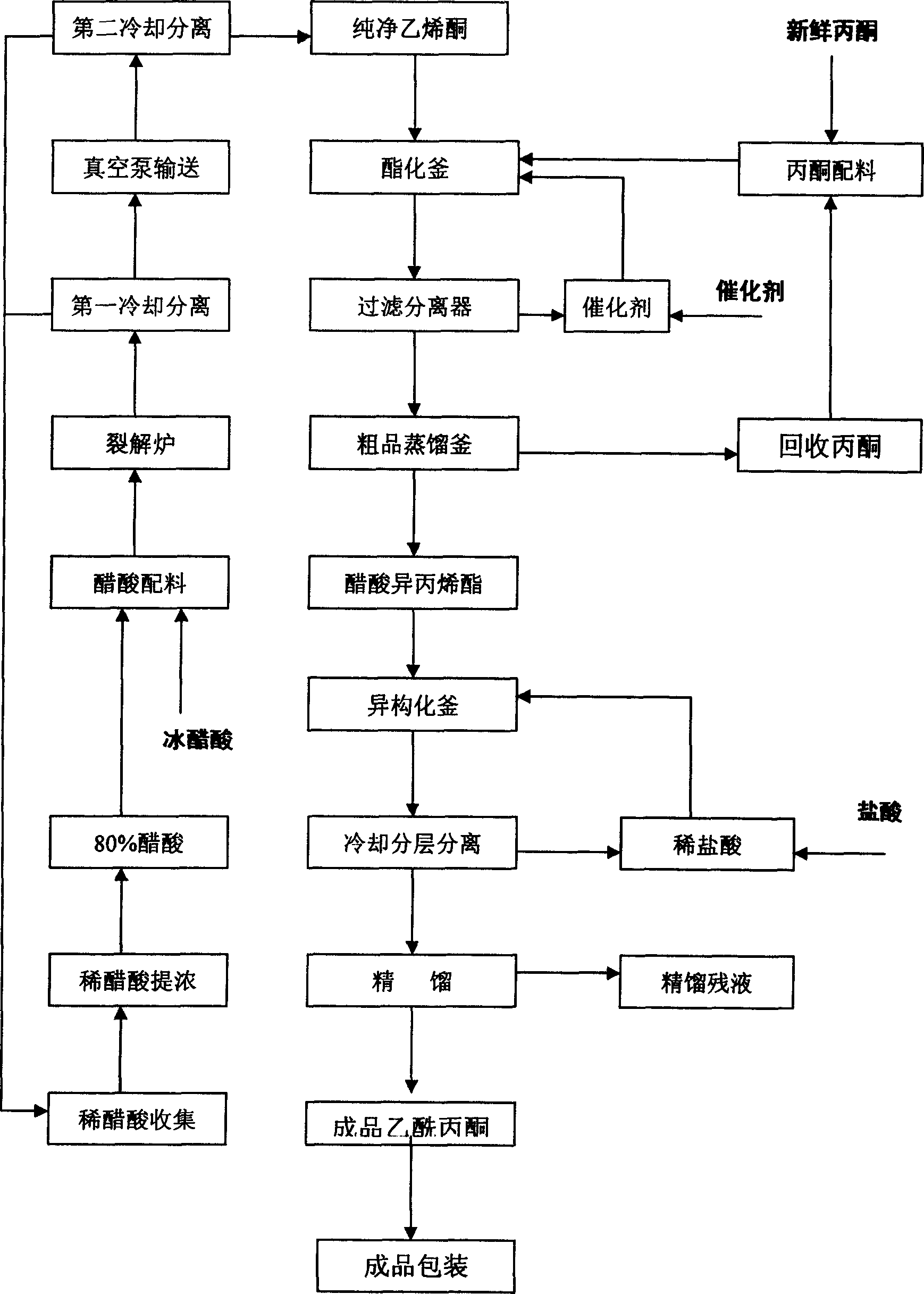

Process for preparing high-purity acetylacetone

InactiveCN1850763AQuality improvementGuaranteed purityOrganic compound preparationCarbonyl compound preparationAcetylacetoneDistillation

This invention relates to high purity acetylacetone preparation method, it contains ketene preparation method, acetone esterification technique, ester liquor distillation and isomerization technique and acetylacetone rectification technique. Acetone selected from fresh acetone process is mixed with crude distilled and unreacted acetone selected from recovery process through acetone matching process, and then they are cooled by cryogen. Cold acetone prepared during matching process is filled into esterifying kettle, stibium, cobalt and manganese complex esterification catalyst are added, and pure ketene is filled into the kettle and is absorbed by esterification system. The catalysts in synthesized mixed ester liquor is eliminated through filtration separator process, the ester liquor from filtration is filled into crude steam kettle for crude steaming, then it is filled into acetic acid iso propylene ester process to get acetic acid iso-propylene ester. Then the ester get is filled into isomerization kettle for isomerization, muriate acid is added and temperature is risen, then crude acetylacetone is got after the acetic acid iso propylene ester rearrangement. High purity acetylacetone is got after rectification.

Owner:王龙集团有限公司

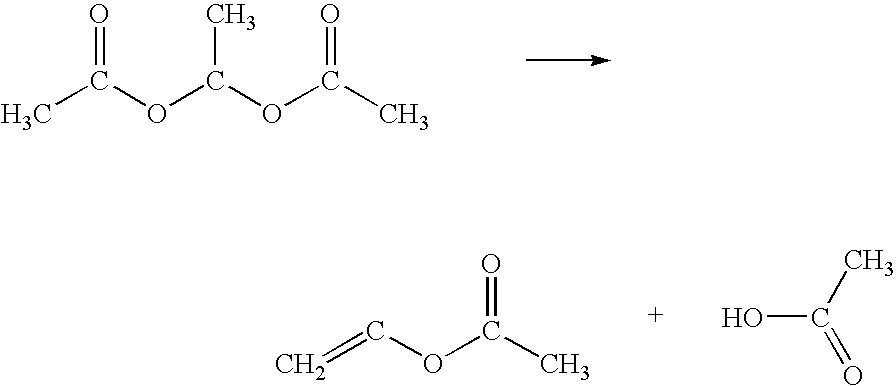

Integrated process for the production of vinyl acetate from acetic acid via acetaldehyde

InactiveUS20100168466A1High selectivity and yieldOrganic compound preparationPreparation from ketenes/polyketenesAcetic anhydridePalladium

This invention provides an integrated multistep economical process for the production of vinyl acetate monomer (VAM) from acetic acid in the vapor phase. First, acetic acid is selectively hydrogenated over a hydrogenating catalyst composition to form acetaldehyde. Acetaldehyde so formed can be converted to ethylidene diacetate via reaction with acetic anhydride. In a subsequent step so formed ethylidene diacetate is thermally decomposed to form VAM and acetic acid. Alternatively, acetaldehyde formed in the first step can selectively be reacted with ketene to form VAM. In an embodiment of this invention reaction of acetic acid and hydrogen over platinum and iron supported on silica selectively produces acetaldehyde in a vapor phase at a temperature of about 300° C., which is selectively hydrogenated over platinum supported catalyst to form ethanol and dehydrated over NAFION catalyst to form ethylene at a temperature of about 185° C., which is mixed with molecular oxygen, acetic acid and reacted over a palladium / gold / potassium catalyst supported on titania to form VAM at a temperature of about 150° C. to 170° C.

Owner:CELANESE INT CORP

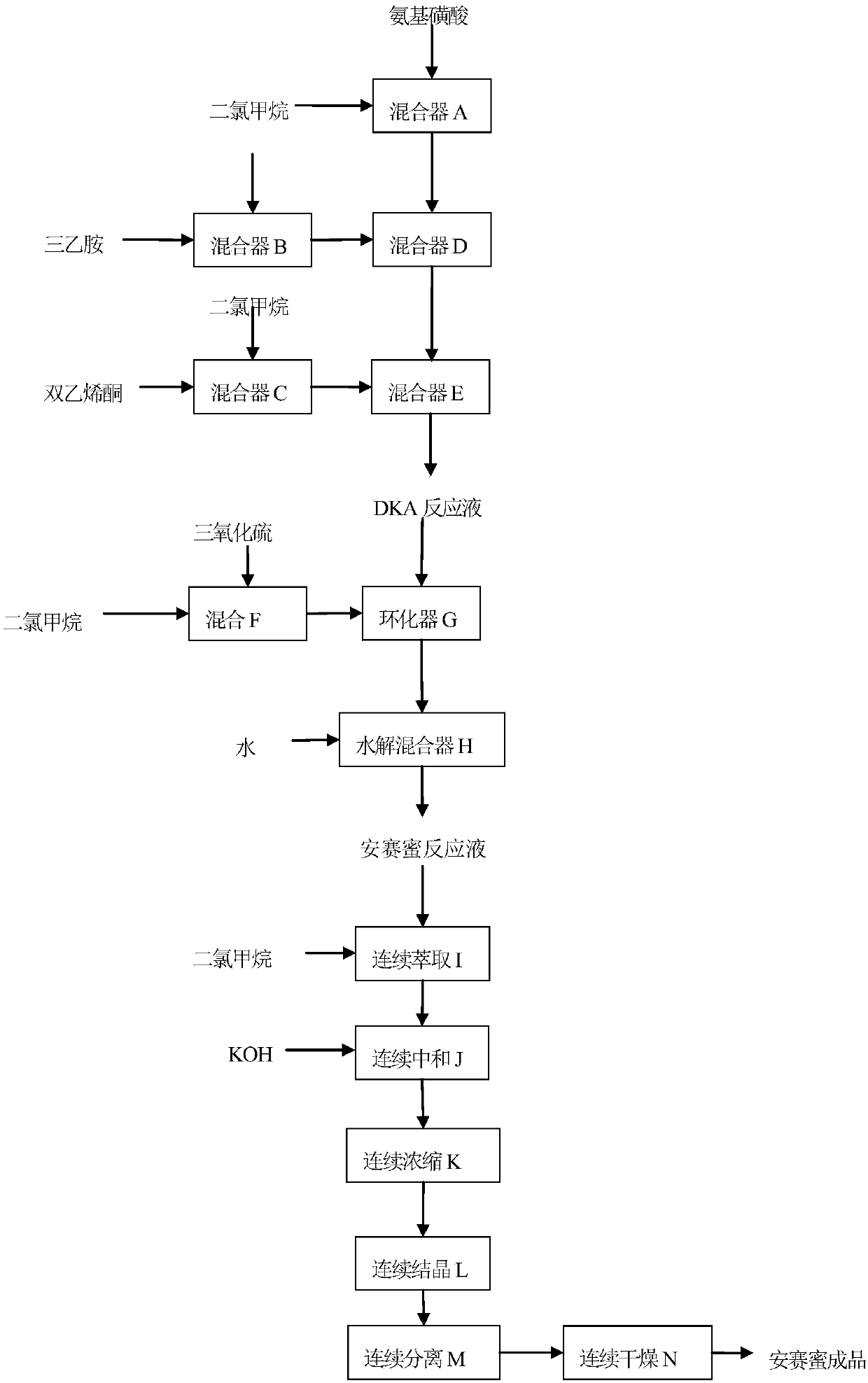

Method for continuously producing acesulfame potassium

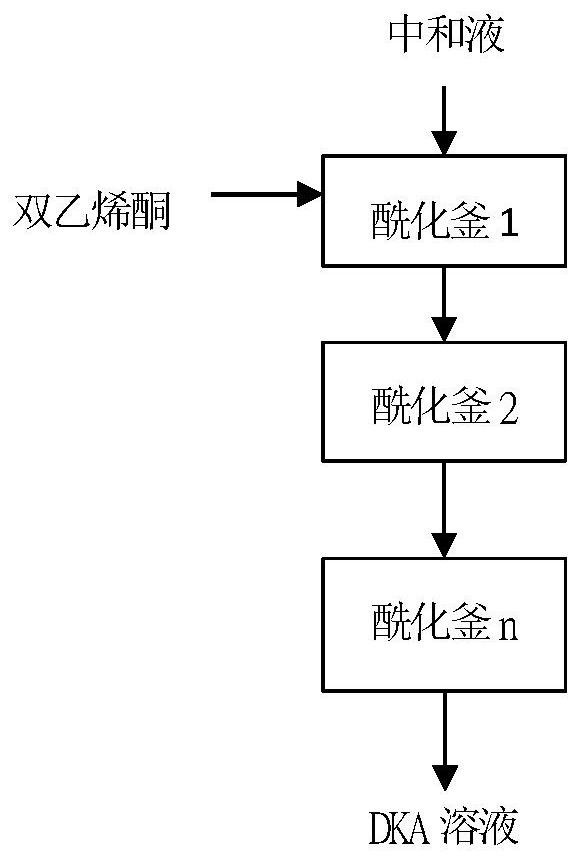

The invention belongs to the field of chemical production, and provides a method for continuously producing acesulfame potassium, which comprises the following steps: continuously mixing and dissolving sulfamic acid and dichloromethane, continuously neutralizing with a triethylamine solution, introducing the neutralized reaction solution and ketene dimer into a continuous reactor, and carrying outaddition acylation reaction to obtain a DKA reaction solution; sulfur trioxide and solvent micro-mixing: S03, enabling dichloromethane to enter a micro-mixer, so as to prepare a cyclizing agent; cyclization and hydrolysis: continuously feeding the DKA reaction solution and a cyclizing agent into a cyclization microreactor to generate a cyclization reaction solution, and continuously feeding the cyclization reaction solution into a hydrolysis microreactor to obtain an acesulfamic acid reaction solution; enabling the acesulfame acid reaction liquid and dichloromethane to enter continuous extraction equipment, enabling an extracted organic phase and a potassium hydroxide aqueous solution to enter a continuous neutralization reactor to obtain acesulfame acid potassium reaction liquid, and subjecting the acesulfame acid potassium reaction liquid to continuous concentration, continuous crystallization, continuous separation and continuous drying to obtain the acesulfame acid potassium finished product. The process has the characteristics of simple process, low cost, good product quality, continuous whole process and the like.

Owner:NANTONG ACETIC ACID CHEM +1

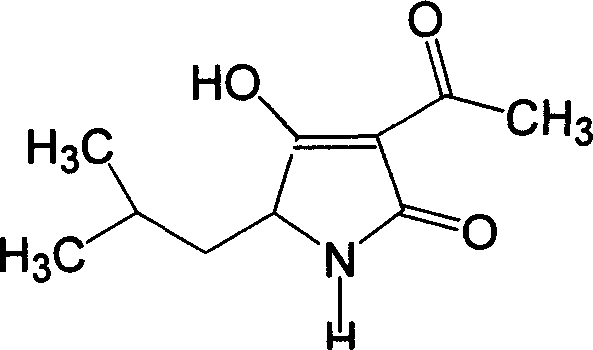

Synthesis of tenuazonic acid and iso-tenuazonic acid

InactiveCN1817859AProduction equipment requirements are simpleSimple and fast operationOrganic chemistryAlcoholTenuazonic acid

Synthesis of tenuazonic acid and isotenuazonic acid is carried out by taking amino acid as initial material, esterifying by alcohol, neutralizing by sodium alcoholate, acidylating by diketene, cyclizing and acidifying under the existence of sodium alcoholate to obtain final product. It is simple, safe and cheap, has more yield and better quality.

Owner:NANJING AGRICULTURAL UNIVERSITY

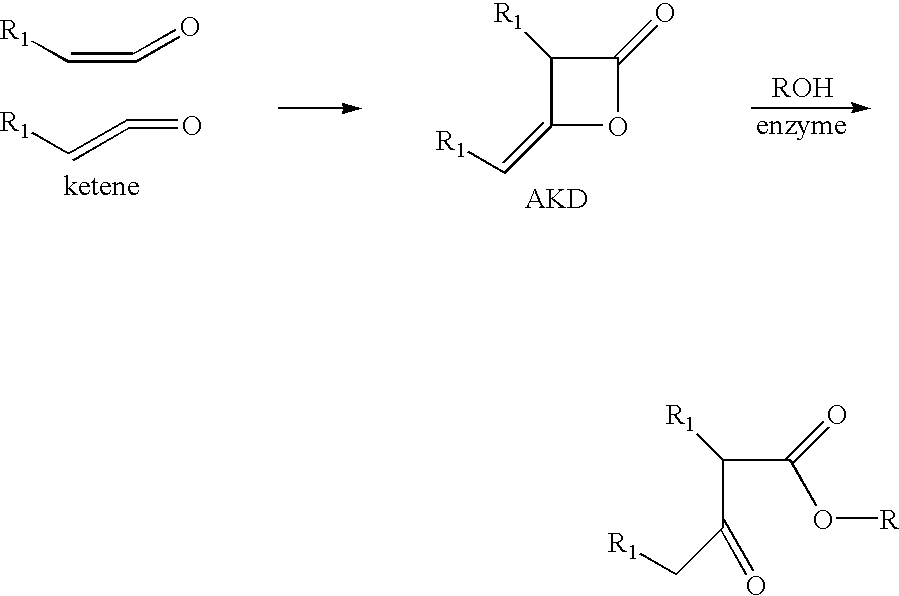

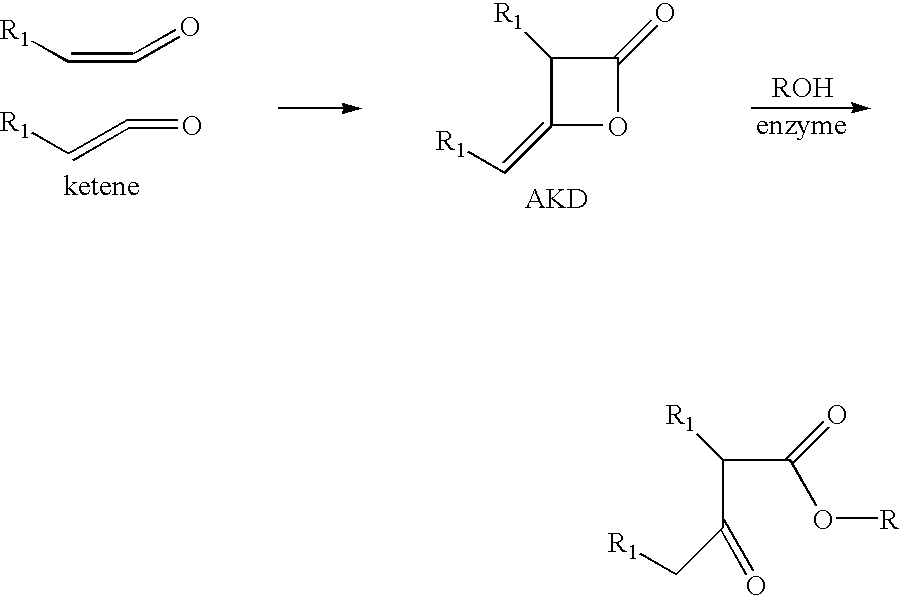

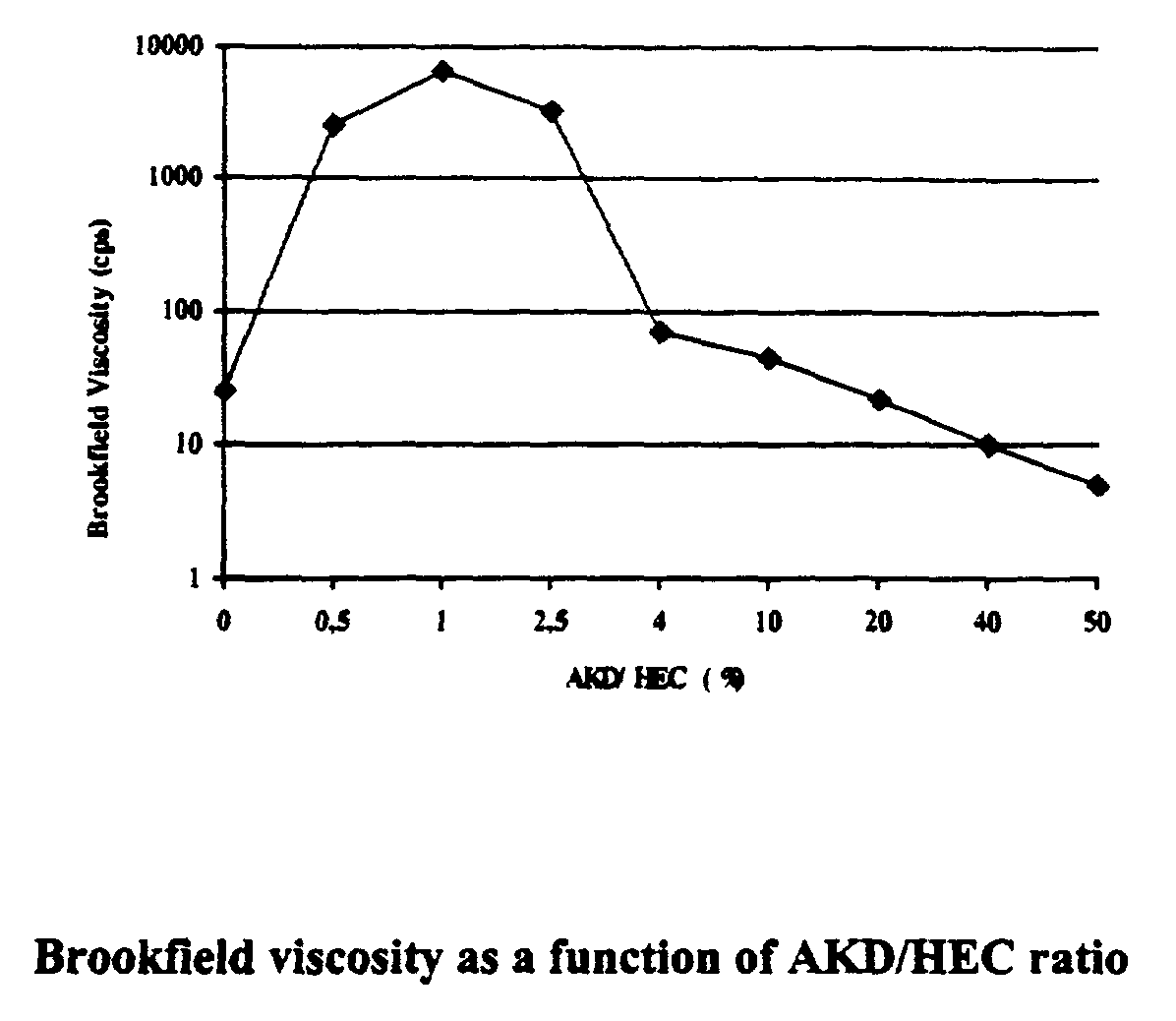

Esterified polysaccharide products and beta-lactone ring opened ketene dimer products containing the compositions, and process of making the same

Esterified polysaccharides and the process of making such products are disclosed. The process can be enzymatic where an enzyme is used as a catalyst for the reaction. The process can also be chemical where no enzyme is used. Novel Products are obtained through lipase-catalyzed beta-lactone ring opening alcoholysis of ketene dimers and the process of making such compositions containing products.

Owner:SOLENIS TECH CAYMAN

Continuous acylation synthesis method in acesulfame potassium synthesis

The invention belongs to the field of chemical production, and particularly relates to a continuous acylation synthesis method in acesulfame potassium synthesis, wherein the method comprises the following steps: partially paving a synthesis material of sulfamic acid and triethylamine, namely a neutralization reaction solution, dropwisely adding a certain amount of diketene, reacting to obtain a preparation solution, continuously feeding the neutralization reaction solution and diketene into a reactor, and carrying out continuous acylation reaction to obtain a DKA reaction solution. Compared with traditional single-kettle intermittent dropwise adding of diketene, the method has the advantages that the heat exchange speed is increased, the production period is shortened, the production efficiency is improved, and meanwhile, the problems of unstable quality, potential safety hazards and the like caused by manual operation are solved.

Owner:NANTONG ACETIC ACID CHEM +1

High-efficiency environment-friendly ketene dimer production technique

ActiveCN104262299AReduce analytic phenomenaReduce aggregationOrganic chemistryPtru catalystEthylic acid

The invention discloses a high-efficiency environment-friendly ketene dimer production technique which comprises the following steps: (1) gasifying an acetic acid water solution into acetic acid gas, mixing with a catalyst phase, and cracking in a cracking furnace at 680-698 DEG C to generate ketene gas, wherein the outlet pressure of the cracking furnace is controlled at the absolute pressure value of 2-20 KP; (2) delivering the purified ketene gas to an absorption unit with a vacuum pump, wherein the pressures before and after the pump are respectively 2-20 KP and 100-120 KP, and the temperature difference change of the absorption liquid is controlled to be less than 10 DEG C; (3) respectively sending the absorption liquid into a high temperature polymerization tank and a low temperature polymerization tank to perform primary and secondary polymerization, thereby obtaining the crude product ketene dimer; (4) carrying out vacuum rectification on the crude product ketene dimer to obtain a ketene dimer finished product; and (5) under the action of a combustion-supporting oxidizing gas medium, delivering the rectification residue to a combustion furnace to perform oxidation treatment while controlling the delivery pressure at 6-10 kgf / cm<2>. The technique has the advantages of fewer side reactions, high product yield and no solid waste generation.

Owner:南通宏信化工有限公司

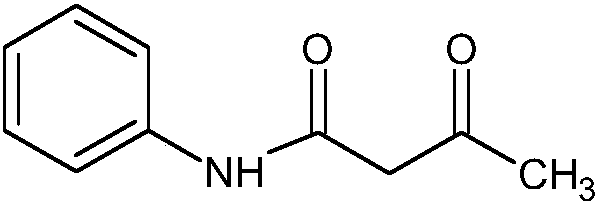

Preparation method for N-acetyl acetanilide

ActiveCN103224455APrevent mutual condensationReduce the amount of waterOrganic compound preparationCarboxylic acid amide separation/purificationBiotechnologyEthenone

The invention relates to a preparation method for N-acetyl acetanilide. The method comprises the following steps of adding N-acetyl acetanilide crystal seeds and an emulsifying agent to deionized water at a temperature of 0-10 DEG C to carry out a reaction; then dropwise adding diketene and aniline simultaneously under the control of a certain temperature; keeping the reaction at the temperature; cooling to a temperature of 0 DEG C; filtering and drying to obtain the N-acetyl acetanilide. The method has the advantages of effectively preventing product caking, improving product appearance and performance, increasing product yield and greatly reducing wastewater quantity.

Owner:NANTONG ACETIC ACID CHEM

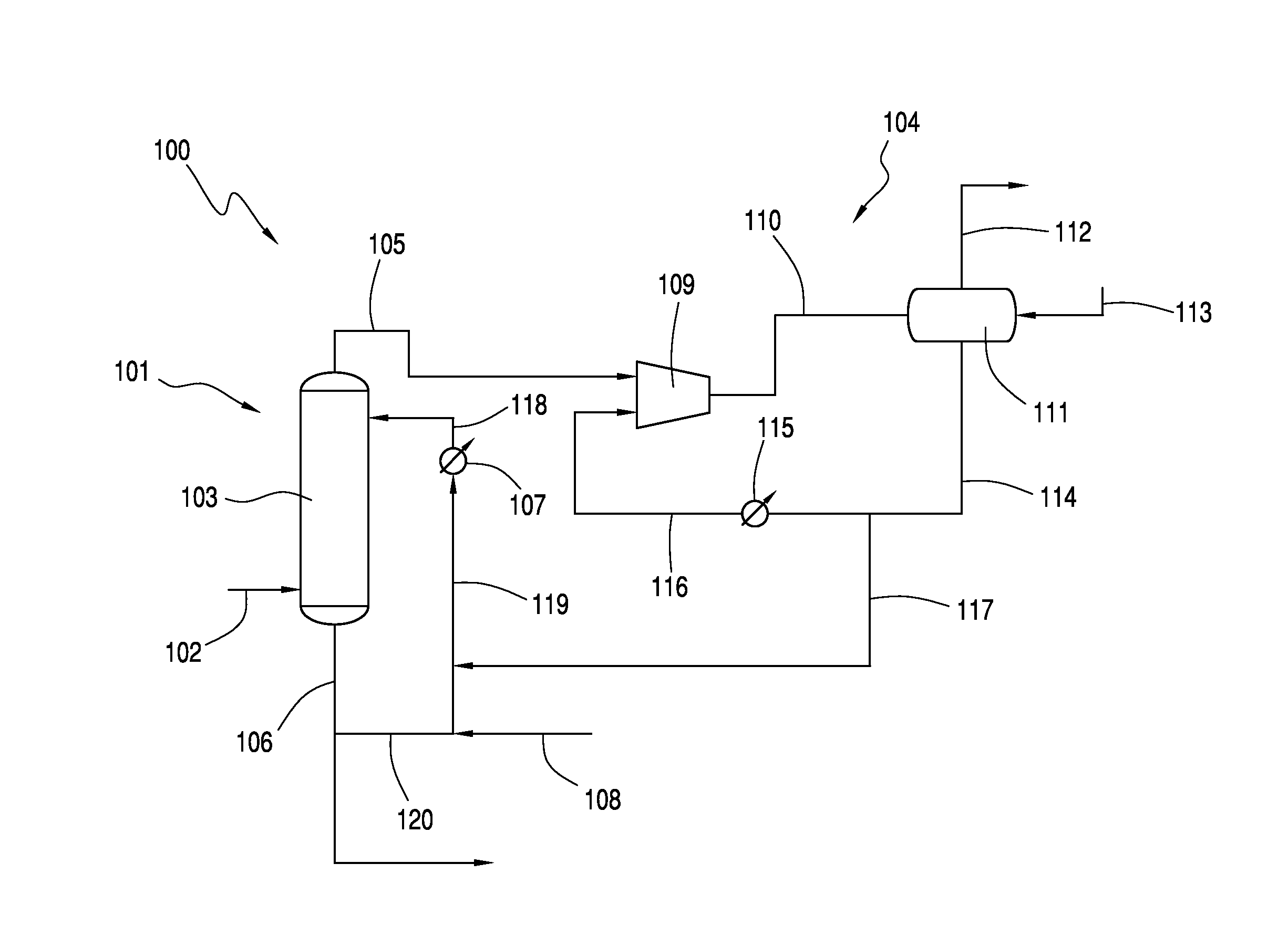

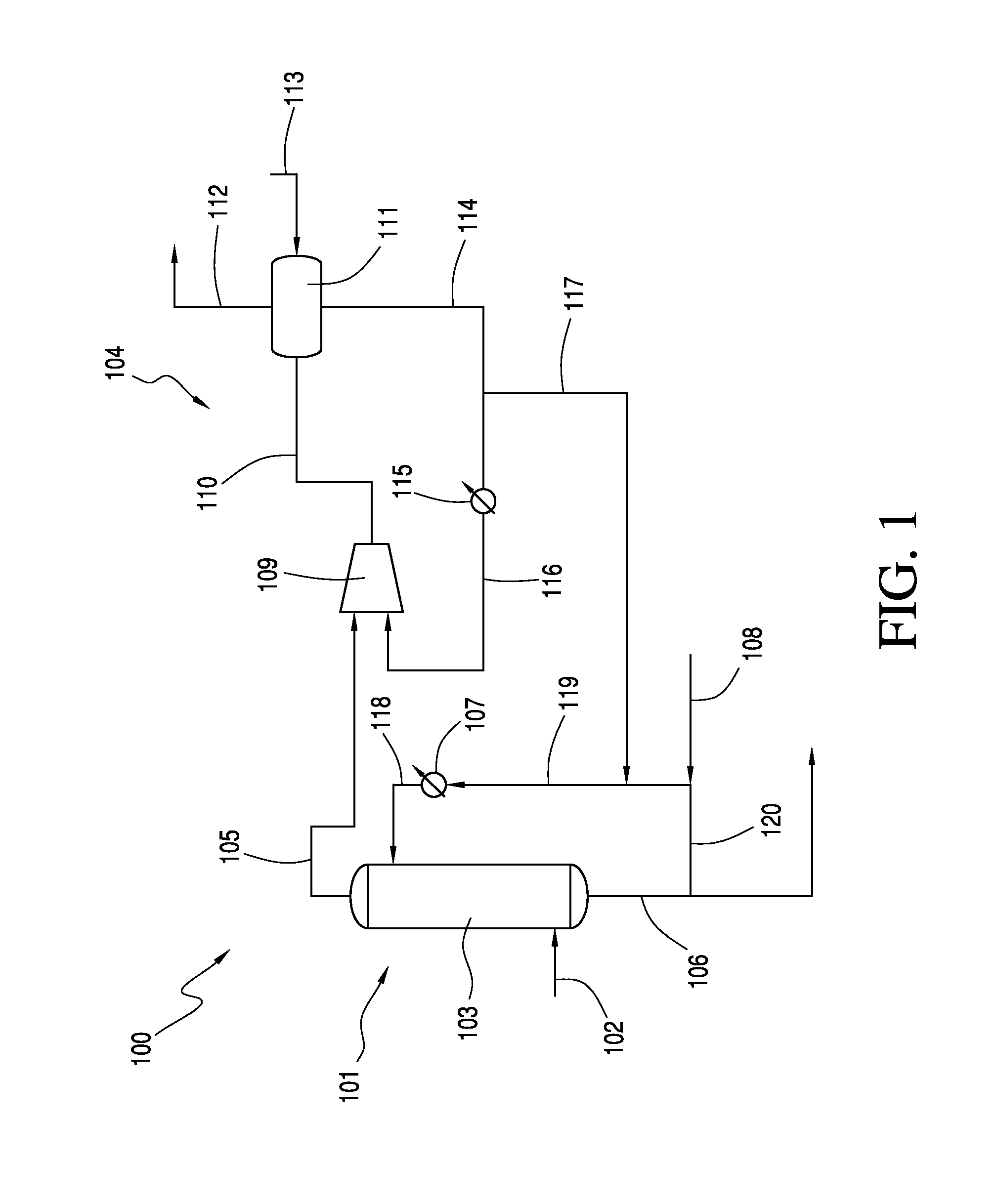

Processes for Preparing Acetic Anhydride

ActiveUS20130197267A1Organic compound preparationCarboxylic preparation from carbon monoxide reactionAcetic acidAcetic anhydride

In one embodiment, the invention is to a process for producing acetic anhydride. The process includes at least a step of carbonylating methanol and / or a methanol derivative with carbon monoxide to form acetic acid, and contacting ketene with the acetic acid to form a crude acetic anhydride product stream and a vent stream having unreacted ketene. The process further comprises a step of directing at least a portion of the vent stream to a liquid ring vacuum compressor having a ring seal fluid comprising acetic acid The unreacted ketene in the portion of the vent stream contacts the ring seal fluid to form supplemental acetic anhydride.

Owner:CELANESE INT CORP

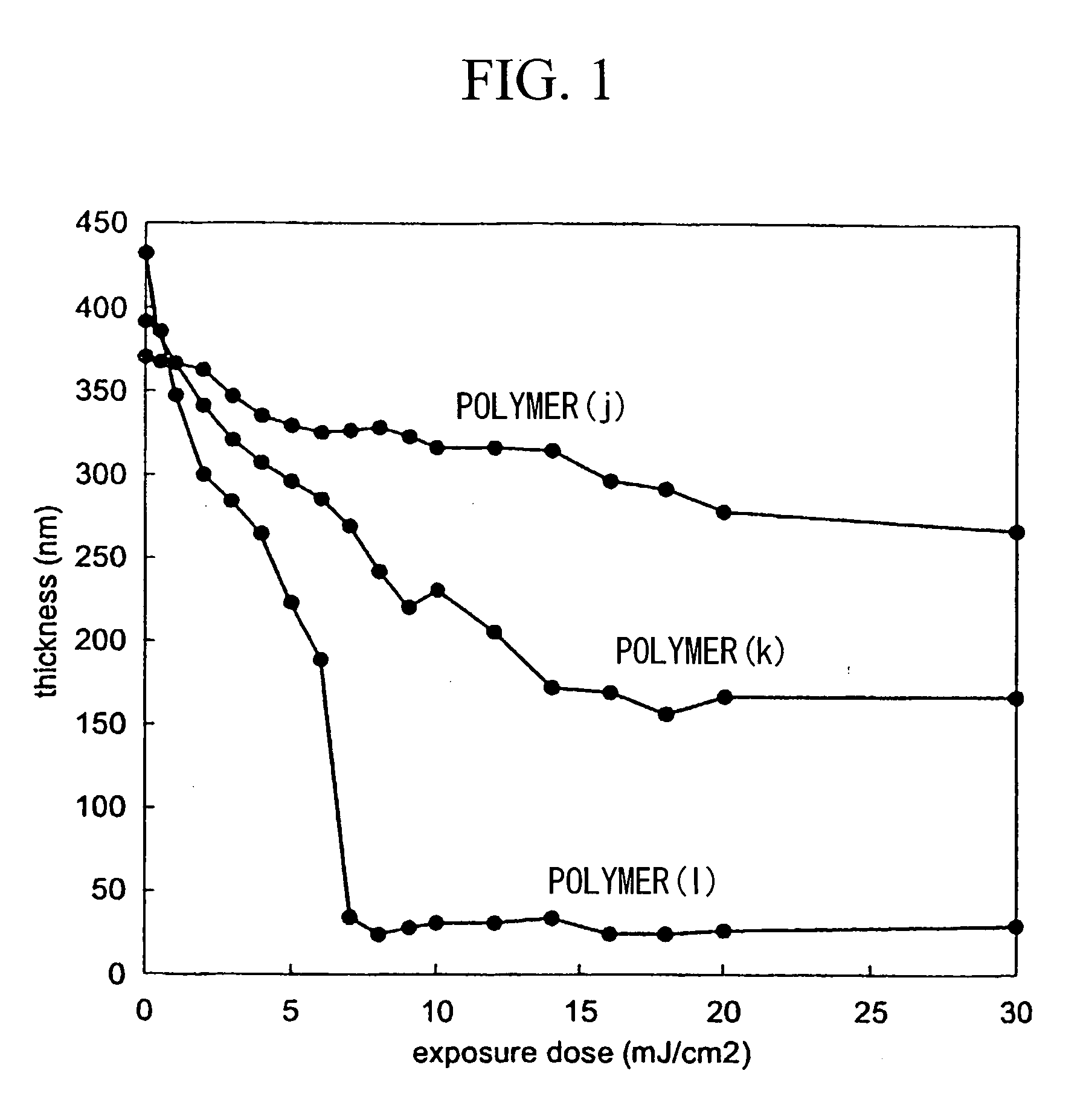

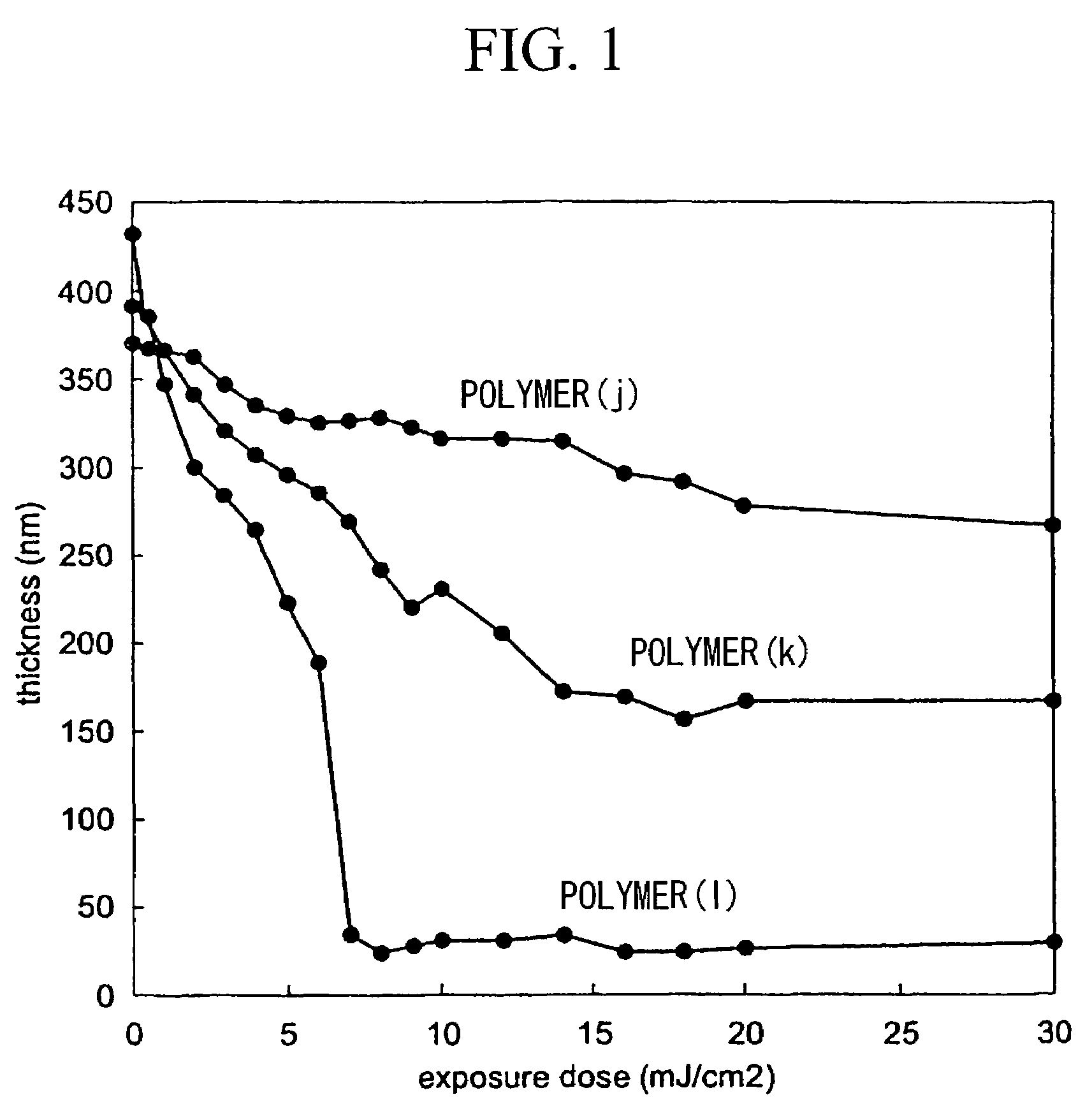

Acid-degradable resin compositions containing ketene-aldehyde copolymer

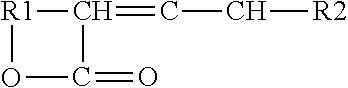

InactiveUS20050130057A1Good light transmissionEasy to shapeImpression capsPhotomechanical apparatusSolubilityResist

It is intended to provide compositions to be used in resists and the like for forming fine patterns with a high sensitivity and a high resolution by increasing the difference in the solubilities between exposed parts and unexposed parts. Acid-degradable compositions contain a polymer having a repeating unit represented by the following general formula (I): wherein R1 and R2 independently represent hydrogen atom, halogen atom, C1-20 hydrocarbon group, a heterocyclic group, a cyano group, a nitro group, C(═O)R4 group, S(O)nR4 group, P(═O)(R4)2 group or M(R4)3 group; R3 represents C1-20 hydrocarbon group or a heterocyclic group: R4 represents C1-20 hydrocarbonoxy group, C1-20 hydrocarbon group, C1-20 hydrocarbonthio group or mono- or di-C1-20 hydrocarbonamino group; M represents a silicon, germanium, tin or lead atom; and n is 0, 1 or 2, and an acid or a compound capable of generating an acid in response to an external stimulus.

Owner:NIPPON SODA CO LTD

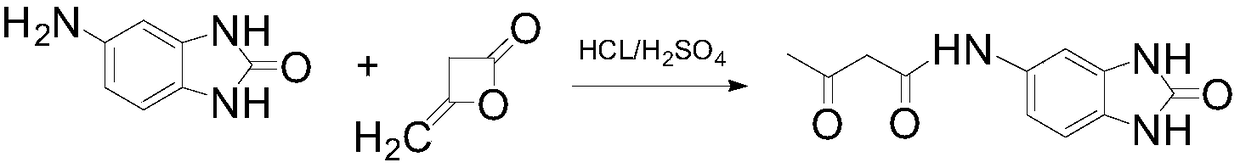

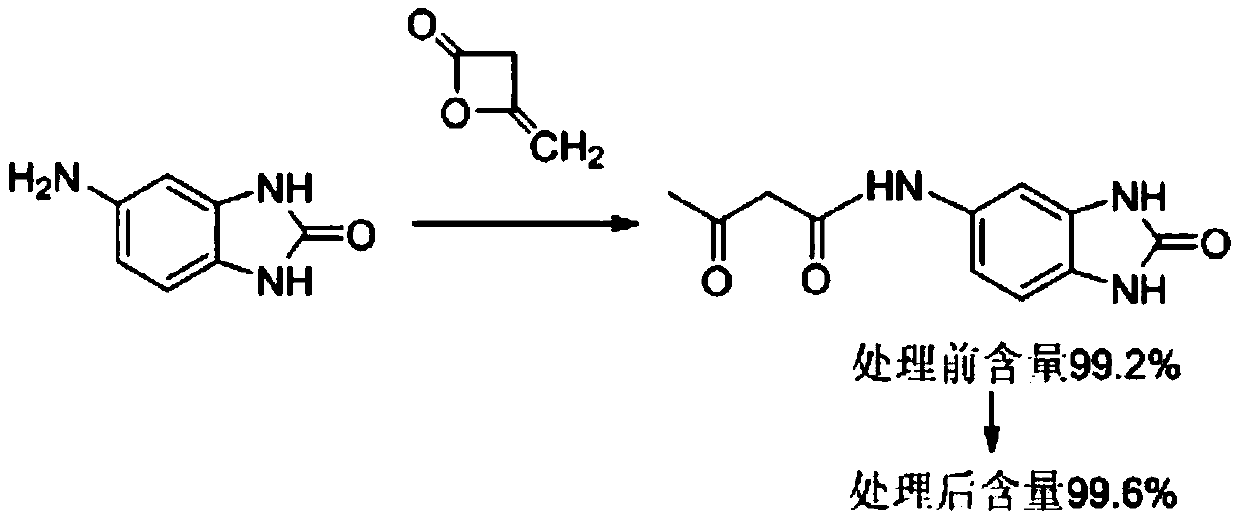

Preparation method of high-purity 5-acetylacetylaminobenzimidazolone

InactiveCN109232435AReduce the impactThe process is simple and easy to controlOrganic chemistryActivated carbonEnvironment effect

The invention discloses a preparation method of high-purity 5-acetylacetylaminobenzimidazolone. According to the technical essentials, the preparation method comprises the following steps: under an acidic condition, adding 5-aminobenzimidazolone, sodium hydrogen sulfite, activated carbon and water and reacting at 65 to 70 DEG C; performing suction filtration to obtain intermediate filtrate; addingdiketene and sodium hydroxide into the filtrate and reacting at 60 to 65 DEG C to obtain the 5-acetylacetylaminobenzimidazolone. The purity of a product obtained by the preparation method is greaterthan 99.5 percent and the yield is greater than 87 percent. The preparation method disclosed by the invention has the advantages of simple and easy-to-control technology, safety in operation, small influences on environment and low production cost.

Owner:SHANDONG HUIHAI PHARMA & CHEM

Treating method and treating device for ketene dimer production residues

ActiveCN103113186AEasy to handleEfficient recyclingOxygen-containing compound preparationOrganic compound preparationPlate heat exchangerEthenone

Owner:ANHUI JINGHE IND

Acid-degradable resin compositions containing ketene-aldehyde copolymer

InactiveUS7105272B2Good light transmissionEasy to shapeImpression capsPhotomechanical apparatusResistSolubility

It is intended to provide compositions to be used in resists and the like for forming fine patterns with a high sensitivity and a high resolution by increasing the difference in the solubilities between exposed parts and unexposed parts. Acid-degradable compositions contain a polymer having a repeating unit represented by the following general formula (I):wherein R1 and R2 independently represent hydrogen atom, halogen atom, C1-20 hydrocarbon group, a heterocyclic group, a cyano group, a nitro group, C(═O)R4 group, S(O)nR4 group, P(═O)(R4)2 group or M(R4)3 group; R3 represents C1-20 hydrocarbon group or a heterocyclic group: R4 represents C1-20 hydrocarbonoxy group, C1-20 hydrocarbon group, C1-20 hydrocarbonthio group or mono- or di-C1-20 hydrocarbonamino group; M represents a silicon, germanium, tin or lead atom; and n is 0, 1 or 2, and an acid or a compound capable of generating an acid in response to an external stimulus.

Owner:NIPPON SODA CO LTD

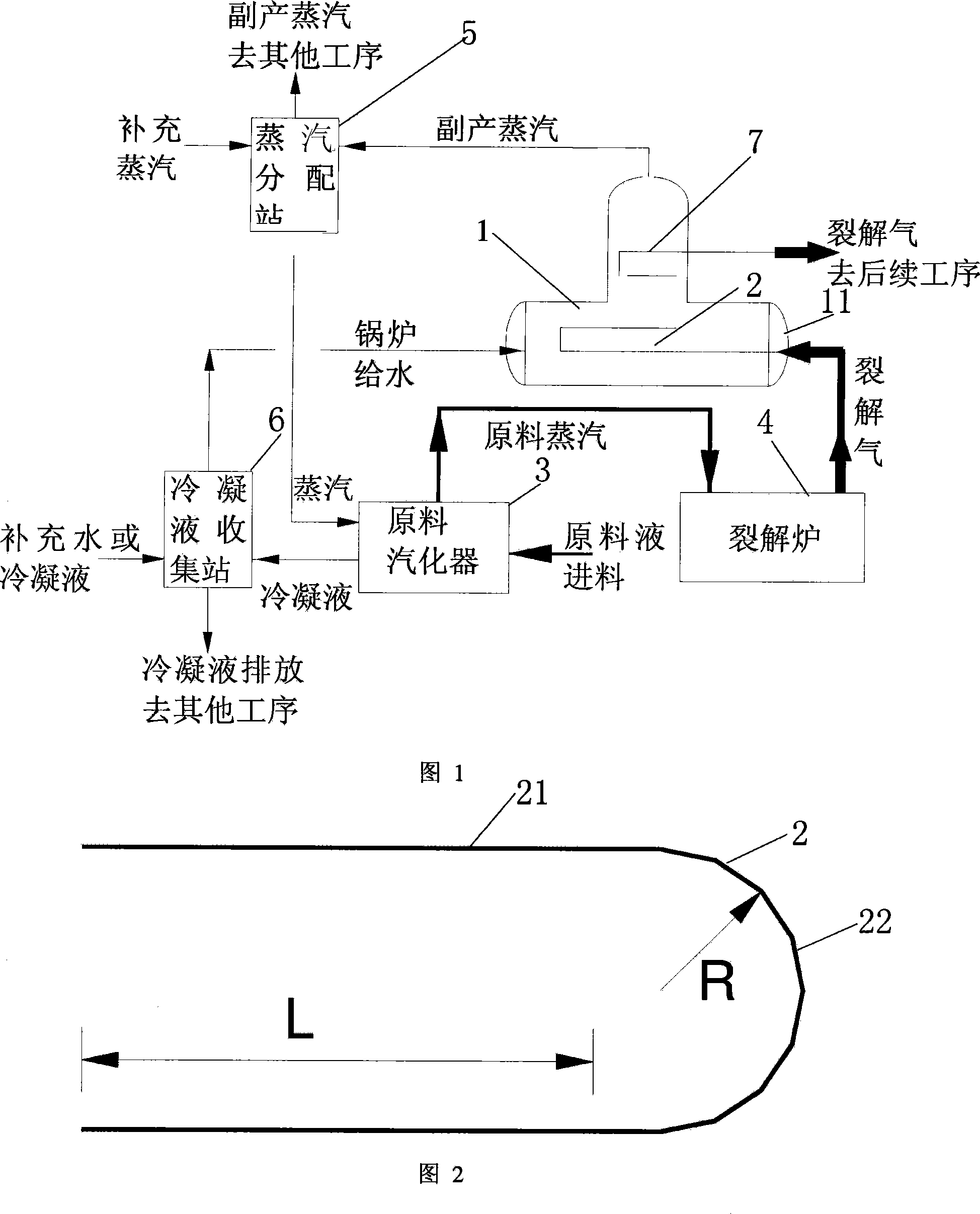

Cracking gas heat comprehensive utilization method and exhaust heat boiler using the method

InactiveCN101451702ARealize indirect comprehensive utilizationAchieve recyclingKetenes preparationSteam generation using hot heat carriersAcetic acidWater resources

The invention discloses a method for utilizing heat of cracking gas in production field of preparation of ketene and derivatives thereof by cracking raw materials like acetic acid or acetone so on and waste heat boiler used in the method. The method uses high pressure cracking gas as heating source by-product steam of the waste heat boiler. The by-product steam of the waste heat boiler can be used as supplement steam of raw material vaporizer and the steam condensate discharged by the raw materials vaporizer can be used as supplement water of the boiler, thus realizing indirect comprehensive utilization of the heat of the cracking gas and recycling of steam and water resources.

Owner:SHANGHAI WUJING CHEM

Preparation method of dehydroacetic acid and sodium salt thereof

The invention provides a preparation method of a dehydroacetic acid. The preparation method sequentially comprises the following steps: a condensation reaction step and an after-treatment step. The preparation method is characterized in that in the condensation reaction step, after a catalyst and a polymerization inhibitor are added into a toluene solvent, ketene dimer is dropwise added, and the heat is preserved to generate a toluene dehydroacetic acid solution; in the after-treatment step, the obtained toluene dehydroacetic acid solution is cooled, filtered, washed and centrifuged to obtain the dehydroacetic acid; and the catalyst is an ethylenediamine acetate catalyst. The invention further provides a preparation method of sodium acetate dehydrogenation, wherein the preparation method comprises the following steps of adding sodium hydroxide into the toluene dehydroacetic acid solution which is obtained in the condensation reaction step; neutralizing and adjusting pH; carrying out active carbon decoloration; and condensing and crystallizing to obtain the sodium acetate dehydrogenation. According to the preparation method of the dehydroacetic acid provided by the invention, excessive polymerization of the ketene dimer is reduced, the side reaction is reduced, and the yield of dehydroacetic acid is improved. The invention further provides a preparation method of the sodium acetate dehydrogenation, wherein the dehydroacetic acid is not needed to be separated, and the yield of sodium dehydroacetate is improved.

Owner:NANTONG ACETIC ACID CHEM

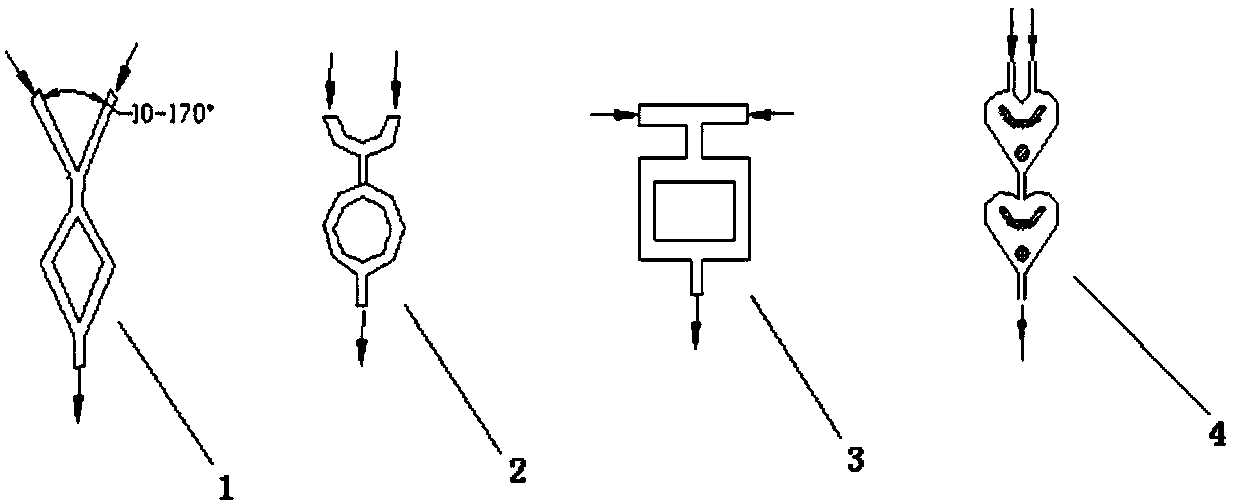

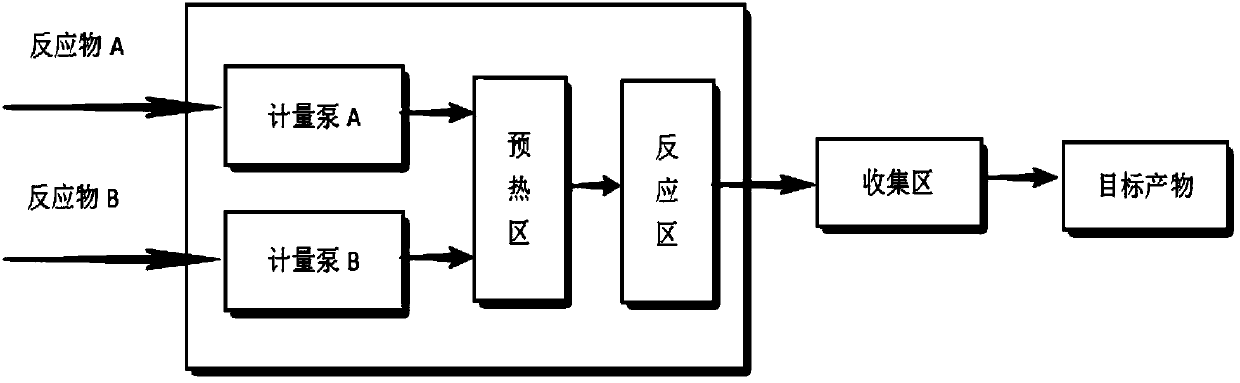

Method for continuously producing methyl acetoacetate by using micro-channel reactor

InactiveCN111039785AExtended service lifeShort reaction timePreparation from ketenes/polyketenesWater methanolPtru catalyst

The invention discloses a method for continuously producing methyl acetoacetate by using a micro-channel reactor, and belongs to the technical field of organic synthesis processes. Diketene and absolute methanol are used as raw materials, an acid or alkali is used as a catalyst, and the preparation process of methyl acetoacetate is continuously completed in a micro-channel reactor system. According to the method, after materials are fed into a micro-channel reactor through metering pumps, preheating, mixing, reacting and separation are performed to obtain a methyl acetoacetate product. In themethod, the temperature and the residence time during the reaction process can be strictly controlled, the reaction temperature can be accurately controlled so as to prevent temperature runaway, and the safety of the reaction apparatus can be improved; due to the strong mass transfer effect of the micro-channel reactor, the mass transfer effect among the raw materials in the reaction system is enhanced, and the reaction efficiency is greatly improved.

Owner:CHANGZHOU UNIV

Continuous preparation method of acetoacetamido triethylamine sulfonate

PendingCN111377834ASimple processLow costOrganic compound preparationSulfuric acid amide preparationReaction temperatureDiketene

The invention discloses a continuous preparation method of acetoacetamido triethylamine sulfonate, comprising the following steps of: continuously mixing and dissolving sulfamic acid and dichloromethane, continuously neutralizing with a triethylamine solution to obtain a neutralization reaction solution, introducing the neutralization reaction solution and diketene into a continuous reactor, and carrying out addition acylation reaction to obtain a DKA reaction solution; wherein the molar ratio of n (sulfamic acid) to n (dichloromethane) in the continuous mixing and dissolving process is 1: (1-20), and the temperature is 0-40 DEG C; in the continuous neutralization, the pH of the neutralization is equal to 7-9, and the neutralization temperature is 10-40 DEG C; in the addition acylation reaction, the molar ratio of n (sulfamic acid) to n (diketene) is 1: (0.5-1.5), the acylation reaction temperature is 0-30 DEG C, and the acylation retention time is 0.01 s to 30 min. The invention provides a process for continuously preparing a DKA solution. The process is simple, low in cost, continuous in the whole process and high in yield.

Owner:NANTONG ACETIC ACID CHEM +1

Method for preparing acetoacetoxy ethyl methacrylate

InactiveCN105541625AResolve separation difficultiesHigh purityOrganic compound preparationPreparation from ketenes/polyketenes(Hydroxyethyl)methacrylateDistillation

The invention discloses a method for preparing acetoacetoxy ethyl methacrylate, which comprises the following steps: mixing hydroxyethyl methacrylate, a polymerization inhibitor, a catalyst and a solvent, and dropwisely adding ketene dimer at 30-160 DEG C; and after the dropwise addition is finished, carrying out thermal reaction under the temperature condition above until the reaction finishes; and after the thermal reaction finishes, distilling to remove the solvent, and continuing distillation to obtain the acetoacetoxy ethyl methacrylate. The method is simple in technique. The product has the advantages of high yield, high purity and stable quality.

Owner:WEIFANG KEMAI CHEM CO LTD

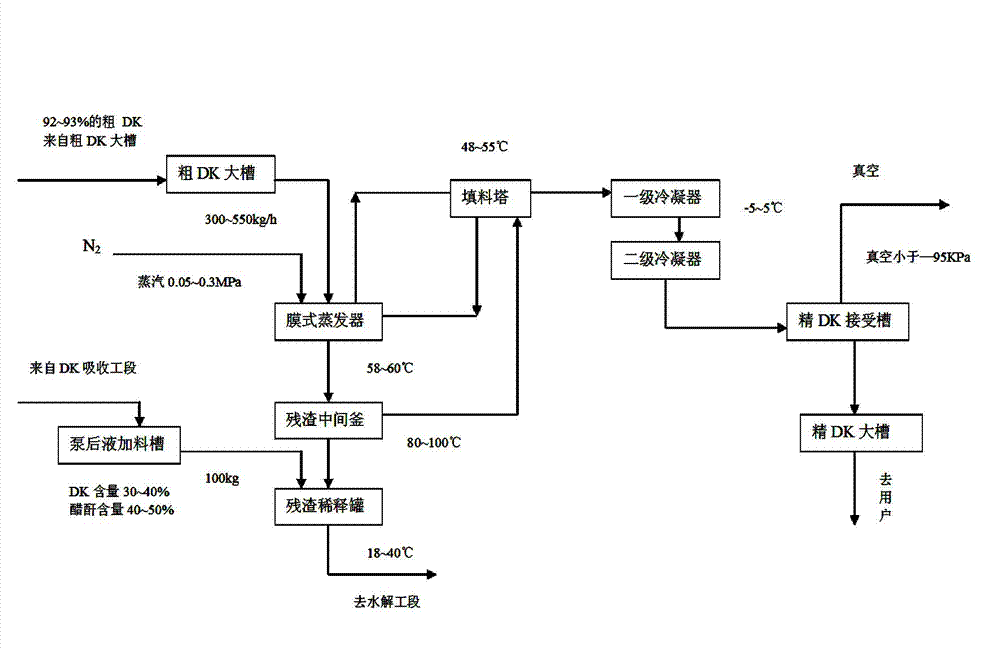

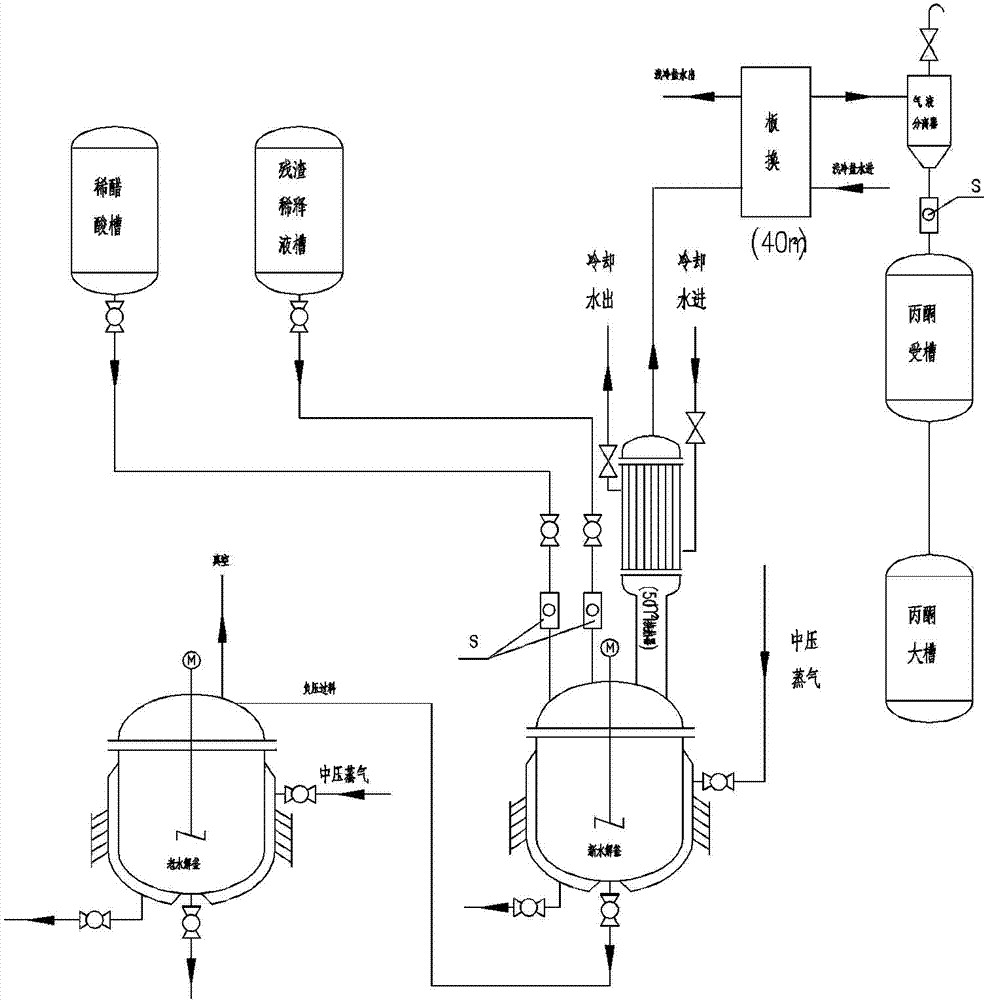

Method for purifying acetone from waste residue and waste water produced in ketene dimmer production process

InactiveCN105111052AReduce manufacturing costIncrease productionCarbonyl compound preparation by hydrolysisCarbonyl compound separation/purificationEthylic acidEthenone

The invention discloses a method for purifying acetone from a waste residue and waste water produced in the ketene dimmer production process. The waste residue is residue diluent, and waste water is concentrated waste water. The method is characterized by comprising three steps that firstly, the residue diluent and dilute acid react to generate acetone; secondly, acetone is recycled from the concentrated waste water; thirdly, the acetone obtained in the first step and the acetone obtained in the second step are mixed for rectification and purification. By the adoption of the method for acetone recycling and purification, the yield can be increased, the content is significantly improved, the additional value is greatly increased, part of the acetic acid in acetone sold externally can be recycled, and the ketene dimmer production cost is effectively saved.

Owner:ANHUI JINGHE IND

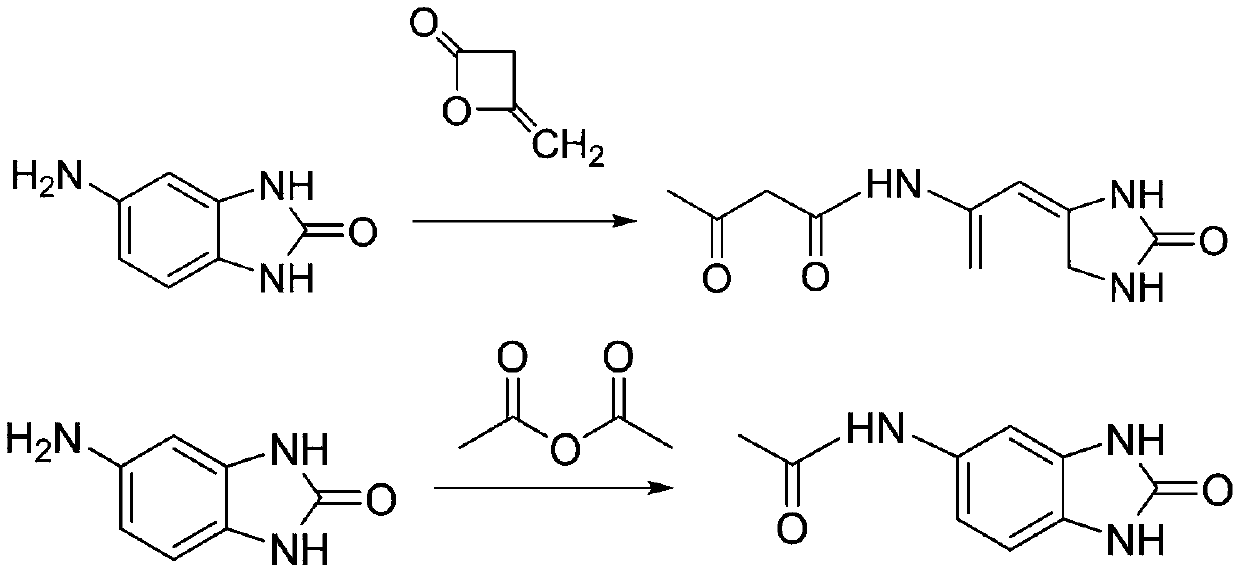

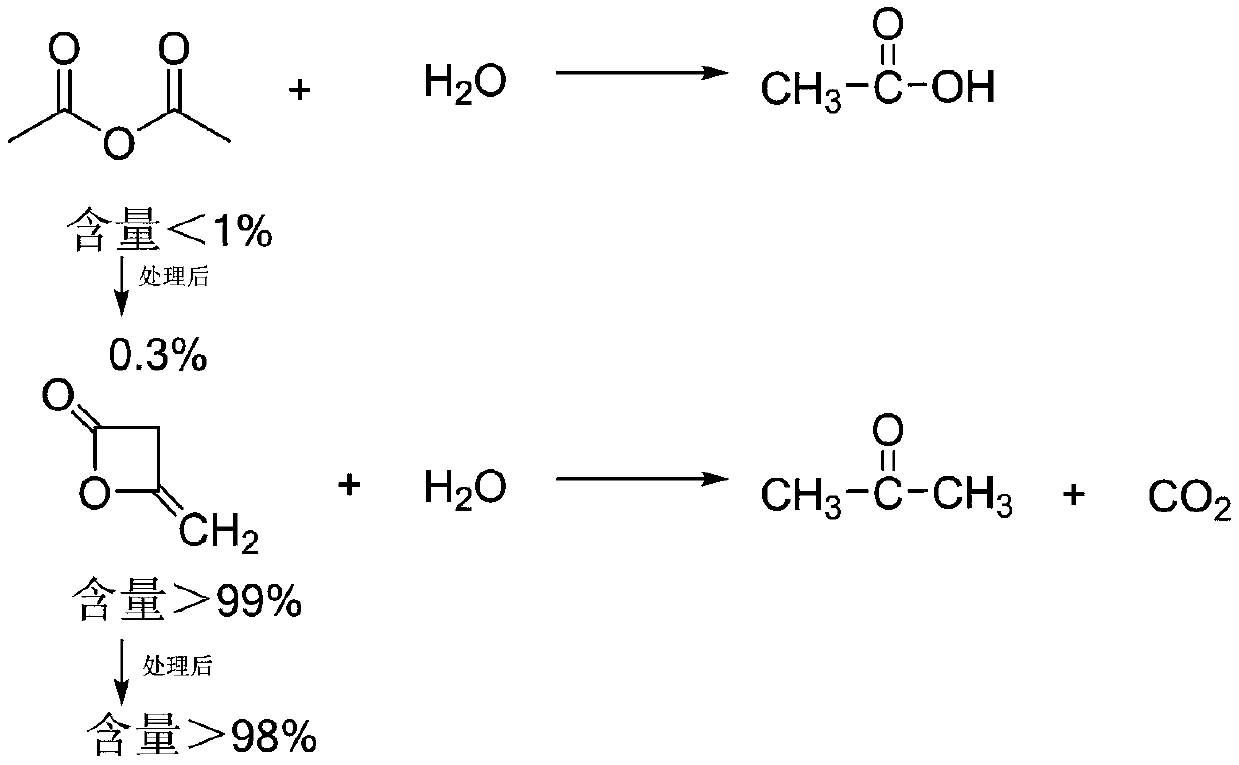

Method for improving quality of 5-acetoacetlaminobenzimdazolone

The invention relates to a method for improving the quality of 5-acetoacetlaminobenzimdazolone. The method comprises the following steps: pre-treating diketene and water at a low temperature to make acetic anhydride in diketene react with water to form acetic acid, then raising the temperature and dropwise adding the treated diketene into 5-aminobenzimidazolone, performing heat preservation for 30min, performing cooling to 45 DEG C, performing material pressing, and performing drying to obtain 5-acetoacetlaminobenzimdazolone. After the pretreatment of diketene and water at the low temperature, acetic anhydride in diketene can be reacted with water to form acetic acid, the purity of diketene is improved, and thus the product purity is improved, the product yield is improved, and the content of 5-acetoacetlaminobenzimdazolone after the treatment is up to 99.6%. The formation of the by-product 5-acetylaminobenzimidazolone is reduced, the by-product content is decreased to be 0.2%, the final product yield is increased, the utilization rate of raw materials is improved, the waste material amount is reduced, the environmental protection investment is reduced, and the production cost isreduced.

Owner:SHANDONG HUIHAI PHARMA & CHEM

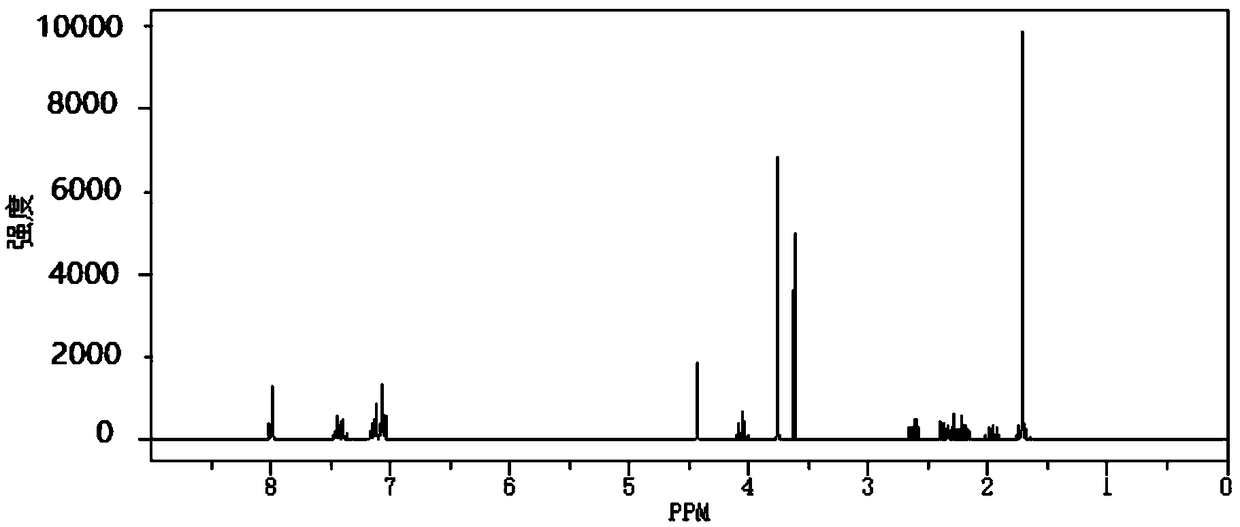

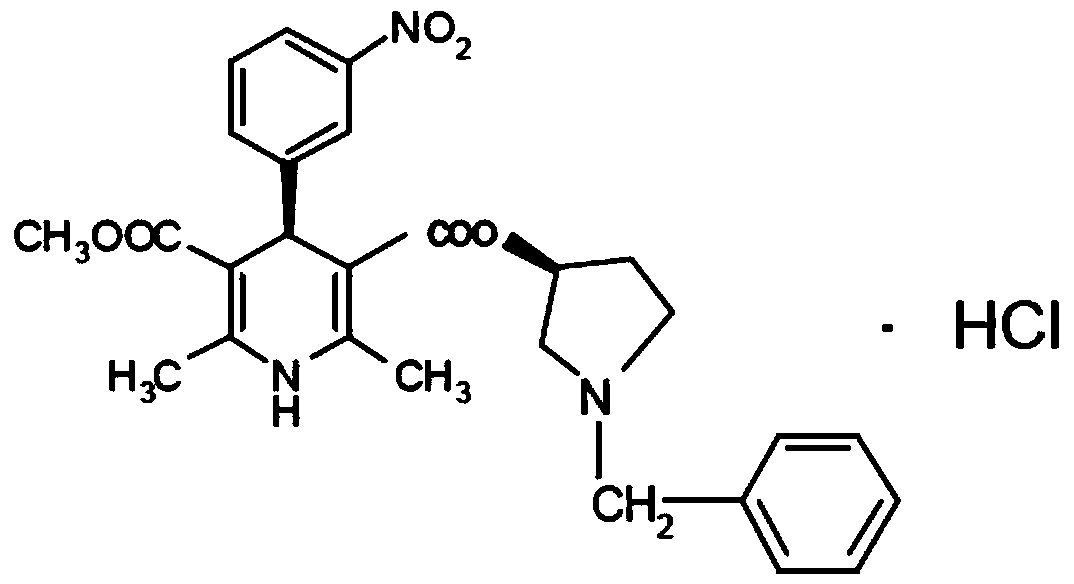

Barnidipine hydrochloride compound and preparation method thereof

The invention discloses a barnidipine hydrochloride compound and a preparation method thereof. The preparation method comprises the following steps: (1) using 3-hydroxypropionitrile to react with diketene, to obtain an intermediate 1; (2) enabling the intermediate 1 to react with m-nitrobenzaldehyde and Beta-amino methyl crotonate, to obtain an intermediate 2; (3) enabling the intermediate 2 to behydrolyzed by strong base, to obtain an intermediate 3; (4) enabling the intermediate 3 to be resolved by chiral organic base, to obtain an intermediate 4; (5) enabling the intermediate 4 to react with thionyl chloride, (S)-1-benzyl-3-pyrrolidinol, and HCI ethanol solution, to obtain a crude product of barnidipine hydrochloride; and (6) performing ethyl alcohol pulping and refining, and ethyl alcohol recrystallization on the crude product of the barnidipine hydrochloride, to obtain the barnidipine hydrochloride.

Owner:森淼(山东)药业有限公司

Treatment and utilization method of acesulfame potassium crystallization waste liquid

InactiveCN111518056AReduce manufacturing costLower potassium levelsOrganic chemistryWater contaminantsPotassium hydroxidePotassium carbonate

The invention provides a treatment and utilization method of acesulfame potassium crystallization waste liquid. Crystallized waste liquid generated in the acesulfame potassium production process is subjected to hydrogen peroxide oxidation treatment, a faded solution only containing inorganic components is obtained, a potassium salt in the waste liquid can be conveniently utilized and can be used for a neutralization reaction in the acesulfame potassium production step to partially replace potassium hydroxide, and material consumption is reduced. Directly concentrating, crystallizing and dryingare carried out to obtain a potassium carbonate byproduct; the method can also be used for preparing other sylvite products. According to the method, the production cost of acesulfame potassium can be reduced, meanwhile, the amount of discharged wastewater can be greatly reduced, the content of potassium in the wastewater is reduced, the pollution of the wastewater to the environment is reduced,and the economic, social and environmental benefits of a process for producing acesulfame potassium by using a diketene-sulfamic acid-sulfur trioxide method are improved.

Owner:ANHUI JINGHE IND

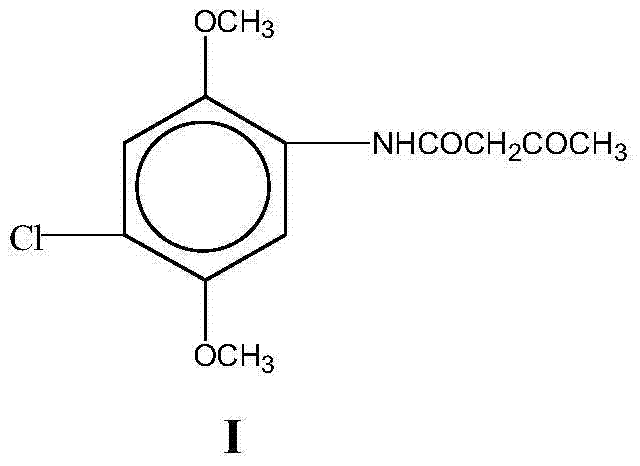

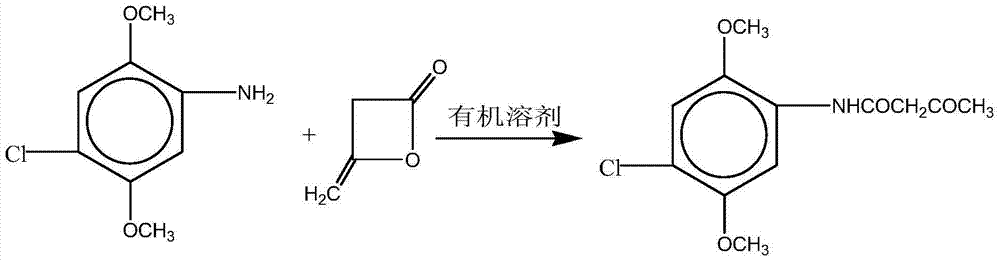

Preparation method of 4-chloro-2,5-dimethoxyacetyl acetanilide

ActiveCN104119247AFacilitate reaction transformationHigh reaction yieldOrganic compound preparationCarboxylic acid amides preparationDiketoneOrganic solvent

The invention relates to a preparation method of 4-chloro-2,5-dimethoxyacetyl acetanilide. The preparation method comprises the following implementation processes: adding an organic solvent and 4-chloro-2,5-dimethoxyaniline to a reaction vessel, dropwise adding diketone at 10-100 DEG C, completing adding diketone after about 0.5-5 hours and then carrying out heat insulation reaction for 0.5-4 hours, cooling the reactant to 0-10 DEG C after reaction is finished, carrying out emptying and filter pressing so as to obtain a crystal substance, namely 4-chloro-2,5-dimethoxyacetyl acetanilide, and circularly applying the filtrate mechanically. The method has the advantages that the obtained product has good quality and high yield; the method is low in cost, achieves zero discharge or micro-discharge of wastewater, meets the environment-friendly production requirement, is simple and convenient to operate and conveniently achieves industrialization.

Owner:XIANGSHUI HENRYDA TECH CHEM

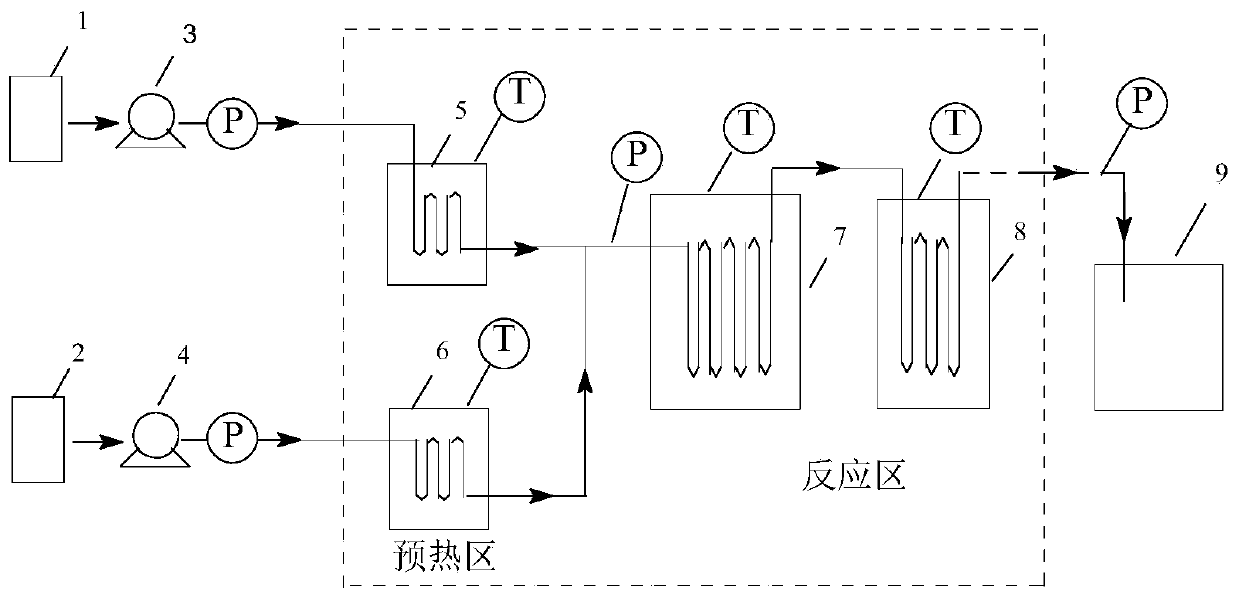

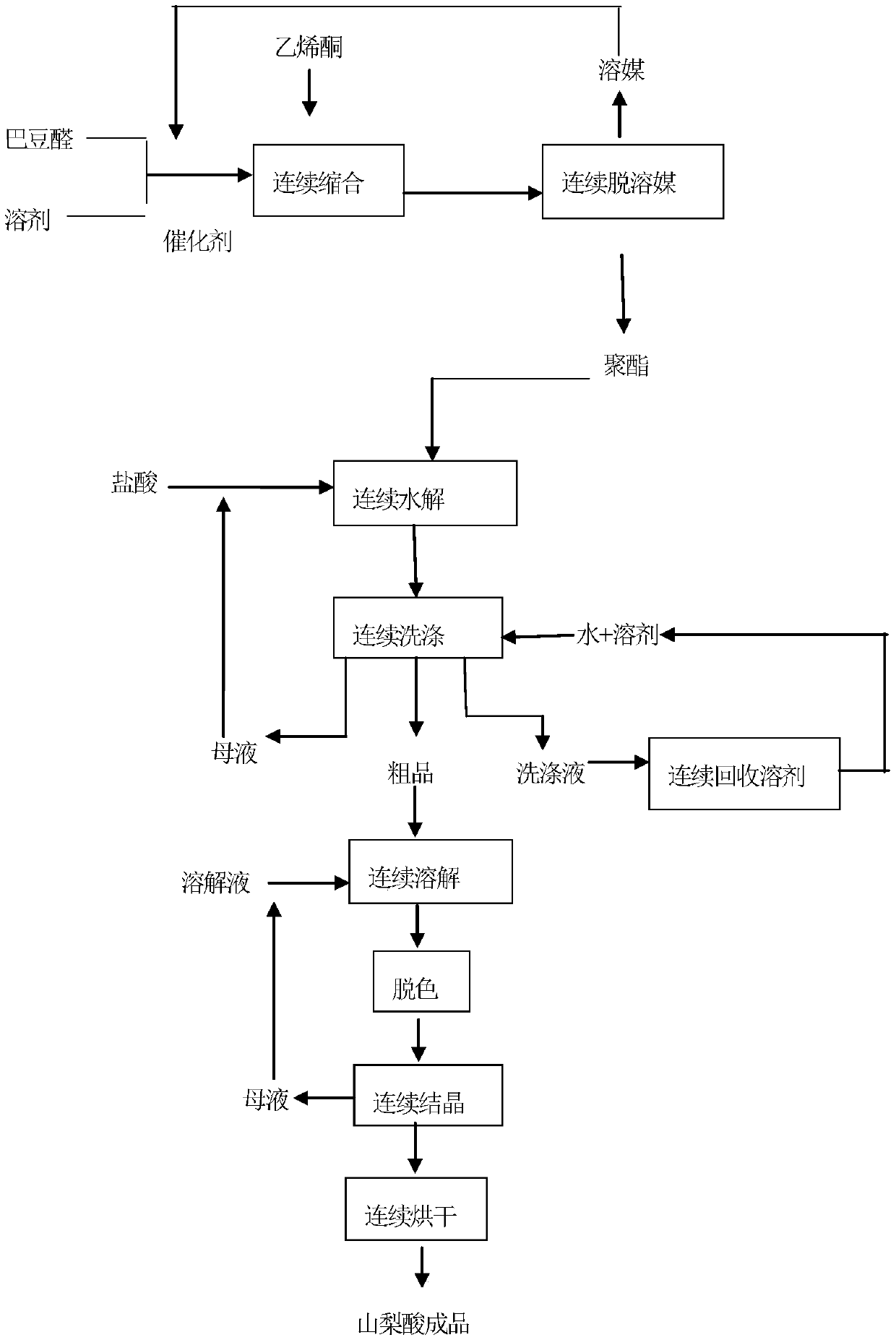

Continuous preparation method of sorbic acid

ActiveCN111377811ARealize cleaner productionBreak the bottleneck of the processPreparation from carboxylic acid esters/lactonesCarboxylic compound separation/purificationCrotonaldehydeSide reaction

The invention belongs to the field of chemical production, and provides a continuous preparation method of sorbic acid; the preparation process relates to five processes of continuous condensation, continuous solvent removal, continuous hydrolysis, continuous washing and continuous crystallization, and all processes from reaction to aftertreatment are continuous processes. The method has the advantages that (1) the reaction retention time is greatly shortened, polymerization of crotonaldehyde or ketene can be inhibited, side reactions are reduced, and the product yield and quality are improved; and (2) the continuous preparation process can cut off feeding in time, so that the harm caused by abnormal reaction is reduced, and the safety coefficient is higher. And (3) continuous integrationof the preparation process is realized, the product production time is shortened, the productivity is increased, the equipment utilization rate is increased, the whole process is simple and easy to operate, and clean production is further realized by recycling the activated carbon.

Owner:NANTONG ACETIC ACID CHEM

Method for synthesizing methyl 4-chloroacetoacetate or ethyl 4-chloroacetoacetate

ActiveCN112500290AAdequate responseReduce usagePreparation from carboxylic acid halidesCarboxylic acid halides preparationWater chlorinationEthyl acetate

The invention discloses a method for synthesizing methyl 4-chloroacetoacetate or ethyl 4-chloroacetoacetate. The synthesis steps are as following: adding a first part of a solvent into a chlorinationkettle, cooling, adding a second part of a solvent and diketene mixed solution, and cooling; introducing chlorine in sections, adjusting the introduction flow rate of chlorine in each section, and after introduction of chlorine is finished, dropwise adding methanol or ethanol, and carrying out esterification reaction; after the esterification reaction is finished, desolventizing and rectifying thereaction liquid to obtain a finished product of methyl 4-chloroacetoacetate or ethyl 4-chloroacetoacetate; in the chlorination reaction process, the traditional constant-flow chlorine introduction mode is changed and is replaced by a segmented introduction and variable-flow-rate mode; compared with the traditional process, multiple times of production experience groping verification confirms thatthe chlorine addition mode of segmented introduction and variable flow rate has the advantages that few chlorine-containing by-products are generated in the synthesis process, the environmental pollution is reduced, and the yield and content of the prepared product are higher.

Owner:JIANGSU HENGAN CHEM

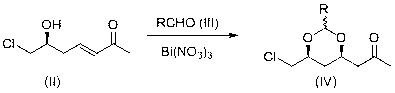

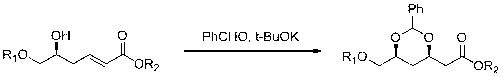

Preparation method of 2-((4R, 6S)-6-chloromethyl-2-alkyl-1,3-dioxane -4-yl)acetic acid

InactiveCN103224484ARaw materials are easy to getMild reaction conditionsOrganic chemistryHaloform reactionChemical synthesis

The invention belongs to the technical field of chemical synthesis, and concretely relates to a p reparation method of 2-((4R, 6S)-6-chloromethyl-2-alkyl-1,3-dioxane-4-yl)acetic acid. The compound is a key intermediate for preparing statin hypolipemic drugs. According to the method, (S)-7-chloro-6-hydroxyheptyl-3-vinyl-2-one is used as raw materials, 1-(6-chloromethyl-2-alkyl-1,3-dioxane-4-yl)propyl-2-one is obtained through addition, and the 2-((4R, 6S)-6-chloromethyl-2-alkyl-1,3-dioxane-4-yl)acetic acid (I) is obtained through a haloform reaction. The method is mild in condition, simple to operate and suitable for industrial production.

Owner:FUDAN UNIV

Preparation method of crystalline N-acetoacetanilide

InactiveCN107652199AEliminate the phenomenon of cloggingUniform crystal shapeOrganic compound preparationCarboxylic acid amide separation/purificationSolventAniline

The invention discloses a preparation method of crystalline N-acetoacetanilide. The method comprises the following steps: reacting aniline with diketene, carrying out condensation on the aniline and diketene, adding an acid accounting for 0.01-0.1% of the weight of the above obtained condensation solution into a condensation kettle, heating the obtained solution to 40-70 DEG C, starting the vacuumof a system, gradually increasing the vacuum degree to 610-460 mmHg from 760 mmHg, keeping the vacuum degree at 610-460 mmHg for 10-50 min, and continuously increasing the vacuum degree to 385-310 mmHg; and decreasing the temperature to 40 DEG C or less, continuously increasing the vacuum degree to 160-85 mmHg within 0.5-2 h, finally reducing the vacuum degree to 10-5 mmHg, keeping the vacuum degree for 15-30 min, shutting down a vacuum pump, and carrying out system emptying, centrifuging and drying to obtain the finished uniformly-crystalline quicksand-like N-acetoacetanilide product. A specific crystallization technology adopting a crystallization assistant is developed in the invention, so the product has the advantages of easiness in crystallization formation, high purity, uniform particles, good fluidity, and no agglomeration after long-term storage. The quality of downstream products is improved.

Owner:NANTONG ACETIC ACID CHEM

Energy-saving efficient isopropenyl acetate synthesis method

ActiveCN105777540AImprove responseIncrease productivityChemical industryPreparation from ketenes/polyketenesSynthesis methodsEthenone

The invention discloses an energy-saving efficient isopropenyl acetate synthesis method which comprises the following steps: (1) feeding acetic acid into a container, performing heating treatment on the acetic acid so as to generate an ethenone gas from the acetic acid in a catalytic cracking manner, introducing the ethenone gas into a cooler; (2) feeding an acetone solution into a mixing dish, simultaneously feeding a catalyst into the mixing dish, mixing, uniformly stirring, pumping the mixed liquid into the cooler by using a metering pump; (3) conveying the mixed gas in the cooler into a synthesis reaction tower, and enabling the mixed gas to generate a reaction gas in the synthesis reaction tower; and (4) condensing the generated reaction gas so as to obtain a coarse product, refining the coarse product, cooling, crystallizing and drying, thereby obtaining a product. According to the energy-saving efficient isopropenyl acetate synthesis method disclosed by the invention, the ethenone gas and the acetone steam are enabled to have homogeneous reaction directly, so that the reaction efficiency is effectively improved, the transfer amount of acetone is greatly reduced, and the comprehensive utilization rate is increased.

Owner:衢州伟荣药化股份有限公司

Preparation method for 5-acetoacetamidobenzimidazolone

ActiveCN110845424AImprove solubilityInhibition of dissolutionOrganic chemistrySodium hydrosulfideDiketene

The invention discloses a preparation method for 5-acetoacetamidobenzimidazolone. The preparation method comprises the following steps: with water as a solvent, adding 5-aminobenzimidazolone, a sodiumhydrosulfide solution and active carbon into the water, carrying out mixing, carrying out a reaction at a certain temperature for a certain period of time, and carrying out filtering so as to obtainan intermediate filtrate; and dropwise adding diketene into the intermediate filtrate at a certain temperature, keeping the temperature for a certain period of time, and carrying out cooling, filtering and drying so as to obtain the 5-acetoacetamidobenzimidazolone. According to the invention, by adoption of the sodium hydrosulfide solution, dissolution of the 5-aminobenzimidazolone can be accelerated, and oxidation of the 5-aminobenzimidazolone can be prevented; H2S gas generated by hydrolyzing of the sodium hydrosulfide at a high temperature can generate the sodium hydrosulfide solution afterbeing absorbed by the sodium hydroxide solution, so the H2S can be recycled, and emission of waste gas is avoided; the water is used as the solvent, so the cost of alcohol used as the solvent is reduced, the potential safety hazard during product drying is avoided, and the reaction time is short. The preparation method provided by the invention has the following advantages: a product purity is larger than or equal to 99.2%; the yield of the product is larger than or equal to 85%; the quality is guaranteed; and the yield is improved.

Owner:SHANDONG HUIHAI PHARMA & CHEM

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com