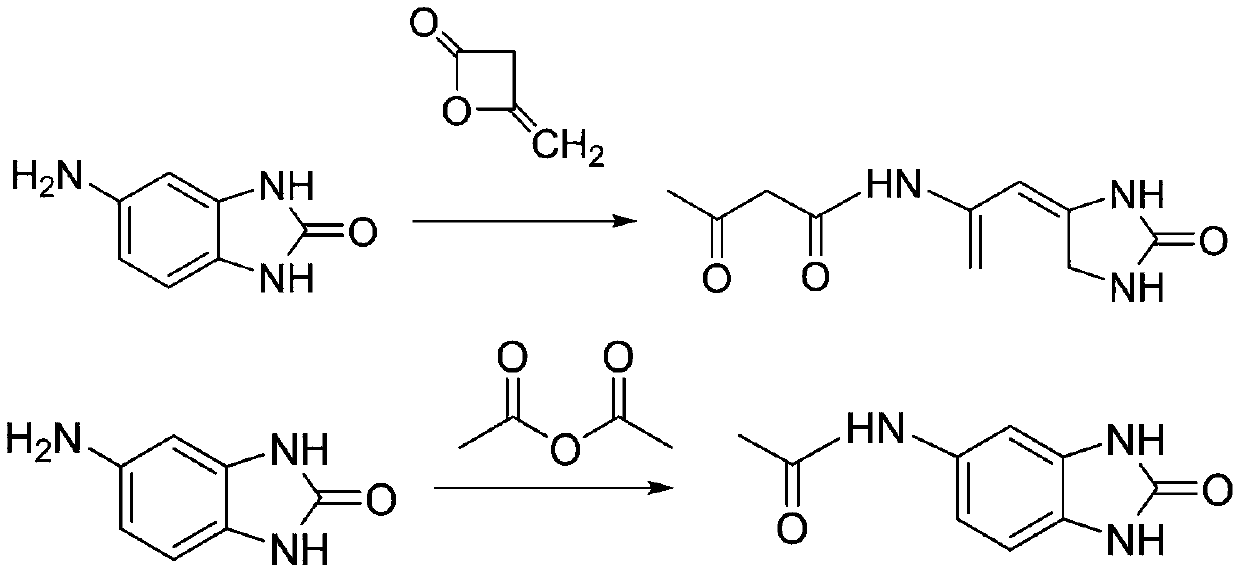

Method for improving quality of 5-acetoacetlaminobenzimdazolone

A technology of acetoacetamidobenzimidazolone and aminobenzimidazolone, which is applied in the field of chemical synthesis, can solve problems such as the use of downstream customers that affect product quality, and achieve the effects of reducing environmental protection investment, improving utilization rate and reducing waste amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

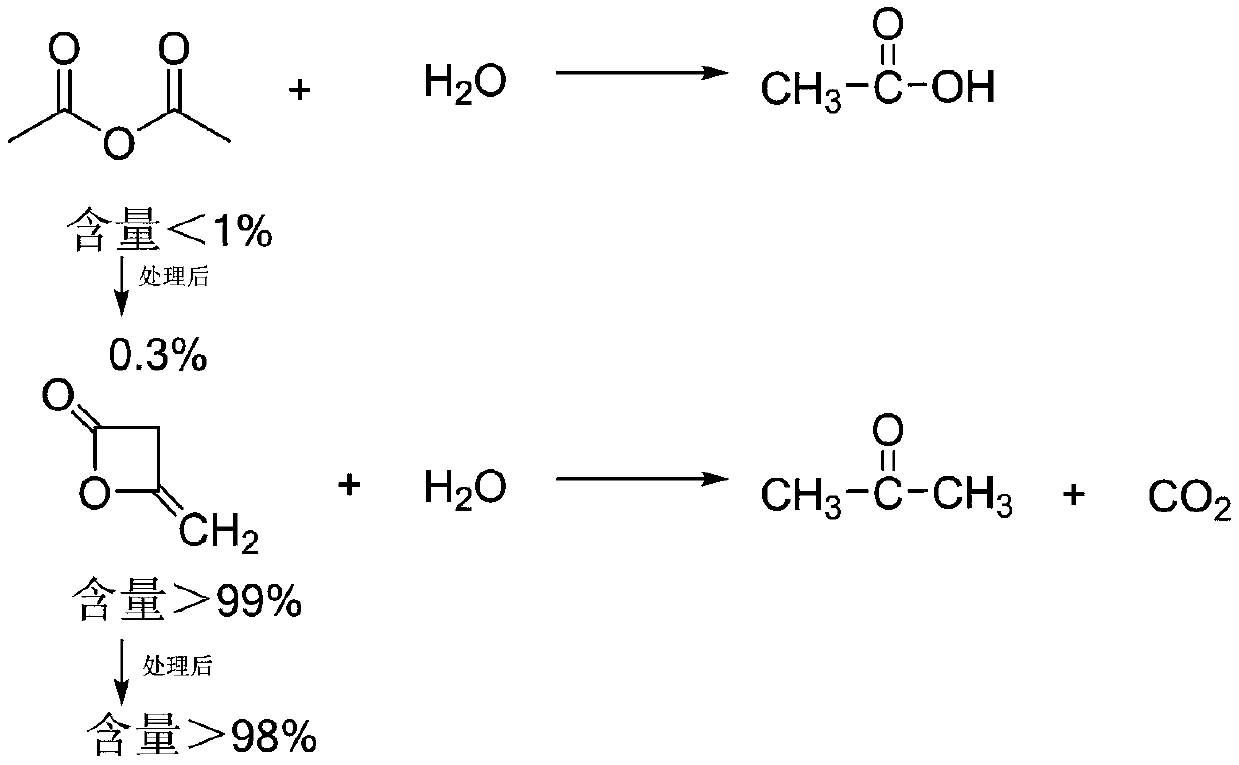

Problems solved by technology

Method used

Image

Examples

Embodiment 1

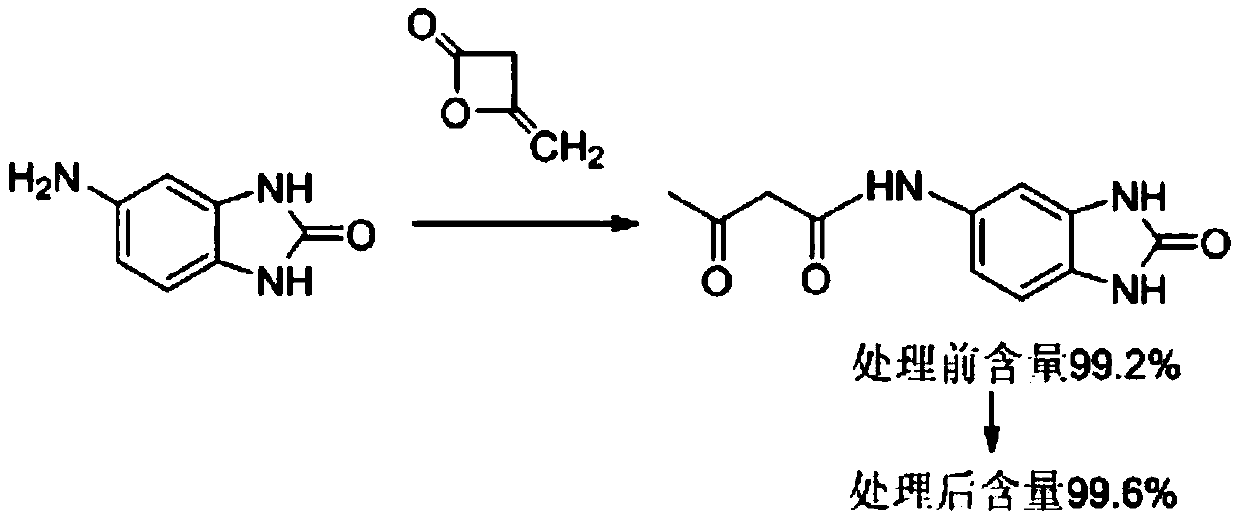

[0024] A method for improving the quality of 5-acetoacetamido benzimidazolone, comprising the following steps:

[0025] 1) Diketene and water are pretreated at -10°C in a mass ratio of 1:66 to obtain a diketene solution;

[0026] 2) Add water and 5-aminobenzimidazolone with a wet weight of 51% into the reaction kettle, the mass ratio of 5-aminobenzimidazolone to water is 13:40, heat up to 75°C, keep it warm for 30 minutes, turn to Feed to the acylation tank;

[0027] 3) Add the pretreated diketene solution dropwise into the acylation kettle, the mass ratio of diketene to 5-aminobenzimidazolone is 1:3, keep it warm for 30 minutes, cool down to 45°C, press the material, and dry to obtain 5- Acetoacetamidobenzimidazolone. The content of 5-acetoacetylaminobenzimidazolone is 99.61%, and the content of by-product 5-acetylaminobenzimidazolone is 0.19%.

[0028] In step 2), sodium bisulfite and activated carbon are also added into the reaction kettle, and the mass ratio of sodium b...

Embodiment 2

[0031] A method for improving the quality of 5-acetoacetamido benzimidazolone, comprising the following steps:

[0032] 1) Diketene and water are pretreated at 0°C in a mass ratio of 1:65 to obtain a diketene solution;

[0033] 2) Add water and 5-aminobenzimidazolone with a wet weight of 51% into the reaction kettle, the mass ratio of 5-aminobenzimidazolone to water is 11:30, heat up to 80°C, keep it warm for 30 minutes, turn to Feed to the acylation tank;

[0034] 3) Add the pretreated diketene solution dropwise into the acylation kettle, the mass ratio of diketene to 5-aminobenzimidazolone is 1:2.5, keep it warm for 35 minutes, cool down to 45°C, press the material, and dry to obtain 5- Acetoacetamidobenzimidazolone. The content of 5-acetoacetylaminobenzimidazolone is 99.64%, and the content of by-product 5-acetylaminobenzimidazolone is 0.16%.

[0035] In step 2), sodium bisulfite and activated carbon are also added to the reactor, and the mass ratio of sodium bisulfite, ...

Embodiment 3

[0038] A method for improving the quality of 5-acetoacetamido benzimidazolone, comprising the following steps:

[0039] 1) Diketene and water are pretreated at -5°C in a mass ratio of 1:62 to obtain a diketene solution;

[0040] 2) Add water and 5-aminobenzimidazolone with a wet weight of 51% into the reaction kettle, the mass ratio of 5-aminobenzimidazolone to water is 12:35, heat up to 85°C, keep it warm for 25 minutes, turn to Feed to the acylation tank;

[0041] 3) Add the pretreated diketene solution dropwise into the acylation kettle, the mass ratio of diketene to 5-aminobenzimidazolone is 1:2, keep it warm for 40 minutes, cool down to 40°C, press the material, and dry to obtain 5- Acetoacetamidobenzimidazolone. The content of 5-acetoacetylaminobenzimidazolone is 99.60%, and the content of by-product 5-acetylaminobenzimidazolone is 0.20%.

[0042] In step 2), sodium bisulfite and activated carbon are also added to the reactor, and the mass ratio of sodium bisulfite, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com