Treating method and treating device for ketene dimer production residues

A technology of diketene and treatment method, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., to achieve the effects of saving time, eliminating potential safety hazards, and effectively recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

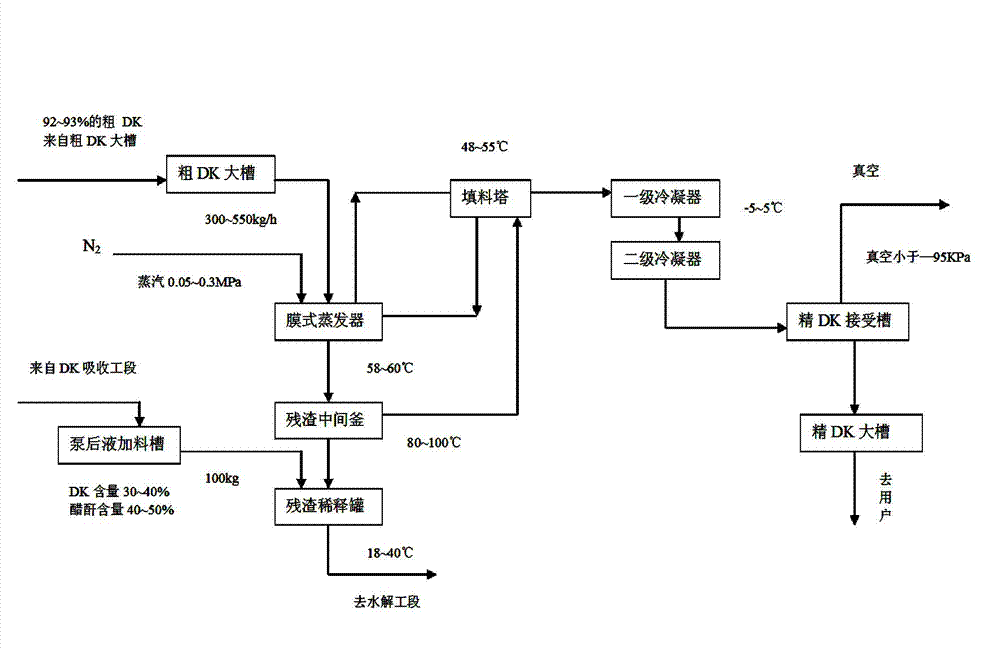

Method used

Image

Examples

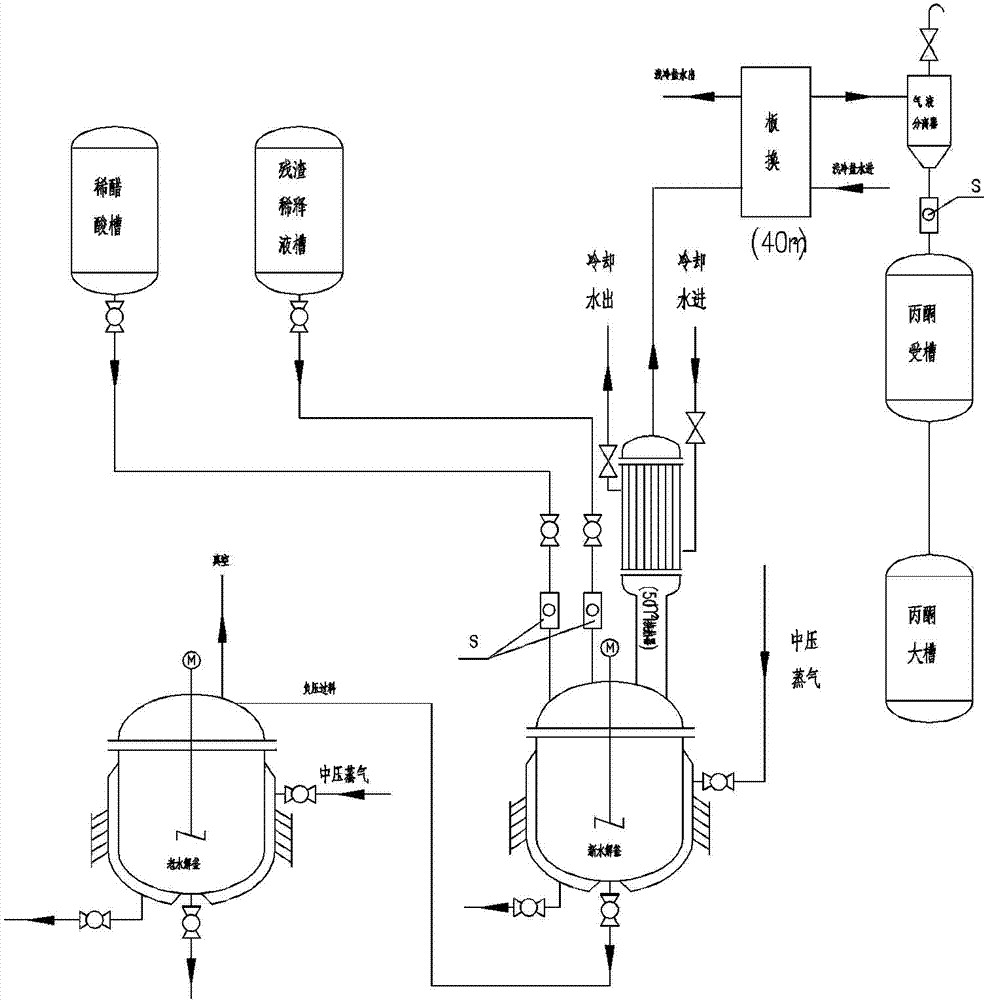

Embodiment 1

[0028] When the residue diluent is normal, first put 900kg of dilute acetic acid (content 45%-55%) into the forward hydrolysis kettle, and heat up the steam in the hydrolysis kettle before starting to open, and the steam pressure is controlled at 0.2MPa. When you see reflux in the reflux sight glass (temperature 80°C-95°C), turn off the steam and start to slowly add the residue diluent (1.8t). When dropping, the pressure of the front hydrolysis tank is controlled at 2-5KPa, and the dropping time is controlled at about 2h. After the dropwise addition, keep warm for 30-60 minutes, and keep the kettle temperature at 90-95°C to make it fully react. At this time, the temperature at the inlet of the plate changer is controlled at 56°C-65°C. This is the time for acetone to be produced, and the discharge will be seen in the sight glass on the top of the acetone receiving tank. The resulting acetone content is about 60%-80%.

[0029] After the heat preservation is over, pull the nega...

Embodiment 2

[0032] If there is a large amount of residue dilution liquid, put 1000kg of dilute acetic acid (content 45%-55%) into the hydrolysis kettle first, and heat the steam to raise the temperature of the hydrolysis kettle before starting to open, and the steam pressure is controlled at 0.2MPa. When you see reflux in the reflux sight glass (temperature 80°C-95°C), turn off the steam and start to slowly add the residue diluent (2t). When dropping, the pressure of the front hydrolysis tank is controlled at 2-8KPa, and the dropping time is controlled at about 2h. After the dropwise addition, keep warm for 1h. Keep the kettle temperature at 90-95°C to make it fully react. At this time, the temperature at the inlet of the plate changer is controlled at 56°C-65°C. This is the time for acetone to be produced, and the discharge will be seen in the sight glass on the top of the acetone receiving tank. The resulting acetone content is about 60%-80%.

[0033] After the heat preservation is o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com