Continuous preparation method of sorbic acid

A sorbic acid, continuous technology, applied in the field of continuous sorbic acid preparation, can solve the problems of potential safety hazards, low equipment utilization rate, cumbersome process operation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

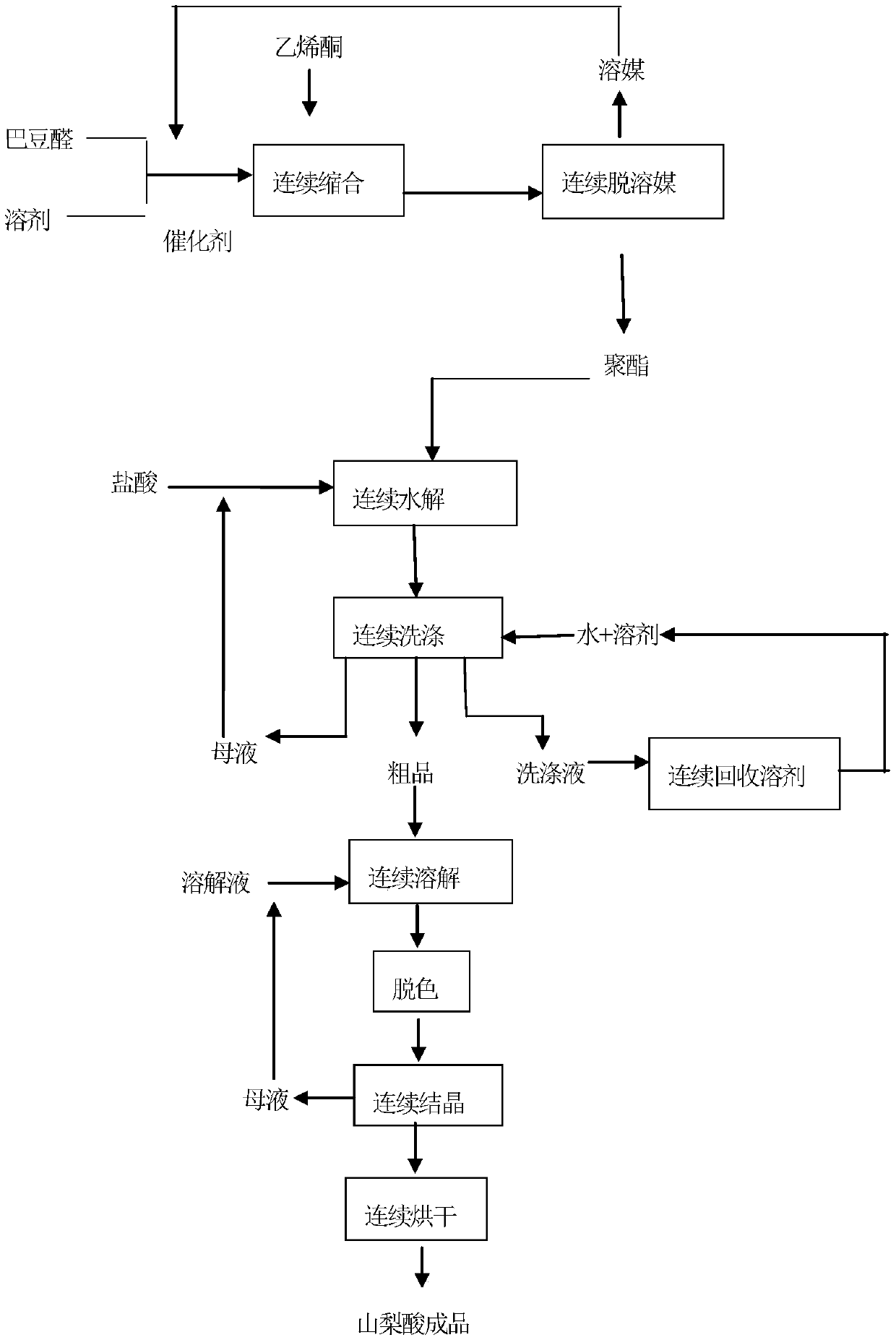

Image

Examples

Embodiment approach

[0037] Further embodiments of the present invention are as follows:

[0038] (1) Continuous preparation of raw materials: crotonaldehyde and solvent are continuously mixed in the pipeline at a mass ratio of 0.3 to 10:1, and then the catalyst is continuously injected into crotonaldehyde and solvent at a ratio of 0.1% to 5% of the total mass of crotonaldehyde and solvent. The crotonaldehyde solution is prepared in the solvent mixture.

[0039](2) Continuous condensation: The vinyl ketone and crotonaldehyde solution prepared by cracking acetic acid are poured into the condensation reactor with a molar ratio of 1:1 to 5 to carry out continuous condensation reaction, and at the same time, the condensed liquid after reaction is exported with equal feed quality (reaction The pressure is 0-0.1MPa, the reaction temperature is 30-80°C, and the residence time of the reaction is 1s-4h.)

[0040] (3) Continuous removal of solvent: the condensed liquid after the reaction enters the continu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com