Clean production process for polyurethane synthetic leather base with ultramicro leather powder as filling material

A technology of clean production and leather powder, applied in the direction of synthetic resin layered products, layered products, textiles and papermaking, etc., can solve the problems of waste of resources, occupation of space, pollution of the environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1. Method for producing polyurethane synthetic leather by direct coating method:

[0036] The process flow is:

[0037] 1. Preparation of ultra-fine leather powder: first use scissors to cut the leather waste into less than 1cm 2 Then use a centrifugal crusher to crush the leather waste. The high-speed rotating blade of the centrifugal pulverizer is used to hit the leather, and high-speed impact is generated between the leather and the leather, and between the leather and the barrel wall to achieve the purpose of crushing. The ultrafine leather powder of 30~80μm can be obtained through the centrifugal crusher. The ultrafine leather powder is grafted or not modified. The modified ultrafine leather powder is modified by maleic anhydride grafting. Sex, belongs to the existing technology.

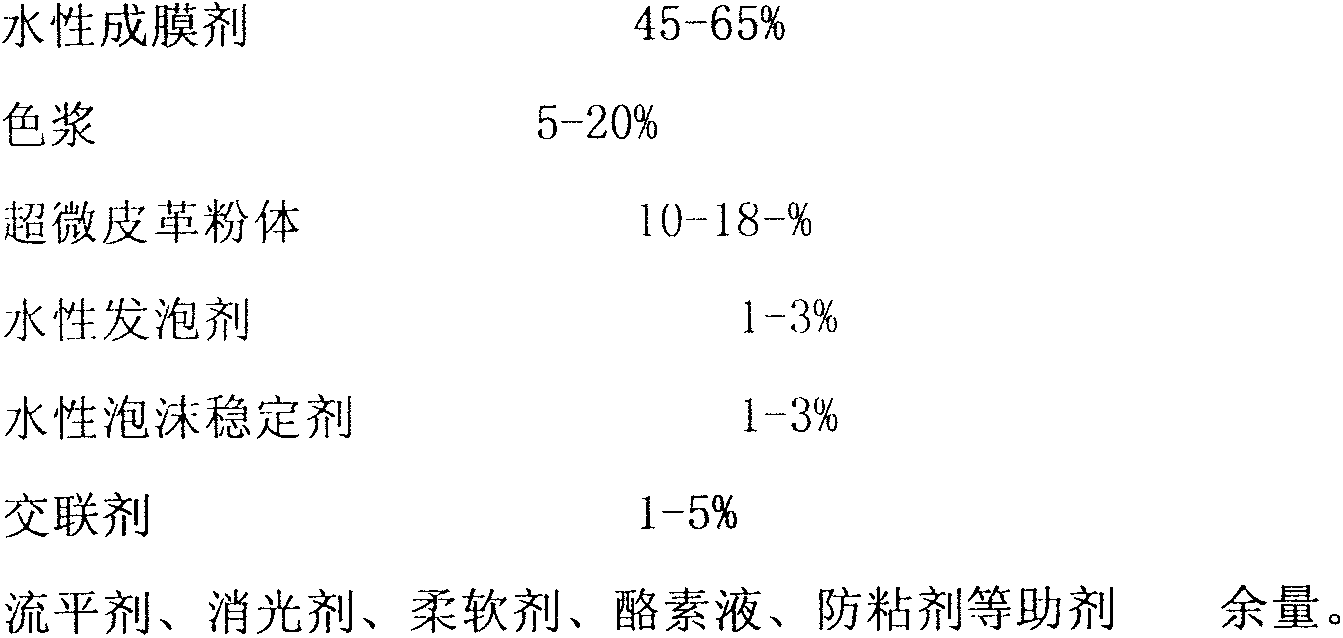

[0038] 2. Preparation of micro-foaming finishing agent: 50 parts of polyurethane resin, 15 parts of water-based color paste, 15 parts of ultra-fine leather powder, 2 parts of foaming ...

Embodiment 2

[0041] Example 2. Production process of polyurethane synthetic leather by indirect coating method:

[0042] 1. Preparation of ultra-fine leather powder: first use scissors to cut it to no more than 1cm 2 Then use a centrifugal crusher to crush the leather waste. The high-speed rotating blade of the centrifugal pulverizer is used to hit the leather, and high-speed impact is generated between the leather and the leather, and between the leather and the barrel wall to achieve the purpose of crushing. The ultrafine leather powder of 30~80μm can be obtained through the centrifugal crusher. The ultrafine leather powder is grafted or not modified. The modified ultrafine leather powder adopts maleic anhydride-acrylic acid grafting. Branch modification.

[0043] 2. Preparation of micro-foaming finishing agent: 55 parts of polyurethane resin, 10 parts of water-based color paste, 20 parts of ultra-fine leather powder, 2 parts of foaming agent, 2 parts of foam stabilizer, 3 parts of crosslink...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com