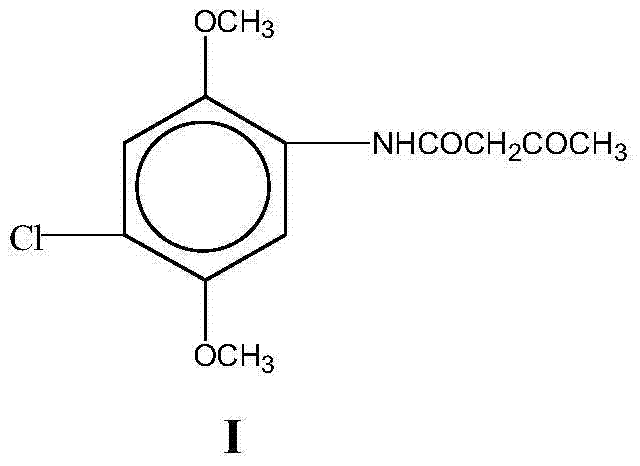

Preparation method of 4-chloro-2,5-dimethoxyacetyl acetanilide

A technology of dimethoxyacetoacetanilide and dimethoxyaniline is applied in the field of preparation of 4-chloro-2,5-dimethoxyacetoacetanilide, and can solve the problems of incomplete reaction, complicated process and environmental pollution and other problems, to achieve the effect of promoting the reaction conversion, improving the reaction yield and reducing the amount of solvent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

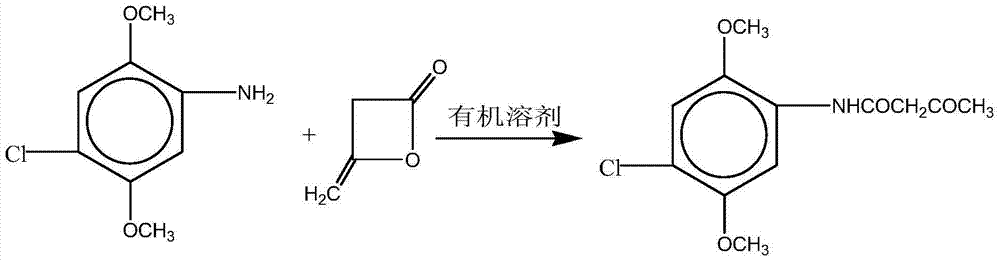

Method used

Image

Examples

Embodiment 1

[0027] Add 30g of 4-chloro-2,5-dimethoxyacetoacetanilide (0.15mol) into a 250ml four-port reaction vessel, add 120ml of 95% ethanol, start stirring, and start to drop 15g of diketene ( 0.18mol), added dropwise within 3 hours, heated up to 60°C, reacted for 3 hours, cooled to 0-2°C after the reaction was completed, filtered, and dried to obtain 39.9g of the product as a white crystal, with a yield of 91.3%. The product is shiny, with a melting point of ≥105°C and a purity of 99.5%. At the same time, the filtered mother liquor is collected and used for the next batch of reactions.

Embodiment 2

[0029] This example provides a preparation method of 4-chloro-2,5-dimethoxyacetoacetanilide, which is basically the same as that of Example 1. The difference is: the filtered mother liquor collected in Example 1 is used as the reaction bottom solution in the following 8 reactions to repeat the cycle, and an average of 42.40g of 4-chloro-2,5-dimethoxyacetoacetanilide can be obtained, and the yield It is 97.2%, a white crystal, shiny, melting point ≥ 105 ℃, purity ≥ 99.5%. Collect and filter the mother liquor. Each batch of product yield, weight and purity are shown in Table 1.

[0030] Table 1

[0031] Mother liquor cycle times

Embodiment 3

[0033] Add 30g of 4-chloro-2,5-dimethoxyacetoacetanilide into a 250ml four-port reaction vessel, add 120ml of 95% ethanol, start stirring, start to add 15g of diketene dropwise at 10°C, and drop it within 3 hours After the addition, heat up to 20°C and react for 6 hours. After the reaction, cool down to 0-2°C, filter, and dry to obtain 39.5 g of white crystals with a yield of 90.5%. The product is shiny and has a melting point of ≥105°C , with a purity of 99.6%. At the same time, the filtered mother liquor was collected and used for the next batch of reactions. 8 batches were applied circularly, and the average yield was about 96.4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com