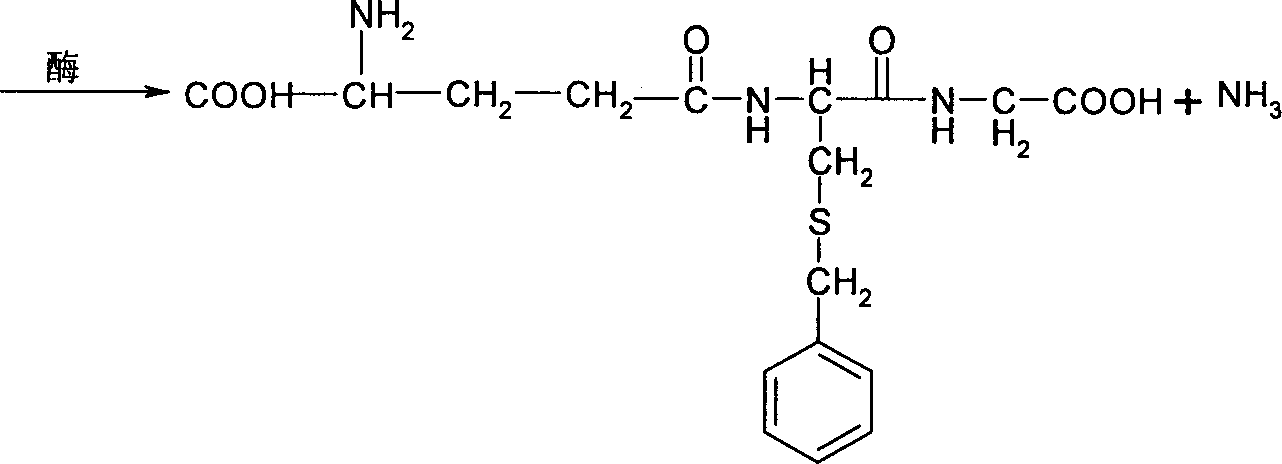

Chemical enzymatic process of synthesizing glutathion

A glutathione, chemical enzymatic technology, applied in the direction of transferase, fermentation, etc., can solve the problems of side reactions, low substrate concentration, affecting enzyme utilization, etc. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Take 20g of sucrose, 30g of corn steep liquor, 10g of peptone, K 2 HPO 4 15g, MgSO 4 0.5g, pH 7.5, add tap water to prepare 1000mL liquid culture medium, prepare 3.5L according to this formula, put it into a 5L fermenter and sterilize it by high-pressure steam at 0.1MPa for 25 minutes for later use. At the same time, divide 50mL of medium into 500mL, add 8 layers of gauze, wrap it in kraft paper, and sterilize it together with the fermenter for later use.

[0031]After taking out the bacterial species preserved in the refrigerator—Bacillus subtillis NX-2 (preservation number is CGMCCNo.0833), it was connected to fresh slant medium (slant medium (g / L): peptone 10, beef extract 3 , NaCl5, agar 20), activated culture for 24 hours, access to seed medium (seed medium (g / L): glucose 20, corn steep liquor 10, peptone 5, K 2 HPO 4 2, MgSO4 0.25) at 32.5°C, 220rpm shaking culture for 20 hours. At the end of the cultivation, connect it to a fermenter, add Sixin organic si...

Embodiment 2

[0040] The preparation and purification methods of γ-glutamyl transpeptidase and the preparation method of the substrate S-benzyl-cysteinylglycine dipeptide are the same as in Example 1.

[0041] Dissolve 0.134g of S-benzyl-cysteinylglycine dipeptide in a 50mL Erlenmeyer flask, add 0.09g of L-glutamine, 10mL of deionized water, adjust the pH to 11.0 with 5mol / L NaOH, and add 1.0U of γ-glutamyl transpeptidase, after mixing evenly, stir and react for 10 hours, and the reaction temperature is 39°C. After the reaction, the reaction solution was micro-filtered to remove the enzyme, and the silica gel thin-layer preparative chromatography, the mobile phase was n-butanol-glacial acetic acid-water (4:1:1, v / v / v), to obtain S-benzyl-glucose Satithione 0.095g, the yield is 48%, and the purity is 95%. Prepare S-benzyl-glutathione in the same way for later use.

[0042] Put 2.0g of S-benzyl-glutathione in the newly prepared Na / liquid ammonia solution, shake slightly until the solution n...

Embodiment 3

[0044] The preparation and purification methods of γ-glutamyl transpeptidase and the preparation method of the substrate S-benzyl-cysteinylglycine dipeptide are the same as in Example 1.

[0045] Dissolve 0.2g of S-benzyl-cysteinylglycine dipeptide in a 50mL Erlenmeyer flask, 0.08g of L-glutamine, 10mL of deionized water, adjust the pH to 10.5 with 5mol / L NaOH, and add 1.0U of γ-glutamyl transpeptidase, after mixing evenly, stir and react for 10 hours, and the reaction temperature is 38°C. After the reaction, the reaction solution was micro-filtered to remove the enzyme, and the silica gel thin-layer preparative chromatography, the mobile phase was n-butanol-glacial acetic acid-water (4:1:1, v / v / v), to obtain S-benzyl-glucose Satithione 0.16g, the yield is 55%, and the purity is 96%. Prepare S-benzyl-glutathione in the same way for later use.

[0046] Put 2.5g of S-benzyl-glutathione in the newly prepared Na / liquid ammonia solution, shake slightly until the solution no longe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com