Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

180 results about "Digital microscopy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A digital microscope is a variation of a traditional optical microscope that uses optics and a digital camera to output an image to a monitor, sometimes by means of software running on a computer.

Lens-less digital microscope

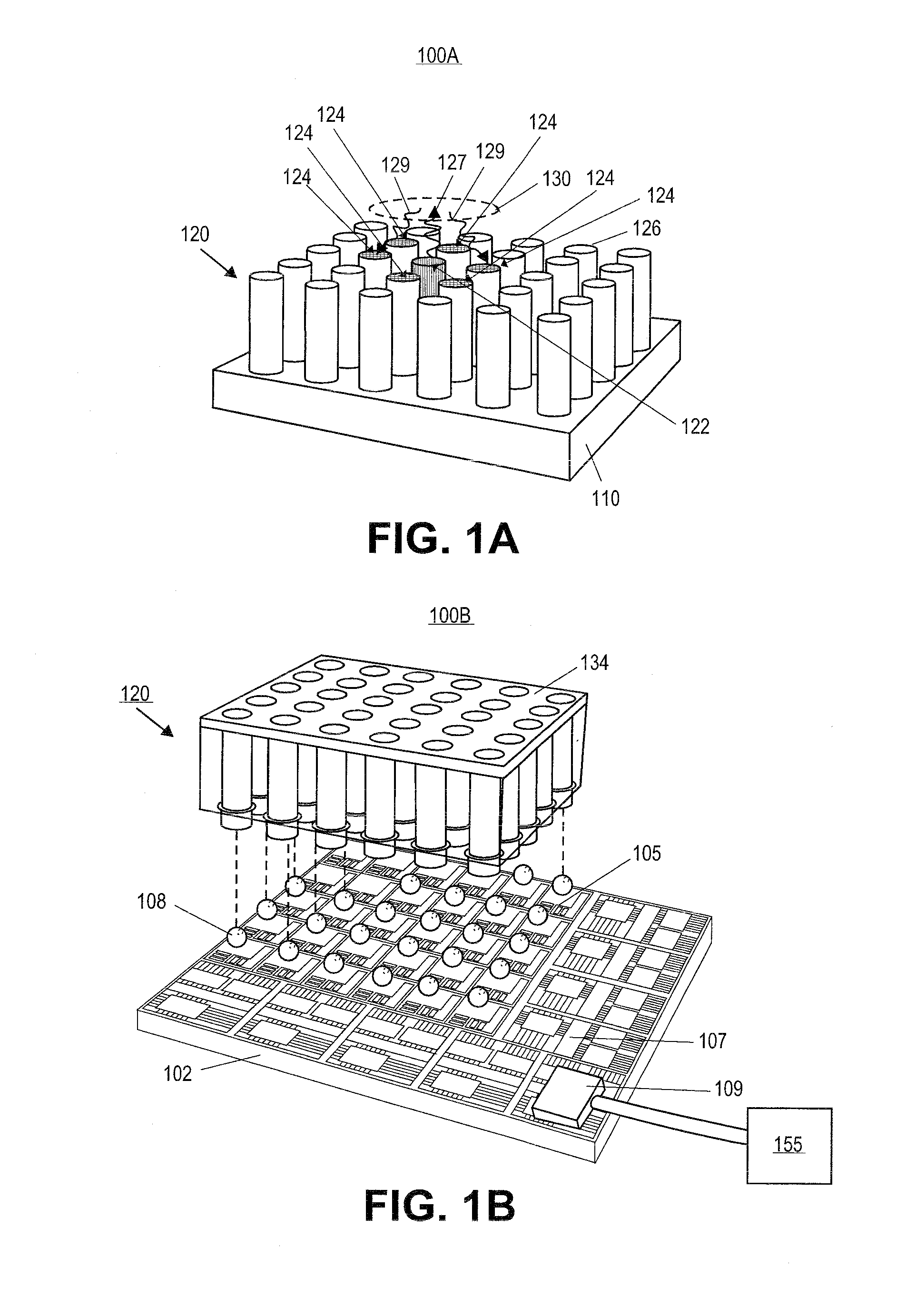

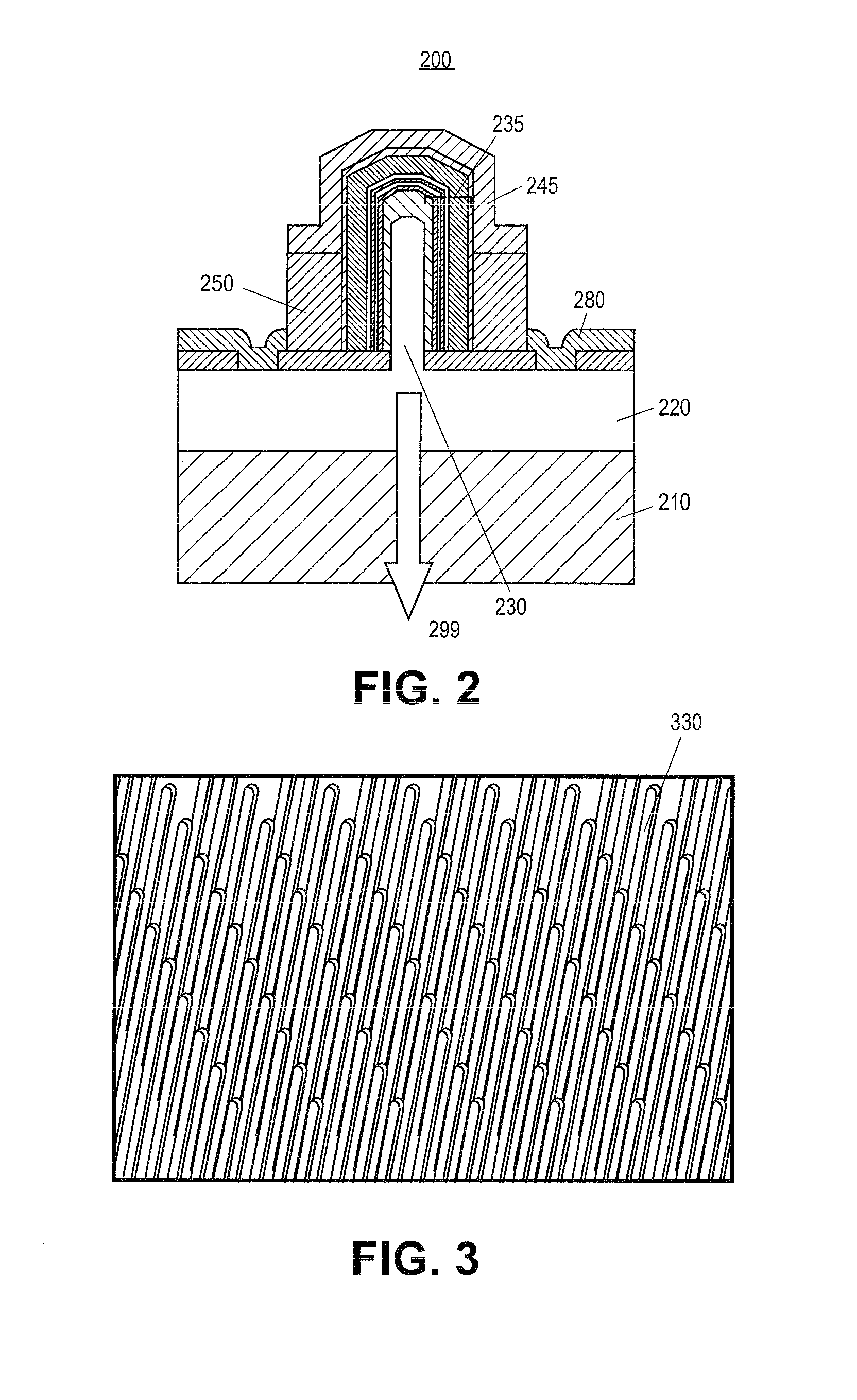

Exemplary embodiments provide microscope devices and methods for forming and using the microscope devices. The microscope device can include a light emitter array with each light emitter individually addressable to either emit or detect light signals. Magnified images of a sample object can be generated by a reflection mechanism and / or a transmission mechanism using one or more microscope devices in an imaging system. Real-time computer control of which microscope pixels are viewed can allow the user to digitally replicate the “fovea” function of human vision. Viewing an object from both sides in the double-sided microscope system and from multiple pixel positions can allow the microscope to reconstruct pseudo-3D images of the object.

Owner:STC UNM

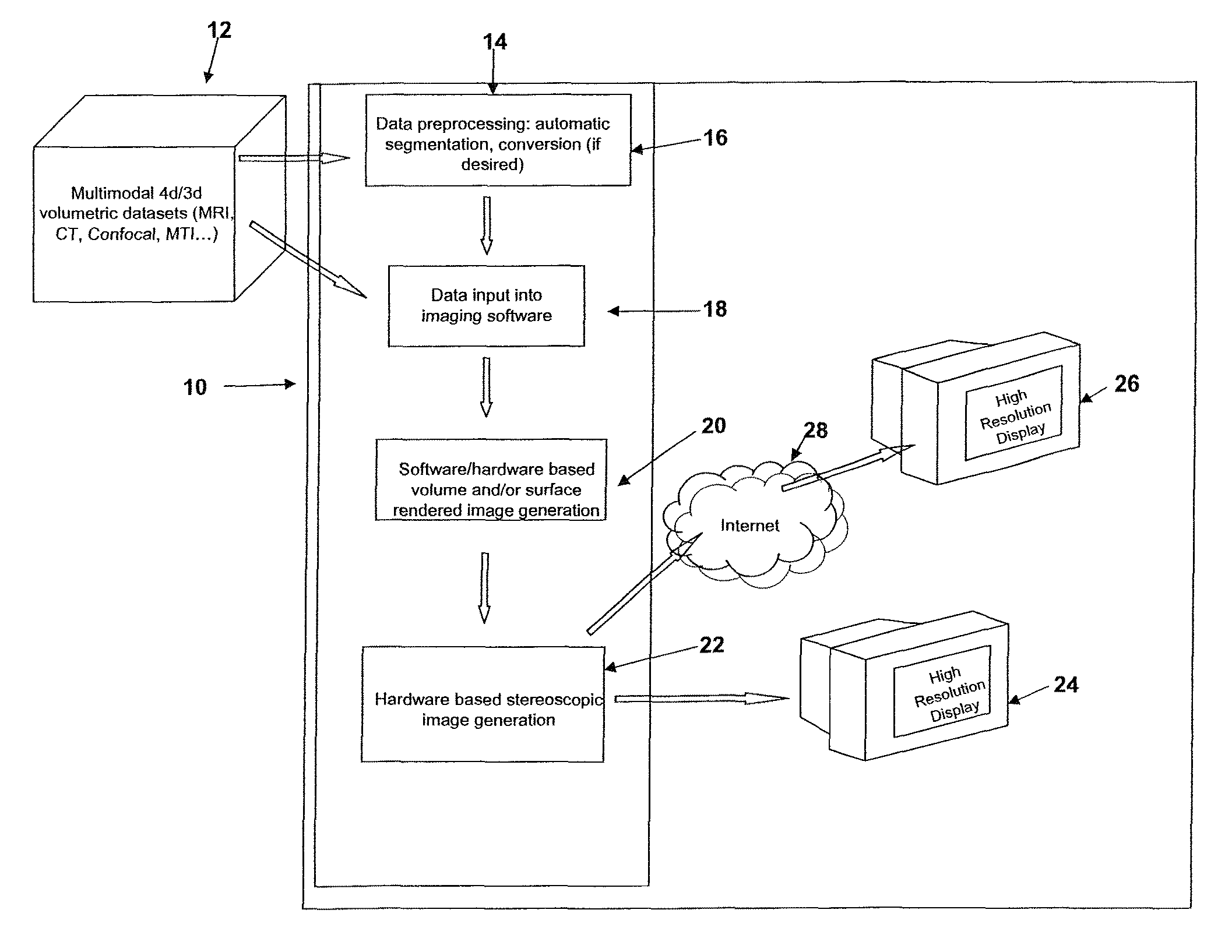

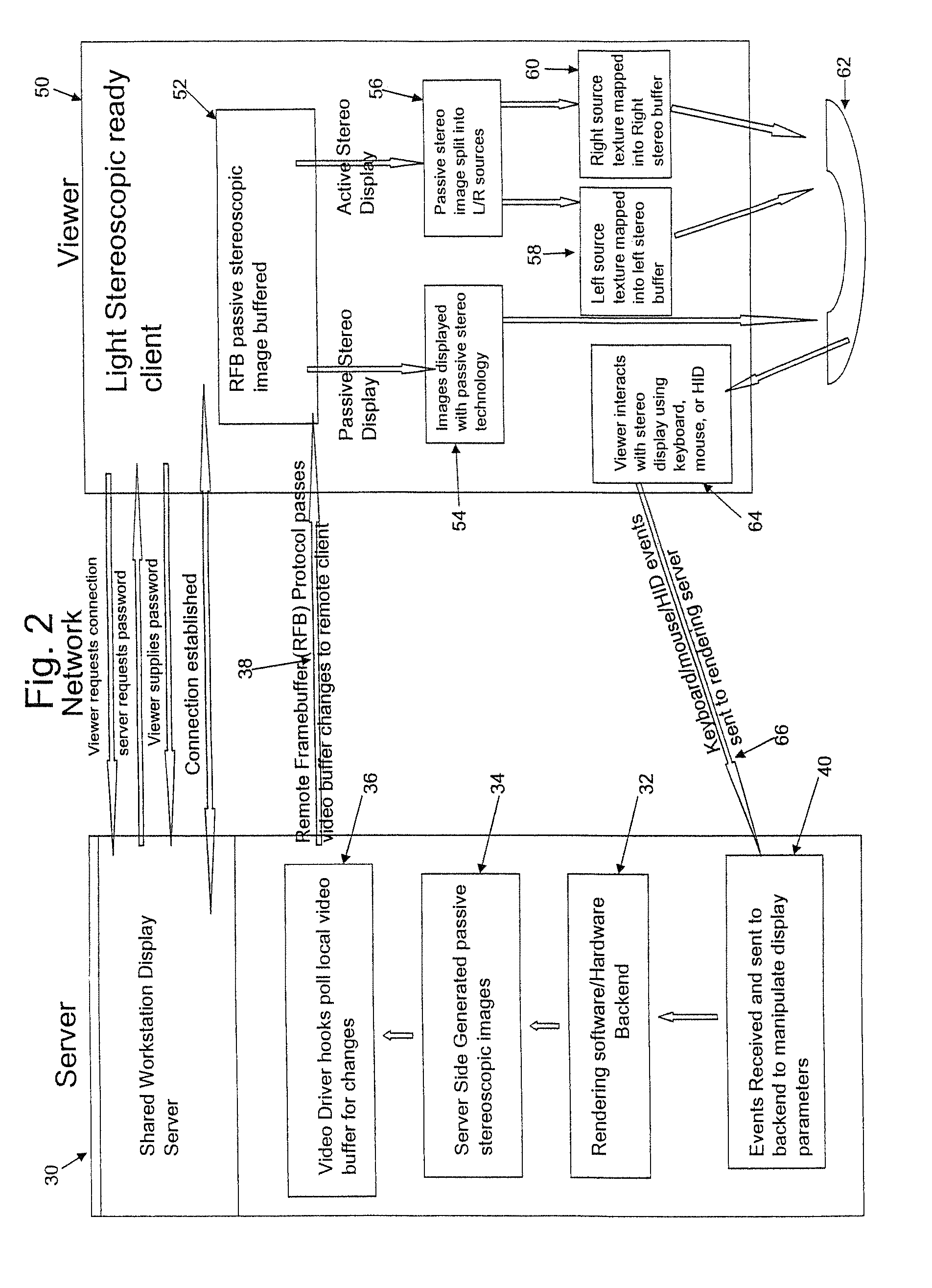

System and methods for multi-dimensional rendering and display of full volumetric data sets

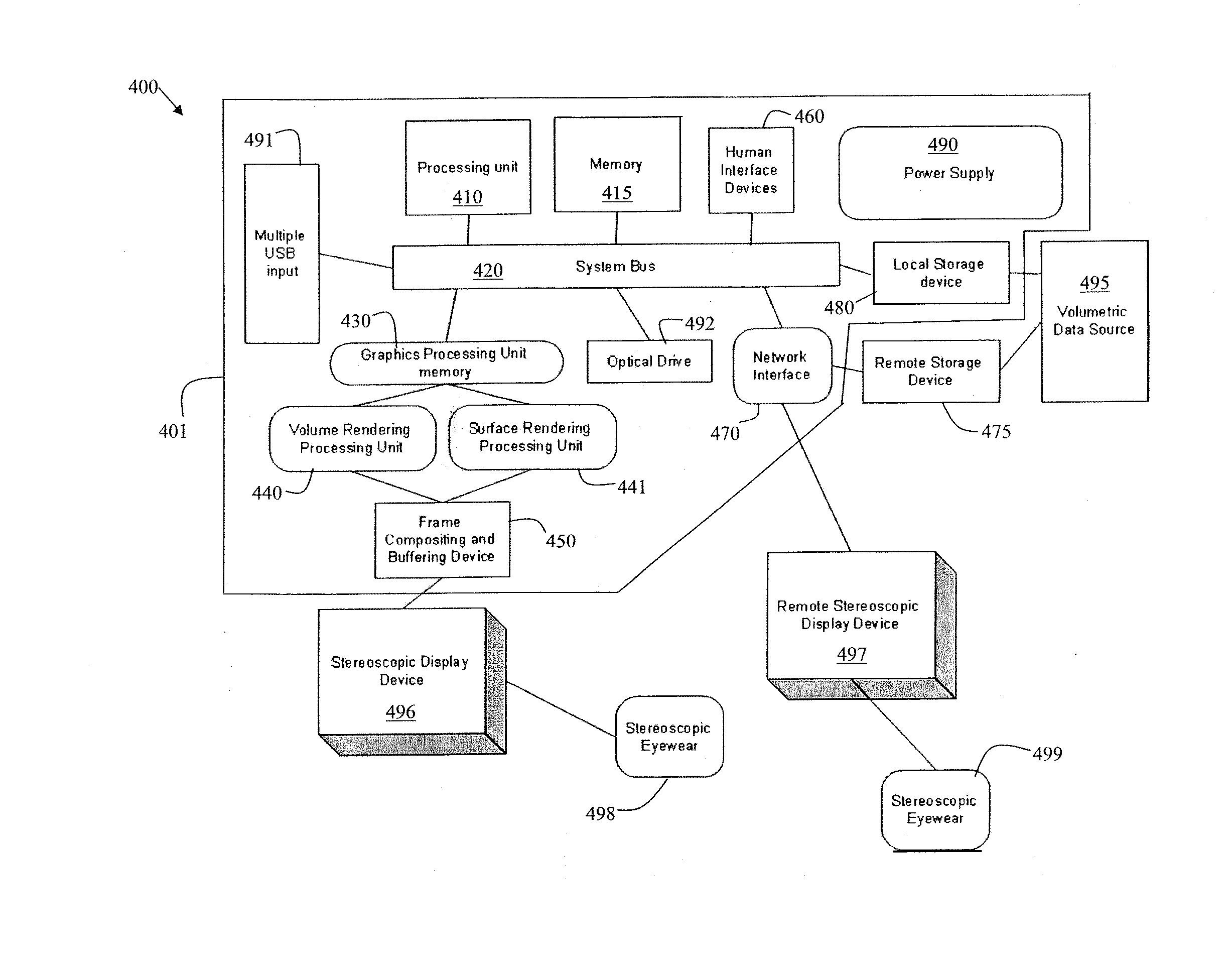

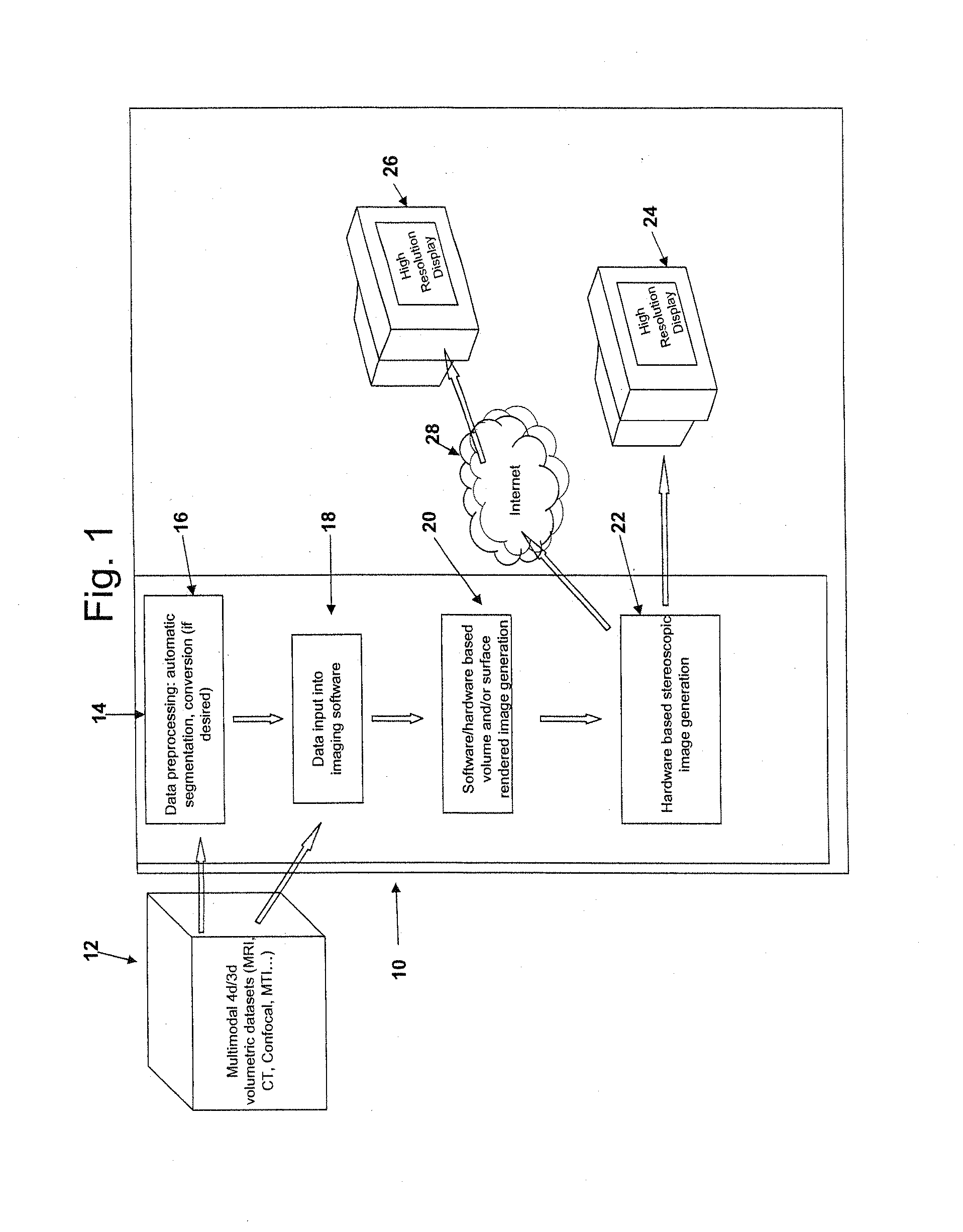

A stand-alone platform and a method for the multi-dimensional rendering, display, manipulation, and analysis of full high resolution volumetric data sets. The systems and methods provide the ability to volumetrically render images with extremely high resolution in applications such as medical imaging procedures, digital microscopy such as in use of a confocal microscope, and other areas where extremely large data sets are produced from the imaging process. Certain embodiments of the system and methods produce left and right eye images of the rendered data, for viewing in parallax via a synchronized headset, and the ability to manipulate the data and display of image data easily and in real time.

Owner:KENT STATE UNIV

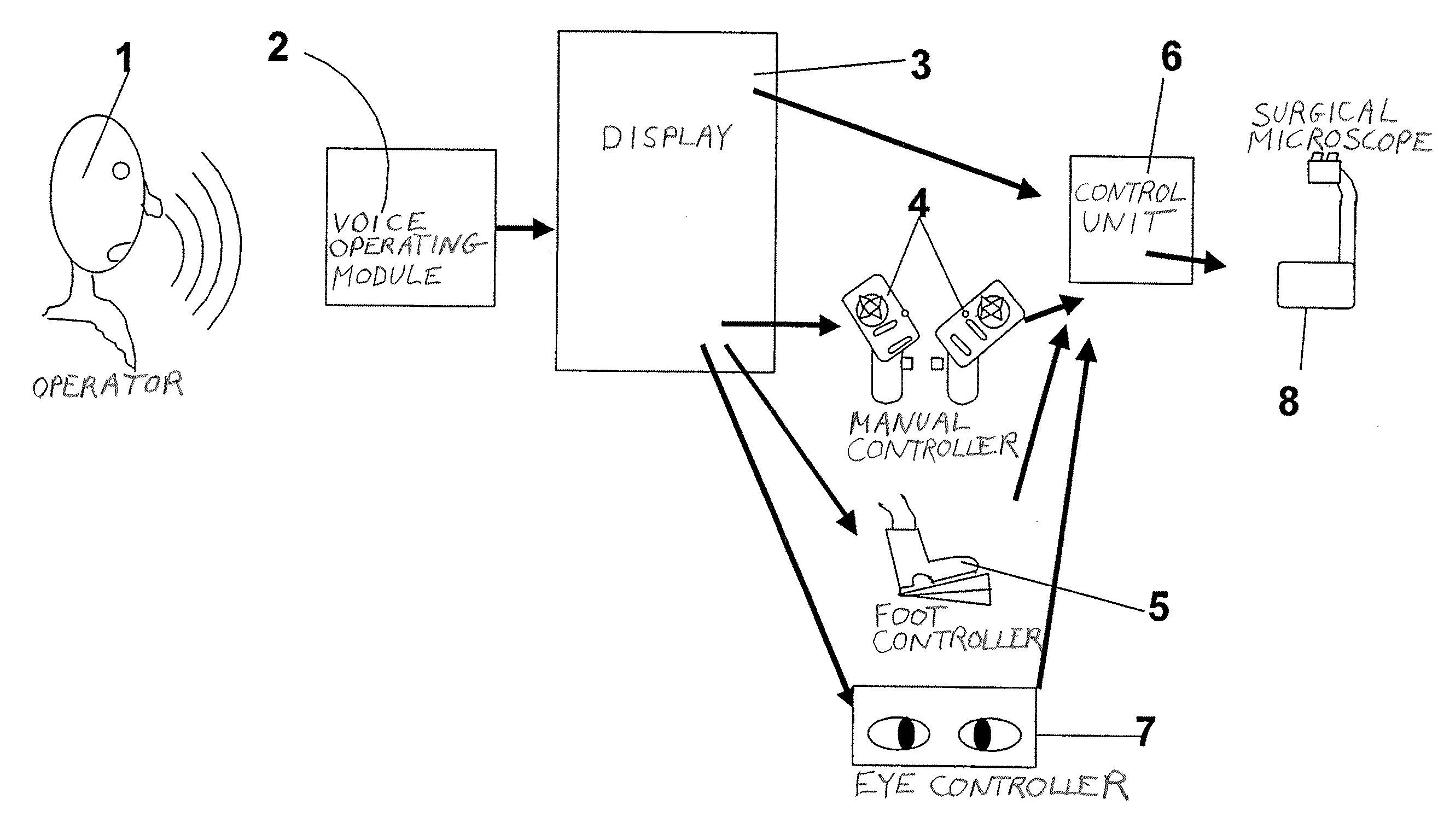

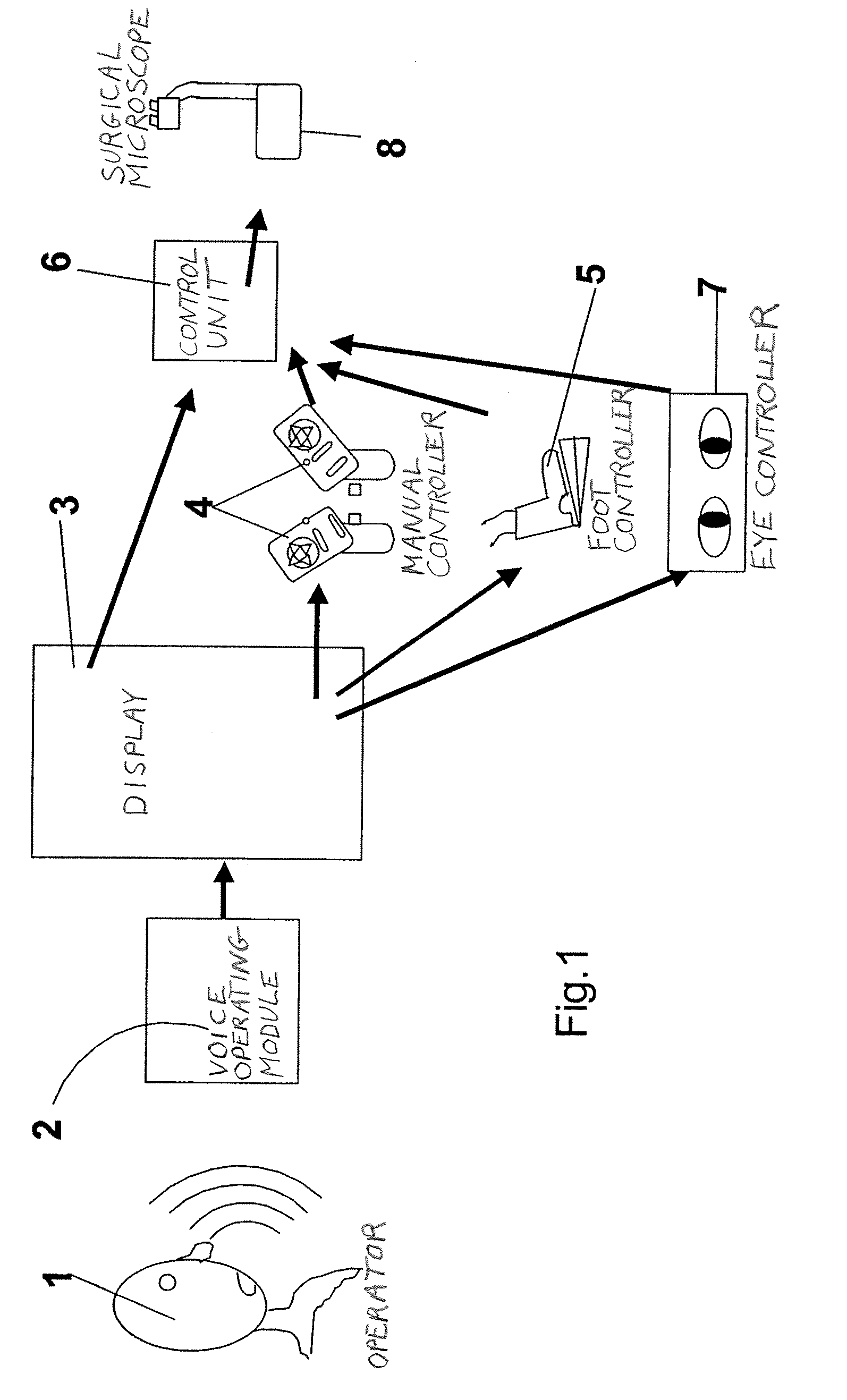

Voice control system for surgical microscopes

A control apparatus, in particular for a surgical microscope (8), has a voice operating unit (2) and at least one other operating unit such as a manual operating unit (4), a foot-controlled operating unit (5), and / or an eye-controlled operating unit (7). The control apparatus executes one set of microscope functions via the voice operating unit (2) and another set of microscope functions via the non-voice operating units (4, 5, and / or 7).

Owner:LEICA INSTR SINGAPORE PTE

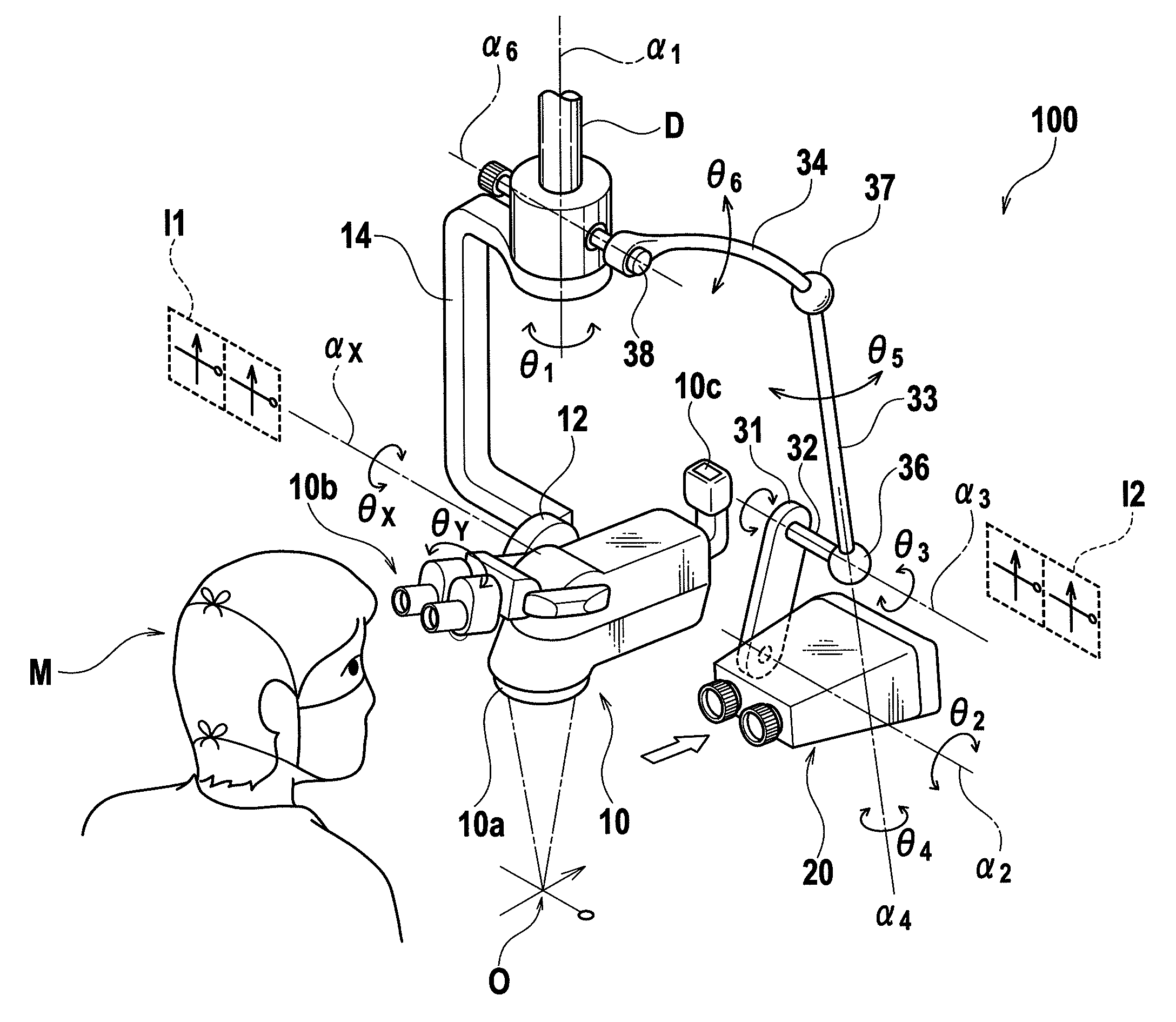

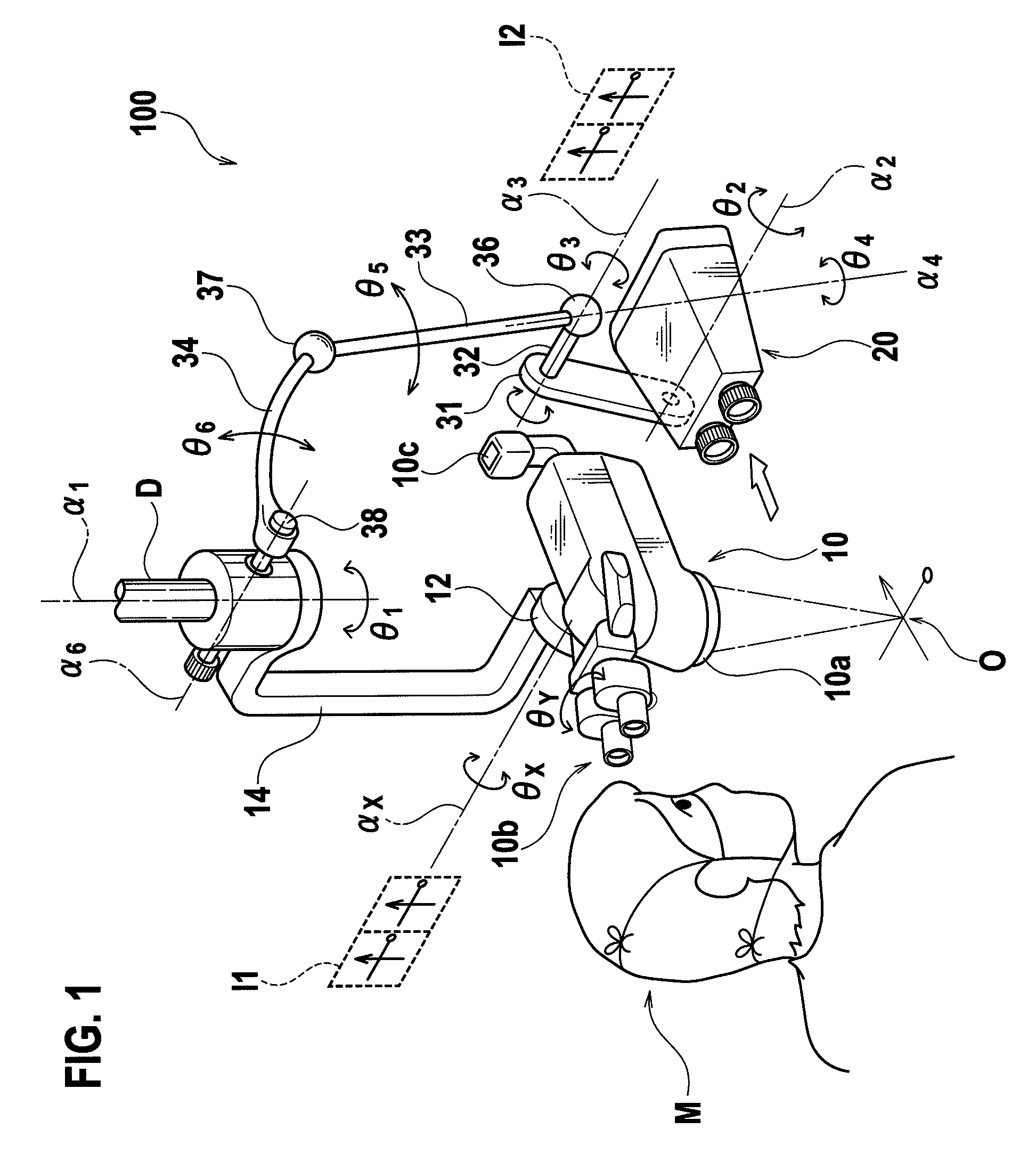

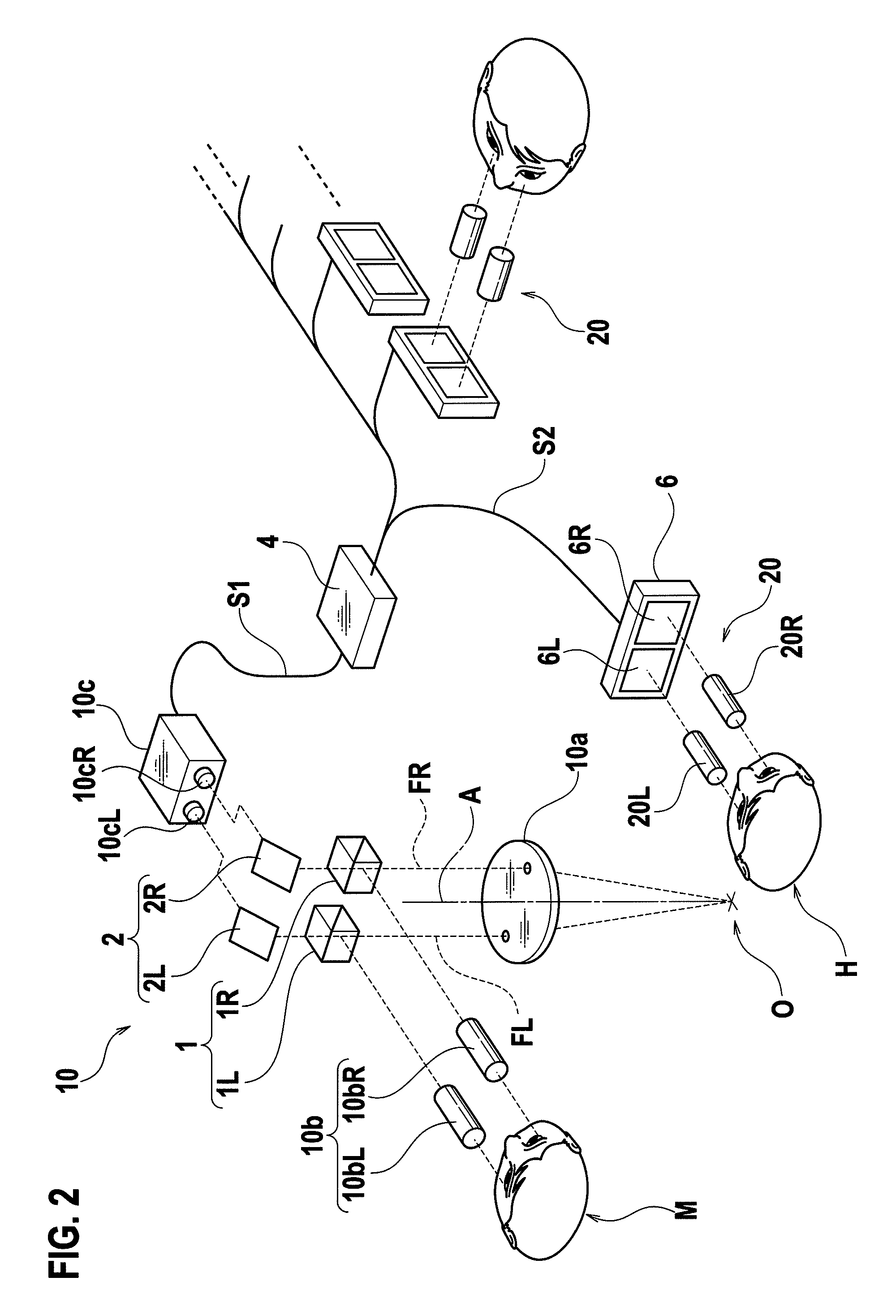

Surgical microscope system

The surgical microscope system includes a first binocular microscope and a first display device. The first binocular microscope includes an objective lens, a first right ocular lens which provides a first image based on a light flux transmitted through the objective lens, and a first left ocular lens which provides a second image based on a light flux transmitted through the objective lens. The first display device can be disposed opposite to or in alignment with the first binocular microscope, and includes a first right-eye image display surface for displaying the first image and a first left-eye image display surface for displaying the second image. The first display device can be reversed about a horizontal axis extending in a direction along which the first right-eye image display surface and the first left-eye image display surface are located in alignment.

Owner:MITAKA KOHKI

Virtual microscope system

ActiveUS20110109735A1Increase speedColor television detailsAbsorption/flicker/reflection spectroscopyLight fluxVirtual slide

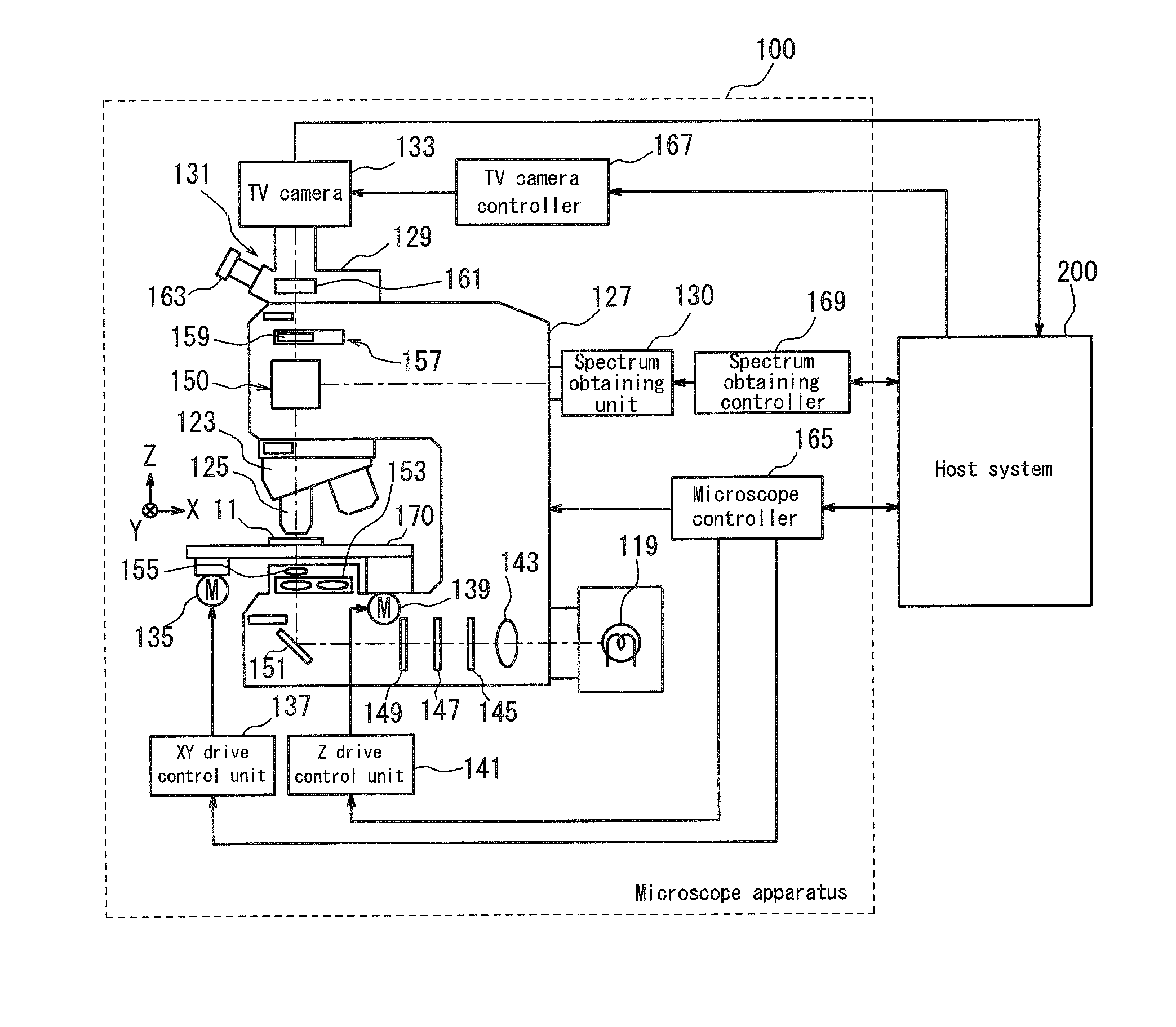

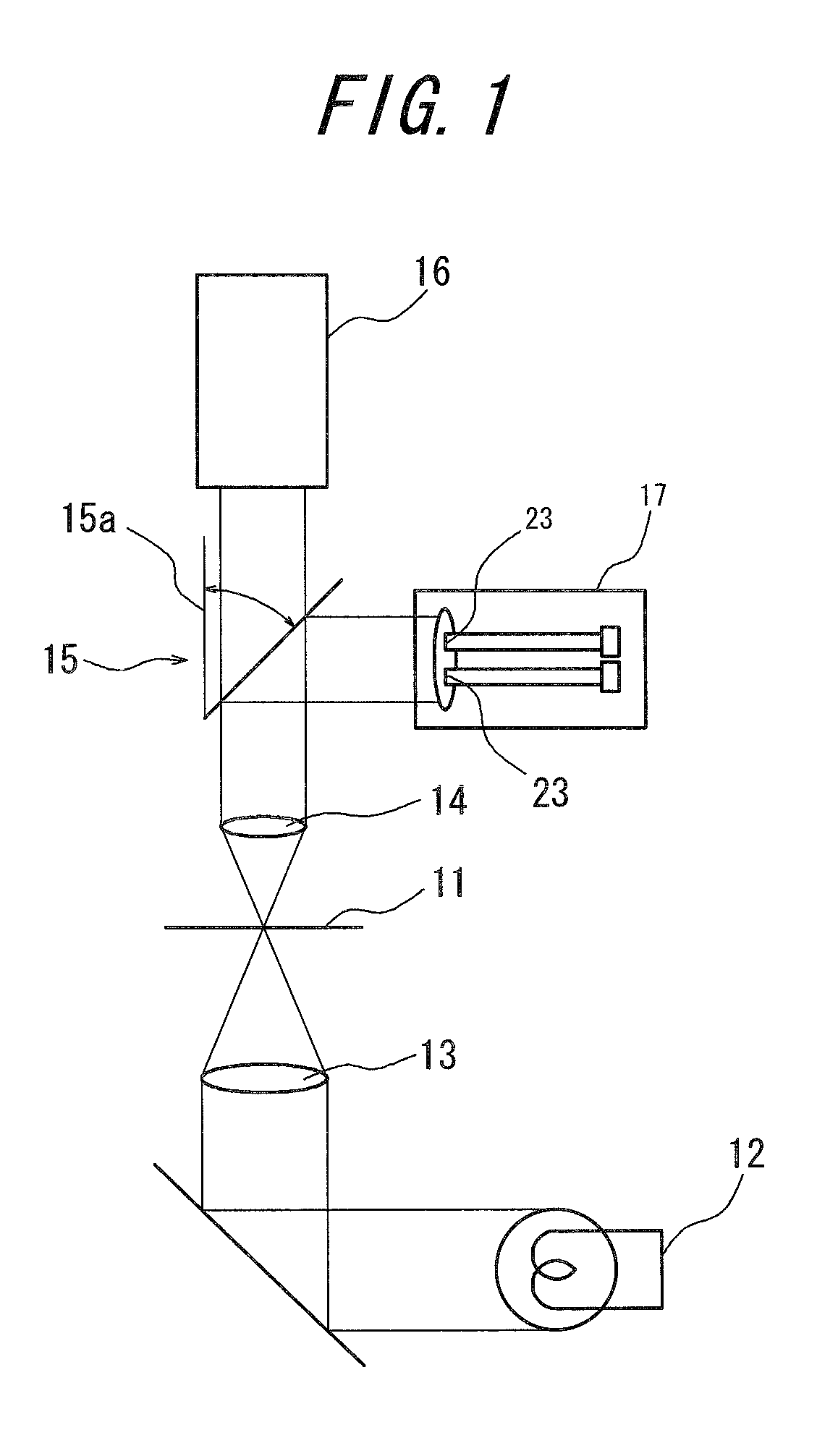

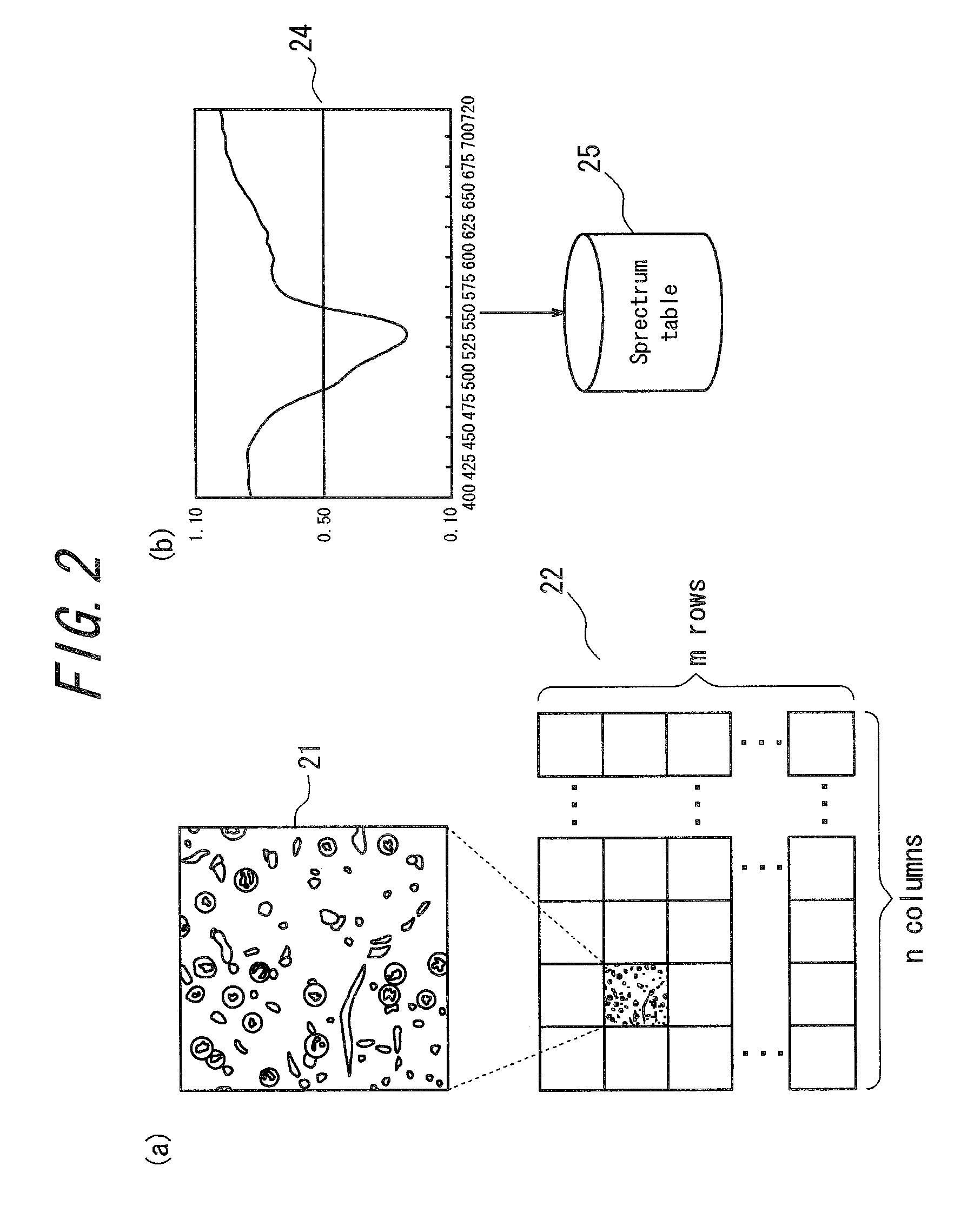

A virtual microscope system capable of obtaining a stained sample image and a statistical data of spectra in a short period of time is provided, the virtual microscope system includes an image obtaining unit for obtaining a stained sample image, a spectrum obtaining unit for obtaining a spectrum of the stained sample image, an optical path setting unit for setting an optical path of a light flux passed through the stained sample with respect to the image obtaining unit and the spectrum obtaining unit and a control unit for controlling to repeat obtaining the stained sample image by the image obtaining unit and obtaining the spectrum of the stained sample image by the spectrum obtaining unit in the observation field of the stained sample to create a virtual slide and a spectrum table of the stained sample.

Owner:EVIDENT CORP

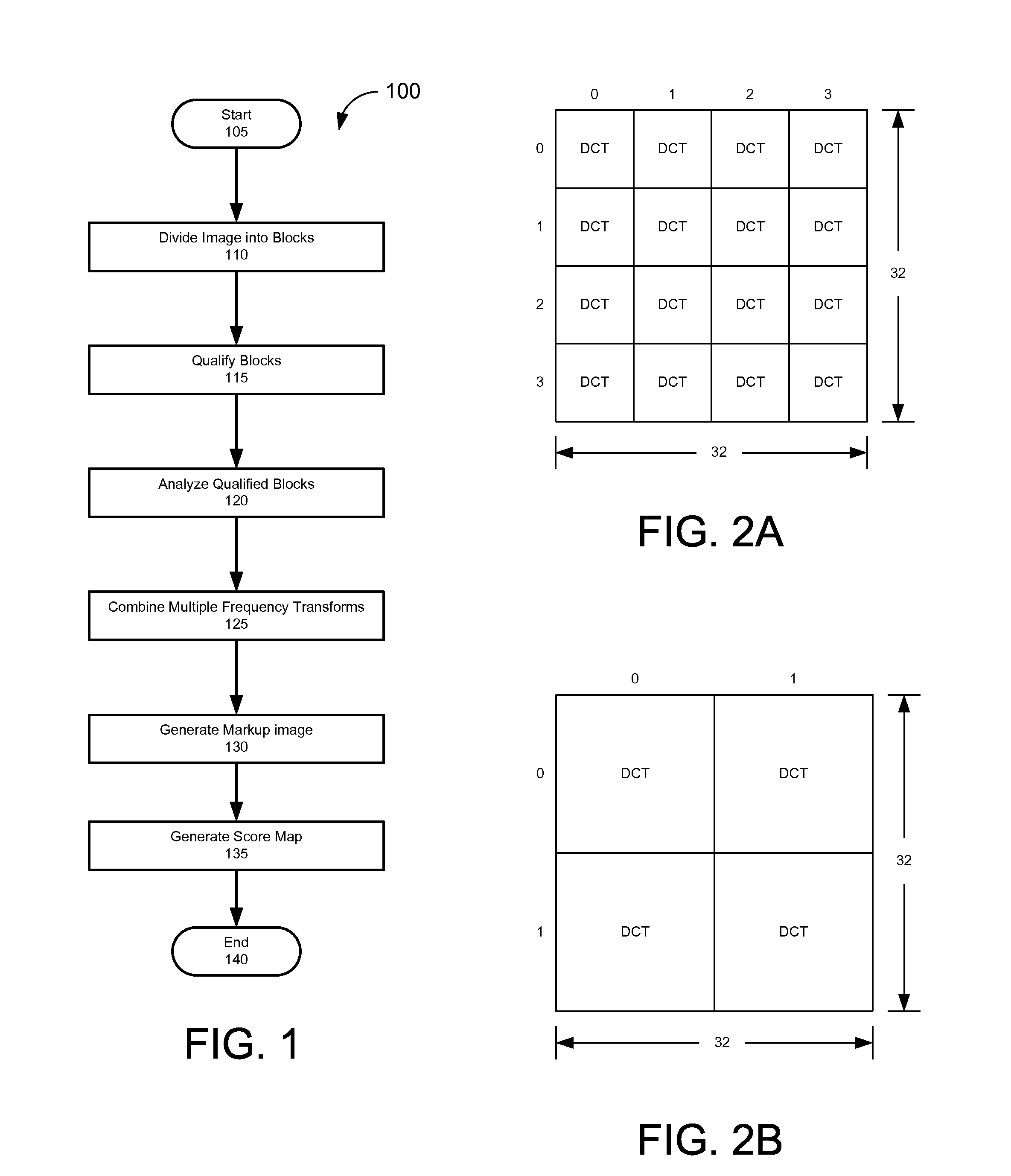

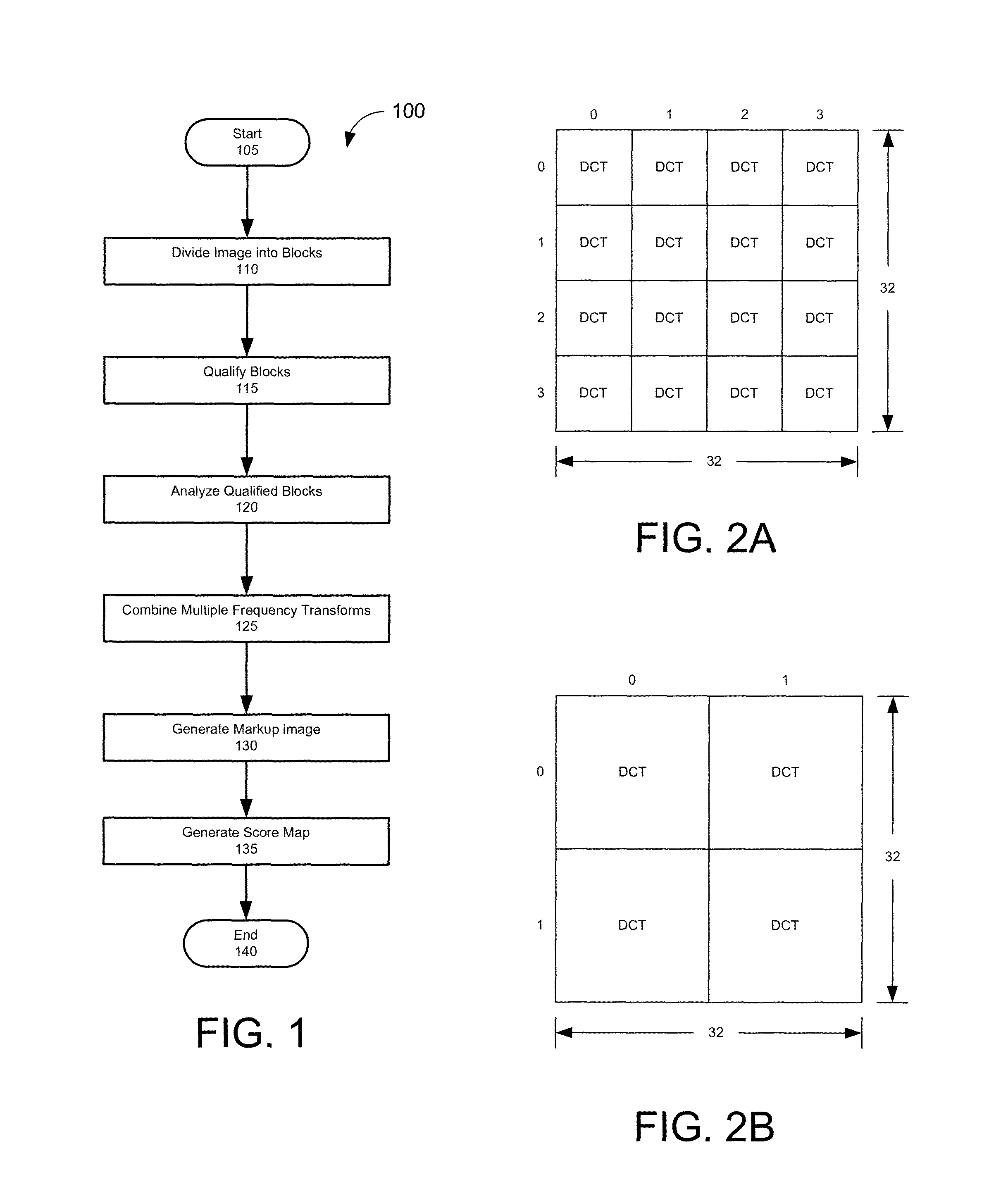

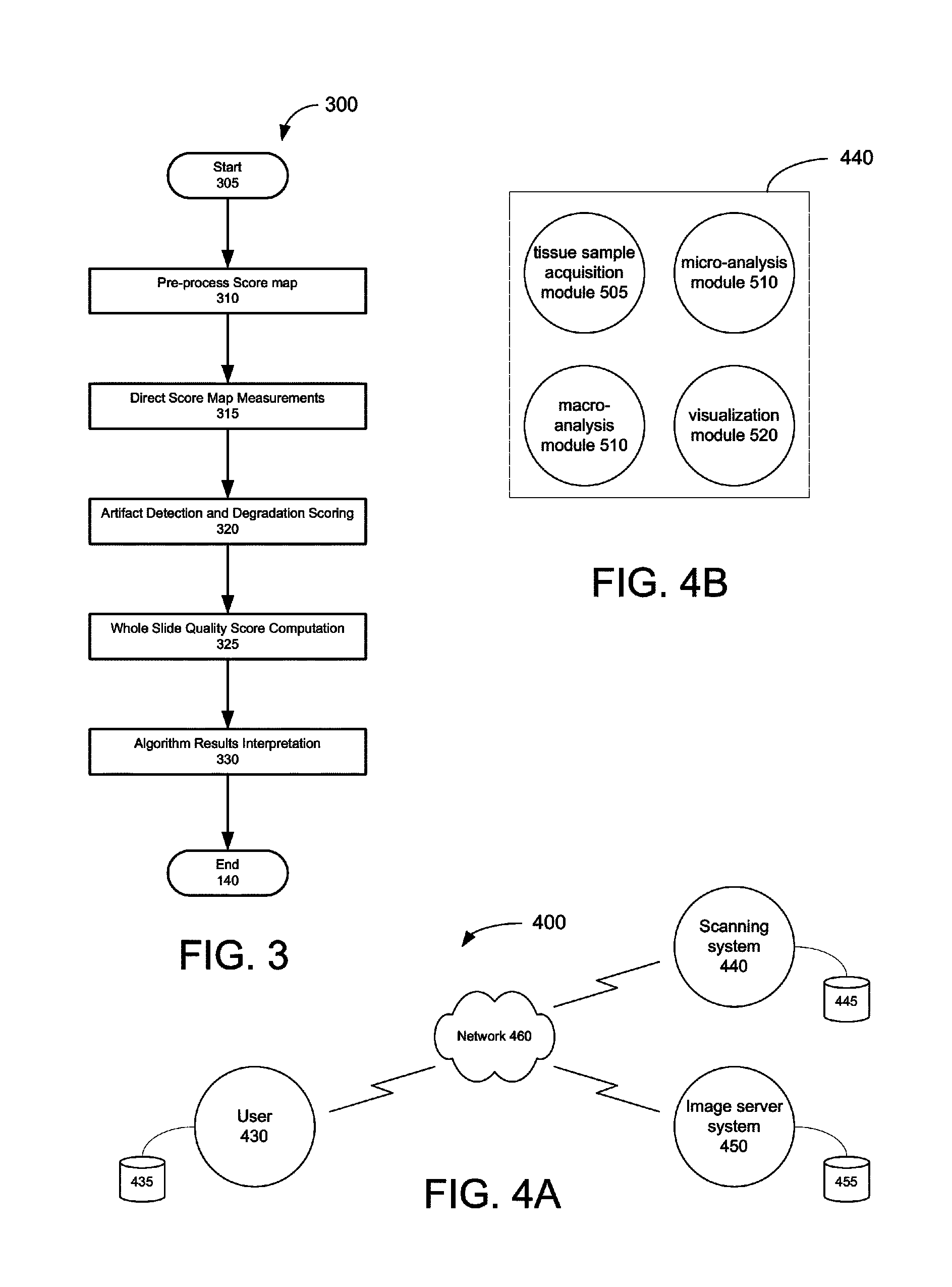

System and Method to Determine Slide Quality of a Digitized Microscope Slide

A system that determines the quality of a digital microscope slide by analyzing digital slide images based on complexity and spatial frequencies. An example embodiment detailed in the application may provide visual feedback on the whole slide quality by overlaying the image with a color coded “heat map” of local area quality. A user provided with the overlap image may obtain both an absolute quality measurement for the whole image and quickly identity the quality variability within the slide.

Owner:LEICA BIOSYST IMAGING

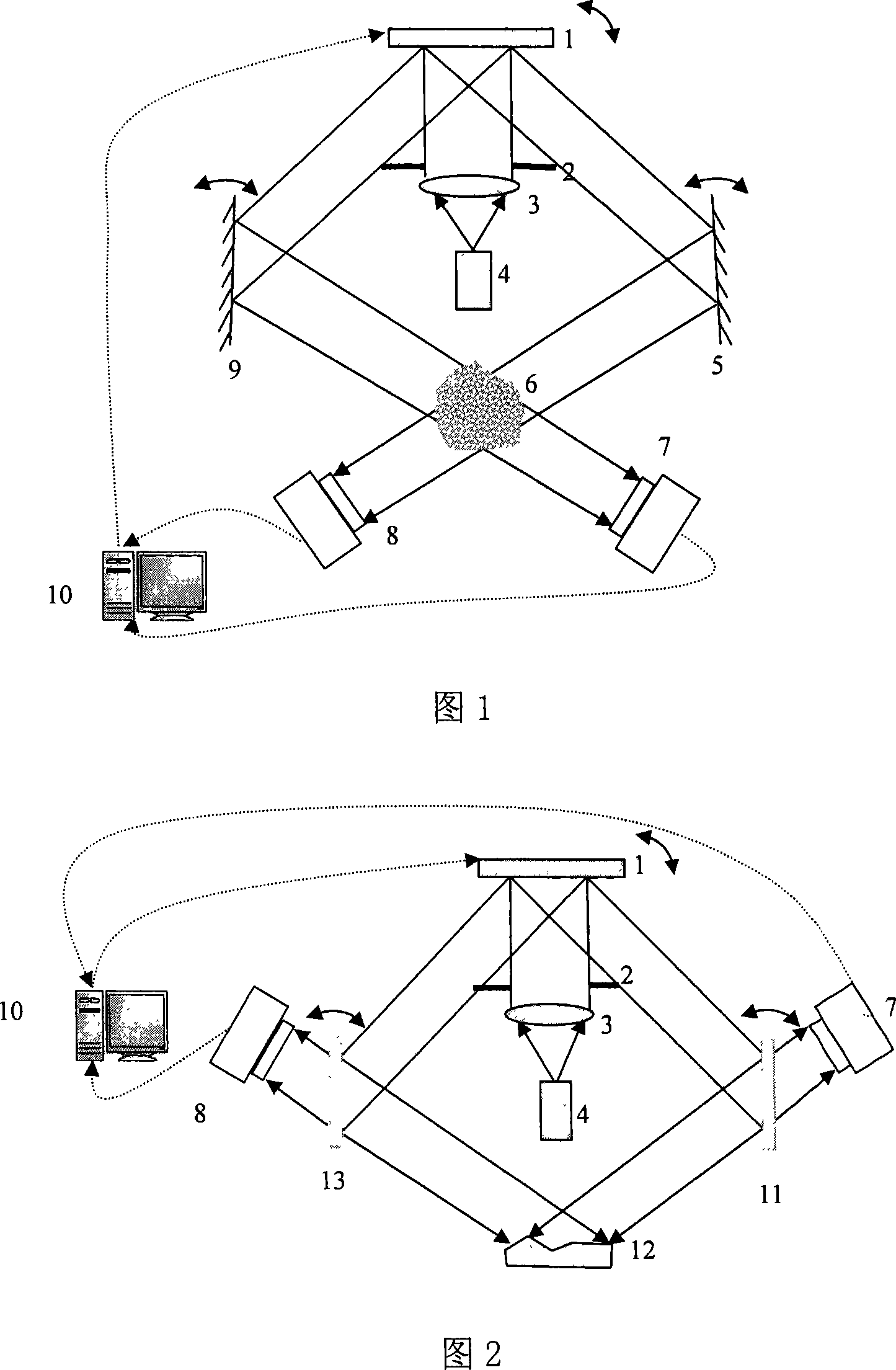

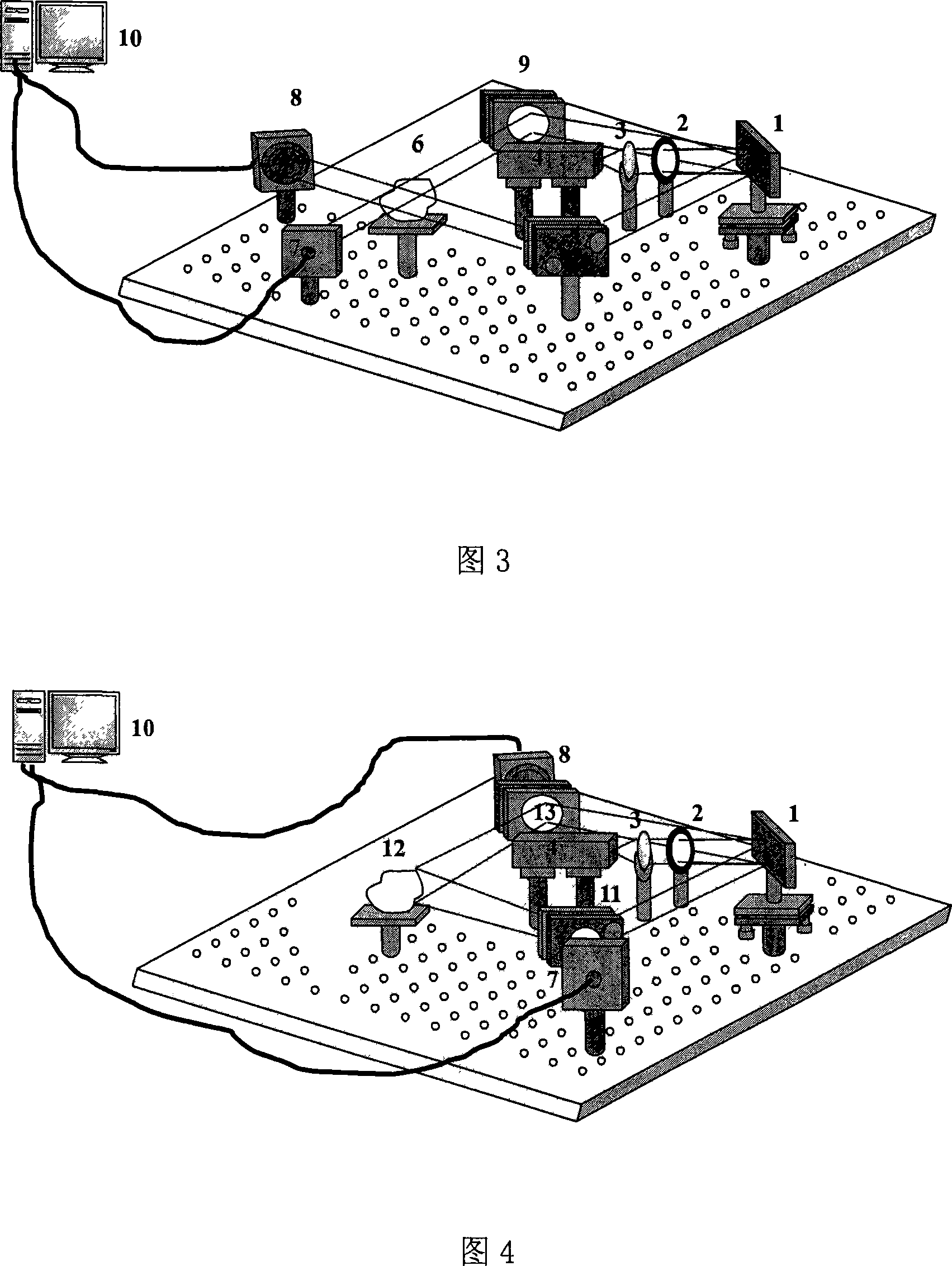

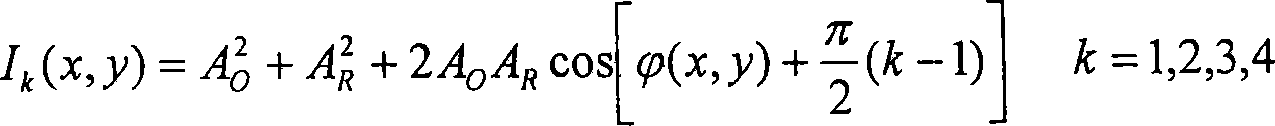

Measuring device and method for transparent substance and reflector based on digital microscope and data synthetic technique

InactiveCN101089550ASimple structureImprove measurement dynamicsUsing optical meansMeasurement deviceObject based

A morphology measurement device of transparent object based on digital micro-lens and data synthetic technology consists of a digital micro-lens, a light source illumination unit, two image receiving units with CCD video cameras and two reflectors. It is featured as utilizing multifunction of reflector and spectroscope as well as light beam modulator undertaken by digital micro-lens in measurement system and applying phase-shift digital hologram technique for realizing high-resolution outline measurement of object to be measured.

Owner:SHANGHAI UNIV

Digital microscopy equipment with image acquisition, image analysis and network communication

InactiveUS20110122242A1Less spaceLow costTelemedicineCharacter and pattern recognitionImaging processingImaging analysis

A digital microscope comprises a housing with an image acquisition, an image processing, and a network communication (APC) module. The APC module can further comprise an image capture unit, coupled to an image sensor with a view to a subject on a slide, the image capture unit receiving an image of the subject. The APC module also comprises an image processing unit, coupled to the image capture unit, the image processing unit enhancing the image with classifications. Also, a network interface of the APC module, coupled to the image processing unit and to a network, the network interface sending the enhanced image across to the network and to receive control commands, the control commands associated with the view of the subject.

Owner:TEXAS INSTR INC

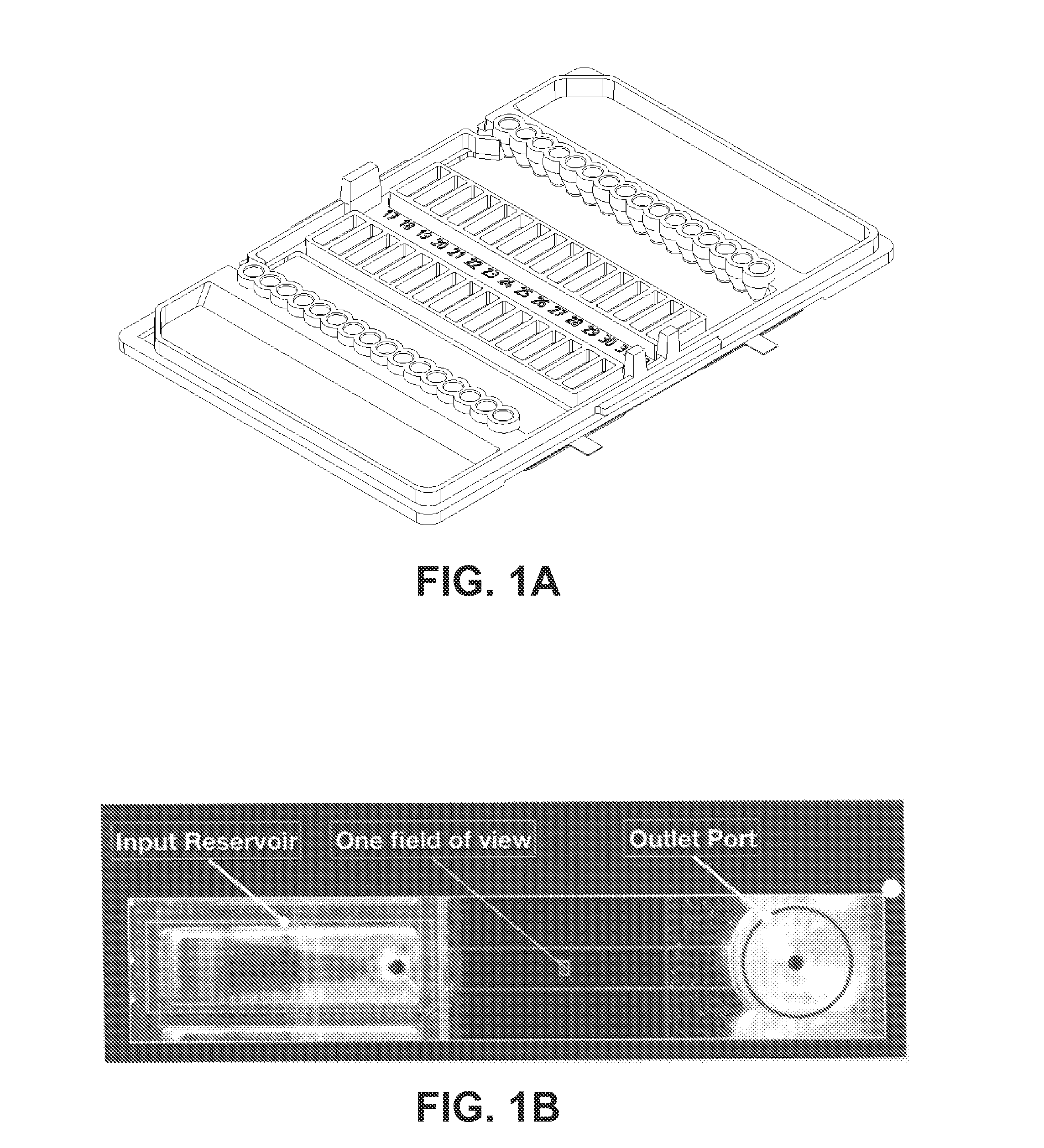

Same-day blood culture with digital microscopy

InactiveUS20150225762A1Inhibit microbial growthReduce and prevent depressionMicrobiological testing/measurementChemiluminescene/bioluminescenceCord blood cultureBiological cell

Generally provided are methods for rapid culture of microorganisms in a sample, including methods for growth and recovery of live microbial cells directly from a sample. Various features include enabling growth of microorganisms in a sample along with a reduction of sample debris that may interfere with microorganism detection, and reduction in toxicities that may inhibit microorganism growth. Further methods for selectively degrading non-viable microbial cells, are provided, for enhanced detection of viable microbial cells following a growth period.

Owner:ACCELERATED MEDICAL DIAGNOSTICS INC

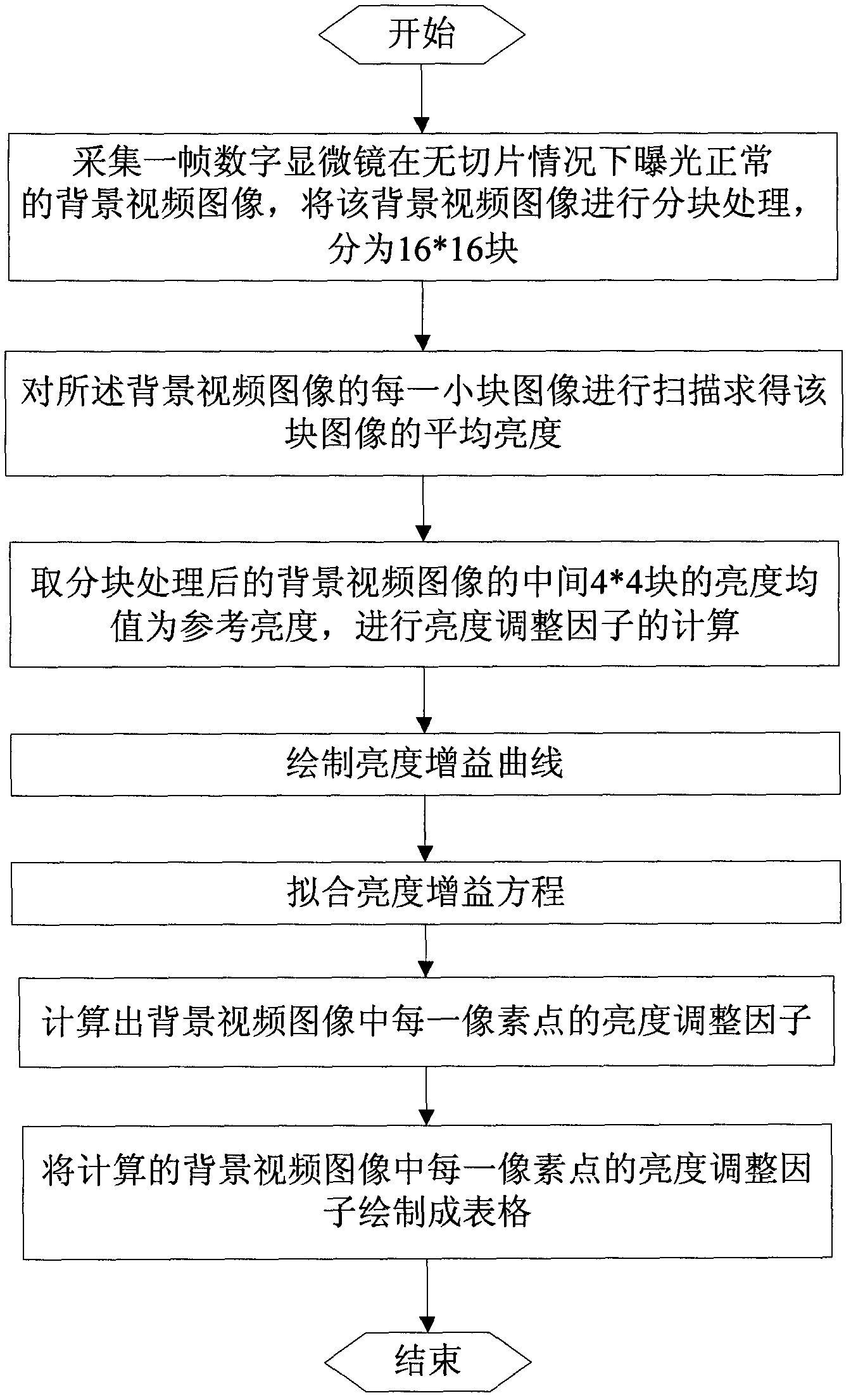

Method for processing microscope video image

InactiveCN102438107AUniform brightnessPromote reductionTelevision system detailsColor television detailsMicroscopic imageDigital image

The invention relates to a method for processing a microscope video image, in particular to an exposure processing method of a digital microscope image, which is characterized in that: for the characteristics that the illumination of an optical microscope digital image system is not uniform, an exposure situation is determined according to a brightness histogram so as to adjust the exposure time; and a brightness gain curve is drawn according to a pure background slice-free background image to obtain a brightness gain equation, and a brightness adjusting factor when the brightness of the pure background slice-free background image is adjusted to be uniform can be calculated through the equation. Under the same condition, a brightness value of a pixel point corresponding to a sliced image is adjusted through the brightness adjusting factor to obtain the brightness homogeneity of the image. Due to the adoption of the method, the homogeneity adjustment of the video image of the optical microscope digital image system can be precisely realized.

Owner:NINGBO UNIV

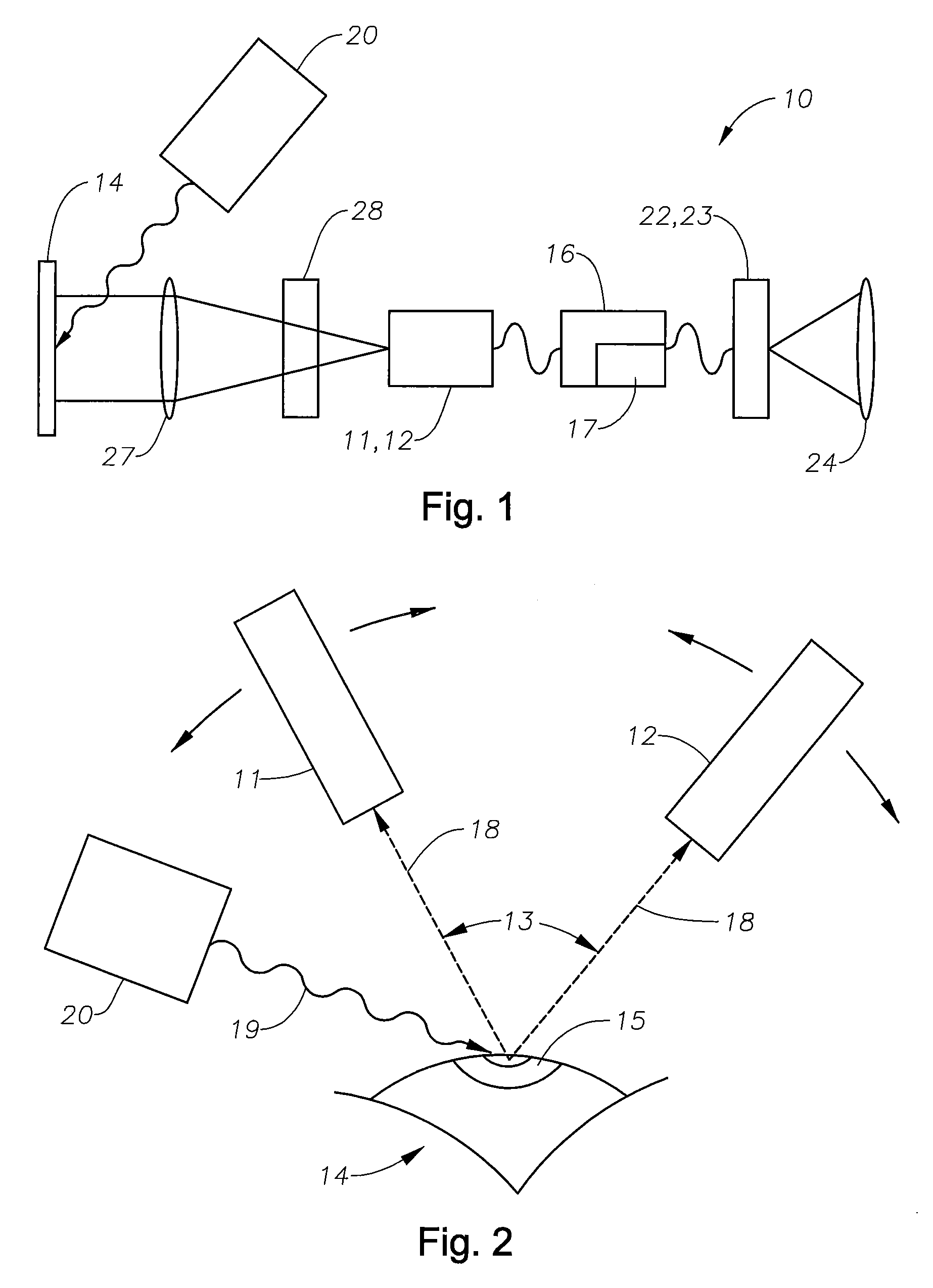

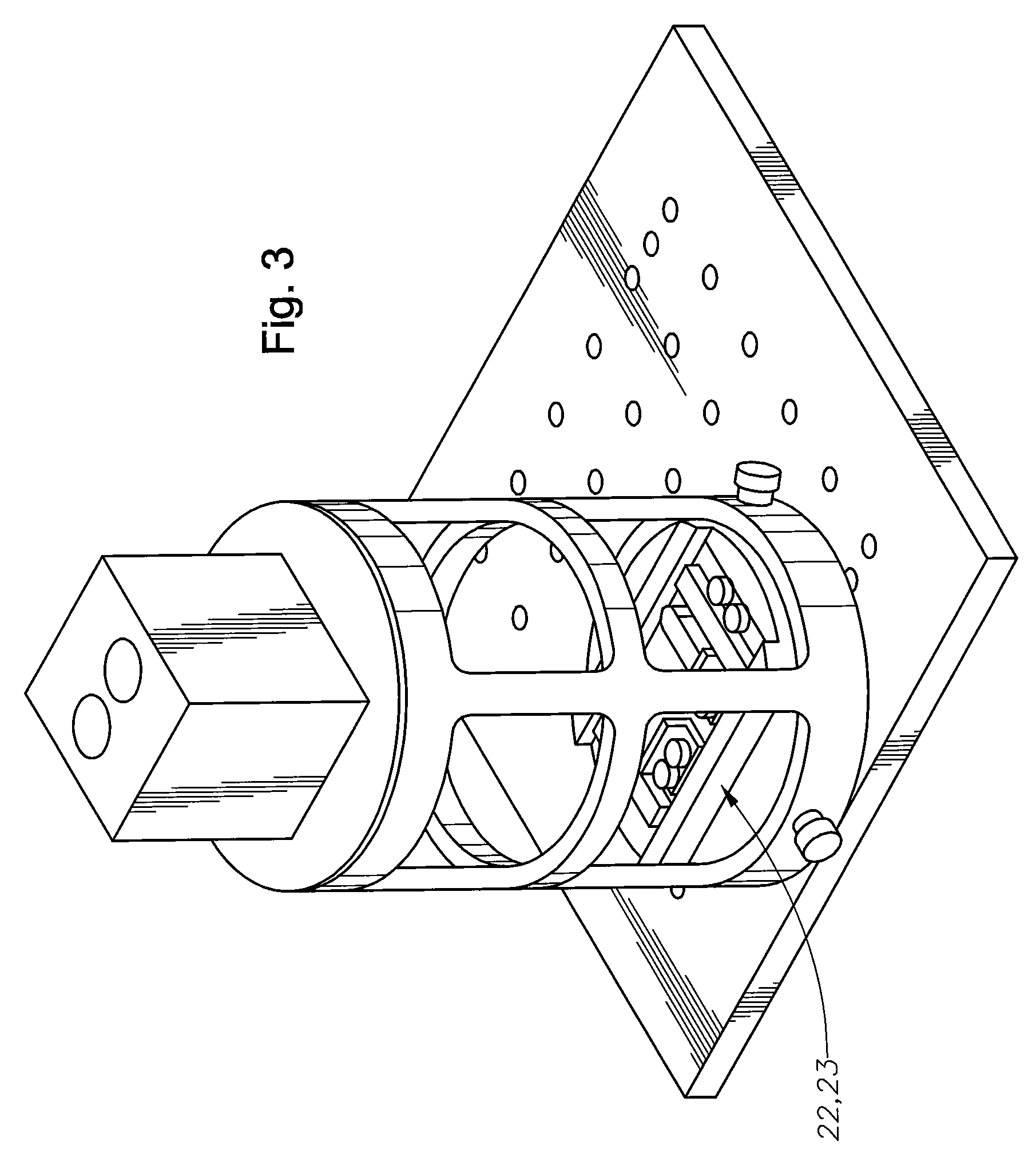

Virtual microscope system for monitoring the progress of corneal ablative surgery and associated methods

A system for visualizing an eye of a patient during corneal surgery includes a processor and a first and second camera in signal communication with the processor. The cameras are positionable for focusing on a cornea positioned for surgery. A first and a second display and optics therefor are in signal communication with the processor and are positionable for viewing through a first and a second eyepiece of a stereo microscope, respectively. Software is resident on the processor for receiving a first and second corneal image from the first and second cameras, for processing the received first and second images for display, and for transmitting the processed first and second images to the first and the second displays, respectively, via the display optics. The displays can then be viewed by a surgeon through the microscope at least during the surgery.

Owner:ALCON INC

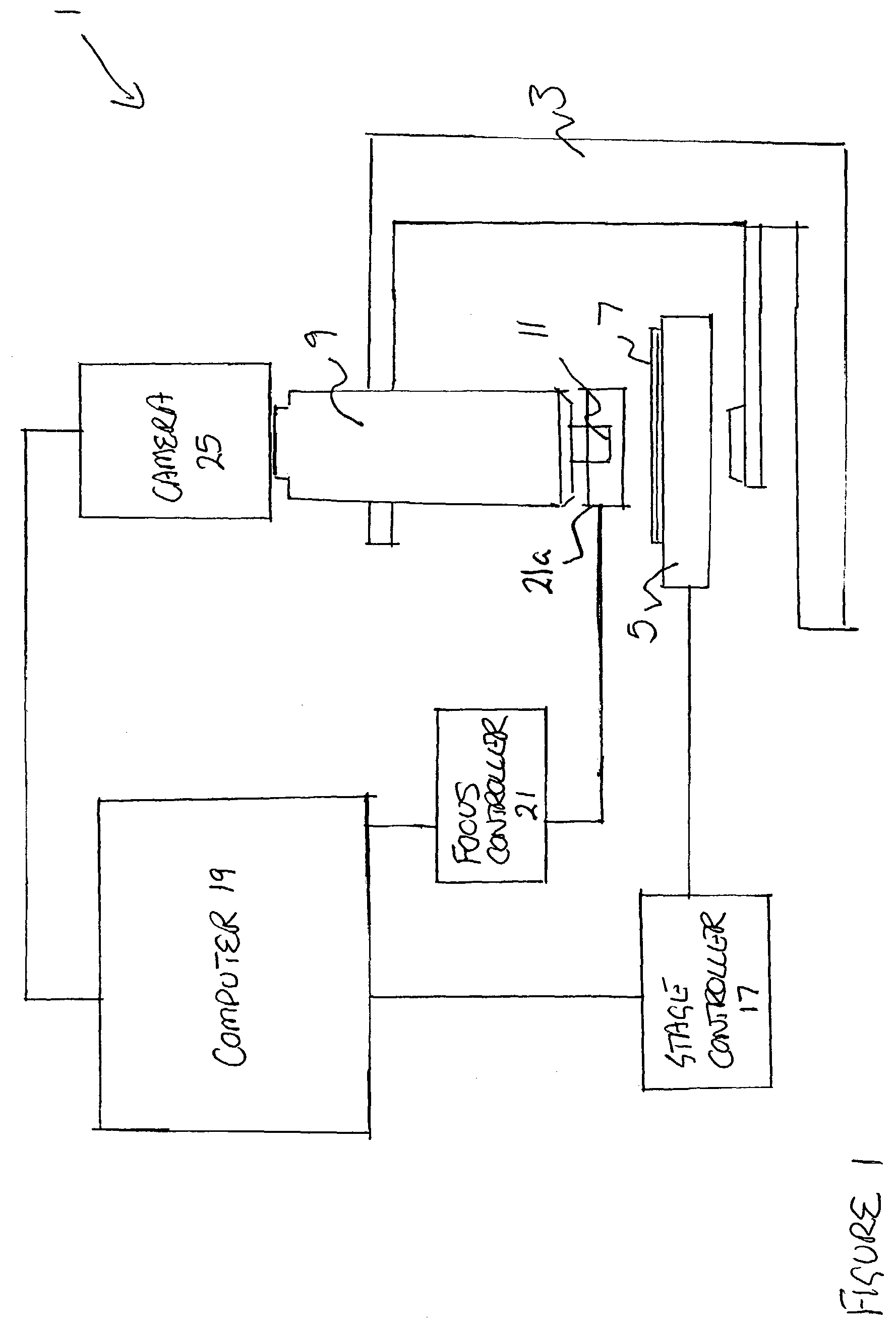

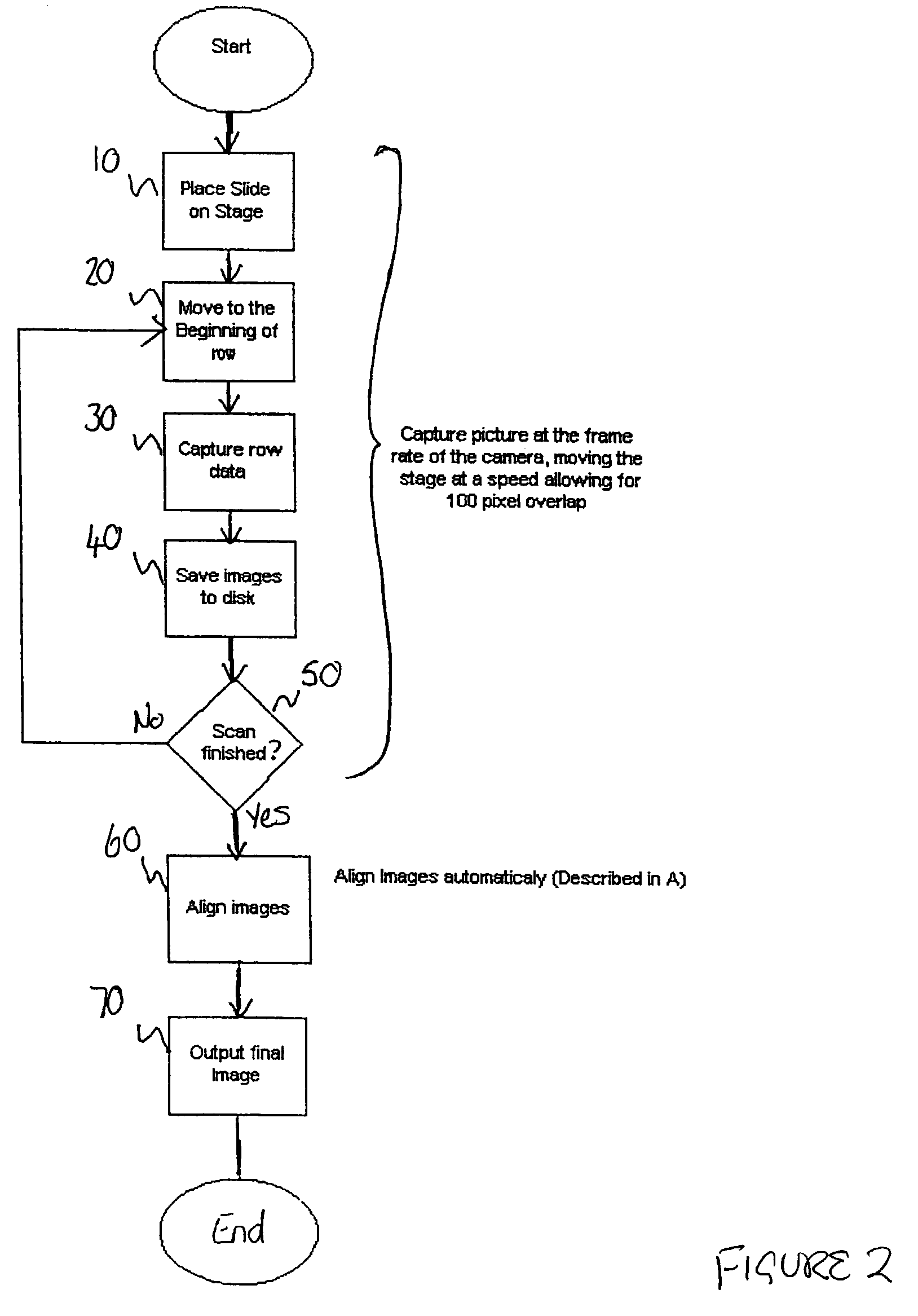

Method and apparatus for acquiring digital microscope images

InactiveUS7388599B2Reduced imaging timeColor television detailsClosed circuit television systemsShutter speedImage system

A method and apparatus for acquiring digital microscope images is disclosed, in which a plurality of magnified images of a specimen are captured for tiling together to provide an overall composite image of the specimen. In accordance with the described method, the specimen is moved relative to an imaging system comprising a microscope and camera in a predetermined path whilst the plurality of magnified images are captured. In a preferred embodiment, the specimen, contained on a slide, is mounted on a movable microscope stage, and is moved beneath the microscope in the predetermined path. The velocity of the movement of the stage and the shutter speed of the camera is computer controlled to capture overlapping, clear images.

Owner:SOURCE BIOSCI

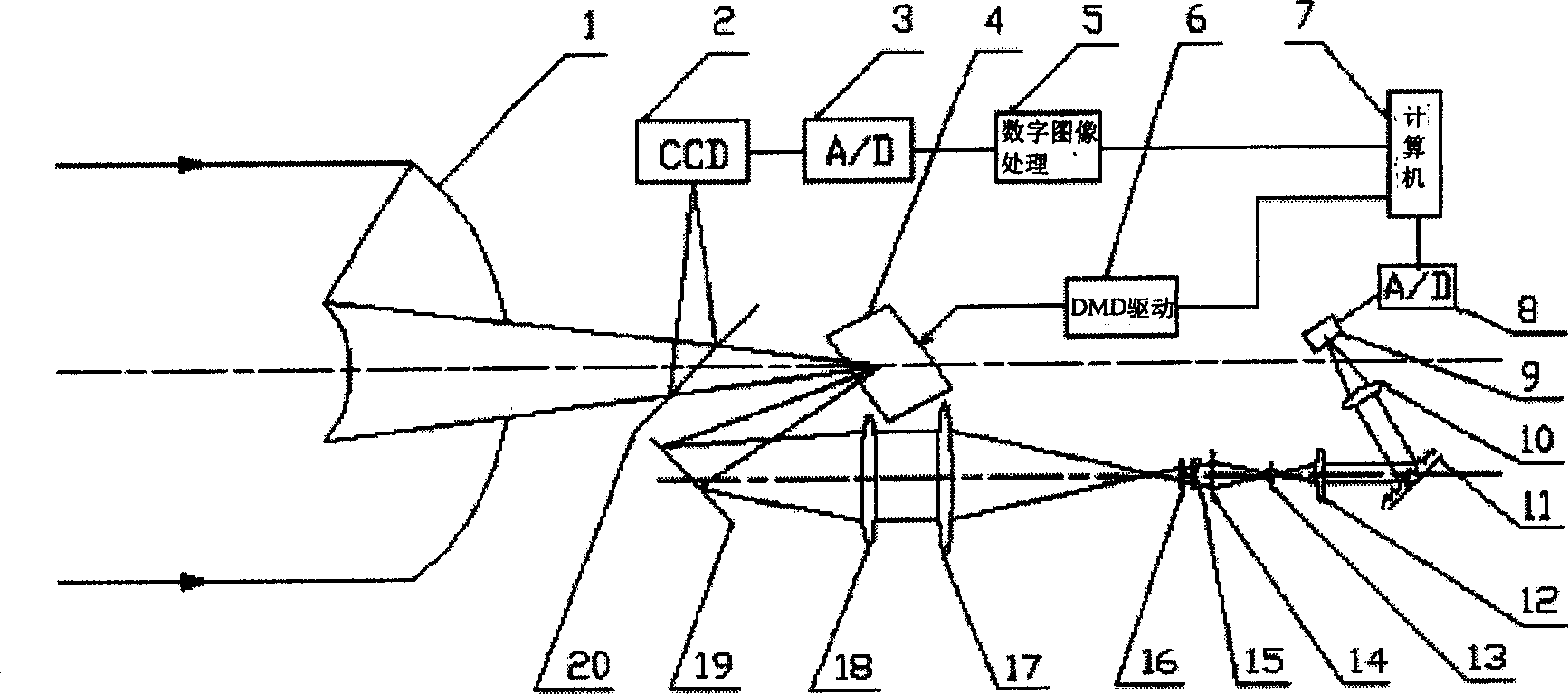

Digital microscope multi-objective imaging spectrometer apparatus

InactiveCN1702452AEliminate the effects ofHigh resolutionColor/spectral properties measurementsPoint objectData acquisition

This invention relates to an optical spectrum instruments of digital microscope multi-imaging, which comprises subsystems of imaging, dimensionality compression, dispersion and collection of spectrum and feedback of digital microscope circuit, wherein, the imaging subsystem comprises pre-telescope, digital microscope, collimation lens and focusing lens; the dimensionality compression subsystem comprises cylindrical micro-lens array and cylindrical lens; feedback subsystem of digital microscope circuit comprises spectroscope, focal plane detector, data gathering chip, digital image processor, computer and digital microscope driver. The invention can rapidly chose a plurality of point objects in large angular field without scanning, and can eliminate the influence of ambient light to improve the system signal-to-noise ratio.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

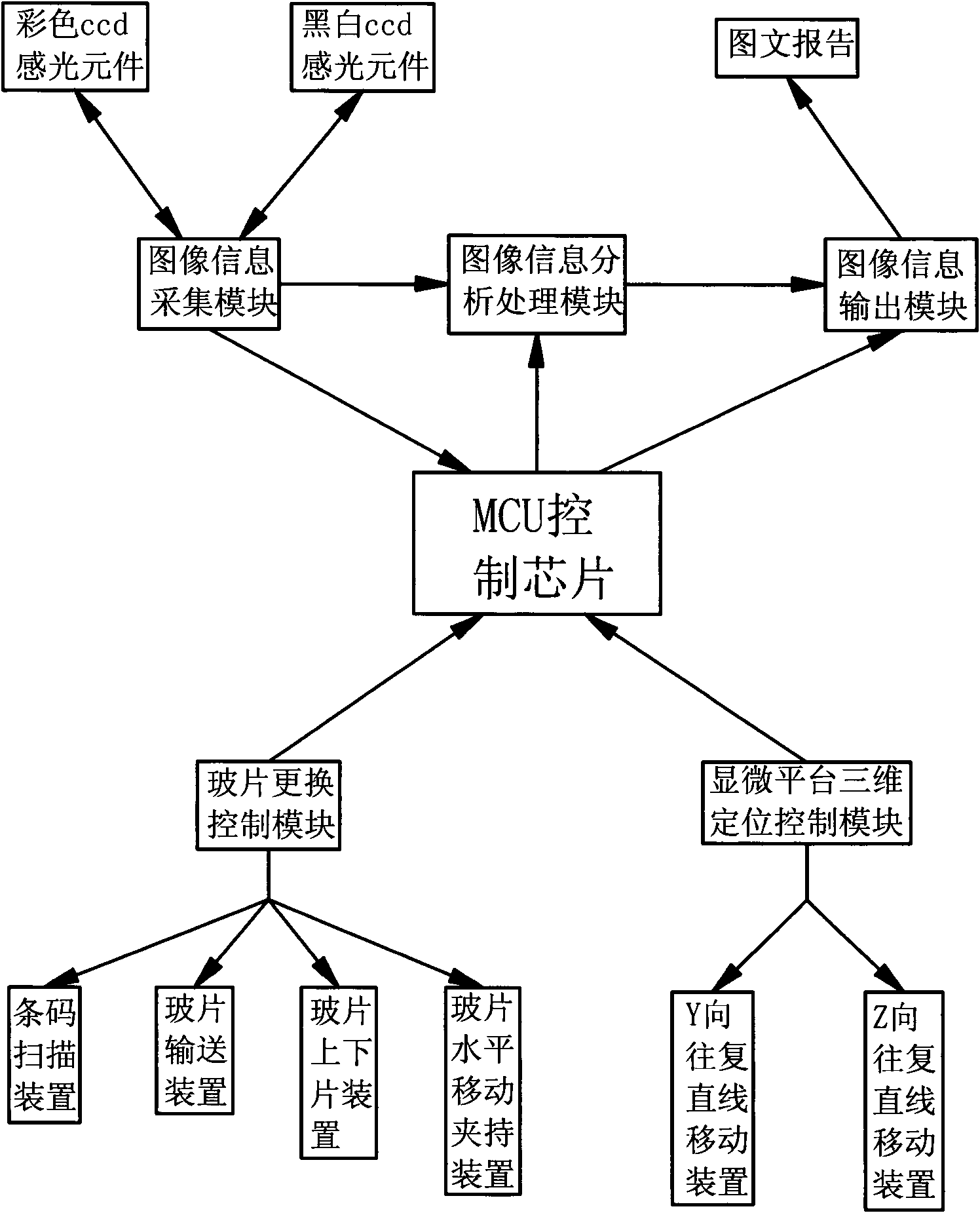

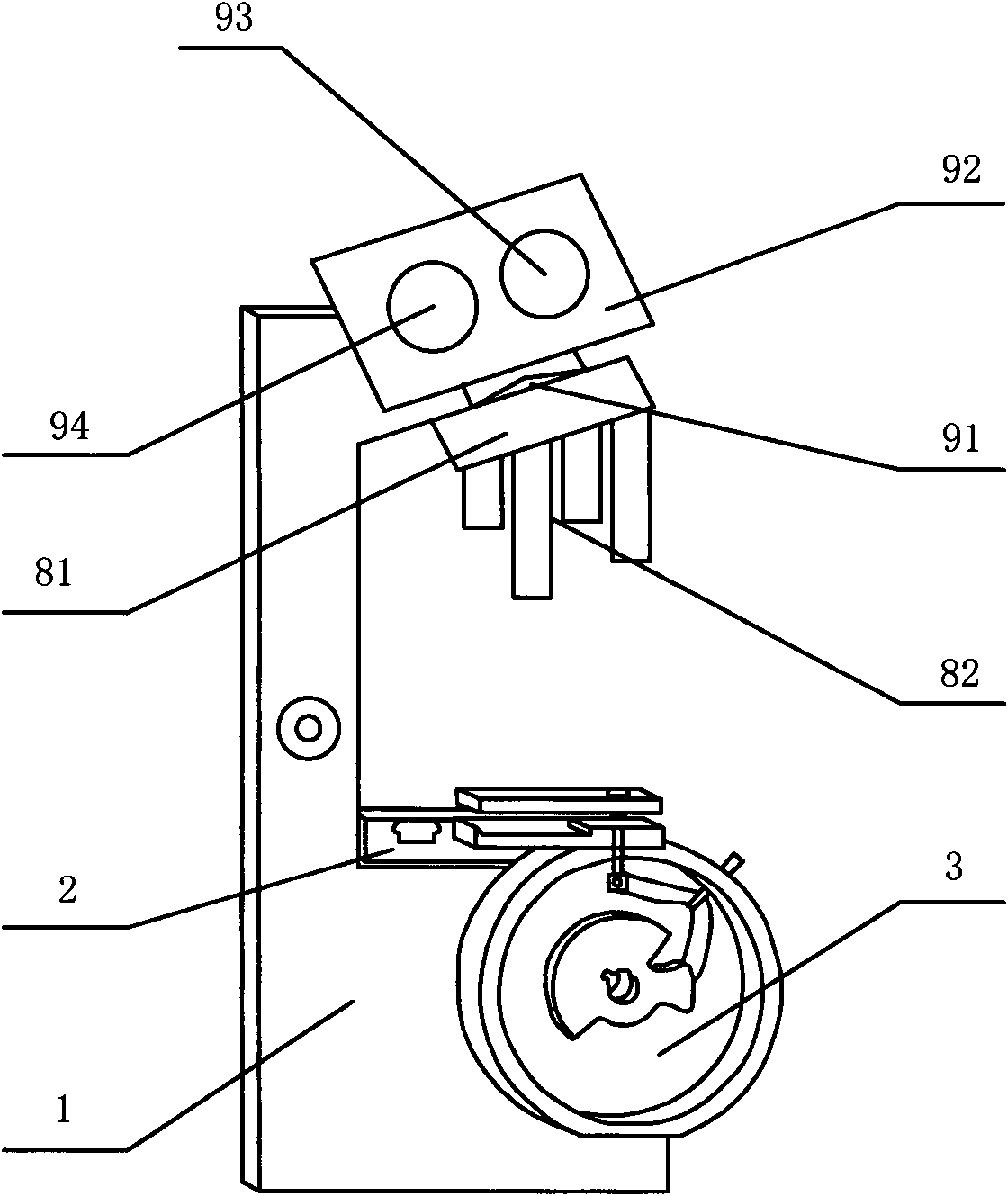

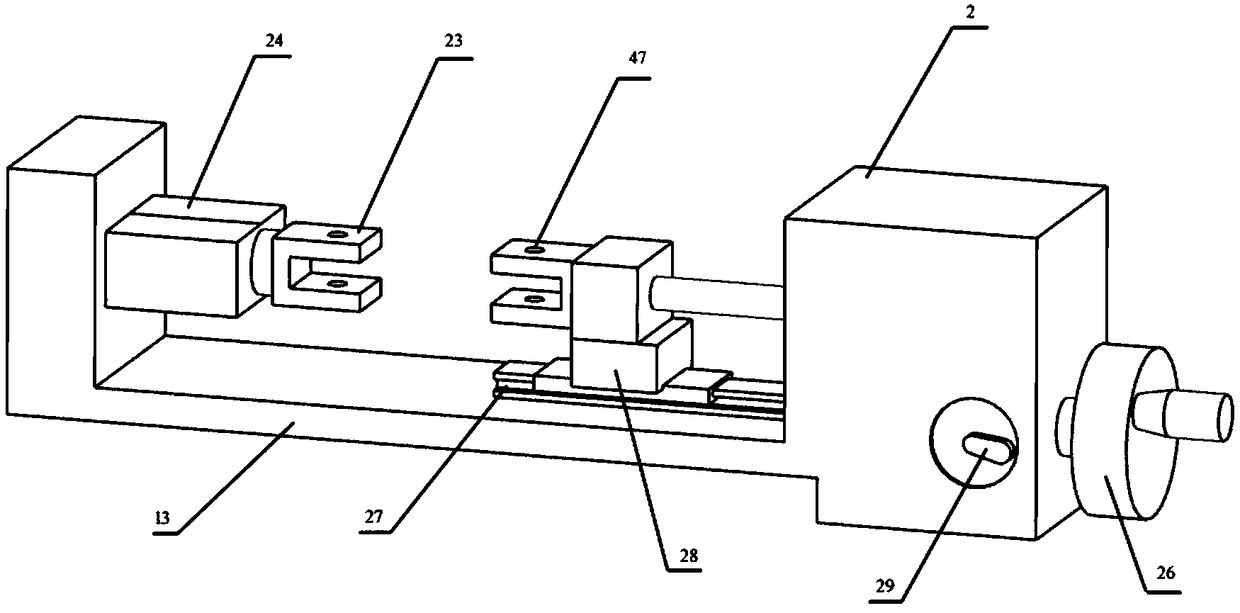

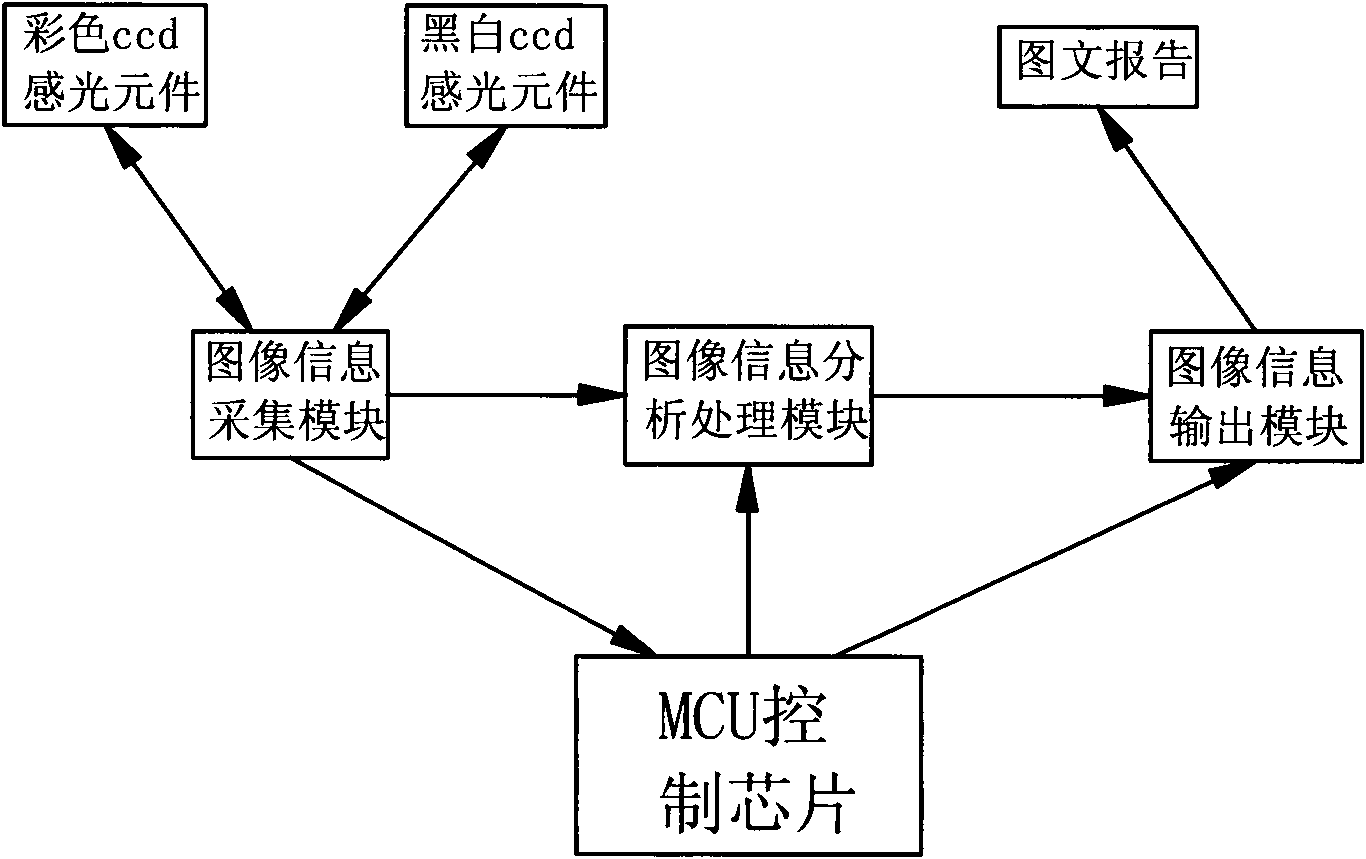

Full-automatic double-ccd photosensitive element digital microscope

ActiveCN102122066ATo achieve the purpose of intelligent screeningGuaranteed effectMicroscopesDigital imageOptical density

The invention discloses a full-automatic double-ccd (charge-coupled device) photosensitive element digital microscope, which is used for acquiring specimen image information by synchronously using a colored ccd photosensitive element and a black-and-white ccd photosensitive element so as to obtain a multifocal plane holographic three-dimensional image, synchronously outputting a specimen reading result according to nucleus integral optical density acquired by the black-and-white ccd photosensitive element, and finally outputting a specimen picture and text report. Additionally, the full-automatic double-ccd photosensitive element digital microscope comprises a slide uploading and unloading device and a horizontal migration clamping device for automatically changing the specimen slide, and then, the slide is located in three dimensions through a three-dimensional frame, so that the colored ccd photosensitive element and the black-and-white ccd photosensitive element can conveniently acquire the image information of the specimen. Thus, the full-automatic double-ccd photosensitive element digital microscope can be used for not only performing morphological observation on the specimen, but also taking digital images for a dyed tissue section so as to form the multi-focal plane holographic three-dimensional image, so that all the information of the cell can be observed in multiple layers and multiple focal planes, and accuracy of early diagnosis is greatly improved.

Owner:湖南港湾科学仪器有限公司

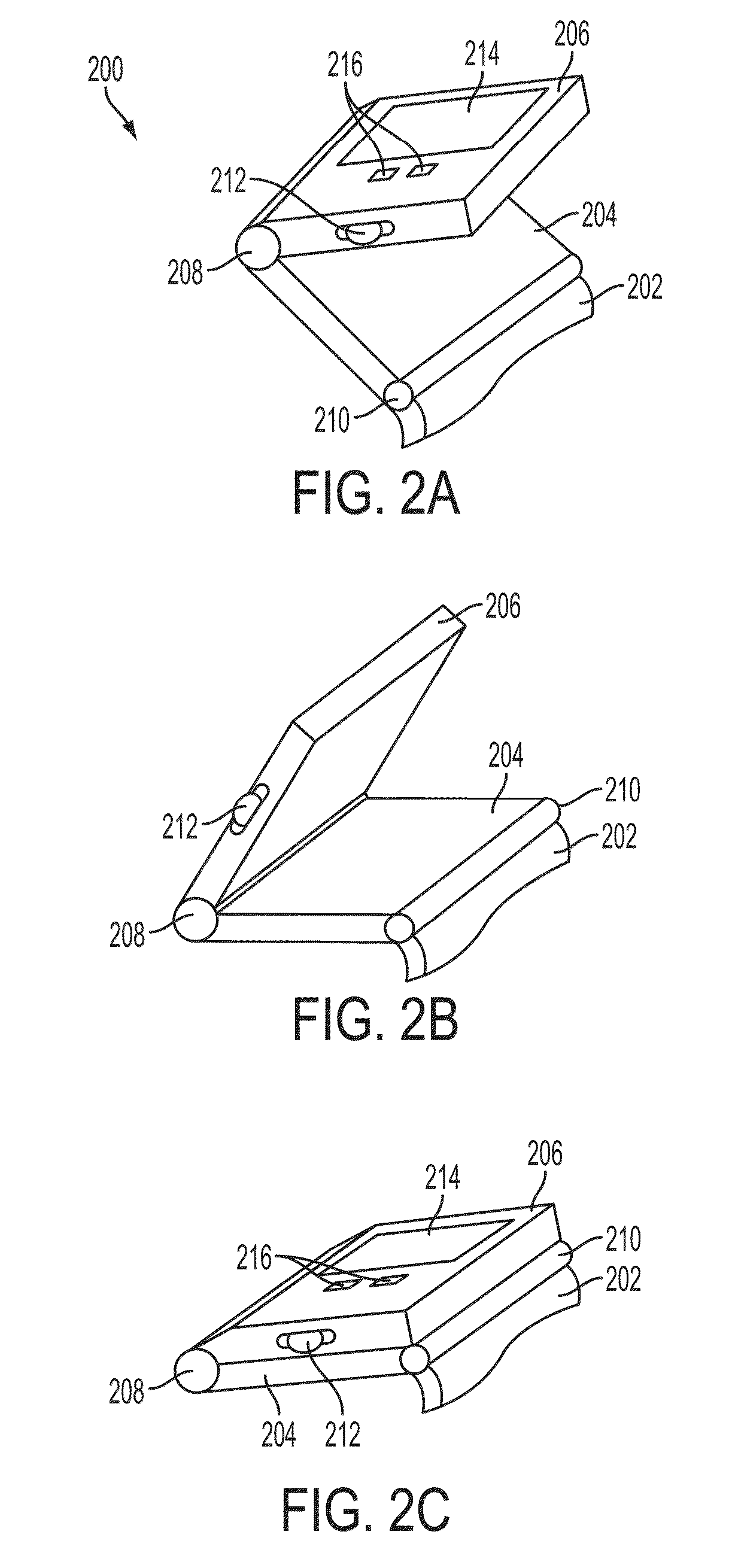

Adjustable digital microscope display

ActiveUS20140327757A1Color television detailsClosed circuit television systemsFluorescenceDisplay device

The present invention relates in general to microscopy systems. In particular, the present invention relates to microscopes rendering digital images of samples, with the capability to digitally control the focus of the microscope system, and the software used to control the operation of the digital microscope system. Further, the present invention relates to a microscope structure that allows for compact and multi-functional use of a microscope, providing for light shielding and control with samples that require specific light wavelength characteristics, such as fluorescence, for detection and imaging.

Owner:BIO RAD LAB INC

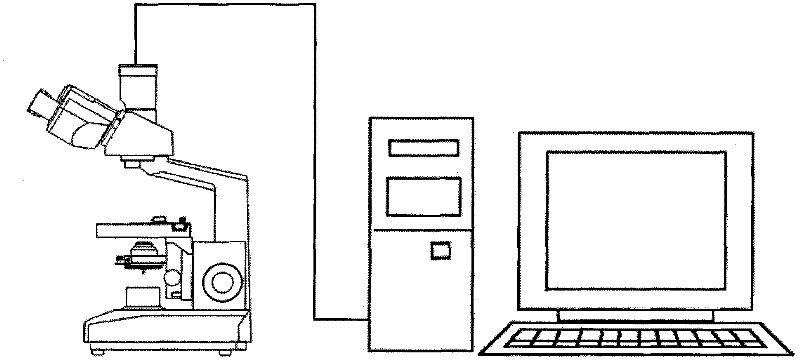

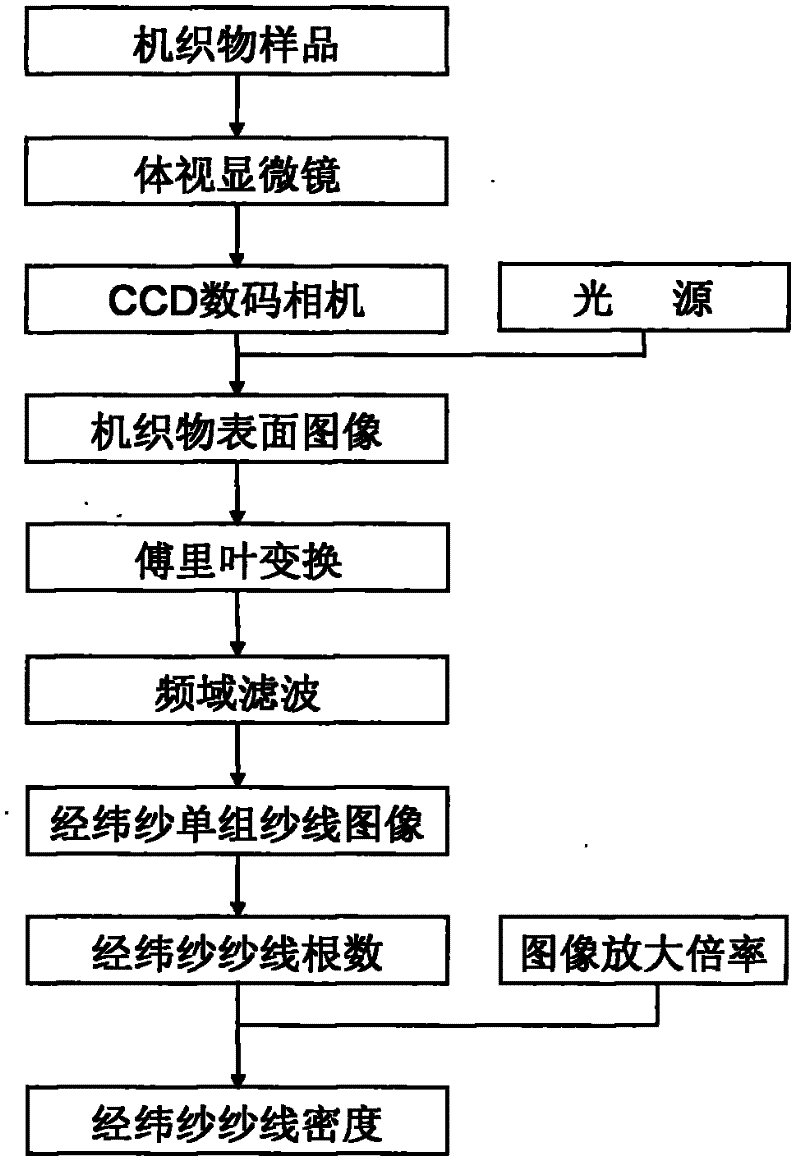

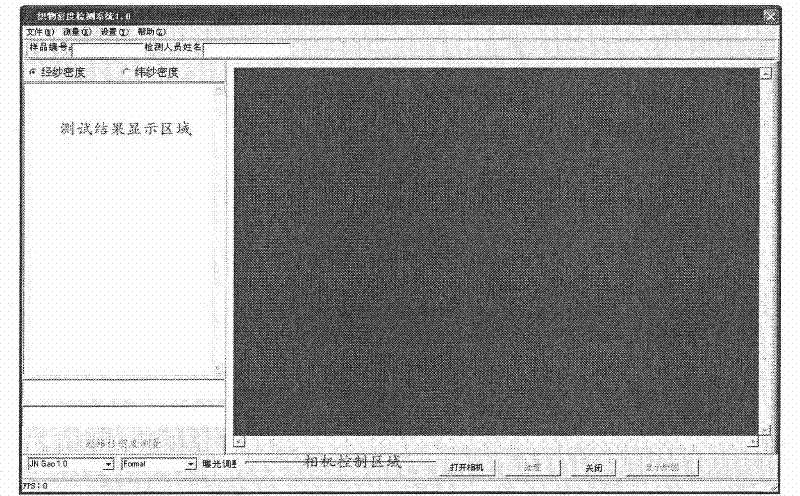

Woven fabric count detector based on digital microscope

InactiveCN102288607ARealize automatic measurementAutomate analysisMaterial analysis by optical meansFiberEngineering

The invention discloses a woven fabric count detector based on a digital microscope, belonging to the field of novel spinning detection instruments. Fabric count refers to the quantities of warp and weft yarns within a unit length of a fabric. The conventional manpower-dependent detection method has the defects of time and labor wasting and high subjectivity, and cannot meet the requirement of spinning production automation obviously. Specific to the technical problem, the digital microscope is taken as image acquisition hardware, and automatic detection of fiber count is realized in combination with an image processing method, so that an automatic woven fabric count detection instrument is realized. A CCD (Charge Coupled Device) digital camera is used for acquiring a fiber surface image amplified by a microscope objective, and a fiber image is read into a computer through a USB (Universal Serial Bus) or an IEEE1394 interface. The obtained fiber image is subjected to Fourier transform, and separation of warp yarns from weft yarns in the fiber image is realized with a frequency domain filtering method. The quantities of warp and weft yarns within certain lengths are counted in a separated single group yarn image, so that the woven fabric count is computed automatically.

Owner:JIANGNAN UNIV

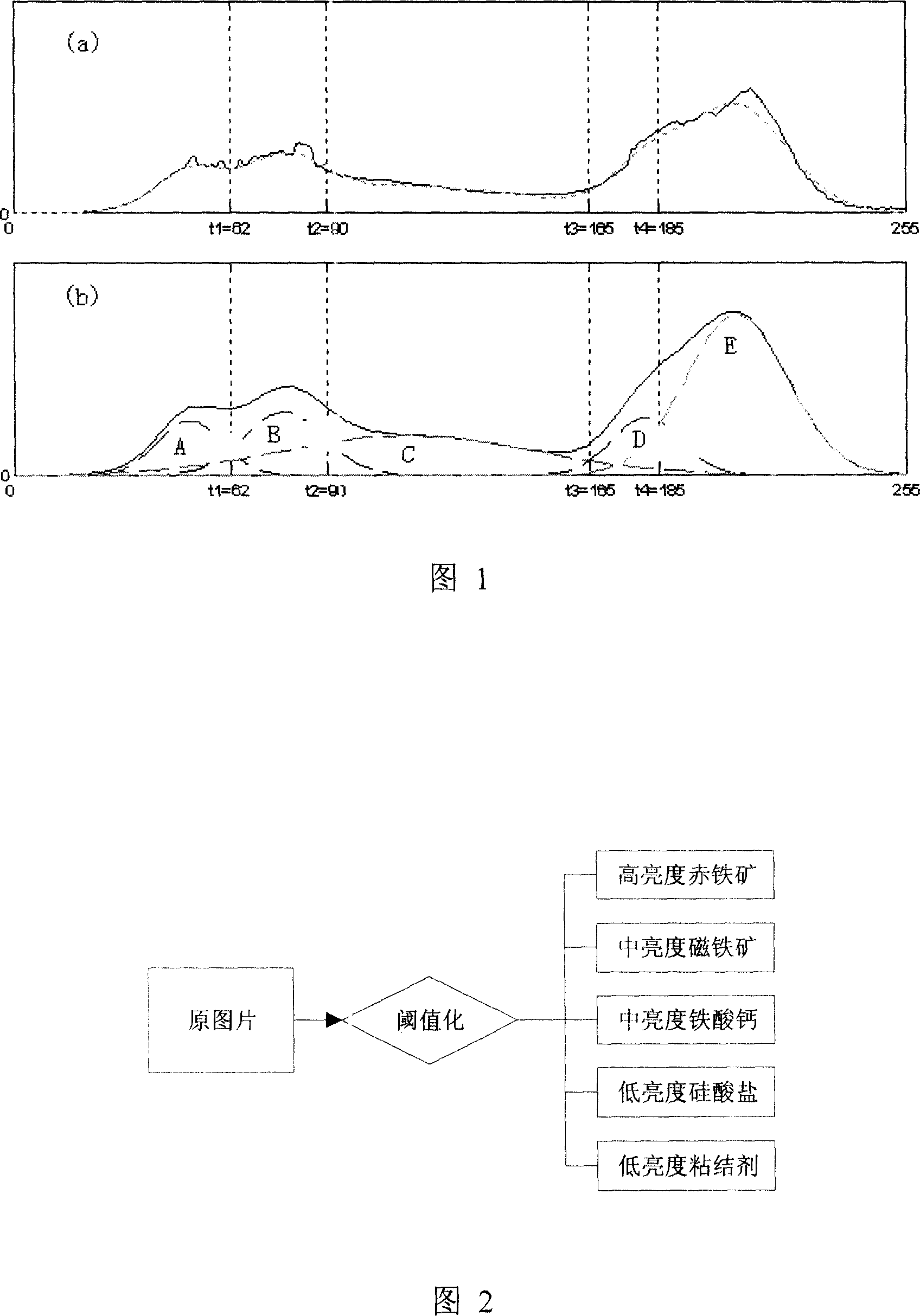

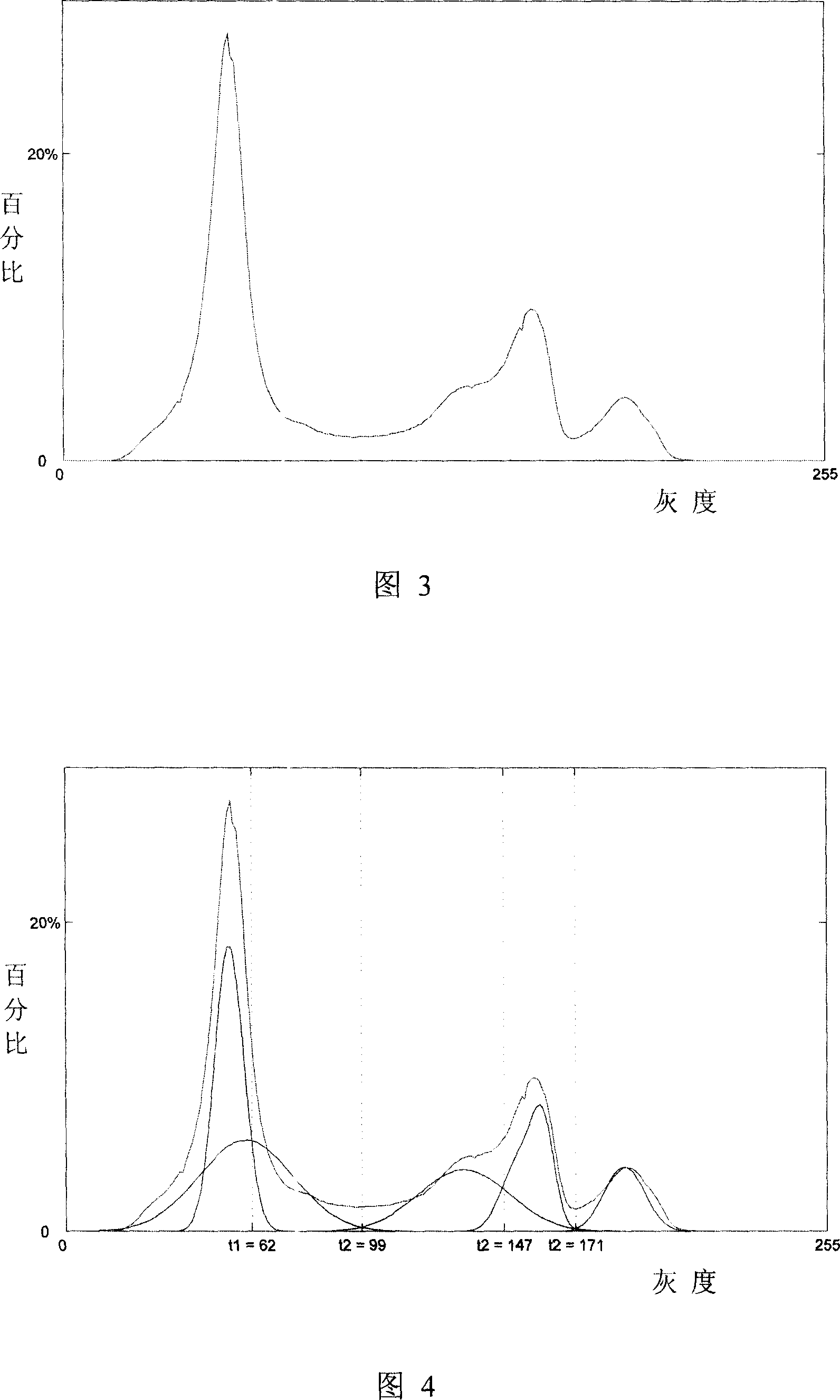

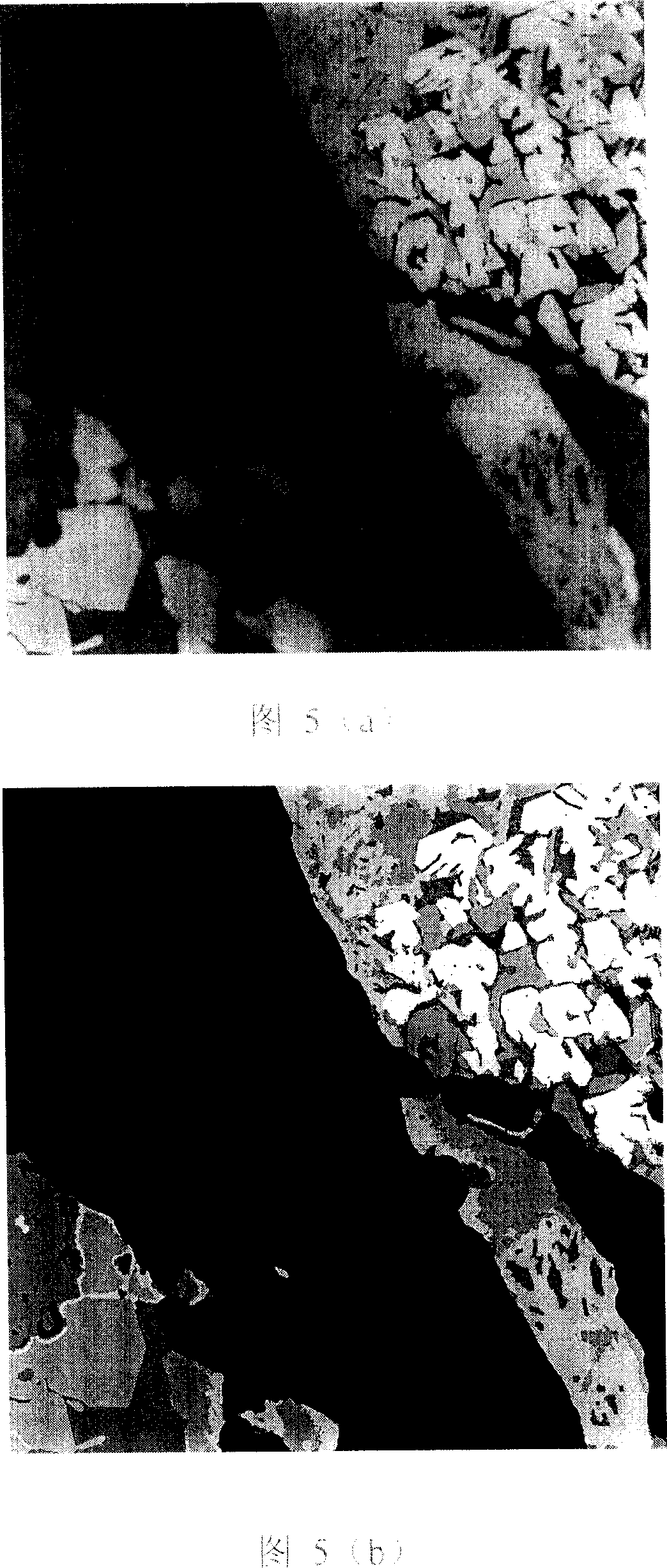

Automatic recognition method for sintered ore essential mineral phase

InactiveCN101131365AAccurate statistical calculationCharacter and pattern recognitionColor/spectral properties measurementsPhase analysisPeak value

This invention relates to sintered mineral phase analysis techniques. It discloses a automatic identification method of major mineral phase in sintered minerals, the method is applicable for automatically find out the optimal threshold value under the condition that distribution of shade of gray of all types of sintered phase are mixed and the regular of peak value distribution is not obvious, that is based on the expectation maximization (EM) methods; using mathematical expectation maximization histogram approximation algorithm, through the fit of Gaussian distribution of different components to obtain the most optimized image segmentation gray threshold; analysis the digital microscopy image of the sintered minerals to acquire optimal threshold value parameters of segmentation of by hematite, magnetite, iron calcium, and silicate binder these five categories, so as to achieve the computer intelligent identification method of hematite, magnetite, iron calcium, and silicate binder, thereby achieving accurate statistical calculation of each phase content by computers, laid a solid and accurate basis for phase analysis of sintered mineral.

Owner:BAOSHAN IRON & STEEL CO LTD +1

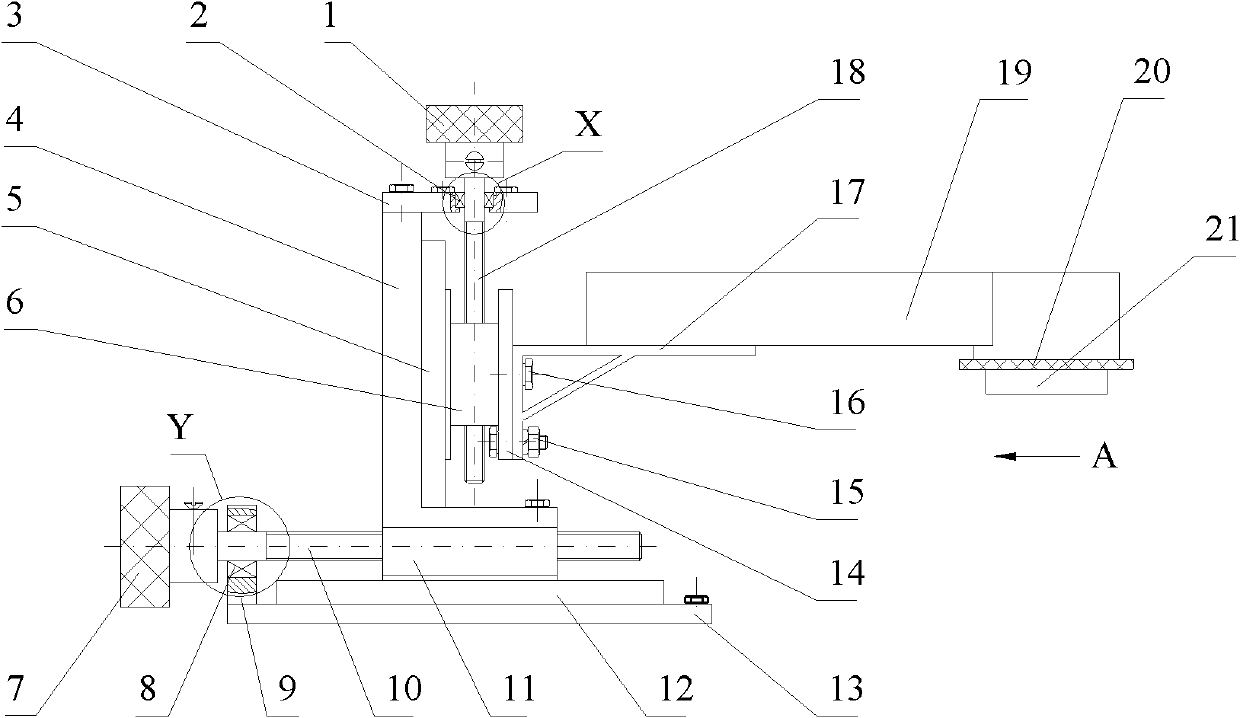

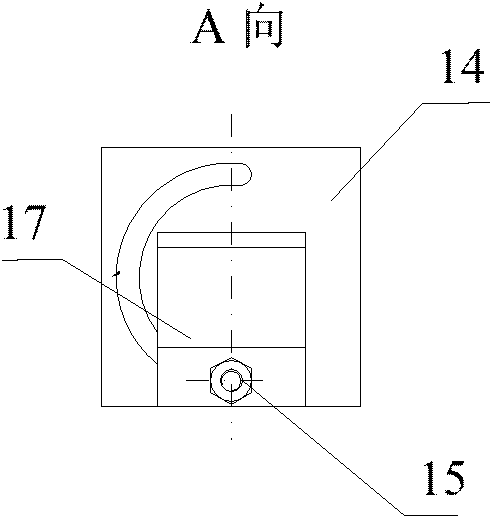

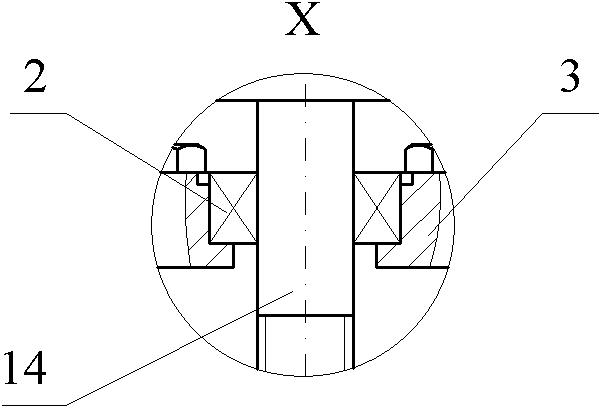

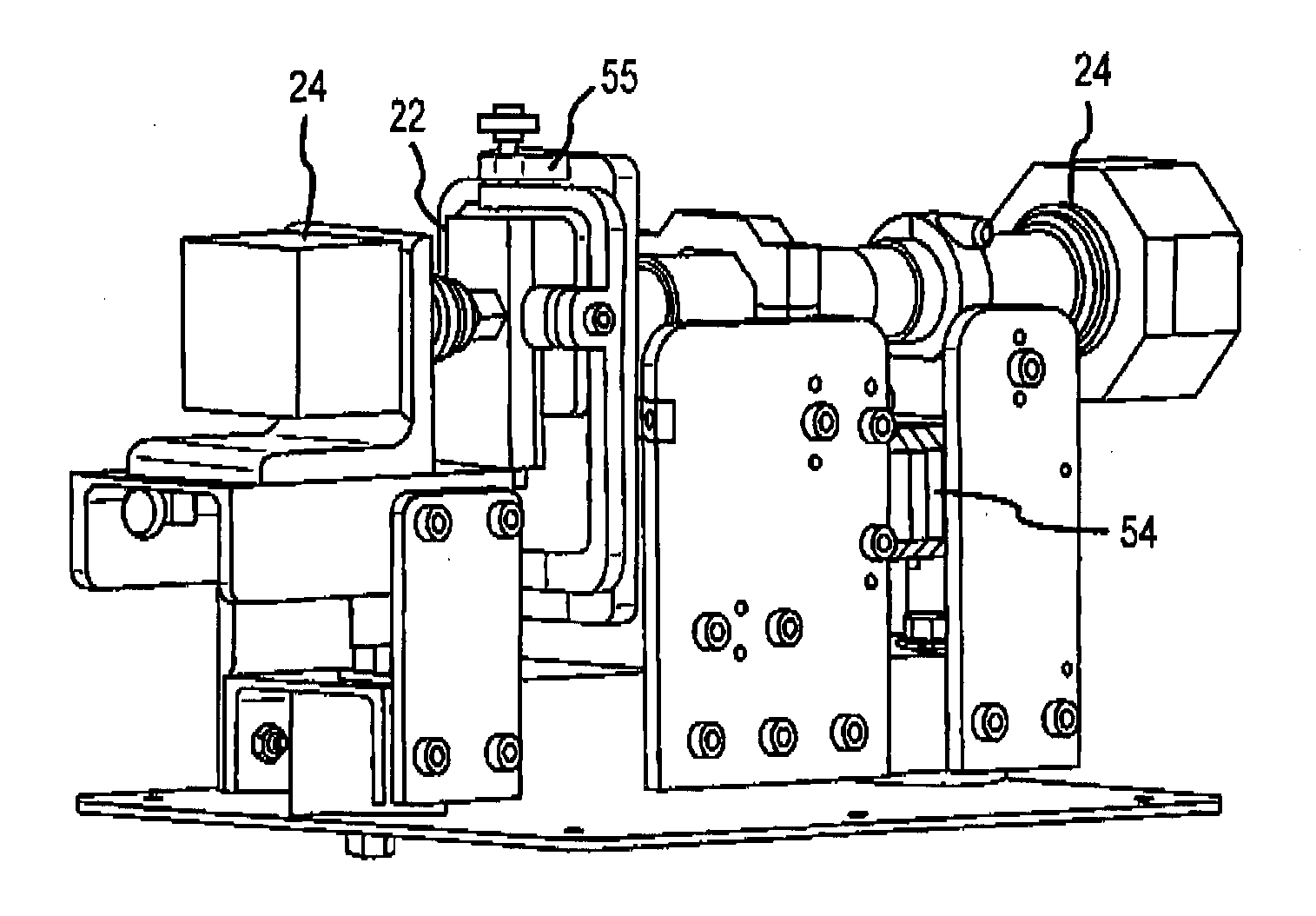

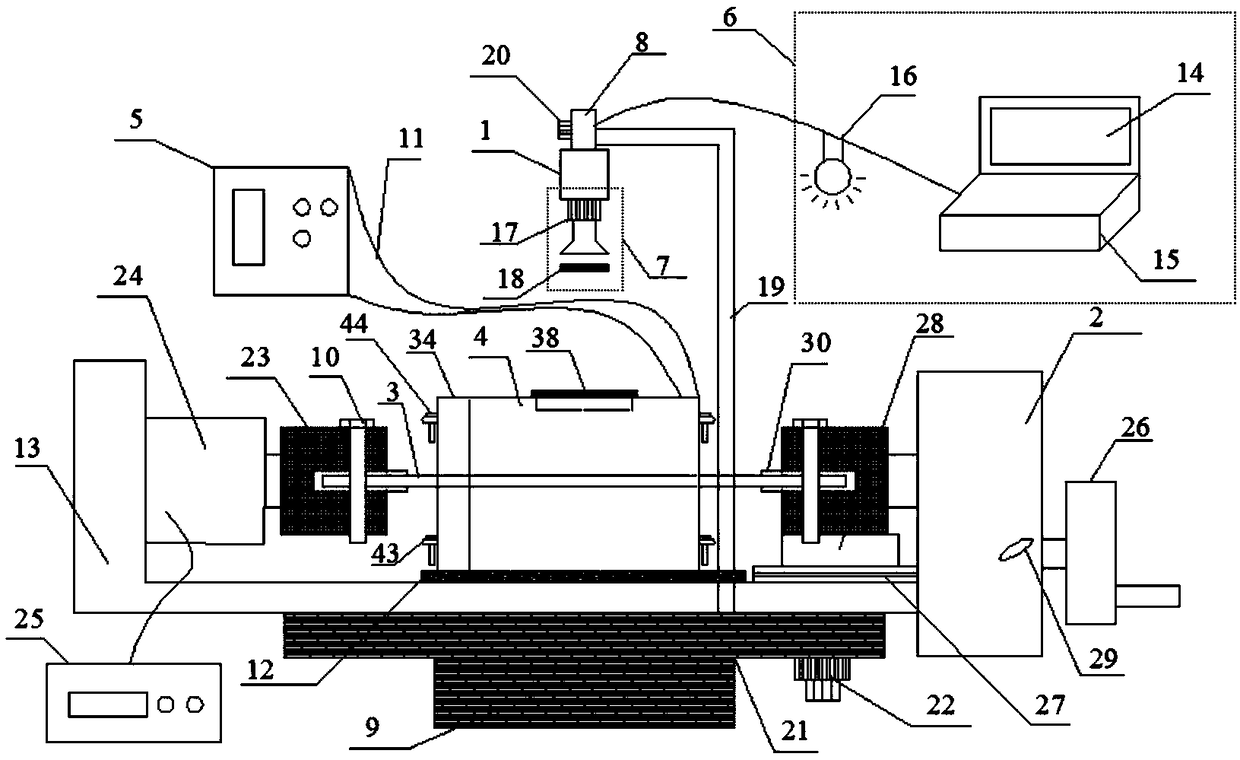

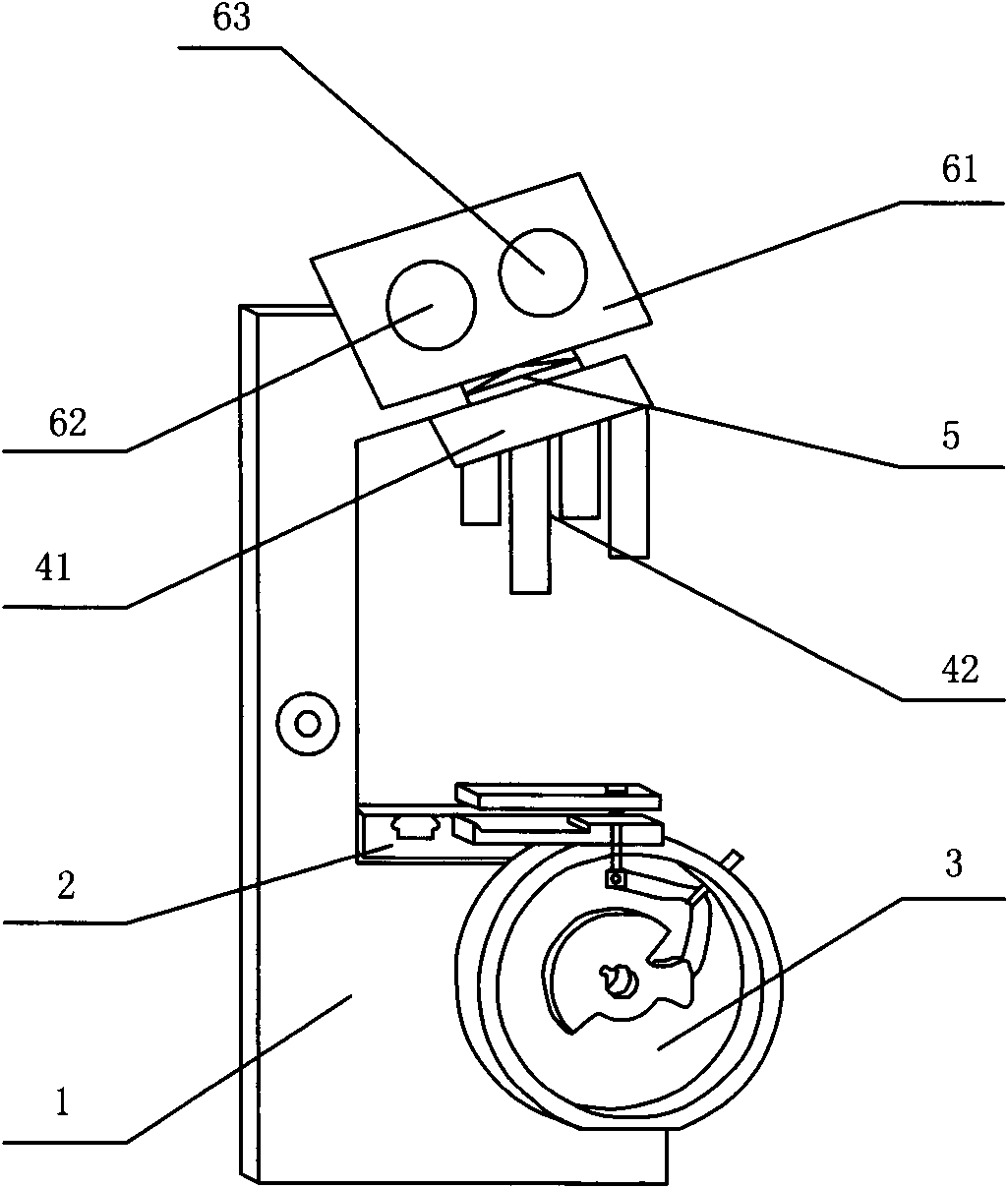

Abrasion in-situ measuring device based on digital image processing and method

ActiveCN102607977AIn-situ automated measurement of visual wearEnables continuous measurementInvestigating abrasion/wear resistanceDigital signal processingImaging processing

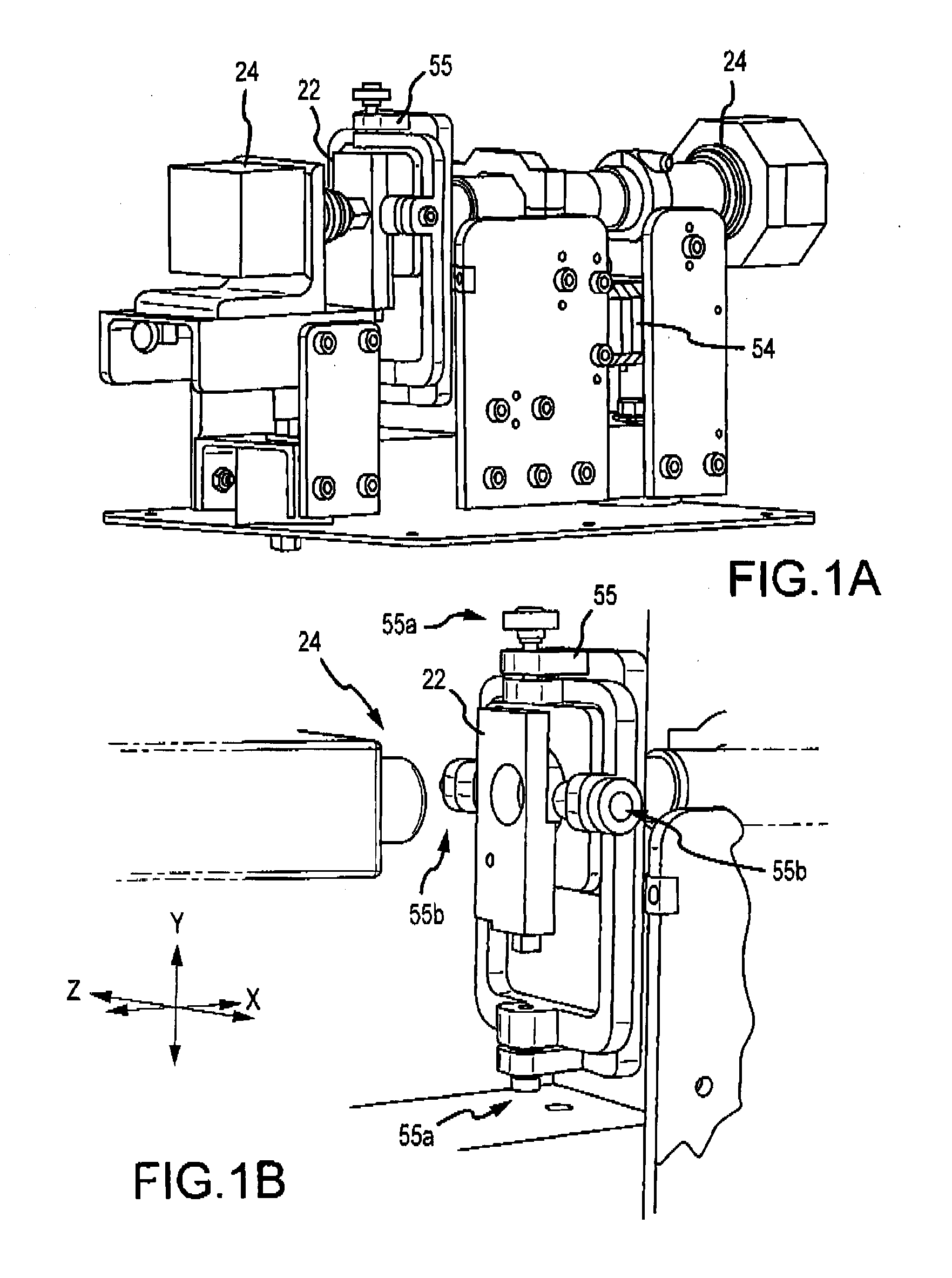

The invention relates to an abrasion in-situ measuring device based on digital image processing and a method. The device comprises a bottom plate, a horizontal displacement device, a vertical displacement device, a semi-arc slot transition plate, a support frame and a digital microscope; the bottom plate is used for supporting the total device in a connected manner and is fixed on a friction abrasion testing machine; the bottom plate is provided with the horizontal displacement device, the vertical displacement device and the semi-arc slot transition plate; the support frame is arranged on the right side of the transition plate and used for supporting the digital microscope; and by the aid of the abrasion in-situ measuring method based on digital image processing, the width value of an abrasion mark is obtained by means of treatments such as graying, binarization and the like for abrasion mark images and calculation of Radon conversion, gradient magnitude and the like. The abrasion mark image of a 'lower test piece' can be acquired accurately and fast, and furthermore, the abrasion image of an 'upper test piece' can be acquired conveniently. Besides, an abrasion mark image processing method is developed to analyze and obtain the width of the abrasion mark, and the in-situ measuring device can precisely measure abrasion marks.

Owner:西安永泽华正信息科技有限公司

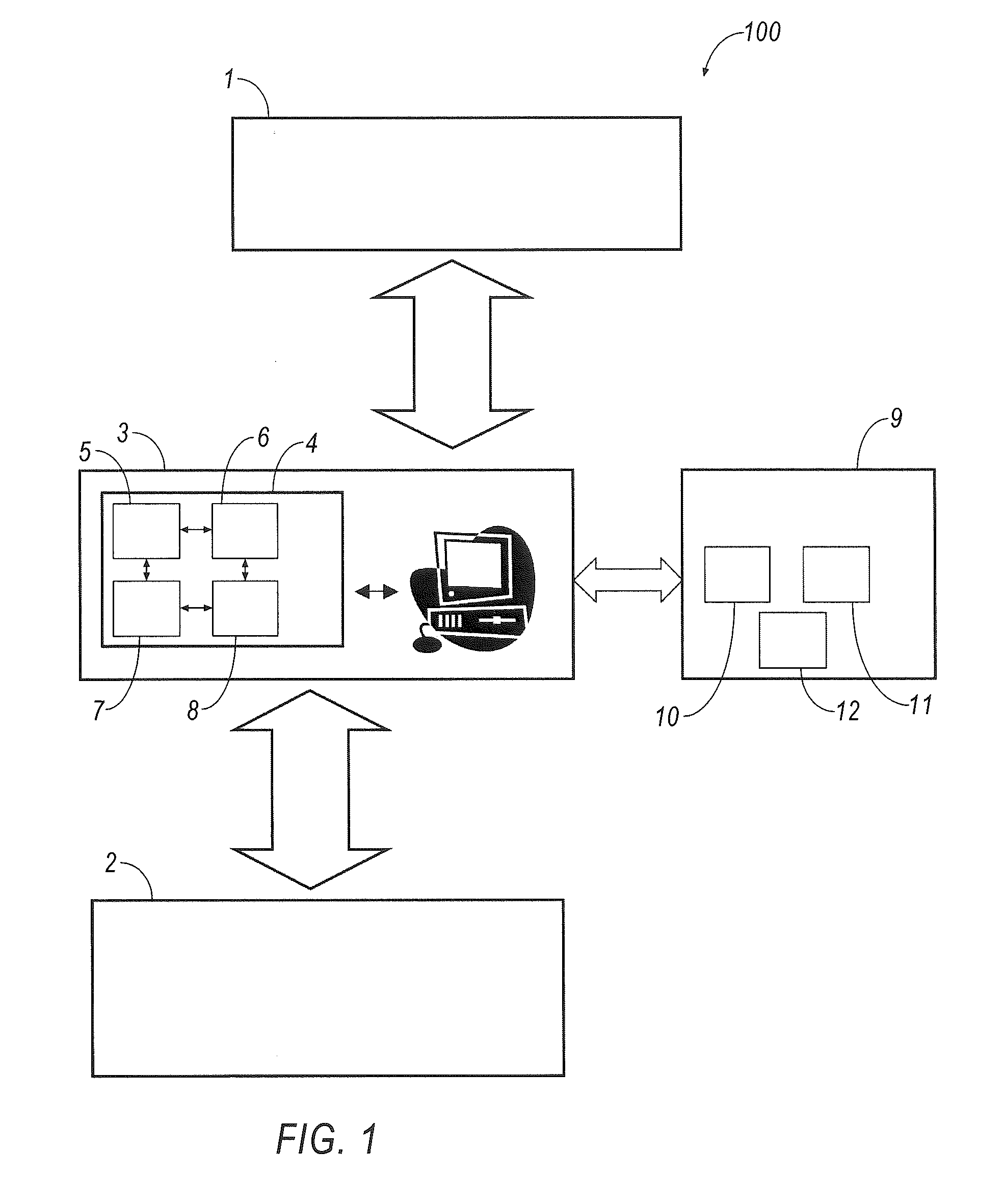

System for applying and reading out an information field identifying and protecting an object

InactiveUS20140205083A1Improve information securityImprove functionalityKey distribution for secure communicationSecret communicationComputer hardwareComputer printing

A hard / software system for applying and reading out an information field identifying and protecting an item, comprises an applying unit, a reading unit, a control unit, and a database unit. The applying unit (for example, a laser or printer) generates the information field and transports it to the item. The control unit comprises an information field data encryption module, a random number generator key, a controlling script configuration module to interact with the applying unit, and a reading and image acquiring module, and a decryption and information output module to interact with the reading unit. The database unit comprises an information field applying unit module, an item material properties module, and an item processing technological mode module for applying the information field. The reading unit can include a digital microscope. The system can apply the information field on various materials, the shape of the item can be plain, cylindrical, etc.

Owner:PRYAKHIN EVGENIY IVANOVICH +2

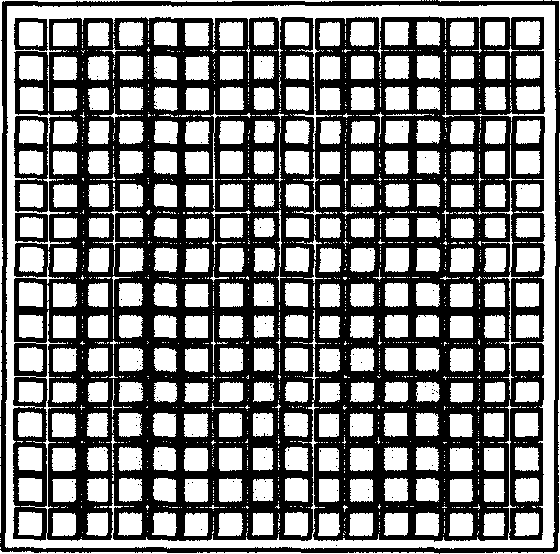

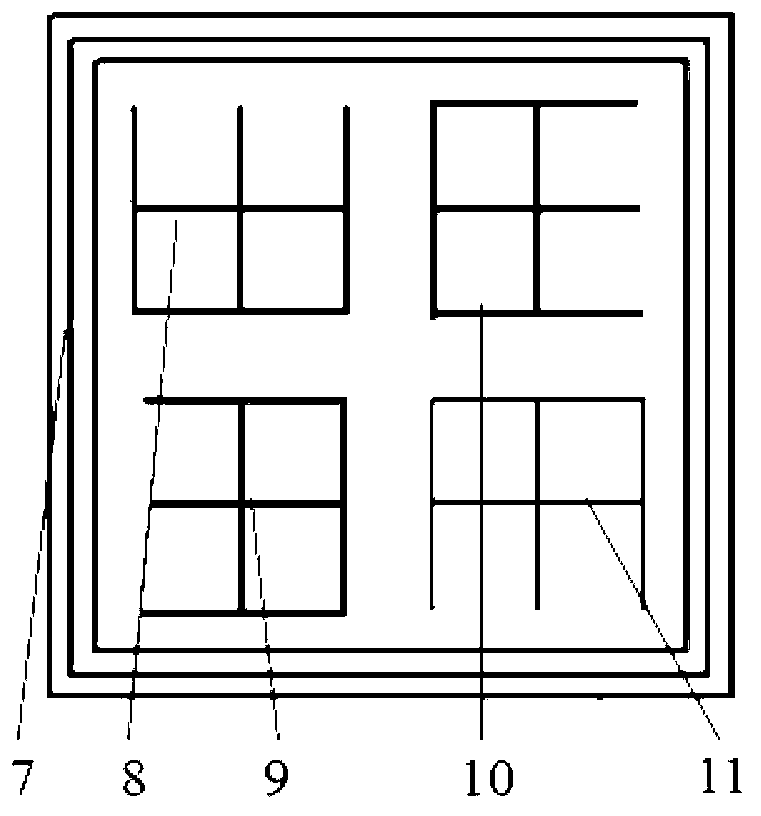

Precision detection device and precision detection method of printing machine

InactiveCN102837497AHigh degree of automationShorten the timePrinting press partsLed arrayPrinting press

The invention discloses a precision detection device of a printing machine, comprising an electronic detection meter and a computer and further comprising a detection printing plate, wherein the electronic detection meter is connected with the computer; the structure of a printing plate image printed on the detection printing plate is formed by combining a square frame with four sign markers arranged in the frame; the structure of the electronic detection meter is that an observation window, an image collection window and a digital microscope are arranged at one side inside a shell of a detector; an LED (Light-Emitting Diode) array light source is arranged at the other side inside the shell of the detector; and scattering glass is arranged between the LED array light source and the image collection window. The invention further discloses a detection method for utilizing the device to detect the precision of the printing machine, comprising the following steps of: printing special detection marks on the printing machine to obtain detected printing sheets; continuously reading 100 detected printing sheets to process analyzed image information data; and finally, obtaining paper transferring and conveying precision of the printing machine. The device and the method, disclosed by the invention, have high precision and automation degree.

Owner:XIAN UNIV OF TECH

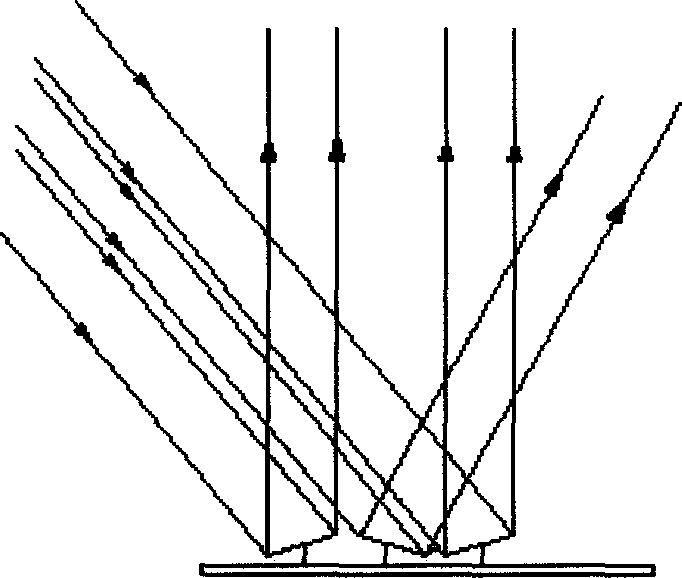

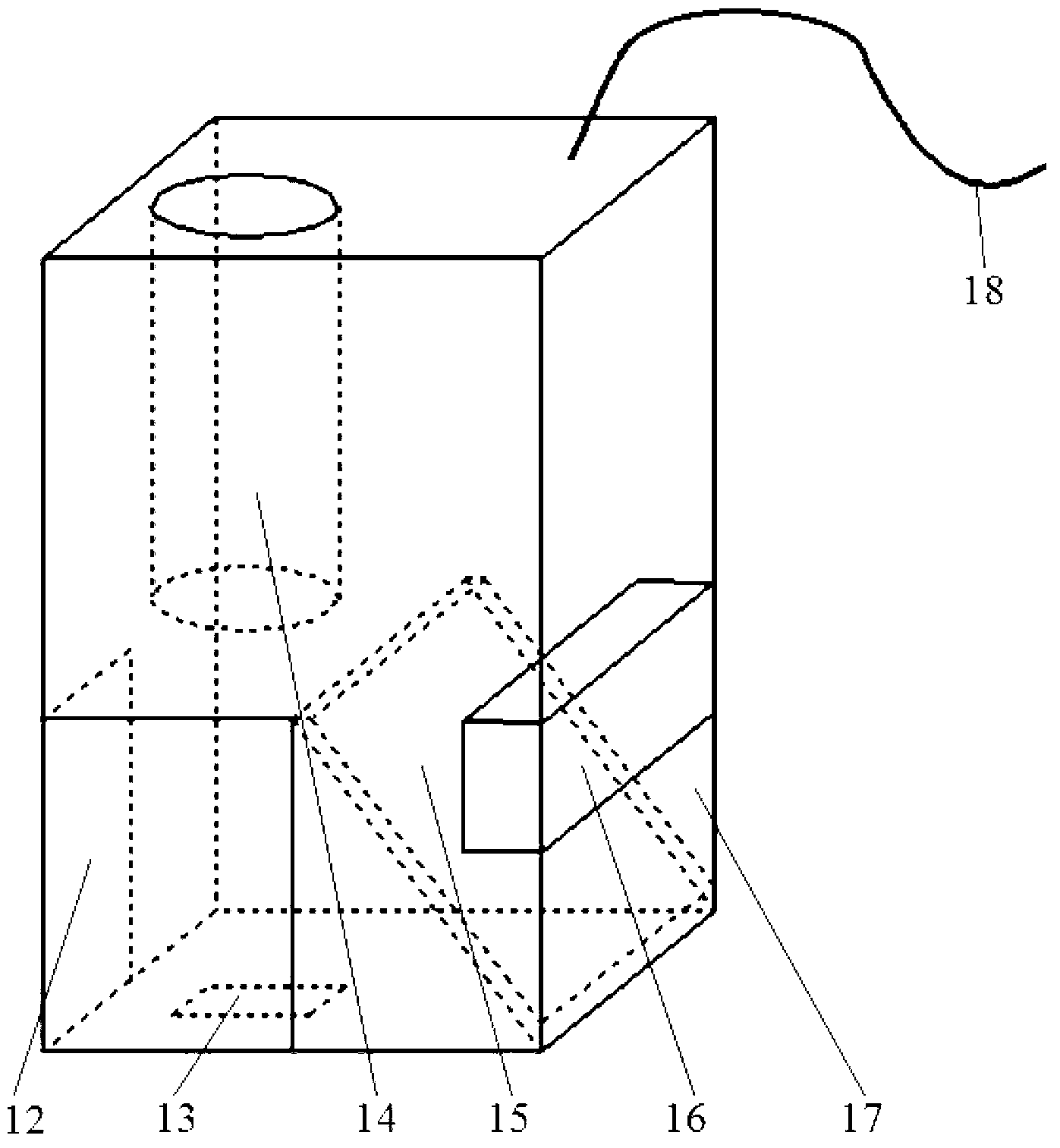

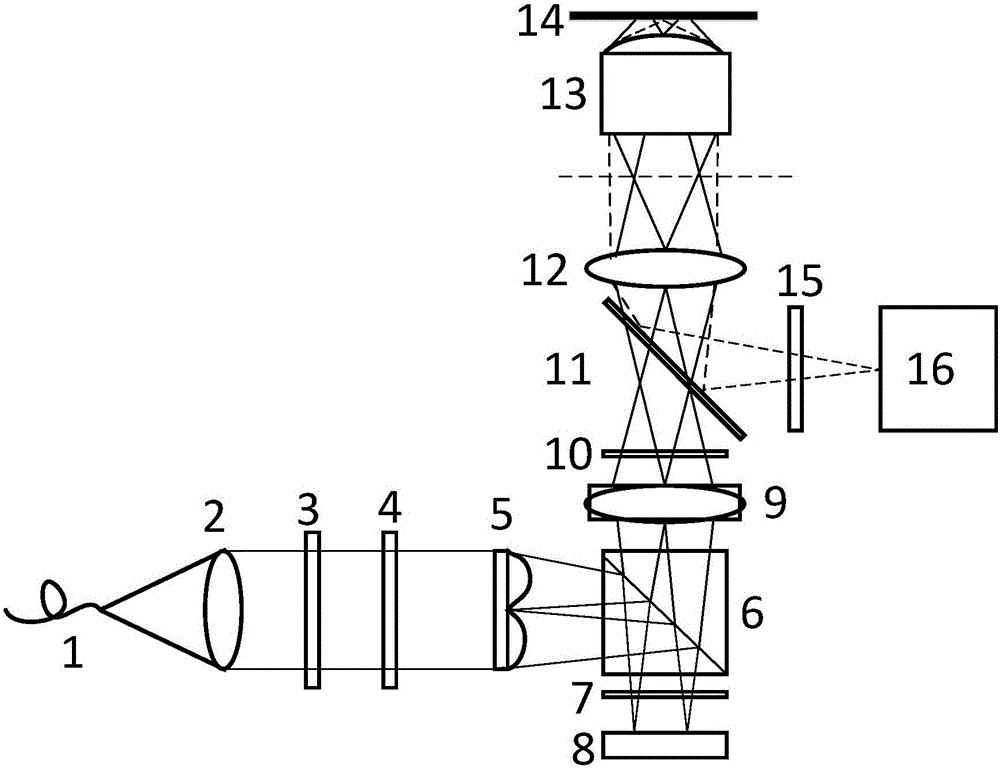

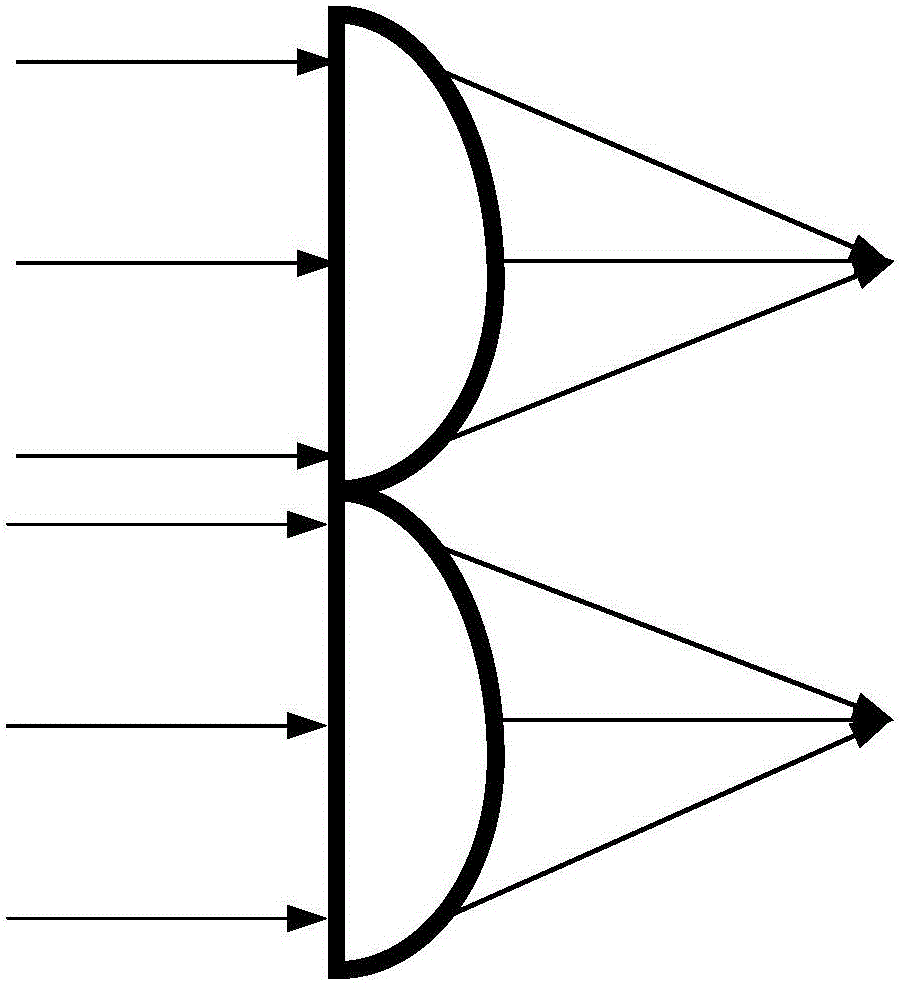

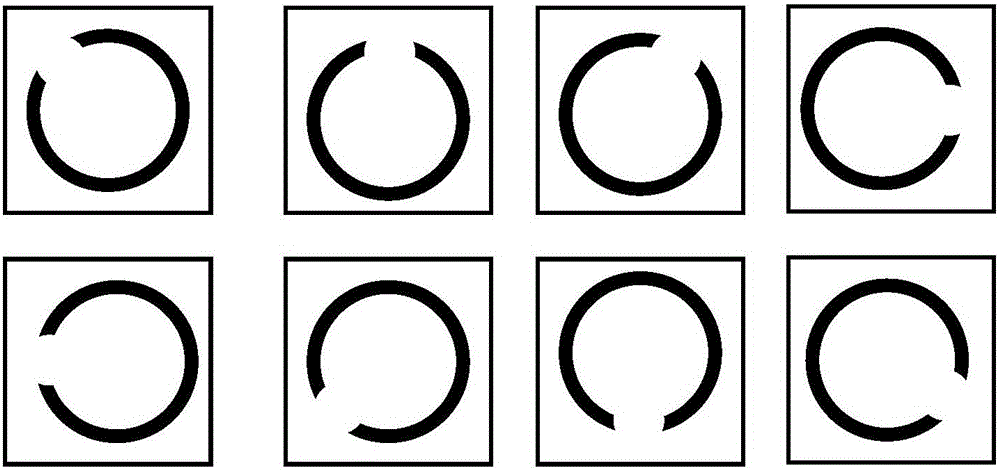

Total internal reflection microscopy method and device based on free-form surface shaping

The invention discloses a total internal reflection microscopy device based on free-form surface shaping.The device comprises a light source and a line polarized light generating module, a free-form surface focusing module, a digital microscopy refection module, an optical enlargement transmission module and a fluorescence imaging module which are sequentially arranged along a light path, wherein the line polarized light generating module is used for converting light beams emitted by the light source into line polarized light; the free-form surface focusing module is used for converting the line polarized light into annular focused light; the digital microscopy refection module is used for selecting annular focused light reflected in an area; the optical enlargement transmission module is used for achieving total internal reflection illumination of the light beams; the fluorescence imaging module is used for exciting a sample to emit fluorescent light and collecting a fluorescent light signal image.The invention further discloses a total internal reflection microscopy method based on free-form surface shaping.According to the total internal reflection microscopy method and device based on free-form surface shaping, no mechanical vibration module is adopted, scanning is conducted more stably, and noise is lower; the utilization rate of laser energy is higher, and an imaging view field is more uniform; a DMD control controls scanning, the angle is more accurate, and it is helpful to achieve layered scanning and 3D image reconstruction.

Owner:ZHEJIANG UNIV

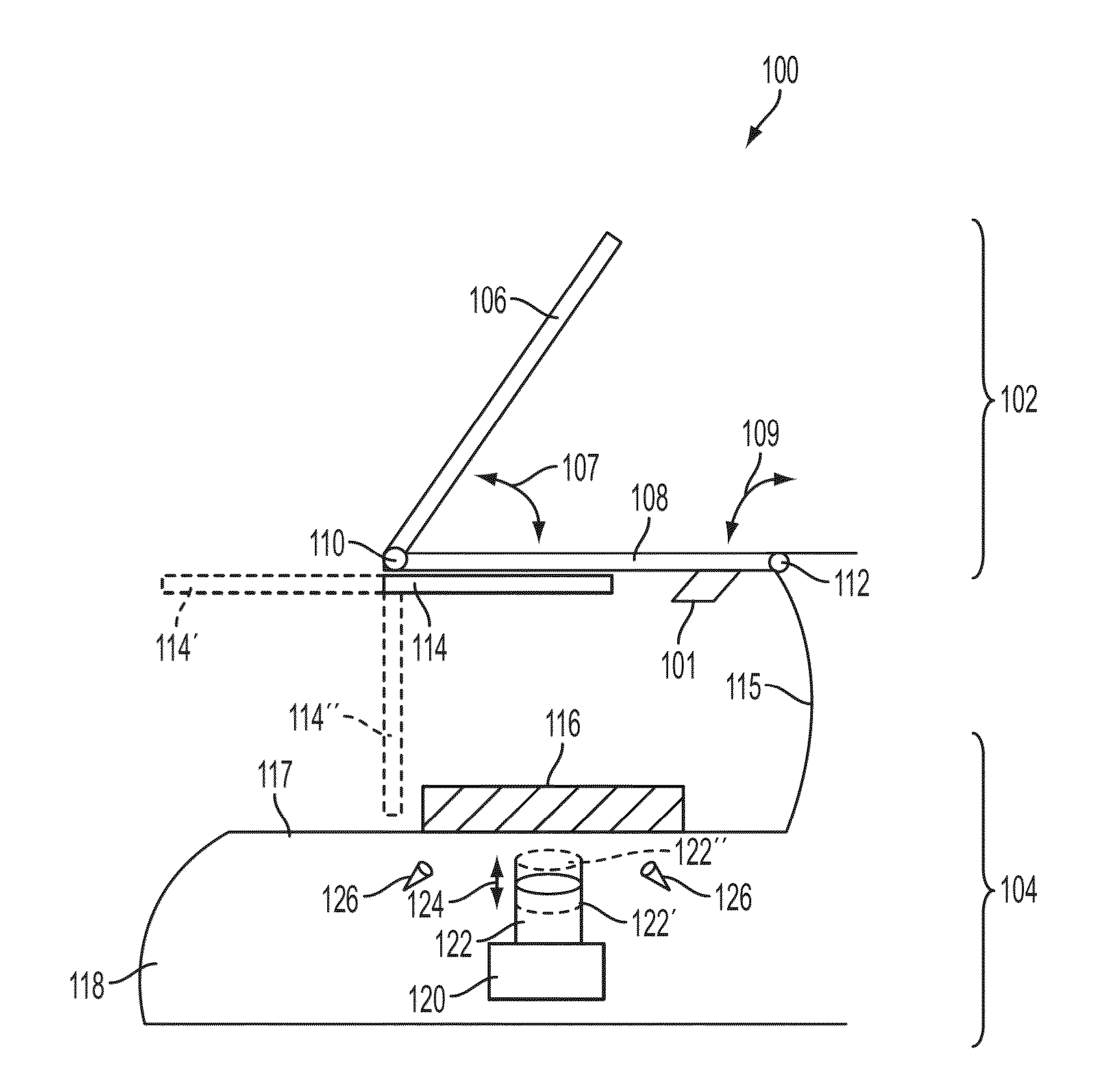

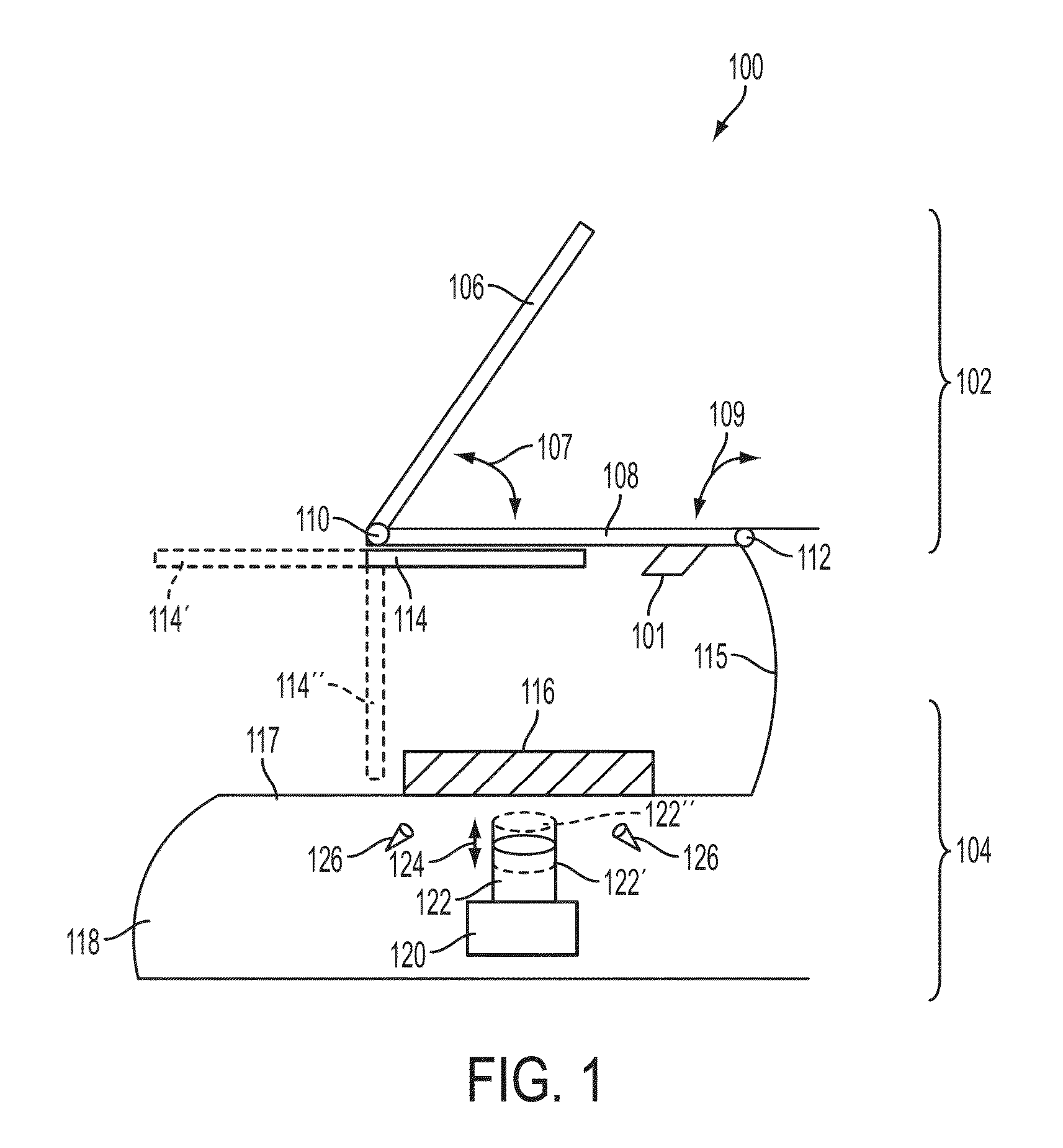

System and methods for multi-dimensional rendering and display of full volumetric data sets

InactiveUS8743109B2High resolutionCost efficient3D-image rendering3D modellingData setMulti dimensional

A stand-alone platform and a method for the multi-dimensional rendering, display, manipulation, and analysis of full high resolution volumetric data sets. The systems and methods provide the ability to volumetrically render images with extremely high resolution in applications such as medical imaging procedures, digital microscopy such as in use of a confocal microscope, and other areas where extremely large data sets are produced from the imaging process. Certain embodiments of the system and methods produce left and right eye images of the rendered data, for viewing in parallax via a synchronized headset, and the ability to manipulate the data and display of image data easily and in real time.

Owner:KENT STATE UNIV

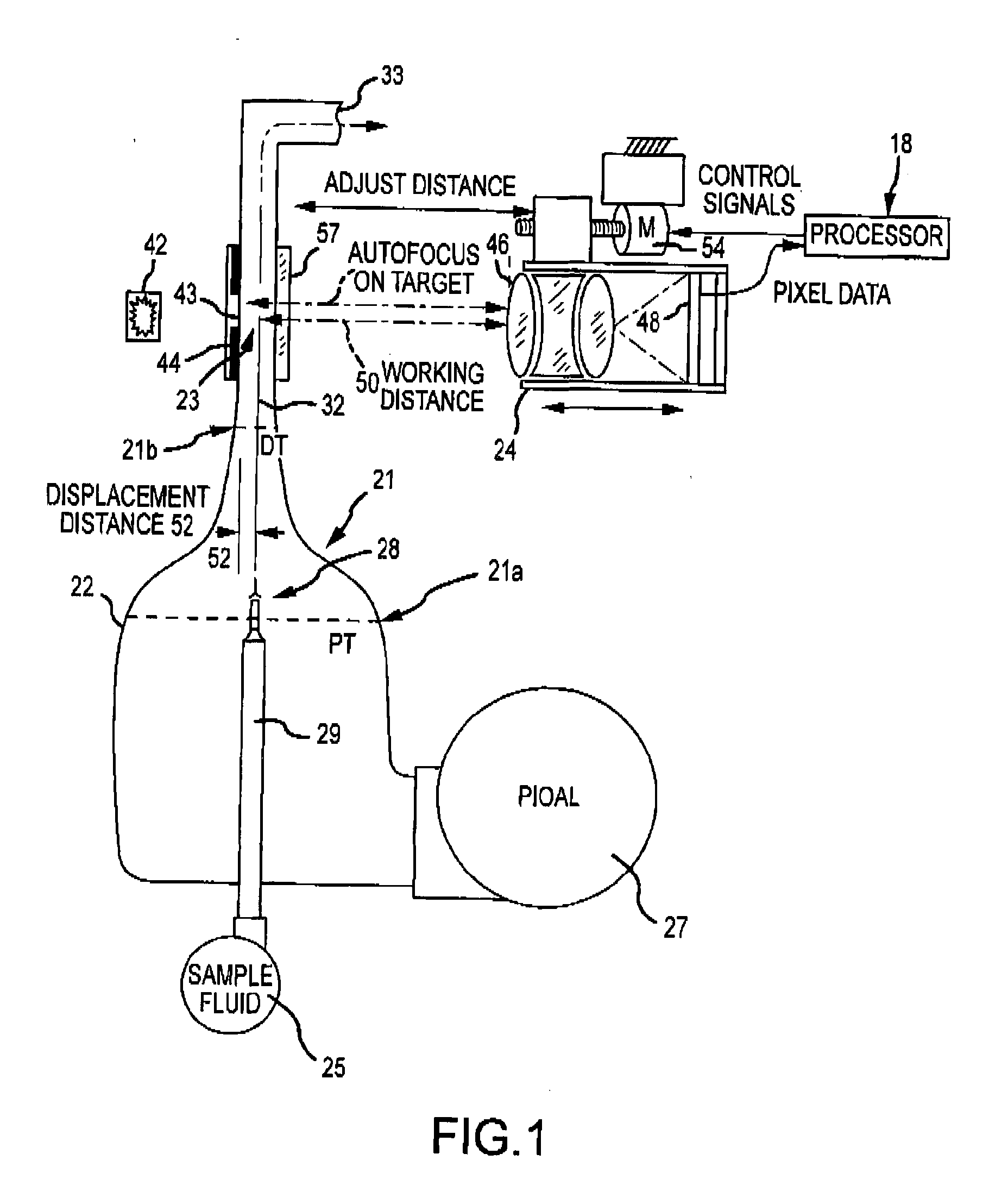

Hematology systems and methods

ActiveUS20160041083A1High and low viscosityHigh viscosityImage enhancementBioreactor/fermenter combinationsMedicine.hematologyStream flow

Aspects and embodiments of the instant disclosure provide a particle and / or intracellular organelle alignment agent for a particle analyzer used to analyze particles contained in a sample. An exemplary particle and / or intracellular organelle alignment agent includes an aqueous solution, a viscosity modifier, and / or a buffer. Embodiments also encompass systems, compositions, and methods for analyzing a sample containing particles. Particles such as blood cells can be categorized and counted by a digital image processor. A digital microscope camera can be directed, for example using certain focusing techniques, into a flowcell defining a symmetrically narrowing flowpath in which the sample stream flows in a ribbon flattened by flow and viscosity parameters between layers of sheath fluid. Blood cell images can be collected and analyzed using dynamic range extension processes and systems.

Owner:IRIS INT

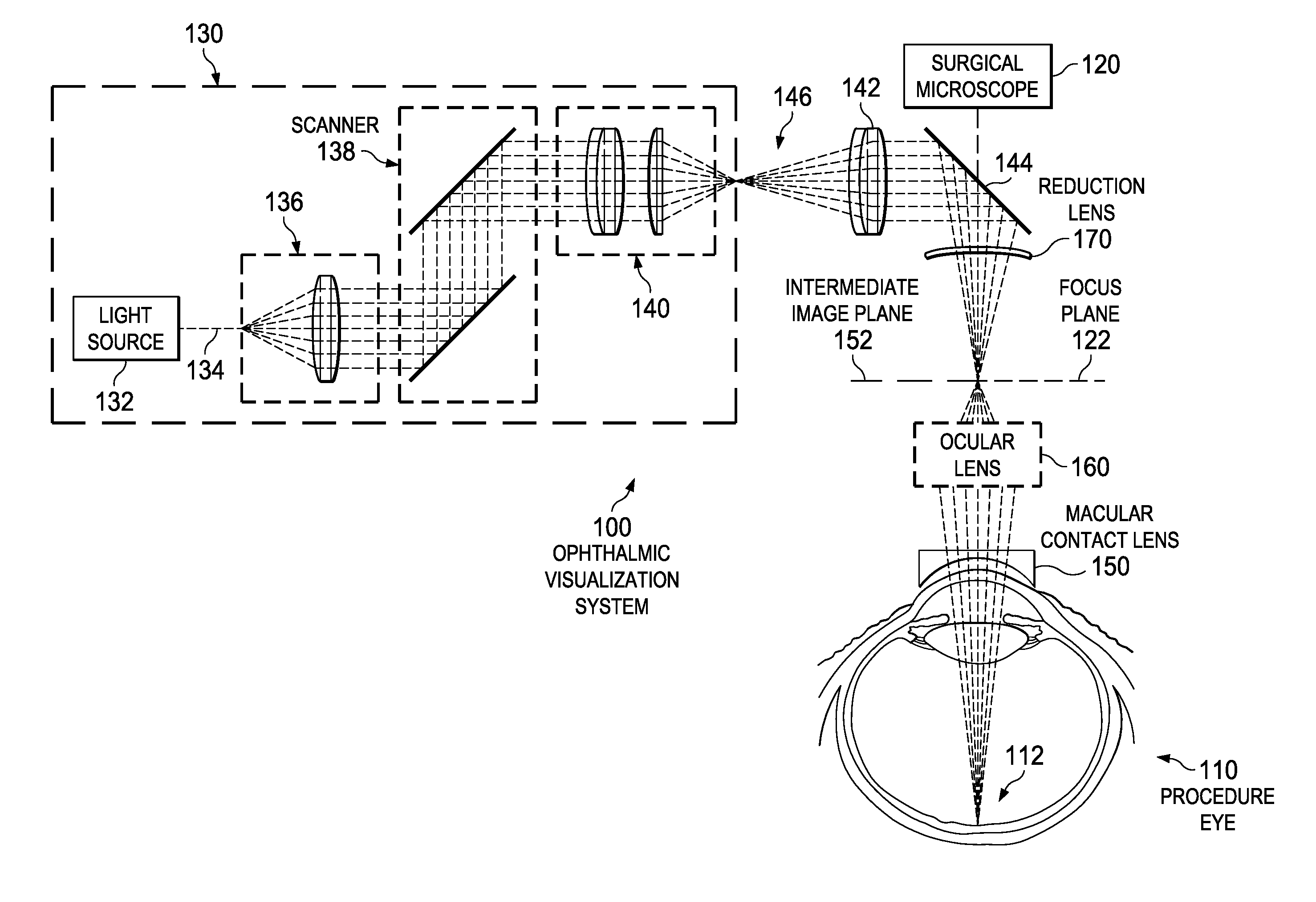

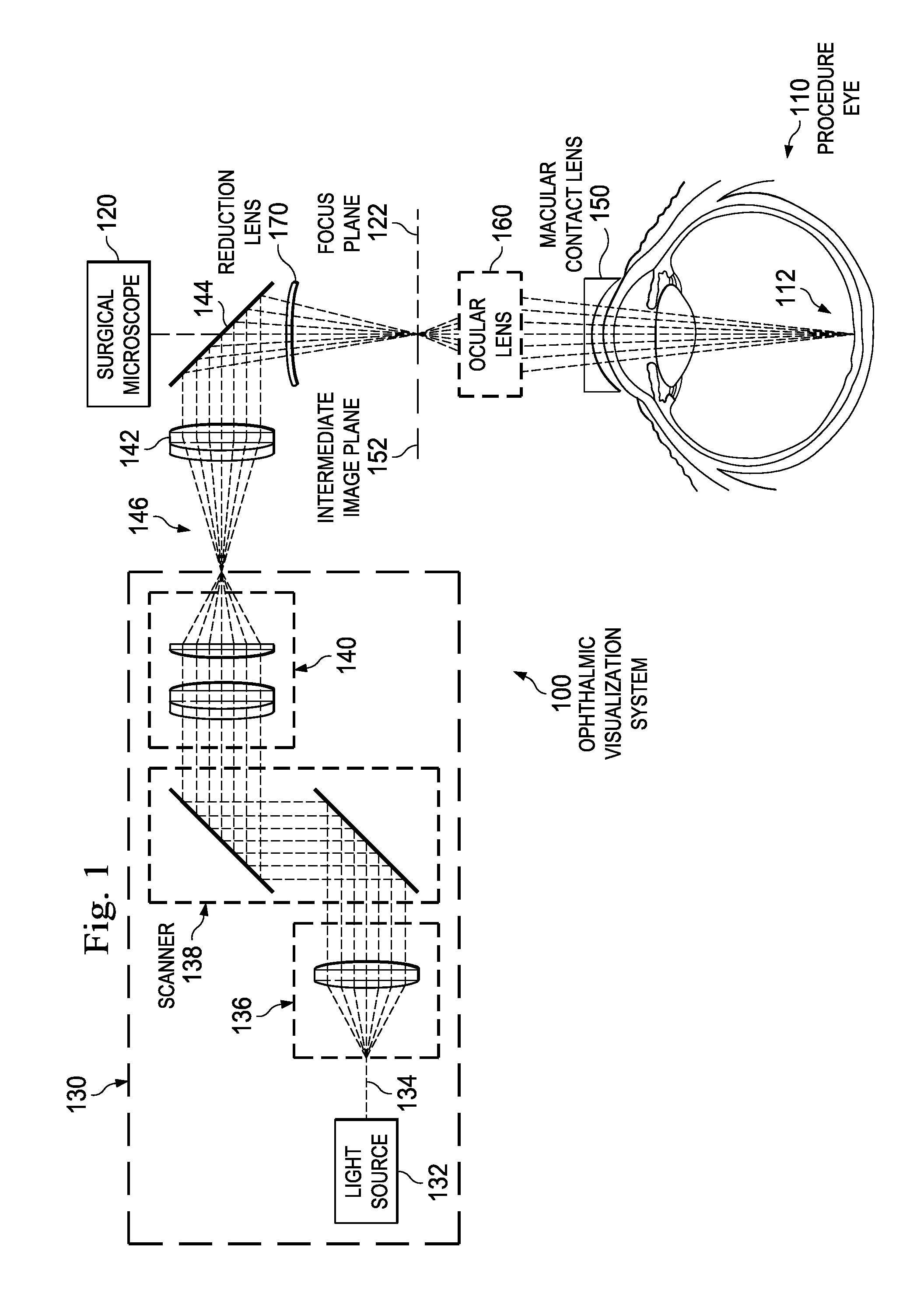

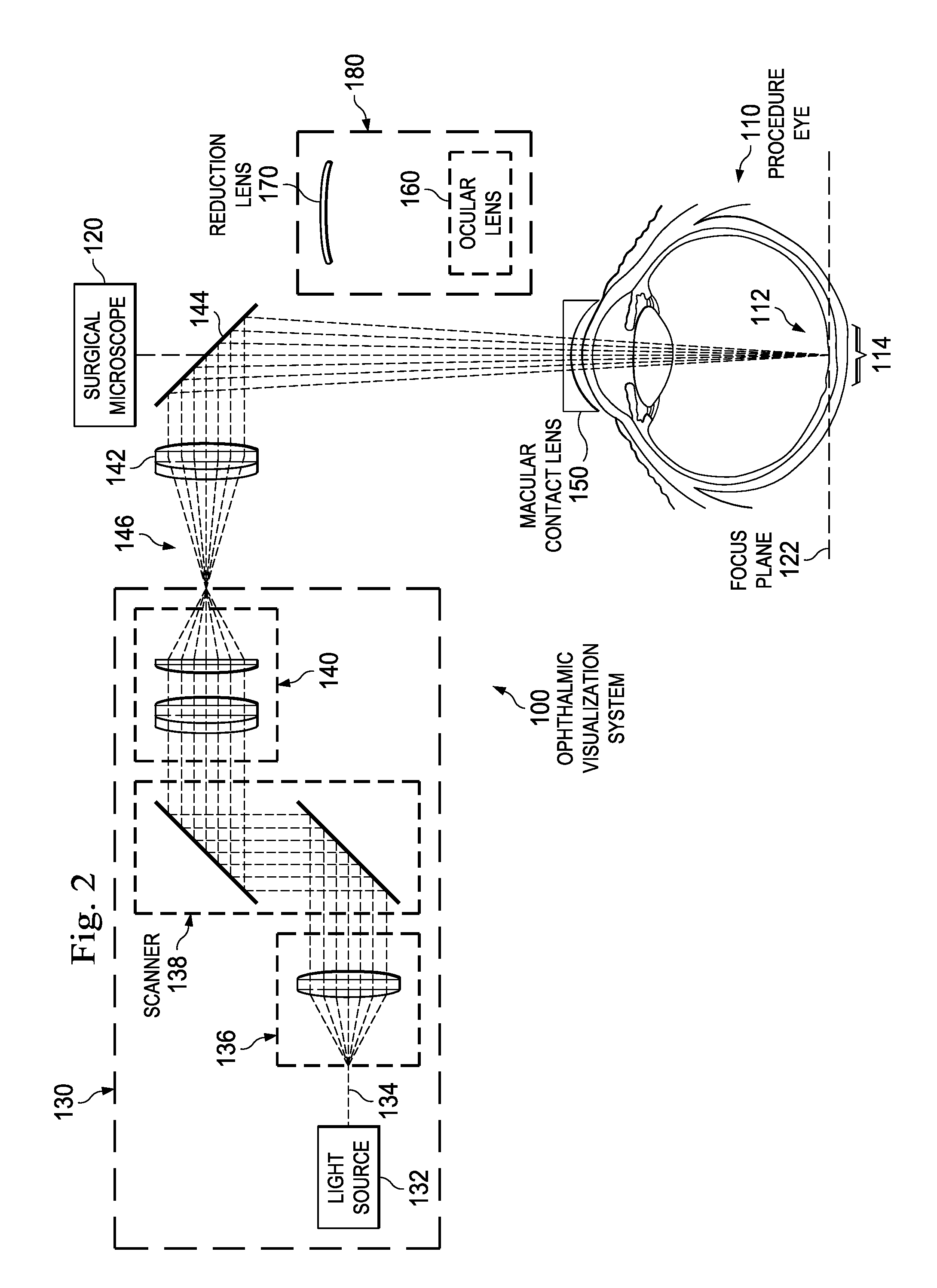

Oct surgical visualization system with macular contact lens

InactiveUS20160183782A1Wide field of viewLaser surgerySurgical instrument detailsOcular operationEyepiece

An ophthalmic visualization system can include an ocular lens positioned between a macular contact lens coupled to a procedure eye and a surgical microscope. The ocular lens can guide a light beam through the macular contact lens and into the procedure eye, and in combination with the macular contact lens generate an intermediate image of the procedure eye at an image plane between the procedure eye and the surgical microscope. The system can include a reduction lens positioned in the optical path between the surgical microscope and the ocular lens. The reduction lens and / or ocular lens can align a focus plane of the surgical microscope with the image plane. A method of visualizing a procedure eye in an ophthalmic procedure can include positioning an ocular lens and a reduction lens between a macular contact lens and a surgical microscope; and scanning the procedure eye with a light beam.

Owner:NOVARTIS AG

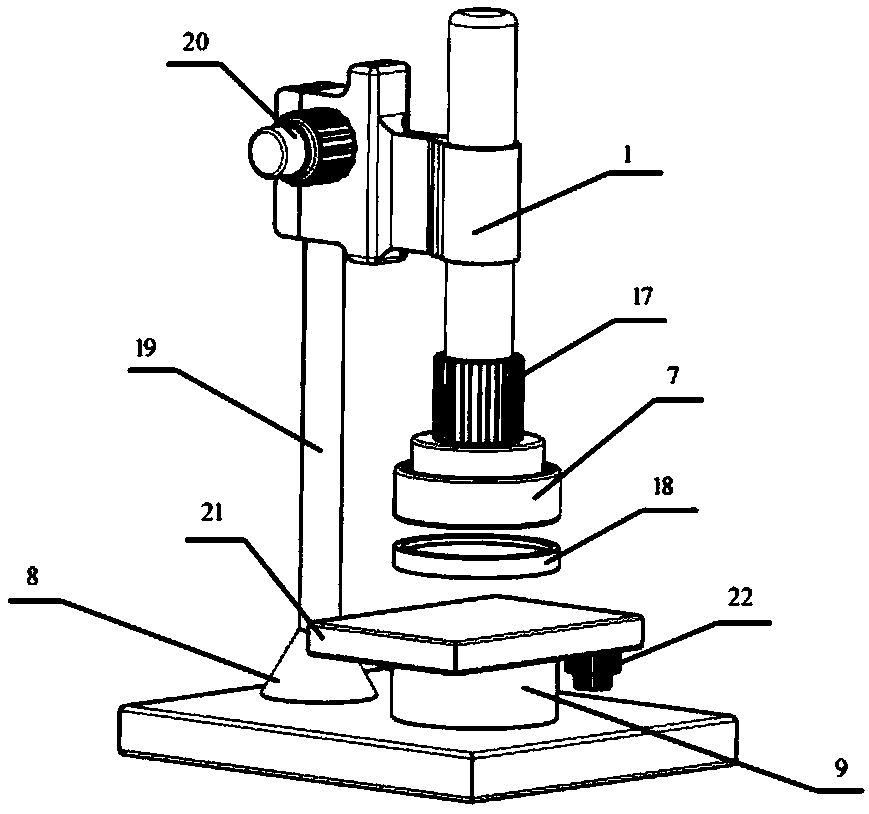

Ceramic matrix composite material high-temperature air environment substrate crack observation system and observation method

PendingCN108760526ARealize the observation of cracksAchieve observationPreparing sample for investigationMaterial strength using tensile/compressive forcesObservation systemGlass sheet

The invention discloses a ceramic matrix composite material high-temperature air environment substrate crack observation system and an observation method. The system comprises a digital microscope, atension testing device, a test sample, a heating device and a temperature controller, wherein the digital microscope comprises a platform main control system, a zoom lens, a lens base and a two-dimensional moving device; the test sample is horizontally mounted on the tension testing device; the tension testing device is horizontally arranged on the two-dimensional moving device; a rectangular transparent quartz glass plate is embedded above the heating device and is horizontally placed on a thermal insulating pad of the base of the tension testing device; the zoom lens is aligned to the centerof the test sample through the transparent quartz glass plate; the heating device is connected with the temperature controller. The tension testing device, the split type micro heating device and thedigital microscope are all independent individuals and are convenient to mount and dismount, and in an atmospheric environment, matrix cracks of the ceramic matrix composite material can be conveniently observed under the action of high-temperature air and stress loads.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

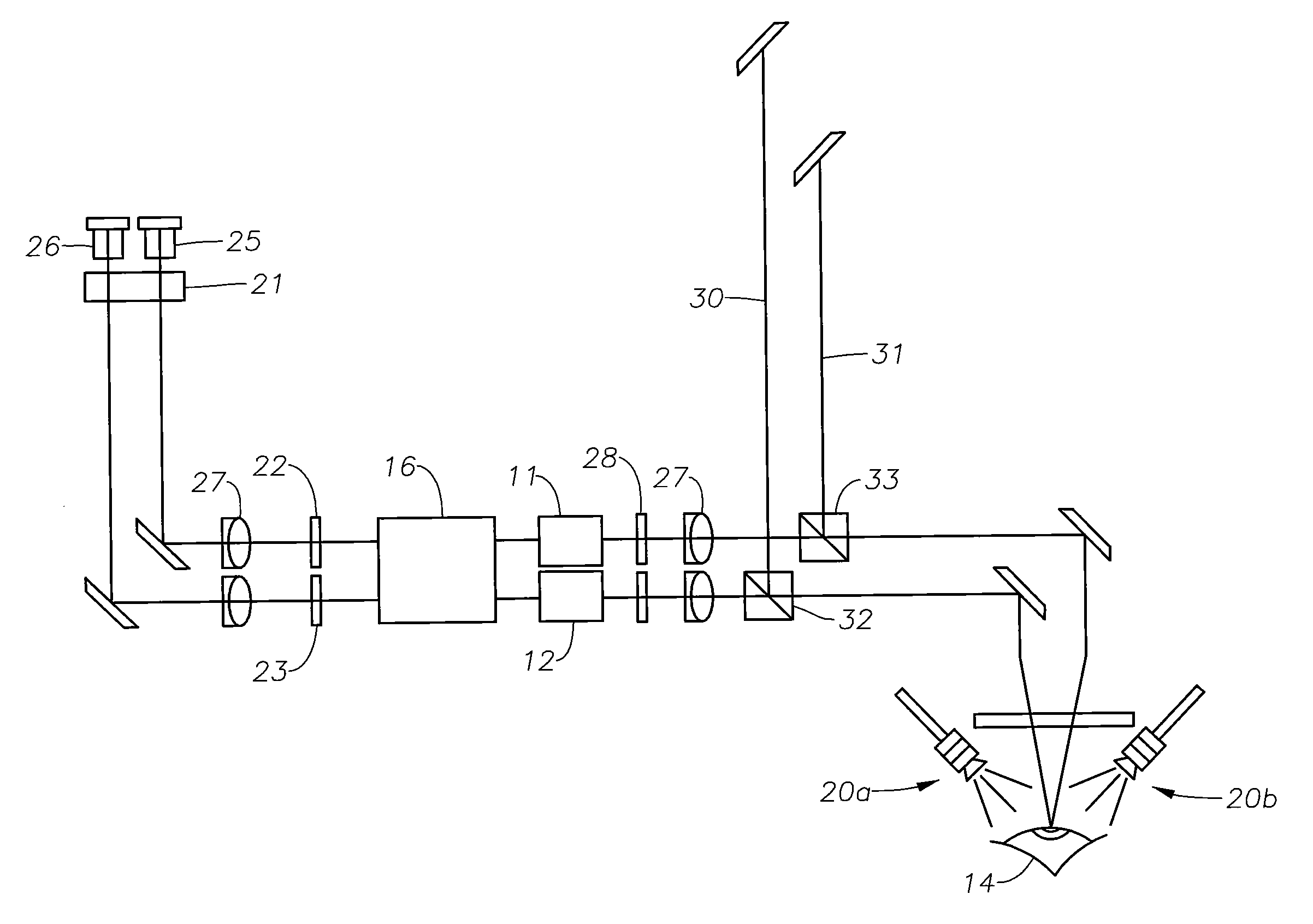

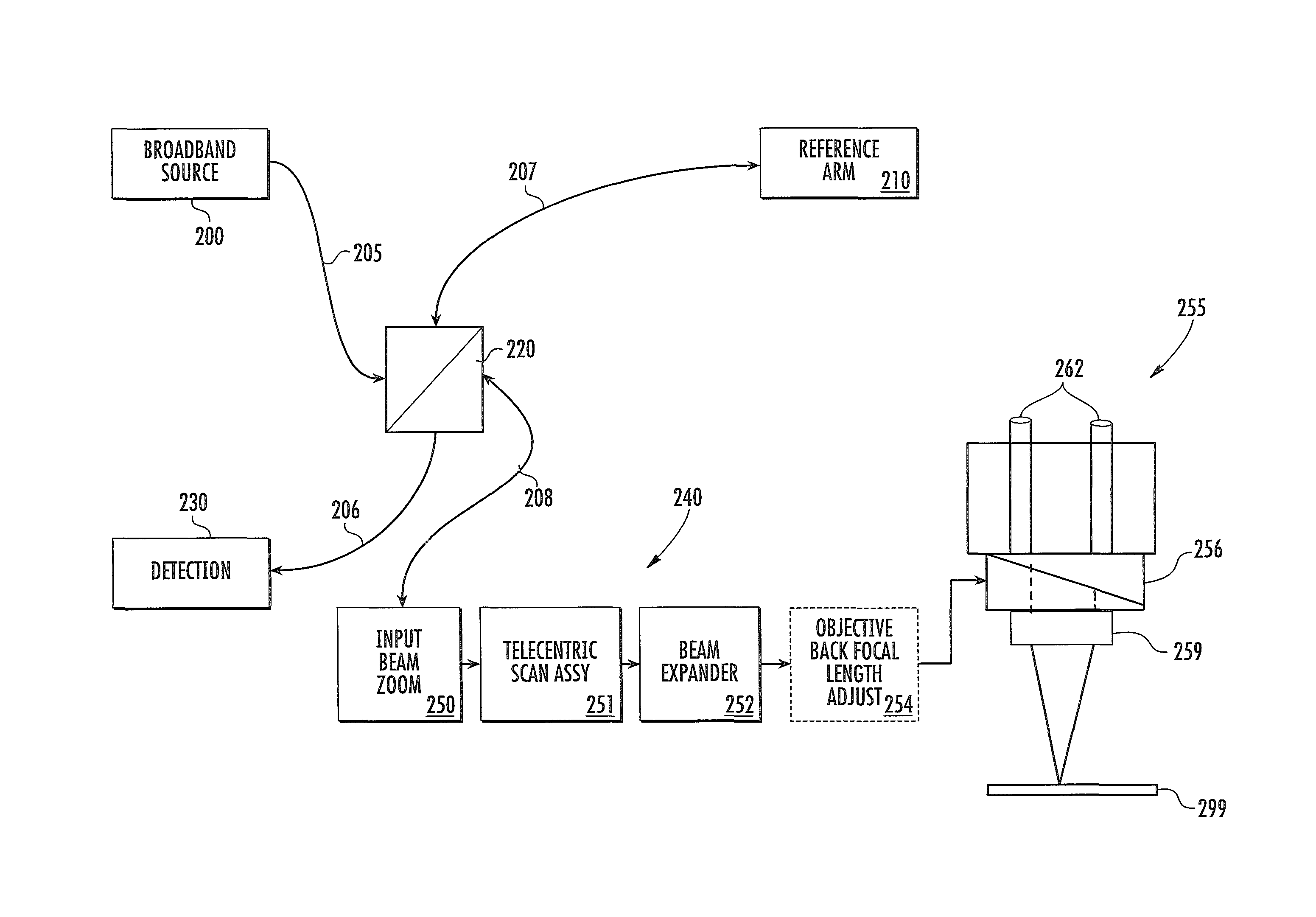

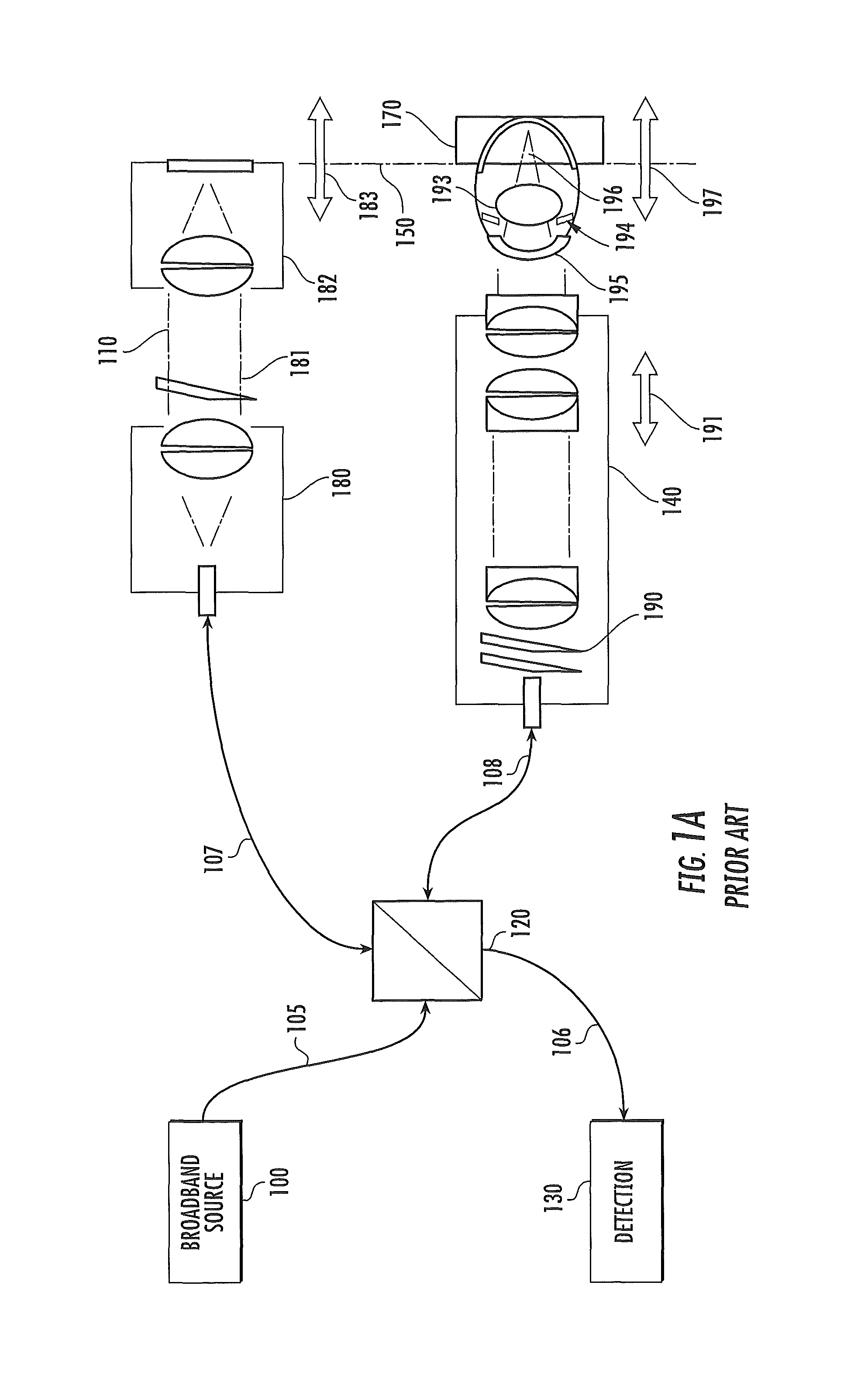

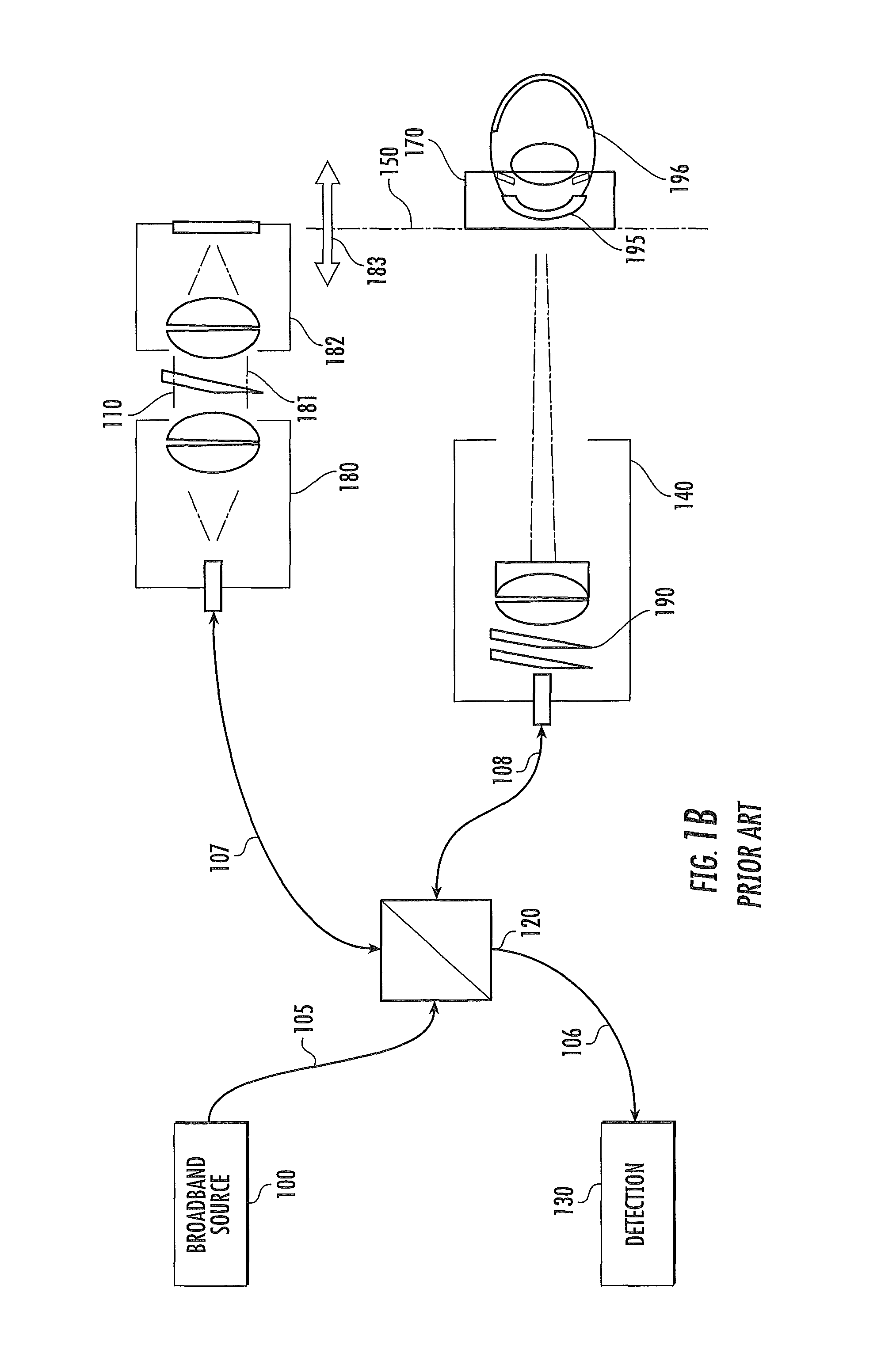

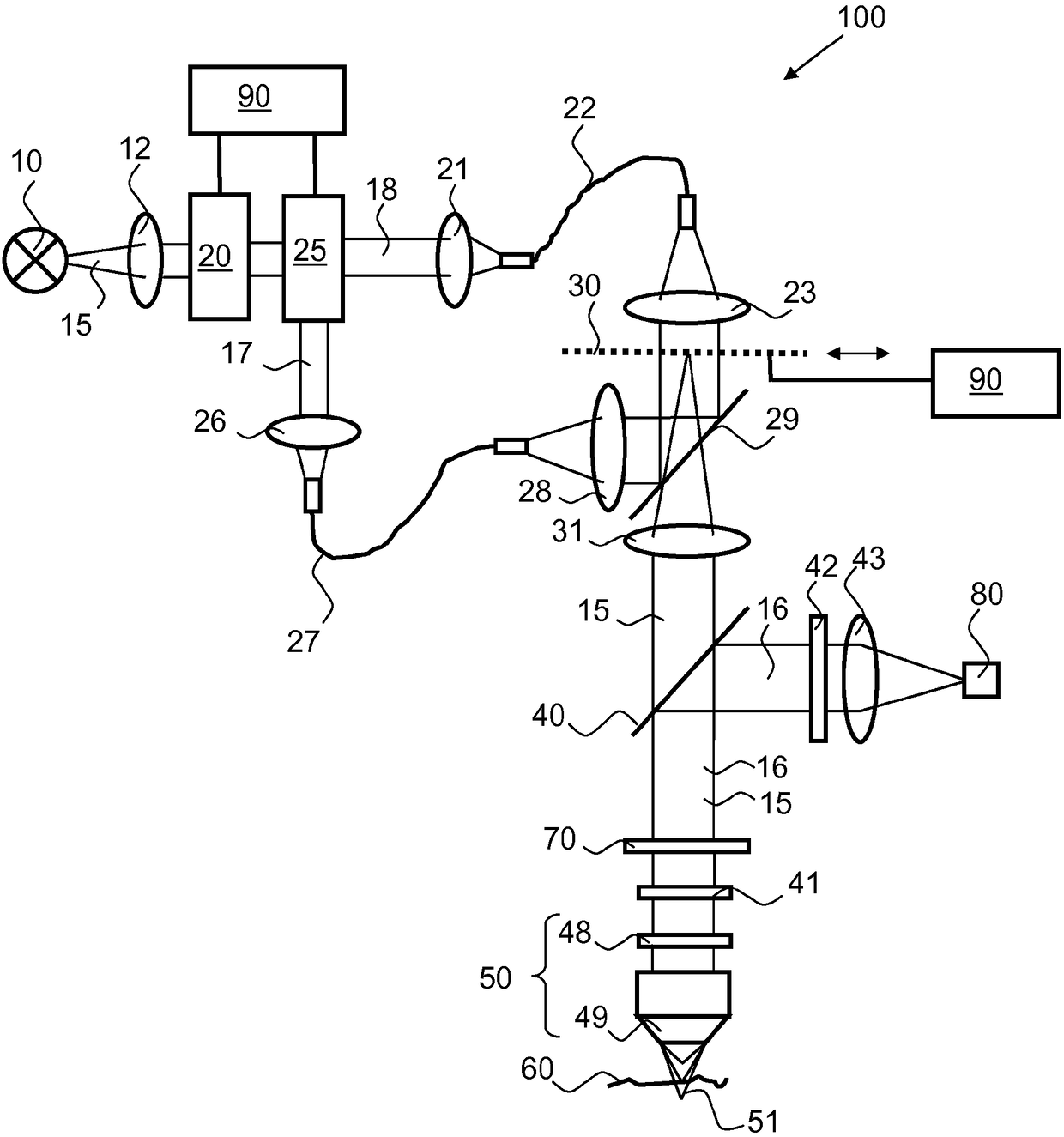

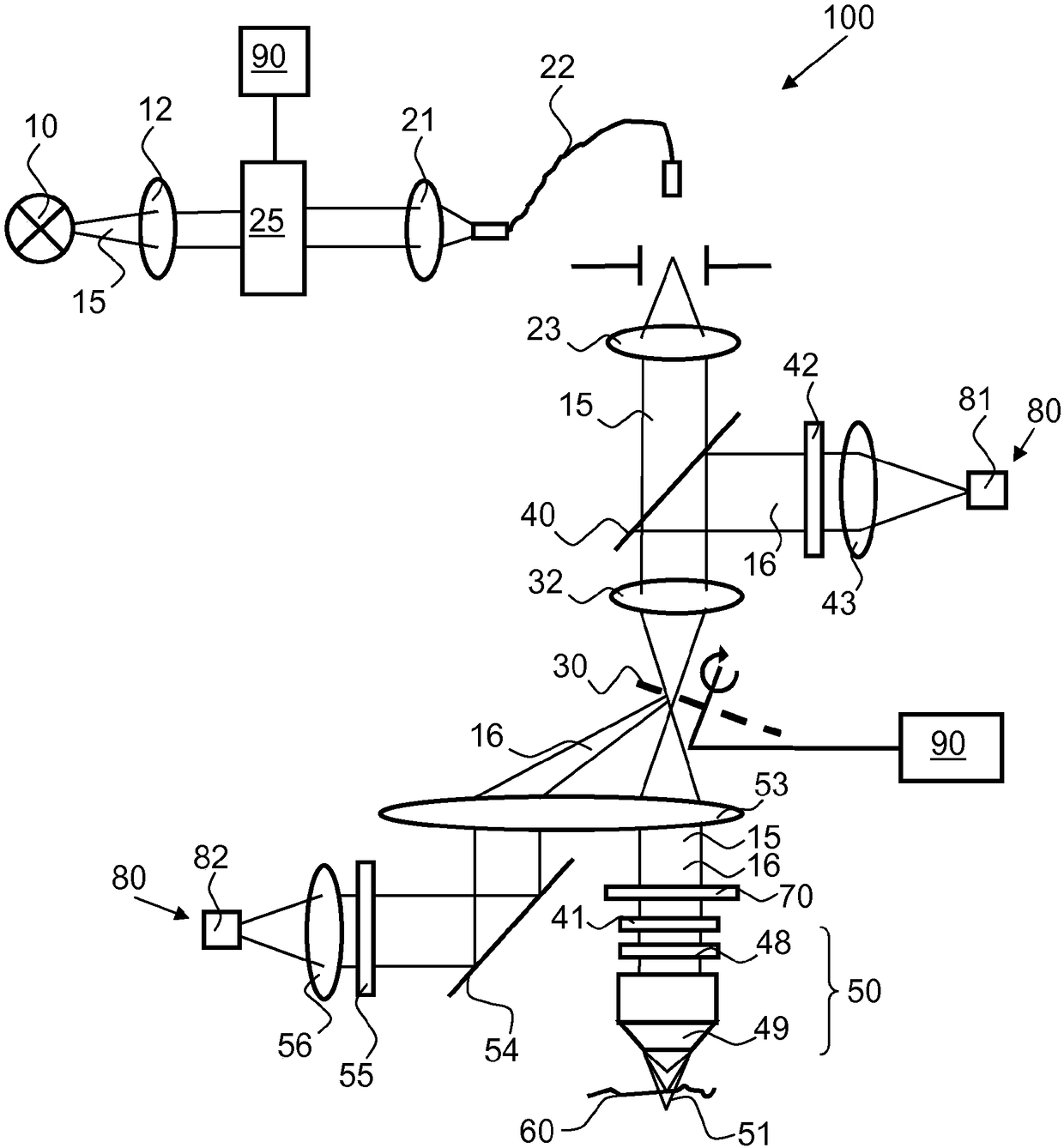

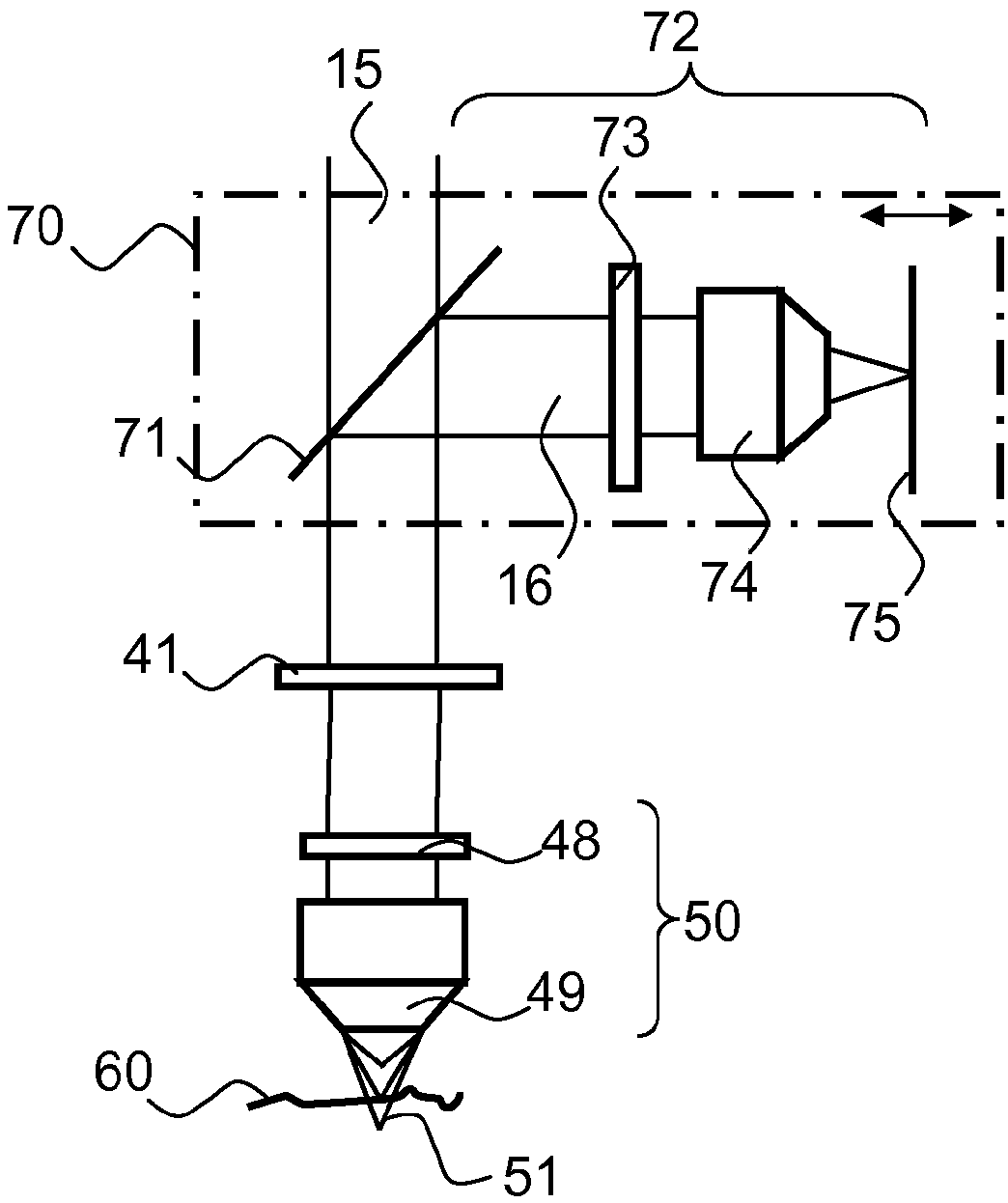

Surgical microscopes using optical coherence tomography and related methods

Some embodiments of the present inventive concept provide optical coherence tomography (OCT) systems for integration with a microscope. The OCT system includes a sample arm coupled to the imaging path of a microscope. The sample arm includes an input beam zoom assembly including at least two movable lenses configured to provide shape control for an OCT signal beam; a scan assembly including at least one scanning mirror and configured for telecentric scanning of the OCT signal beam; and a beam expander configured to set the OCT signal beam diameter incident on the microscope objective. The shape control includes separable controls for numerical aperture and focal position of the imaged OCT beam.

Owner:BIOPTIGEN

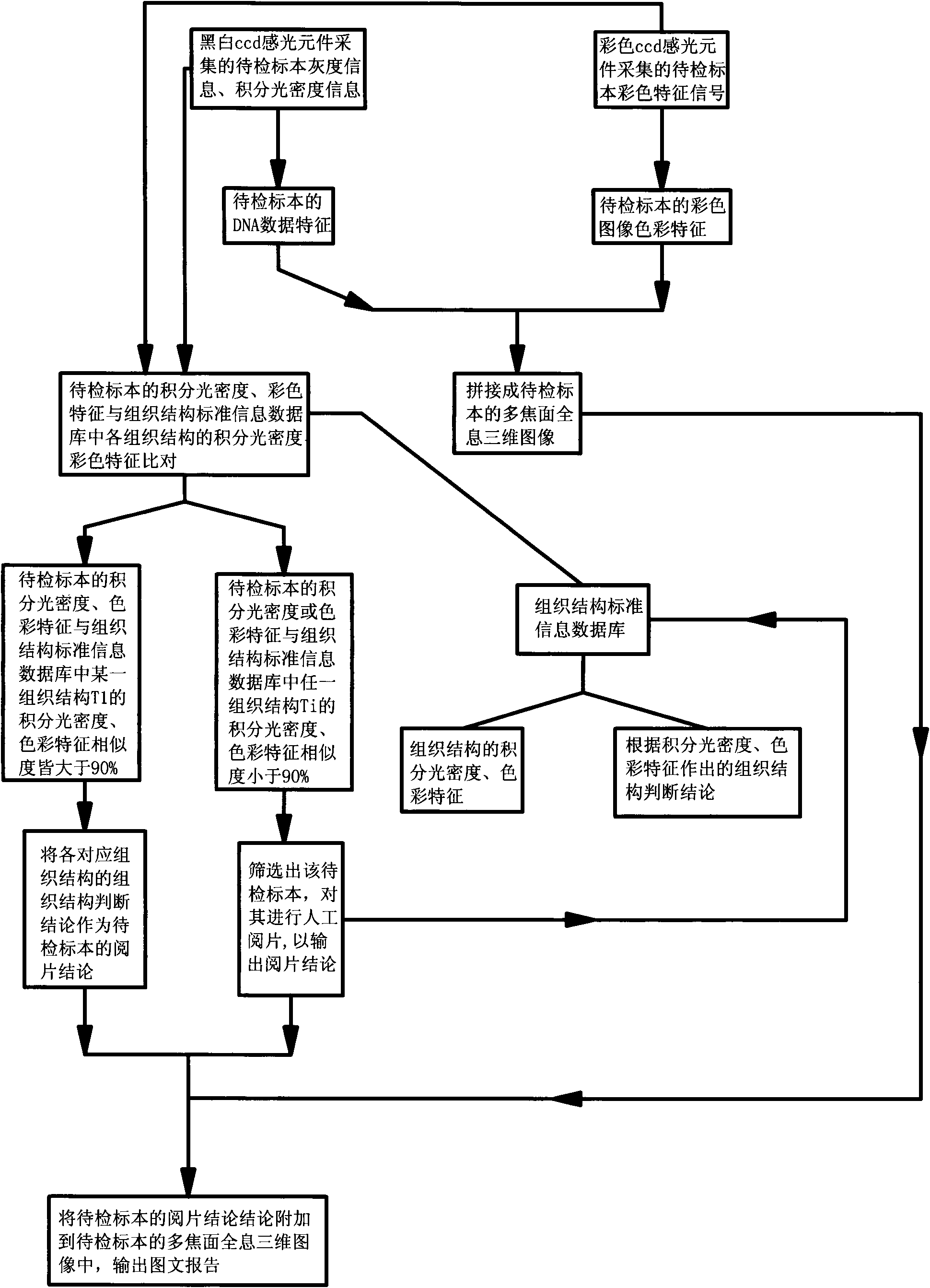

Biological digital microscope with double ccd (charge coupled device) light sensitive elements and photographic image processing method thereof

ActiveCN102147523AEasy to observeImprove accuracyMaterial analysis by optical meansCharacter and pattern recognitionGraphicsImaging processing

The invention discloses a biological digital microscope with double ccd (charge coupled device) light sensitive elements and a photographic image processing method thereof, wherein a colour ccd light sensitive element and a black and white ccd light sensitive element are used for collecting image information; the black and white ccd light sensitive element collects a gray scale and integrating optical density information of a specimen cell nucleus; the colour ccd light sensitive element collects a colour characteristic signal of a specimen image; the three-dimensional split joint of a specimen picture is performed by the gray scale of a specimen cell nucleus, the integrating optical density information and colour characteristic signal of a specimen image, so as to form a multi-focal plane holographic three-dimensional image; simultaneously, a film reading conclusion is output according to the integrating optical density information of a cell nucleus; finally a graphics context report of the specimen to be examined is output; therefore the biological digital microscope disclosed by the invention can perform conventional morphological observation for the specimen, as well as can perform digital photographing for the dyed DNA (deoxyribonucleic acid) for forming a multi-focal plane holographic three-dimensional image which is convenient for observing all the information of the cell in a multilayer and multi-focal plane mode; and the accuracy of early diagnosis is greatly improved.

Owner:南京福怡科技发展股份有限公司

Light microscope and method for image recording using a light microscope

InactiveCN108254909AMaterial analysis by optical meansUsing optical meansImage recordingOptoelectronics

Owner:CARL ZEISS MICROSCOPY GMBH

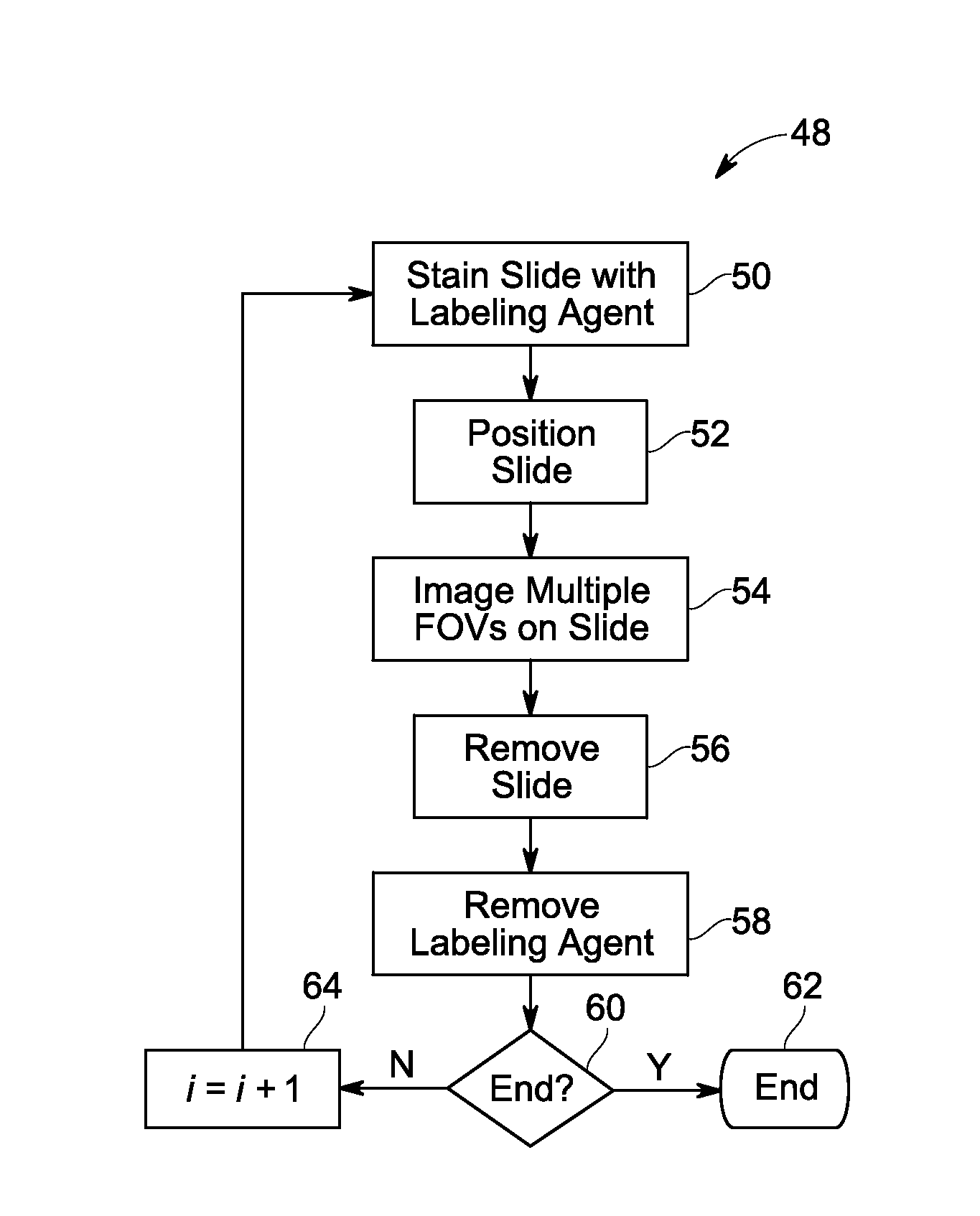

Image quality assessment of microscopy images

ActiveUS20140270425A1Automatic detectionImage enhancementImage analysisMicroscopic imageImaging quality

Automated assessment of registration quality, focus, and area defects in sequentially acquired images, such as images acquired by a digital microscope, is disclosed. In one embodiment, acquired images are registered and whole-image defects are automatically detected based on a figure of merit generated by the registration process. In related implementations, area defects may be automatically detected by calculating correlations in localized image regions for images acquired in different imaging rounds.

Owner:LEICA MICROSYSTEMS CMS GMBH

System and method to determine slide quality of a digitized microscope slide

Owner:LEICA BIOSYST IMAGING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com