Ceramic matrix composite material high-temperature air environment substrate crack observation system and observation method

A technology of composite materials and high-temperature air, which is applied in the direction of analyzing materials, using stable tension/pressure to test the strength of materials, measuring devices, etc., can solve the problems of complex clamping, high cost, and large volume of test pieces, and achieve The effect of simple structure, small test operation difficulty and simple disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further explained below in conjunction with the accompanying drawings.

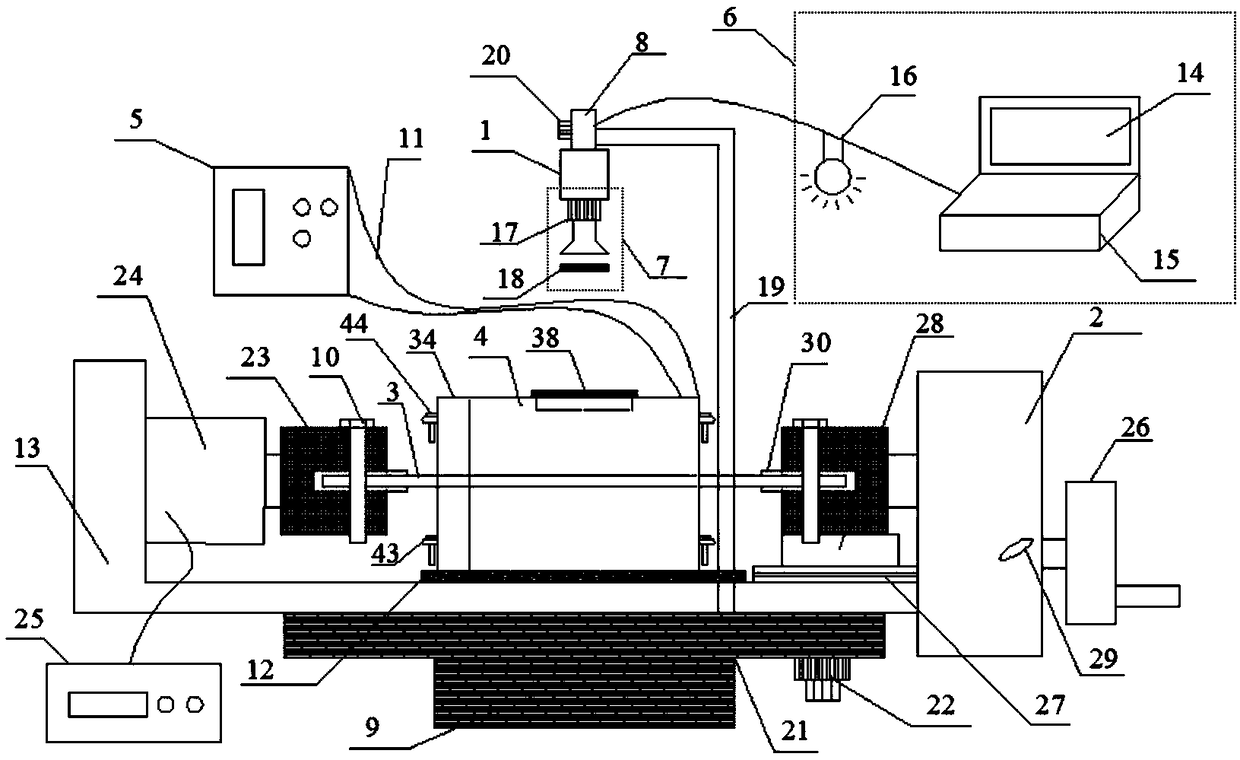

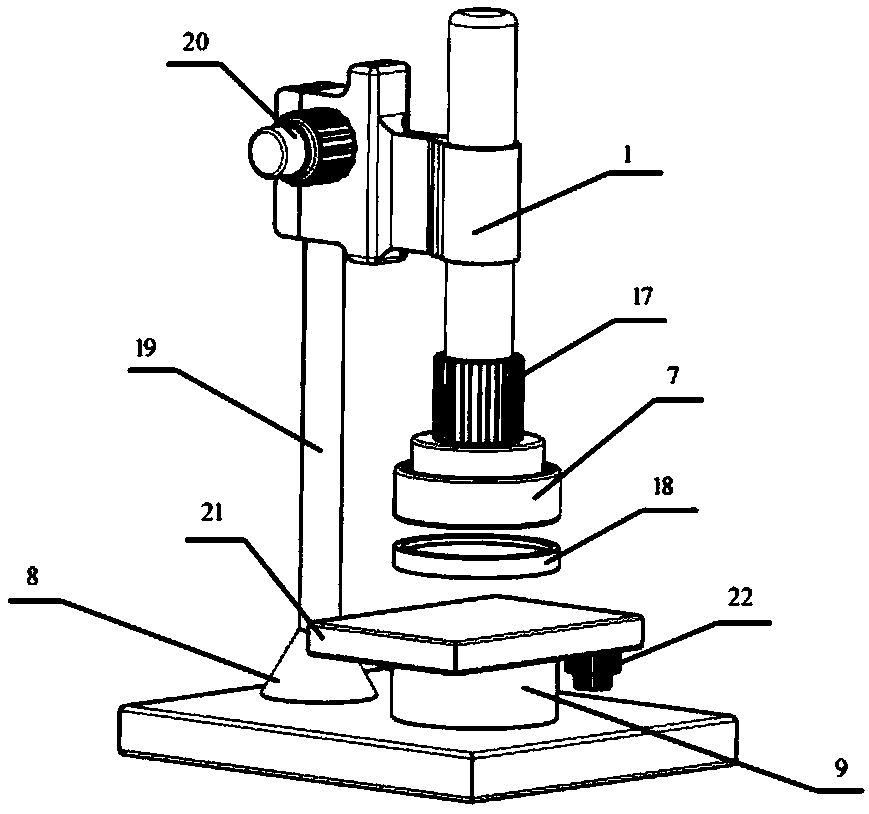

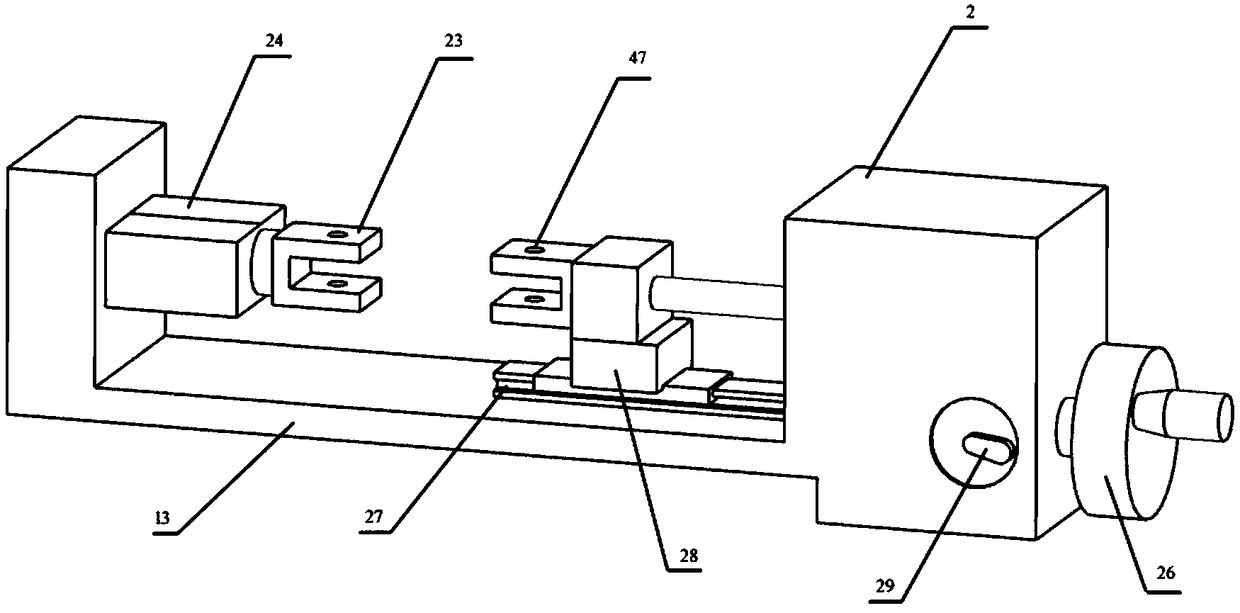

[0040] like figure 1 As shown, a ceramic matrix composite material matrix crack observation system in high temperature air environment, including: digital microscope 1, tensile test device 2, test sample 3, heating device 4, temperature controller 5, digital microscope includes a desktop main control system 6. Zoom lens 7, mirror holder 8, two-dimensional mobile platform 9, desktop main control system 6 includes display screen 14, LED lamp 16, main controller 15, display screen 14 shows the situation of material surface in real time, LED lamp 16 is used for To illuminate the surface of the test sample 3, the main controller (15) is connected with the LED lamp (16) and the zoom lens (7). The test sample 3 includes the ceramic matrix composite material, and the zoom lens 7 can be used for the ceramic matrix composite material surface. The main controller receives and st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com