Total internal reflection microscopy method and device based on free-form surface shaping

A total internal reflection and free technology, applied in microscopes, optics, instruments, etc., can solve the problems of uneven light field and low utilization rate of light energy, and achieve uniform imaging field of view, high utilization rate of laser energy and low noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

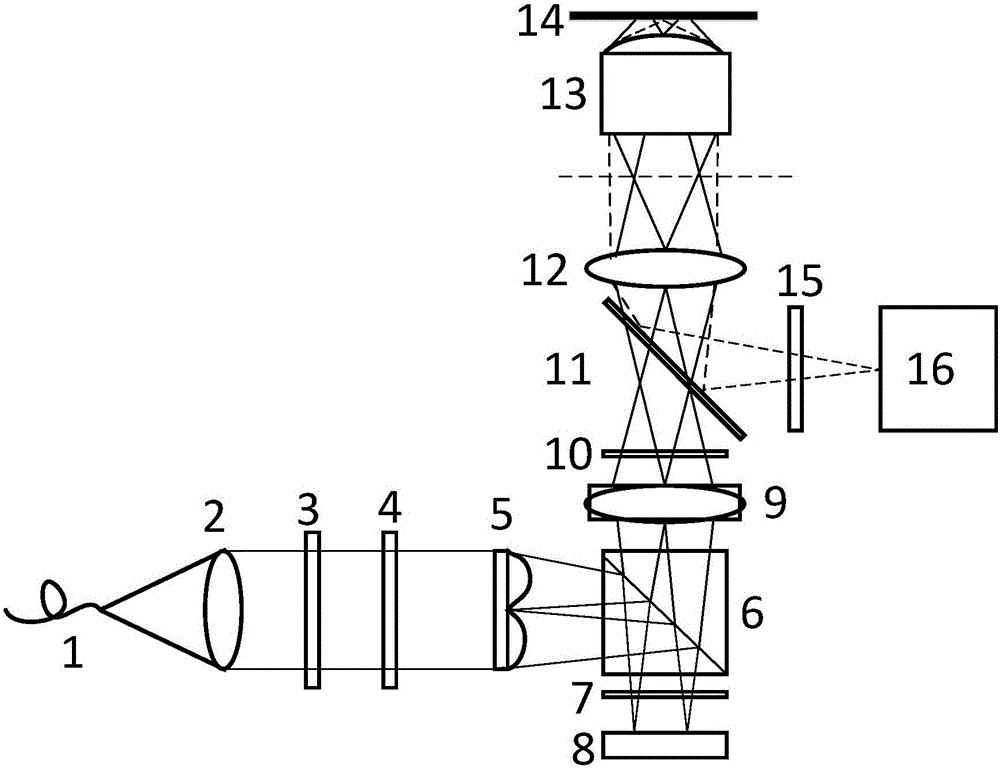

[0036] Such as figure 1 As shown, a total internal reflection microscopy device based on free-form surface shaping includes: fiber laser 1, collimator lens 2, polarizer 3, half-wave plate 4, free-form surface lens 5, polarization beam splitter prism (PBS )6, quarter-wave plate 7, digital micromirror (DMD) 8, variable focal length collimating lens 9, quarter-wave plate 10, dichromatic mirror 11, microscopic field lens 12, total internal reflection microscope Micro objective lens 13, sample 14, optical filter 15 and CCD16.

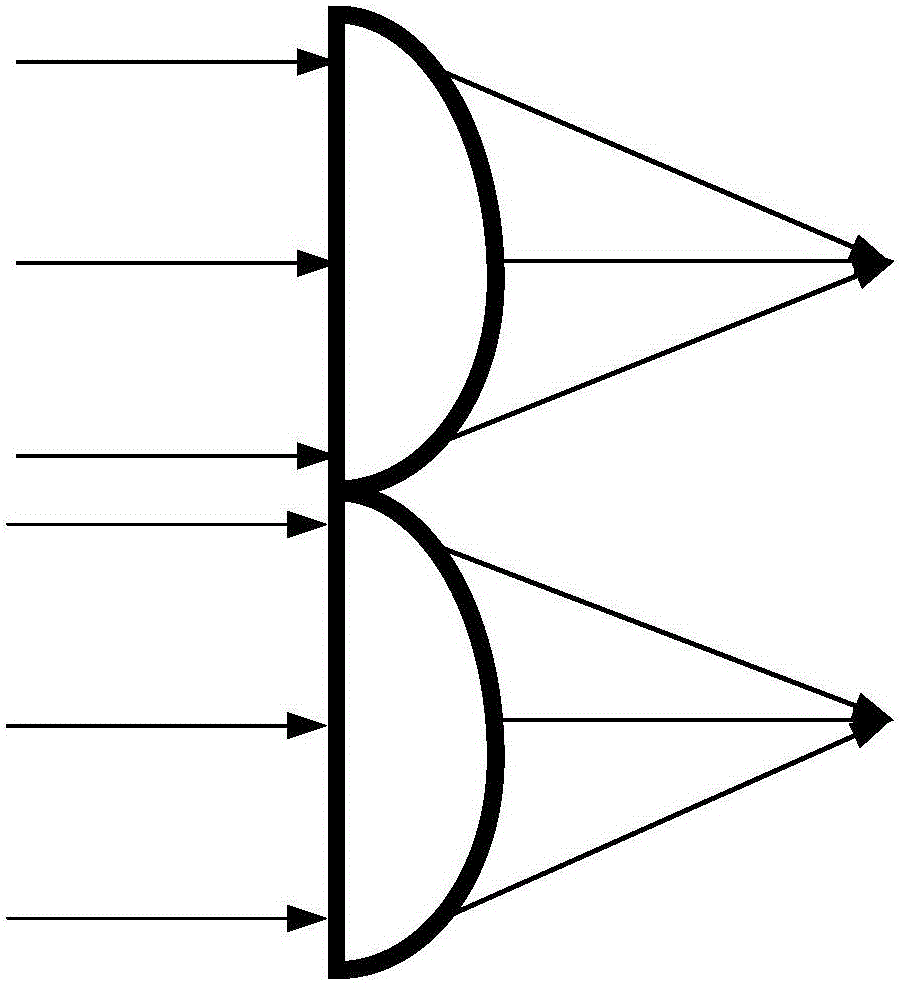

[0037]Laser 1, collimator lens 2, polarizer 3, half-wave plate 4 and free-form surface lens 5 are centered on the same optical axis, the laser light emitted by laser 1 becomes a parallel beam through collimator lens 2, and polarizer 3 makes The light beam becomes linearly polarized light, the half-wave plate 4 can change the polarization direction of the polarized light, and the free-form surface lens 5 can focus the light beam into an annular light spot, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com