Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32 results about "Digestion chambers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Digestion chambers are a histologic finding in nerves that are undergoing Wallerian degeneration.

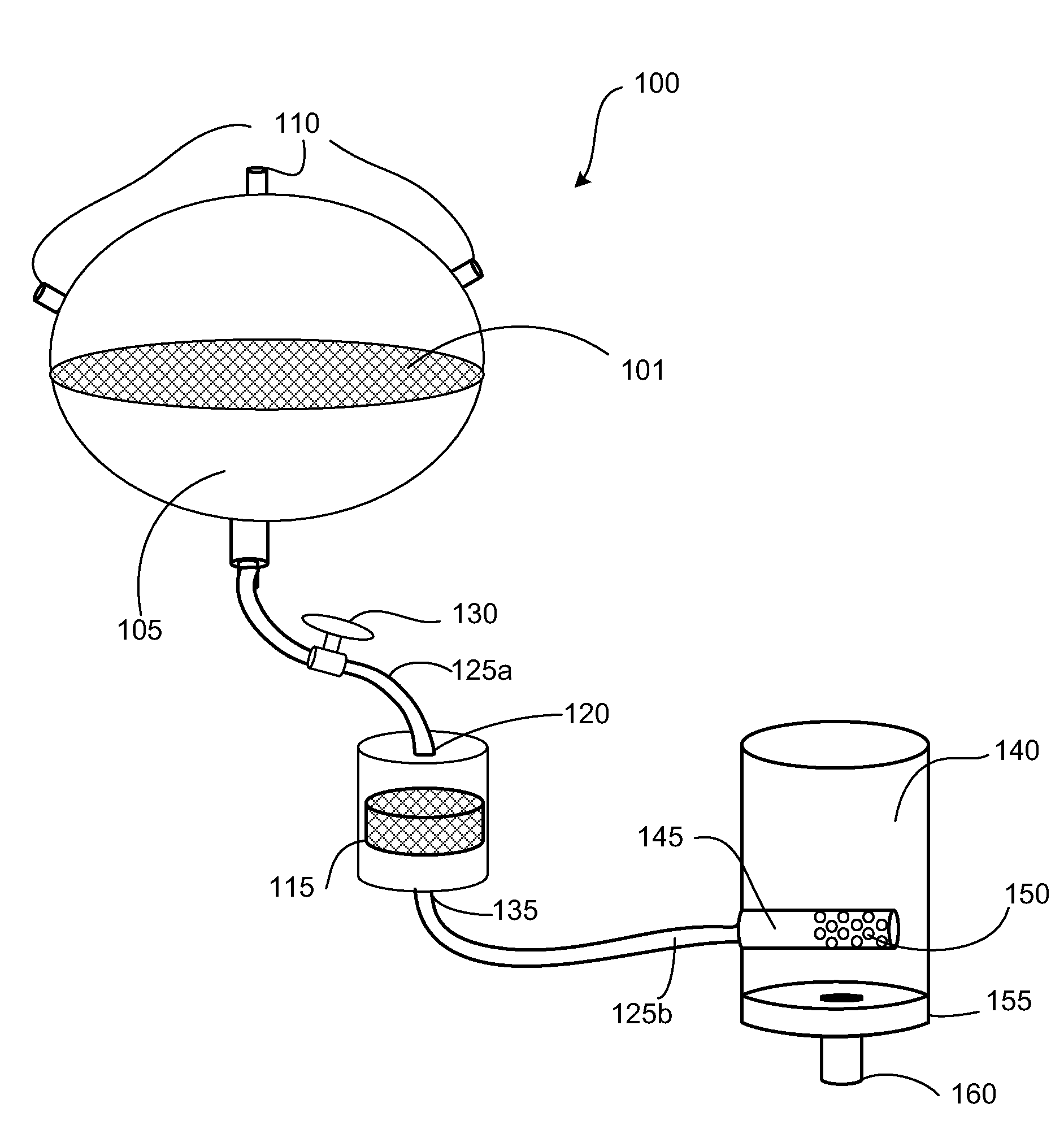

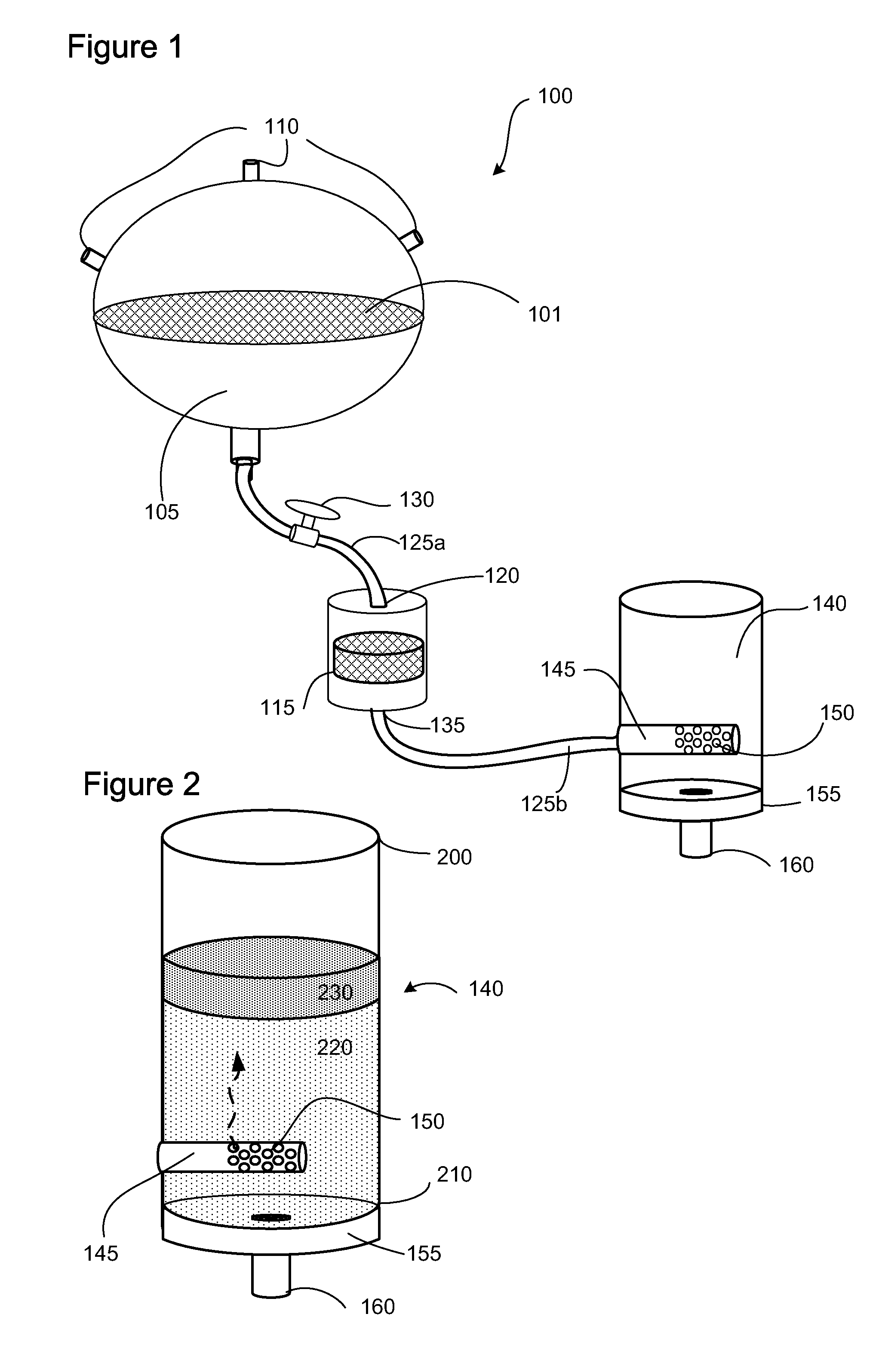

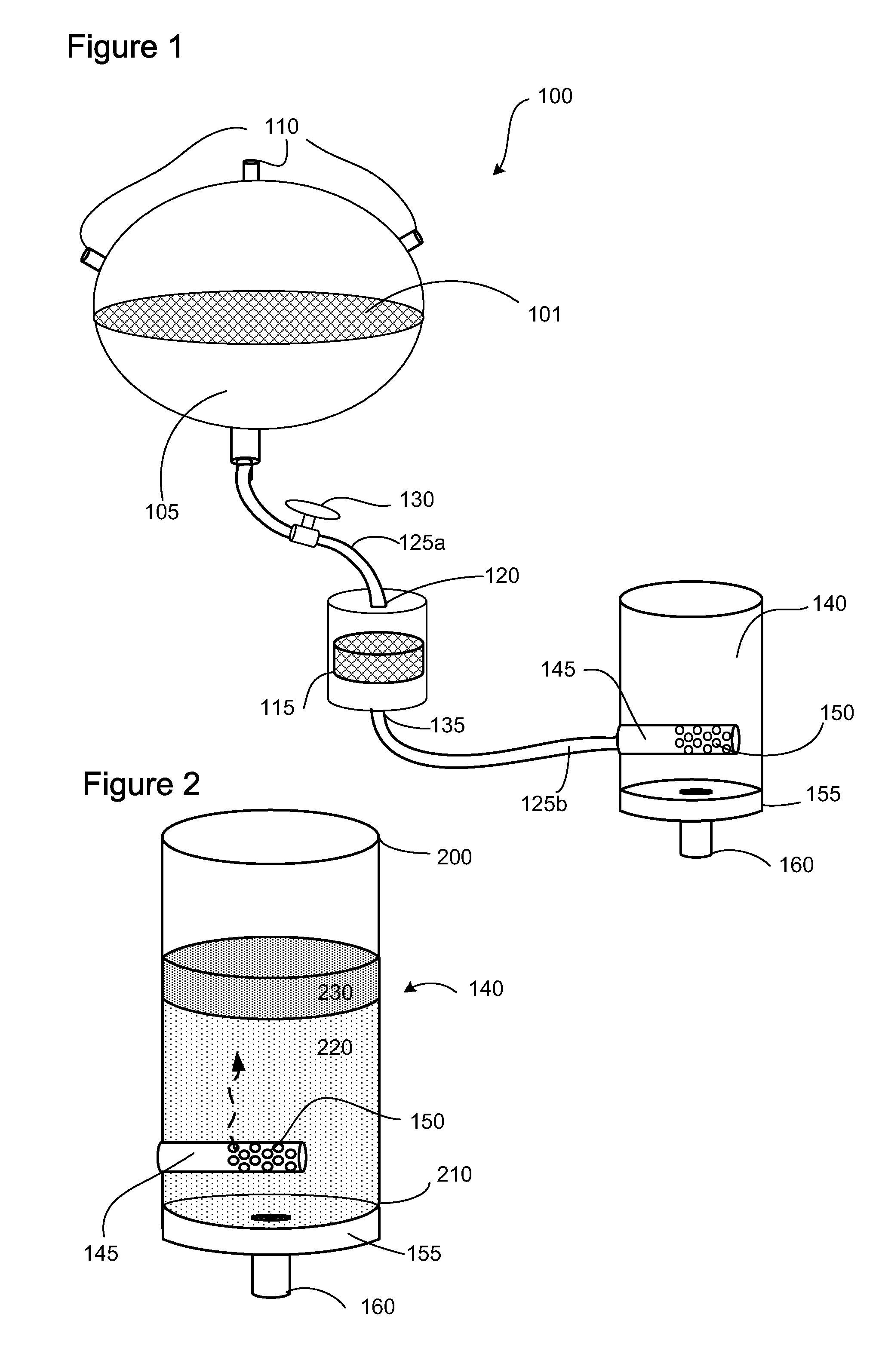

Apparatus and Methods for Cell Isolation

ActiveUS20100285588A1Reduce cloggingMaximize surface areaBioreactor/fermenter combinationsBiological substance pretreatmentsMixed cellMixed Cellular Population

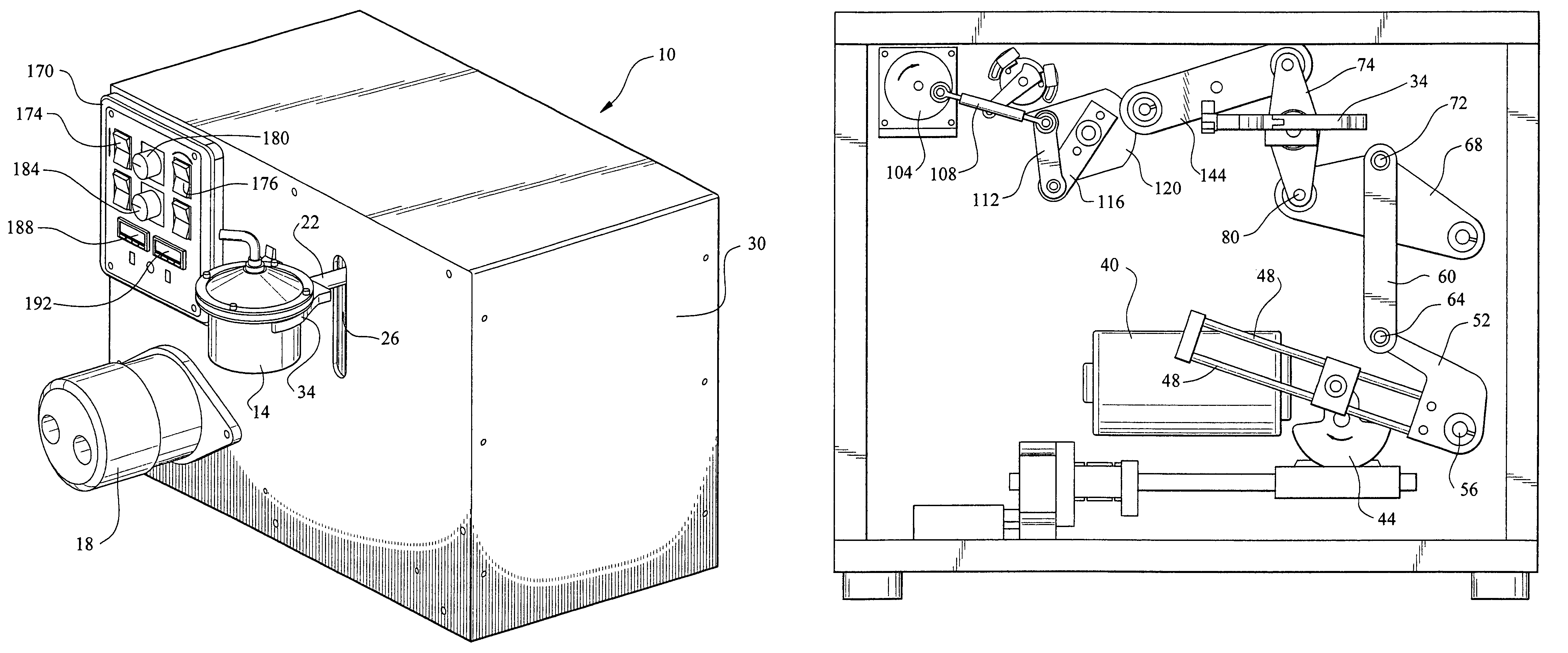

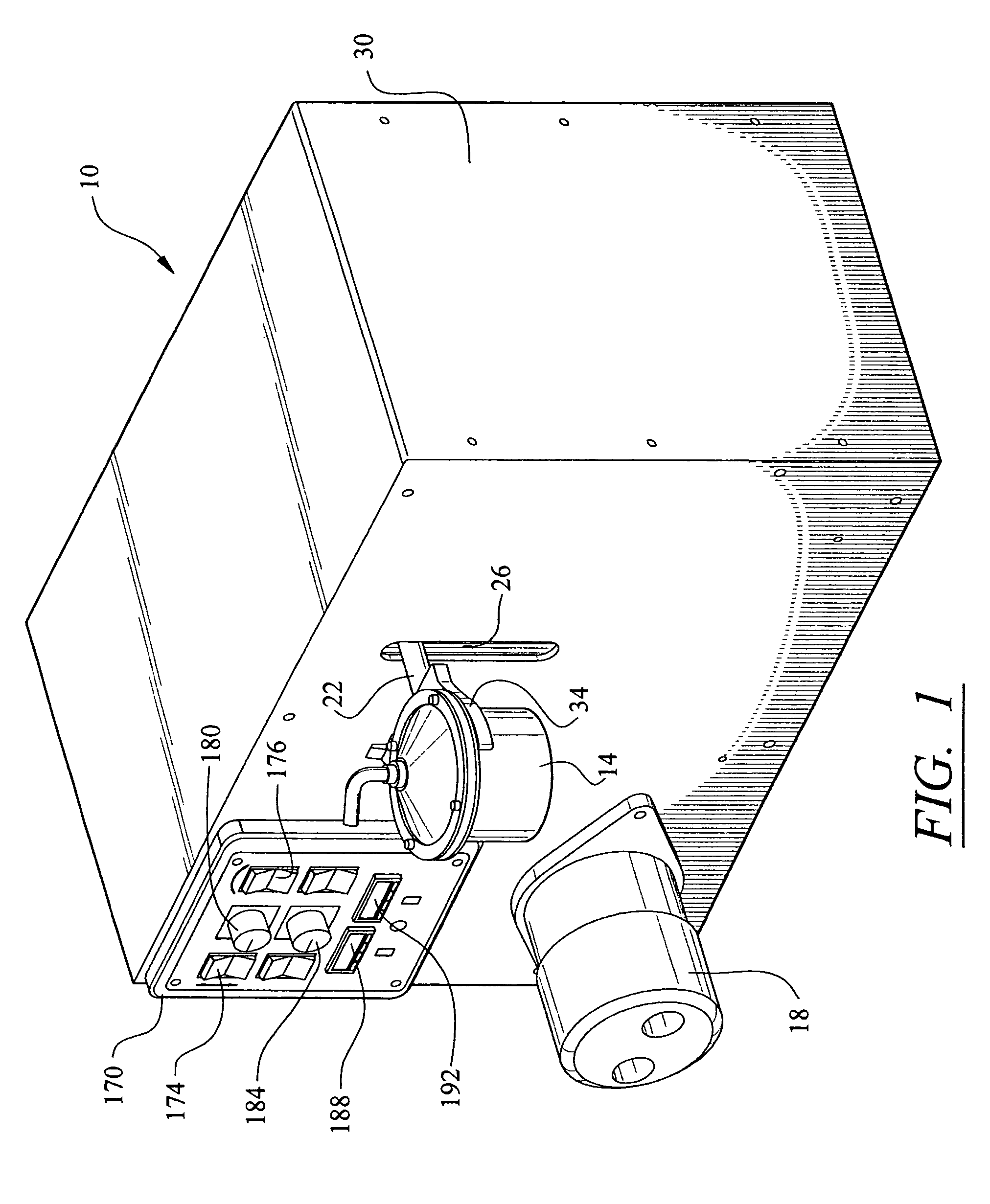

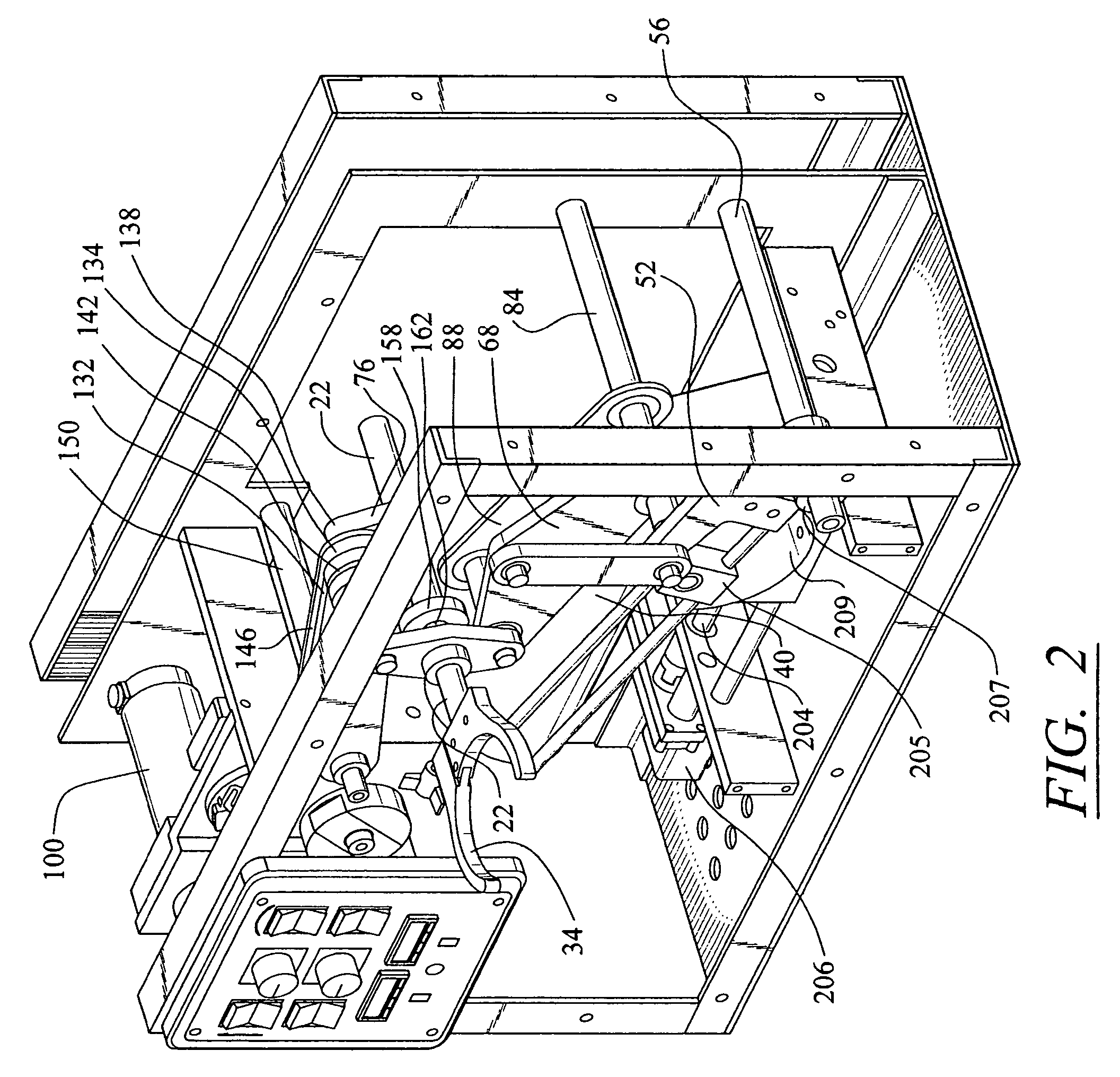

A unitary apparatus for isolating cells from adipose tissue including a lipid separation processor with a dispersing head equipped with a plurality of ports and a digestion chamber for dissociation of the constituent cells disposed in adipose tissue. The lipid separating apparatus is useful for the separation of lipids and adipocytes from a mixed cell population. A cell seeding chamber may be attached to the cell isolation apparatus. The components of the apparatus may be packaged in modular kit form.

Owner:INGENERON

Cassette for isolation, amplification and identification of DNA or protein and method of use

InactiveUS20050176135A1Bioreactor/fermenter combinationsBiological substance pretreatmentsElectrophoresisDigestion chambers

The present invention is directed to a device for DNA analysis. More particularly, the present invention is directed to a cassette which comprises a first chamber suitable for isolating DNA from a biological sample that is suspected of containing a target DNA, one or more second chambers suitable for amplifying any target DNA found in the sample, a chamber suitable for digesting the target DNA with restriction endonucleases, a medium for separation of the digestion fragments, and a channel connecting the digestion chamber to the separation medium and being of suitable size for transferring at least a portion of the contents of the digestion chamber to the separation medium. Typically, the medium for separation of the digestion fragments is an electrophoretic medium. The cassette of the present invention can also be used for the separation and identification of a protein of interest in a biological sample. It is within the scope of the present invention that the cassette also contains one or more internal waste chambers into which used reagents and biological sample can be directed and stored for disposal with the cassette. It is also within the scope of the present invention that the cassette contains a chamber for storage or receipt of a biological control sample.

Owner:JONES BRIAN

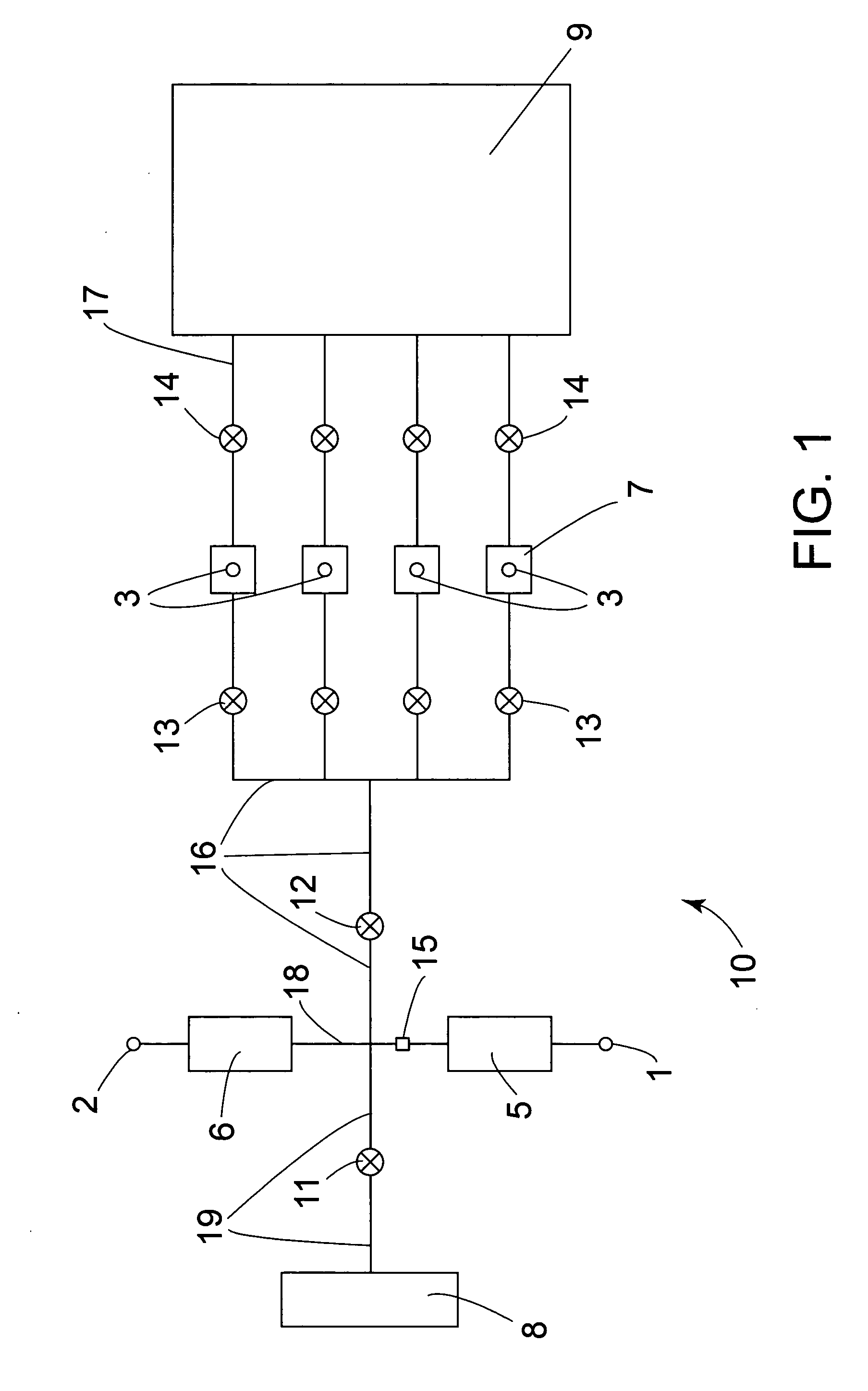

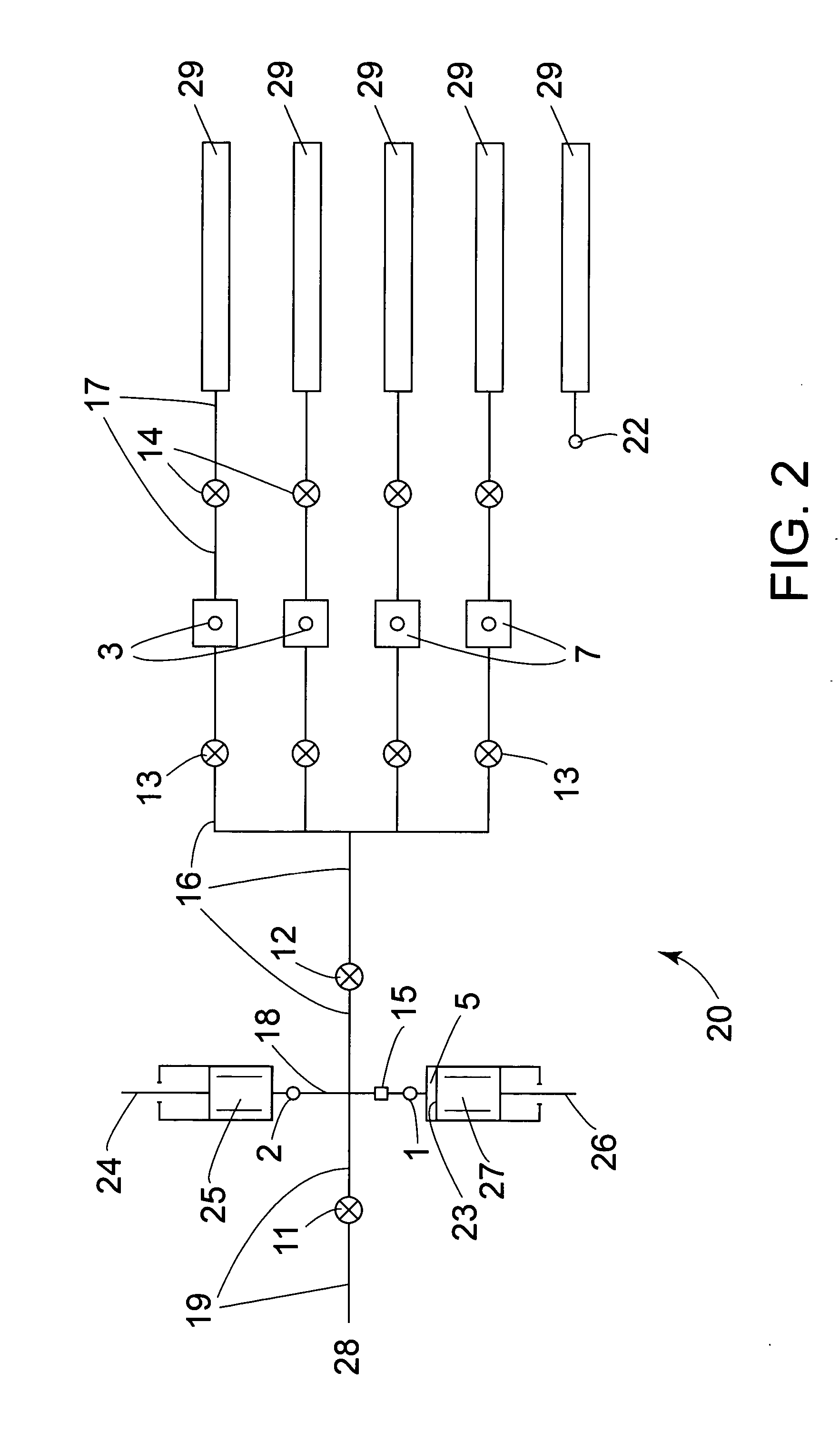

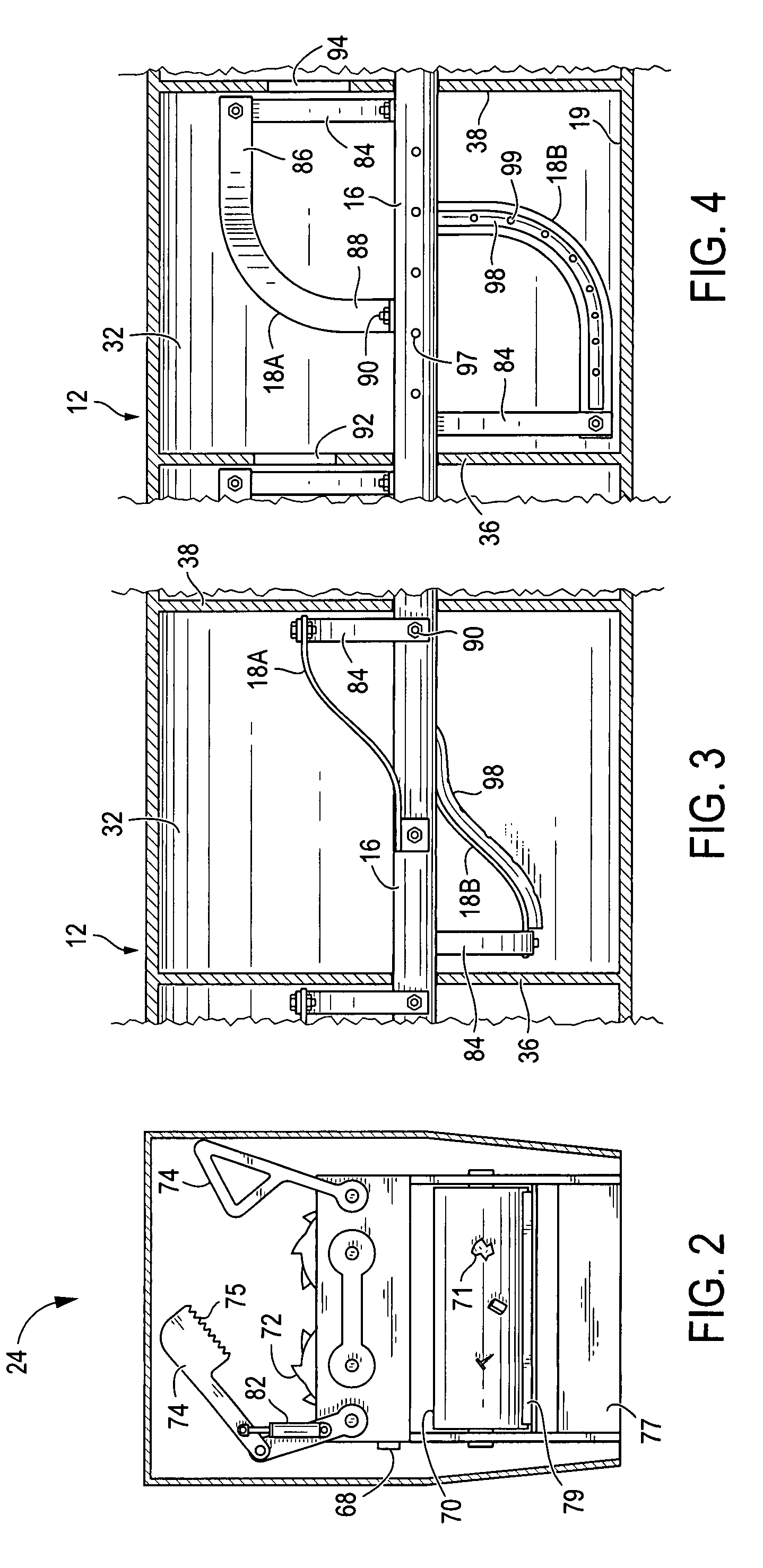

Automated composting system

InactiveUS7520457B1Easy to processReduce the effective heightBioreactor/fermenter combinationsBio-organic fraction processingProduct gasDigestion chambers

A composting system with a digestion chamber, an auger shaft with at least one mixing vane, and a power unit. The power unit can be hydraulic and can also power a shredding unit and an input conveyor system. A barrier wall can be interposed between those elements and the digestion chamber. The digestion chamber can be divided into subchambers, and sequentially lower apertures can promote a progression of organic material. A malfunction sensor can sense a malfunction of the auger shaft, the shredding unit, or another component. A malfunction report can be provided, including to a remote receiver. The report can include a determined location of the composting system and can be directed to a selected receiver based on the malfunction. Fluids, including gasses and liquids, can be introduced by a supply source in combination with apertures along the auger shaft and / or a mixing vane.

Owner:POITRAS BRIAN +1

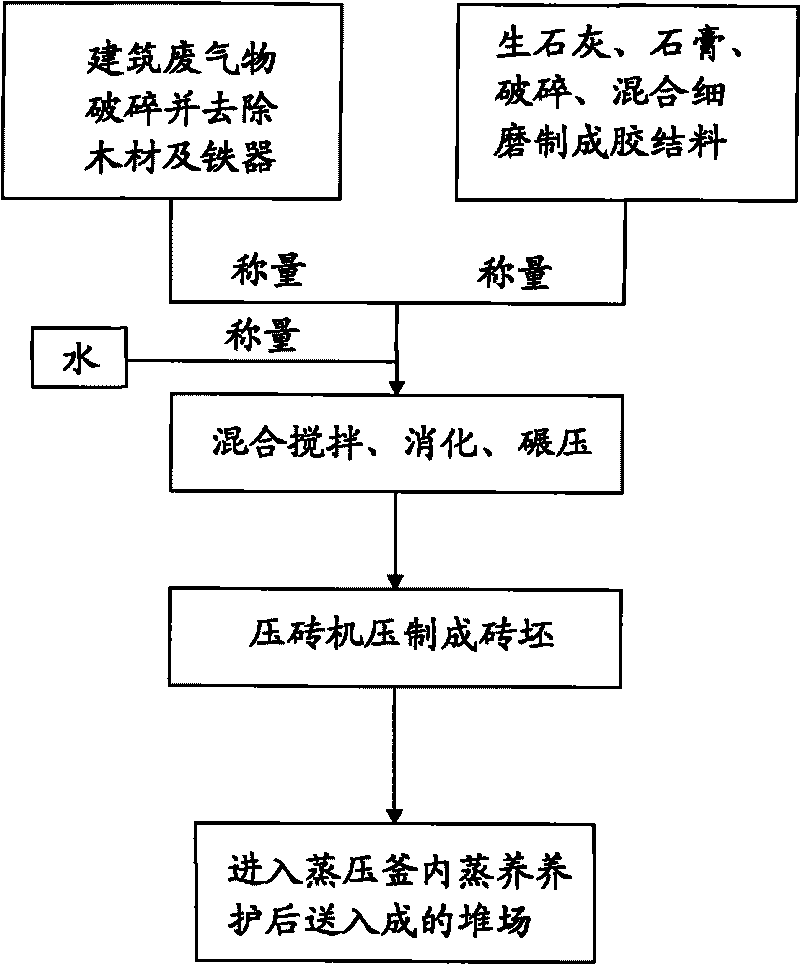

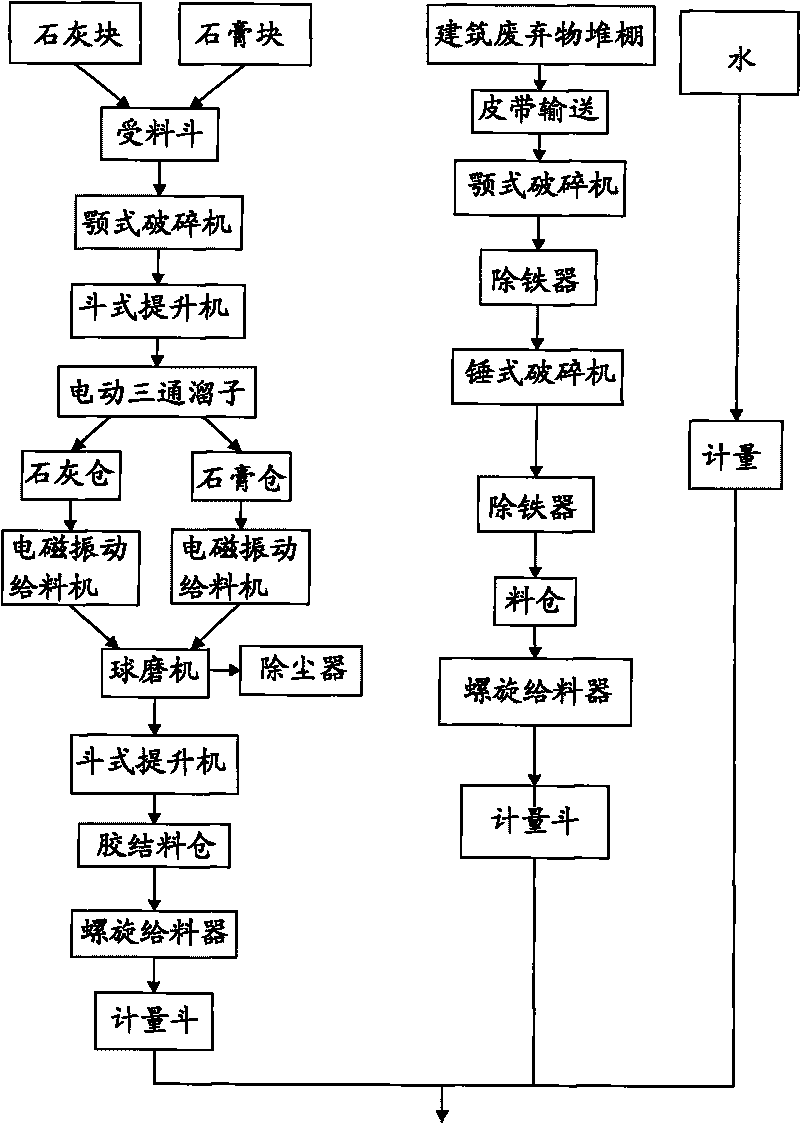

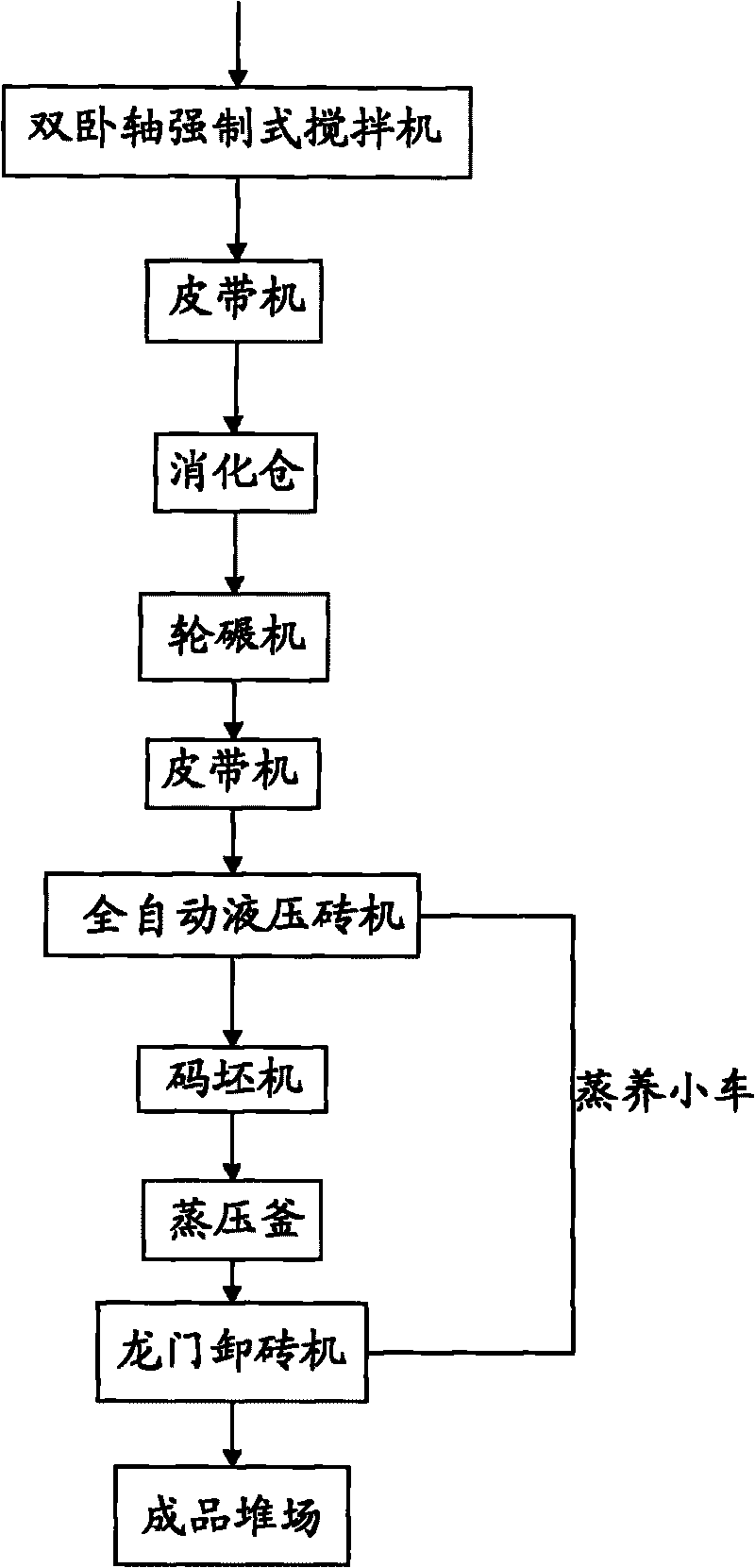

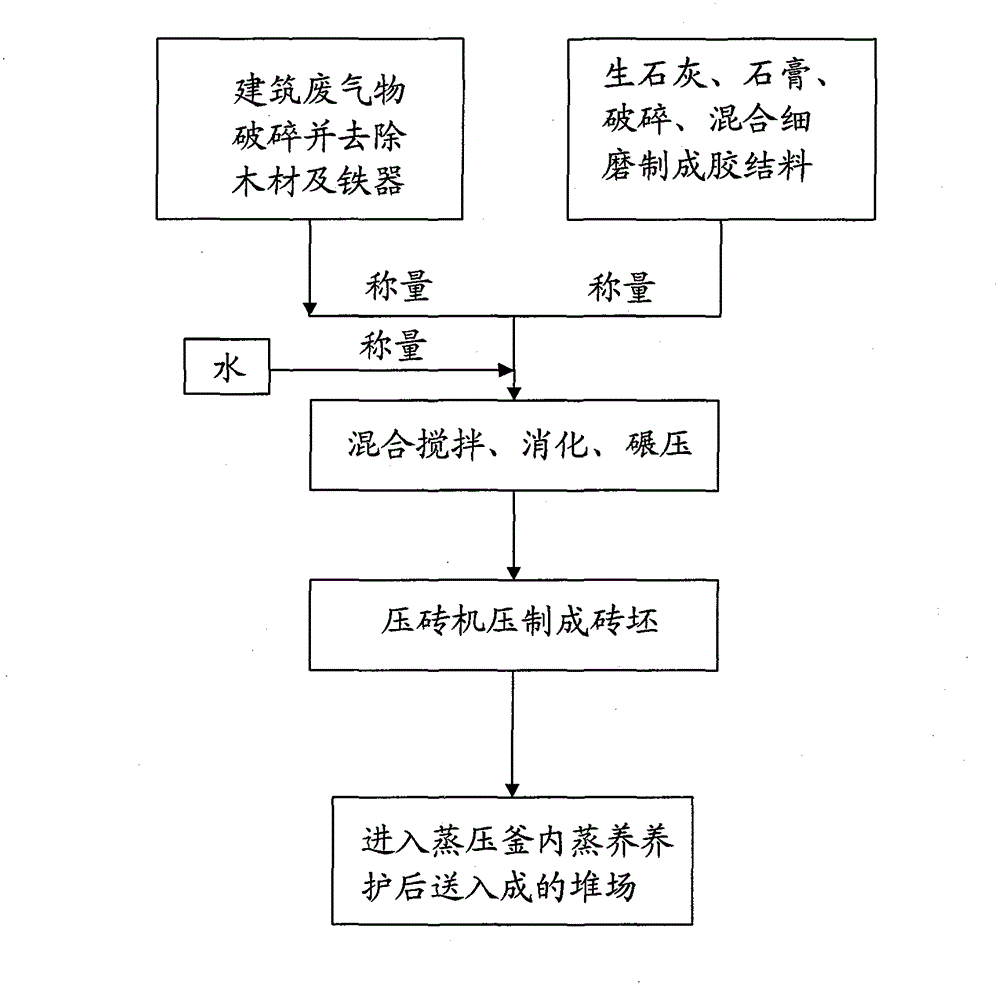

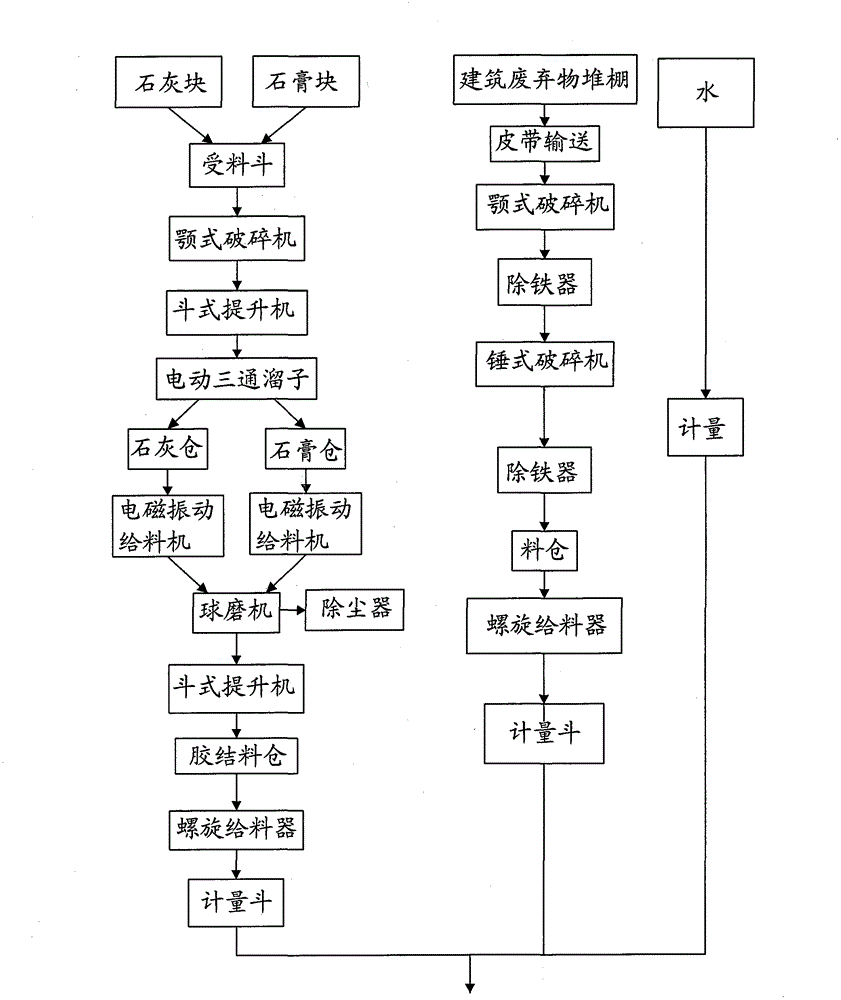

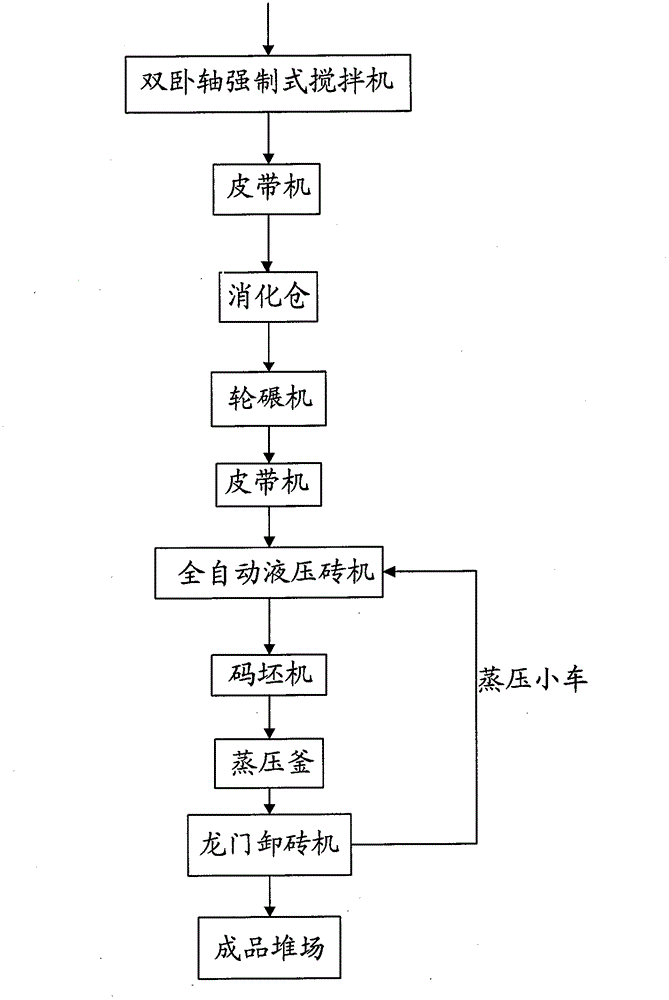

Process for producing regenerated building waste autoclaved brick

Owner:FUJIAN UNIV OF TECH +1

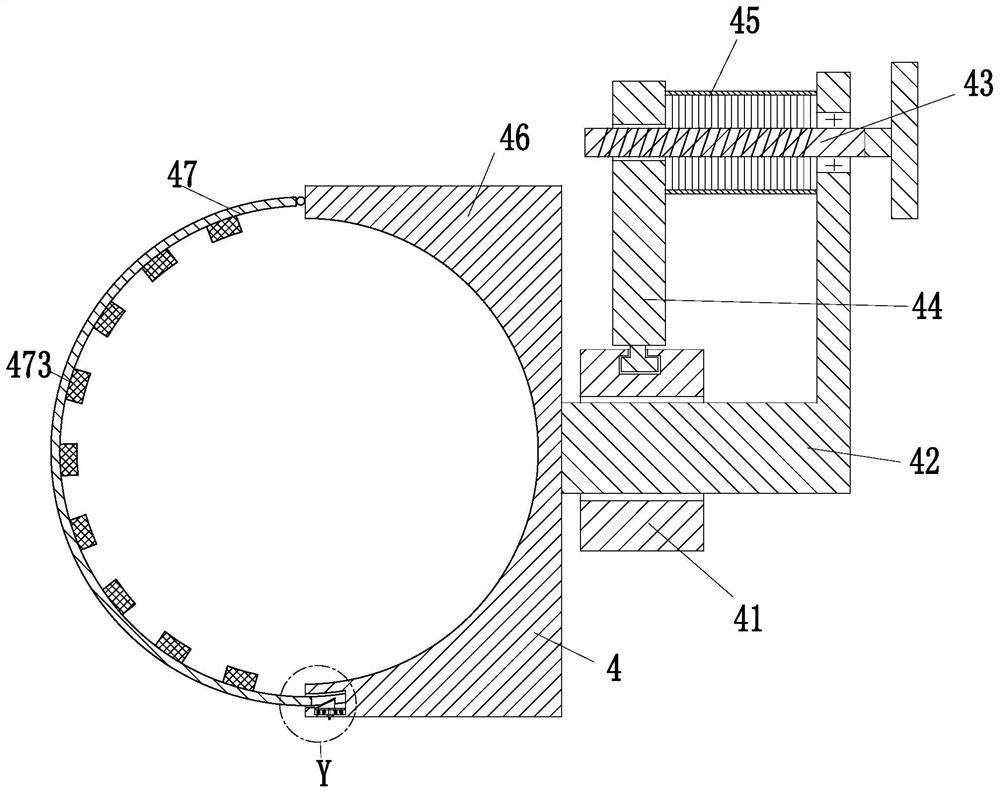

Orbital shaker for cell extraction

InactiveUS7188994B2Rotating receptacle mixersShaking/oscillating/vibrating mixersCell extractionCrystallography

Owner:MIAMI UNIVERISTY OF +1

Apparatus and methods for cell isolation

ActiveUS8309342B2Avoid cloggingReduce cloggingBioreactor/fermenter combinationsBiological substance pretreatmentsMixed cellMixed Cellular Population

A unitary apparatus for isolating cells from adipose tissue including a lipid separation processor with a dispersing head equipped with a plurality of ports and a digestion chamber for dissociation of the constituent cells disposed in adipose tissue. The lipid separating apparatus is useful for the separation of lipids and adipocytes from a mixed cell population. A cell seeding chamber may be attached to the cell isolation apparatus. The components of the apparatus may be packaged in modular kit form.

Owner:INGENERON

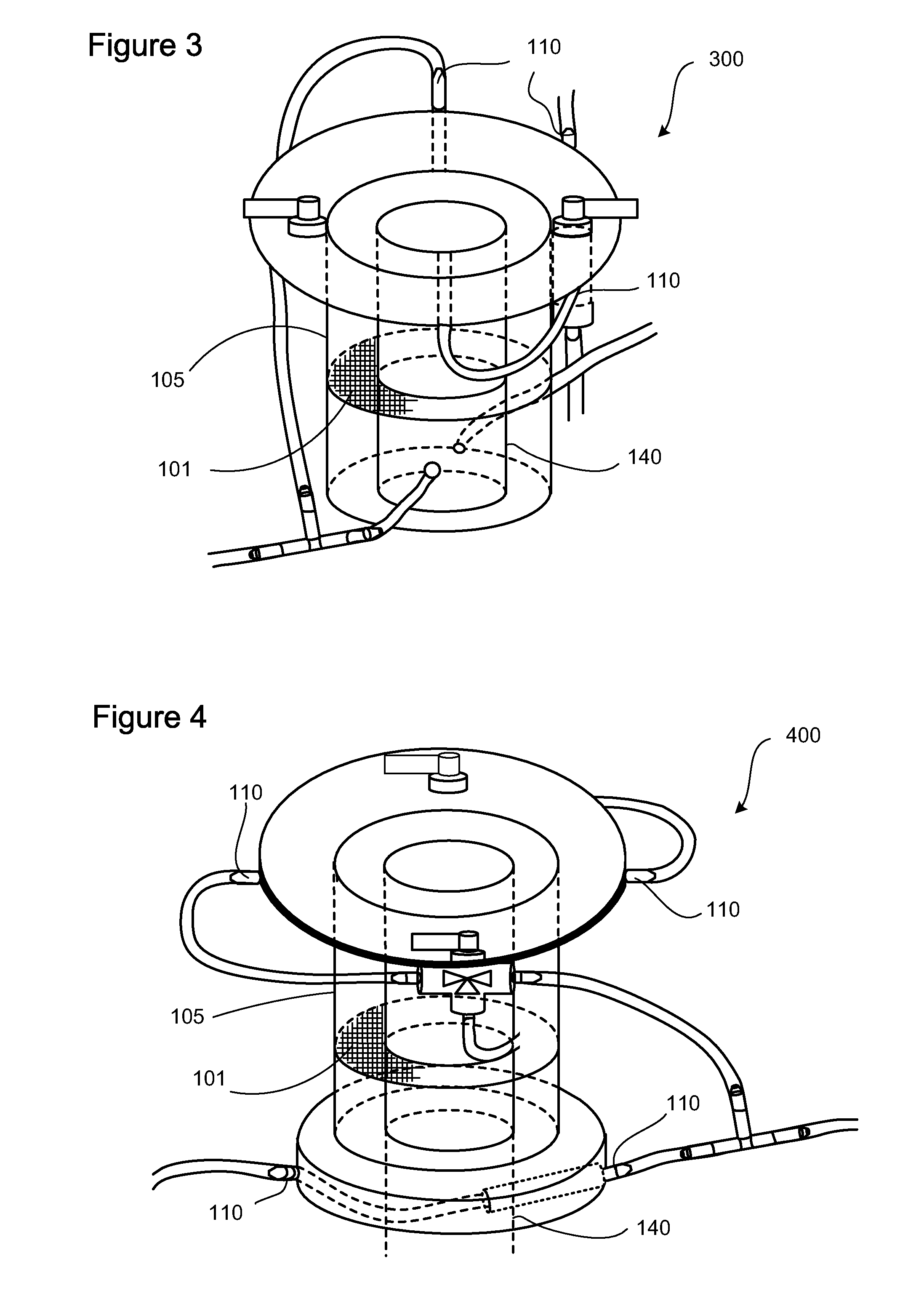

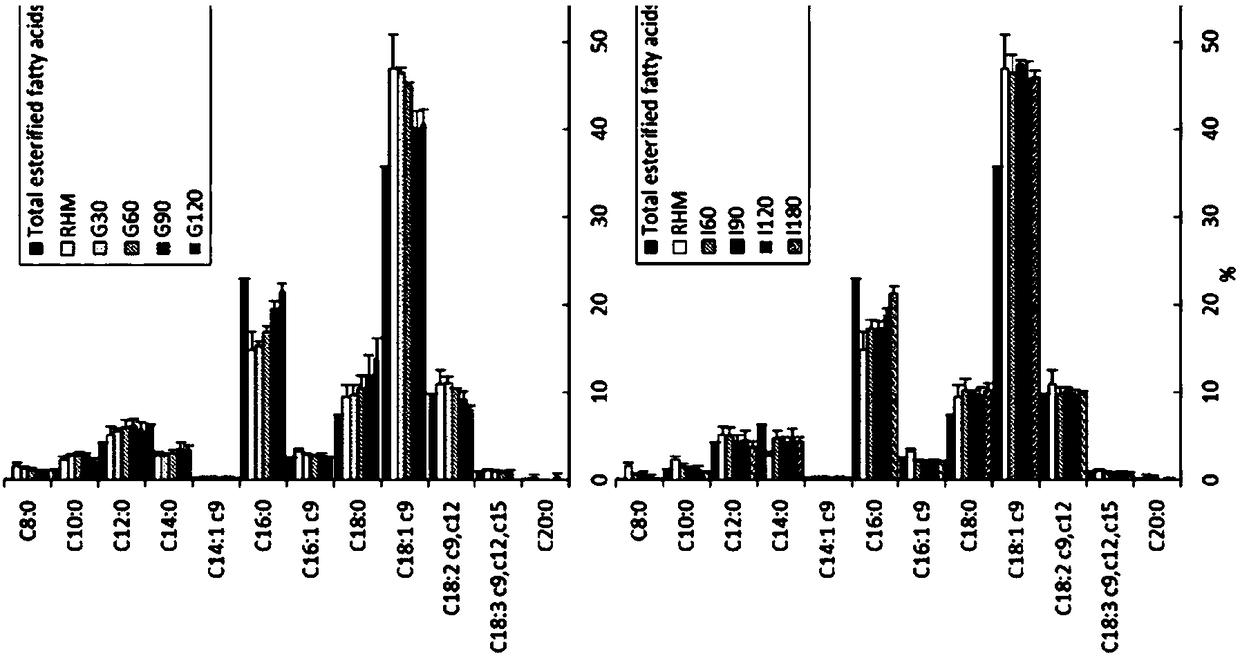

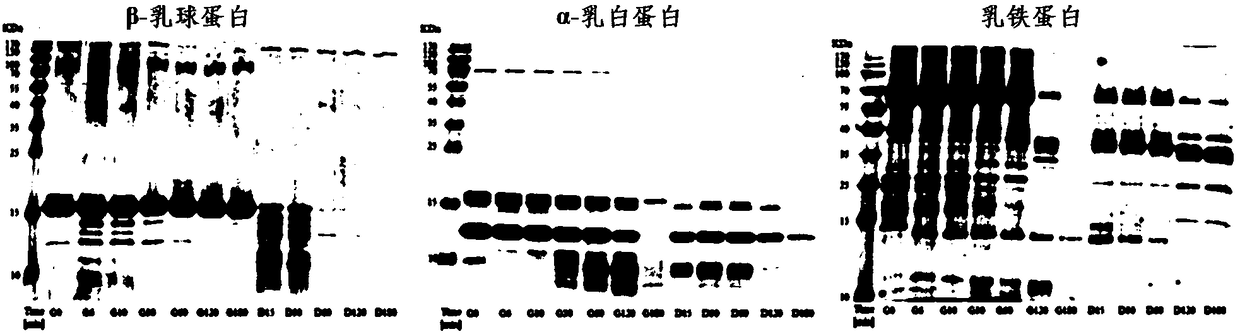

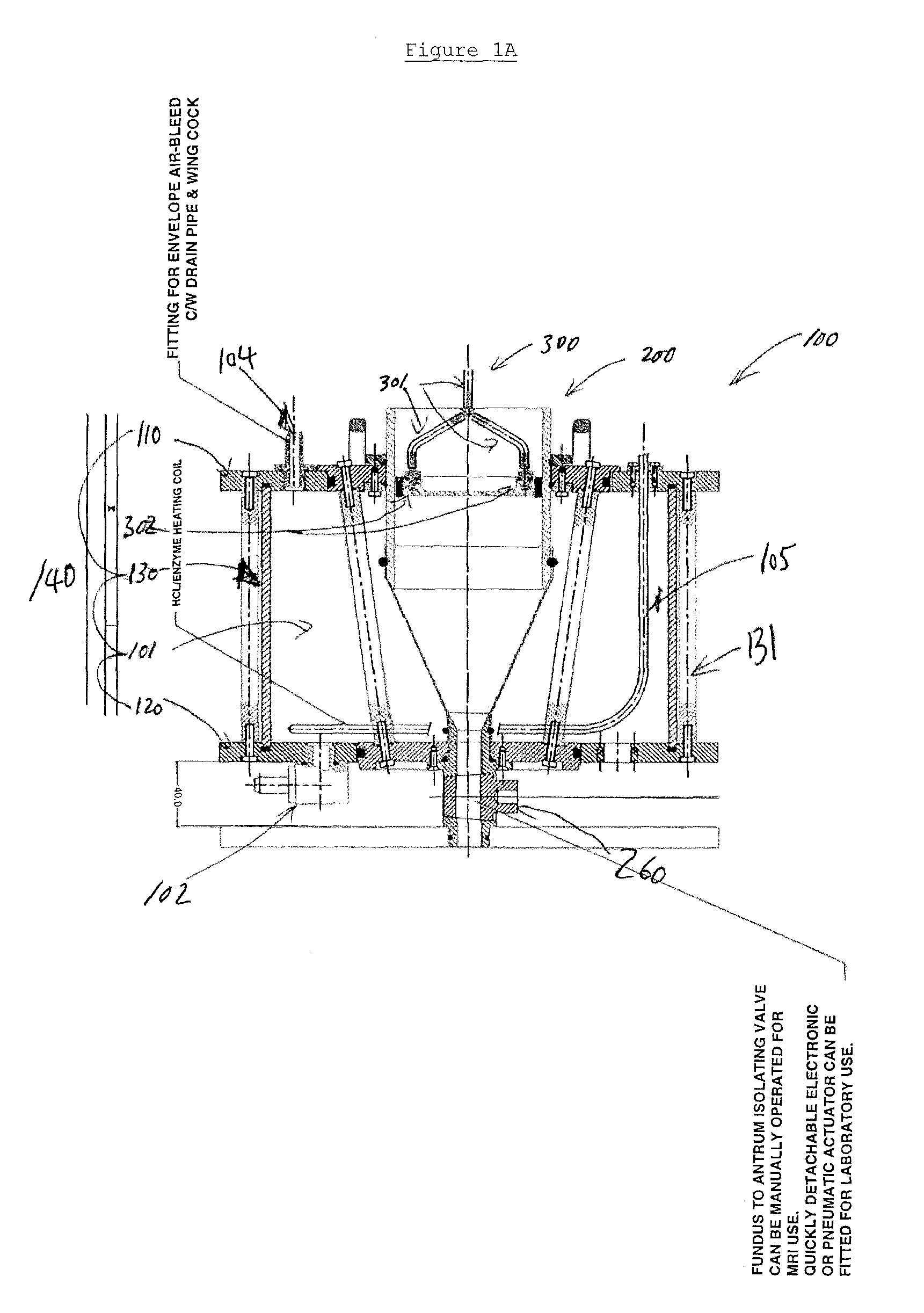

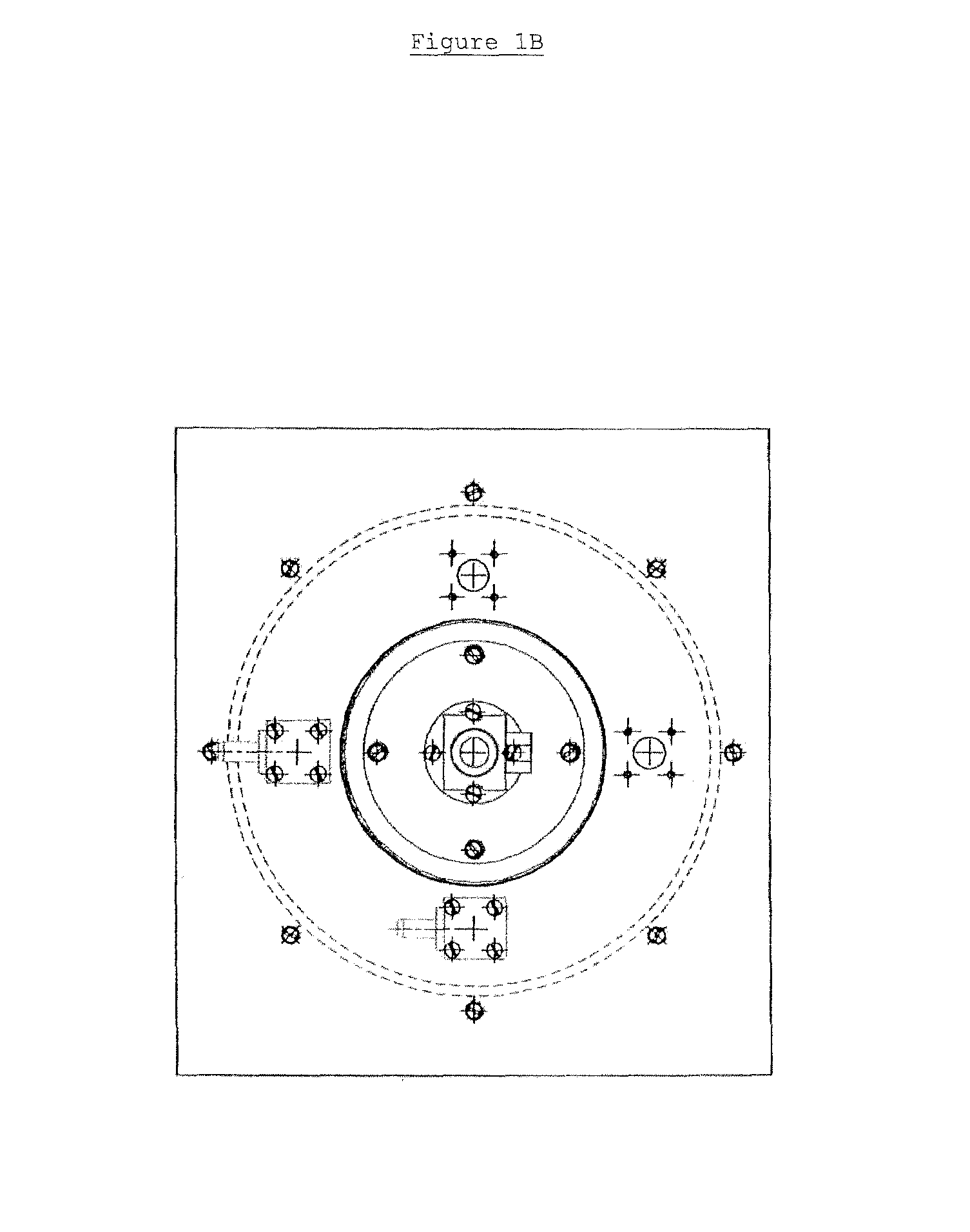

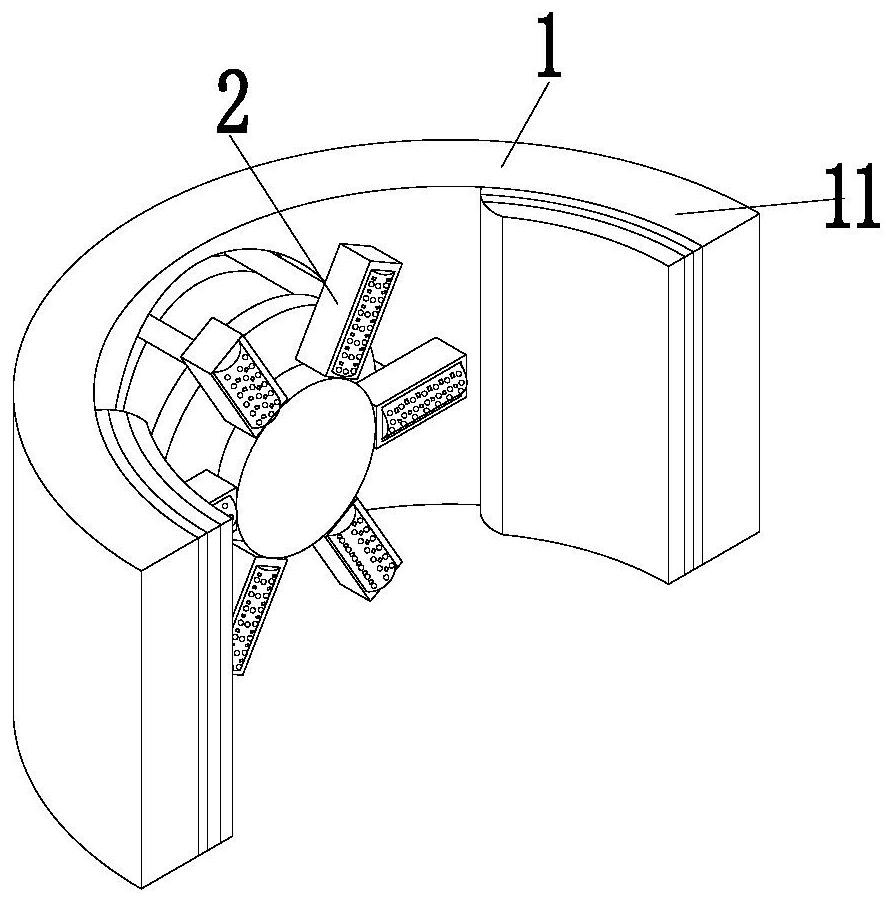

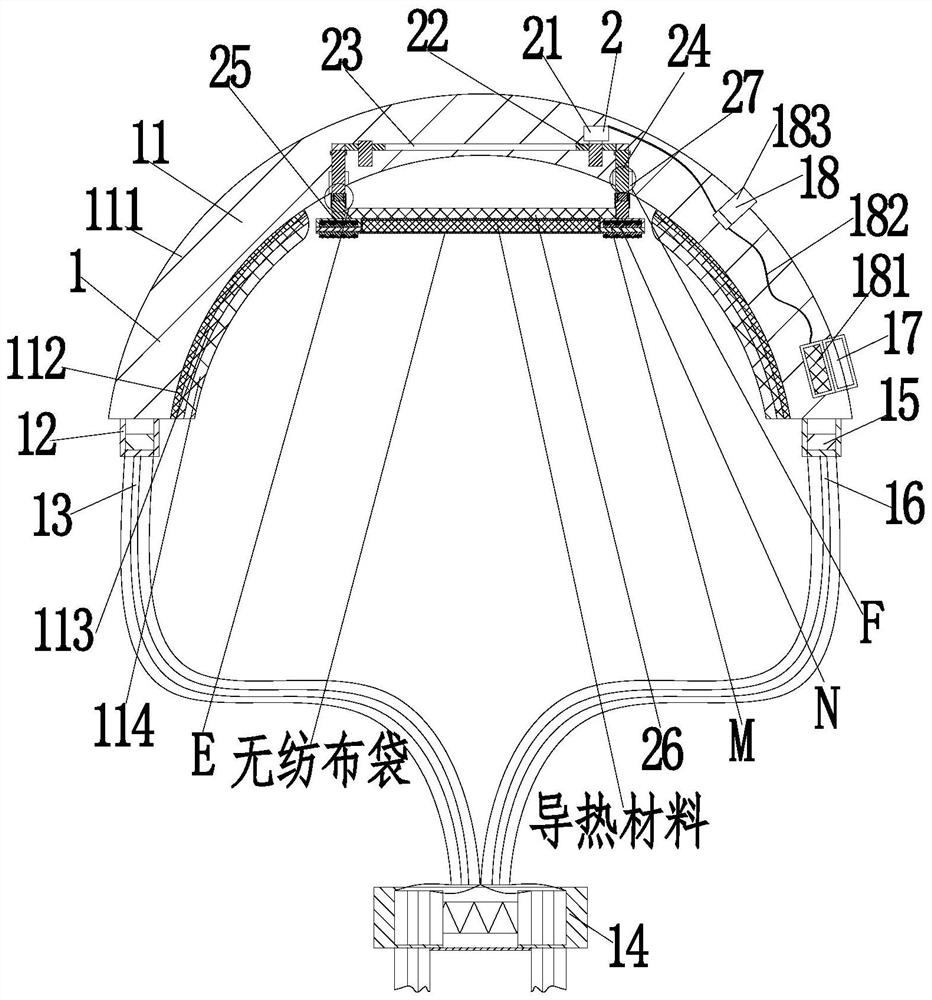

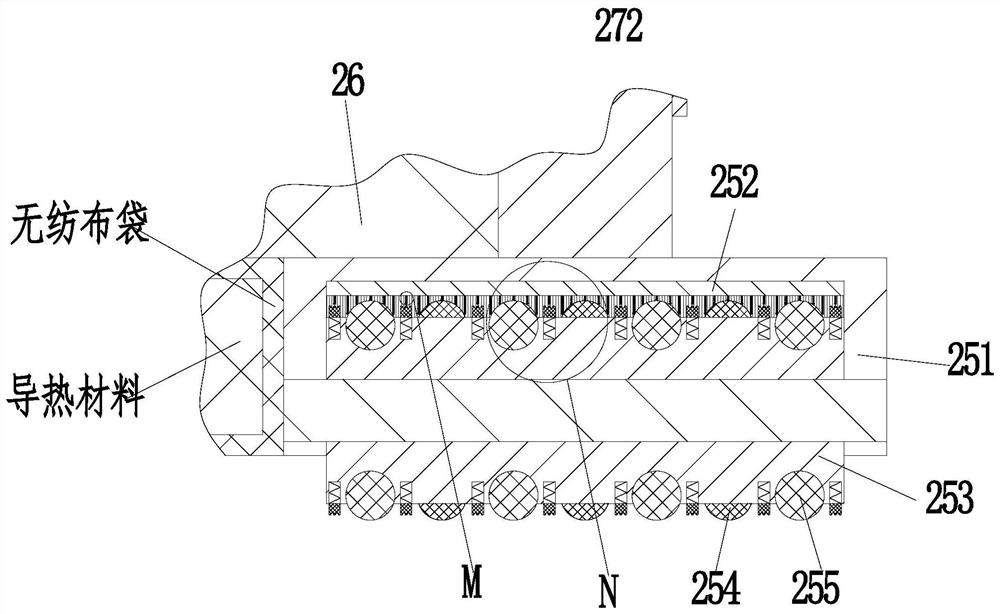

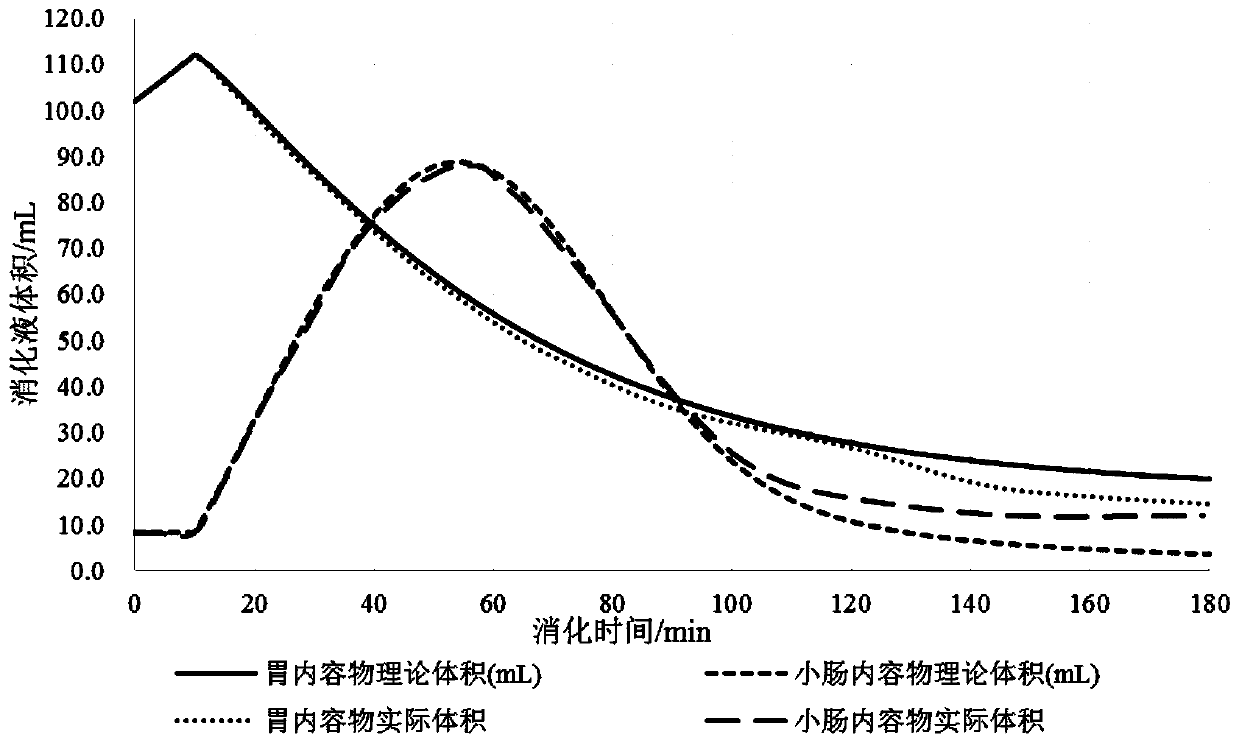

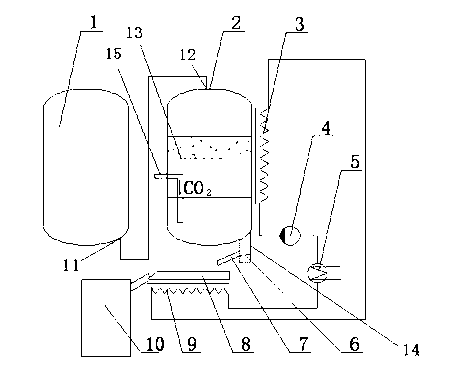

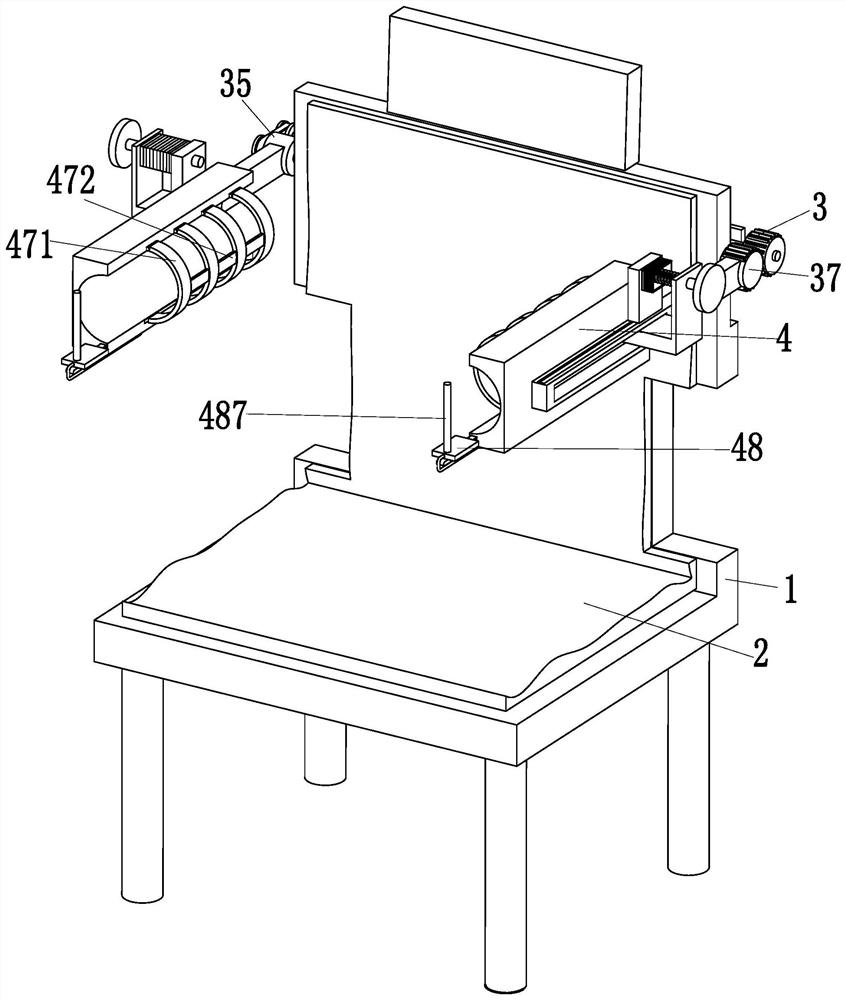

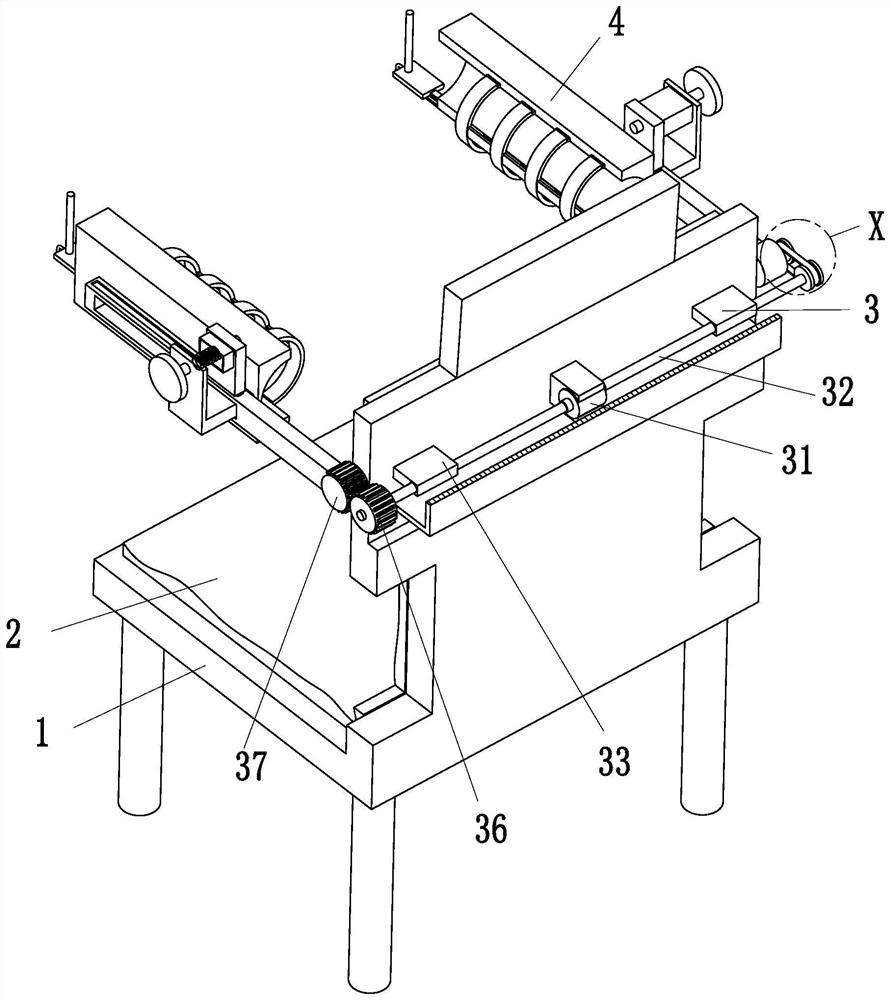

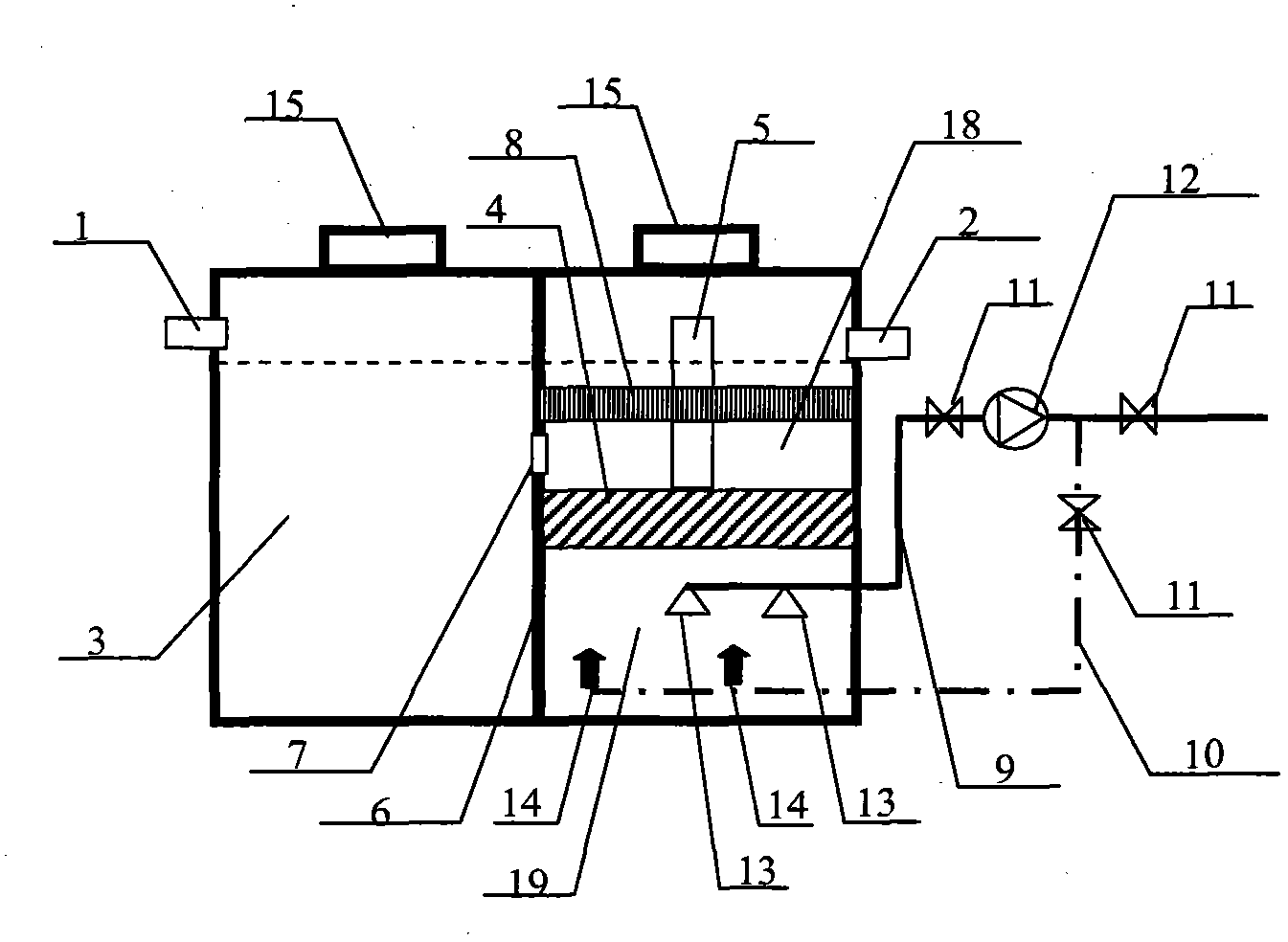

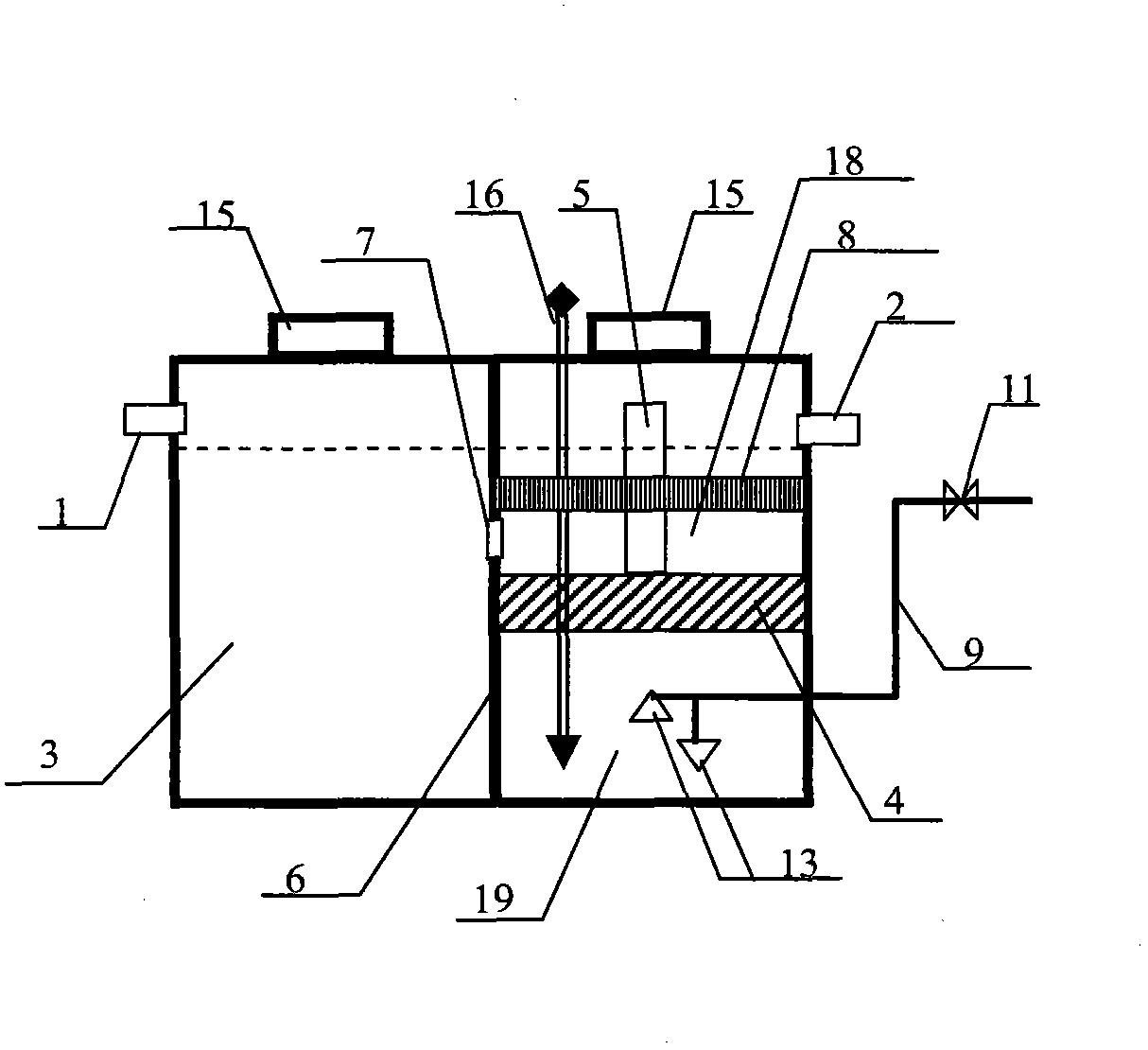

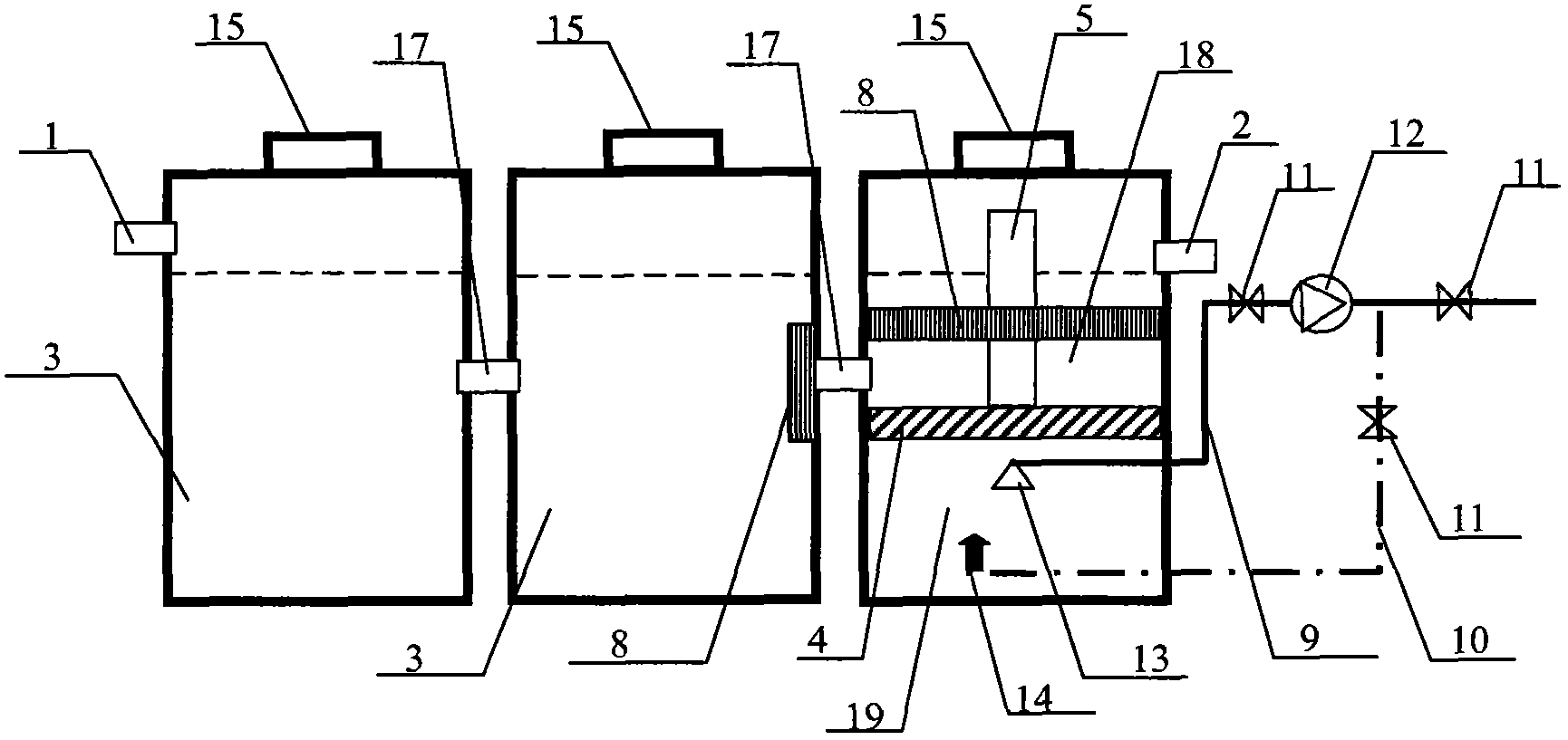

Human body stomach-small intestine digestion simulation method and device

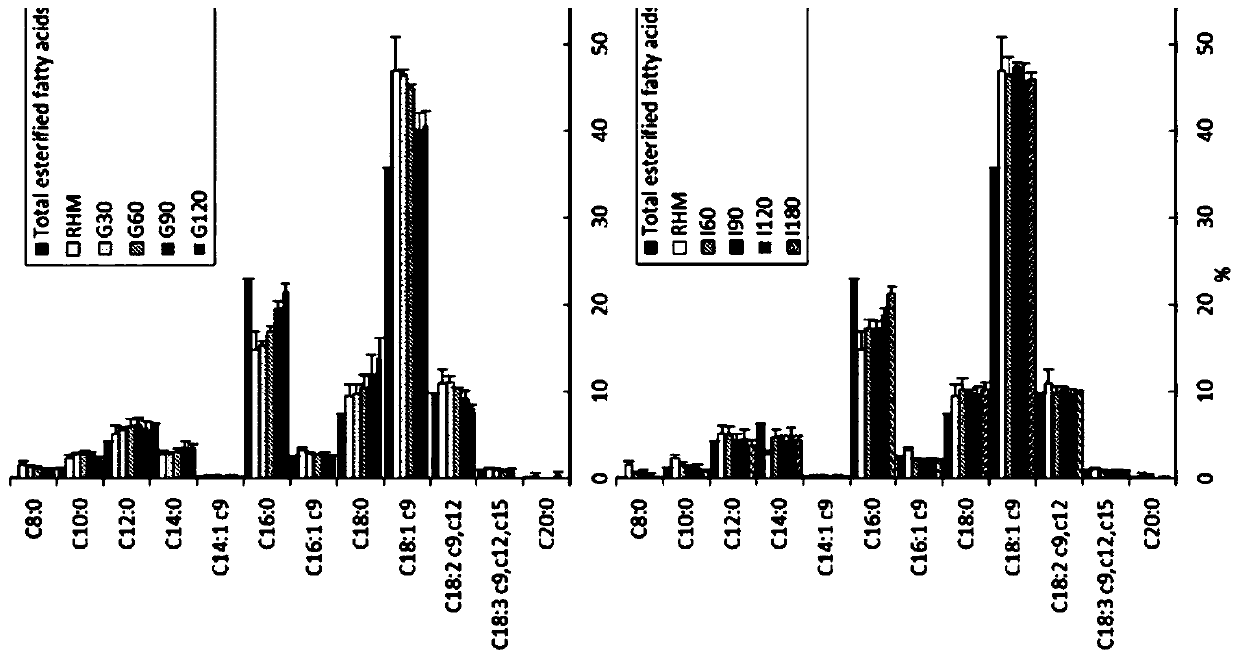

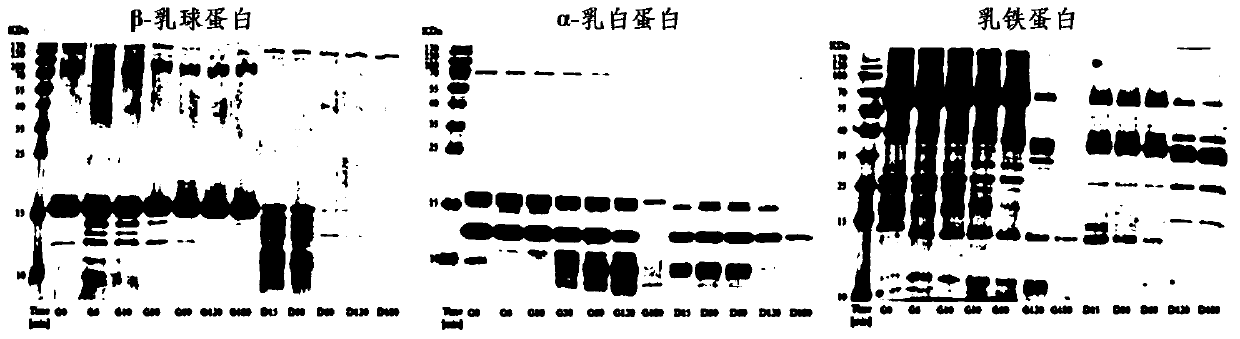

ActiveCN108364553ARealize real-time dynamic regulationReal-time streamingEducational modelsHuman bodyCutinase

The invention discloses a human body stomach-small intestine digestion simulation method and device. According to the invention, real time dynamic control over pH values of the stomach and a small intestine digestion chamber is realized and pH dynamic curve can be output at the same time. Through regulating stomach emptying speed and intestine transport speed in real time, real time flow of food between different digestive tracts is realized. Human body stomach-small intestine digestion state and environment are simulated more truly and more comprehensively. According to the invention, simulation of an external digestion process of different people such as premature infants, term infants, adults and aged people can be realized. Rabbit gastric lipase or cutinase are used in simulated gastric fluid, so that human gastric lipase is simulated more truly.

Owner:JIANGNAN UNIV +1

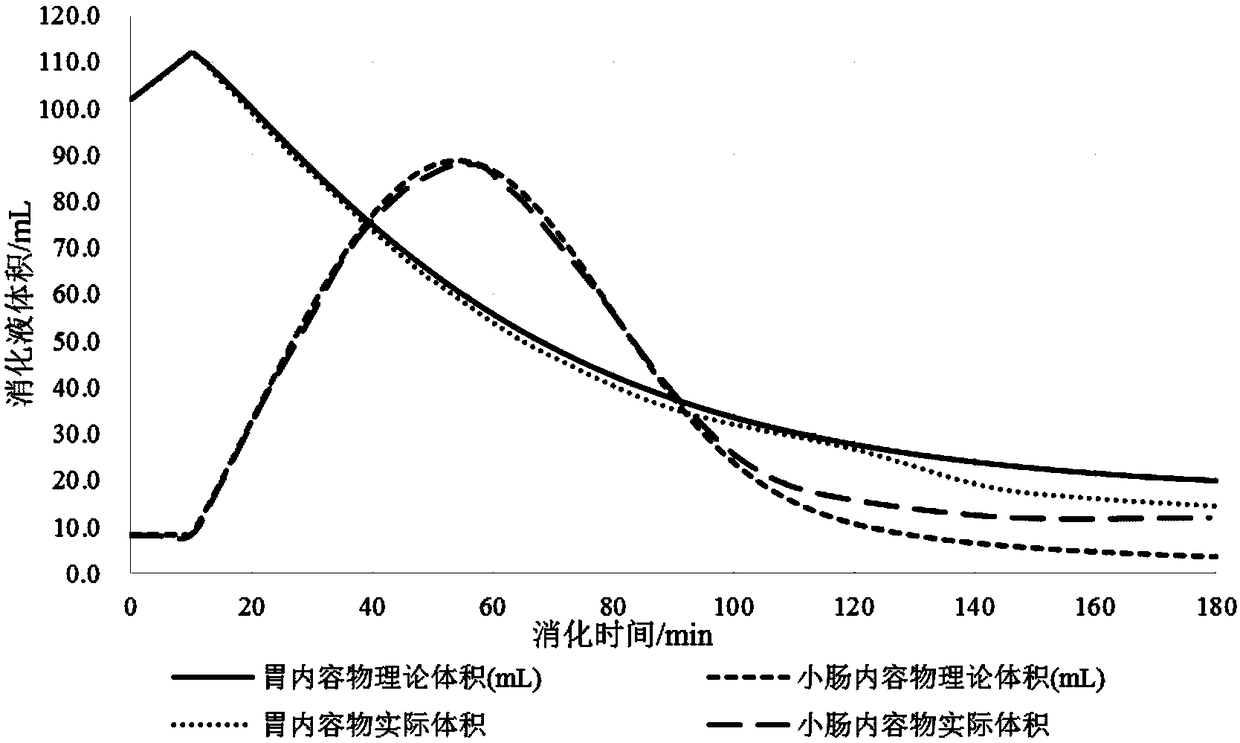

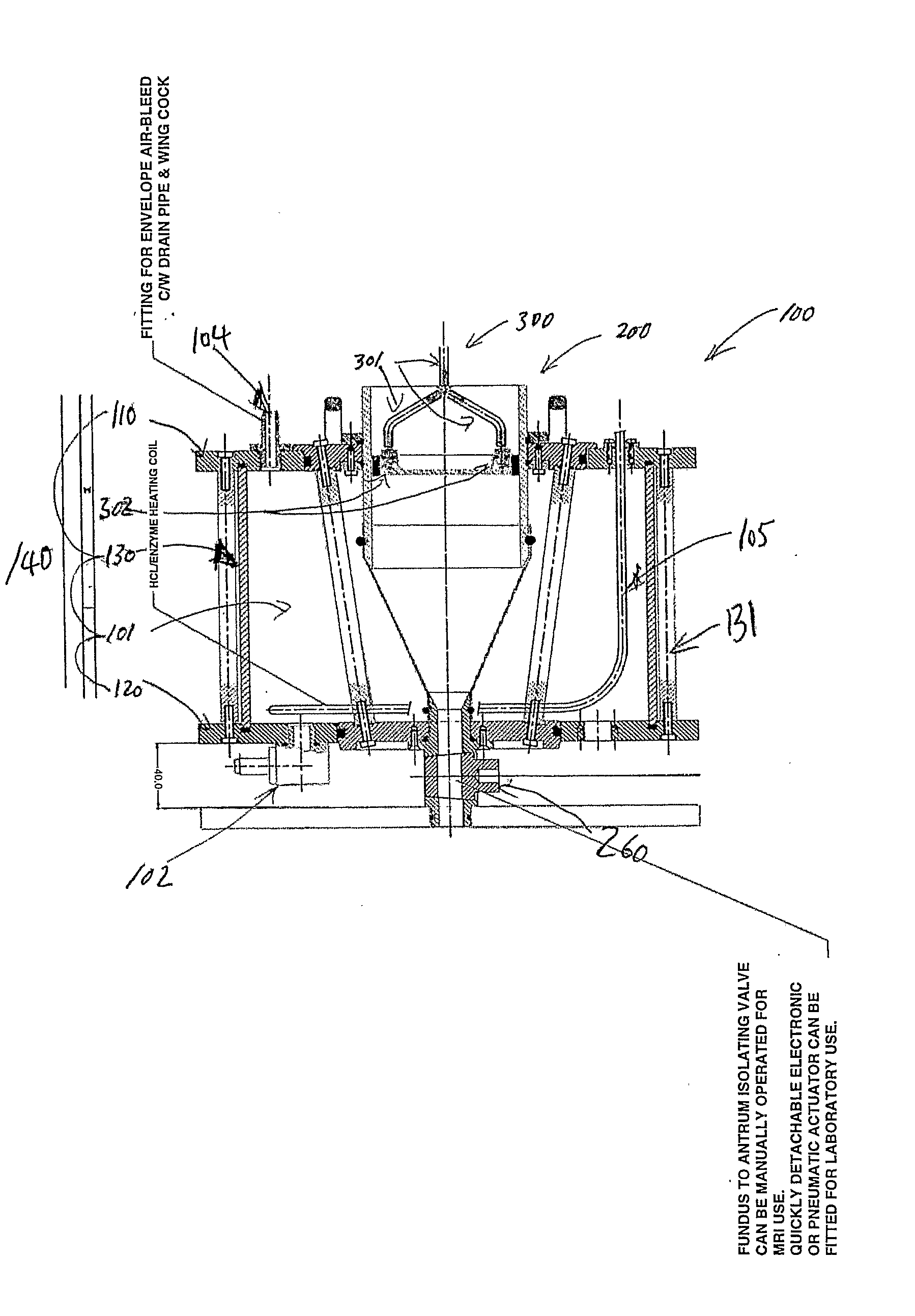

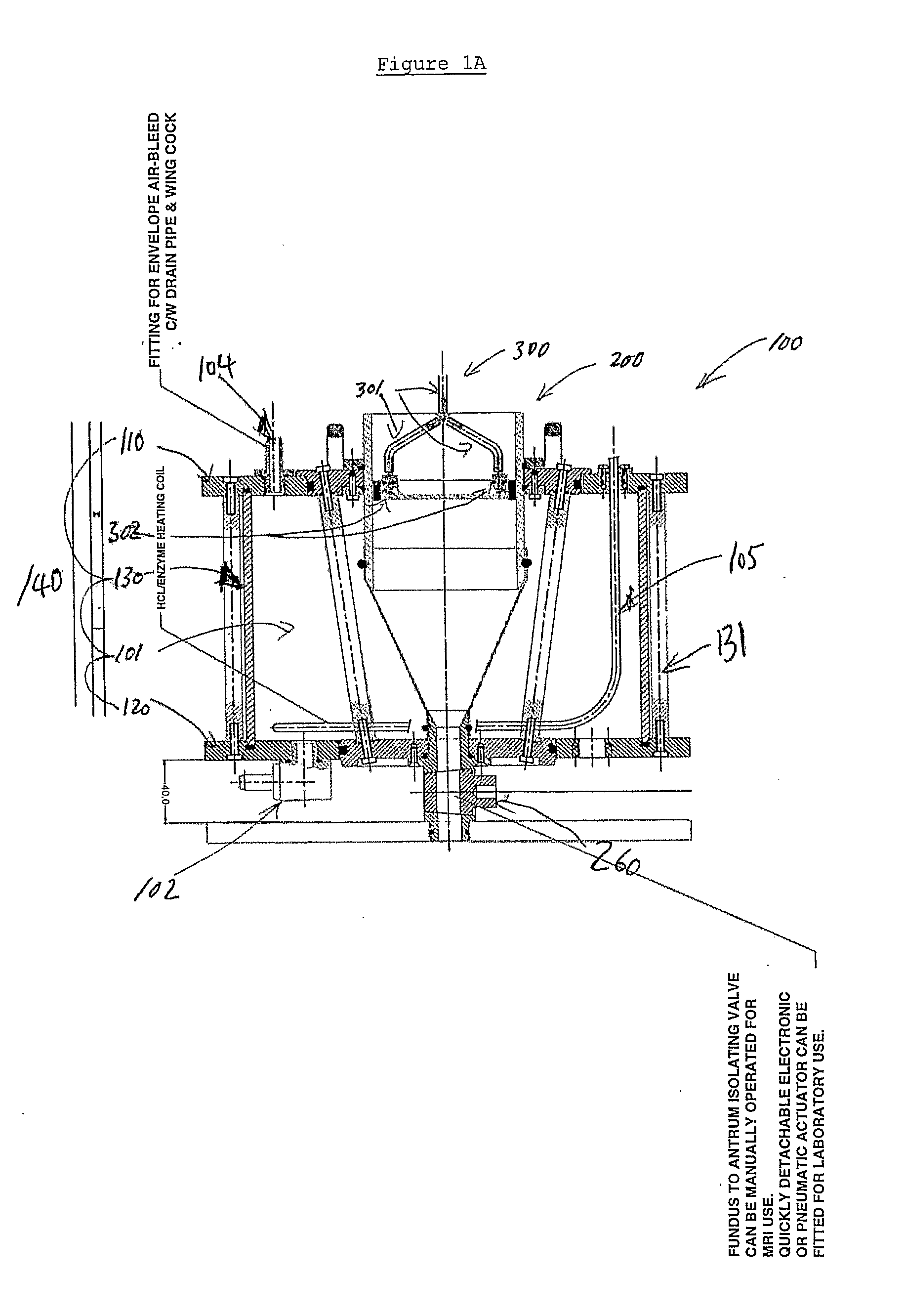

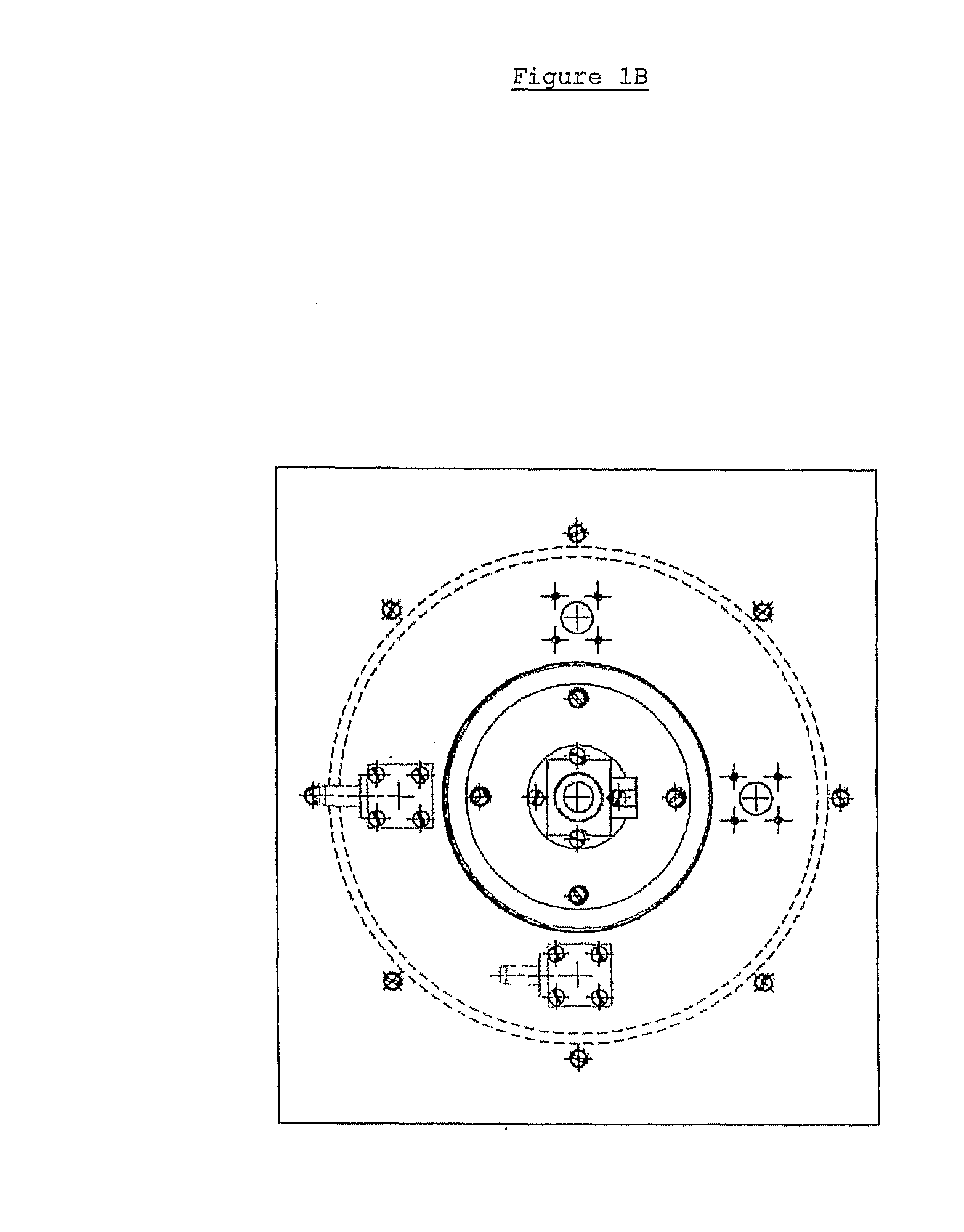

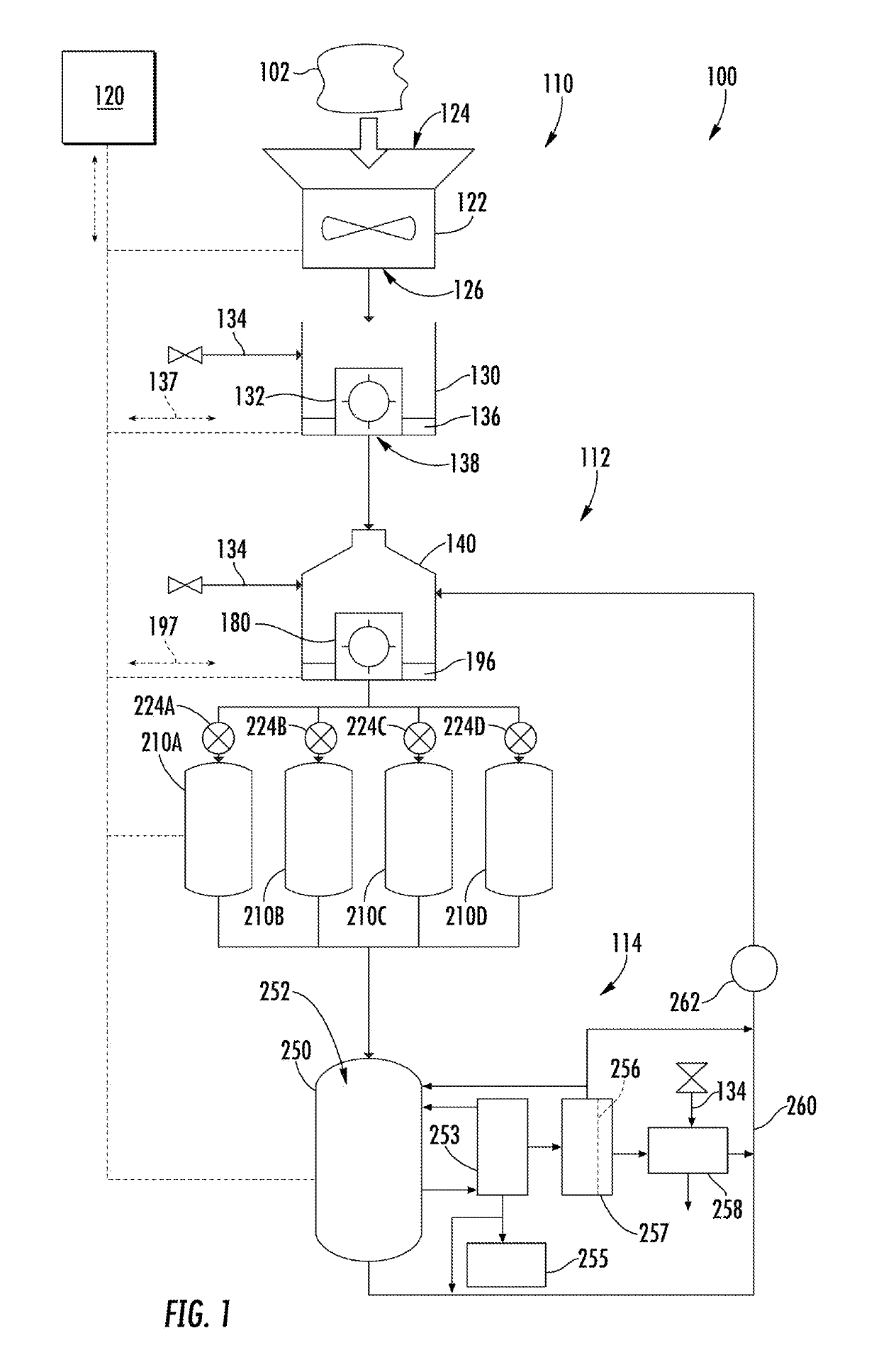

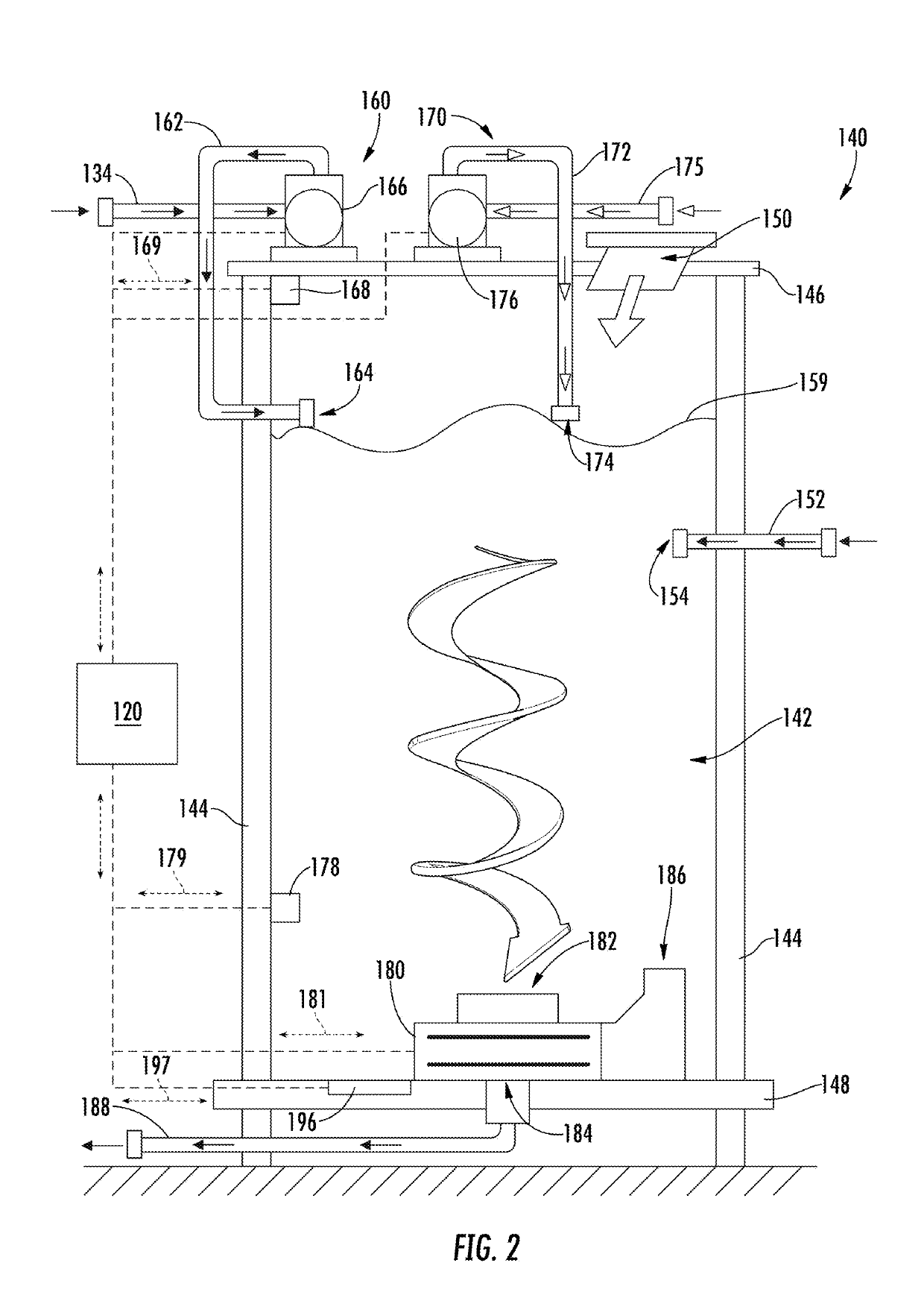

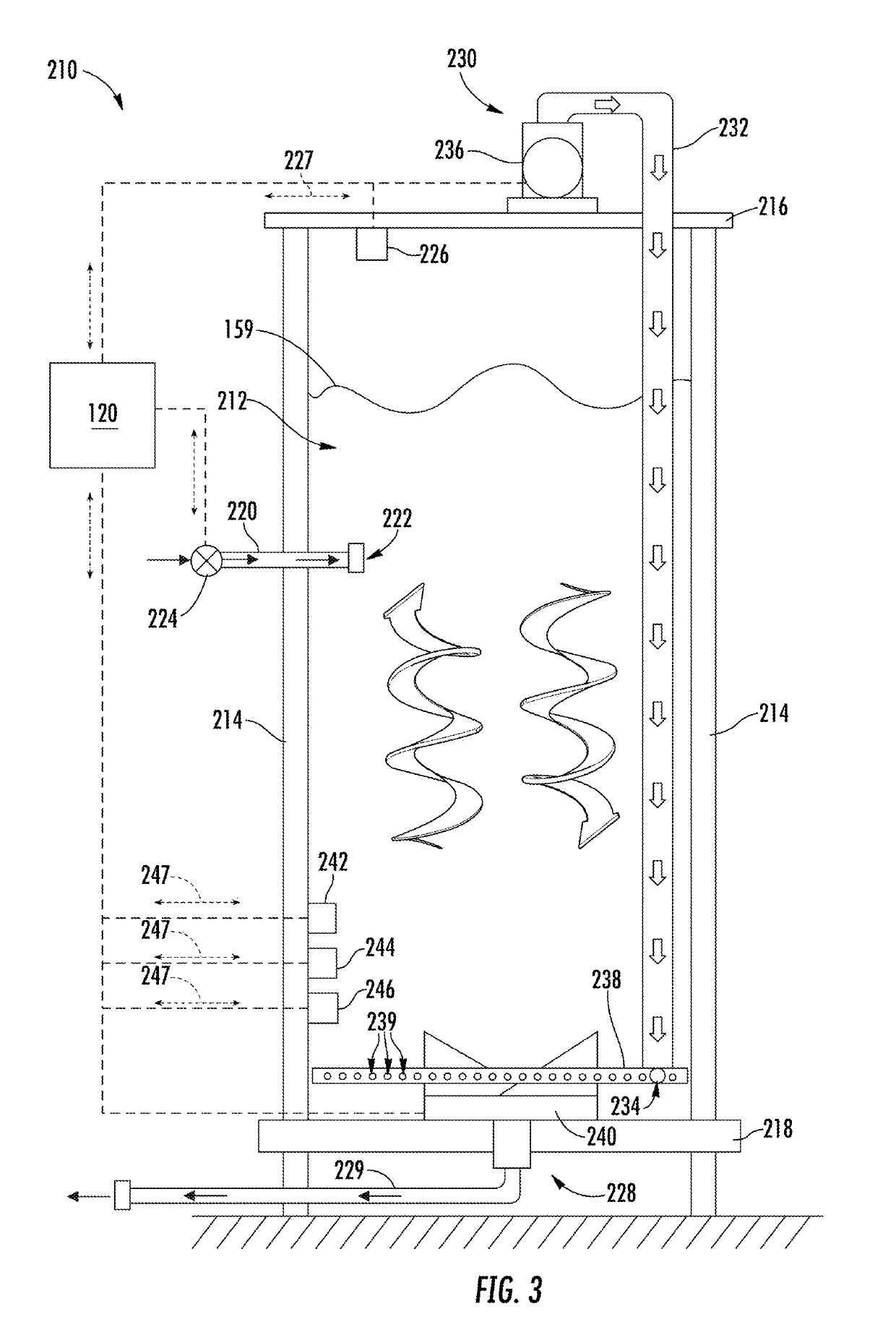

Apparatus, System and Method

ActiveUS20080206728A1Mild mixingEasy to cleanShaking/oscillating/vibrating mixersFlow mixersDigestion chambersBiomedical engineering

This invention provides an apparatus for simulating digestion of a foodstuff, which apparatus comprises: (a) an outer containment vessel into which fluid can be introduced and removed via at least one orifice, and (b) an inner digestion chamber comprising a rigid portion (240) through which the foodstuff can be introduced and a flexible portion (250) which tapers from the rigid portion to an aperture (260) from which the foodstuff can be removed wherein said inner chamber is seχurable within the outer vessel such that reversible alteration of fluid pressure within the outer vessel causes reversible partial compression of the flexible portion for mixing foodstuff present therein. Also provided is an apparatus for simulating mechanical digestion of a foodstuff, which apparatus comprises: (a) an outer cylinder (534) including in a first end wall an entry port through which the foodstuff can be introduced, and at the opposite second end an opening for receiving an inner cylinder (532), and in the side wall proximal to the first end wall an exit port from which the foodstuff can be removed, (b) an inner cylinder (533) slidably mounted within the outer cylinder and including in a first end wall an aperture through which the foodstuff can be reversibly forced between the inner and outer cylinders, and at the opposite second end an opening for receiving a plunger, and (c) a plunger slidably (530) mounted within the inner cylinder for drawing the foodstuff through the entry port and aperture into the inner cylinder, wherein the aperture is within a resilient diaphragm secured within the end wall of the inner cylinder, and wherein the volume of the inner cylinder is between 20 and 200 ml. The invention also provides systems and methods for simulating digestion of a foodstuff.

Owner:PLANT BIOSCI LTD

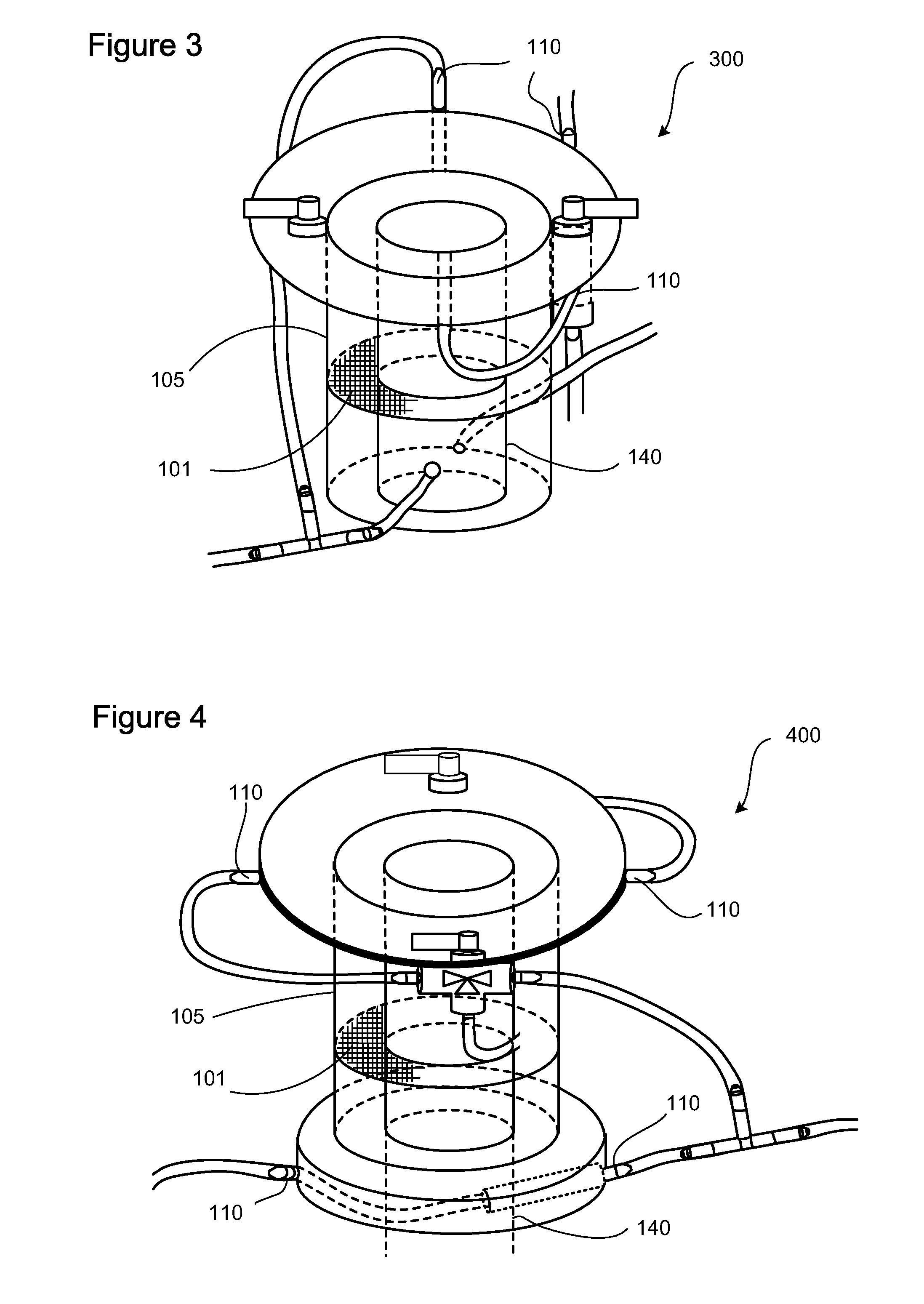

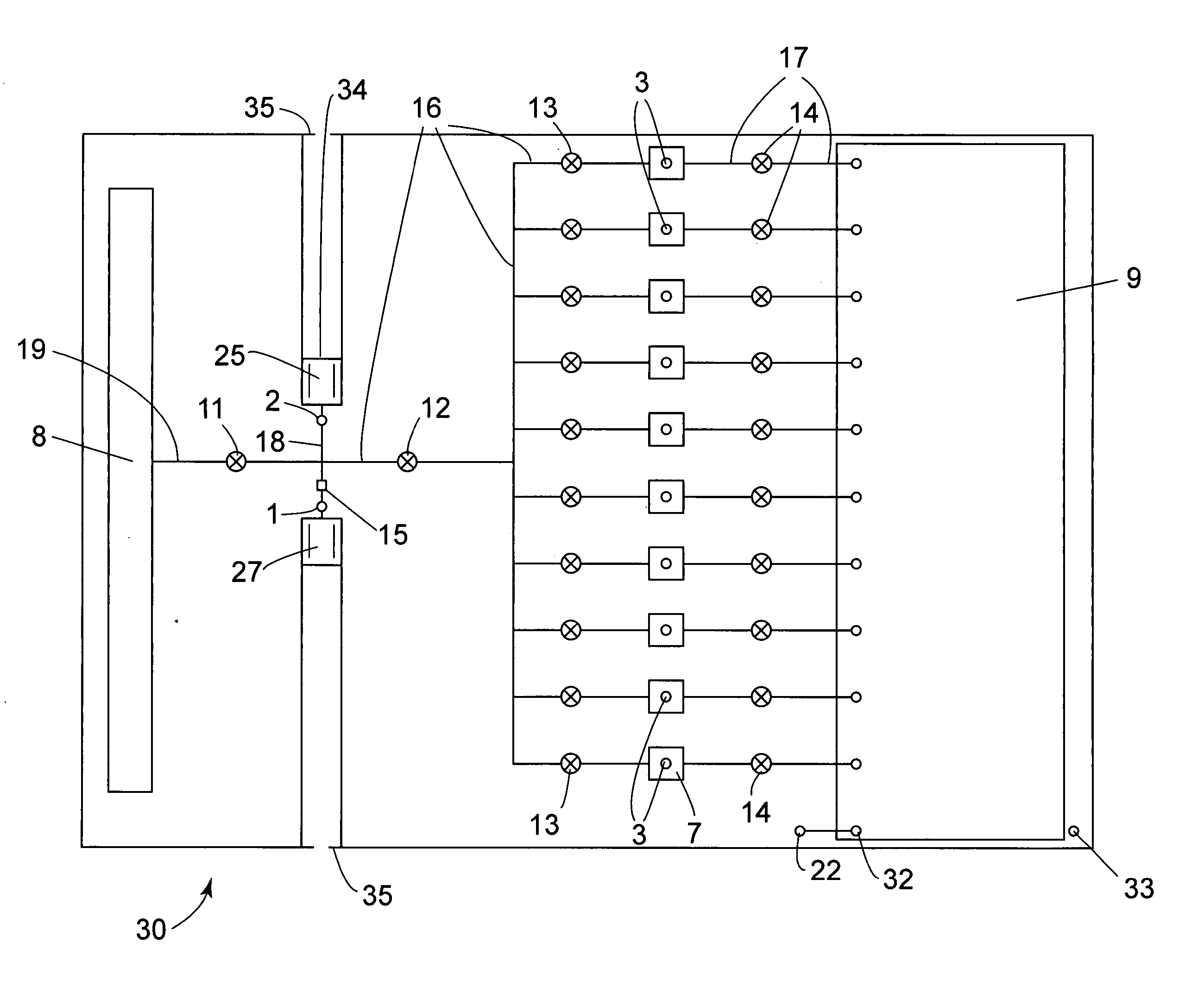

Cell separation apparatus

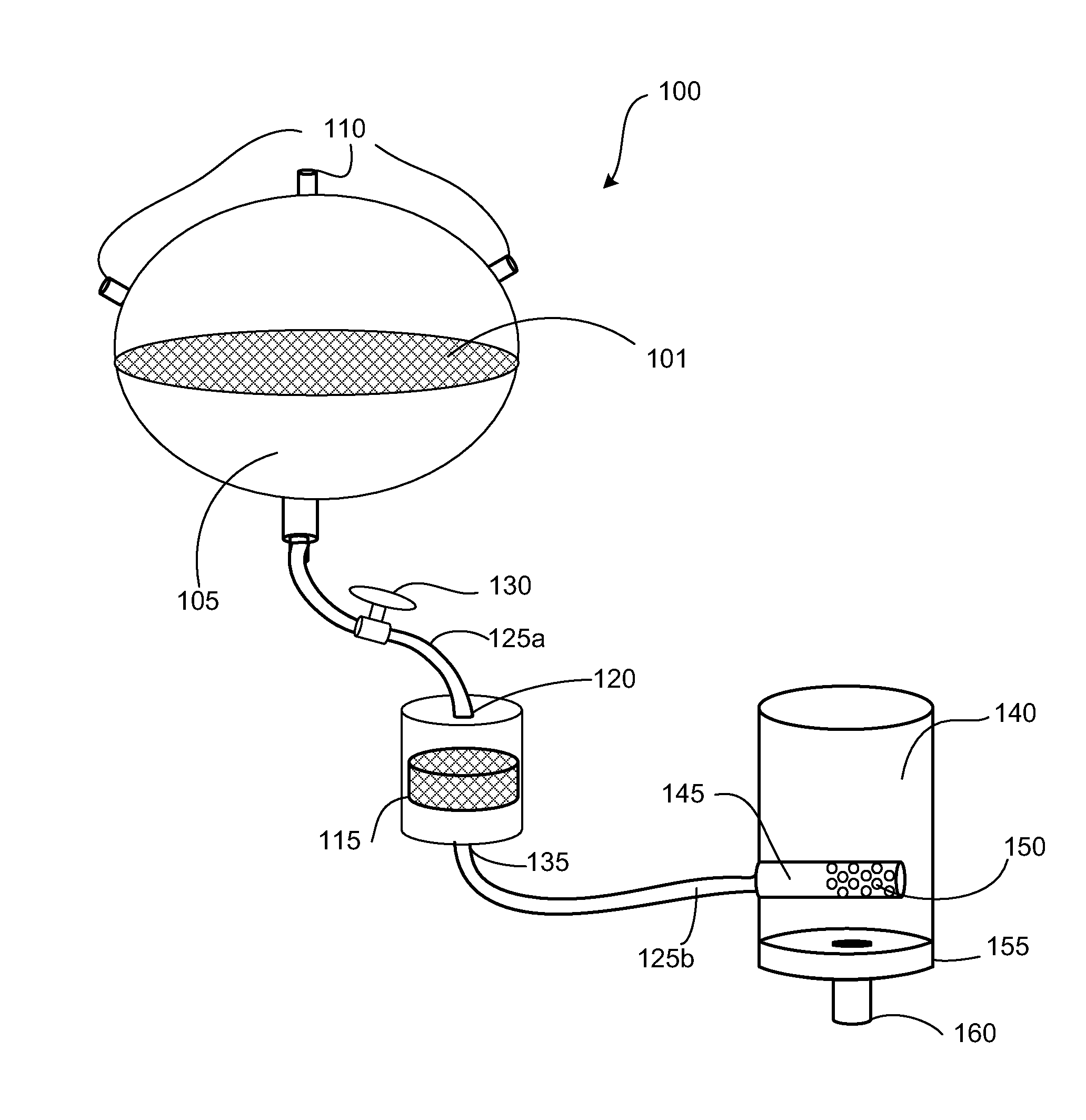

InactiveUS20070218553A1Easy to optimizeReduce manpowerBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringCell separation

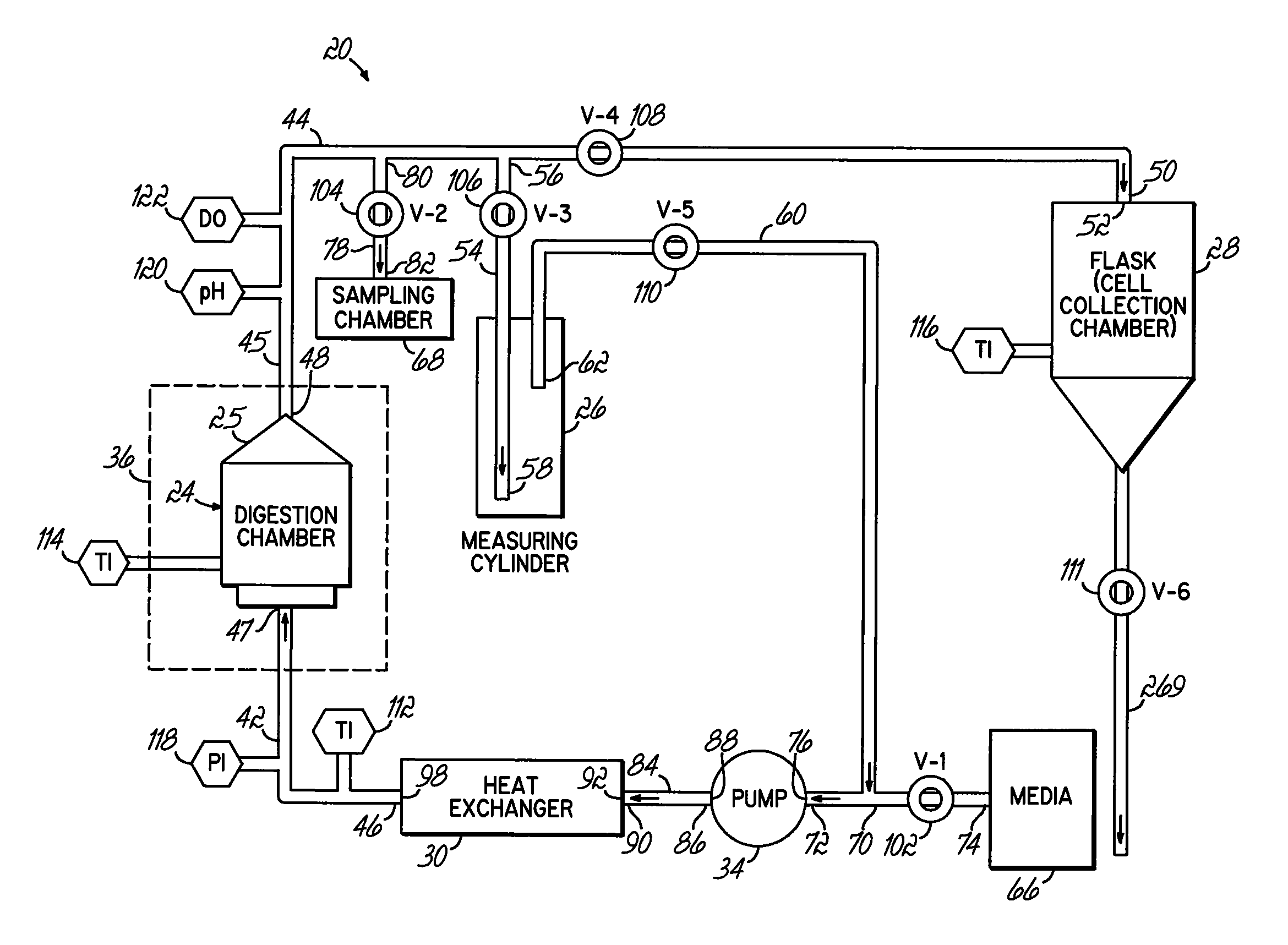

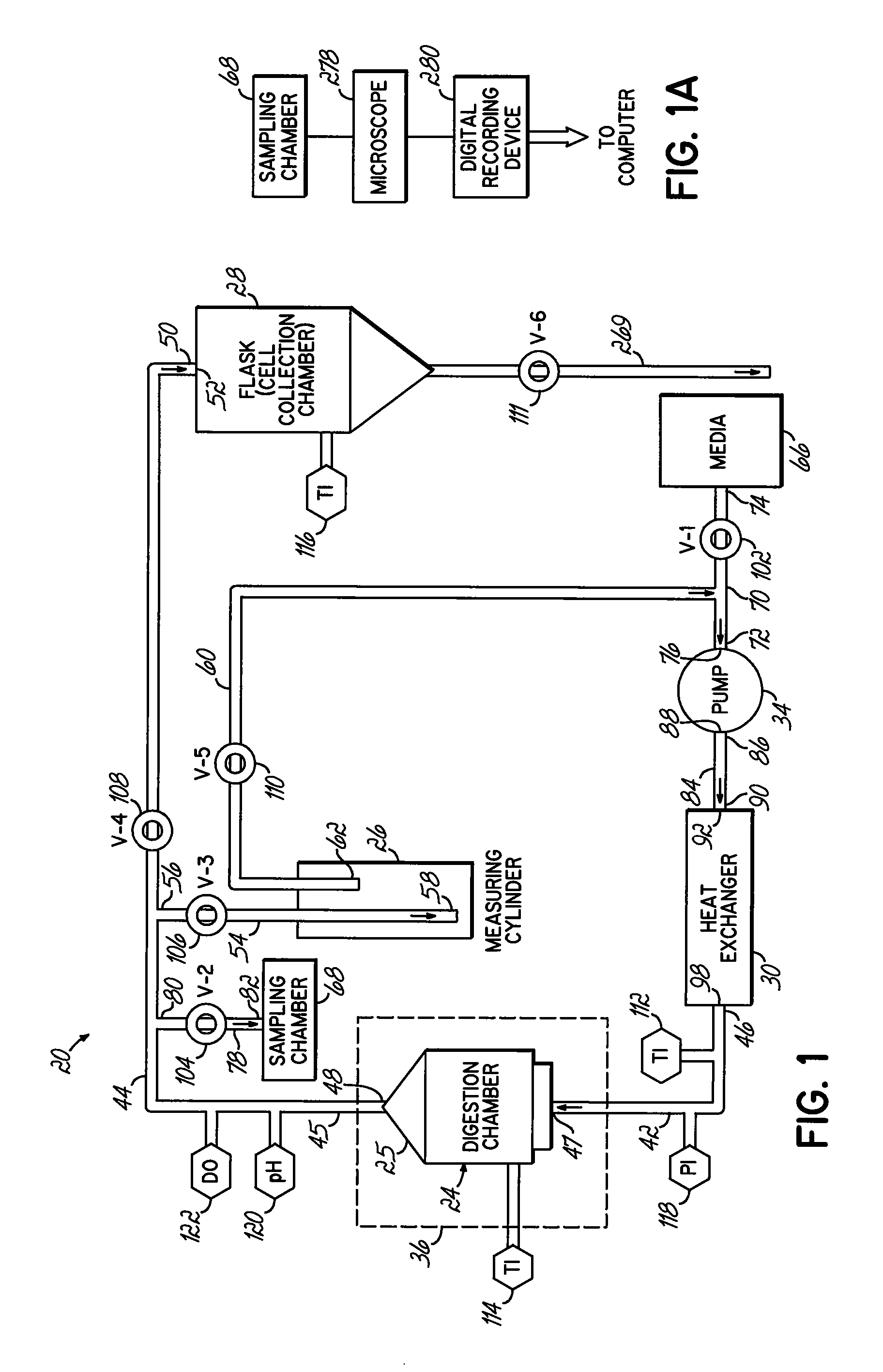

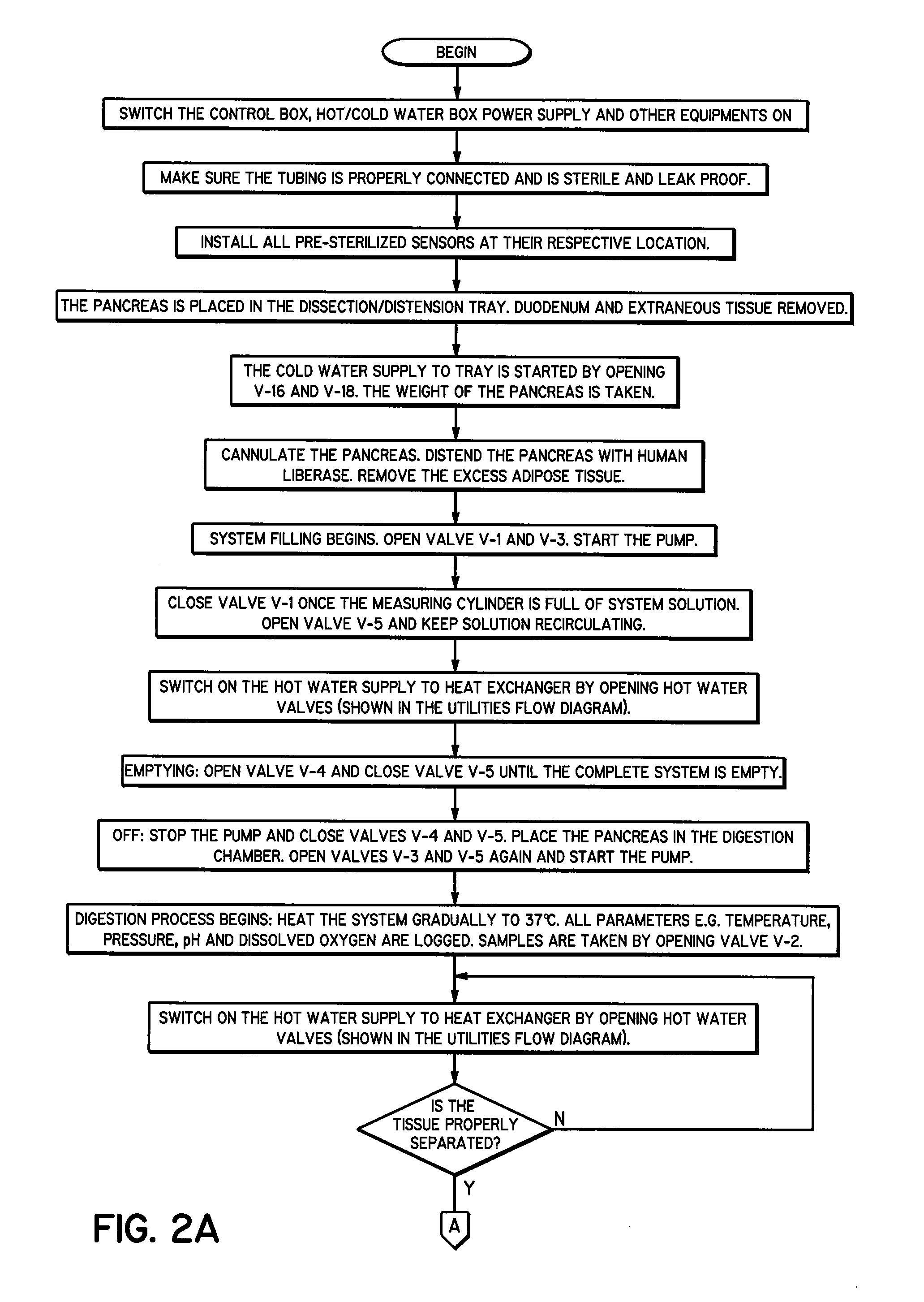

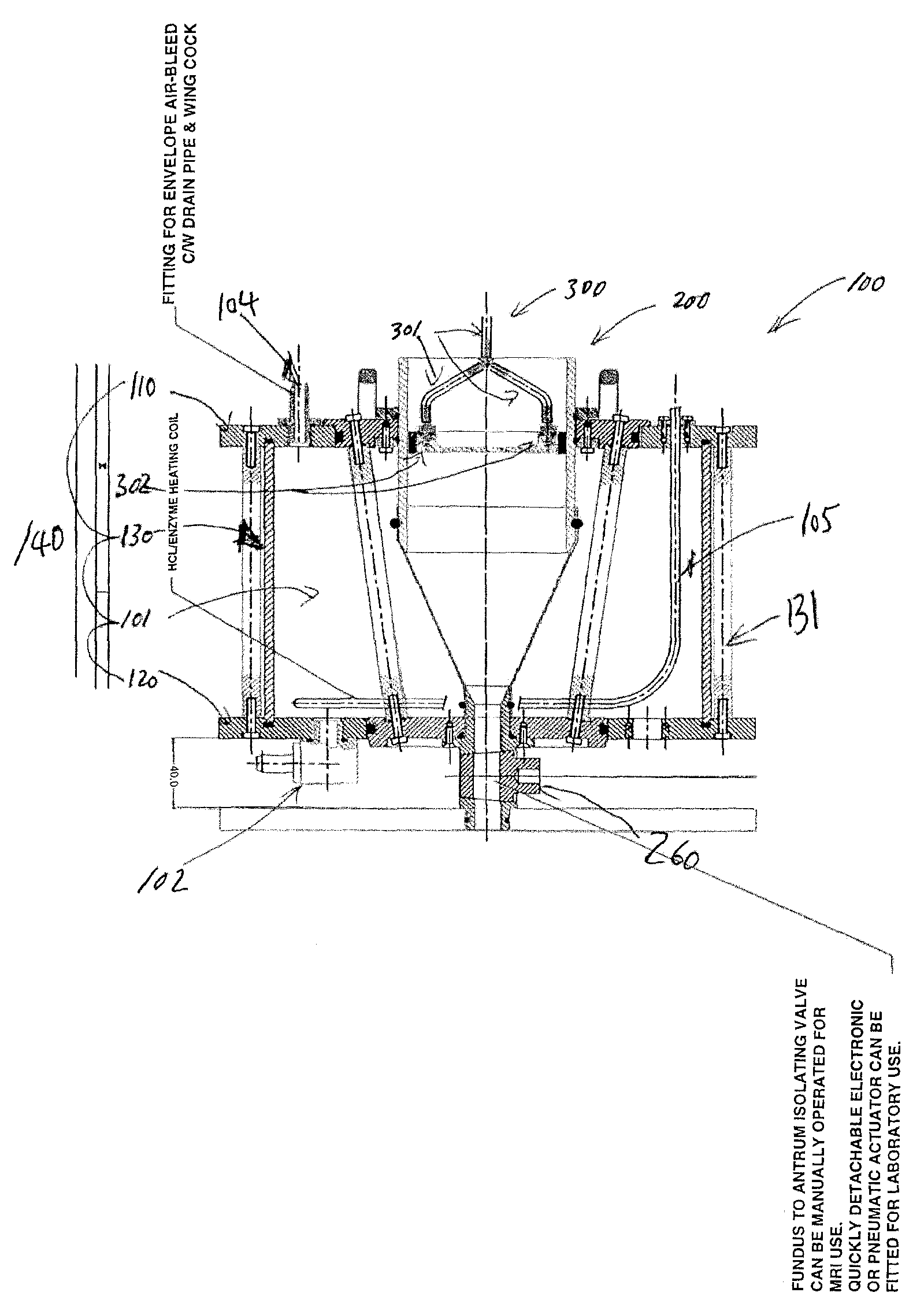

An apparatus 20 for the separation of a subpopulation of cells from an intact organ or other biological material is provided. The apparatus 20 includes: (1) a digestion chamber 24 that integrates the primary digestion process, (2) a measuring cylinder 26, (3) a cell collection chamber 28, (4) a heat exchanger 30 for raising and lowering temperatures in the digestion chamber 24 to activate or inactivate enzymes, (5) sensors 112, 114, 116, 118, 120, 122 to complete a closed feedback loop for allowing optimization of the digestion process, and (6) mock cells which mimic the cells to be harvested and which are used to fully optimize the process without unnecessary destruction of harvested cells. The manipulation of the digestion process may be manual or may be automated under computer control.

Owner:RODRIGUEZ RILO HORACIO L +5

Dynamic gastric model

ActiveUS8092222B2Mild mixingEasy to cleanShaking/oscillating/vibrating mixersFlow mixersDynamic topic modelEngineering

This invention provides an apparatus for simulating digestion of a foodstuff, which apparatus comprises: (a) an outer containment vessel into which fluid can be introduced and removed via at least one orifice, and (b) an inner digestion chamber comprising a rigid portion through which the foodstuff can be introduced and a flexible portion which tapers from the rigid portion to an aperture from which the foodstuff can be removed wherein said inner chamber is securable within the outer vessel such that reversible alteration of fluid pressure within the outer vessel causes reversible partial compression of the flexible portion for mixing foodstuff present therein. The invention also provides systems and methods for simulating digestion of a foodstuff.

Owner:PLANT BIOSCI LTD

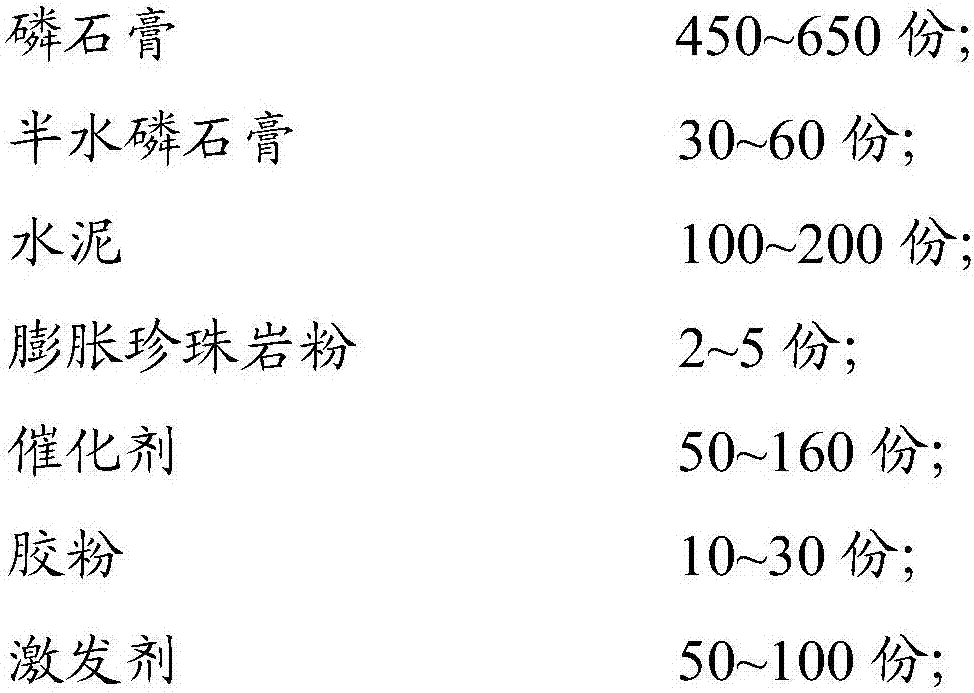

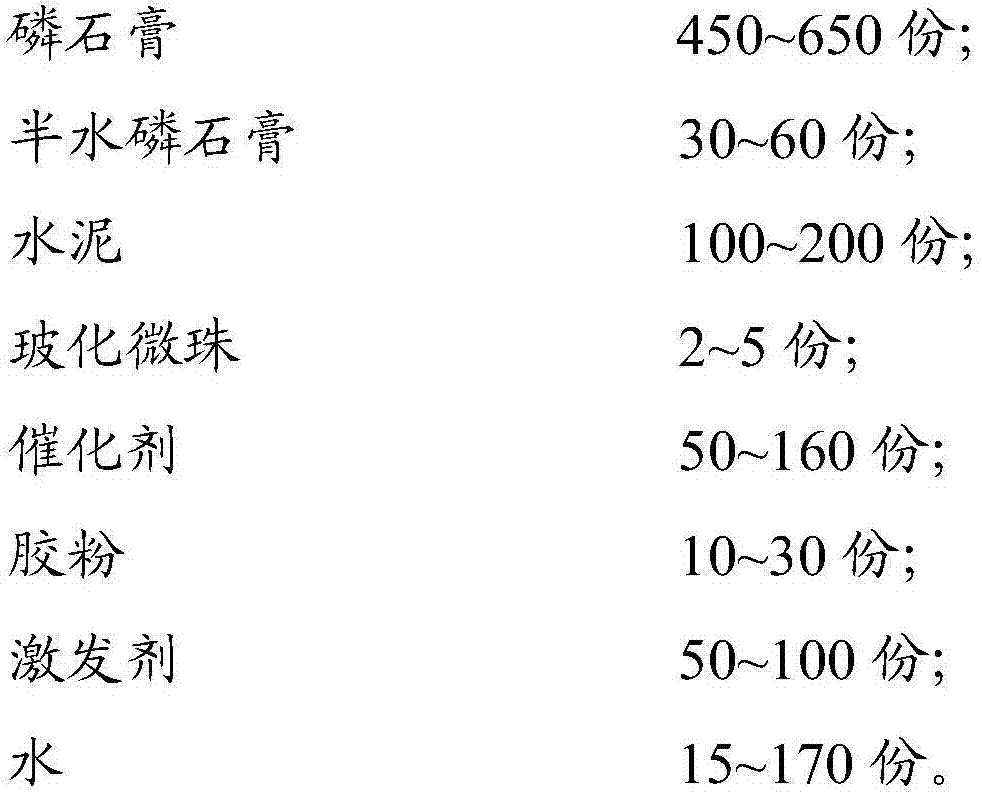

Sintering-free phosphor gypsum ceramsite and preparation method thereof

InactiveCN107200492AStable structureImprove hydrophilicitySolid waste managementPhosphorExpanded clay aggregate

The invention provides a sintering-free phosphor gypsum ceramsite and a preparation method thereof. The sintering-free phosphor gypsum ceramsite is prepared from the following raw materials in parts by weight: 450 to 650 parts of phosphor gypsum, 30 to 60 parts of semi-hydrated phosphor gypsum, 100 to 200 parts of cement, 2 to 5 parts of expanded perlite powder or vitrified micro-balls, 50 to 160 parts of catalyst, 10 to 30 parts of glue powder, 50 to 100 parts of activator, and 15 to 170 parts of water. The preparation method comprises the following steps of adding the raw materials into a forced type stirrer to stir, adding into a digestion chamber to catalyze, and finally sending into a double-roller granulating machine to granulate. The sintering-free phosphor gypsum ceramsite has the advantages that by using the solid waste of the phosphor gypsum, the low-density and high-strength ceramsite is obtained without sintering, and is used as a coarse aggregate of buildings; the energy-saving effect is realized in raw materials and processing.

Owner:福建中凯环保科技有限公司

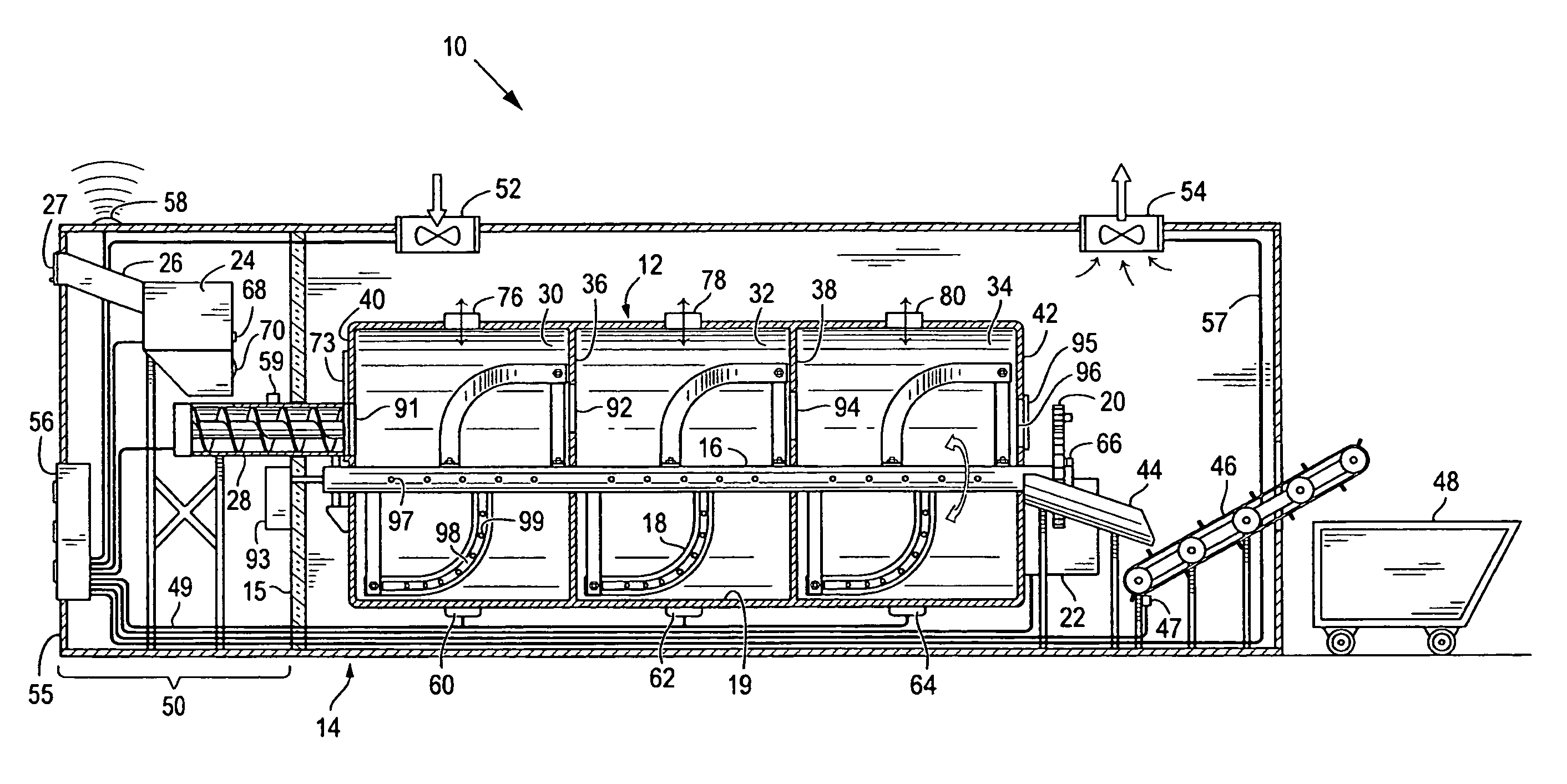

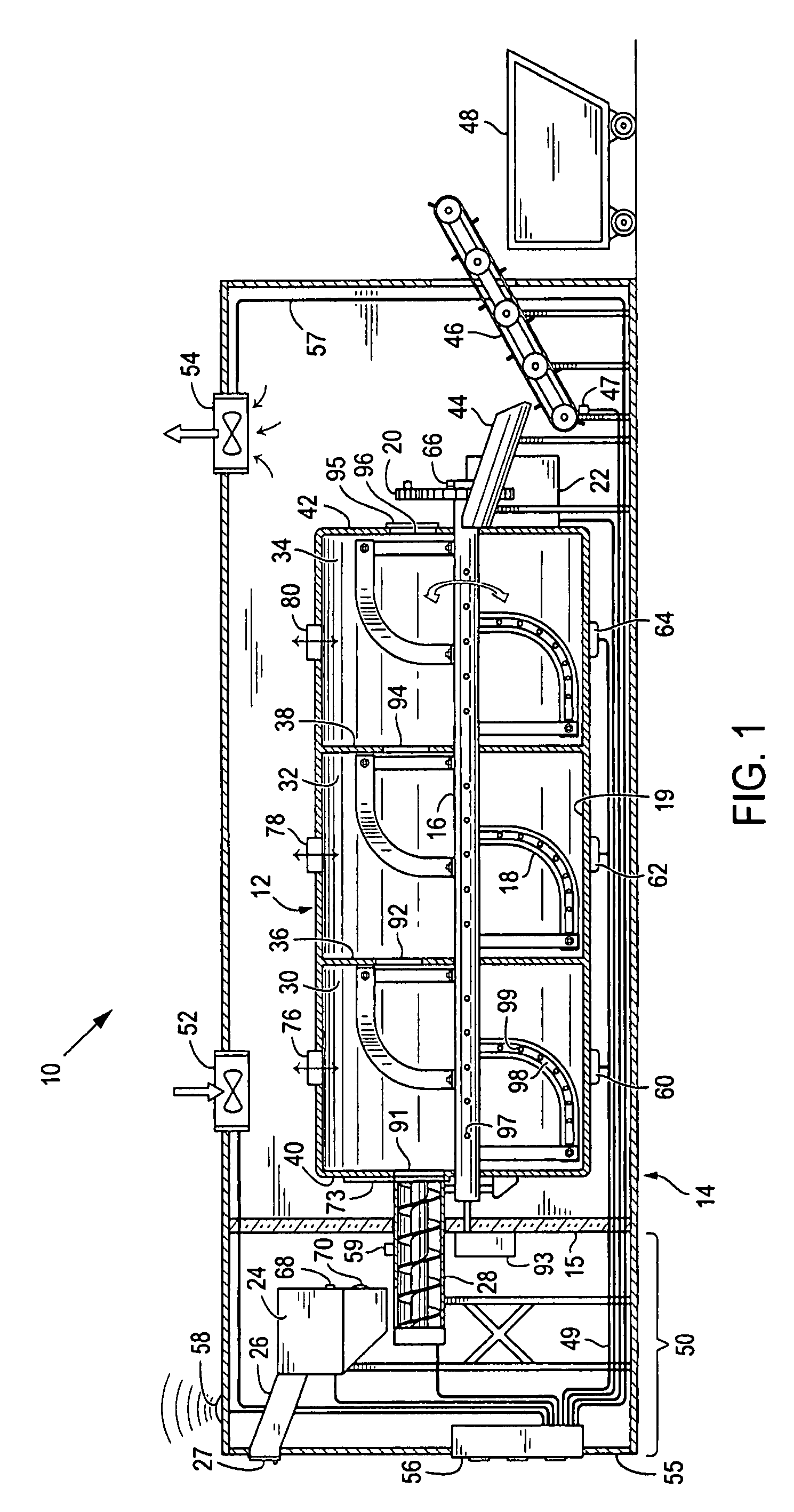

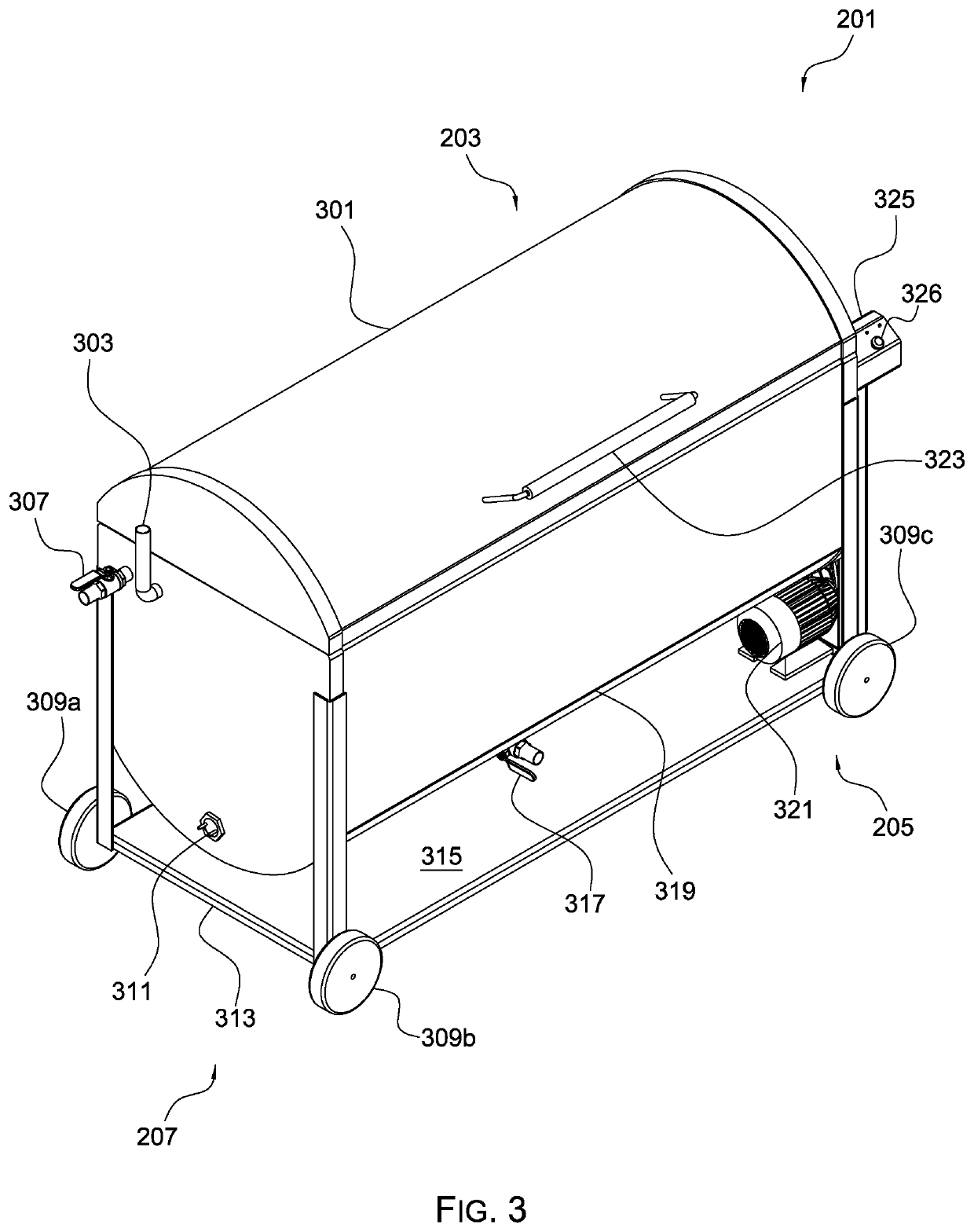

Rotating tissue digestor system and method of use

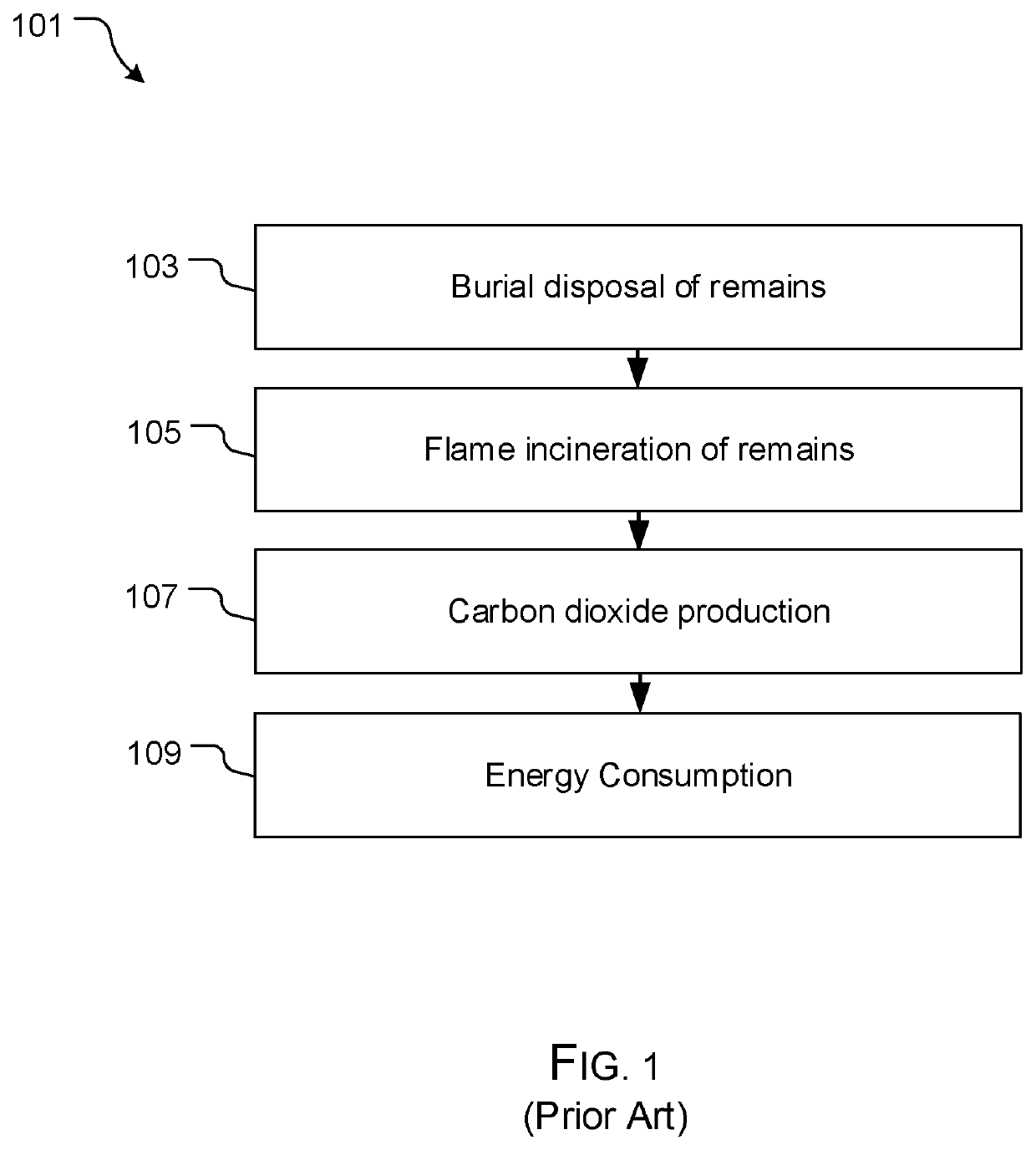

ActiveUS10835773B2Safely dissolved and separatedDischarge safetySolid waste disposalTransportation and packagingTemperature controlControl system

A tissue digester system includes a container for housing a digestion chamber having an exterior vessel for holding digestor fluid and an interior vessel, the container extending from a first end to a second end, the interior vessel having perforations and having baffles extending from an interior surface of the interior vessel; a lid secured to the exterior vessel and to provide access to the digestion chamber; one or more heating elements positioned to apply heat to the digestion chamber; a motor engaged with the interior vessel and to create rotational movement of the interior vessel; a control system, having a temperature controller; and a movement controller; the control system is to rotate the interior vessel and heat the digestion chamber based on user commands; and the digestion chamber is to break down remains through application of the digestor fluid to the tissue remains.

Owner:MASON PHILIP

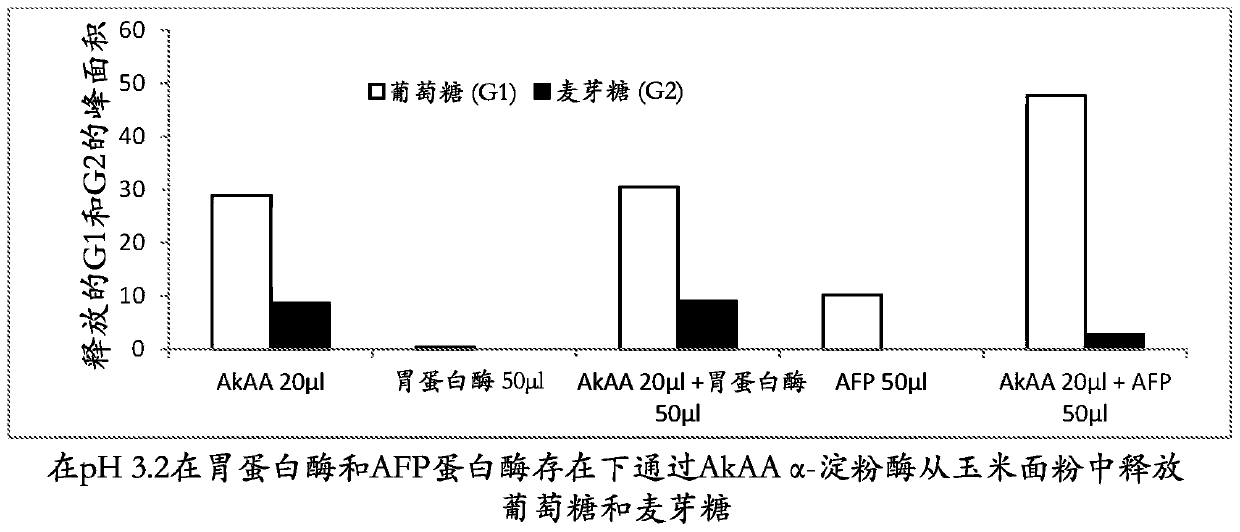

Use of low ph active alpha-1,4/1,6-glycoside hydrolases as a feed additive for ruminants to enhance starch digestion

Disclosed are uses at least one alpha-1,4 / 1,6-glycoside hydrolase (GLCH) as a feed additive for a ruminant wherein said hydrolase: (a) has at least 20% activity at pH less than or equal to 3 in the presence of pepsin as compared to activity of the hydrolase at pH 6 in the presence of pepsin, (b) said hydrolase is active in at least two of three digestive chambers of a ruminant comprising a rumen,an abomasum and a small intestine and (c) the hydrolase works with pancreatic amylase to increase glucose yield.

Owner:DUPONT NUTRITION BIOSCIENCES APS

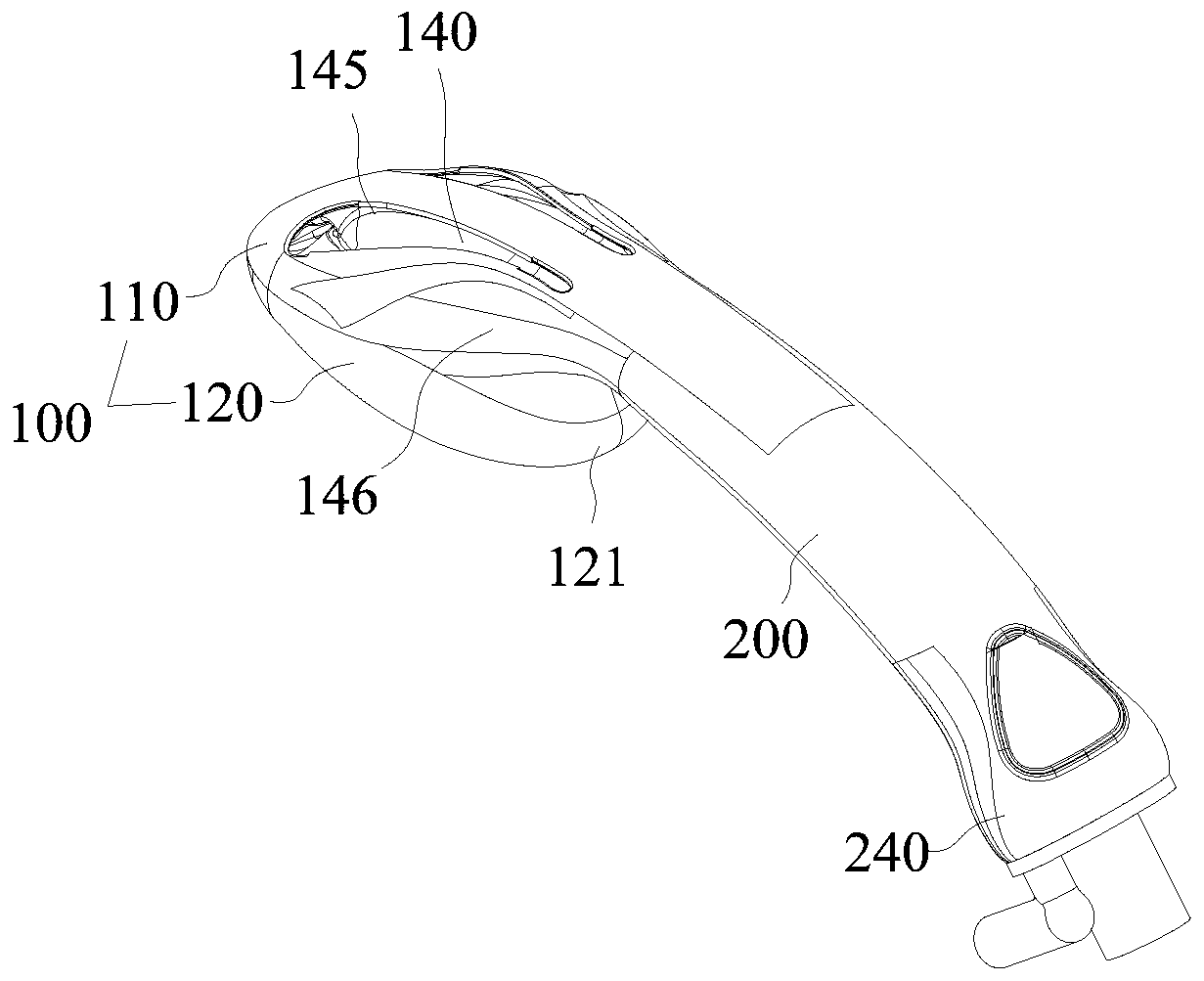

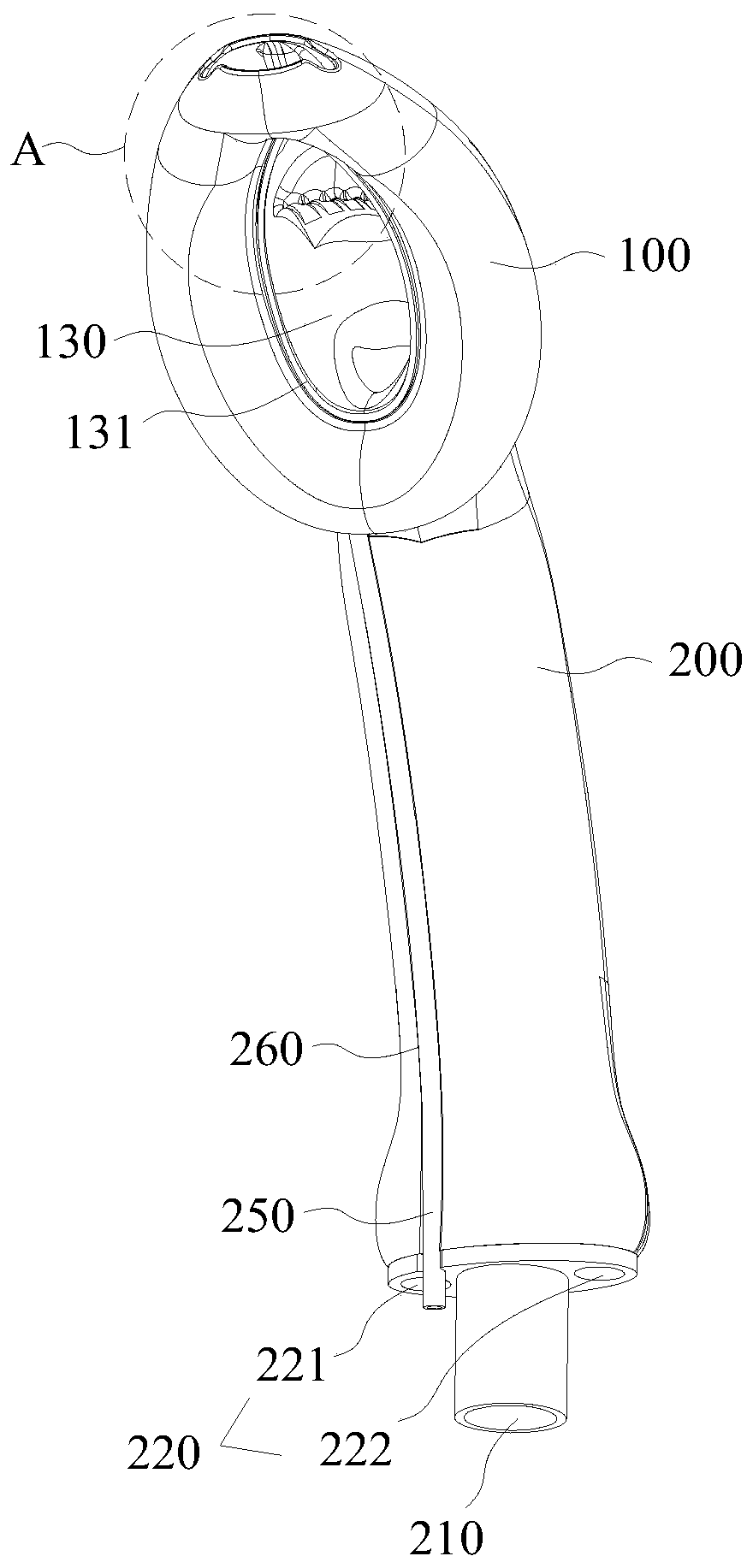

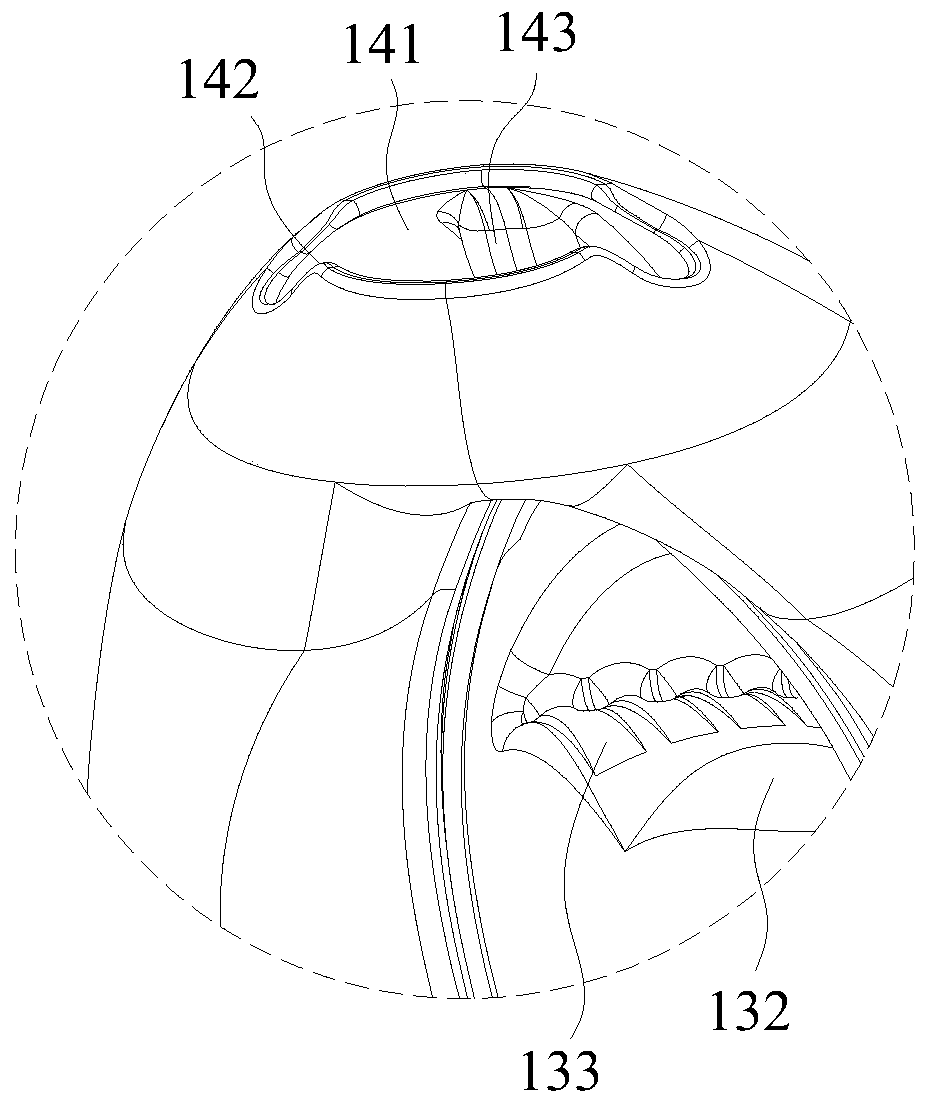

Fish mouth type laryngeal mask trachea duct capable of performing rinsing with three cavities

PendingCN110652642AEffective isolationEasy alignmentTracheal tubesRespiration chamberLaryngeal Masks

The invention discloses a fish mouth type laryngeal mask trachea duct capable of performing rinsing with three cavities. The fish mouth type laryngeal mask trachea duct capable of performing rinsing with three cavities comprises a hood body, wherein a respiration chamber which communicates with a respiratory tract and a digestion chamber which communicates with a digestive tract are arranged in the hood body; the digestion chamber is provided with a digestion opening through which the digestion chamber communicates with the digestive tract; the periphery wall of the digestion chamber is gradually contracted from one end away from the digestion opening to the digestion opening; a plurality of protrusions are arranged at the edges of the digestion opening, and can be mutually closed becauseof surrounding extruding pressure in the process that the fish mouth type laryngeal mask trachea duct capable of performing rinsing with three cavities is inserted into the throat part, so that the digestion opening is contracted. Through the adoption of the technical scheme of the fish mouth type laryngeal mask trachea duct capable of performing rinsing with three cavities disclosed by the invention, an opening corresponding to the digestive tract can be quickly and accurately aligned to the digestive tract to be inserted, and the operation time is shortened.

Owner:ANHUI EXPLORATION MEDICAL DEVICES TECH CO LTD

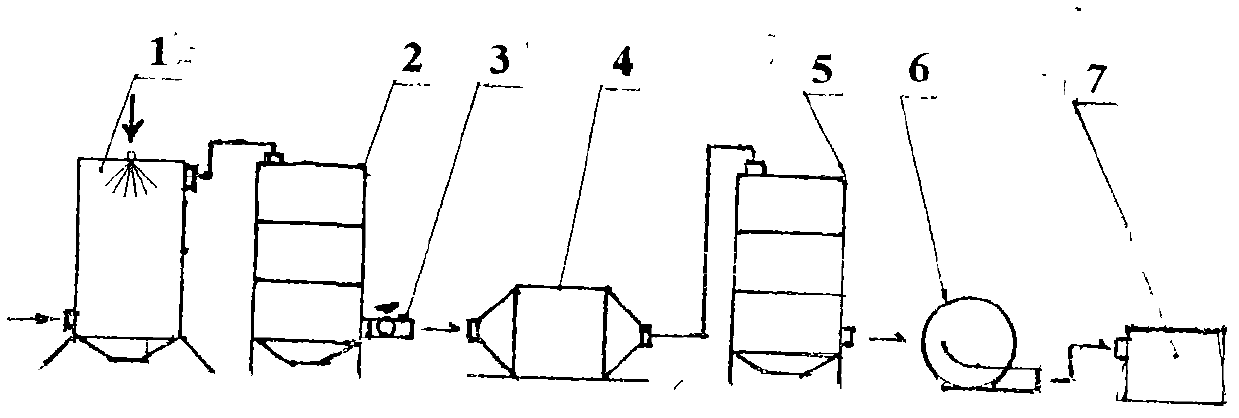

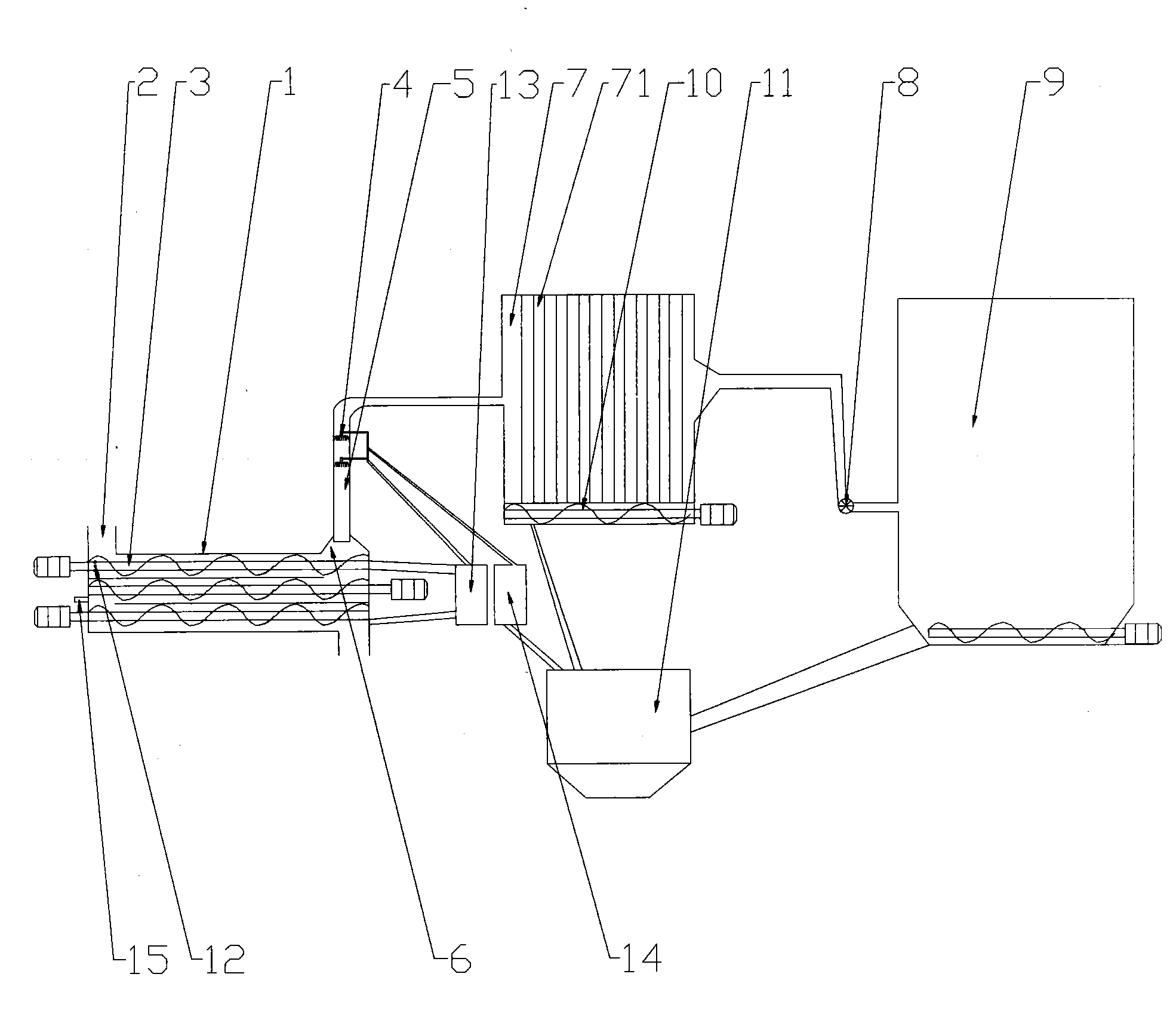

System for controlling industrial boiler flue gas pollution by ionization technology

InactiveCN102961953ALess investmentLow costCombination devicesLighting and heating apparatusEcological environmentCooling tower

The invention relates to a system for controlling industrial boiler flue gas pollution by an ionization technology. According to the system, industrial boiler exhaust gas is treated by a cooling tower 1, a bag type dust collector 2, an air control valve 3, an ionization machine 4, a bag type dust collector 5, a draught fan 6, and a flue gas digestion chamber 7, and then clean air is discharged. The system has the advantages that: various harmful gases and dust are carbonized into powder solids by a high-temperature and high-pressure electric field, the powder solids are then collected by the bag type dust collector 5, an estimated total purification removal rate can reach 98%, and the collected carbides can serve as an agricultural fertilizer , thus avoiding massive discharge of CO2, SO2, NO2 and other harmful gases to result in greenhouse effect aggravation and ecological environment destruction. The technology involved in the invention has the characteristics of simple and reliable equipment, good pollution control effect, and no need of consuming ammonia auxiliary material. Industrially developed European countries all adopt different ionization methods, which have better effects than electron beam and other technologies, and the ionization technology is a control method falling in between physics and chemistry.

Owner:明峰

Indoor exercise instrument with digestion assisting effect

InactiveCN112190456AAffect the service lifeAffect the effect of massageRoller massageCleaning using toolsPhysical medicine and rehabilitationNose

The invention relates to an indoor exercise instrument with a digestion assisting effect. The indoor exercise instrument with the digestion assisting effect comprises a fixing device and a massage device, wherein the massage device is fixedly installed at the inner end of the fixing device; the fixing device comprises an arc ring, C-shaped hanging rods, a rear waistband, a double-hole pig nose buckle, a tension sensor, an alarm, a charging connector and a control frame; and the massage device comprises a first motor, a chain wheel, a toothed chain belt, fixing columns, massage heads, a first heating plate and a sliding rail. The situation that the service life of the rear waistband is affected and the mechanical massage effect is affected due to the fact that the tension of the rear waistband is larger due to the use habit of a user is prevented through the fixing device, the belly of the user is massaged clockwise through the massage device, and due to the fact that dyspepsia is related to the anatomical position of large intestines, the large intestines start from the right lower belly and end at the left lower belly, the digestion speed is increased through the clockwise direction, namely the normal movement direction of intestinal contents, and the umbilical region of the user is kept warm.

Owner:THE AFFILIATED HOSPITAL OF QINGDAO UNIV

A human stomach-small intestine digestion simulation method and device

ActiveCN108364553BRealize real-time dynamic regulationReal-time streamingEducational modelsHuman bodyCutinase

The invention discloses a human body stomach-small intestine digestion simulation method and device. According to the invention, real time dynamic control over pH values of the stomach and a small intestine digestion chamber is realized and pH dynamic curve can be output at the same time. Through regulating stomach emptying speed and intestine transport speed in real time, real time flow of food between different digestive tracts is realized. Human body stomach-small intestine digestion state and environment are simulated more truly and more comprehensively. According to the invention, simulation of an external digestion process of different people such as premature infants, term infants, adults and aged people can be realized. Rabbit gastric lipase or cutinase are used in simulated gastric fluid, so that human gastric lipase is simulated more truly.

Owner:JIANGNAN UNIV +1

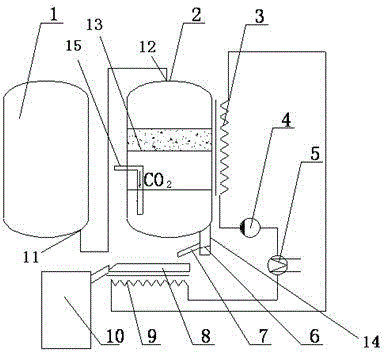

Equipment and technology of calcium oxide producing with calcium sulfate

ActiveCN103058245AAvoid wastingHigh purityEnergy inputCalcium/strontium/barium oxides/hydroxidesSulfateDigestion chambers

The invention provides equipment and technology of calcium oxide producing with calcium sulfate. The equipment comprises a calcining kiln, a digestion chamber and a secondary calcining kiln, wherein the calcining kiln is communicated with a feed port at the top of the digestion chamber through a discharge port I at the bottom of the calcining kiln, the digestion chamber is divided into two layers which are separated through a filter screen I in the middle. A carbon dioxide inlet pipeline is arranged on the side wall of the digestion chamber and leads to the bottom of the digestion chamber, a discharge port II is arranged at the bottom of the digestion chamber and is provided with a filter screen II and a separating hopper, the filter screen II is in an inclined structure, a heat exchanger is arranged outside the wall of the digestion chamber, the separating hopper directly leads into a drying chamber with an open structure, the drying chamber is communicated with the secondary calcining kiln, the heat exchanger is connected with a heater, a condenser and a circulating pump in a closed mode in sequence through pipelines, and the heater is positioned at the bottom of the drying chamber. The invention further includes the technology of waste heat recovering with the equipment. Energy consumption is reduced by 10% or more, meanwhile purity and production efficiency of the calcium oxide product can be improved.

Owner:XIANGFU NEW BUILDING MATERIAL HUNAN

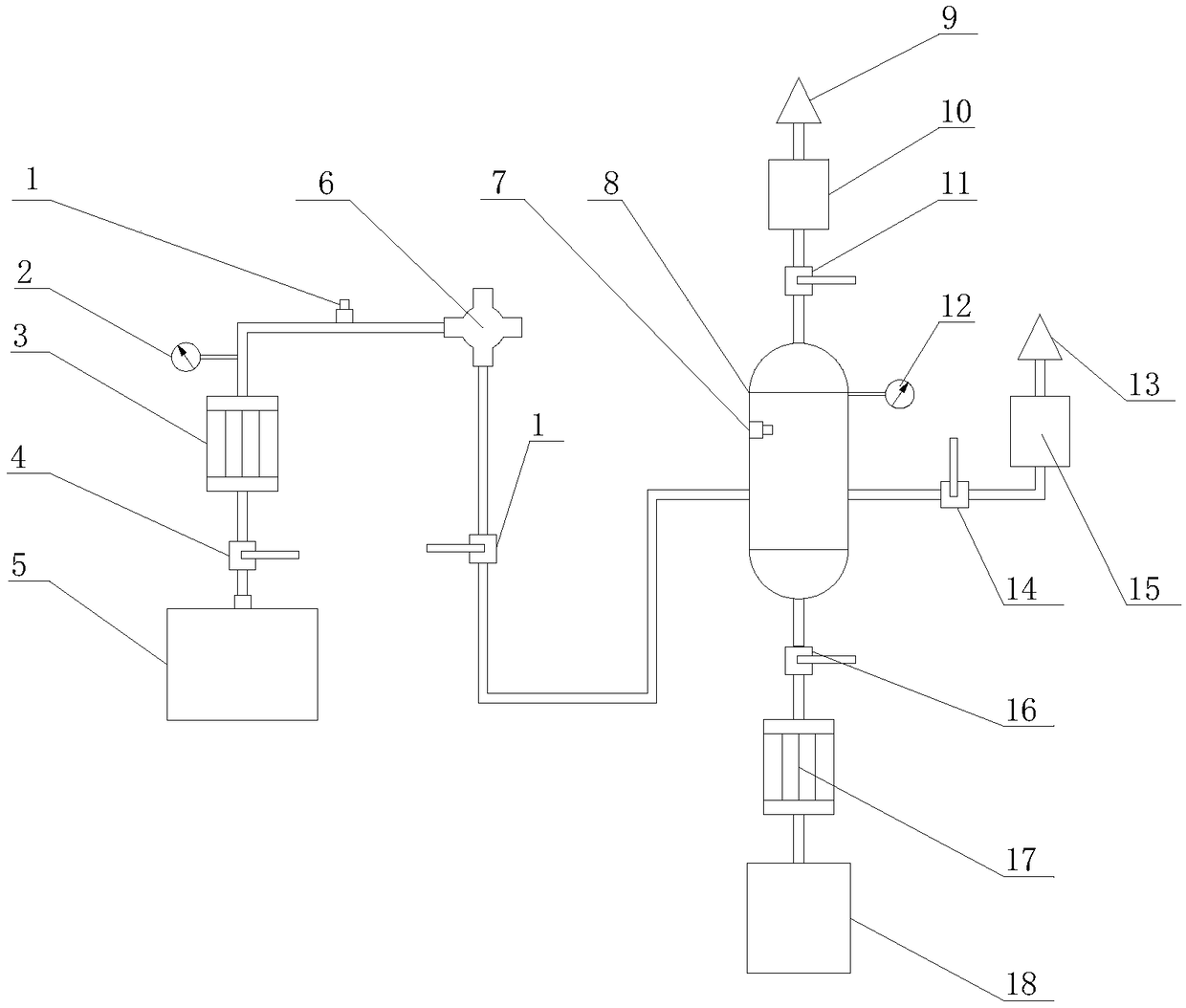

Chemical detection device for water quality

InactiveCN108872524AAvoid cloggingPrecisely control delivery volumePreparing sample for investigationTesting waterSolenoid valveWater quality

The invention relates to a chemical detection device for water quality and belongs to the technical field of chemical detection equipment. The chemical detection device for the water quality comprisesa sample charging basket, a multi-way valve, a high-temperature and high-pressure digestion chamber and a vacuum pump, wherein the sample charging basket, the multi-way valve and the high-temperatureand high-pressure digestion chamber are communicated in sequence through a pipeline; a circulating pump and a flow meter are arranged on the pipeline between the sample charging basket and the multi-way valve; a solenoid valve is arranged on the pipeline between the multi-way valve and the high-temperature and high-pressure digestion chamber; a liquid discharging opening is formed in the lower end of the high-temperature and high-pressure digestion chamber; the liquid discharging opening is communicated with the vacuum pump and a waste liquid bucket in sequence; a safety pressure relief valveis arranged on a side wall of the high-temperature and high-pressure digestion chamber; the safety pressure relief valve is communicated with a first filter and a first air outlet in sequence. According to the chemical detection device for the water quality, provided by the invention, the vacuum pump is vacuumized to pump out liquid in the high-temperature and high-pressure digestion chamber, sothat the pipeline blocking is effectively prevented.

Owner:江苏天泽教育咨询有限公司

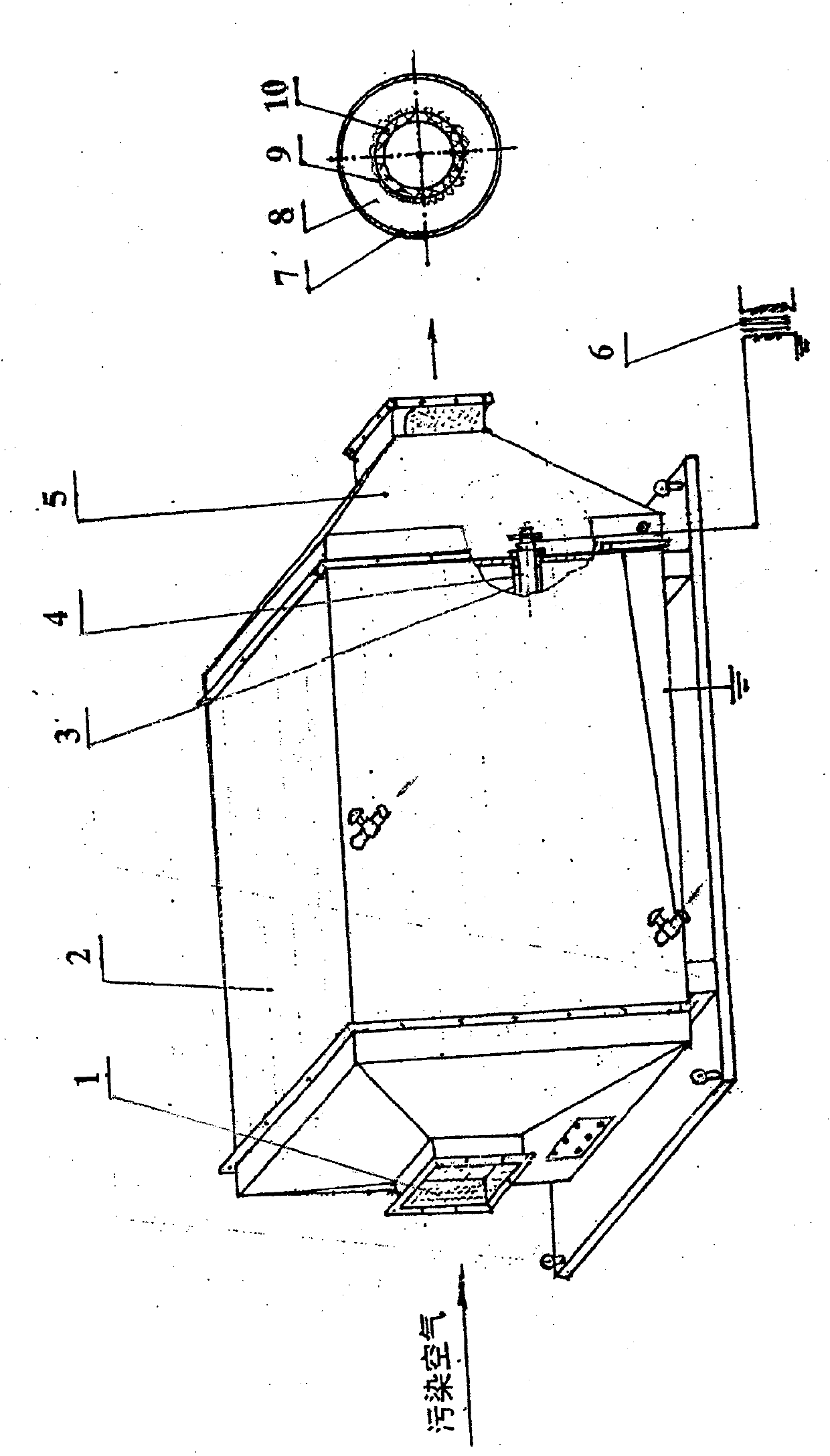

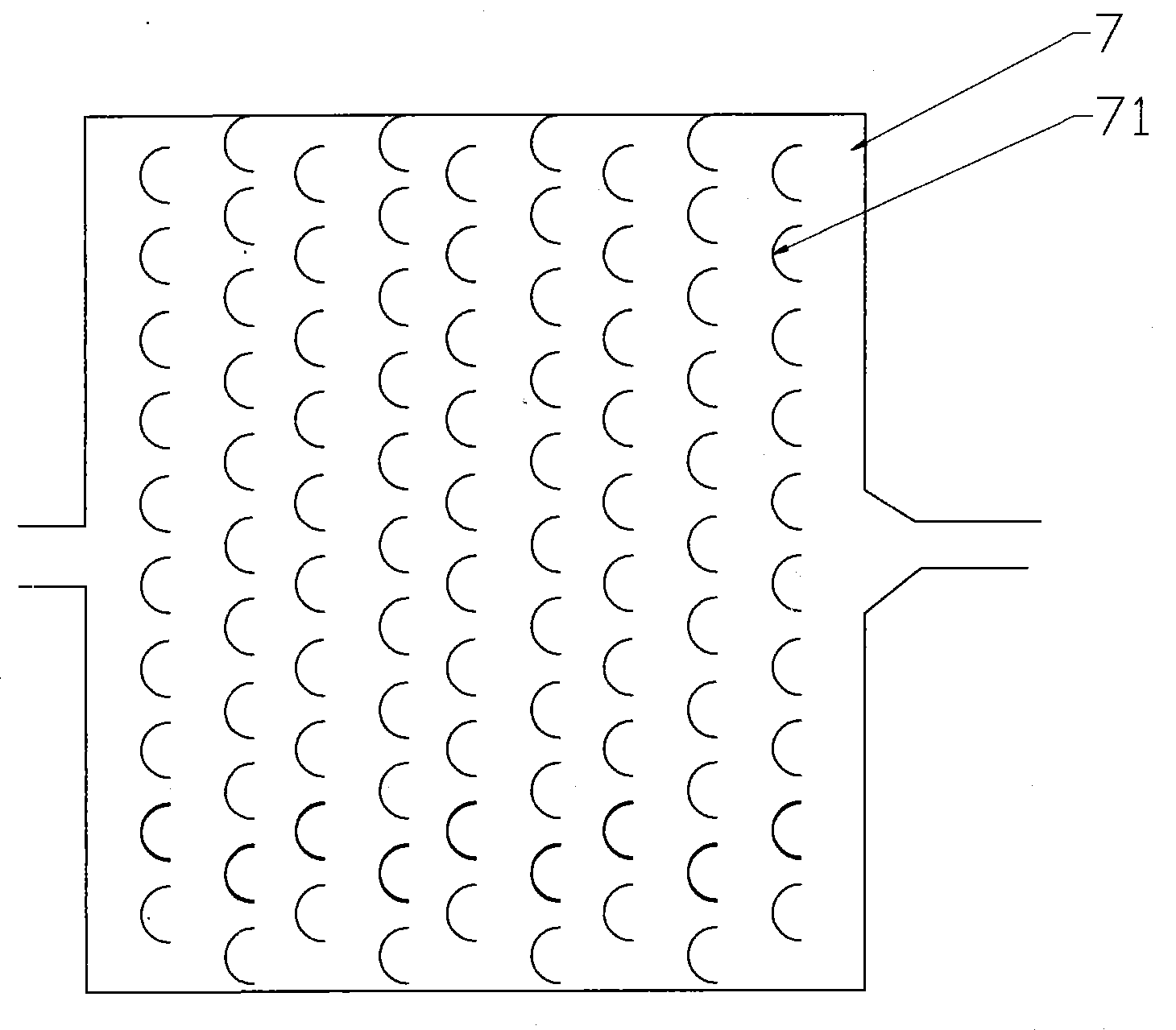

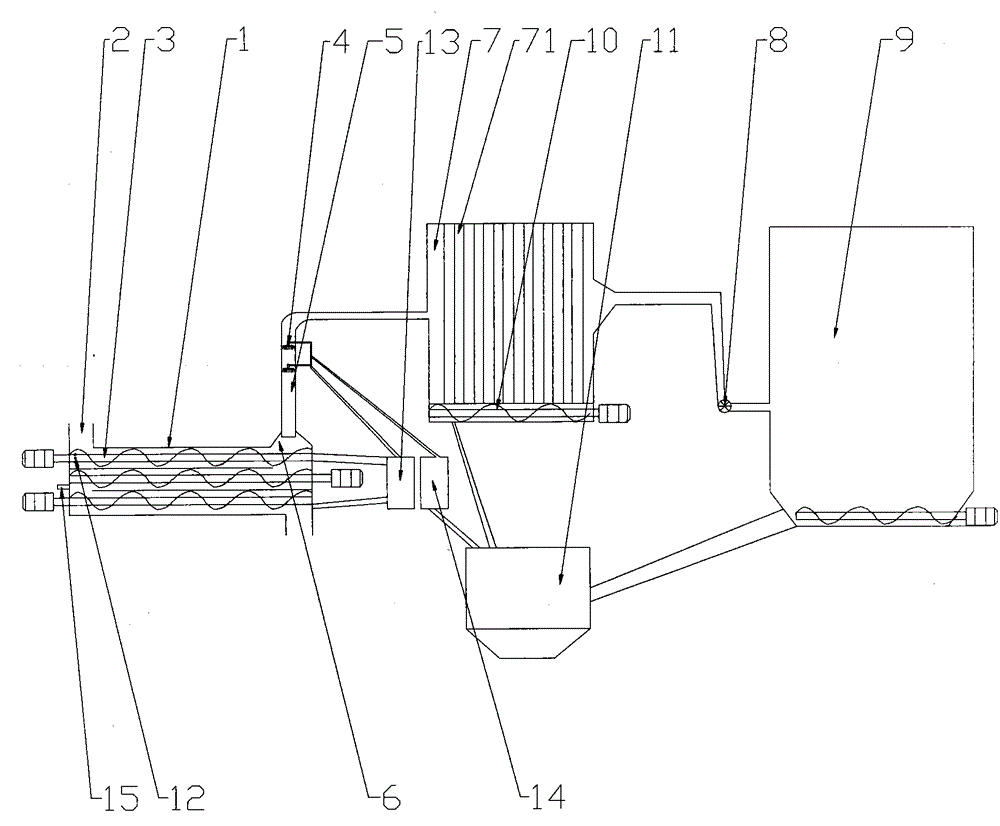

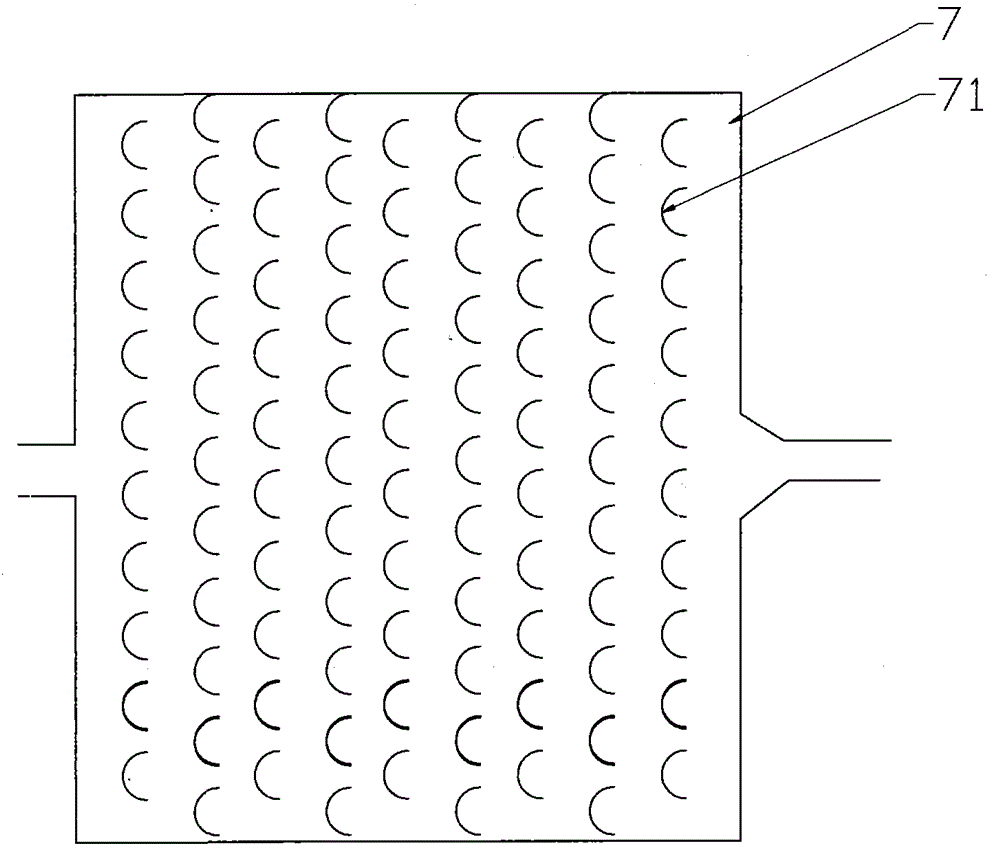

Calcium hydroxide production line

ActiveCN104291370AInnovative designReasonable structureCalcium/strontium/barium oxides/hydroxidesCalcium hydroxideProduction line

The invention provides a calcium hydroxide production line and relates to the field of calcium hydroxide production. The calcium hydroxide production line comprises a digester, hierarchical atomizers, a purifier, a decompression filter, a sewage treater, a fan and a high pressure pump, wherein the digester comprises an inner layer and an outer layer, wherein the outer layer is a heat exchange water layer and the inner layer is a digestion chamber; a water spraying hole is formed in an upper screw stirring shaft and arranged under a feeding hole; an exhaust opening is arranged on the digester on the other side opposite to the feeding hole; the exhaust opening is communicated with the gas inlet of the purifier by virtue of the hierarchical atomizers and a pipeline; the purifier is an airtight hollow chamber with a gas inlet and a gas outlet; a plurality of rows of C-shaped dust collectors are arranged inside the purifier; the decompression filter is a housing defined by a filter screen and provided with a gas inlet; the cross section of the bottom of the decompression filter is V-shaped; the bottom of the sewage treater is funnel-shaped; the sewage treater is communicated with the water inlet of the sewage high pressure pump by use of a pipeline. The calcium hydroxide production line is capable of reducing the production cost and reducing the environmental pollution.

Owner:陶纪琛

Digestion-aiding indoor exercise apparatus

InactiveCN112914949AAvoid irregular damageAvoid Disengagement SituationsChiropractic devicesPhysical medicine and rehabilitationEngineering

The invention relates to a digestion-aiding indoor exercise apparatus. The digestion-aiding indoor exercise apparatus comprises a seat, a seat cushion, a driving device and two arm positioning devices, wherein the seat cushion is laid on the seat, the driving device is mounted at the upper end of the seat, and the two arm positioning devices are mounted at the left end and the right end of the driving device. With the digestion-aiding indoor exercise apparatus, the problems that in order to avoid accidents during exercise, the old or postoperative rehabilitation personnel can move only under the accompanying or assistance of other people, other people need to accompany the old or postoperative rehabilitation personnel all the time, and the exercise under the assistance of other people easily has the incomplete and irregular actions, so that the digestion-aiding effect is not achieved, and the bodies of the personnel are injured, are solved.

Owner:THE AFFILIATED HOSPITAL OF QINGDAO UNIV

Biological waste management systems

Biological waste management systems are provided herein. A waste management system may include a waste shredder, an accumulator tank, a water supply, a digester tank, and a grinder pump. The accumulator tank may define an accumulation chamber downstream from the waste shredder to receive a shredded biologic waste or a decomposition agent. The water supply may be in fluid communication with the accumulator tank to provide a water flow to the accumulation chamber. The digester tank may define a digestion chamber in fluid communication with the accumulation chamber to receive a slurry mixture comprising the biologic waste and the decomposition agent. The grinder pump may be disposed in fluid communication with the accumulation chamber to grind the slurry mixture upstream from the digester tank.

Owner:ENVIROPURE SYST INC

Biogas system

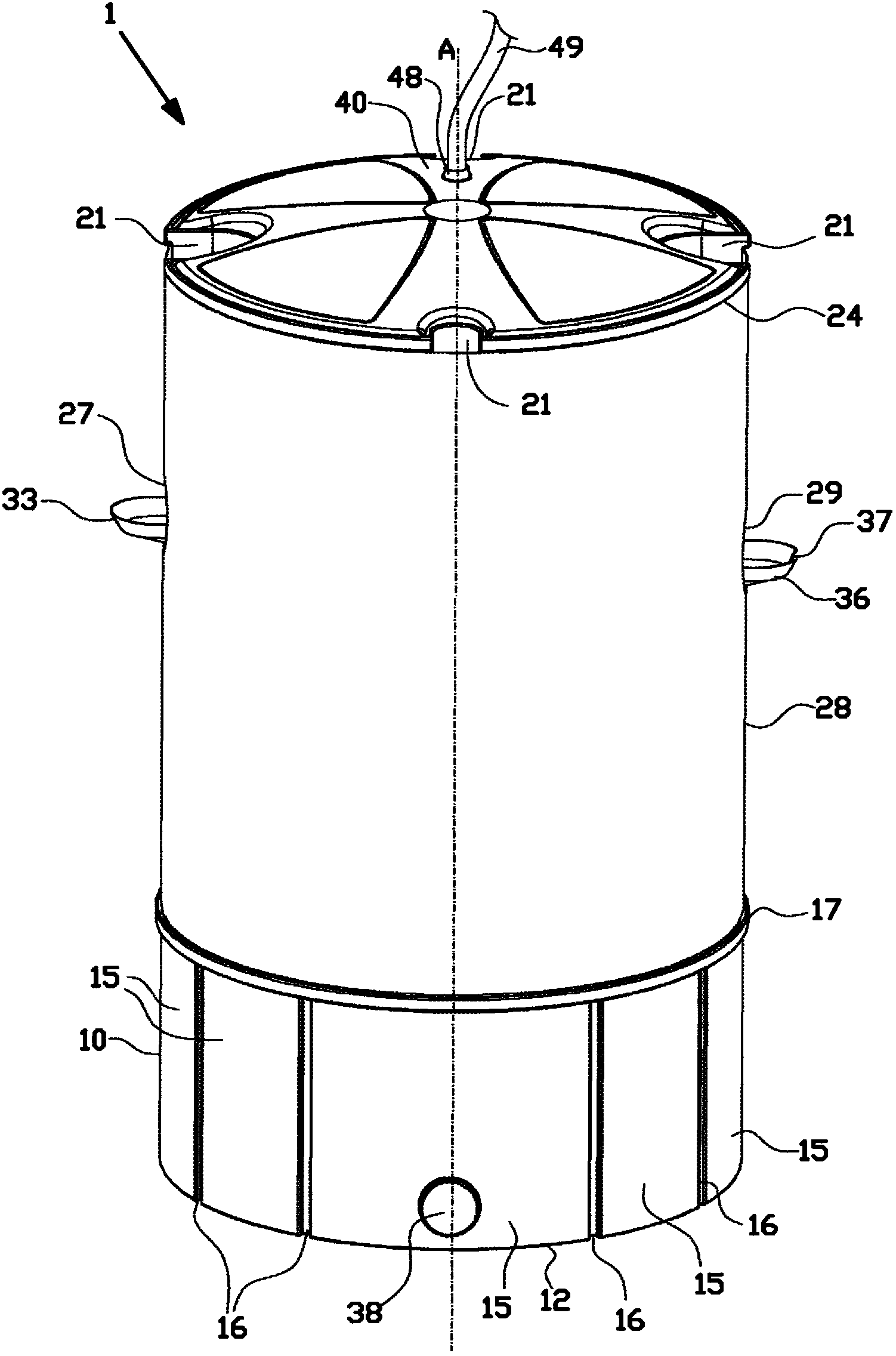

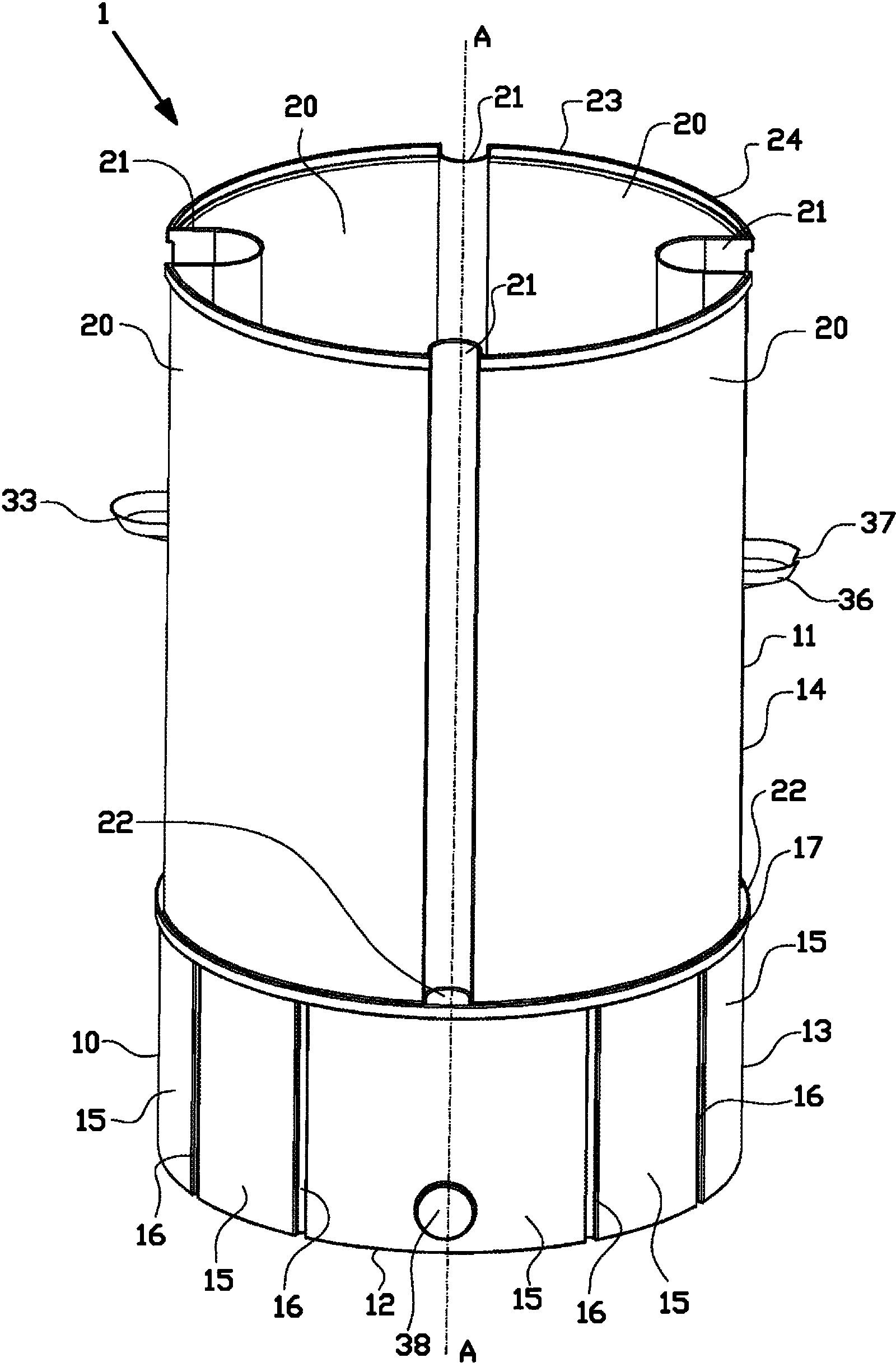

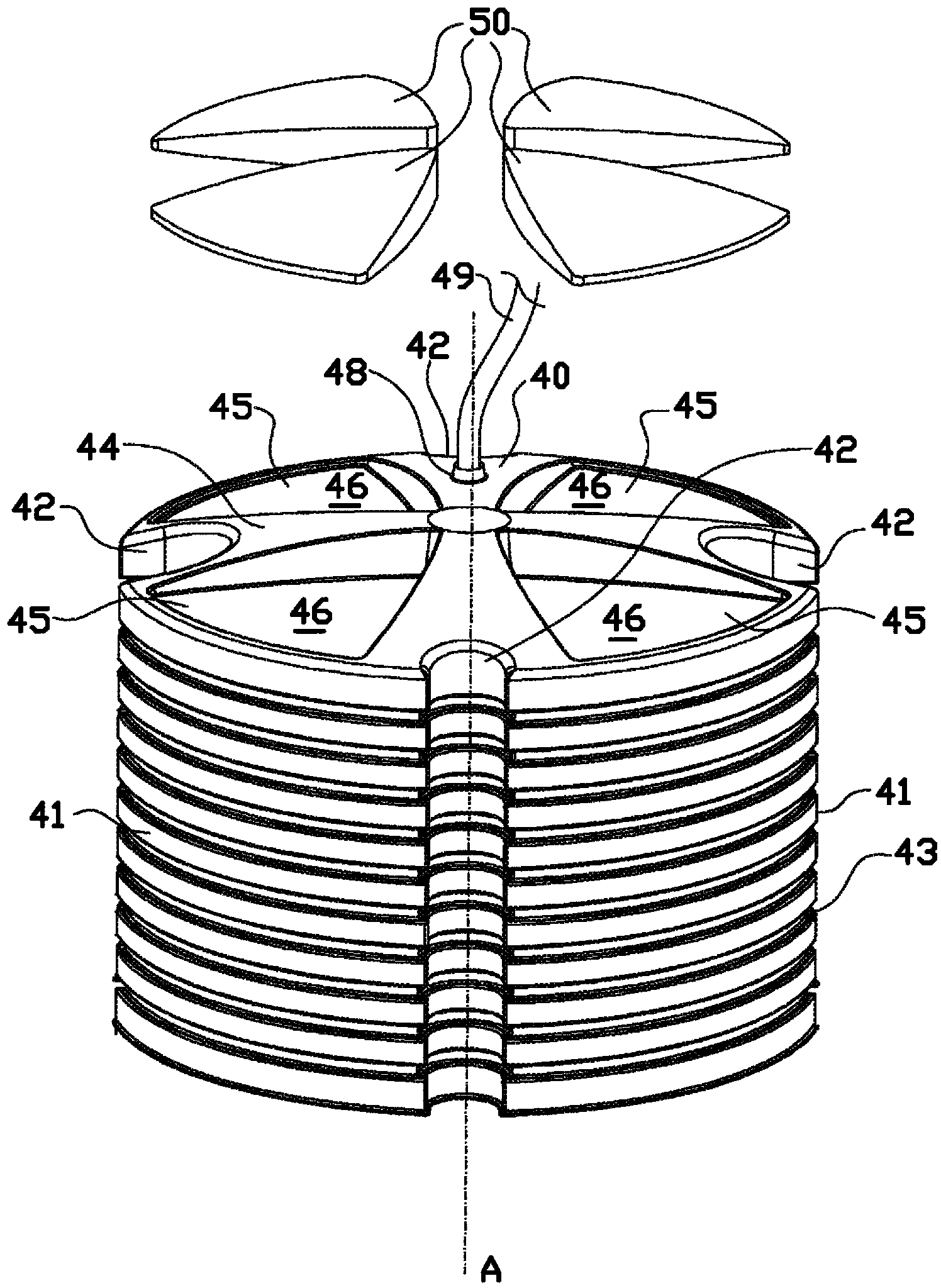

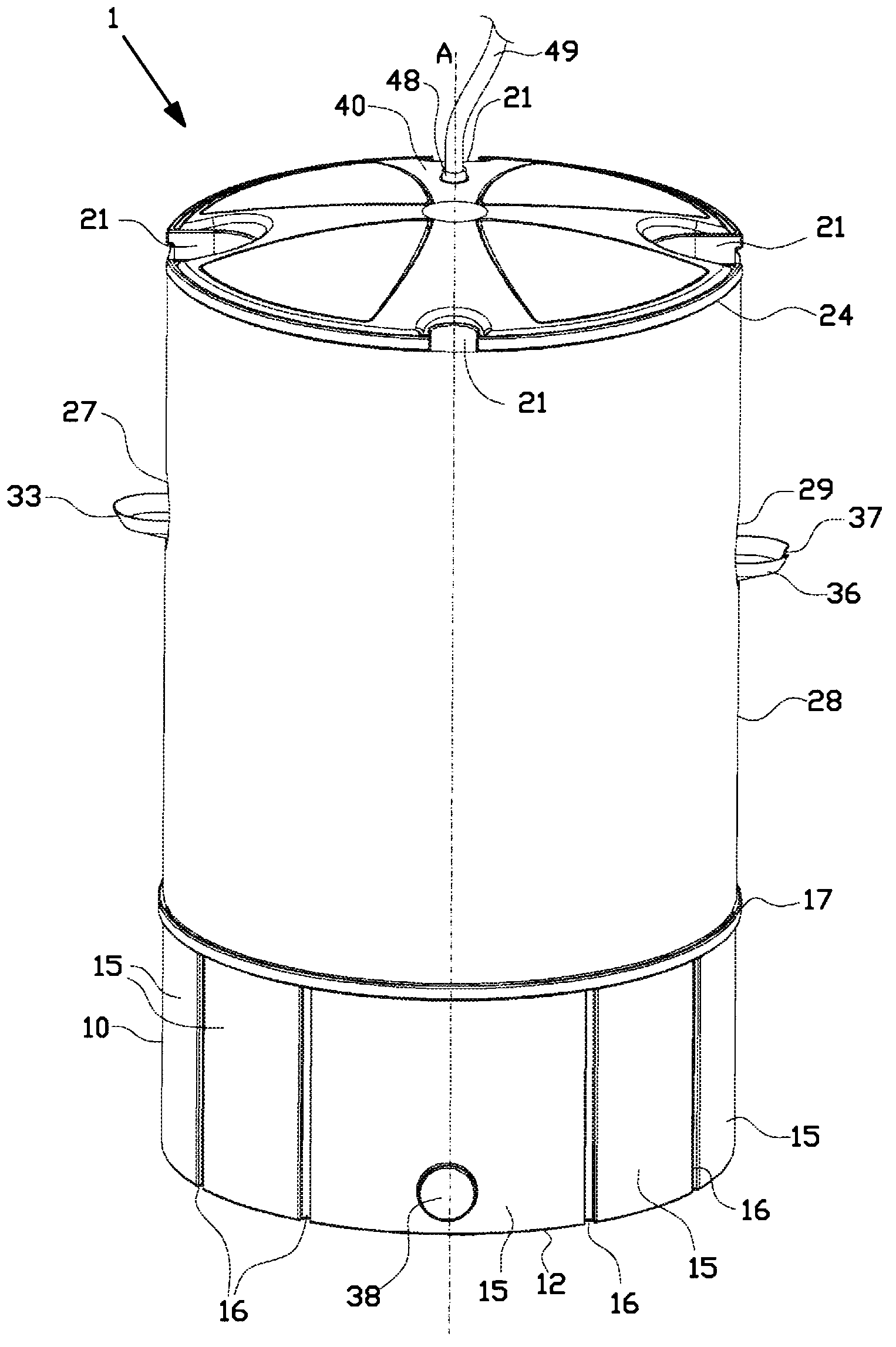

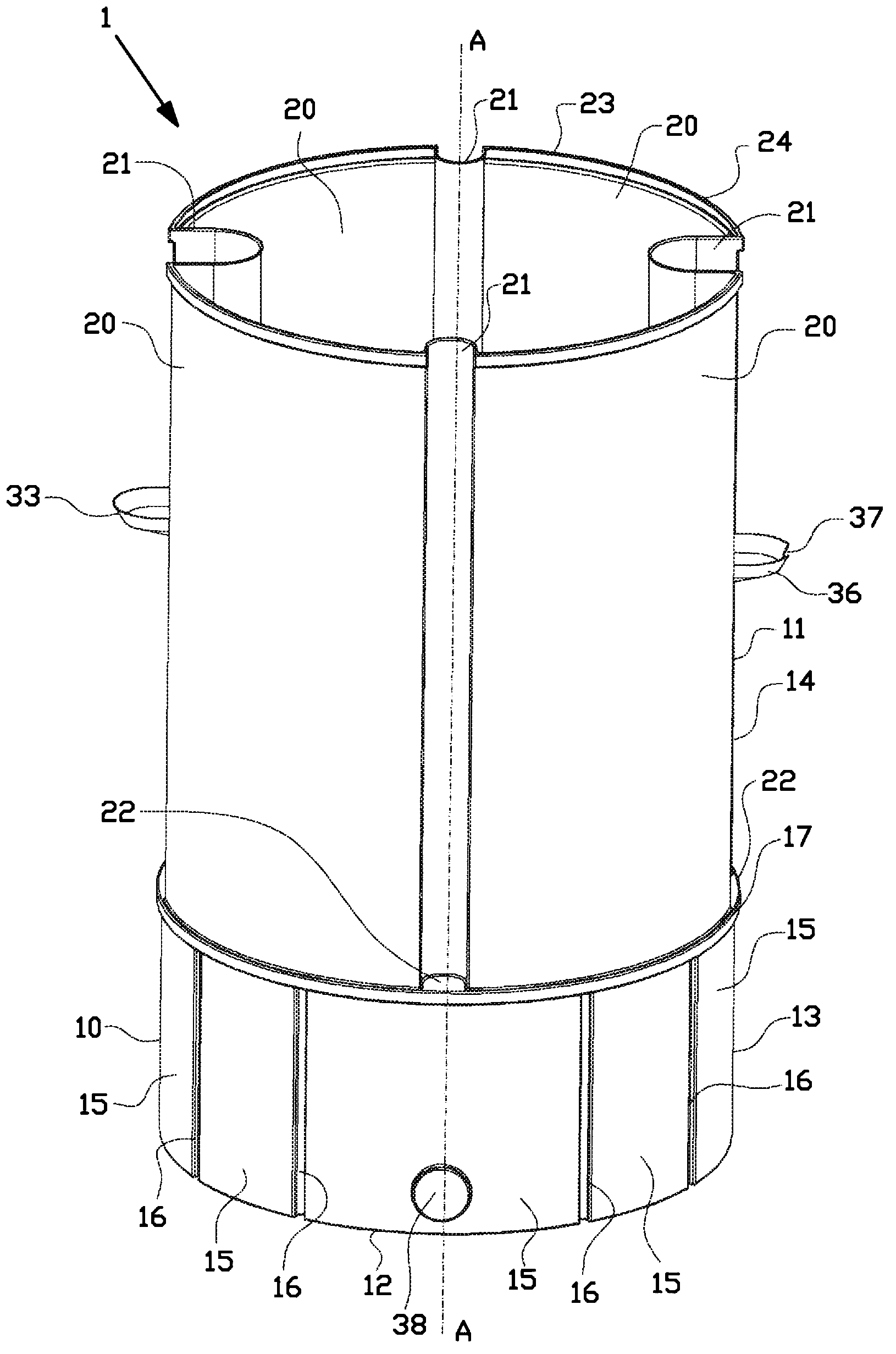

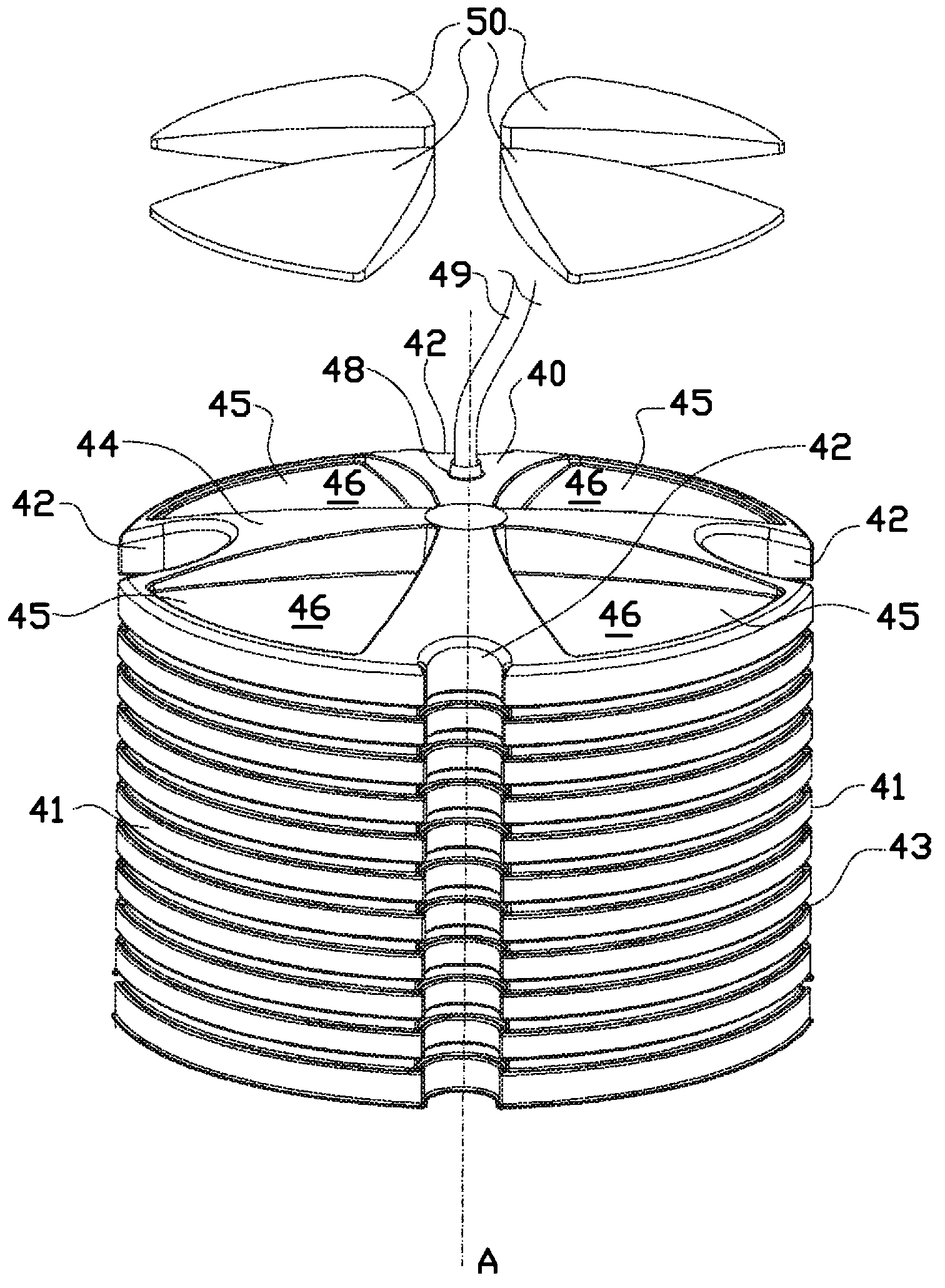

The invention relates to a biogas system comprising a cylindrical digestion vessel having a bottom wall, a first circumferential wall and a top opening to define a digestion chamber to be filled with a digestive mixture, and a cover having a top side, a second circumferential wall and a bottom opening to define a gas storage chamber, wherein the cover is inserted in the digestion vessel via the top opening with its bottom opening directed towards the bottom wall to capture gas that is released inside the digestion chamber, wherein the digestion vessel comprises first elongated guides and the cover comprises second elongated guides, wherein the first elongated guides are at least partly inserted into the second elongated guides.

Owner:SIMGAS IP

Biogas system

The invention relates to a biogas system comprising a cylindrical digestion vessel having a bottom wall, a first circumferential wall and a top opening to define a digestion chamber filled with a digestive mixture, and a cover having a top side, a second circumferential wall and a bottom opening to define a gas storage chamber, wherein the cover is inserted in the digestion vessel via the top opening with the bottom opening directed towards the bottom wall to capture gas that is released inside the digestion chamber, wherein the digestion vessel comprises first elongated guides and the cover comprises second elongated guides, wherein the first elongated guides are at least partly inserted into the second elongated guides.

Owner:SIMGAS IP

A kind of calcium hydroxide production line

ActiveCN104291370BInnovative designReasonable structureCalcium/strontium/barium oxides/hydroxidesProduction lineCalcium hydroxide

The invention provides a calcium hydroxide production line and relates to the field of calcium hydroxide production. The calcium hydroxide production line comprises a digester, hierarchical atomizers, a purifier, a decompression filter, a sewage treater, a fan and a high pressure pump, wherein the digester comprises an inner layer and an outer layer, wherein the outer layer is a heat exchange water layer and the inner layer is a digestion chamber; a water spraying hole is formed in an upper screw stirring shaft and arranged under a feeding hole; an exhaust opening is arranged on the digester on the other side opposite to the feeding hole; the exhaust opening is communicated with the gas inlet of the purifier by virtue of the hierarchical atomizers and a pipeline; the purifier is an airtight hollow chamber with a gas inlet and a gas outlet; a plurality of rows of C-shaped dust collectors are arranged inside the purifier; the decompression filter is a housing defined by a filter screen and provided with a gas inlet; the cross section of the bottom of the decompression filter is V-shaped; the bottom of the sewage treater is funnel-shaped; the sewage treater is communicated with the water inlet of the sewage high pressure pump by use of a pipeline. The calcium hydroxide production line is capable of reducing the production cost and reducing the environmental pollution.

Owner:陶纪琛

Process for producing regenerated building waste autoclaved brick

The invention discloses a process for producing a regenerated building waste autoclaved brick, which comprises the following steps: A, crushing the building waste till the granularity thereof is below 5 millimeters, and removing ironware and wood; B, crushing calcined lime and gypsum respectively, mixing the crushed calcined lime and gypsum according to a certain proportion, fine-grinding the mixture to form a cementing material for production, and storing the cementing material for later use respectively; C, mixing and stirring the crushed building waste, the cementing material of the calcined lime and the gypsum and water according to a certain proportion to form a mixture, digesting the mixture through a digestion chamber, and then rolling and uniformly stirring the mixture; D, feeding the digested mixture to a brick press to form a brick blank; and E, feeding the brick blank into a still kettle, steaming the brick blank, and then conveying the steamed brick blank to a finished product storage yard. According to the process, standard bricks or common hollow bricks are produced by using the building waste; the compressive strength, breaking strength, freezing resistance, dry shrinkage value and the like of the bricks can reach the national standards; and the process has the advantages of simple process, easily-obtained materials, low machining cost and the like.

Owner:FUJIAN UNIV OF TECH +1

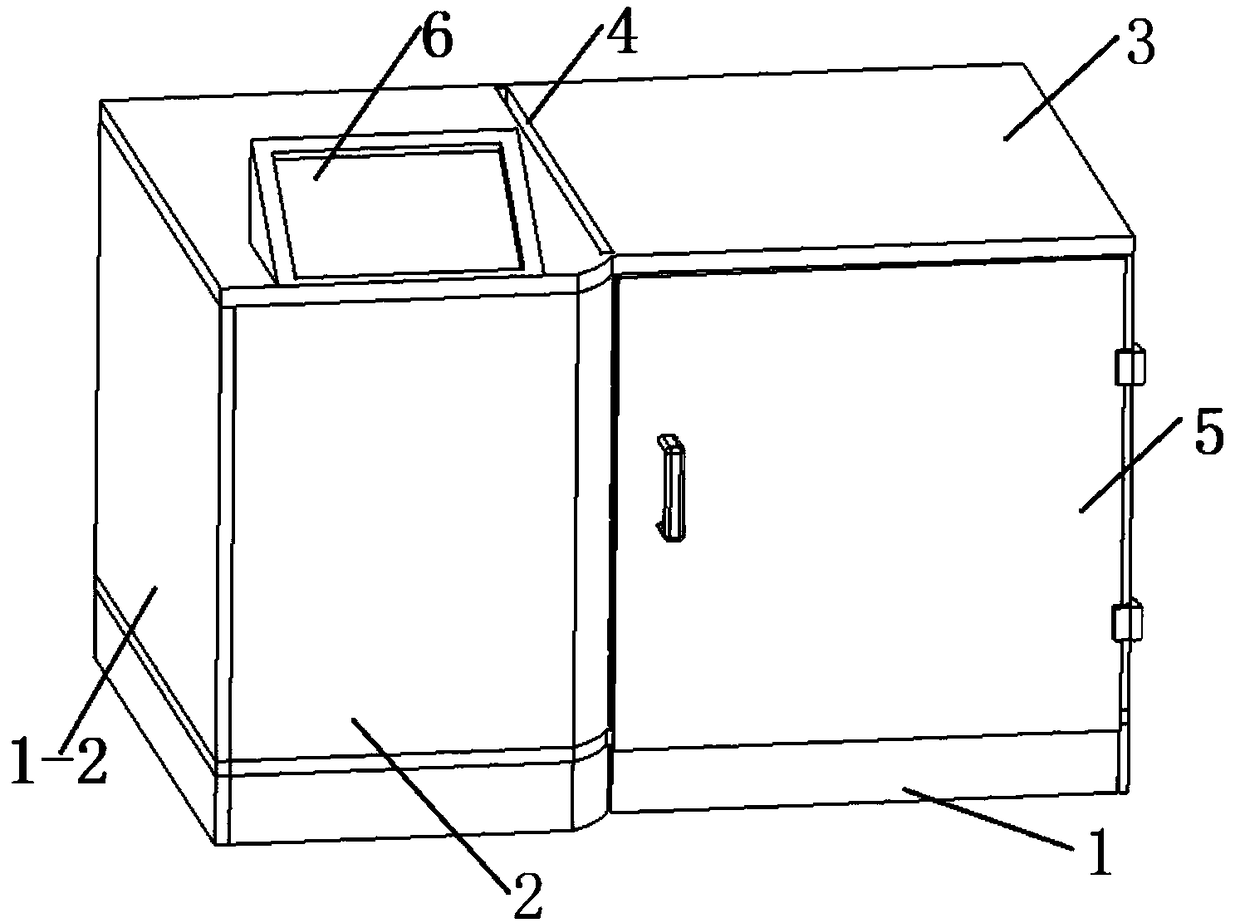

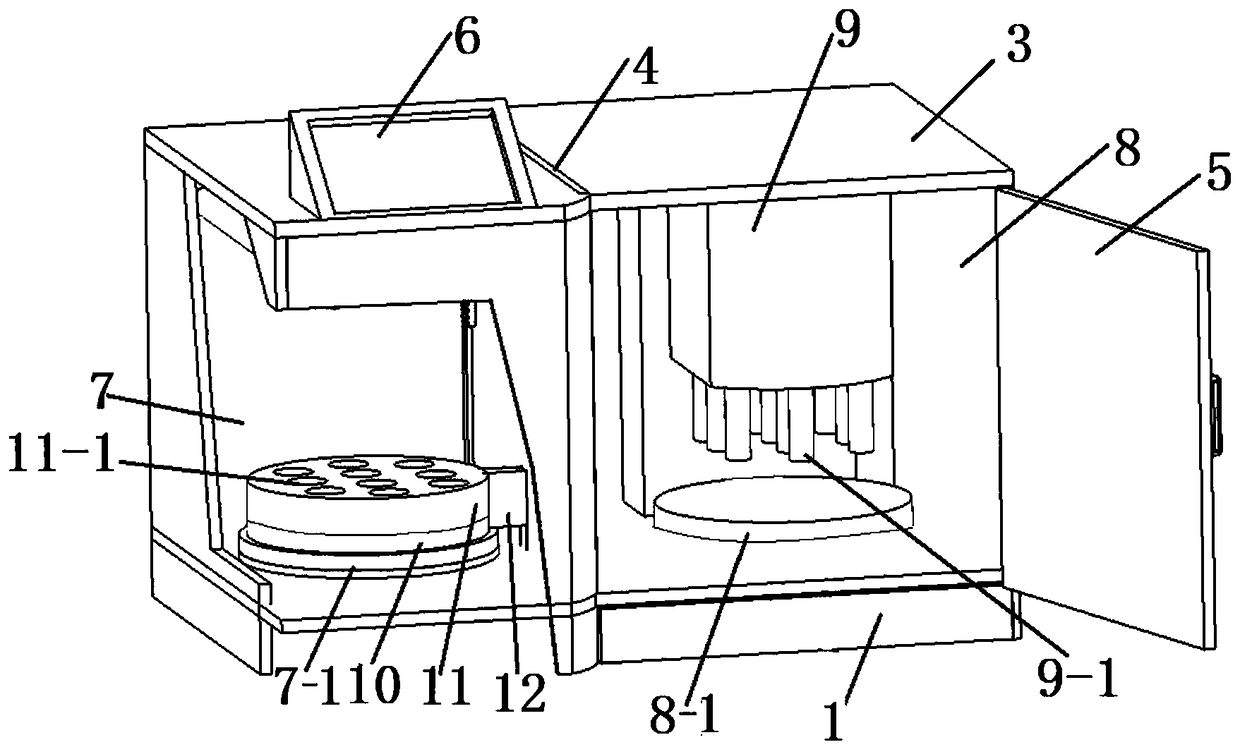

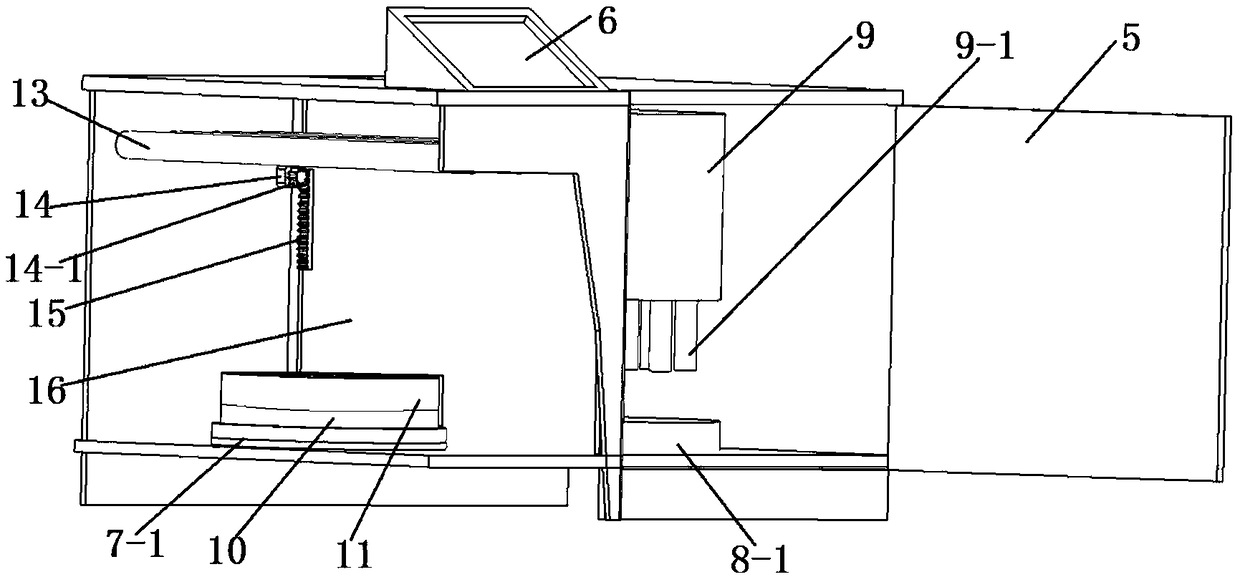

Sample digestion and heavy metal detection integrated device

ActiveCN109443903AAvoid pollutionEasy to operatePreparing sample for investigationElectric machineryEngineering

Disclosed is a sample digestion and heavy metal detection integrated device. The sample digestion and heavy metal detection integrated device comprises a housing, a digestion chamber, a detecting chamber and a vertical baffle, wherein the digestion chamber is used for digesting samples; the detecting chamber is used for detecting digested samples; the vertical baffle is used for being embedded into the housing for separating the inside of the housing into the digestion chamber and the detecting chamber; the inside of the digestion chamber is provided with a heating disc, a conveying disc, a detecting disc and an ultraviolet radiant lamp; the inside of the detecting chamber is provided with a detector, a detecting disc, a swing arm, a rotating rod, a bearing and a motor, one end of the swing arm is arranged on the rotating rod, the other end of the swing arm is fixedly provided with a conveying disc, the top inside the digestion chamber is provided with the ultraviolet radiant lamp, thebottom inside the digestion chamber is provided with the heating disc, the conveying disc connected with the swing arm is suspended above the heating disc, and the conveying disc and the swing arm can rotate horizontally around the rotating rod inside the digestion chamber onto the detecting disc at the bottom of the detecting chamber. The sample digestion and heavy metal detection integrated device combines sample digestion and heavy metal detection and achieves intelligent operation from digestion to detection as well as ultraviolet radiation.

Owner:四川众望安全环保技术咨询有限公司

Digested sludge recycling method and device

InactiveCN104163488ASolve the consumption problemAvoid secondary pollutionTreatment using aerobic processesTreatment with anaerobic digestion processesRefluxResource utilization

The invention provides a digested sludge recycling method and a digested sludge recycling device. The device is mainly characterized in that the device is a multi-stage sewage treatment device provided with an internal-circulation reflux-jet mixing and discharging system, or a stirring mixing and pressure-difference discharging system. The device is composed of a sludge pretreatment space and a sludge-sewage separation treatment unit. The upper part of the sludge-sewage separation treatment unit is a sewage treatment space, and the lower part of the sludge-sewage separation treatment unit is a sludge digestion chamber. In the sludge digestion chamber, accumulated digested sludge is mixed and stirred, and is mixed with sewage, such that high-water-content slurry is formed, and the high-water-content slurry can be discharged through the discharging system and can be utilized in agricultural productions. With the method and the device, when sewage is being treated, digested sludge is converted into liquid slurry and can be utilized, such that resource utilization is realized, and secondary pollution is avoided. The method and the device facilitate energy saving and emission reduction.

Owner:赵峰

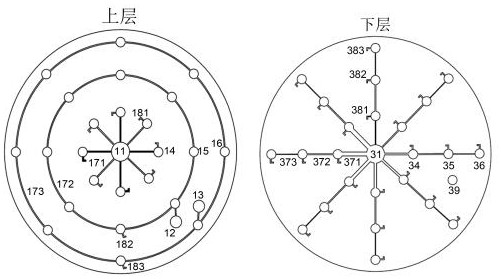

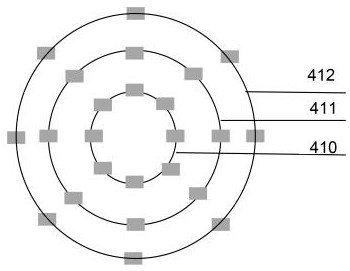

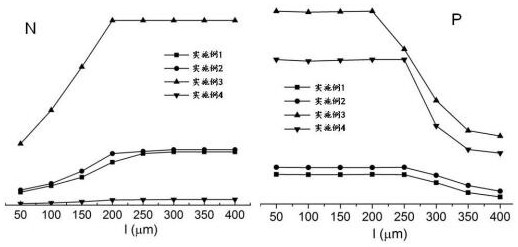

A microfluidic chip and detection method for detecting nitrogen and phosphorus content in water

ActiveCN110006882BRapid and controllable preparationAdjustable sizeMaterial analysis by observing effect on chemical indicatorLaboratory glasswaresEngineeringDigestion chambers

The invention provides a microfluidic chip and a detection method for detecting the content of nitrogen and phosphorus in a water body. The microfluidic chip includes an upper layer, a membrane layer, a lower layer, and a support layer arranged sequentially from top to bottom, and the upper layer, the membrane layer, the lower layer, and the support layer are all circular; wherein: the upper layer is provided with an upper layer reagent Injection port, N upper-layer mixing chambers, N upper-layer digestion chambers, N upper-layer color chambers; the lower layer is provided with lower-layer reagent injection ports, N lower-layer mixing chambers, N lower-layer digestion chambers, and N lower-layer color chambers . A reference pool; the upper layer reagent injection port overlaps with the upper layer reagent injection port and is separated by a diaphragm layer. The invention also provides a detection method for detecting the content of nitrogen and phosphorus in the water body by using the microfluidic chip. The microfluidic chip of the present invention can realize rapid, convenient and controllable preparation of digestion solutions with different concentrations.

Owner:SHANDONG POLYTECHNIC

Equipment and technology of calcium oxide producing with calcium sulfate

ActiveCN103058245BAvoid wastingHigh purityEnergy inputCalcium/strontium/barium oxides/hydroxidesSulfateDigestion chambers

The invention provides equipment and technology of calcium oxide producing with calcium sulfate. The equipment comprises a calcining kiln, a digestion chamber and a secondary calcining kiln, wherein the calcining kiln is communicated with a feed port at the top of the digestion chamber through a discharge port I at the bottom of the calcining kiln, the digestion chamber is divided into two layers which are separated through a filter screen I in the middle. A carbon dioxide inlet pipeline is arranged on the side wall of the digestion chamber and leads to the bottom of the digestion chamber, a discharge port II is arranged at the bottom of the digestion chamber and is provided with a filter screen II and a separating hopper, the filter screen II is in an inclined structure, a heat exchanger is arranged outside the wall of the digestion chamber, the separating hopper directly leads into a drying chamber with an open structure, the drying chamber is communicated with the secondary calcining kiln, the heat exchanger is connected with a heater, a condenser and a circulating pump in a closed mode in sequence through pipelines, and the heater is positioned at the bottom of the drying chamber. The invention further includes the technology of waste heat recovering with the equipment. Energy consumption is reduced by 10% or more, meanwhile purity and production efficiency of the calcium oxide product can be improved.

Owner:XIANGFU NEW BUILDING MATERIAL HUNAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com