Chemical detection device for water quality

A detection device, water quality chemistry technology, applied in measuring devices, testing water, scientific instruments, etc., can solve the problems of multi-way valve influence, damage to multi-way valve, inaccurate measurement, etc., to prevent contamination of gas reagents and prevent damage. The effect of opening the valve and preventing the phenomenon of liquid channeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

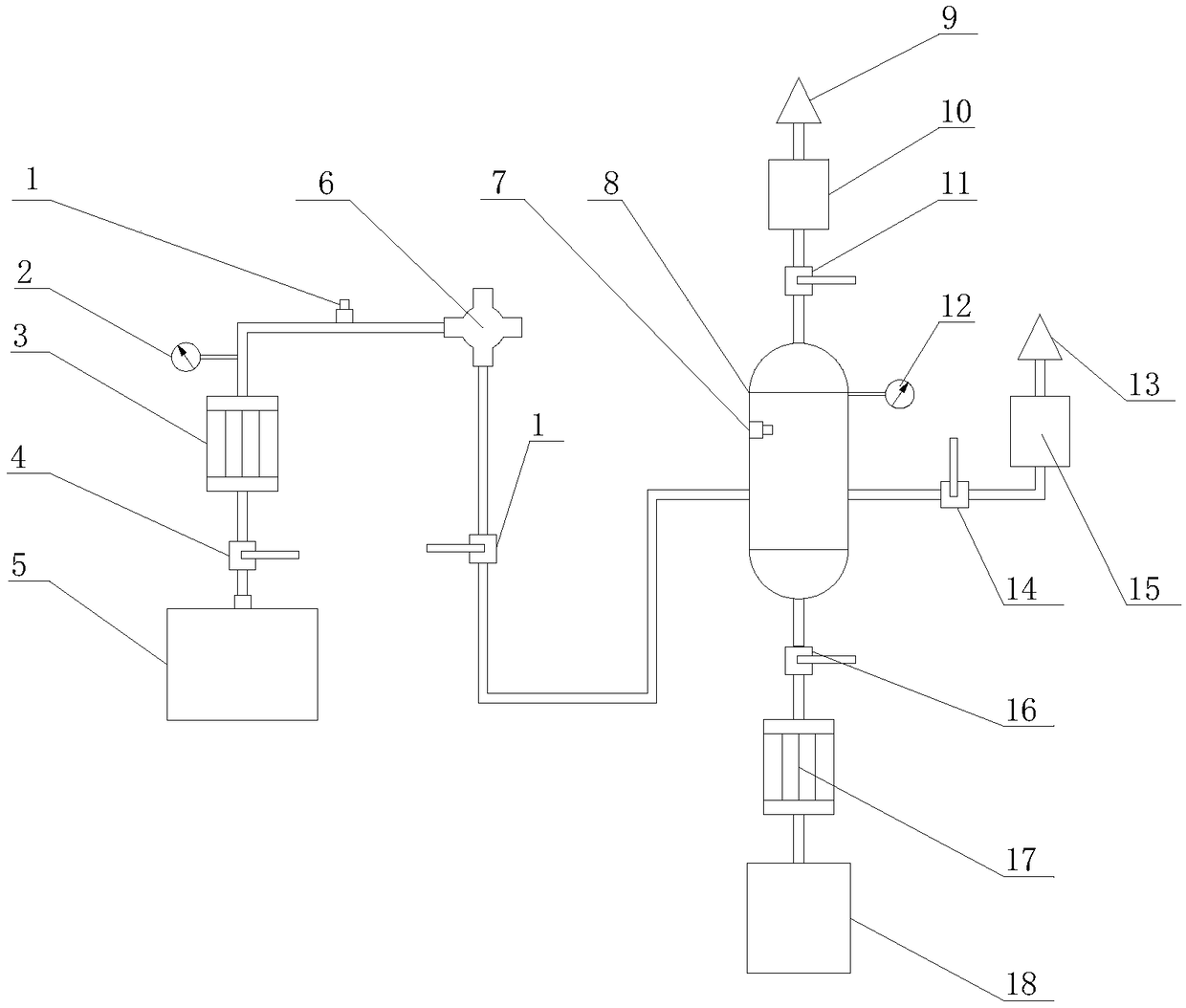

[0023] The water quality chemical detection device of the present embodiment, such as figure 1 As shown, it includes a sample material tank 5, a multi-way valve 6, a high-temperature and high-pressure digestion chamber 8 and a vacuum pump 17. The sample material tank 5, the multi-way valve 6 and the high-temperature and high-pressure digestion chamber 8 are sequentially connected through pipelines, and the sample material tank 5 and the multi-way A circulation pump 3 and a flow meter 2 are installed on the pipeline between the through valve 6, a solenoid valve 19 is installed on the pipeline between the multi-way valve 6 and the high-temperature and high-pressure digestion chamber 8, and a discharge valve is installed at the lower end of the high-temperature and high-pressure digestion chamber 8. The drain port and the liquid discharge port are connected with a vacuum pump 17 and a waste liquid bucket 18 in turn; a safety relief valve 14 is arranged on the side wall of the high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com