Sintering-free phosphor gypsum ceramsite and preparation method thereof

A technology of phosphogypsum and ceramsite, which is applied in the field of building materials, can solve problems such as not being able to be used as building materials, insufficient strength, and polluting the environment, and achieve the effects of increasing cement utilization, improving cohesiveness, and improving the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

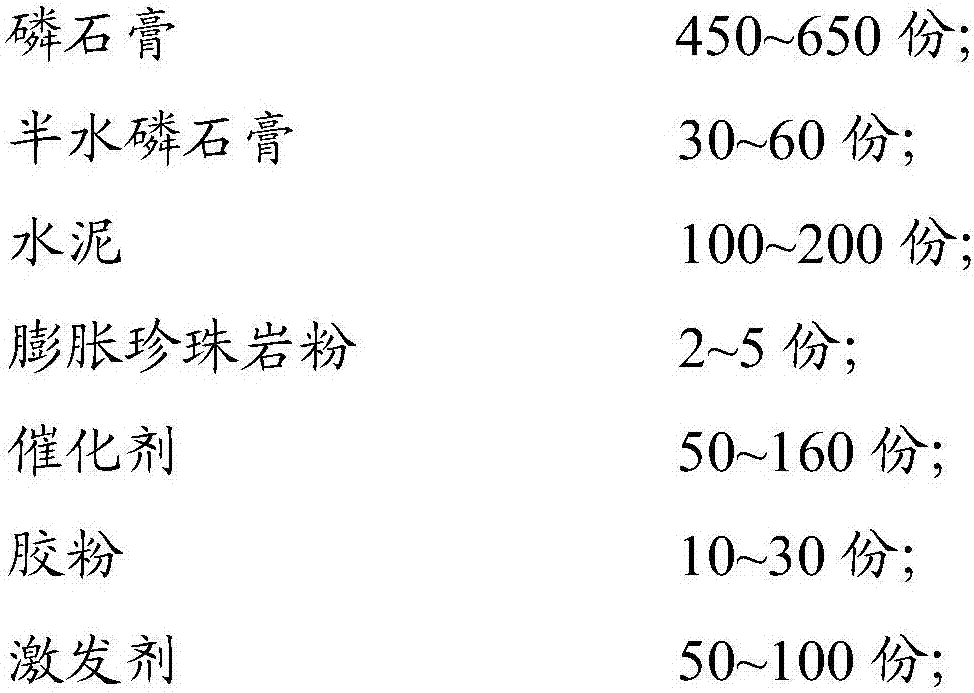

[0034] A non-fired phosphogypsum ceramsite, comprising raw materials and proportions by weight are:

[0035]

[0036]

Embodiment 2

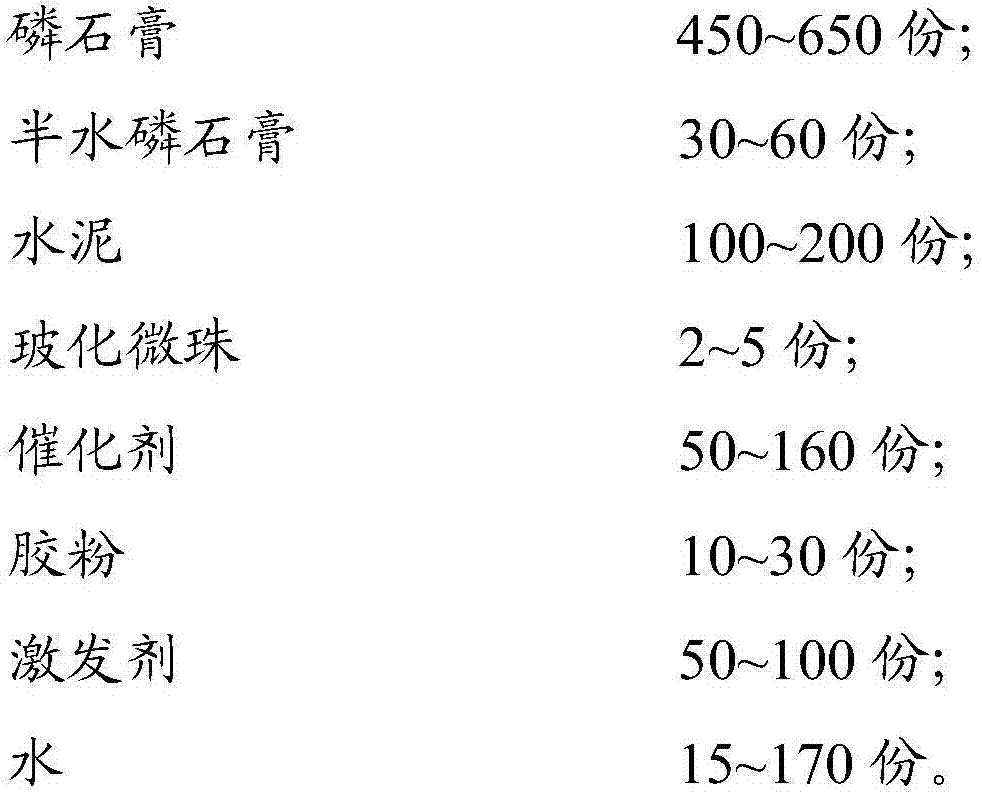

[0038] A non-fired phosphogypsum ceramsite, comprising raw materials and proportions by weight are:

[0039]

Embodiment 3

[0041] A non-fired phosphogypsum ceramsite, comprising raw materials and proportions by weight are:

[0042]

[0043] Specifically, the cement is Portland cement, preferably, the grade of Portland cement is 42.5R; the phosphogypsum hemihydrate is double-calcined from phosphogypsum, and is a cementitious material.

[0044] A kind of preparation method of non-fired phosphogypsum ceramsite, described method is:

[0045] S1 Add any one of the above-mentioned non-fired phosphogypsum ceramsite into the forced mixer and stir evenly;

[0046] After the S2 raw materials are evenly stirred, add water into the forced mixer and continue stirring for 8 to 10 minutes to obtain a mixture;

[0047] S3 sends the mixture obtained after being stirred by the forced mixer to the digestion chamber for catalytic treatment, and the time is 1 to 2 hours;

[0048] S4 sends the mixture processed in the digestion chamber to a double-roller granulator for granulation to obtain ceramsite;

[0049] S5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com