Biogas system

A biogas and container technology, applied in the field of biogas systems, can solve problems such as unfavorable cap tipping and jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

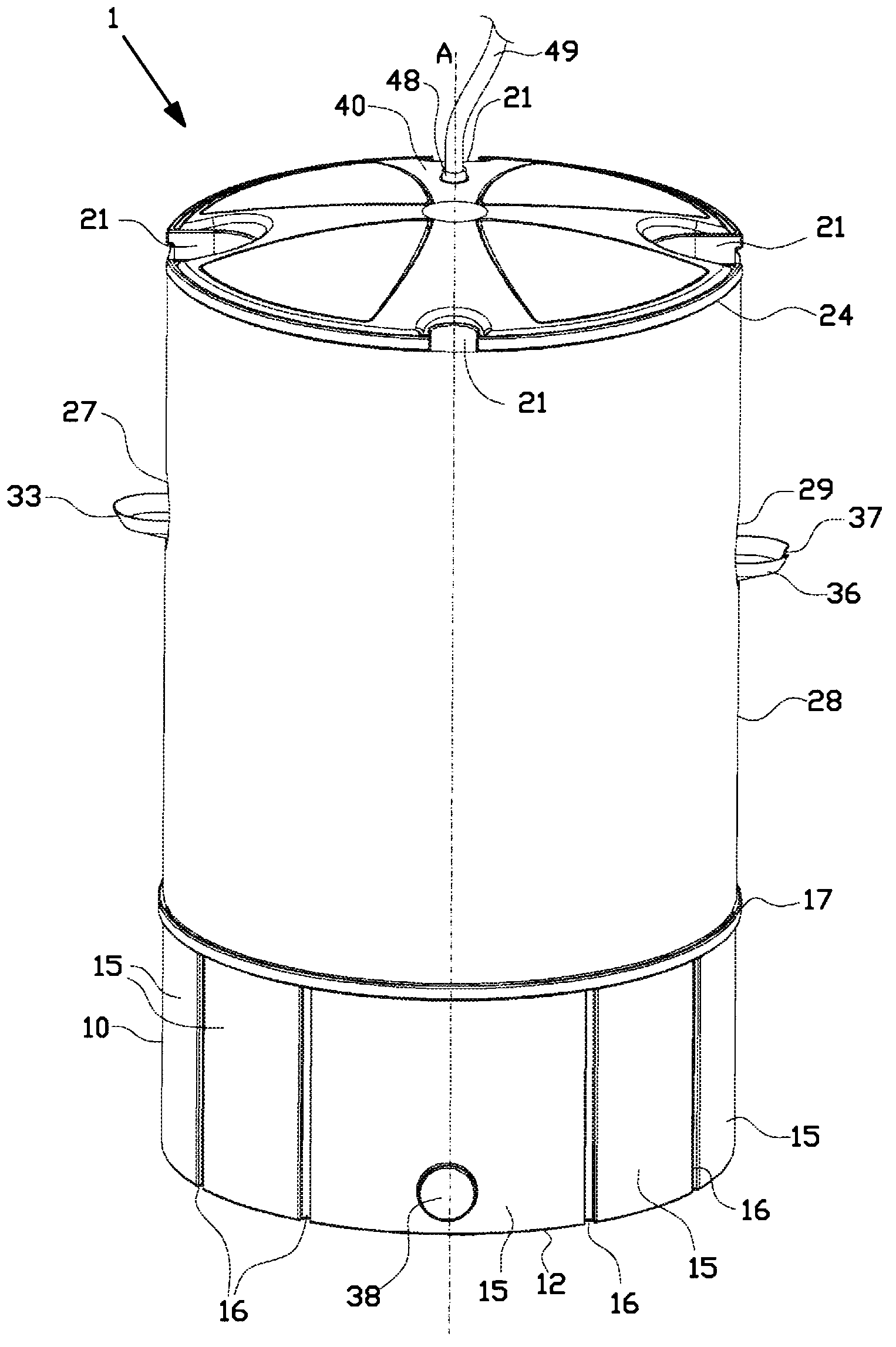

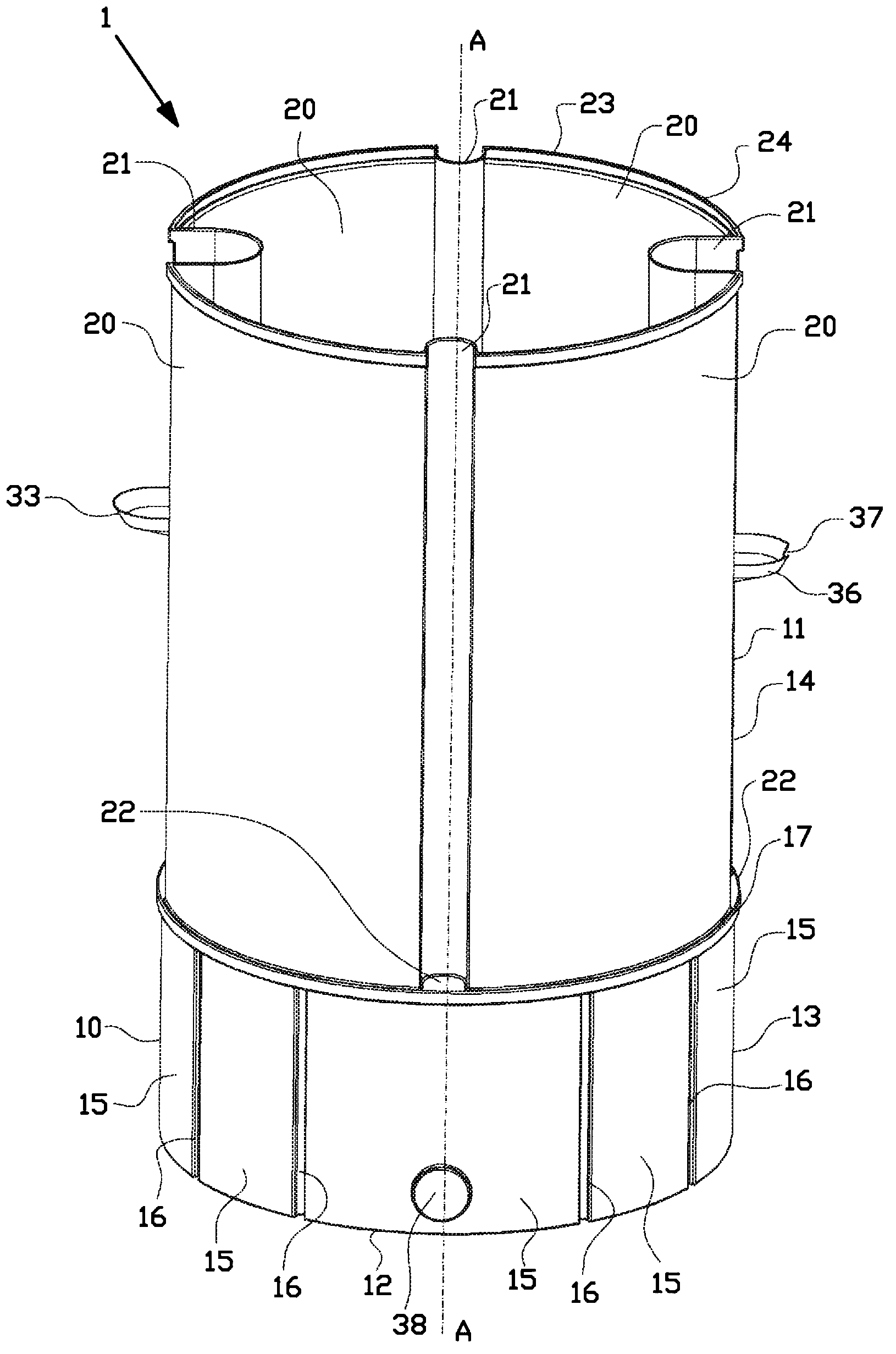

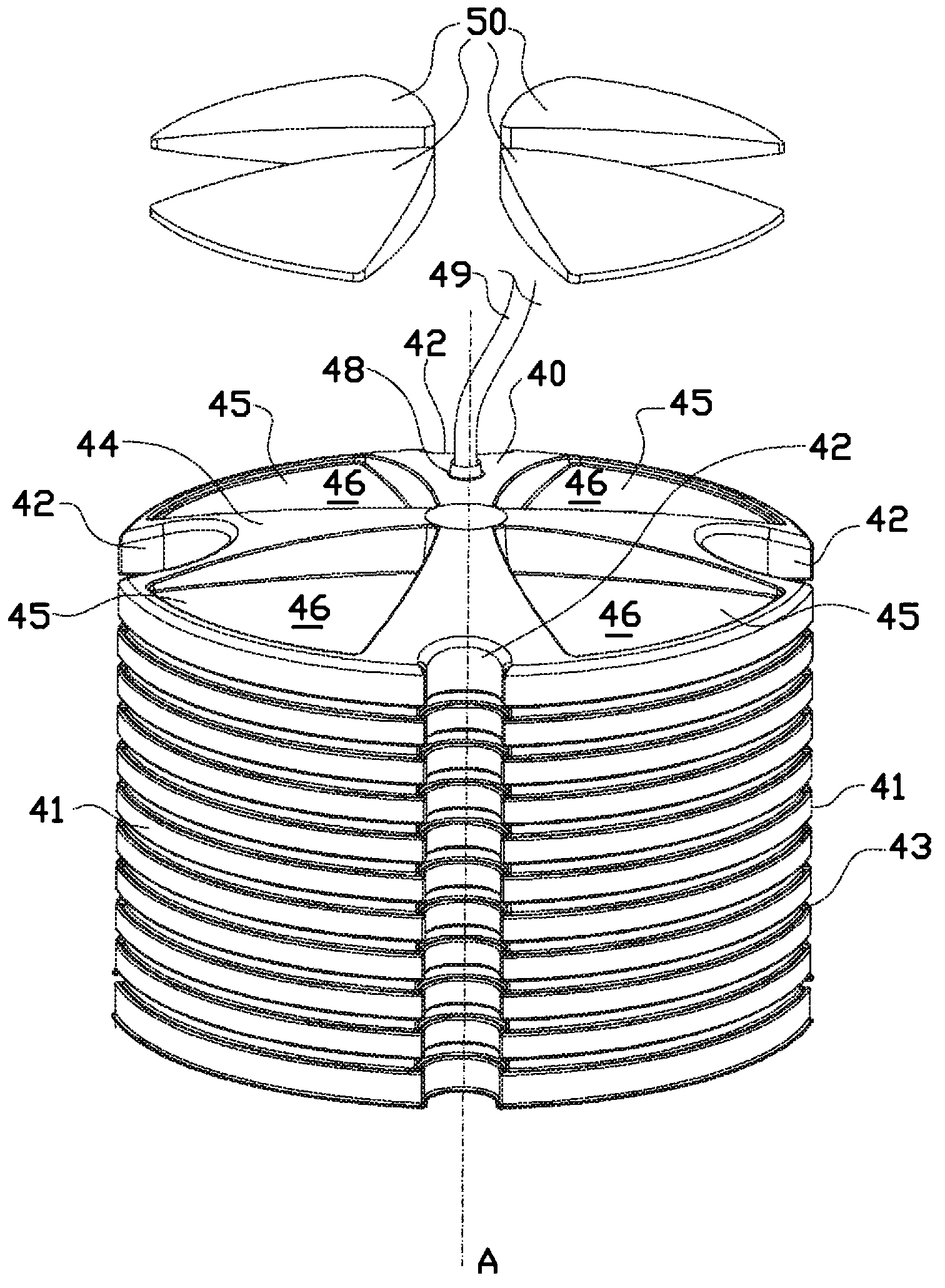

[0049] figure 1 A biogas system 1 according to a first embodiment of the invention is shown. Figure 2A and 2B Some of these components are shown in more detail. The interior of the biogas system 1 consists of Figure 3A and Figure 3B show.

[0050] Such as figure 1 and Figure 2A As shown in , the biogas system 1 comprises a thin-walled digestion vessel 10 comprising a peripheral wall 11 (with a centerline A) and a bottom wall 12, both of which have a constant wall thickness of 4 millimeters at any point. The cylindrical wall 11 defines a digestion chamber 19 and can be roughly divided into a lower slurry section 13 and an upper gas capture section 14 . The digestion vessel 10 is made of a thermoplastic resin such as polyethylene by rotational molding which will be described in detail below.

[0051] At the slurry section 13 , the peripheral wall 11 comprises a first cylindrical wall section 15 which merges into a total of four groups of two concave reinforcing ribs ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com