System for controlling industrial boiler flue gas pollution by ionization technology

A polluting gas and high-voltage technology, applied in separation methods, dispersed particle separation, lighting and heating equipment, etc., can solve the problems of high cost of ammonia water consumption, large floor space, secondary pollution, etc., and achieve low investment and low cost , the effect of simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

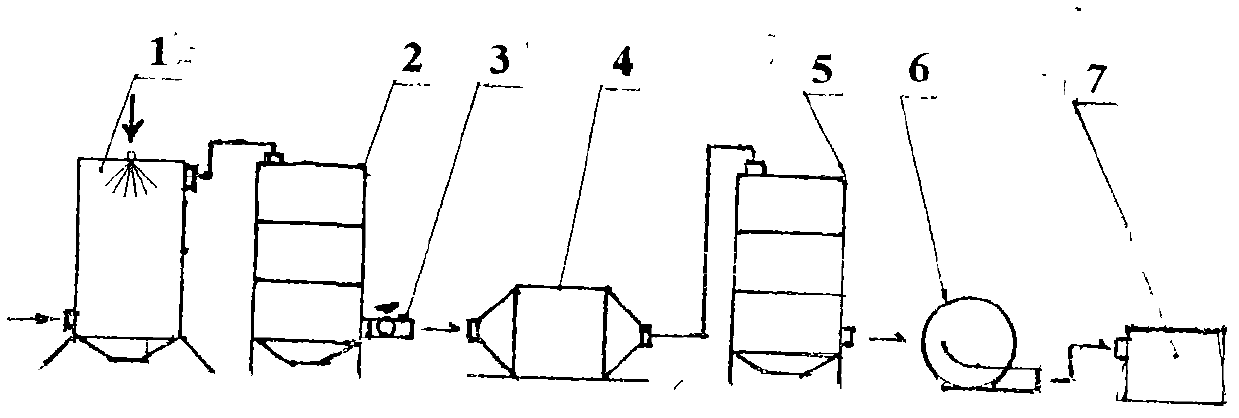

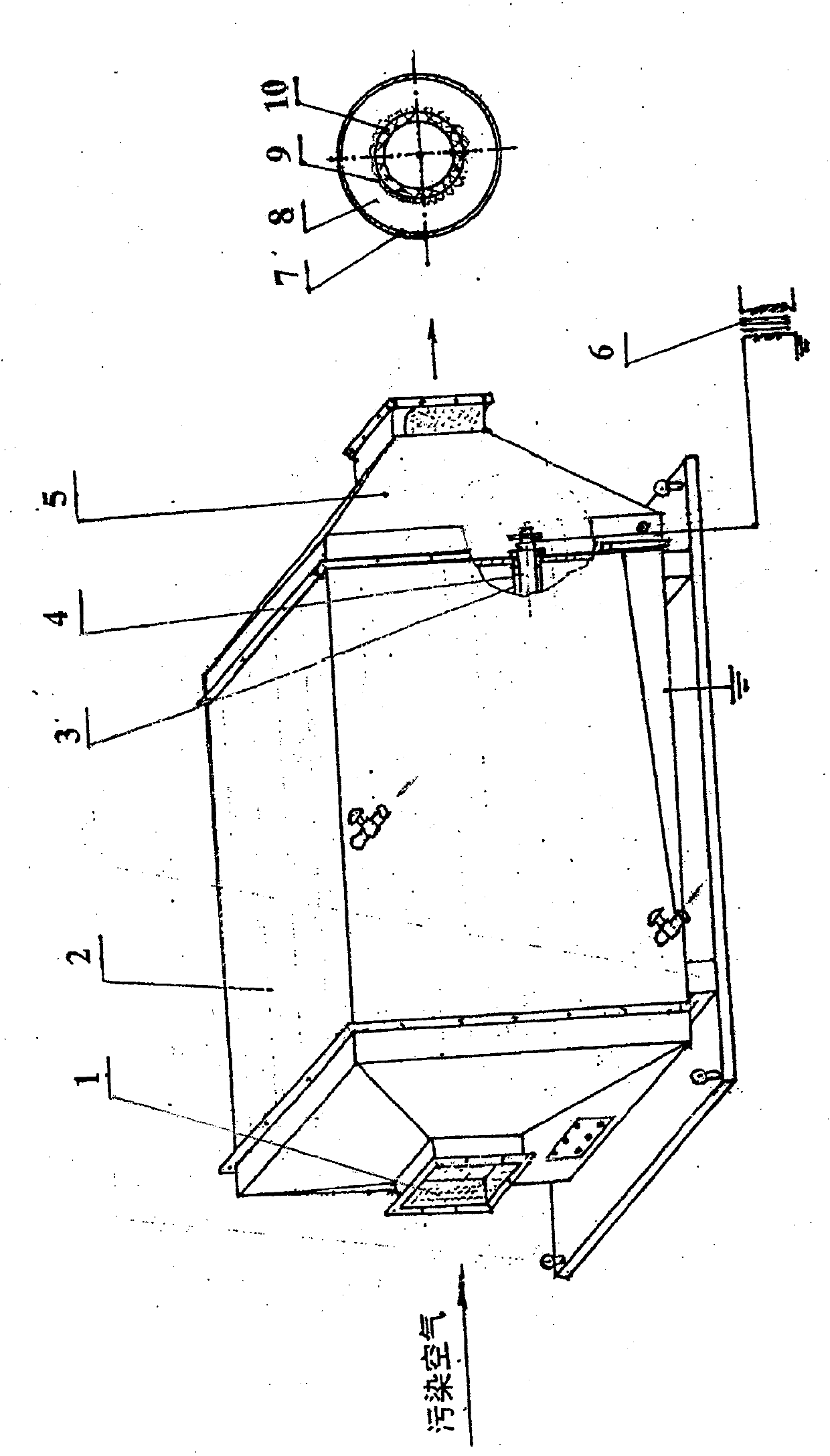

[0014] According to attached figure 1 Shown: first let the industrial boiler waste gas enter the cooling tower 1, and with the cooperation of the spraying device, the large particles of dust will settle down with the temperature, and the rest of the gas will enter the dust collector 2, and the removal of particulate dust is beneficial to the ionizer 4, which works better , The ionization voltage is about 20,000 volts, and the electric field discharge temperature is about 2000°C, so that CO2, SO2, NO2 and other harmful gases and dust are carbonized into powdery solid substances. The ionization process is also a carbonization combustion process. There must be enough oxygen. The air control valve 3 is to adjust the supply of air to keep it in the best carbonization state. The carbonized solid powder enters the bag filter 5 together and is The collected carbides are used as agricultural fertilizers, and the remaining pure air enters the gasification chamber and is discharged to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com