Calcium hydroxide production line

A calcium hydroxide and production line technology, applied in the direction of calcium/strontium/barium oxide/hydroxide, etc., can solve the problems of blockage of pipelines and processing equipment, time-consuming and labor-intensive equipment maintenance, unsatisfactory processing effect, etc. The effect of less electricity, novel design and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

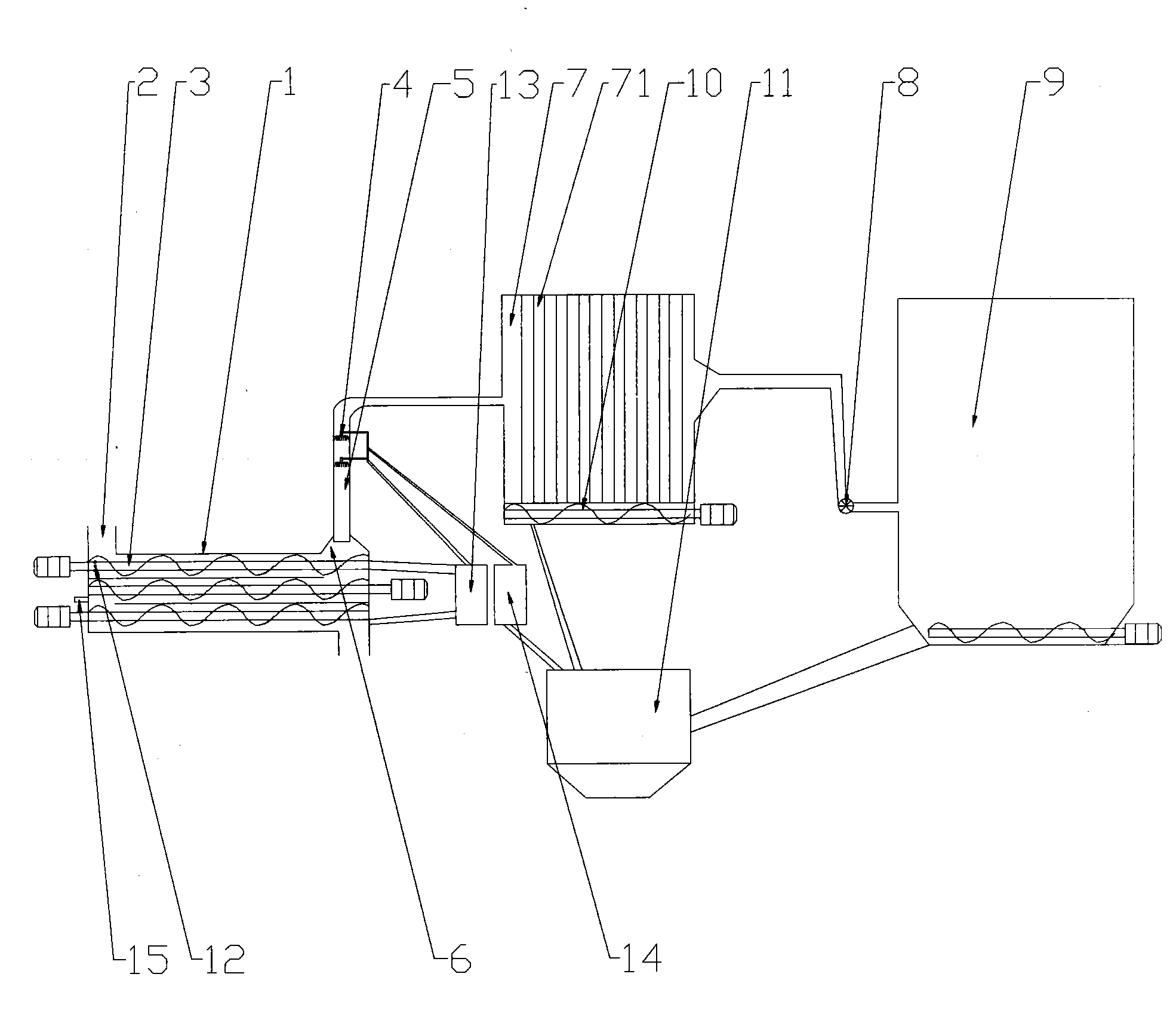

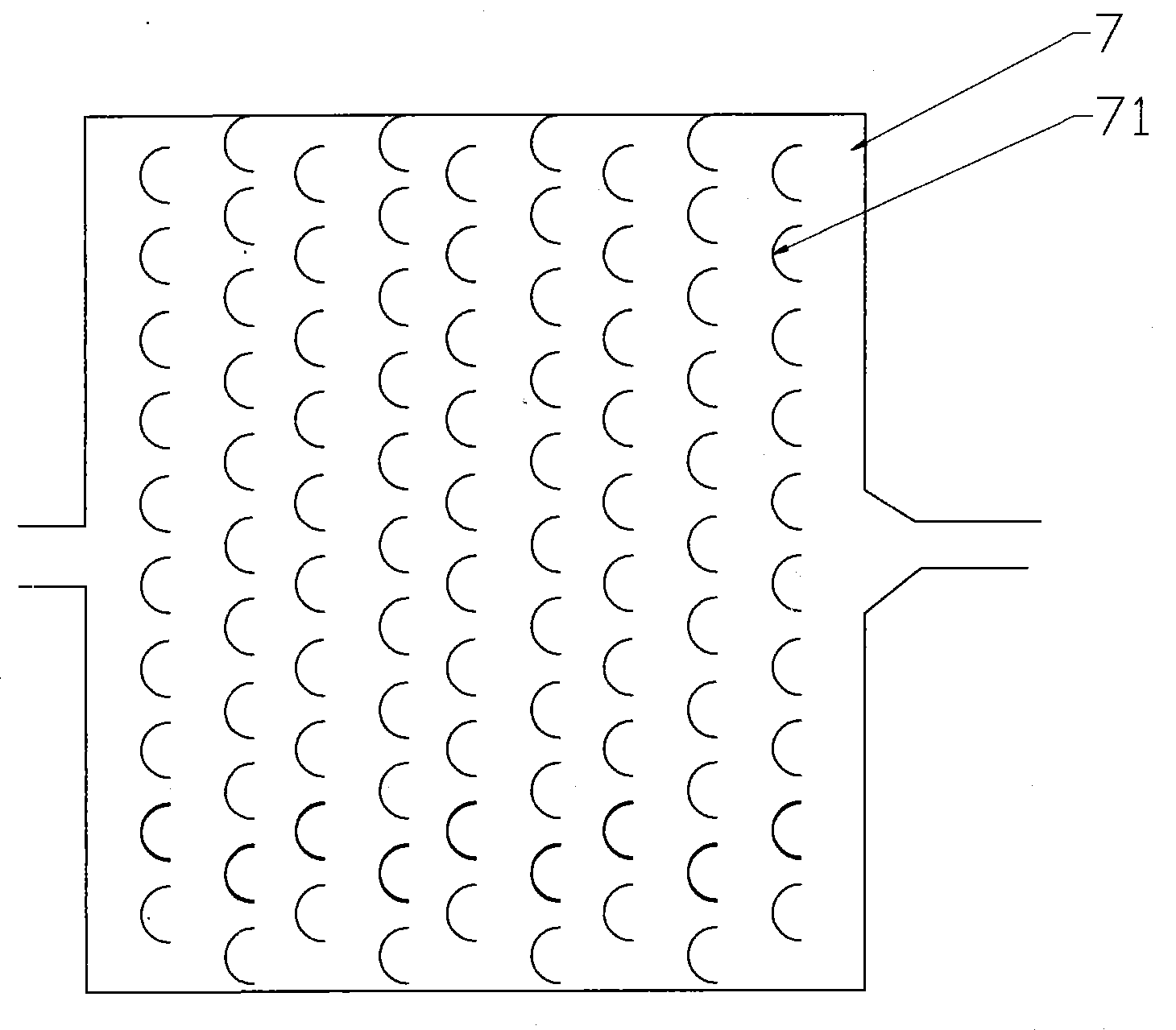

[0026] Such as figure 1 with figure 2 As shown, a calcium hydroxide production line includes a digester 1, a graded atomization device, a purifier 7, a pressure loss filter 9, a sewage processor 11, a fan 8 and a high-pressure pump 13.

[0027] The digester includes an inner layer and an outer layer, the outer layer is a water exchange layer, the water exchange layer includes a cold water inlet 15 and a hot water outlet, the inner layer is a digestion chamber, and the digestion chamber includes an upper digestion chamber arranged from top to bottom. bin, the middle digestion bin and the lower digestion bin, the upper spiral stirring shaft 3 located in the upper digestion bin is hollow, and the upper spiral stirring shaft 3 is provided with a number of water spray holes 12 at the position below the feed port 2, and the water spray holes 12 surround On the spiral stirring shaft 3, the water inlet of the high-pressure pump 13 is connected with the hot water outlet through the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com