Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Reduce the effective height" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

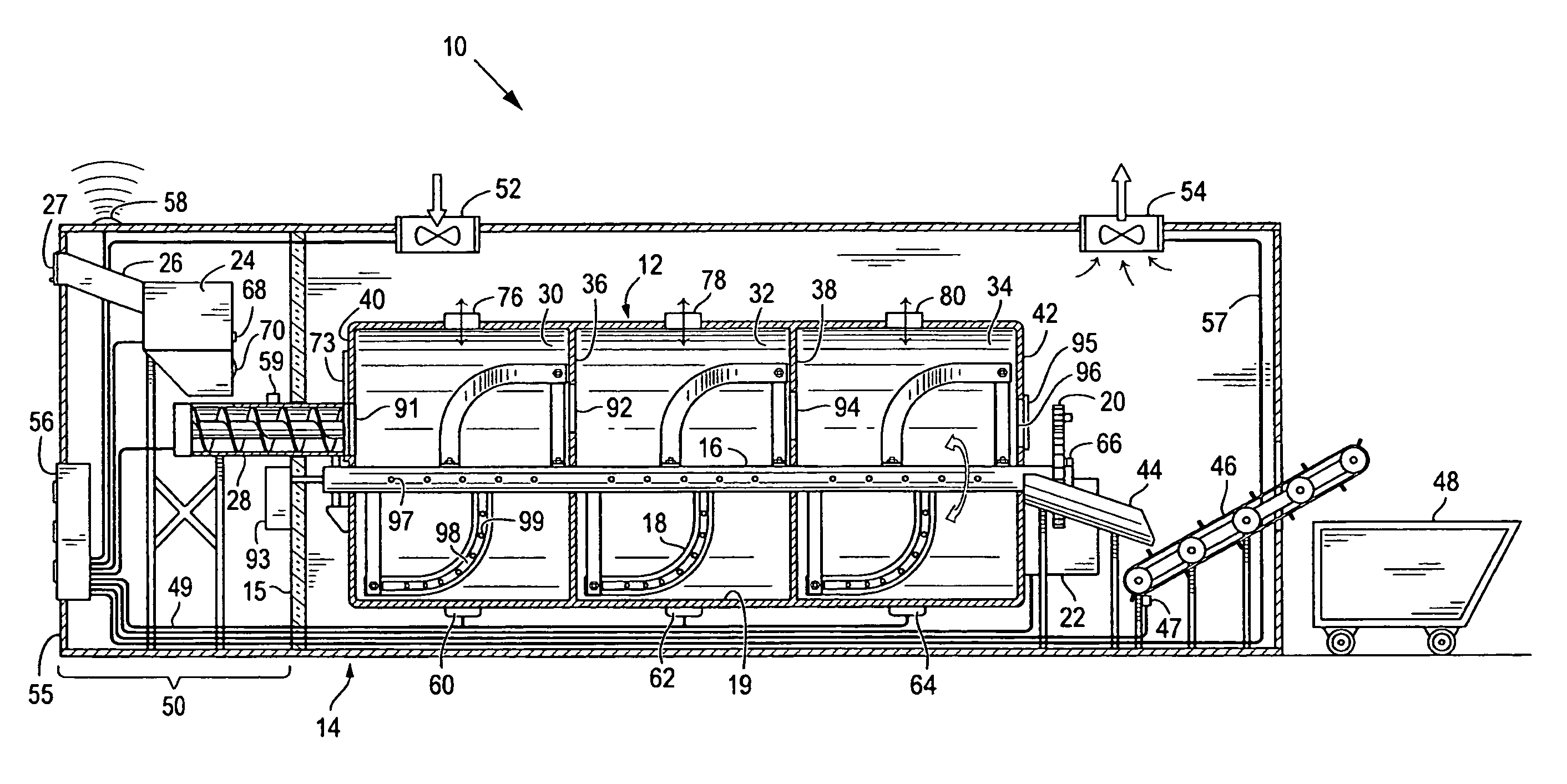

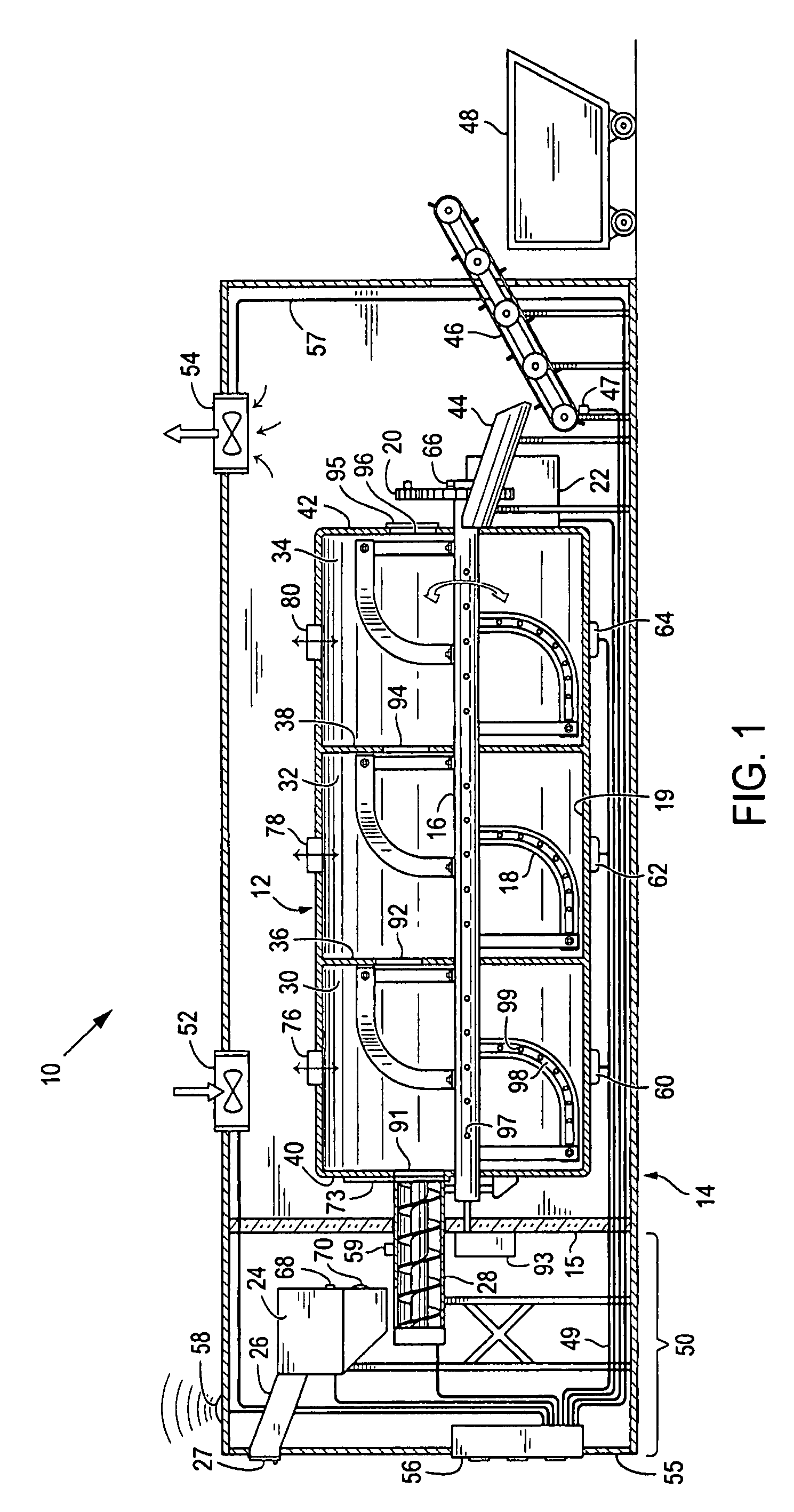

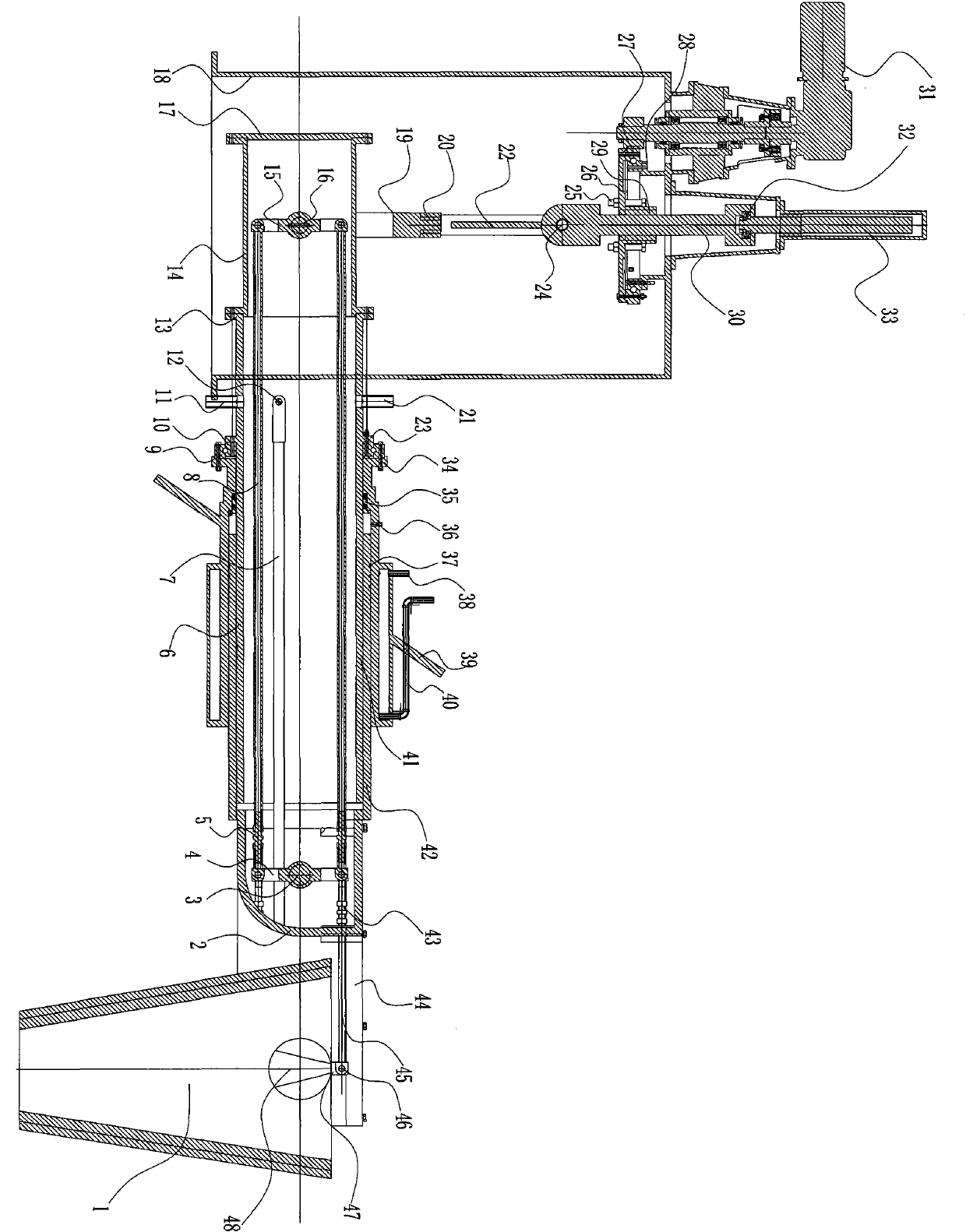

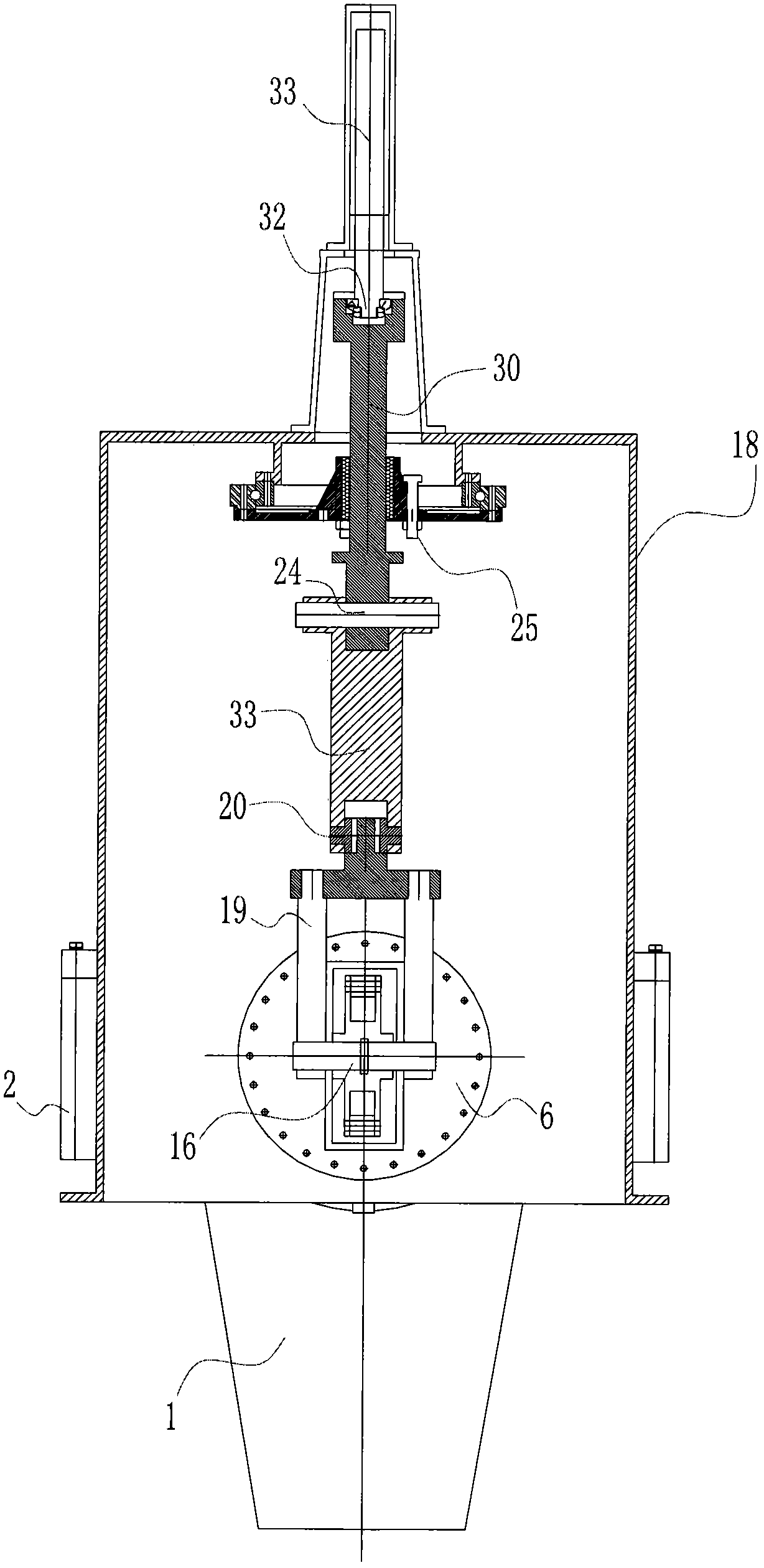

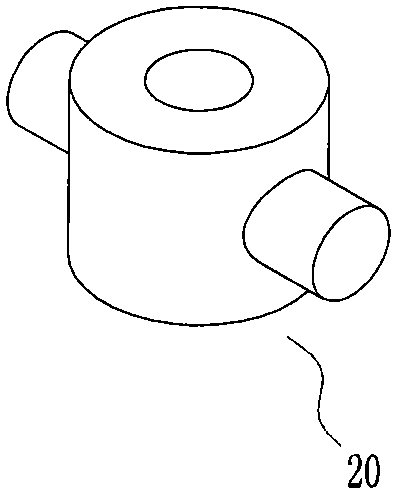

Automated composting system

InactiveUS7520457B1Easy to processReduce the effective heightBioreactor/fermenter combinationsBio-organic fraction processingProduct gasDigestion chambers

A composting system with a digestion chamber, an auger shaft with at least one mixing vane, and a power unit. The power unit can be hydraulic and can also power a shredding unit and an input conveyor system. A barrier wall can be interposed between those elements and the digestion chamber. The digestion chamber can be divided into subchambers, and sequentially lower apertures can promote a progression of organic material. A malfunction sensor can sense a malfunction of the auger shaft, the shredding unit, or another component. A malfunction report can be provided, including to a remote receiver. The report can include a determined location of the composting system and can be directed to a selected receiver based on the malfunction. Fluids, including gasses and liquids, can be introduced by a supply source in combination with apertures along the auger shaft and / or a mixing vane.

Owner:POITRAS BRIAN +1

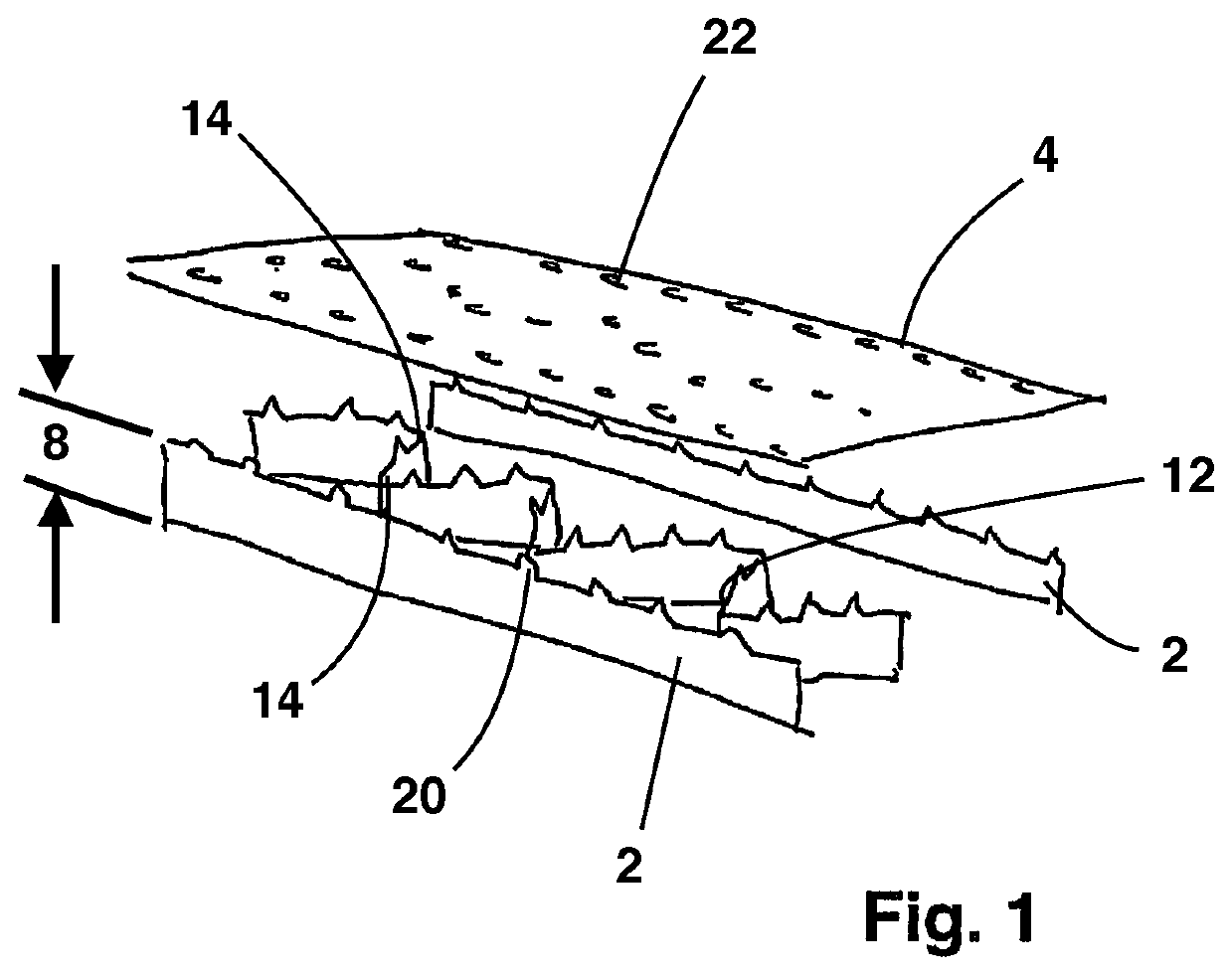

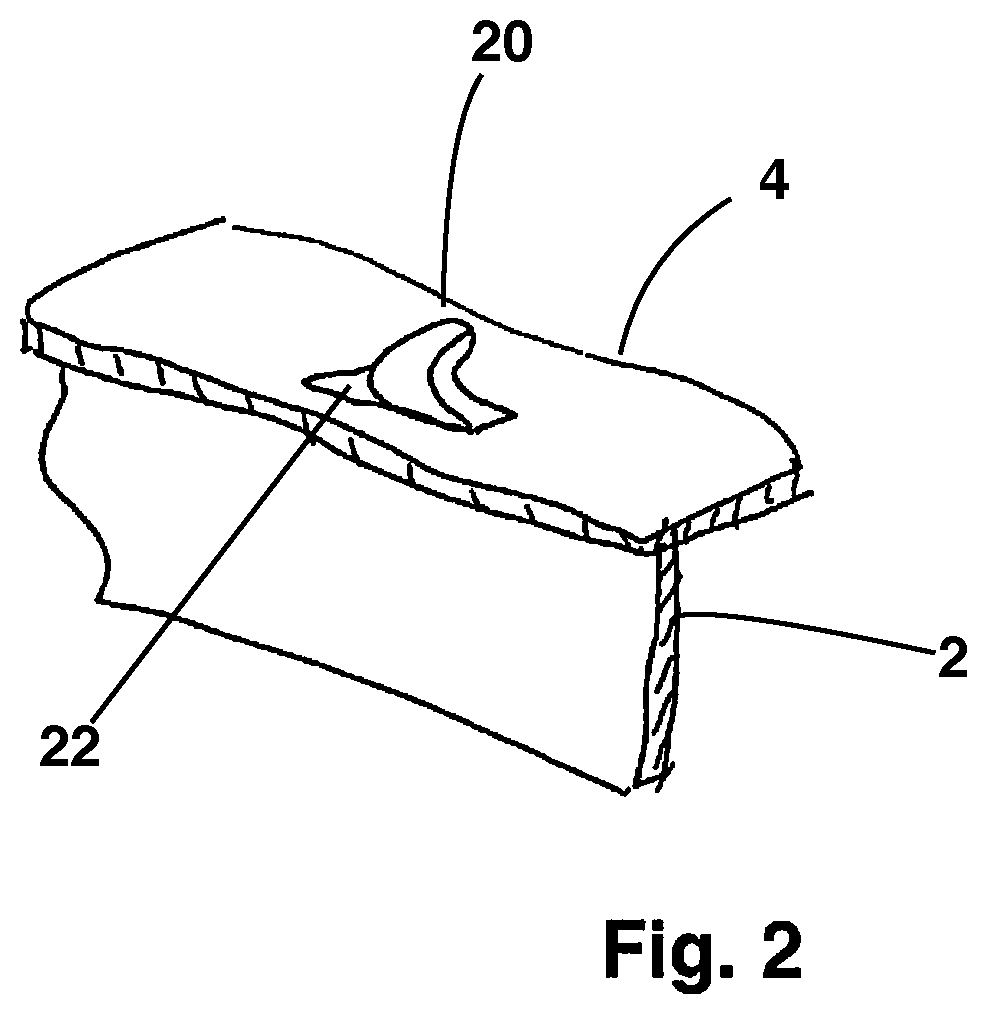

Round hexagon screw and method for its production

The invention concerns an outer hexagon round screw and a method for production of the screw. The screw cap is formed here essentially in the kind of a Torx head, with an outer hexagon round contour (5) and a flange (4) having a slope (4.1) reaching in the direction of the outer hexagon round contour (5) under an angle (alpha) thereby assuring a force engagement with a tool. The slope (4.1) of the flange (4) follows immediately to the outer hexagon round contour (5) such that the overall height (k) of the head (3) is substantially decreased, wherein at the same time the height (t1) of the outer hexagon round contour (5) assures a reliable force engagement. The production of the flange (4) and of the outer hexagon round contour (5) is performed either by scraping with a scraping tool or by head flattening or upset compressing or compression molding, wherein additionally a socket is formed in the head region. (FIG. 1).

Owner:ESKA SACHSISCHE SCHRAUBENWERKE

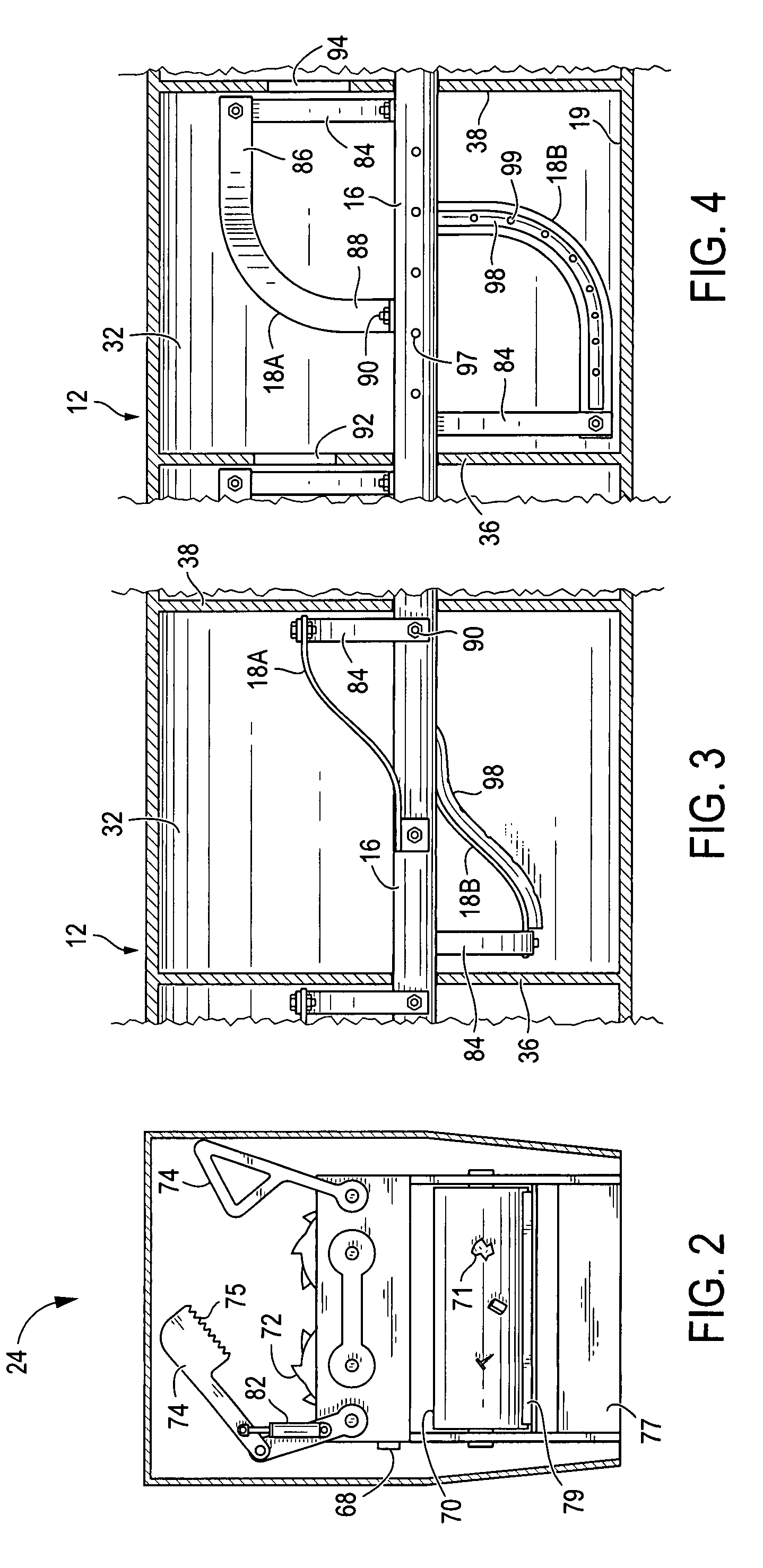

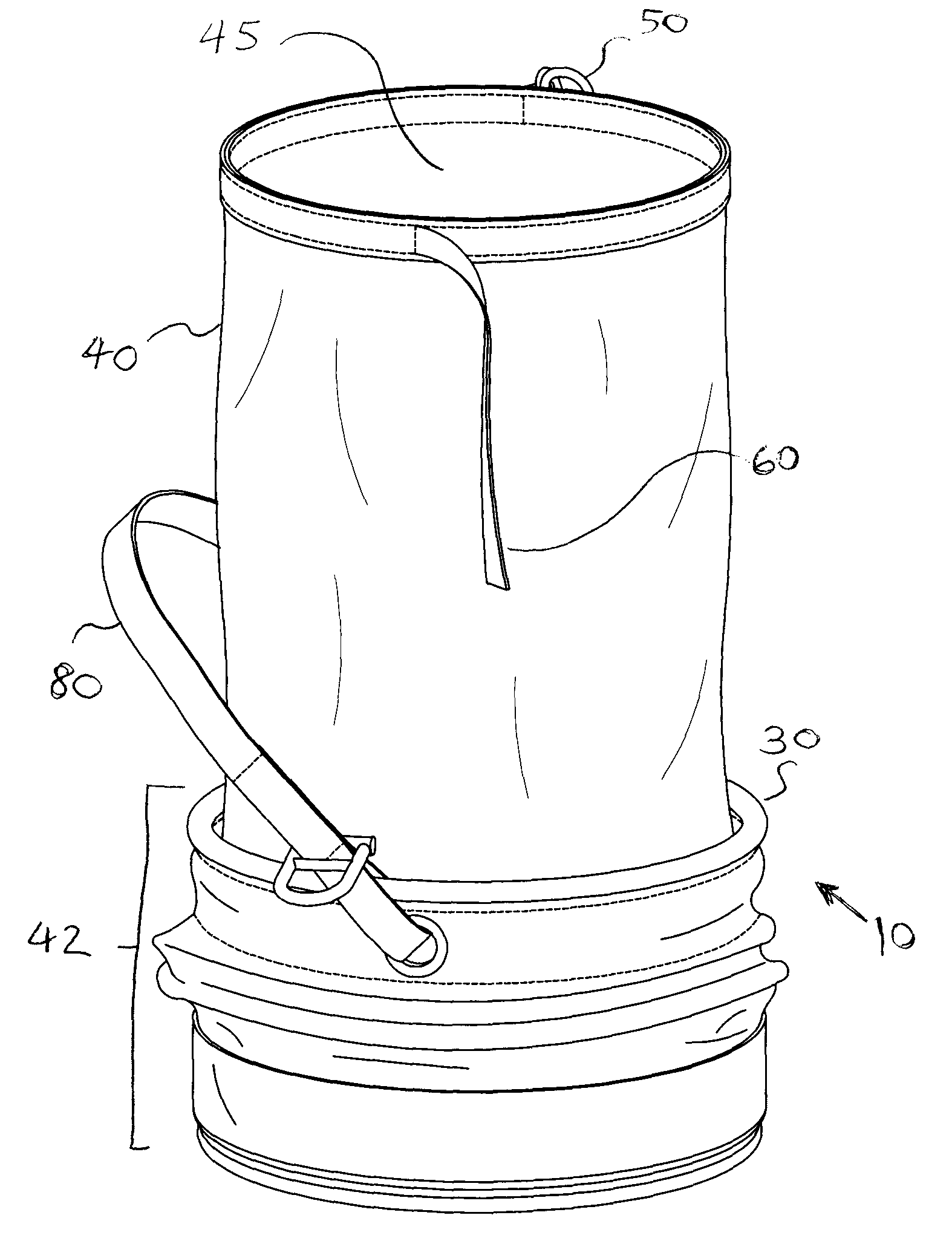

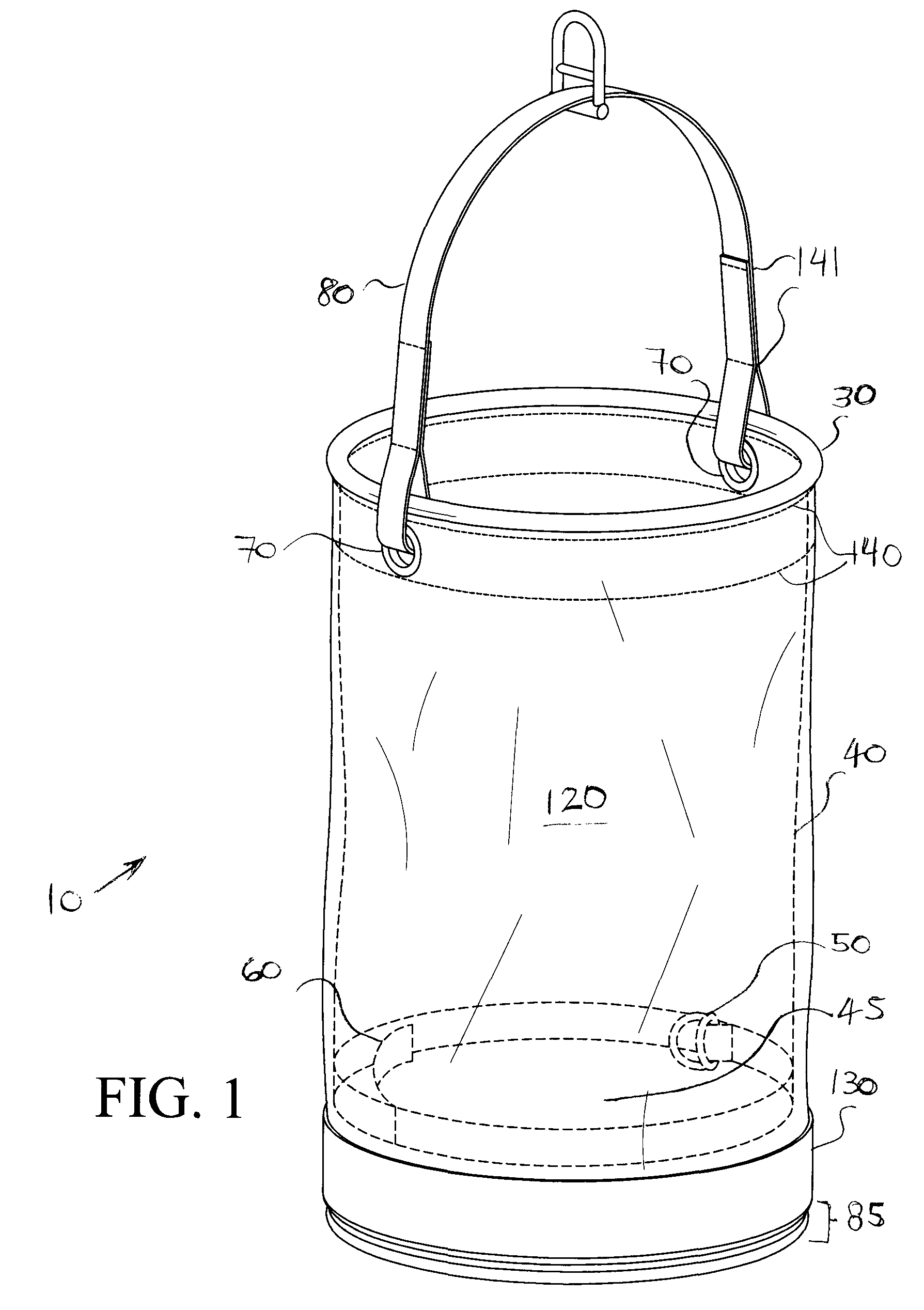

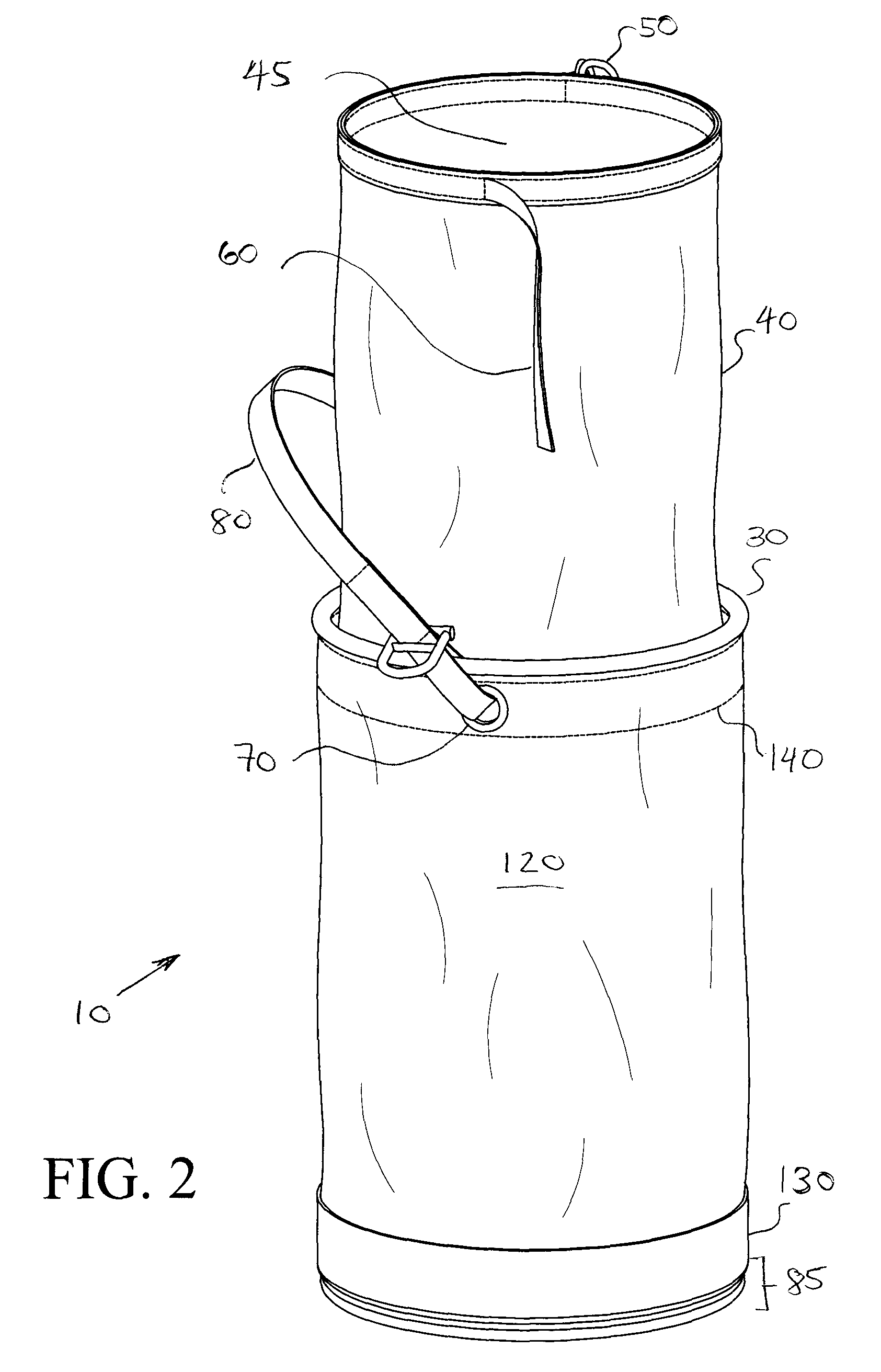

Tool Bucket

InactiveUS20090250470A1Increase the effective heightReduce the effective heightLarge containersOther accessoriesEngineeringMechanical engineering

Owner:MERRICK BRYCE +1

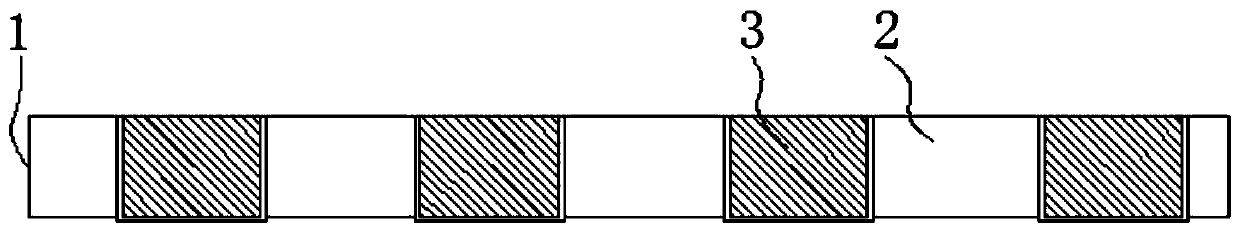

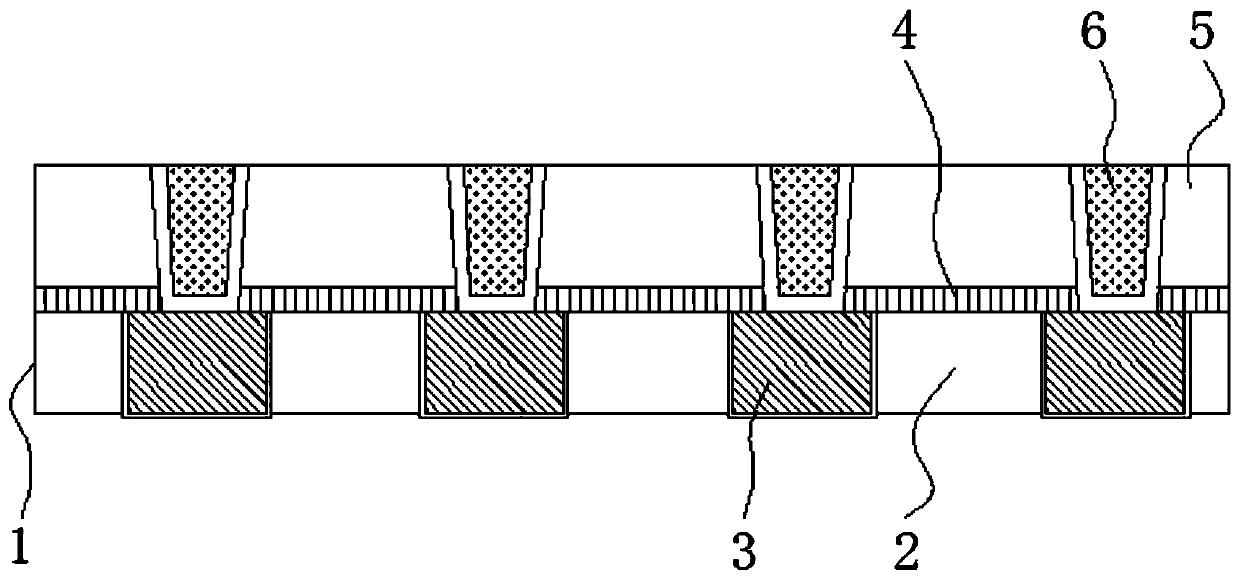

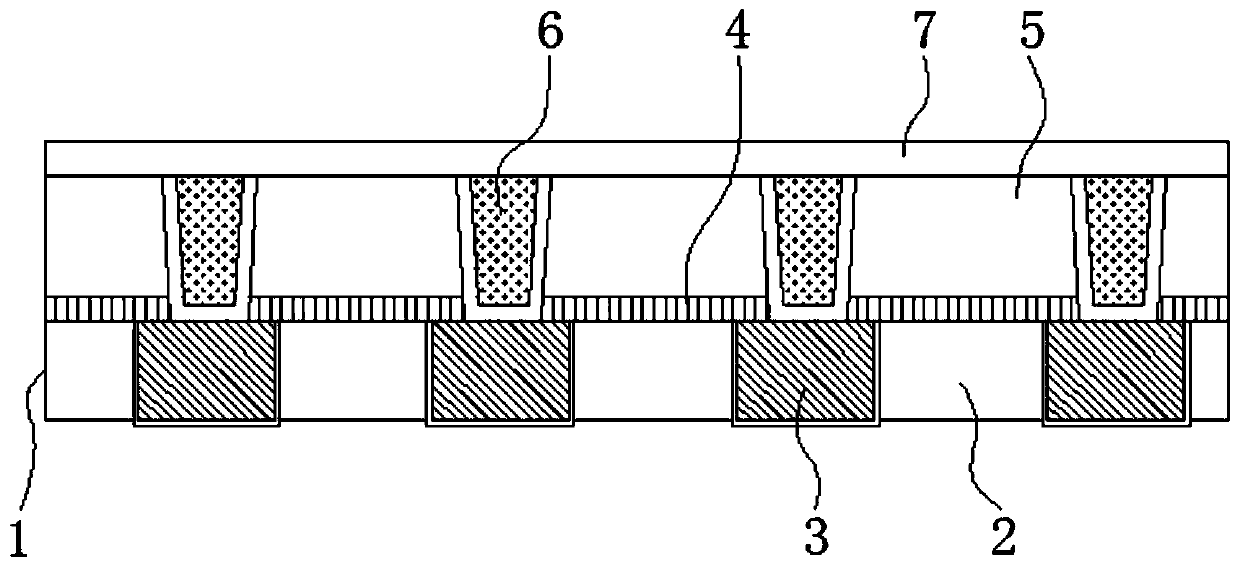

Method for preparing magnetic tunnel junction unit array

ActiveCN110112288AImprove electrical performanceImprove yieldMagnetic-field-controlled resistorsDigital storageCMOSEngineering

The invention discloses a method for preparing a magnetic tunnel junction unit array. The method concretely comprises the steps of: providing a CMOS substrate with a metal connection line Mx (x is notless than 1) with a polished surface; on the CMOS substrate with the metal connection line Mx with the polished surface, manufacturing a BEV (Bottom Electrode Via); manufacturing a bottom electrode contact / bottom electrode on the BEV; depositing a magnetic tunnel junction multilayer film and a top electrode on the flattened bottom electrode, graphically defining a magnetic tunnel junction pattern, etching the top electrode, the magnetic tunnel junction and the bottom electrode metal, and finally depositing an insulating covering layer around the etched magnetic tunnel junction. The method forpreparing the magnetic tunnel junction unit array manufactures a W BEV, a non-Cu bottom electrode contact / bottom electrode, a magnetic tunnel junction and a top electrode on a CMOS metal connecting line with the polished surface, and allows BEV (Bottom Electrode Via), BEC (Bottom Electrode Contact), BE (Bottom Electrode), MTJ (Magnetic Tunnel Junction) and TE (Top Electrode) to be sequentially and upwards overlapped and aligned.

Owner:SHANGHAI CIYU INFORMATION TECH

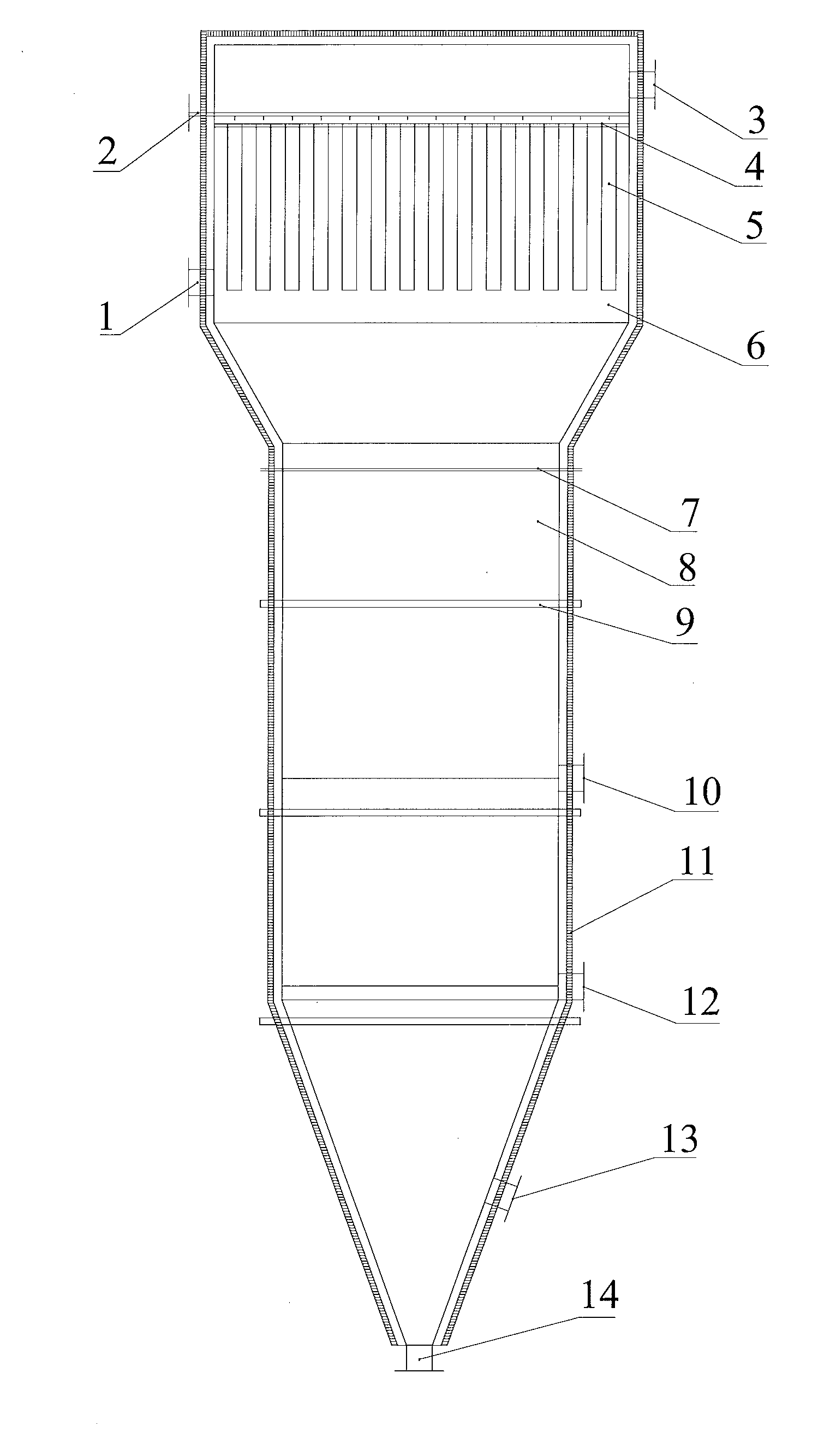

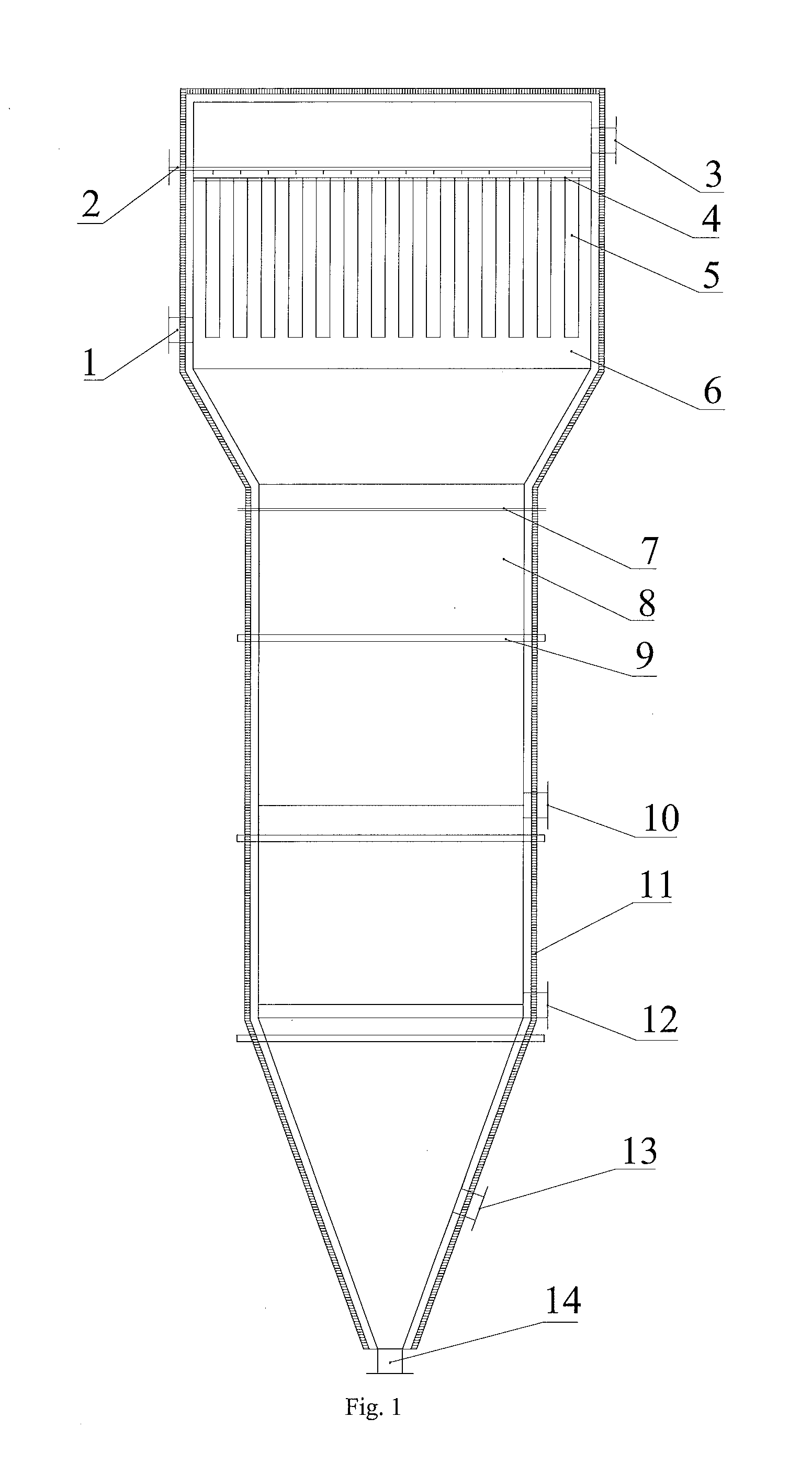

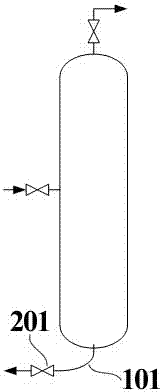

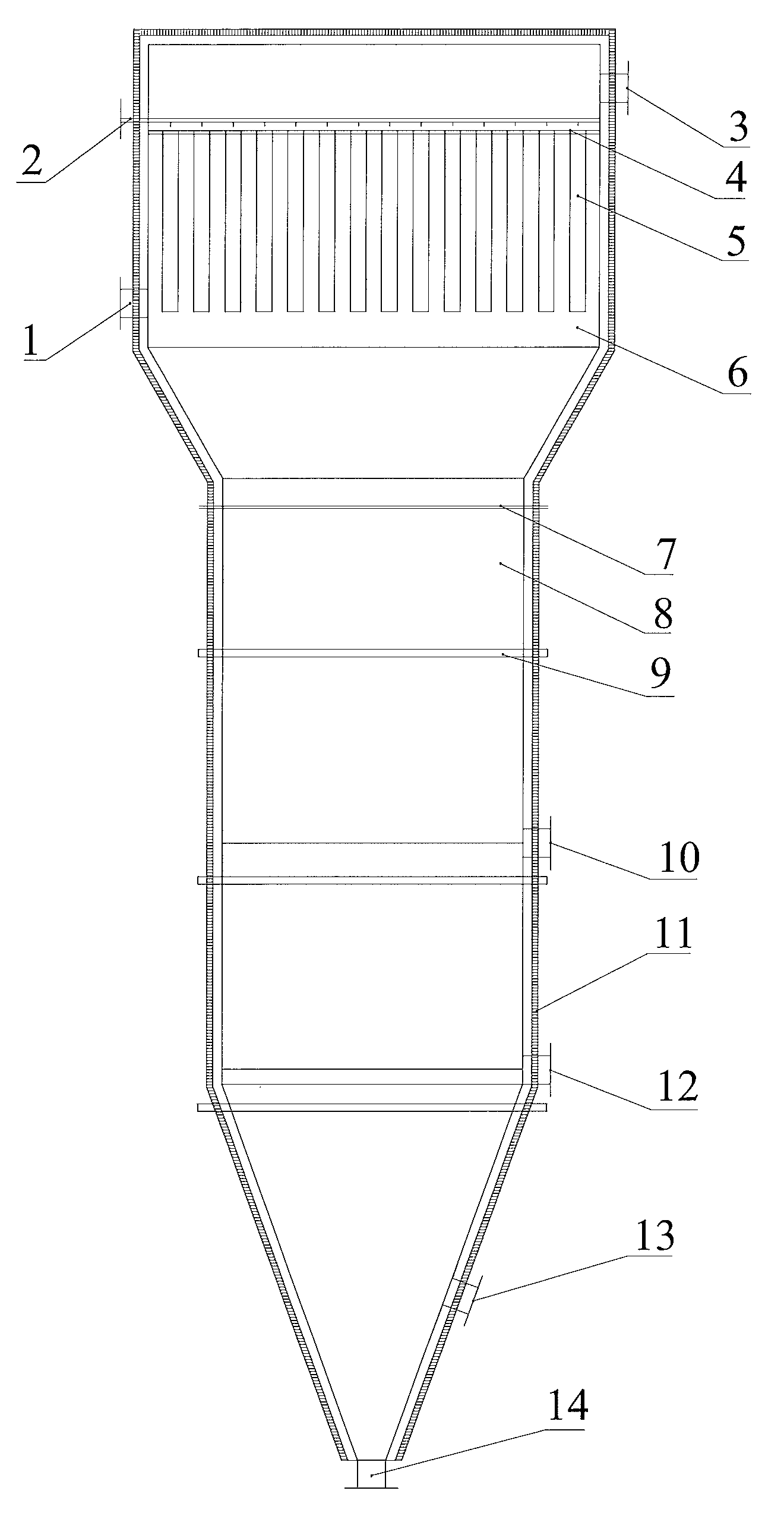

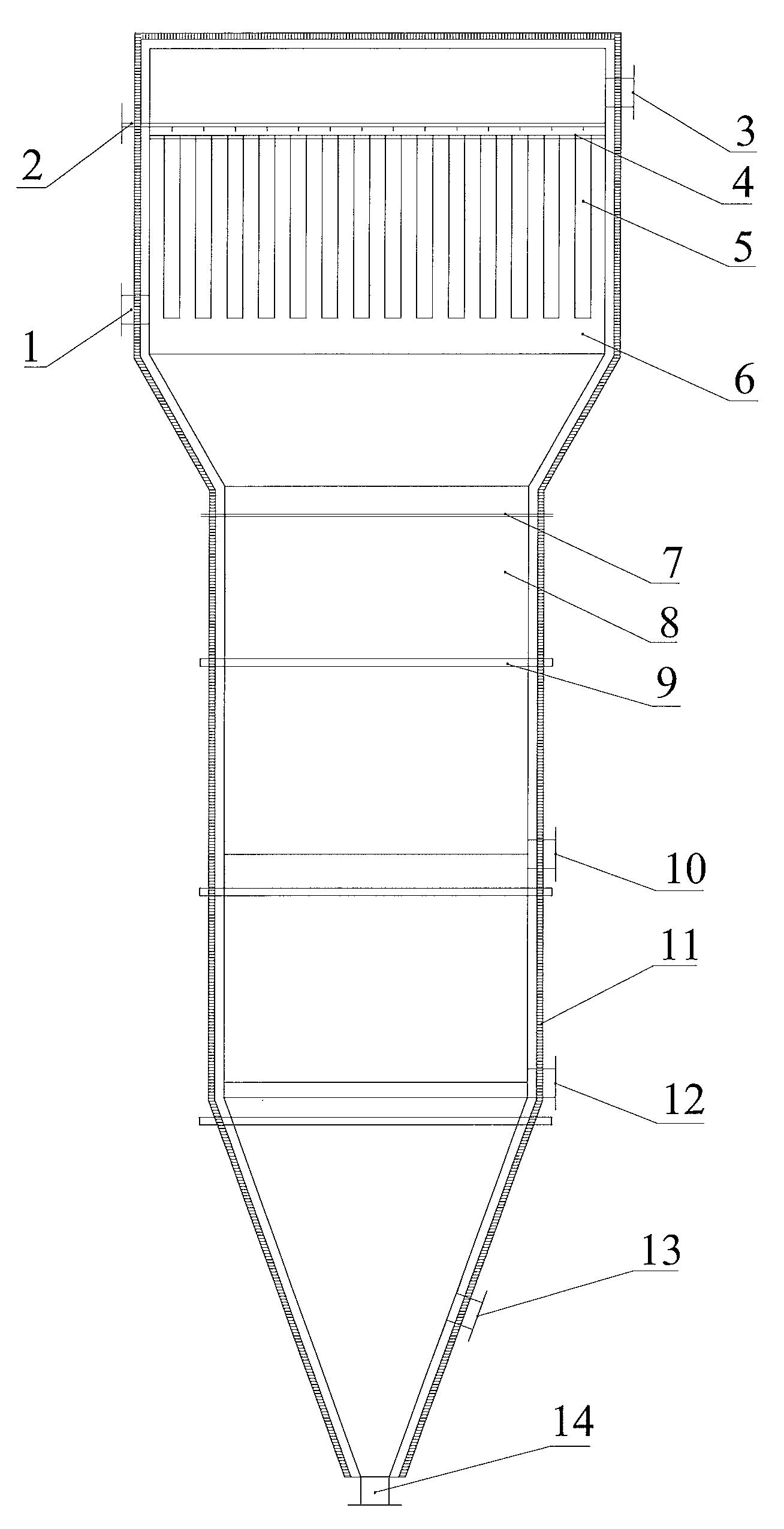

Deacidification process and apparatus thereof

ActiveUS20150044128A1Improve the immunityLarge fluctuationsGas treatmentSilicaProcess engineeringAtmosphere

A deacidification apparatus and a deacidification process using the apparatus are disclosed. The deacidification apparatus includes a deacidification furnace, of which a furnace upper section, a furnace middle section and a furnace lower section are provided in upper, middle and lower portions respectively, wherein a gas-solid mixture inlet (1), a exhaust outlet (3) and a filtered air port (2) are provided on the furnace upper section, a product outlet (13) is provided on the furnace lower section, the upper portion of the deacidification is mounted with a filter (5) to which the gas-solid mixture inlet (1), the exhaust outlet (2) and the filtered air port (3) are connected, the filtered air port (2) is connected with a gas pulse device and a vacuum device by a three-way connecting device, and the exhaust outlet (3) is connected with atmosphere or connected with the vacuum device.

Owner:GUANGZHOU GBS HIGH TECH & IND

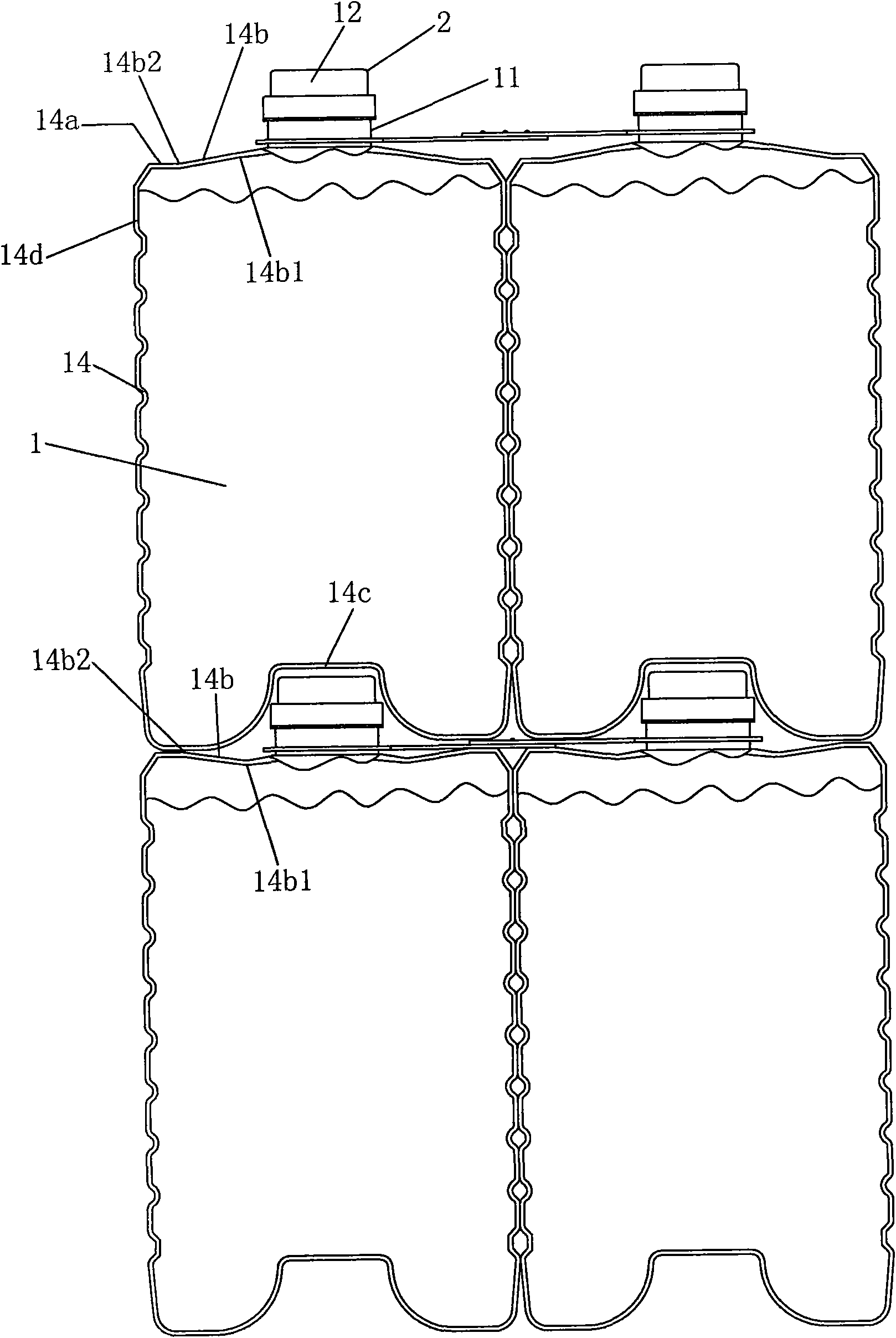

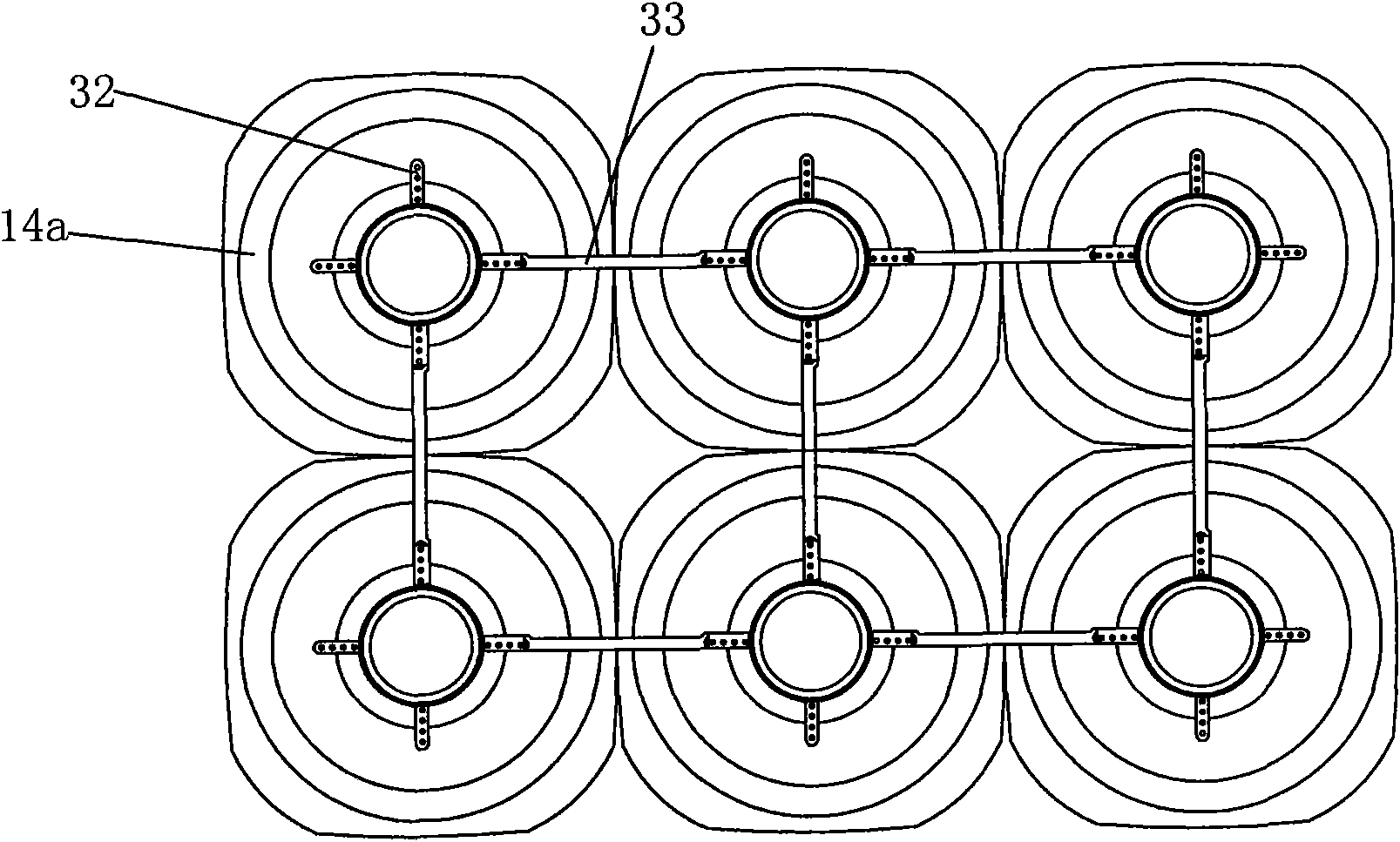

Stacking method of PET (Polyethylene Terephthalate) packaging bottles

InactiveCN102040023AReduce the effective heightIncrease profitRigid containersPolyethylene terephthalateDie casting

The invention discloses a stacking method of bottles made of a PET (Polyethylene Terephthalate) material through blowing, drawing and casting, which is characterized in that a bottle neck and a bottle mouth are die-cast; a bottle body is blown and drawn, an inclined surface and a horizontal surface are formed at the top of the bottle body, a bend exists between the inclined surface and the horizontal surface, and a fold is reserved on the inclined surface; a bottle bottom is provided with a concave part; a bottle is fixed through a connecting piece to form a basic stacking unit; the stacking unit is placed on the other stacking unit, so that the concave part of each bottle of the stacking unit on an upper layer can be correspondingly sleeved in the cover and the neck of each bottle of the stacking unit on a lower layer; and each bottle of the stacking unit on the lower layer is pressed, so that the inclined surface is overturned and inwards sunk at the fold and also bent at the bend, a shoulder is formed outside the bend of each bottle, and the bottom of each bottle of the stacking unit on the upper layer is respectively supported by each shoulder. The method disclosed by the invention solves the problems on stacking stability and safety of PET bottles, and the warehousing or transportation cost is lowered.

Owner:徐楚雄

Preparation process of cast steel insulated feeder covering agent

InactiveCN105537524AWith feverThermal insulationFoundry mouldsFoundry coresDual effectThermal insulation

The invention discloses a preparation process of a cast steel insulated feeder covering agent. The cast steel feeder covering agent is prepared by 4-8 wt% of aluminum powder, 25-354 wt% of coal ash, 15-18 wt% of perlite, 14-18 wt% of acidized graphite, 10-15 wt% of carbon powder, 2-3 wt% of triggering agent and 8-22 wt% of other materials. The prepared covering agent has dual effects of heating and thermal insulation, can obviously improve the feeder feeding capacity, reduces effective feeder height, saves molten steel, improves the casting quality and yield, and is an effective cast steel feeder covering agent worthy of popularization and application.

Owner:李玲

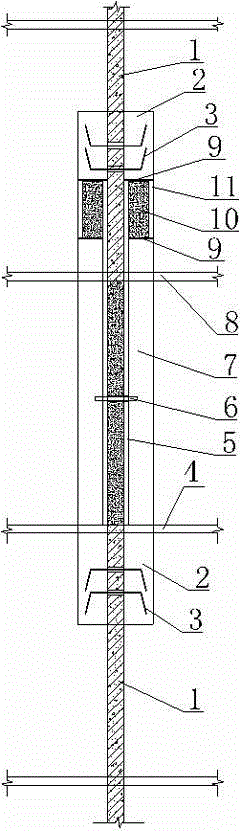

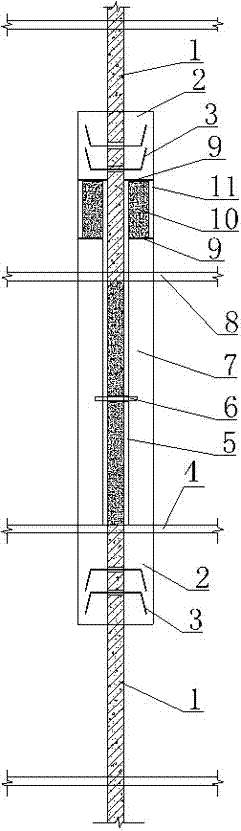

Replacement unloading structure and construction method for vertical component

The invention discloses a replacement unloading structure and construction method for a vertical component. The replacement unloading structure comprises support components fixedly mounted at the upper end and the lower end of the replaced vertical component; unloading columns positioned on the two sides of the vertical component are arranged between the support components; an unloading jack is arranged between the unloading columns and the support component at the upper end. According to the replacement unloading structure disclosed by the invention, the two support components are arranged on the upper and lower sides of the component required to be replaced, then the unloading columns and the unloading jack are arranged, and the vertical component is used as a benchmark, loads required to be unloaded are transmitted to the vertical component through the upper support component, the unloading jack, the unloading columns and the lower support component; compared with a conventional replacement technology, the replacement unloading structure has the advantages that the occupied space is less, original space can be rapidly recovered after replacement, the construction period is shortened, the cost is reduced greatly, and obvious social benefits and economic benefits are realized.

Owner:SICHUAN INSITITUTE OF BUILDING RES

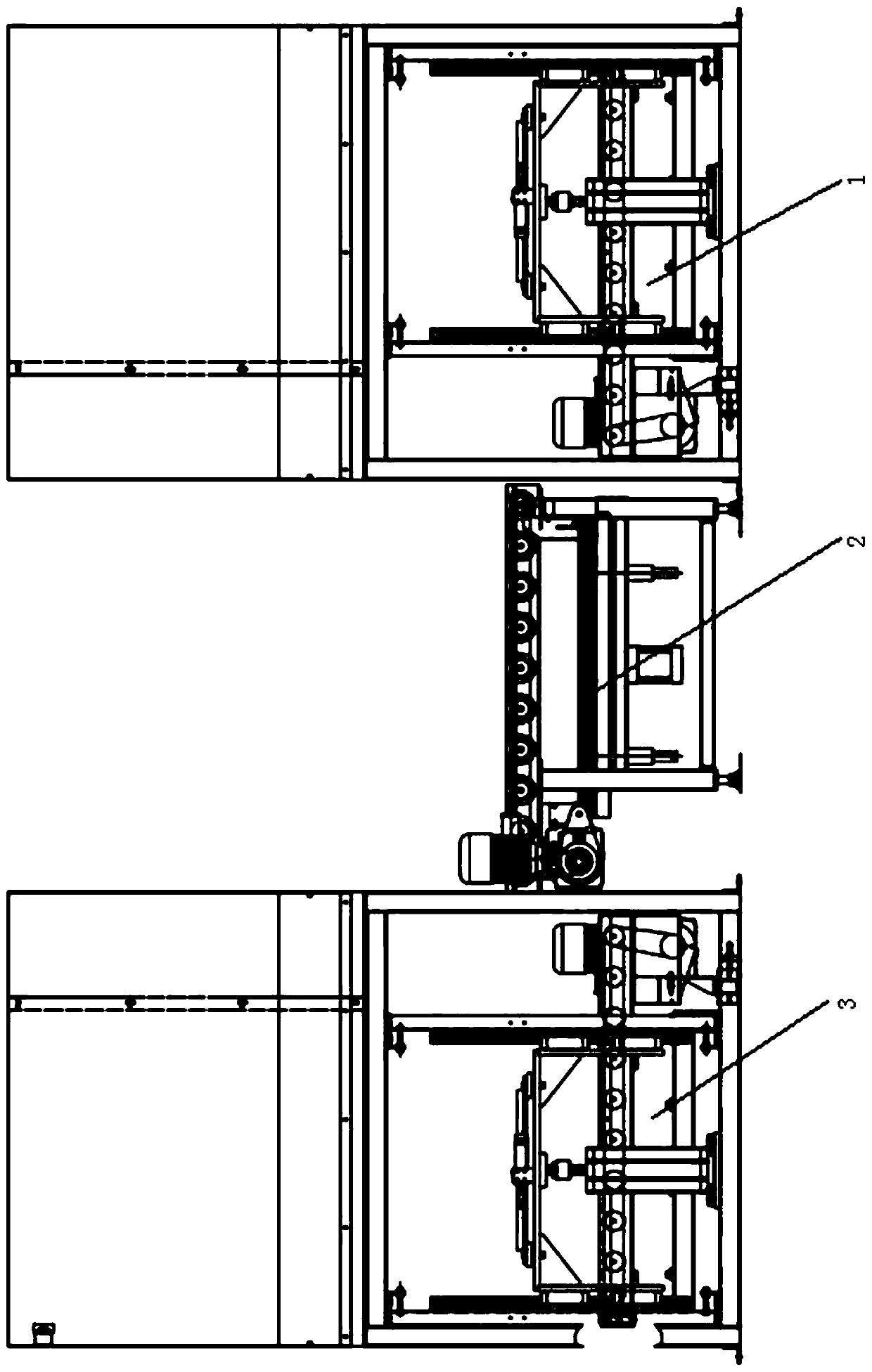

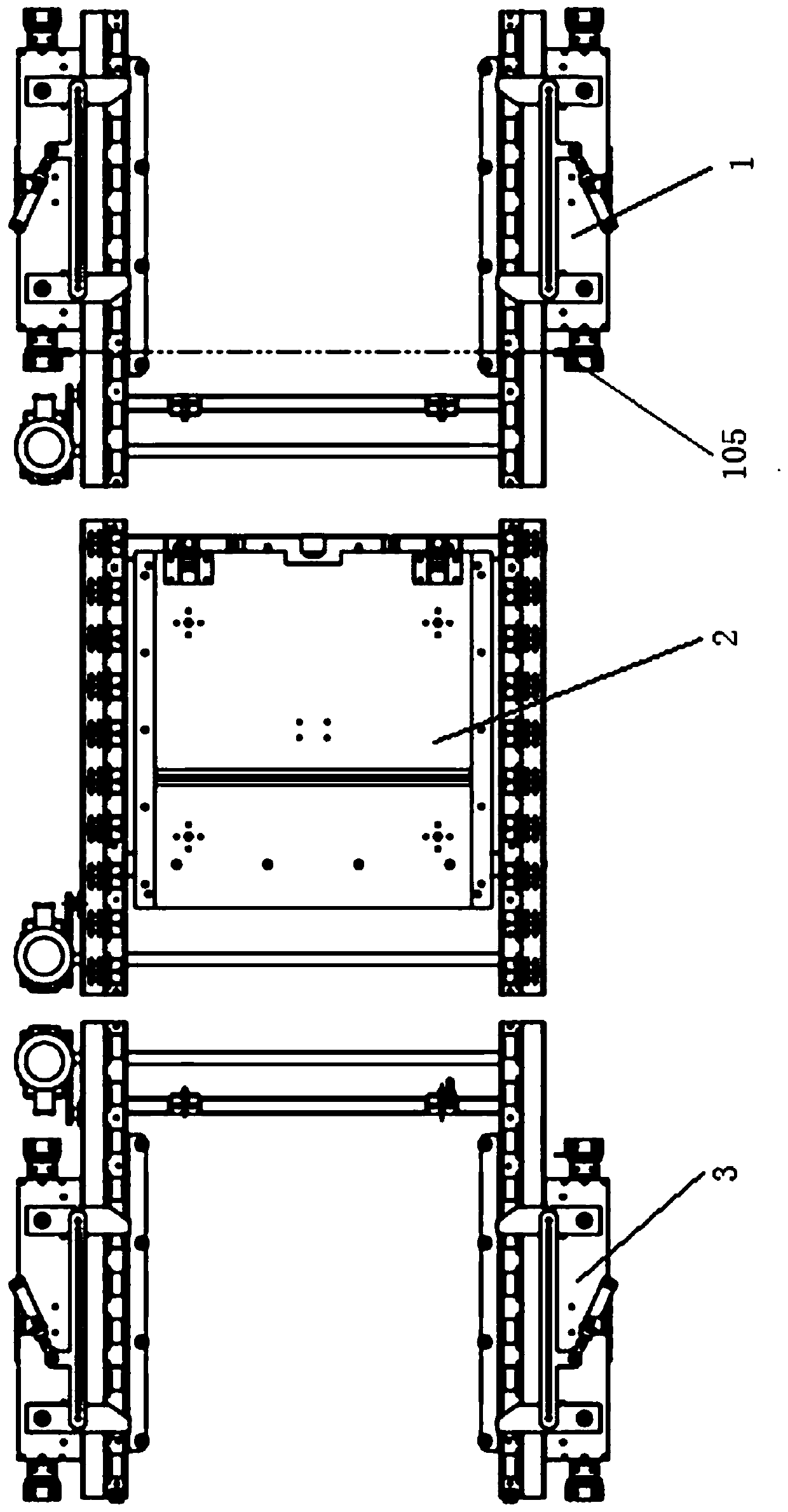

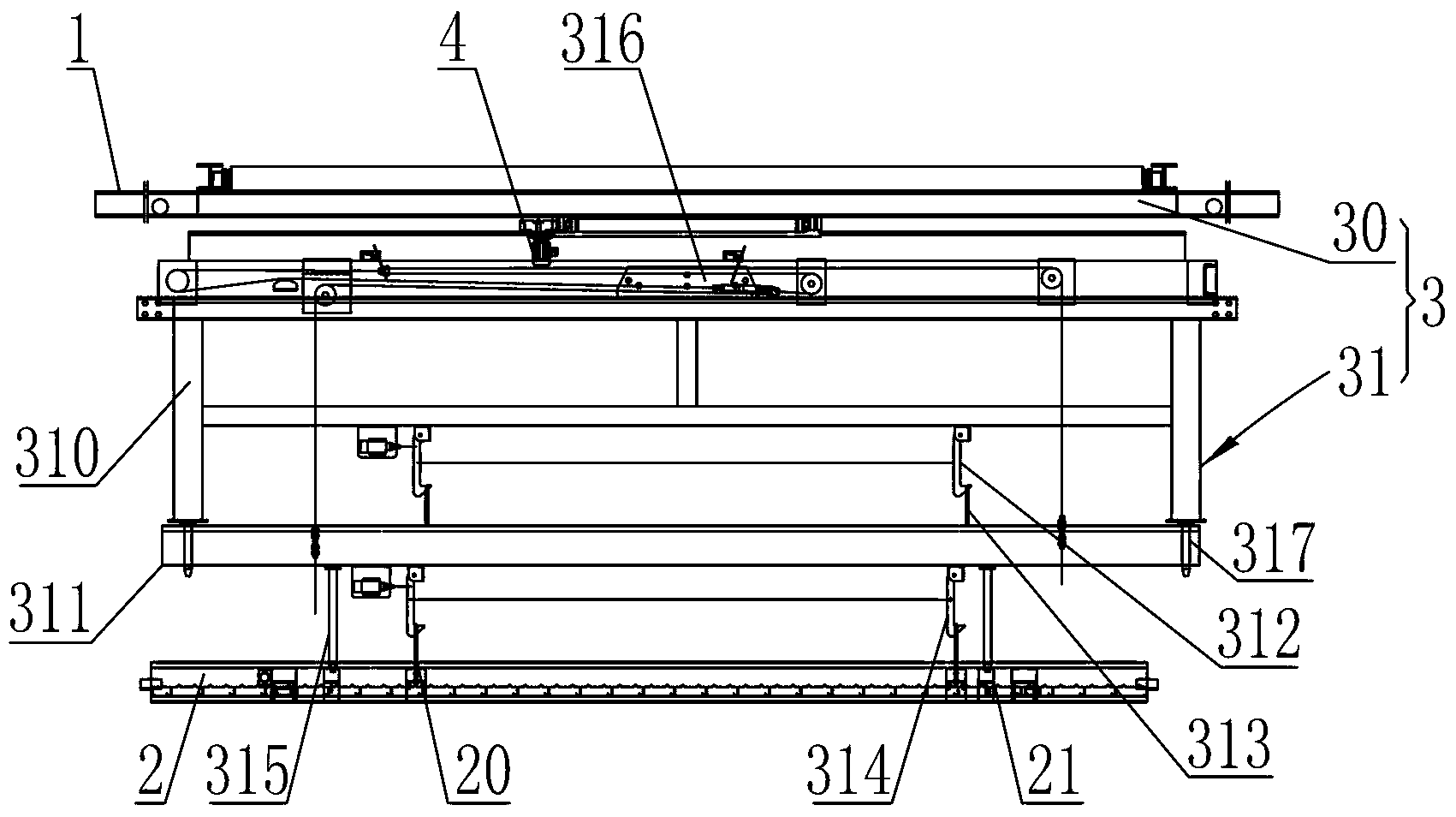

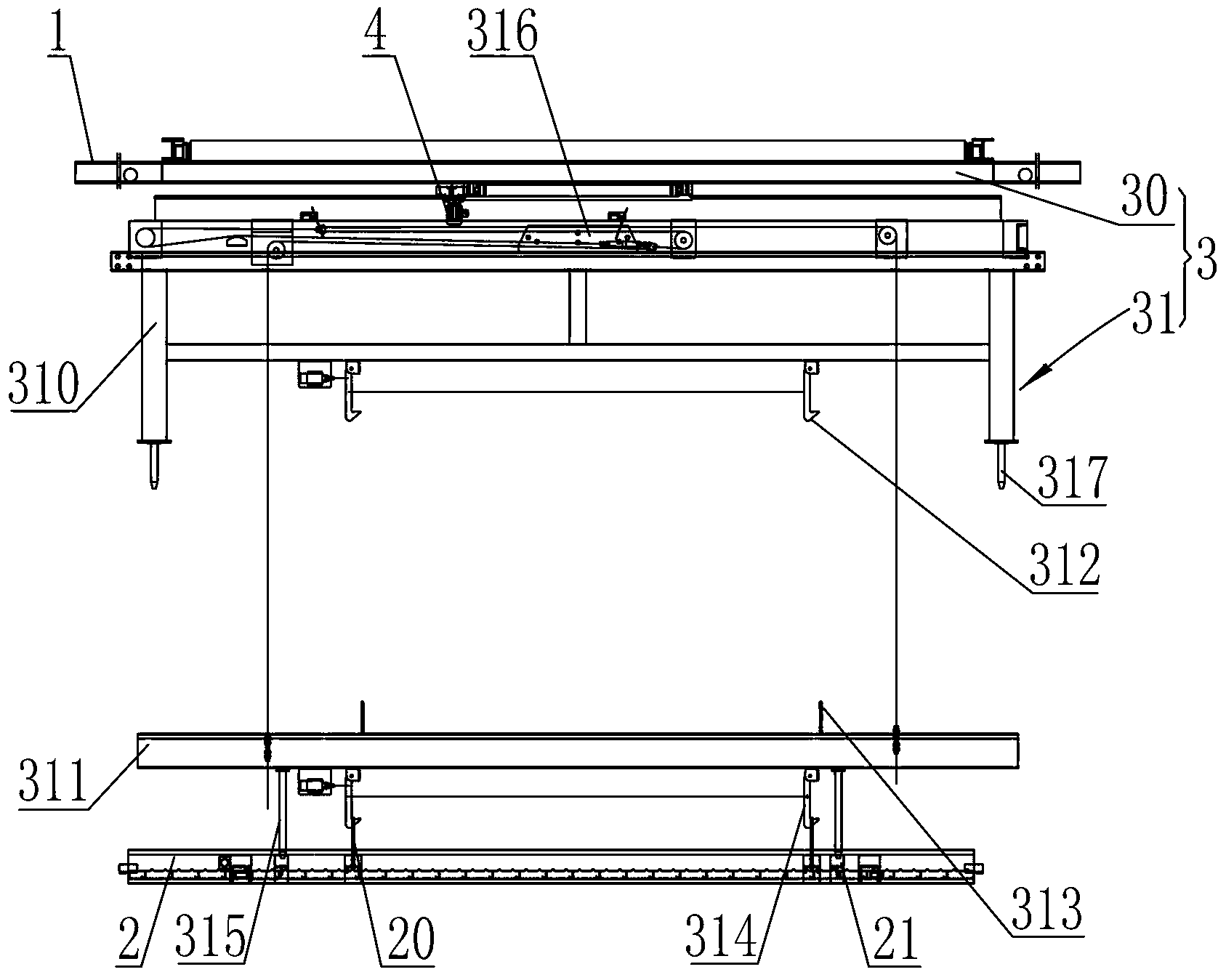

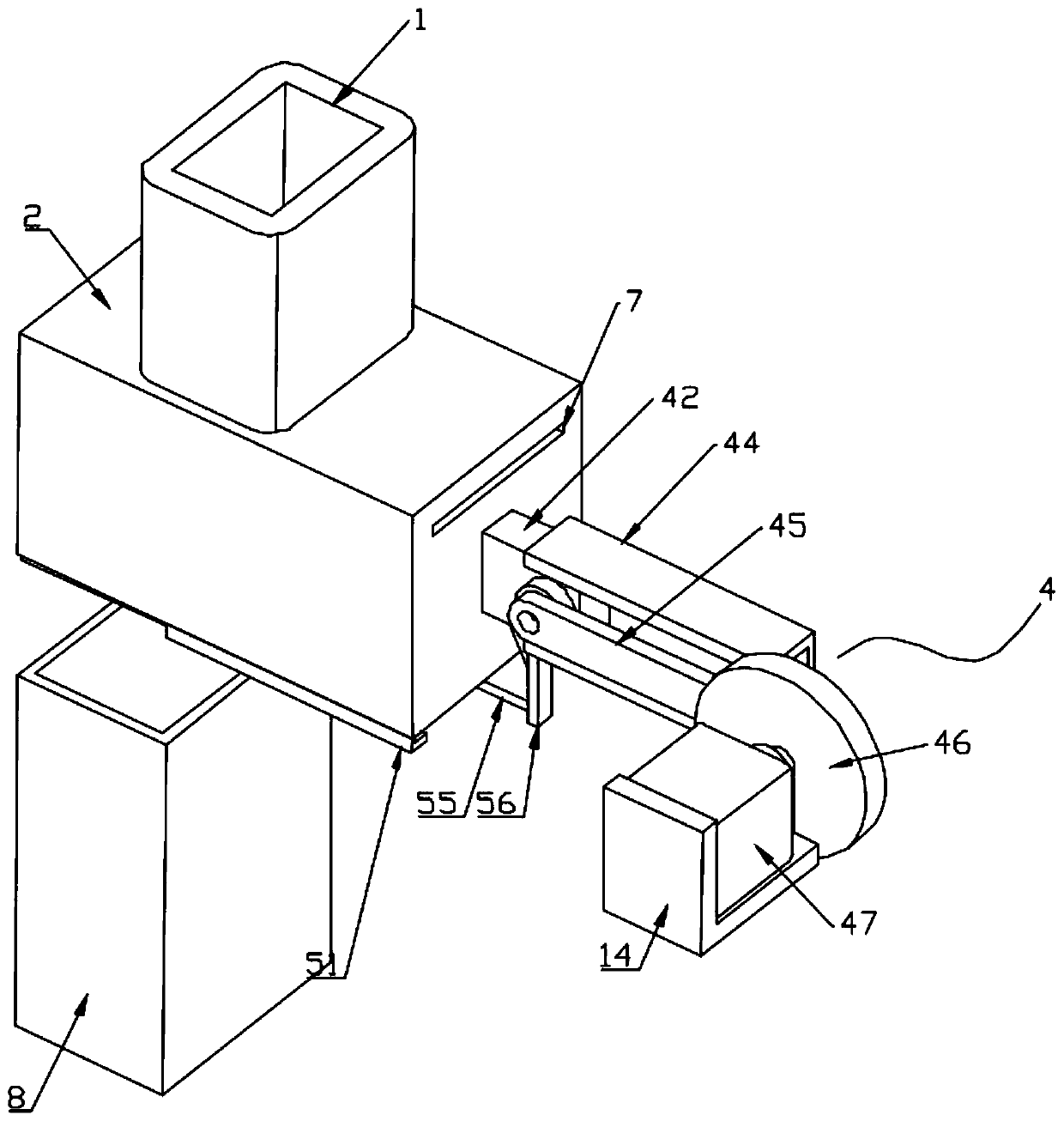

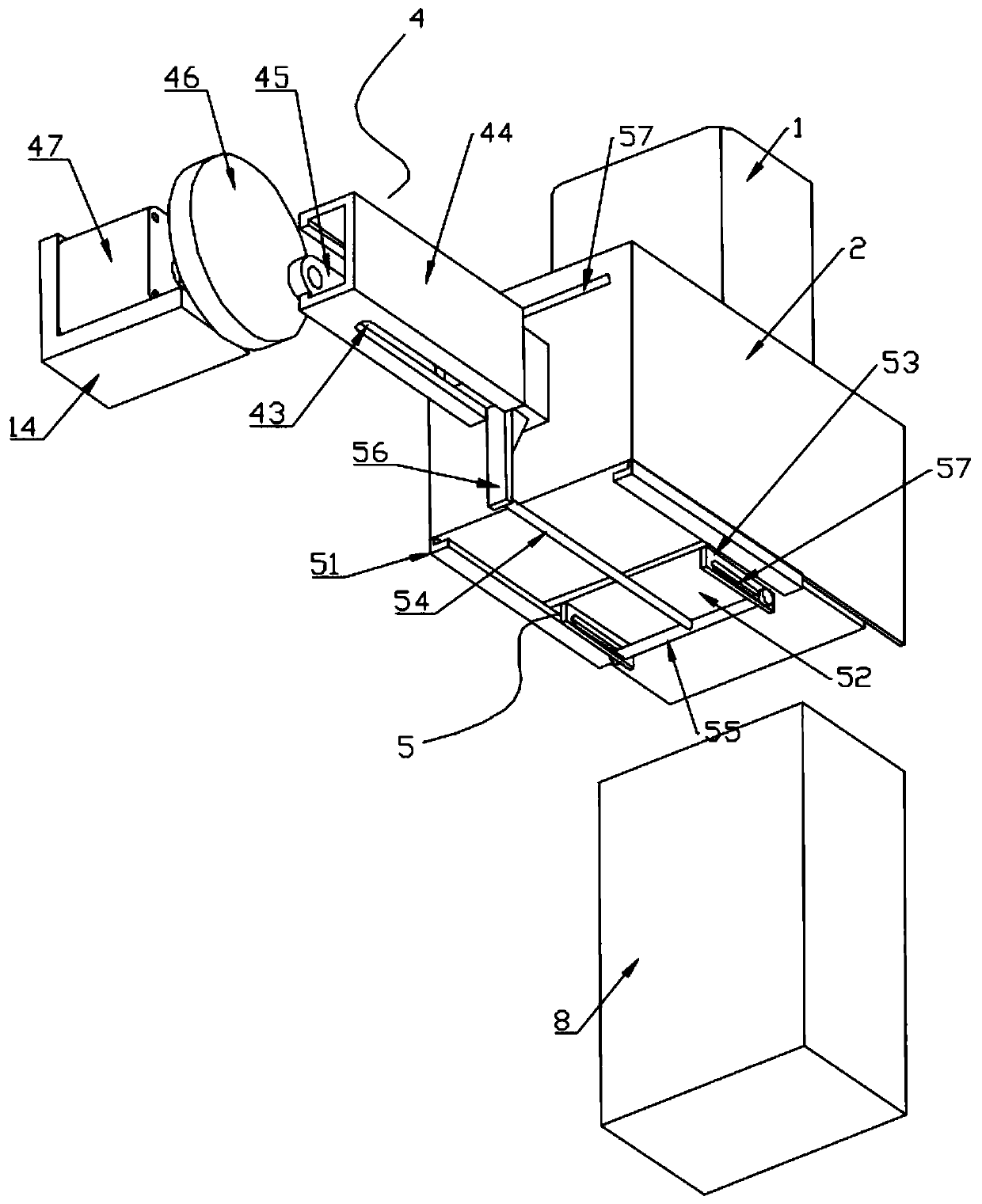

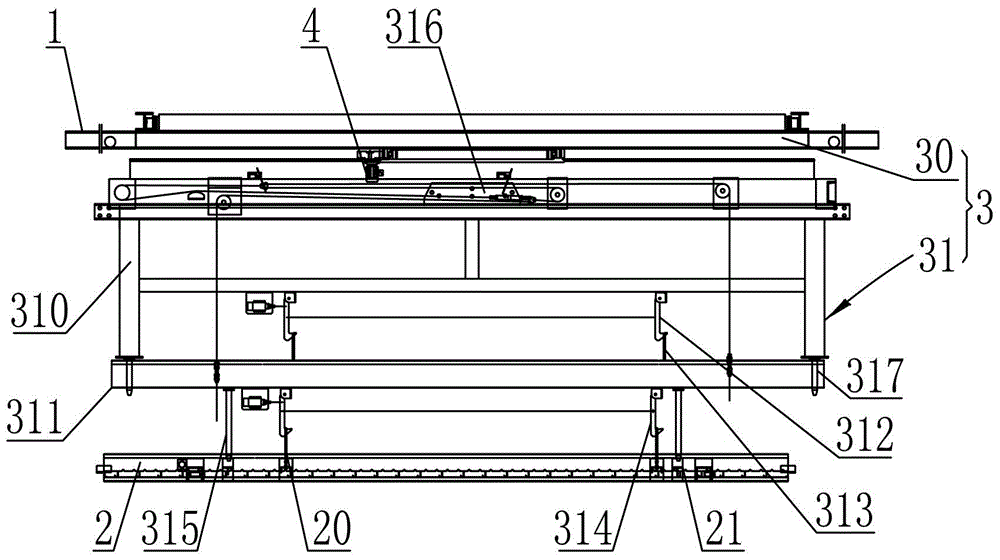

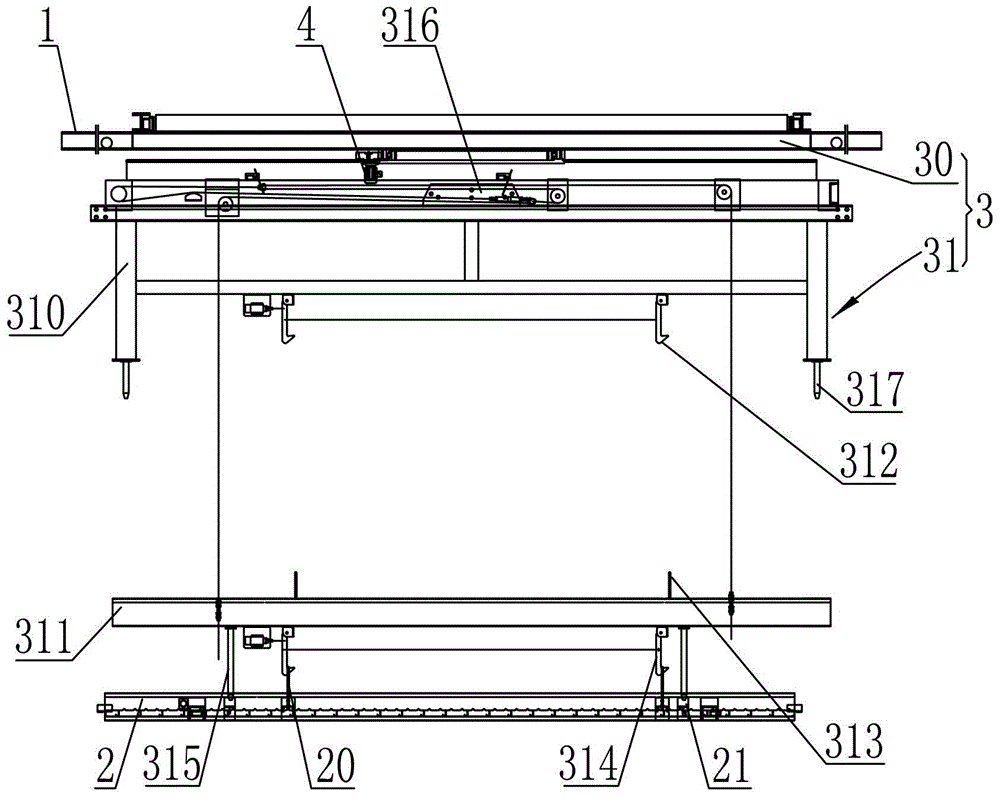

Unstacking and stacking machine

ActiveCN109720883AEasy in and outWide range of applicationsStacking articlesDe-stacking articlesTelescopic cylinderSprocket

The invention relates to an unstacking and stacking machine which solves the technical problems of inconvenient feeding and discharging, low unstacking and stacking efficiency, narrow application range, incapability of cooperating with a robot to realize intelligent feeding and discharging, and large volume of an existing unstacking and stacking machine. The technical scheme is as follows: the unstacking and stacking machine comprises a transmission positioning mechanism as well as an unstacking mechanism and a stacking mechanism which are respectively arranged at the inlet and outlet of the transmission positioning mechanism; the unstacking mechanism comprises two groups of frames which are symmetrically arranged, two groups of lifting mechanisms which are respectively arranged in the twogroups of frames, first conveying mechanisms which are arranged in the two groups of lifting mechanisms and lug telescopic mechanisms which are respectively arranged at the tops of the two groups oflifting mechanisms and are symmetrically arranged; the ends, close to the transmission positioning mechanism, of the two frames are connected with each other through a cross beam; the first conveyingmechanisms comprise first motors and two groups of sprocket chain assemblies; the lug telescopic mechanisms comprise telescopic cylinders, T-shaped connecting plates, two lug plates and cylinder supports; and the stacking mechanism and the unstacking mechanism have the same structure and opposite working process.

Owner:SHAANXI AEROSPACE ELECTROMECHANICAL ENVIRONMENTAL ENG DESIGNING INST CO LTD

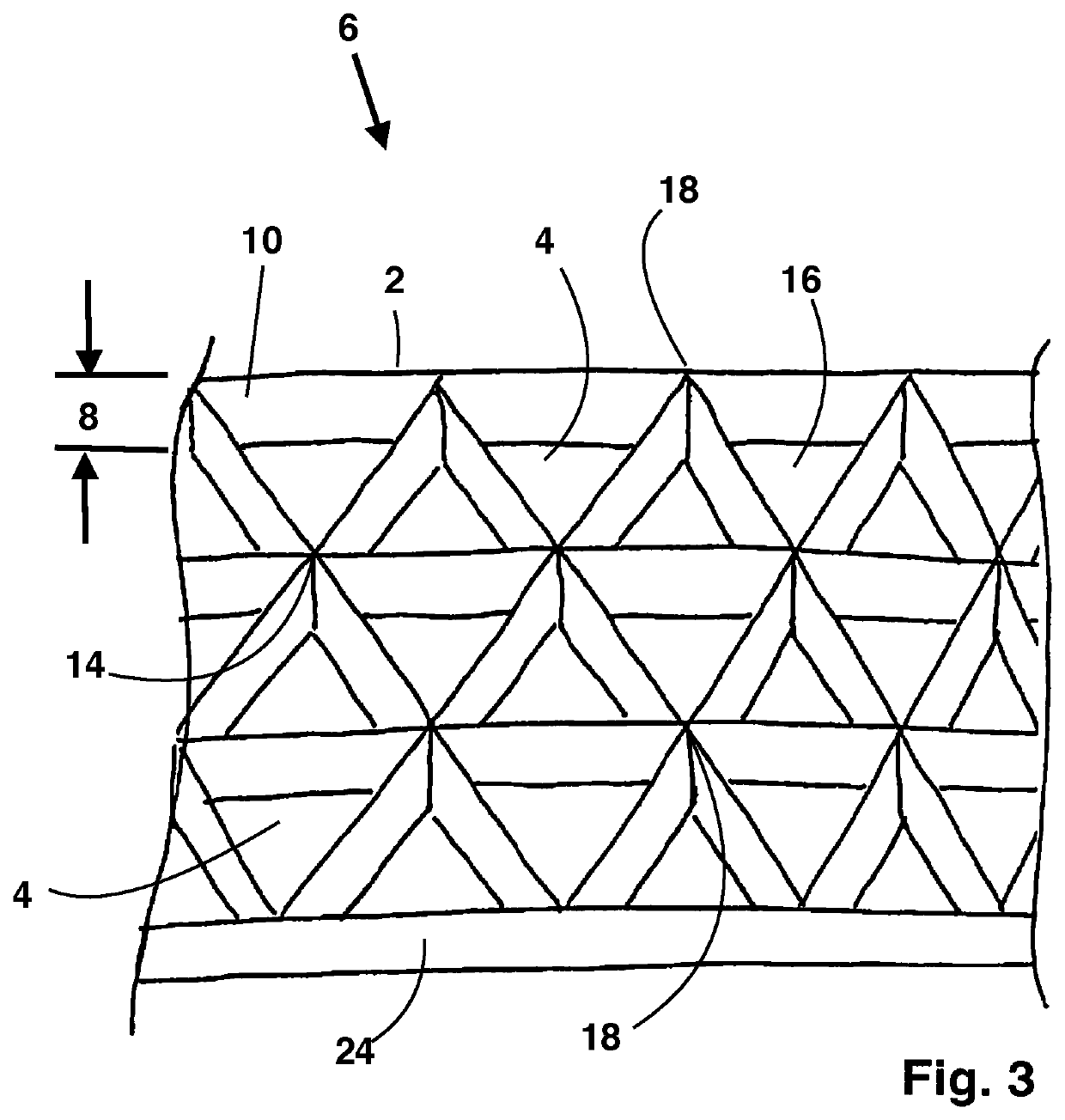

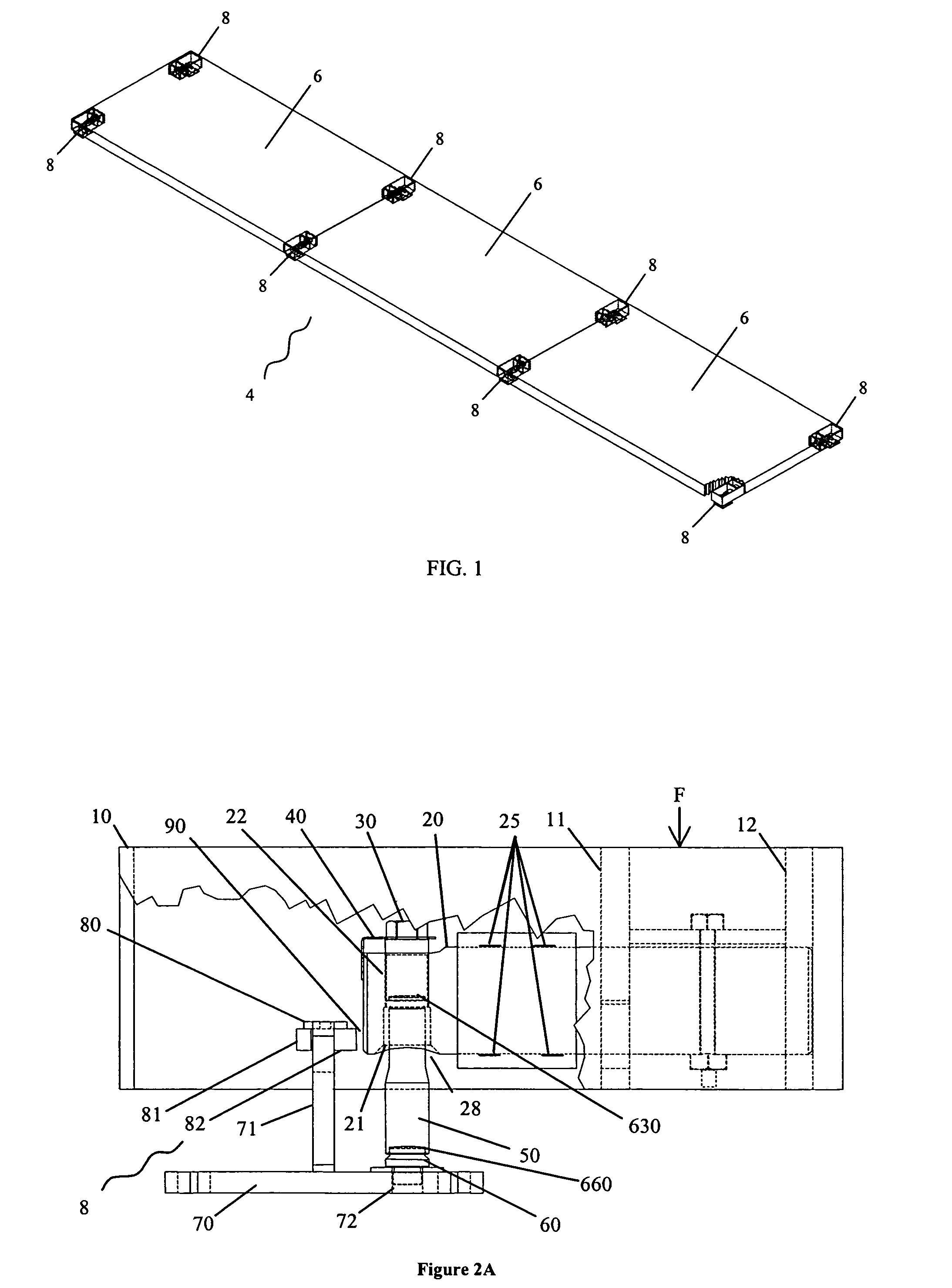

Apparatus, method and system for manufactured structures

ActiveUS10835977B1Avoid the needReduce componentsPower plant fuel tanksWeight reductionMechanical engineeringMetal foam

A metallic structure defines ribs and a skin supported by the ribs. The ribs may be defined by metal strips and the skin may be attached to the ribs. Alternatively, the skin may be defined by a plurality of tiles and the ribs may be defined by flanges of each of the plurality of tiles that cooperate to define the ribs. Tiles may be attached to separate rib lattice. Structurally weak locations at nodes where ribs intersect may be reinforced. The components may be brazed together and the stiffness of adjacent locations in the structure adjusted in the brazing operation to reduce the difference in stiffness and to reduce resulting stress risers. The metallic structure may be armored using metal foam to absorb the energy of a projectile.

Owner:PIASECKI AIRCRAFT CORP

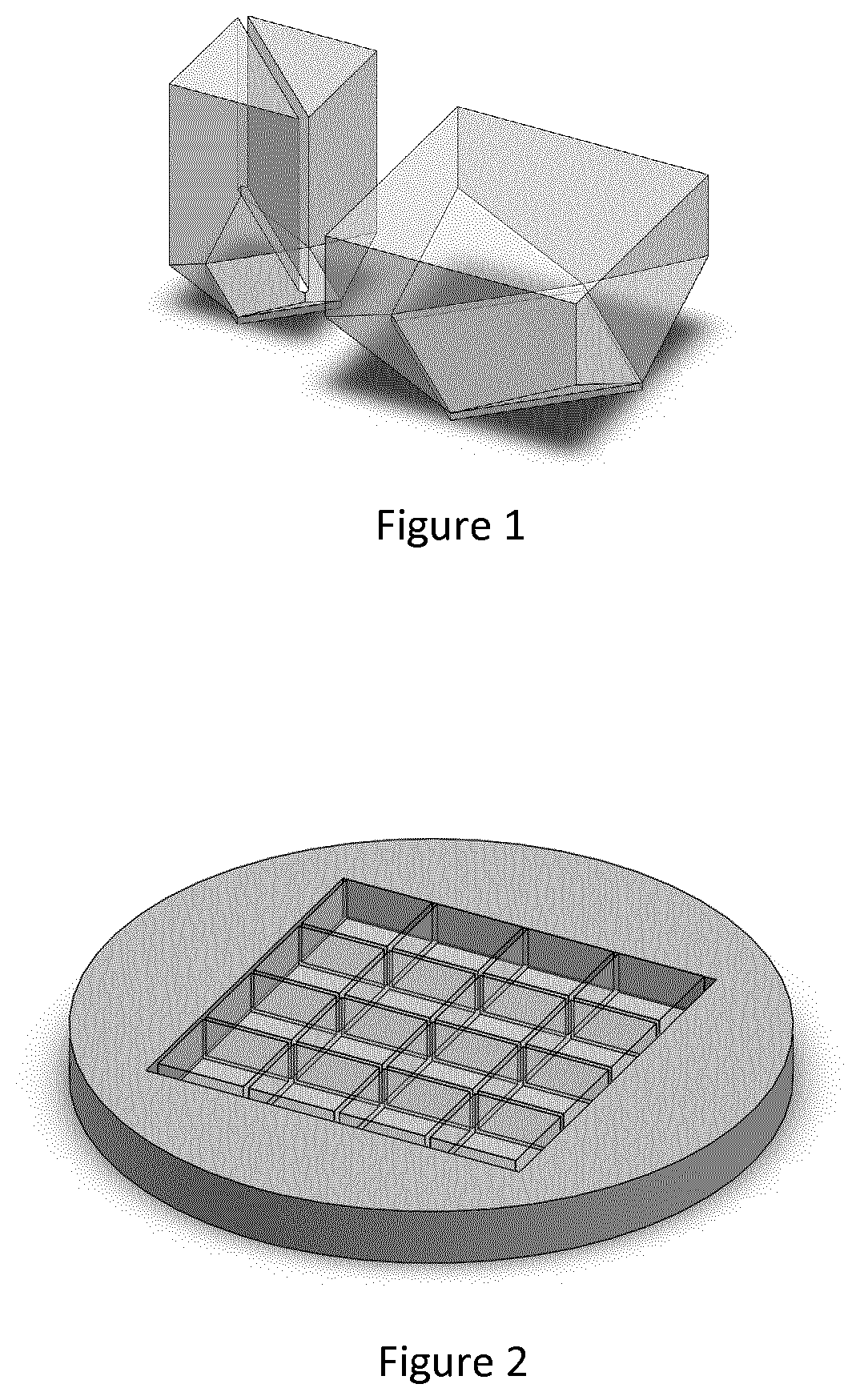

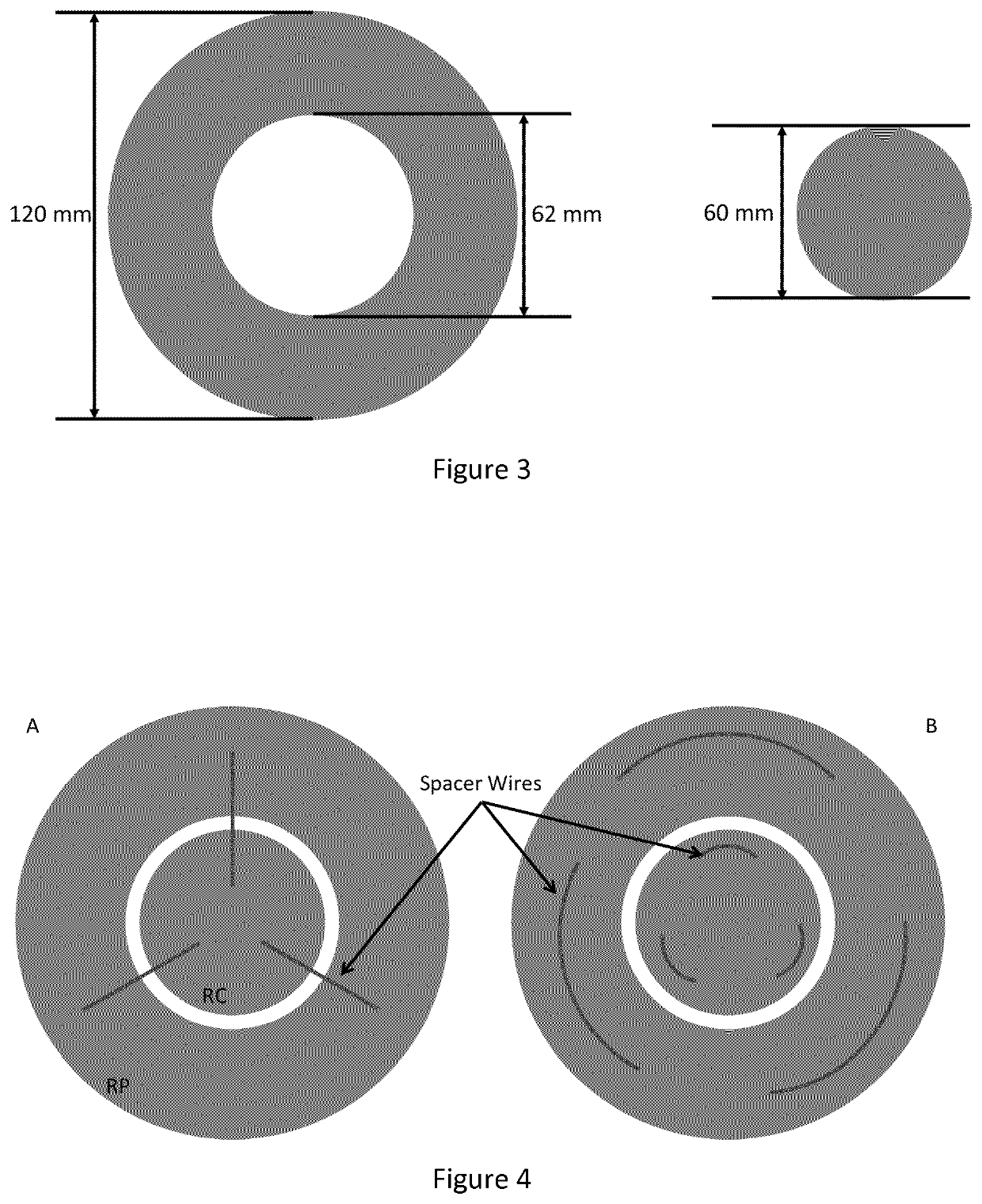

Synthesis of thick single crystal diamond material via chemical vapour deposition

ActiveUS20200087782A1Reduce the effective heightCommercially viablePolycrystalline material growthAfter-treatment detailsPhysicsSingle crystal

A method of fabricating a plurality of single crystal CVD diamonds. The method includes mounting a plurality of single crystal diamond substrates on a first carrier substrate. The plurality of single crystal diamond substrates is subjected to a first CVD diamond growth process to form a plurality of single crystal CVD diamonds on the plurality of single crystal diamond substrates. The plurality of single crystal CVD diamonds are mounted in a recessed carrier substrate and subjected to a second CVD diamond growth process.

Owner:ELEMENT SIX TECH LTD

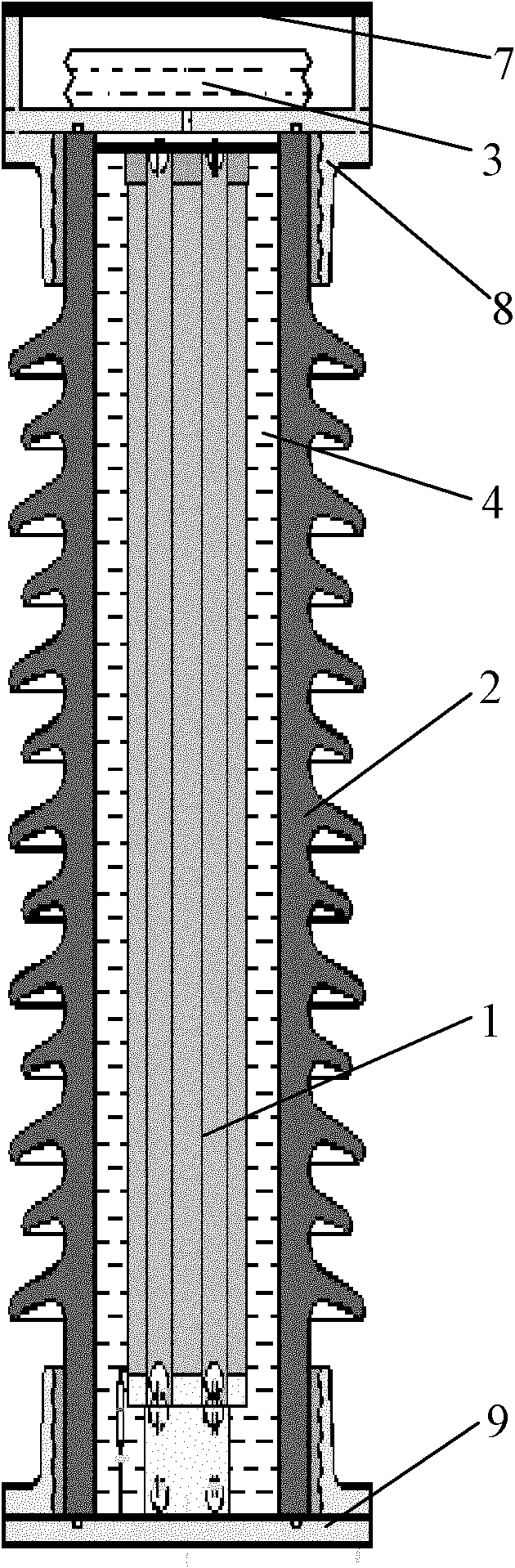

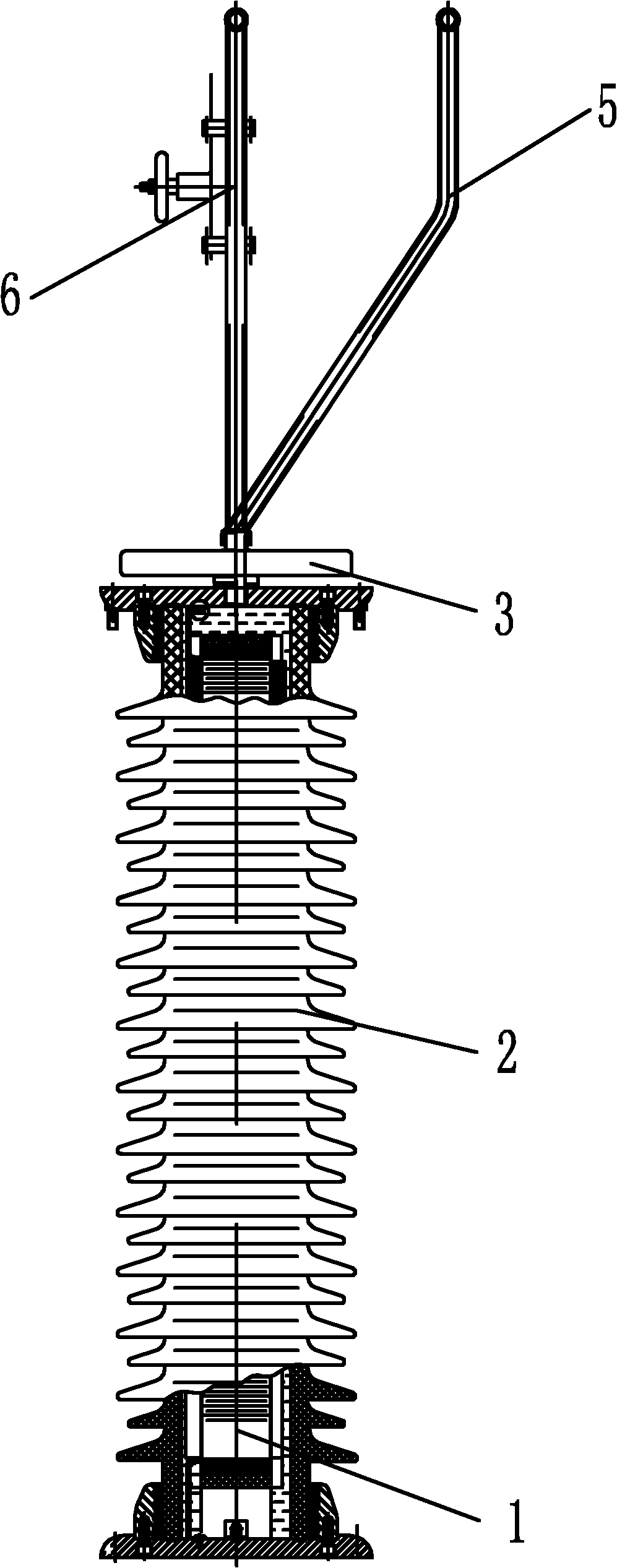

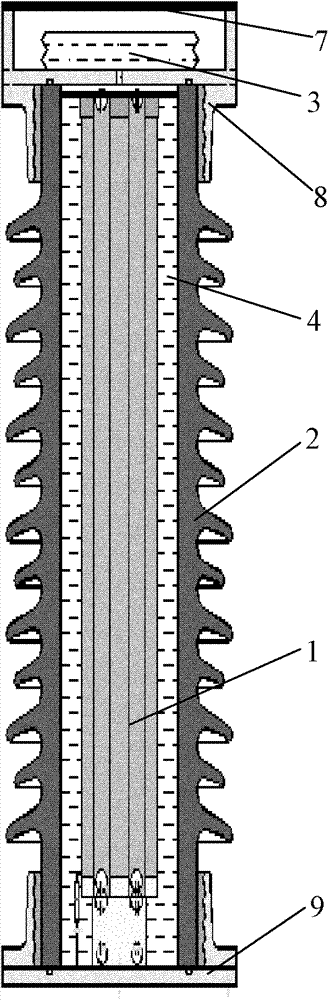

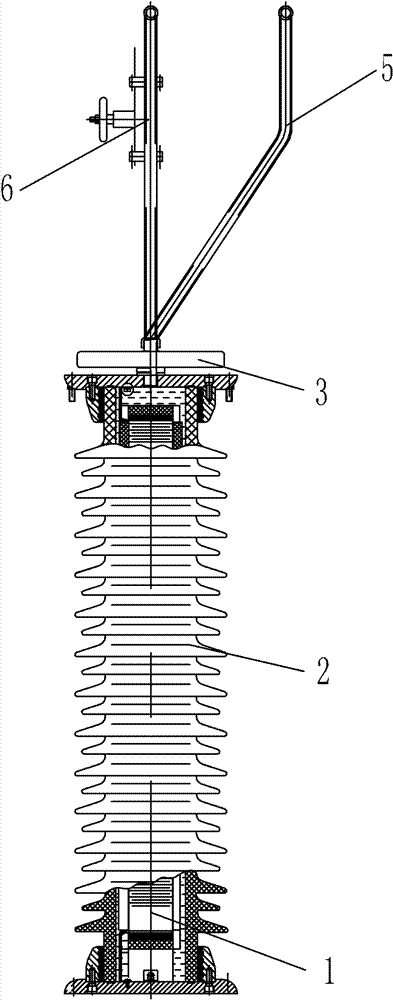

External-expander capacitive voltage transformer and vacuum treatment method thereof

ActiveCN102082024AReduce the effective heightSmall inner diameterTransformers/inductances coolingTransformersTransformerEffective height

The invention discloses an external-expander capacitive voltage transformer and a vacuum treatment method thereof. The voltage transformer comprises a casing, a core and an expander, wherein the core is arranged in the casing and is sealed by an upper sealing cover and a lower sealing cover at the two ends of the casing; the expander is arranged at the upper end of the upper sealing cover of the casing; and the casing is filled with insulating oil. An oil-filled expander is arranged outside a porcelain sleeve, so that the amount of oil and pressure inside the porcelain sleeve can be effectively adjusted, excessive pressure can be effectively released and the porcelain sleeve is safer and more stable. An external expander can have a small size and is arranged outside the porcelain sleeve, so that effective height of the porcelain sleeve is saved and the size and weight of a product are remarkably reduced. In the vacuum treatment method, drying, degassing, oil injection and soaking can be performed on each equipped product at one time, so that vacuum treatment time is shortened, labor intensity is lowered, the treatment capacity of insulating oil is reduced and the using amount of the insulating oil is decreased.

Owner:CHINA XD ELECTRIC CO LTD

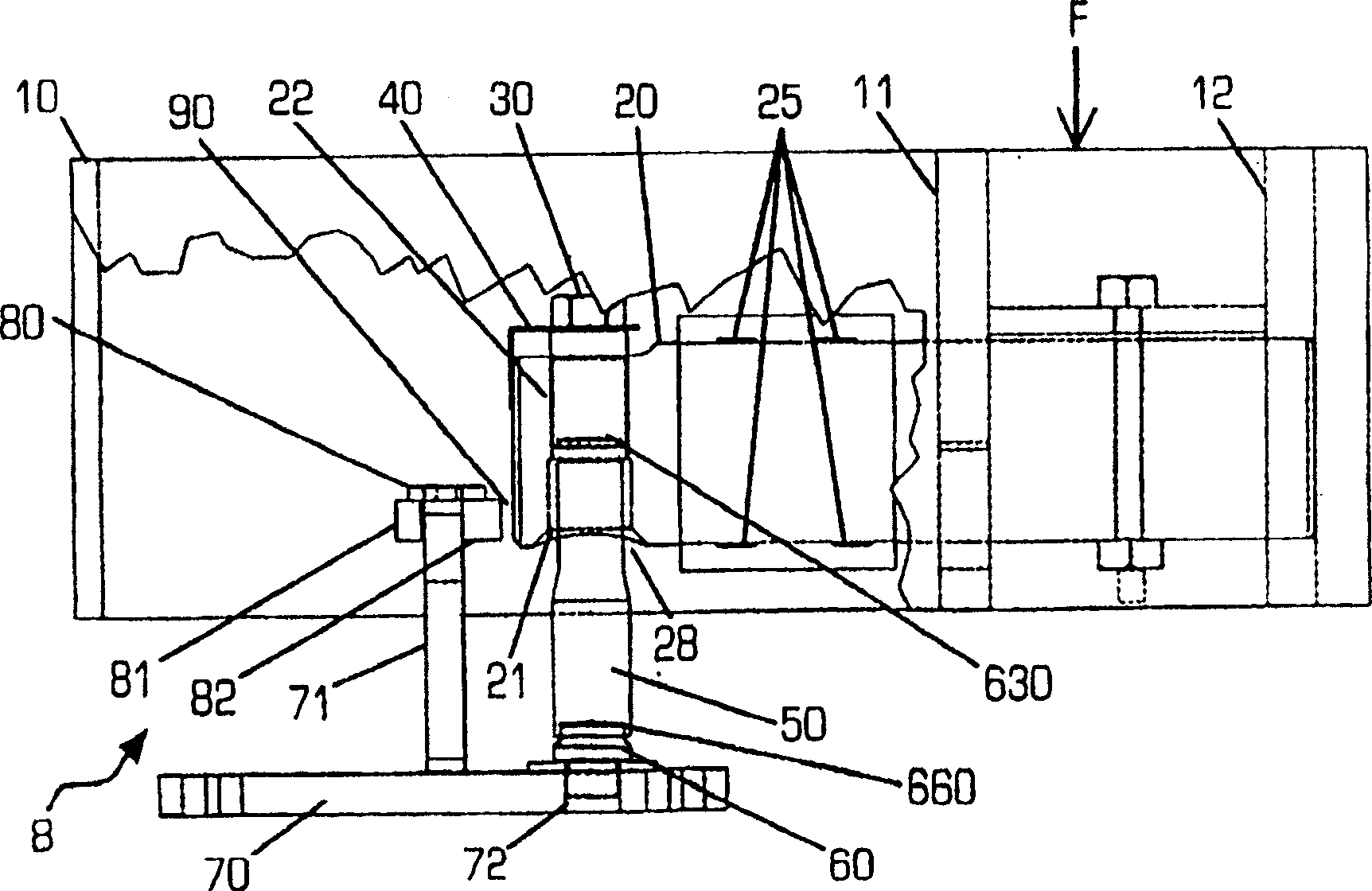

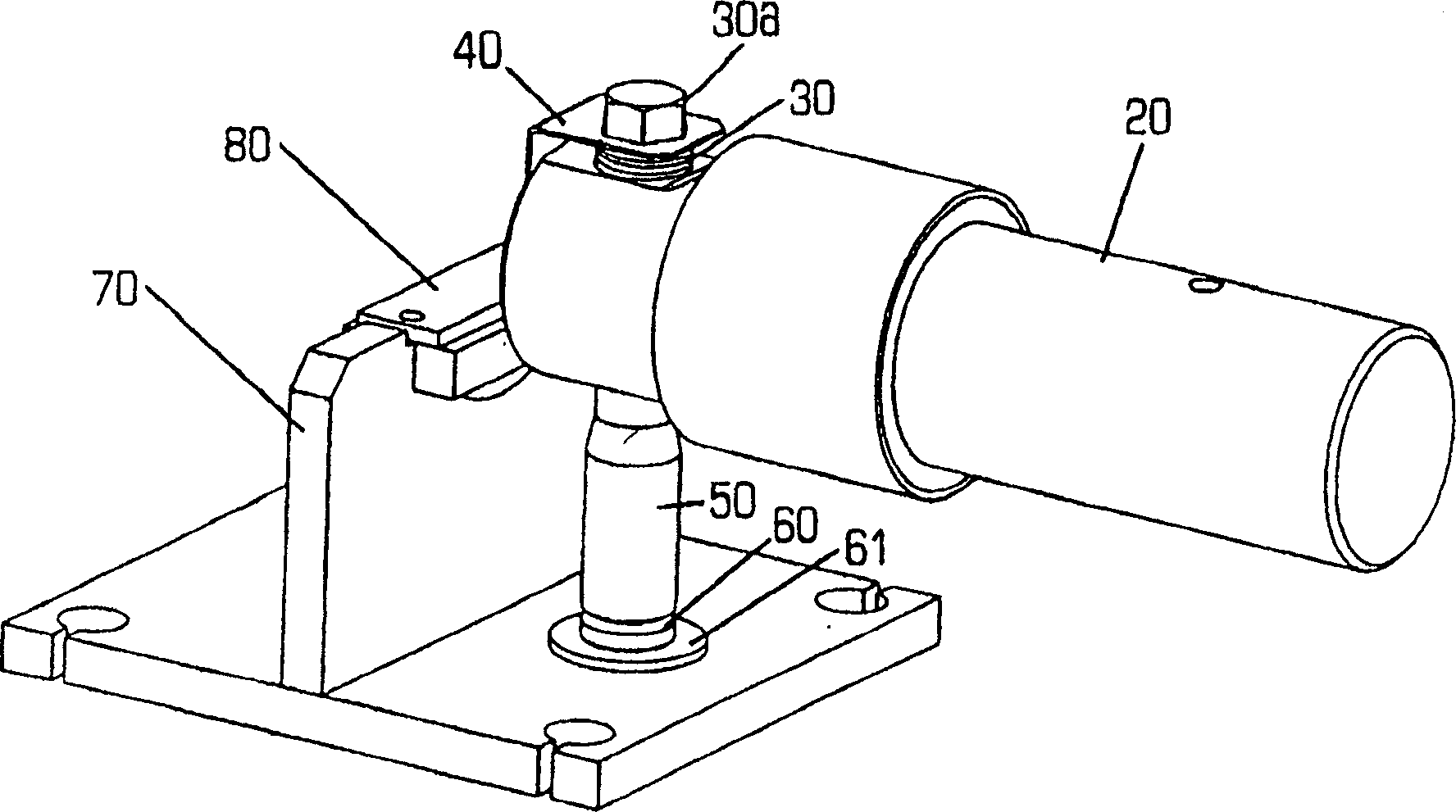

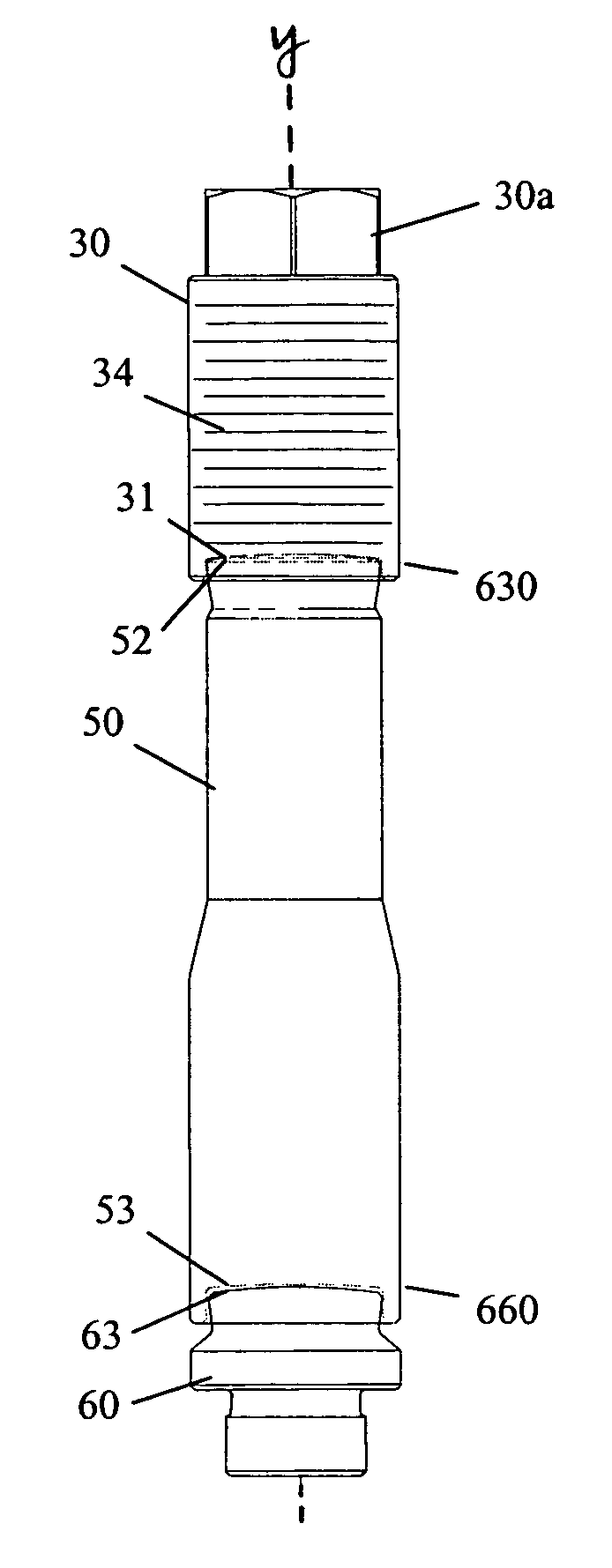

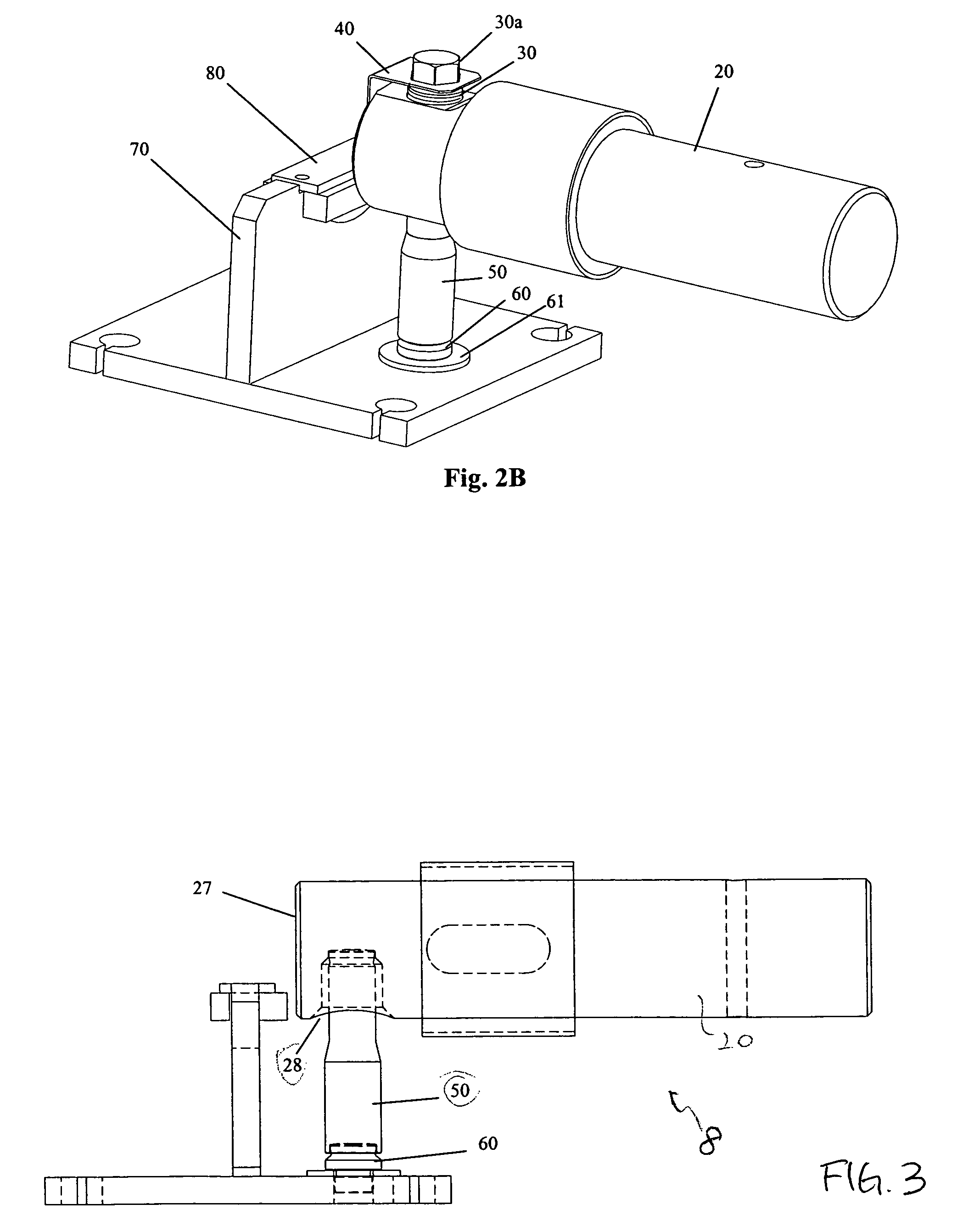

Support structure for a load-bearing device

A mechanism for reducing horizontal force in load measurement is presented. The mechanism includes a structure having surfaces of nonuniform radii of curvature (e.g., oblate spheroid surfaces) at both ends. The ends of the structure contact a force-sensor coupling element and a base-coupling element, forming two interfaces. Each interface includes a contact area between a convex surface and a concave surface. When a horizontal force is applied, the contact area at each interface shifts, allowing the structure to tip from the vertically aligned position that it is in when no horizontal force is applied. Compared to conventional mechanisms, the structure of the invention has a lower effective height because interfaces between oblate spheroid surfaces allow a larger angle of deflection than flat interfaces. The oblate spheroid interfaces also allow deflection to occur with less wear and tear at the interfaces compared to the flat-interfaced structures.

Owner:AVERY WEIGH-TRONIX

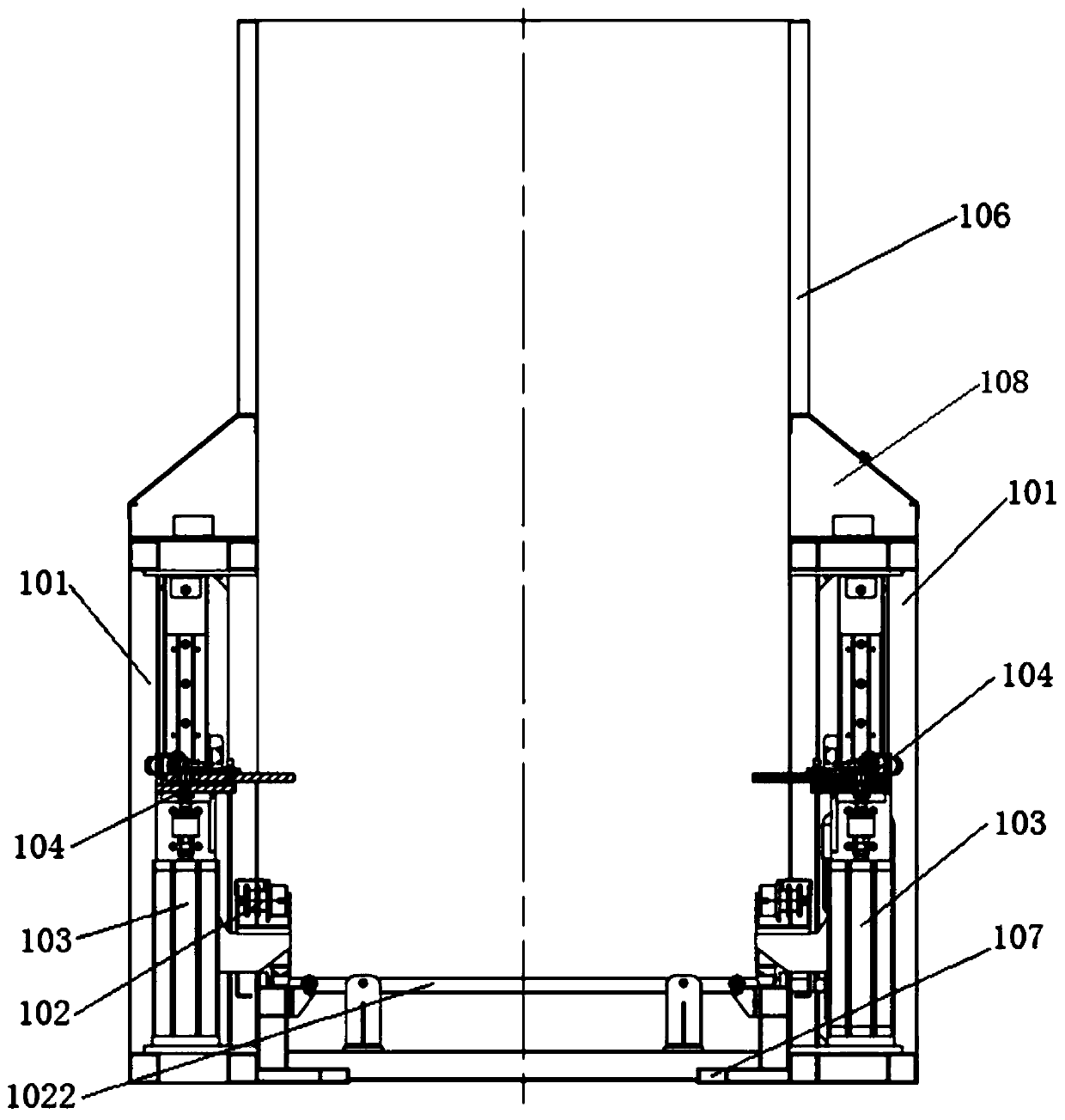

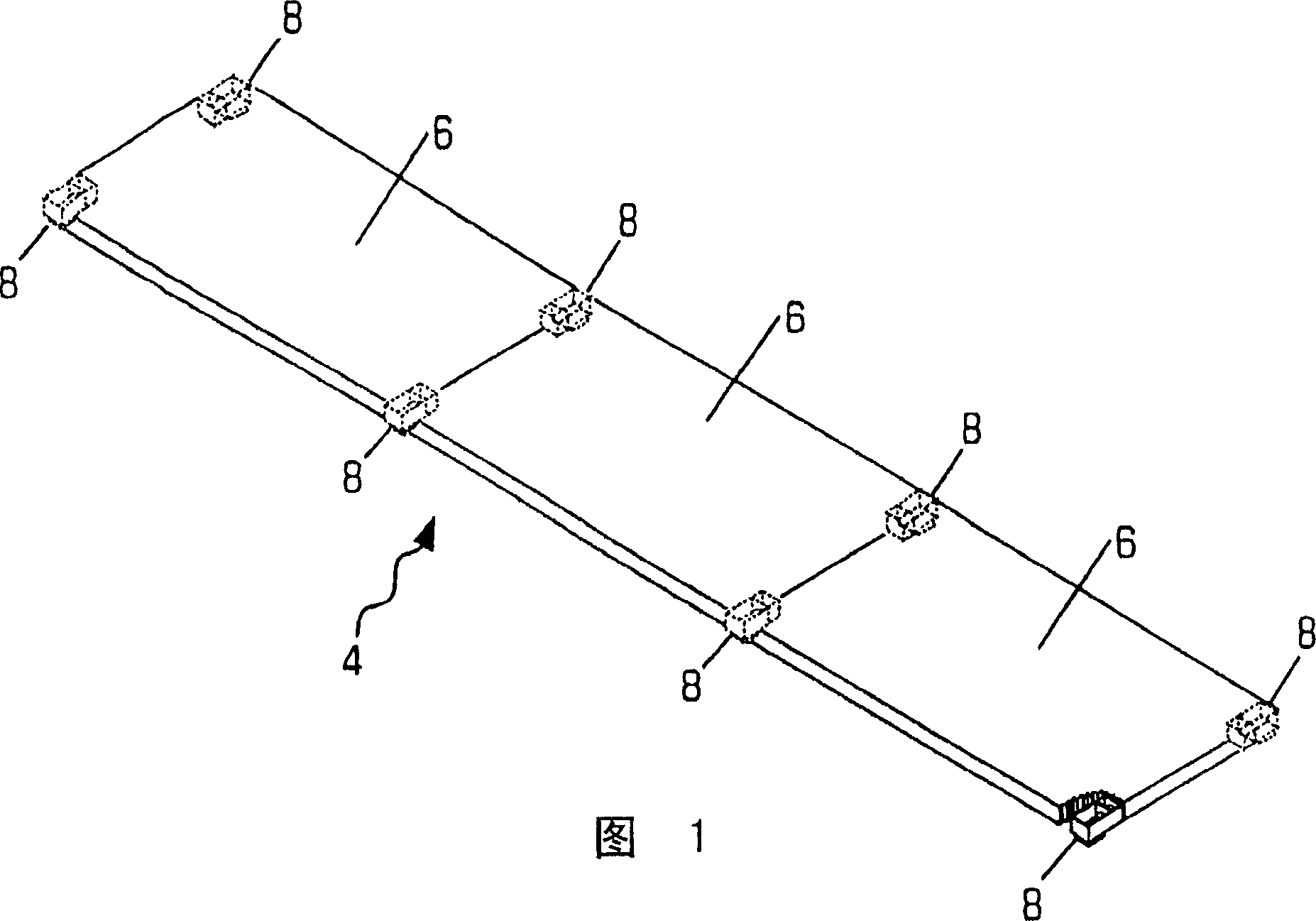

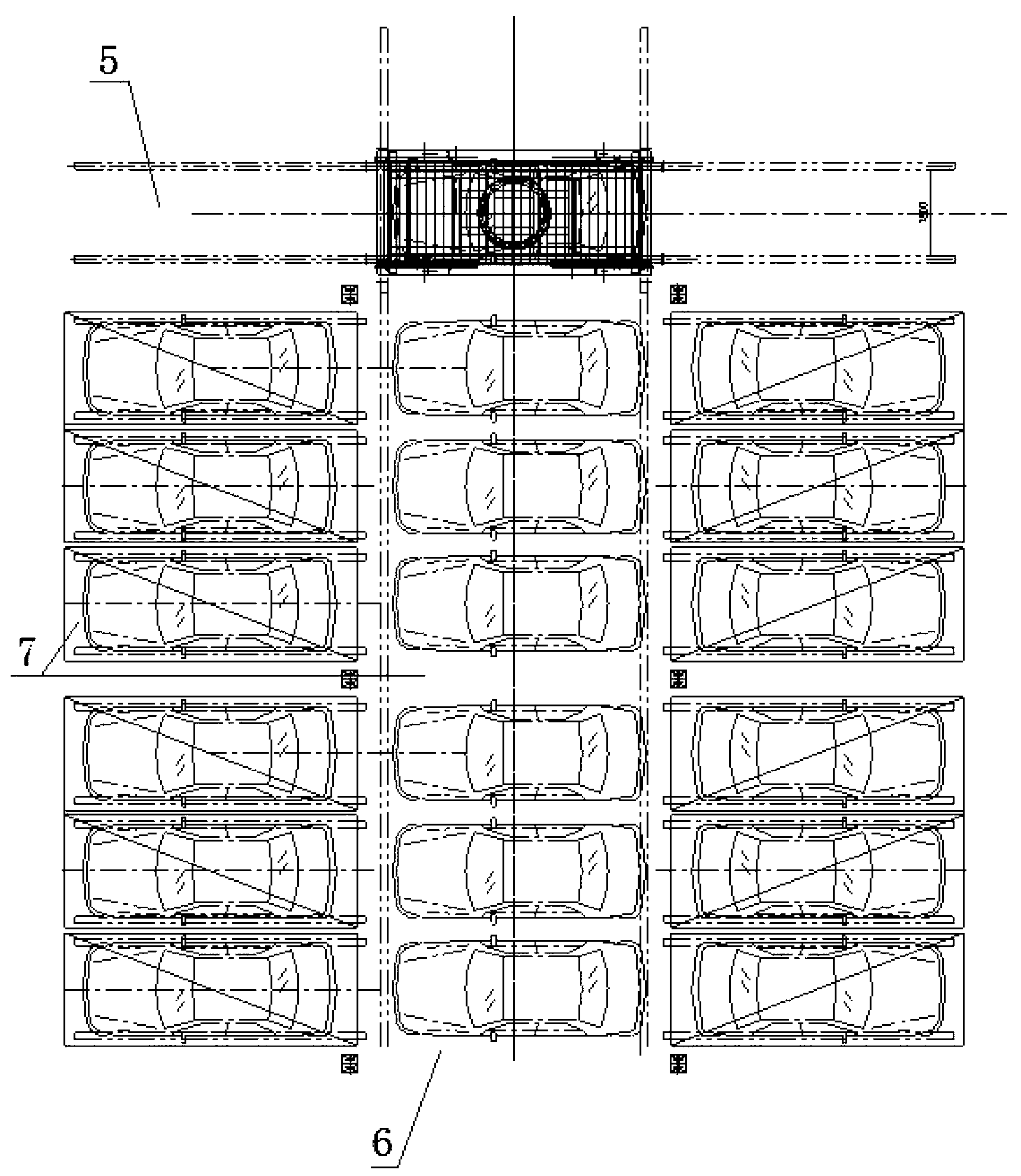

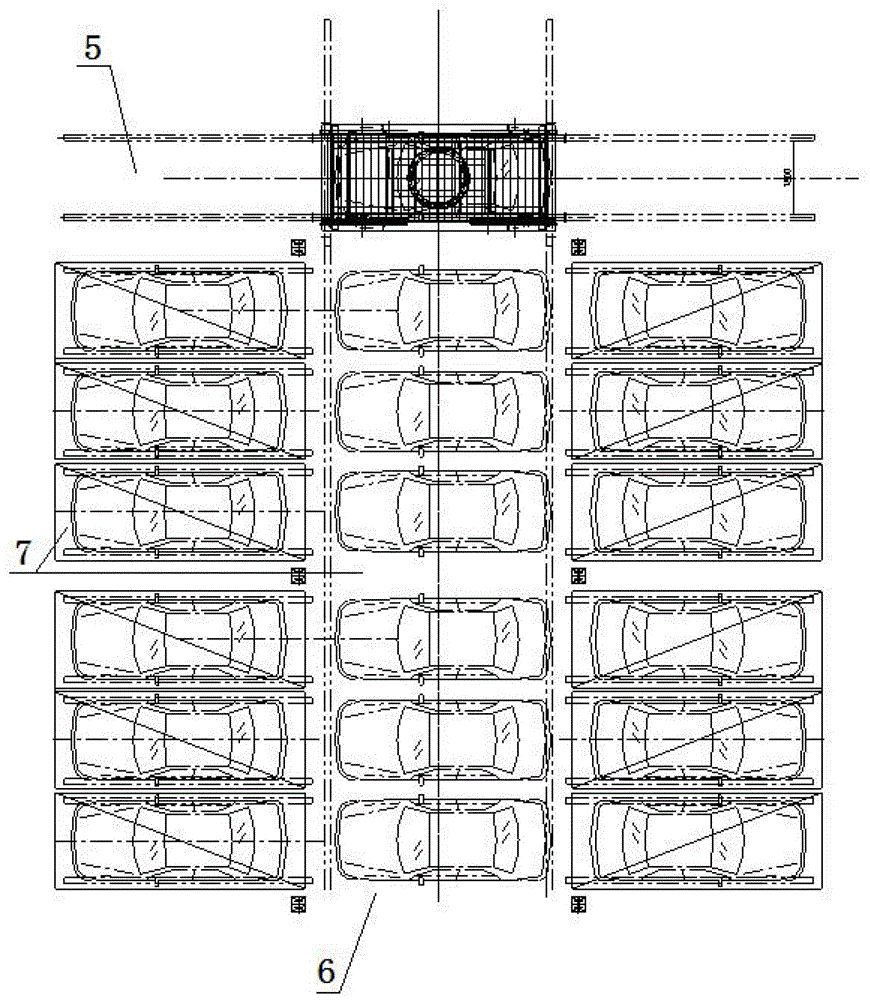

Intelligent parking equipment of roadway and method for modifying parking area thereof

ActiveCN103321460ASimple organizationReduce the effective heightParkingsAutomotive engineeringSmart parking

The invention relates to intelligent parking equipment of a roadway. The intelligent parking equipment comprises parking units; each parking unit comprises a traveling track, a vehicle carrying pallet, a moving assembly and a control system, the traveling tracks are erected on the top of a parking area, each vehicle carrying pallet is placed at a corresponding parking lot, and first lifting lugs are arranged on the vehicle carrying pallets; each moving assembly comprises a traveling framework and a lifting mechanism, the traveling frameworks can travel along the traveling tracks, the lifting mechanisms are connected onto the traveling frameworks, and first lifting hooks are arranged on the lifting mechanisms and can hook the first lifting lugs. A method for modifying the parking area of the roadway includes that the parking area comprises a main road, branch roads and a plurality of parking lots, the parking lots are arranged on the branch roads in a division manner, the intelligent parking equipment of the roadway is arranged in the parking area, and the corresponding vehicle carrying pallet is placed on each parking lot. The intelligent parking equipment and the method have the advantages that mechanisms are simple, convenient and flexible, can be independently used or can be combined with one another; the heights of parking garages are reduced, the parking garages are applicable to space with a limited height, and the utilization rate can be increased by 33-50% by means of slightly digging existing parking garages.

Owner:SUZHOU DAFANG SPECIAL VEHICLE

Support structure for a load-bearing device

ActiveUS7004040B2Reduce measurement loadReduce the effective heightApparatus for force/torque/work measurementForce measurement by elastic gauge deformationOblate spheroidEffective height

Owner:AVERY WEIGH-TRONIX

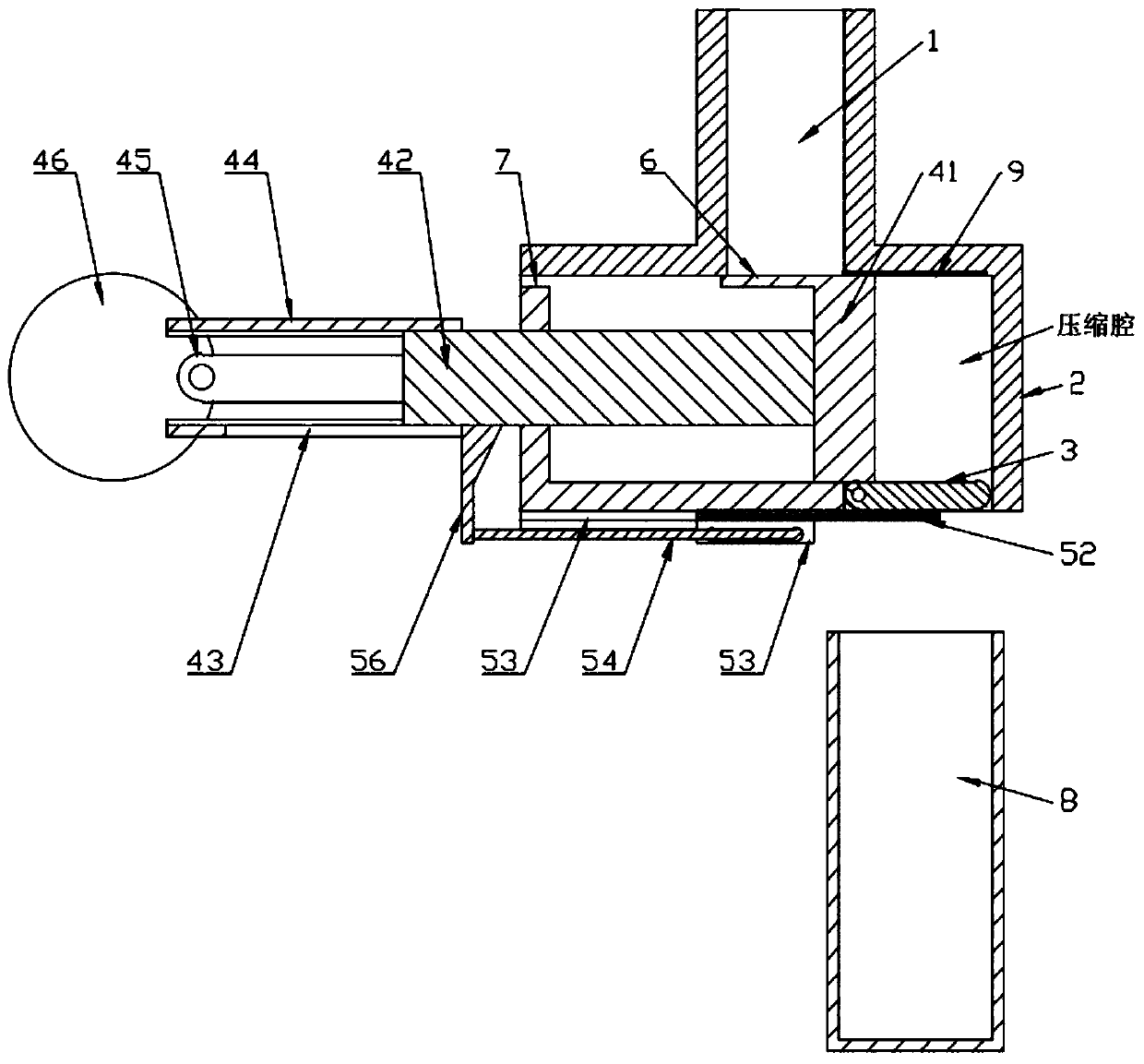

Garbage classification treatment equipment and garbage can applying same

InactiveCN110406867AImplement regular compression processingImplement automatic compressionRefuse transferringStorage devicesCompression moldingEngineering

The invention discloses garbage classification treatment equipment and a garbage can applying the same, and relates to the technical field of garbage treatment. The equipment comprises a feeding channel, a piston cylinder, a compression mechanism, a falling plate and an opening and closing mechanism, wherein the feeding channel is formed in the top of the piston cylinder, the compression mechanismis used for realizing compression molding of garbage, the falling plate is hinged to the bottom of the right end of the piston cylinder and is connected to the opening and closing mechanism, and theopening and closing mechanism is connected with the compression mechanism and realizes automatic opening and closing of the falling plate under the driving of the compression mechanism. According to the garbage classification treatment equipment and the garbage can applying the same, regular compression treatment of the garbage can be realized by means of the compression mechanism, the size of thegarbage is reduced, the garbage can be transferred to a garbage treatment plant after a collecting barrel is filled with the garbage, and the treatment capacity of an existing garbage can is improved, and in addition, the garbage can be automatically compressed and collected by means of the opening and closing mechanism in linkage with the compression mechanism.

Owner:MAANSHAN XINQIAO IND DESIGN CO LTD

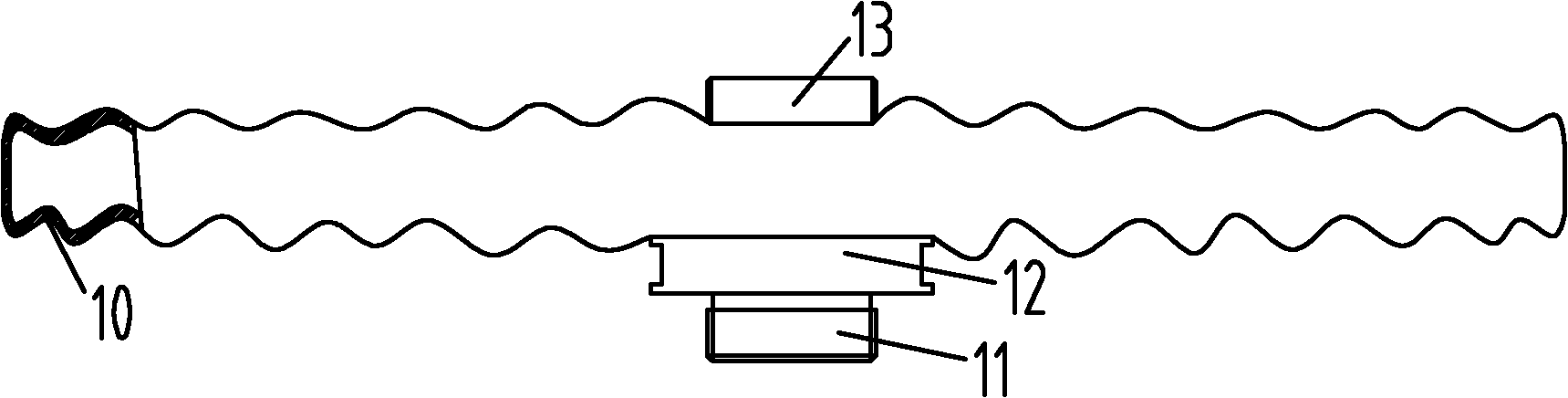

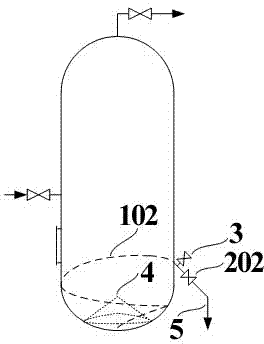

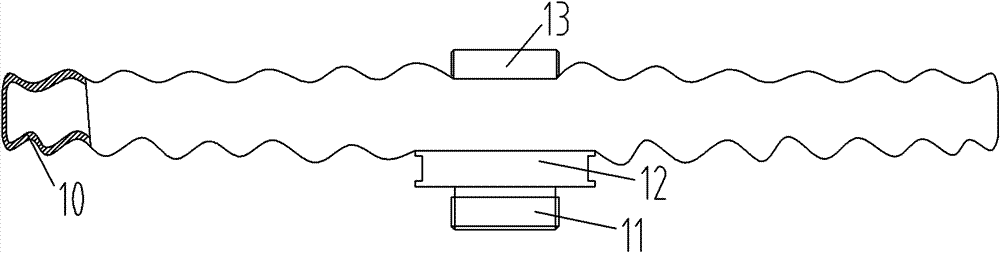

Conduit-drainage anti-freezing and anti-blocking device used in equipment container and method thereof

ActiveCN103566847BSolve the blockageReduce the effective heightLiquid degasificationDispersed particle filtrationPetrochemicalPetroleum

The invention relates to the technical fields of petrochemical industry production and equipment container manufacturing, and in particular to an anti-freezing and anti-blocking device for the bottom conduit-drainage pipelines and valves of gas-water separators, air-cooling towers, water-cooling towers and industrial wind-buffering tanks. In the conduit-drainage anti-freezing and anti-blocking device disclosed by the invention, a drainage pipeline is rotated upwards to a certain height in the form of a gyroscope curve along the inner wall of an equipment container from the lowest part of the container at first, and then the pipeline stretches out of the equipment container along the tangential direction of the wall of the equipment container, a drainage valve can be installed immediately after the drainage pipeline stretches out of the equipment container, and a pipeline is connected behind the drainage valve to a trench or other residual liquid recovery systems. The conduit-drainage anti-freezing and anti-blocking device disclosed by the invention is capable of thoroughly solving the problem of congelation blockage of the conduit-drainage pipelines and the valves in winter.

Owner:CHINA PETROLEUM & CHEM CORP

A displacement and unloading structure and construction method of vertical components

The invention discloses a replacement unloading structure and construction method for a vertical component. The replacement unloading structure comprises support components fixedly mounted at the upper end and the lower end of the replaced vertical component; unloading columns positioned on the two sides of the vertical component are arranged between the support components; an unloading jack is arranged between the unloading columns and the support component at the upper end. According to the replacement unloading structure disclosed by the invention, the two support components are arranged on the upper and lower sides of the component required to be replaced, then the unloading columns and the unloading jack are arranged, and the vertical component is used as a benchmark, loads required to be unloaded are transmitted to the vertical component through the upper support component, the unloading jack, the unloading columns and the lower support component; compared with a conventional replacement technology, the replacement unloading structure has the advantages that the occupied space is less, original space can be rapidly recovered after replacement, the construction period is shortened, the cost is reduced greatly, and obvious social benefits and economic benefits are realized.

Owner:SICHUAN INSITITUTE OF BUILDING RES

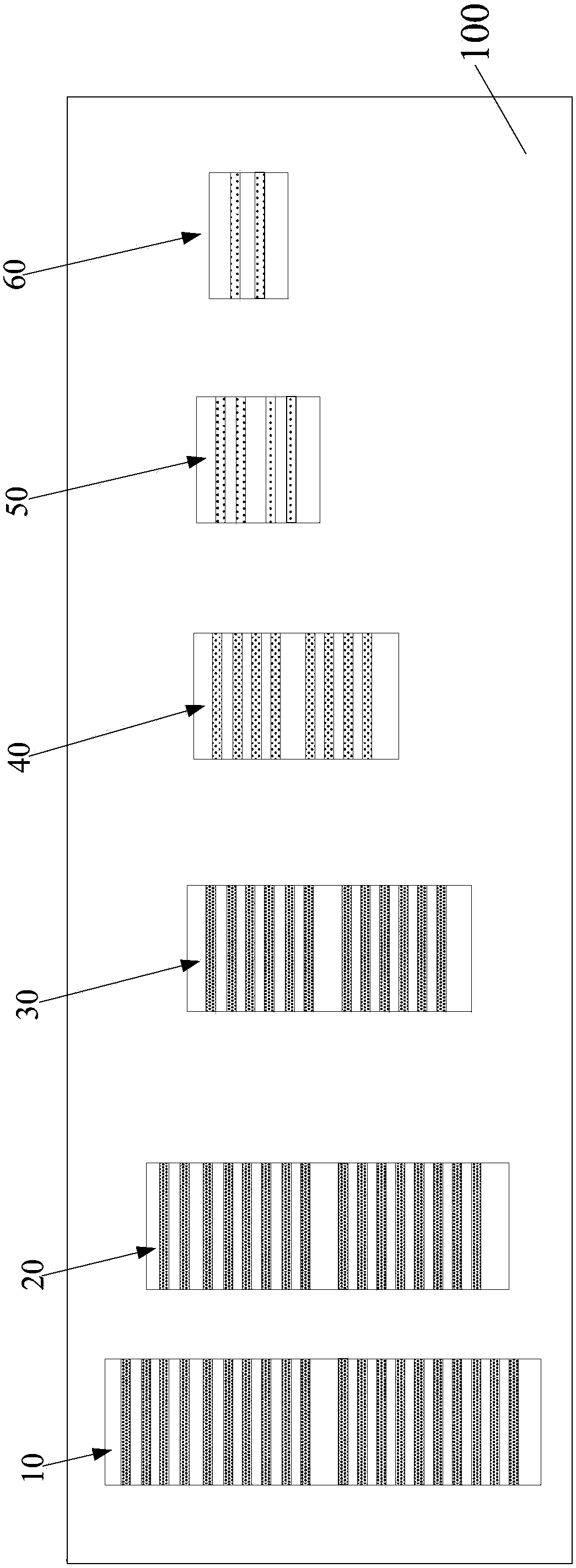

Semiconductor device and forming method thereof

ActiveCN109994471AImprove performanceIncrease the effective heightTransistorSolid-state devicesEffective heightEngineering

Disclosed are a semiconductor device and a forming method thereof. The semiconductor device comprises a semiconductor substrate, a high-frequency type logic standard unit and a low-power-consumption type logic standard unit, wherein the semiconductor substrate comprises a high-frequency region set and a low-power-consumption region set; the high-frequency type logic standard unit is located on thehigh-frequency region set, wherein the high-frequency type logic standard unit has high-frequency type unit height, high-frequency type working frequency and high-frequency type power; the low-power-consumption type logic standard unit is located on the low-power-consumption region set, and the low-power-consumption type logic standard unit has low-power-consumption type unit height, low-power-consumption type working frequency and low-power-consumption type power; the high-frequency type unit height is larger than the low-power-consumption type unit height; the high-frequency type working frequency is greater than the low-frequency type working frequency; the high-frequency type power is greater than the low-frequency type power; the high-frequency type logic standard unit comprises a high-frequency type fin part; the low-power-consumption type logic standard unit comprises a low-power-consumption type fin part; and the effective height of the high-frequency type fin part is larger than that of the low-power-consumption type fin part. The performance of the semiconductor device is improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Intelligent parking equipment of roadway and method for modifying parking area thereof

The invention relates to intelligent parking equipment of a roadway. The intelligent parking equipment comprises parking units; each parking unit comprises a traveling track, a vehicle carrying pallet, a moving assembly and a control system, the traveling tracks are erected on the top of a parking area, each vehicle carrying pallet is placed at a corresponding parking lot, and first lifting lugs are arranged on the vehicle carrying pallets; each moving assembly comprises a traveling framework and a lifting mechanism, the traveling frameworks can travel along the traveling tracks, the lifting mechanisms are connected onto the traveling frameworks, and first lifting hooks are arranged on the lifting mechanisms and can hook the first lifting lugs. A method for modifying the parking area of the roadway includes that the parking area comprises a main road, branch roads and a plurality of parking lots, the parking lots are arranged on the branch roads in a division manner, the intelligent parking equipment of the roadway is arranged in the parking area, and the corresponding vehicle carrying pallet is placed on each parking lot. The intelligent parking equipment and the method have the advantages that mechanisms are simple, convenient and flexible, can be independently used or can be combined with one another; the heights of parking garages are reduced, the parking garages are applicable to space with a limited height, and the utilization rate can be increased by 33-50% by means of slightly digging existing parking garages.

Owner:SUZHOU DAFANG SPECIAL VEHICLE

Vacuum treatment method of external-expander capacitive voltage transformer

ActiveCN102082024BReduce the effective heightSmall inner diameterTransformers/inductances coolingTransformersTransformerEffective height

Owner:CHINA XD ELECTRIC CO LTD

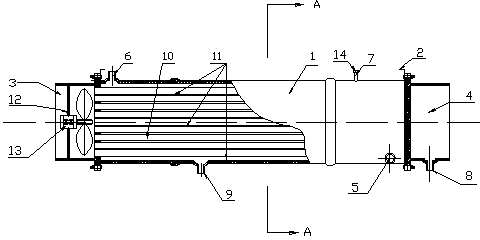

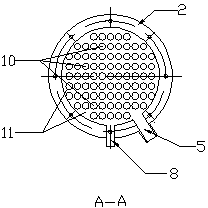

Air tube heat exchanger

InactiveCN103968611AChange temperatureChange humidityEvaporators/condensersSpace heating and ventilation detailsPlate heat exchangerBarrel Shaped

An air tube heat exchanger comprises an outer shell and an installation frame arranged on the outer shell. The air tube heat exchanger is characterized in that the outer shell is in a barrel shape. The two ends of the outer shell are open, an air inlet is formed in one end of the outer shell, and an air outlet is formed in the other end of the outer shell. A liquid inlet, a liquid outlet, an exhaust port, a drainage outlet and a sewage draining outlet are formed in the outer shell. Multiple round tubes are arranged in the outer shell, the two ends of each round tube are open, and a closed liquid cavity is formed between the two ends of each round tube. A filter net and a fan are arranged in the air inlet of the outer shell. The liquid inlet and the liquid outlet are in linkage with a main engine through pipelines. A valve is arranged on the exhaust port. The drainage outlet is connected with a drainage pipe. A power source of the fan is in linkage with the main engine.

Owner:威海瑞冬空调有限公司

Deacidification process and apparatus thereof

A deacidification apparatus and a deacidification process using the apparatus are disclosed. The deacidification apparatus includes a deacidification furnace, of which a furnace upper section, a furnace middle section and a furnace lower section are provided in upper, middle and lower portions respectively, wherein a gas-solid mixture inlet (1), a exhaust outlet (3) and a filtered air port (2) are provided on the furnace upper section, a product outlet (13) is provided on the furnace lower section, the upper portion of the deacidification is mounted with a filter (5) to which the gas-solid mixture inlet (1), the exhaust outlet (2) and the filtered air port (3) are connected, the filtered air port (2) is connected with a gas pulse device and a vacuum device by a three-way connecting device, and the exhaust outlet (3) is connected with atmosphere or connected with the vacuum device.

Owner:GUANGZHOU GBS HIGH TECH & IND

Low-cost slab Q235B steelmaking technology

InactiveCN113073173AStrong deoxygenation abilityImprove liquidityManufacturing convertersProcess efficiency improvementSteelmakingAlloy

The invention discloses a low-cost slab Q235B steelmaking technology. The low-cost slab Q235B steelmaking technology comprises the steps of raw material preparation and pretreatment, lance-lowering oxygen blowing in a converter, deoxidation treatment, covering agent feeding and continuous casting of molten steel. By adopting a compound deoxidizing agent at the end point of converter steelmaking for deoxidation treatment, compared with a traditional Si-Ba-Ca deoxidizing agent, Si-Al-Fe adopted as the deoxidizing agent of the molten steel in the scheme has the advantages that the liquidity of the molten steel can be made to be good, the deoxidizing capacity of Si-Al-Fe is high, aluminum oxide in the molten steel can be reduced, the form of the aluminum oxide can be changed, complete floating of the aluminum oxide is facilitated, thus the molten steel is completely deoxidized, then a yield of alloy in steel billets is effectively improved, after a covering agent is applied after tapping of the molten steel, the solidification time of the molten steel of a riser can be prolonged, thus the feeding capacity of the riser is improved, and the covering agent in the scheme has dual effects of heating and heat preservation so that the feeding capacity of the riser can be obviously improved, and the quality and a yield of slabs are improved.

Owner:福建三宝钢铁有限公司

A cone-shaped shaker distributor

ActiveCN106148620BLow costImprove efficiencyBell-and-hopper arrangementLinear motionAutomatic control

The invention relates to a distributing device for a cone shaker, which is composed of a shaker, a cone and a driving device. The shaker is composed of a hollow main shaft, a tiger's mouth frame and an auxiliary shaft box. , The sub-shaft is perpendicular to the main shaft and intersects. The cone is hung on the trunnion. It shakes back and forth with the main shaft and left and right with the trunnion. The trunnion is driven by the sub-shaft. Pulley type, gear transmission shaft type, the transmission mechanism is enclosed in the water-cooled shaking table, there are two driving methods, the mechanical synthesis is the synthesis of rotation and linear motion, the rotation is driven by the slewing bearing with external teeth, and the ball spline linear bearing It is fixed with the big gear, and the push rod is forced to rotate. At the same time, it moves up and down with the oil cylinder to push the crank and the main rocker arm, so that the main shaft, auxiliary shaft and trunnion shake together. There are electric and hydraulic power (hydraulic cylinder and oil motor) , the main shaft driving mechanism is fixed on the furnace head, and the auxiliary shaft driving mechanism is fixed on the main shaft, and the synthetic cloth movement is controlled by automation.

Owner:僧全松

Synthesis of thick single crystal diamond material via chemical vapour deposition

ActiveUS11486037B2Reduce the effective heightPolycrystalline material growthAfter-treatment detailsPhysical chemistrySingle crystal

A method of fabricating a plurality of single crystal CVD diamonds. The method includes mounting a plurality of single crystal diamond substrates on a first carrier substrate. The plurality of single crystal diamond substrates is subjected to a first CVD diamond growth process to form a plurality of single crystal CVD diamonds on the plurality of single crystal diamond substrates. The plurality of single crystal CVD diamonds are mounted in a recessed carrier substrate and subjected to a second CVD diamond growth process.

Owner:ELEMENT SIX TECH LTD

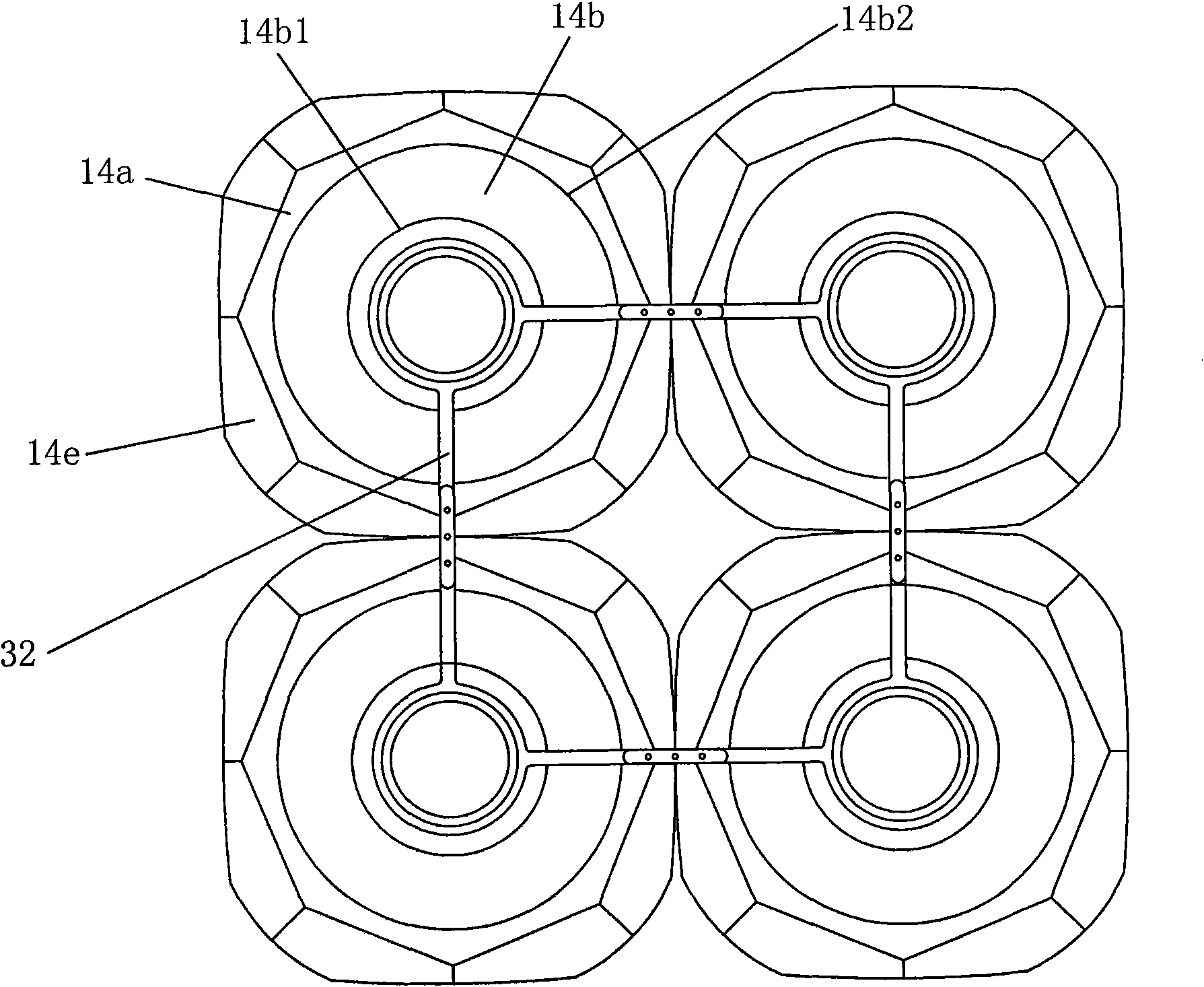

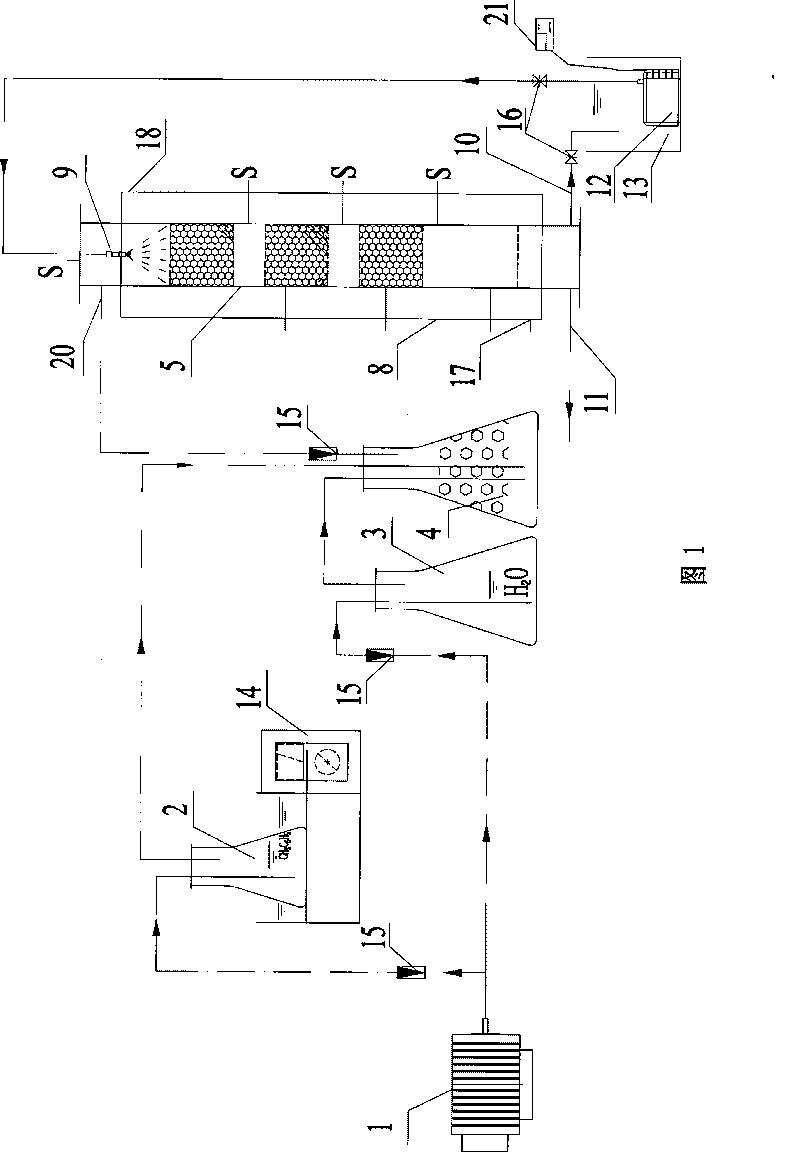

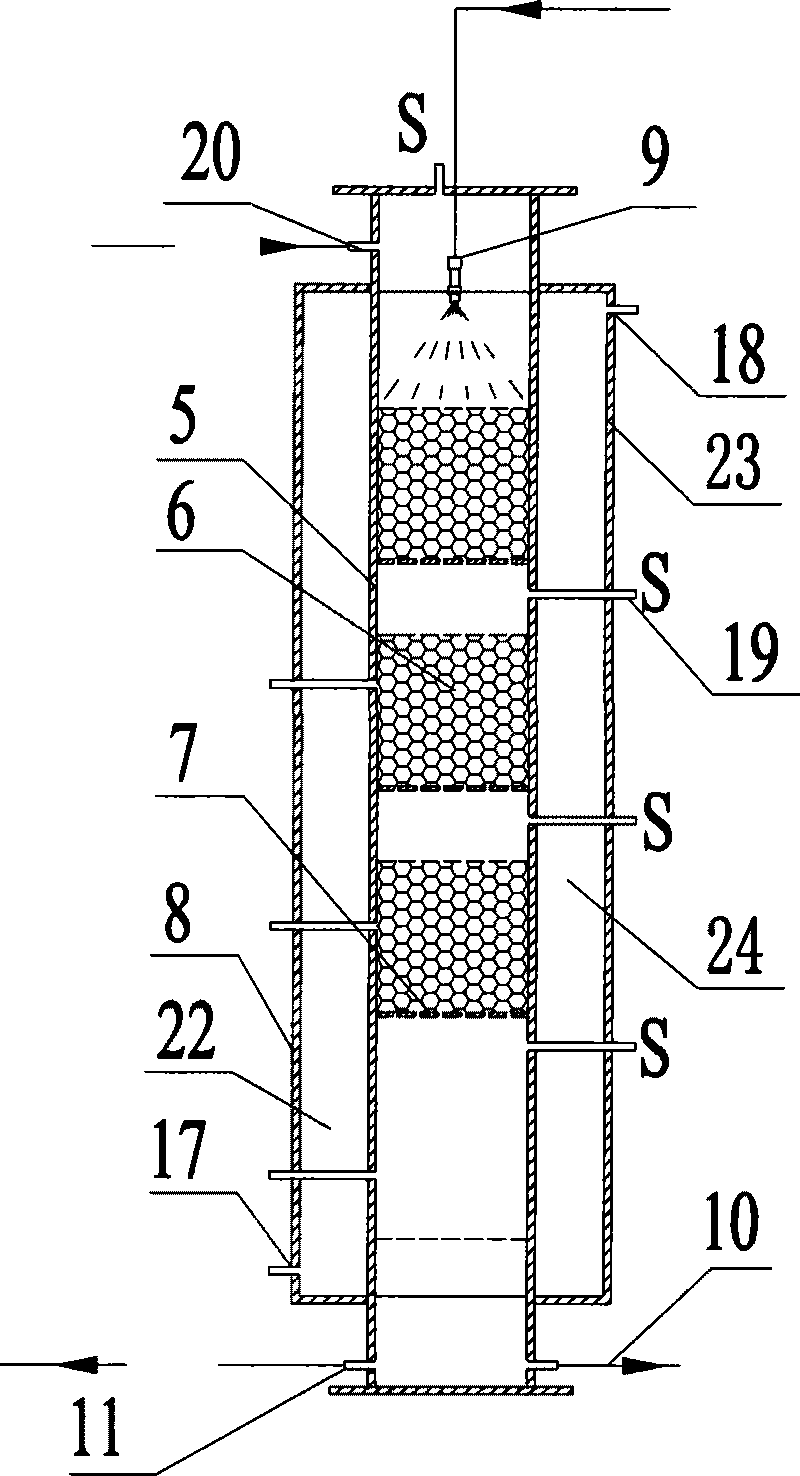

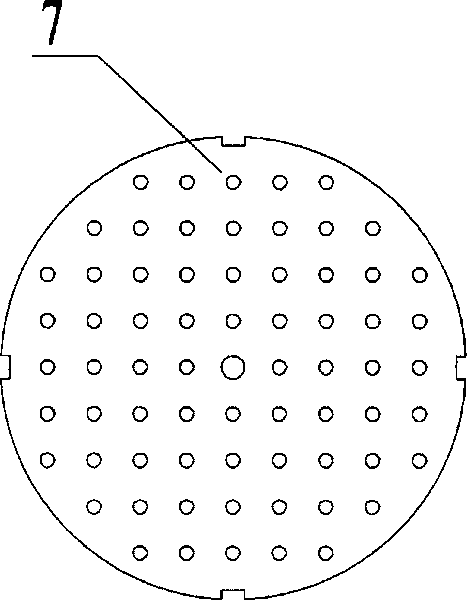

Biological filtering device for treating toluene gas

InactiveCN101264421BEvenly distributedImprove air distribution effectDispersed particle separationAir quality improvementPorosityWater baths

Owner:HUNAN UNIV

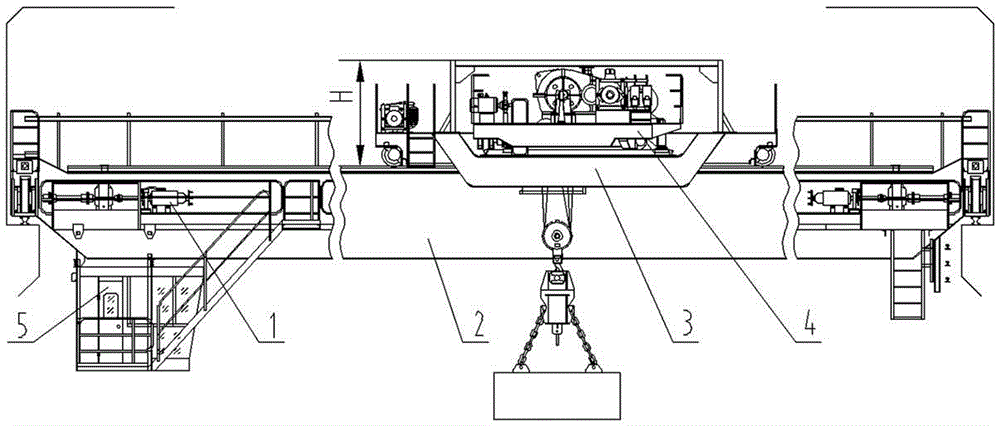

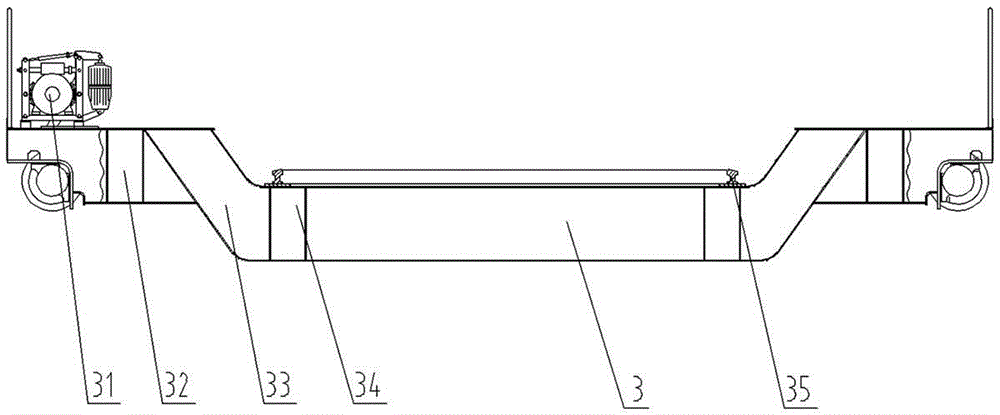

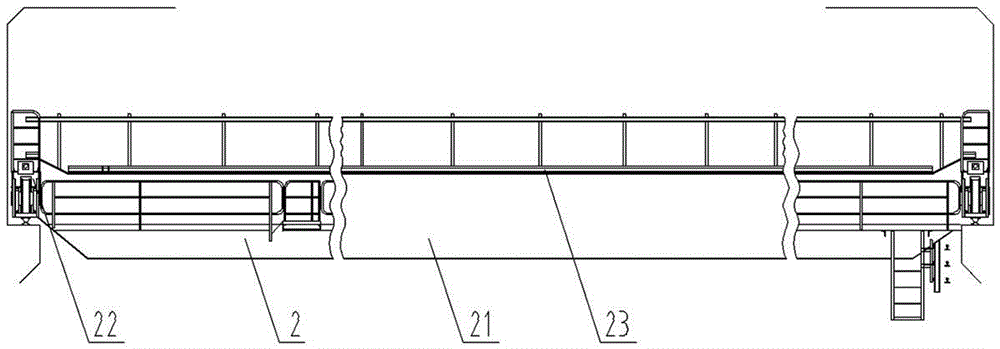

An upper swivel crane suitable for low headroom workshops

ActiveCN103964314BReduce the overall heightLower the altitudeBase supporting structuresBraking devices for hoisting equipmentsArchitectural engineeringStructural engineering

The invention discloses an upper rotating crane suitable for a factory building with a low clearance height, which comprises a cart operating mechanism, a bridge frame, a lower trolley, an upper trolley, and electrical equipment. A cart operating mechanism is arranged at the end beam of the bridge frame; the bridge frame The lower trolley is set above the main girder; the electrical equipment is arranged on the bridge frame; the lower trolley adopts a concave structure in the middle; the upper trolley is set above the lower trolley; the upper surface of the main beam of the bridge frame is lower than the end girder of the upper surface. The invention adopts the concave structure of the lower trolley or the concave structure of the main beam, and reduces the effective height of the rotating part of the upper trolley by means of the central concave; the main beam of the bridge frame adopts a concave structure, which can reduce the height of the bridge frame. The adoption of the above structure reduces the overall height of the crane, so that the crane can be used in occasions where the headroom of the factory building is small. The invention has the advantages of compact structure, reliable operation and small height of the whole machine, and is suitable for workshops with low clearance height.

Owner:YUNNAN HEAVY EQUIP MFG GRP

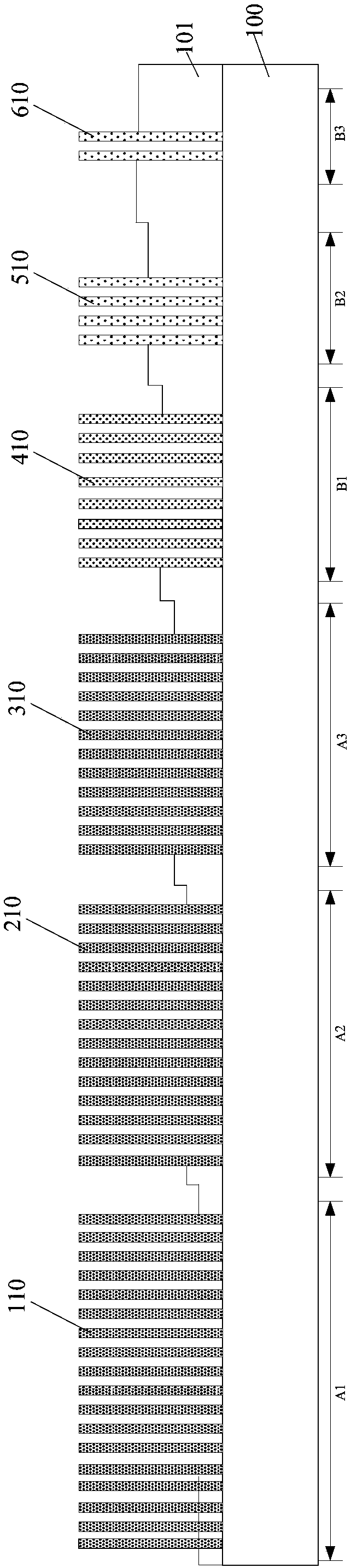

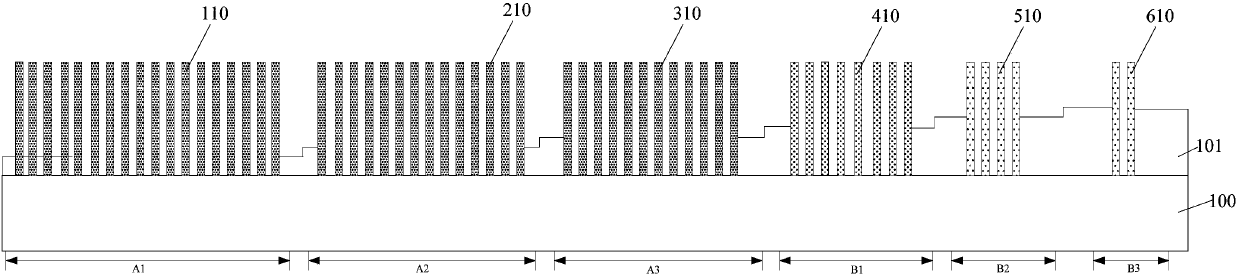

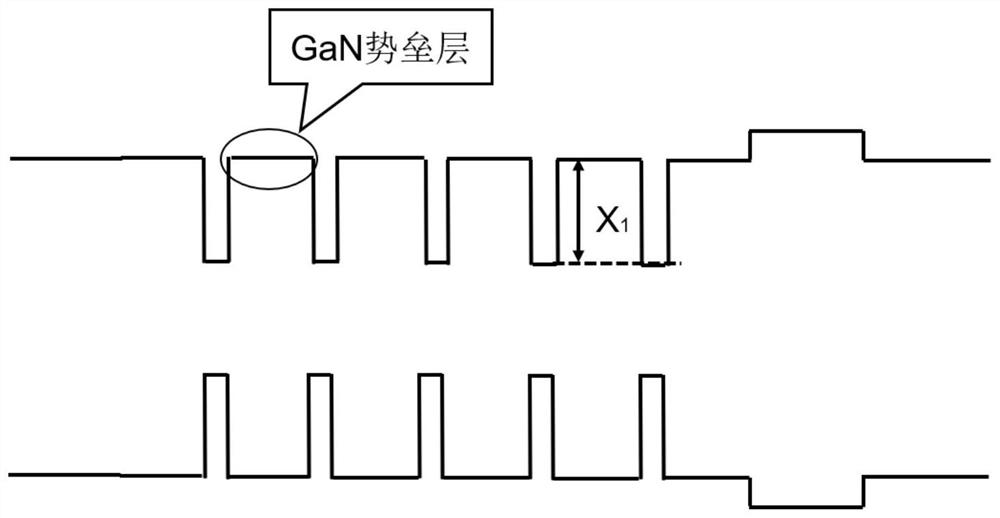

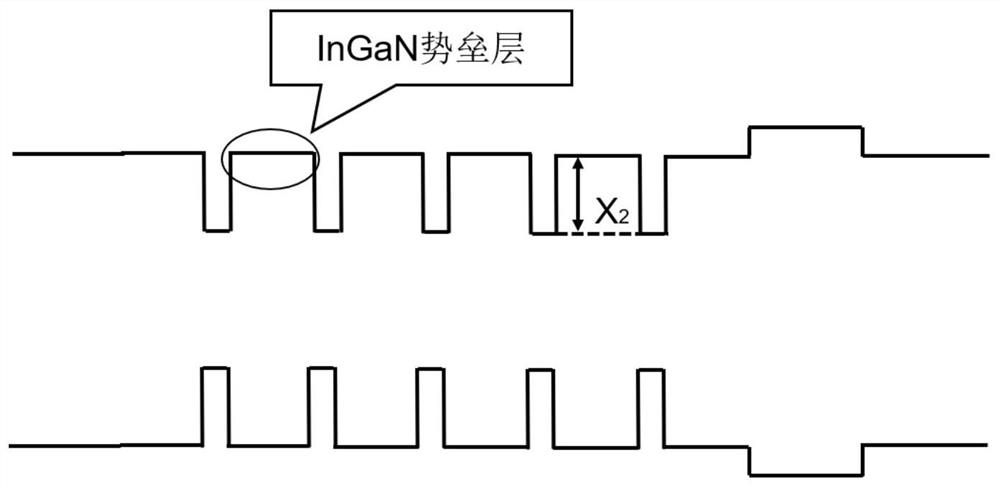

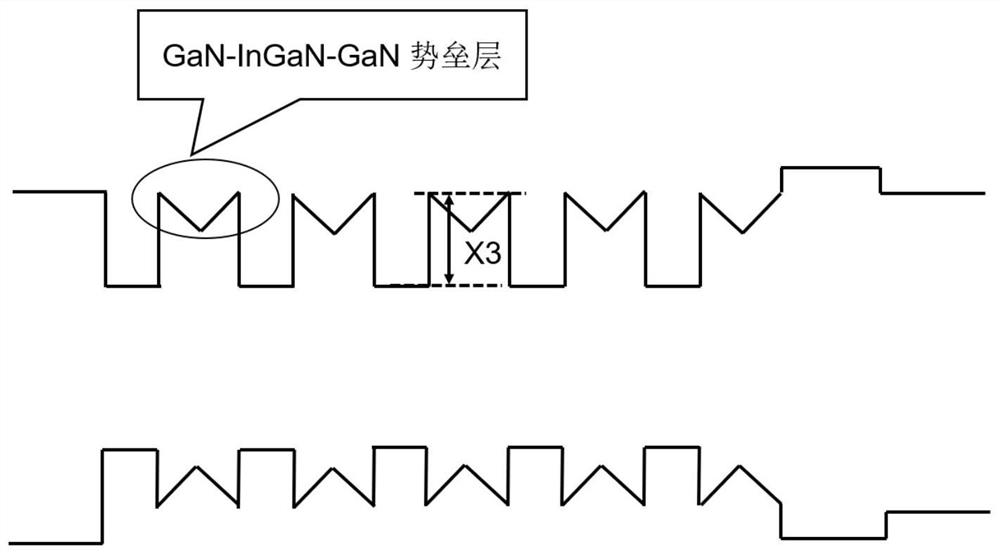

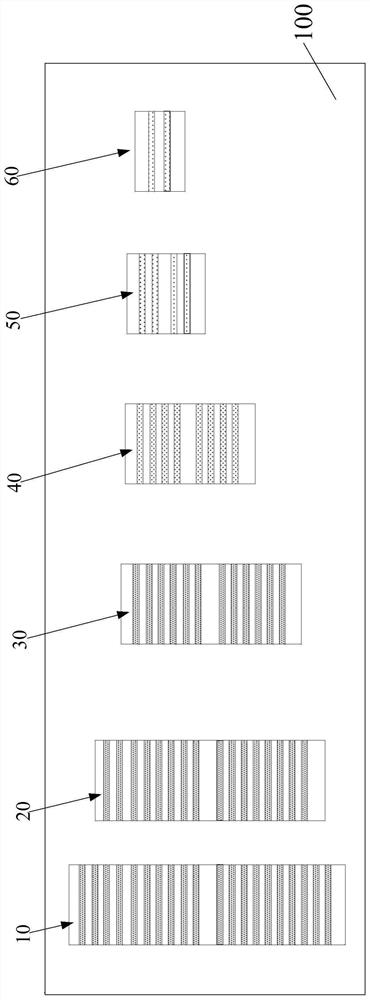

GaN-based LED epitaxial structure of inverted triangular barrier, and growth method thereof

InactiveCN112436079AReduce the effective heightReduced polarizing electric fieldNanotechnologySemiconductor devicesQuantum wellMaterials science

The invention discloses a GaN-based LED epitaxial structure of an inverted triangular barrier, and a growth method thereof. A light-emitting layer is formed by barrier layers and quantum well layers alternately, wherein each barrier layer is a GaN-InxGa1-xN-GaN barrier layer, called a GIG barrier layer for short, and is sequentially formed by one GaN barrier, an InxGa1-xN barrier and one GaN barrier according to the growth sequence, and x in the AlxGa1-xN barrier gradually grows from 0 to 0.15 and then to 0 along the growth direction. The GaN barrier structure of a traditional LED is replacedwith a GIG inverted-triangle-shaped barrier structure, a polarization electric field of a barrier and a quantum well can be effectively reduced through application of an InGaN material in the barrierlayer, the quantum stark effect is effectively inhibited, meanwhile, the effective height of the barrier is not reduced through the special barrier shape provided by the invention, and the inverted triangular potential barrier can still effectively limit current carriers.

Owner:YANGZHOU UNIV

Semiconductor device and method of forming the same

ActiveCN109994471BImprove performanceIncrease the effective heightTransistorSolid-state devicesDevice materialEngineering

A semiconductor device and its forming method, the semiconductor device includes: a semiconductor substrate, the semiconductor substrate includes a high-frequency block group and a low-power block group; a high-frequency type logic standard unit located on the high-frequency block group, a high-frequency type logic Standard cells have high-frequency type cell height, high-frequency type operating frequency, and high-frequency type power; low-power type logic standard cells located on low-power block groups, low-power type logic standard cells have low-power type cell heights , Low power consumption type operating frequency and low power consumption type power, high frequency type unit height is greater than low power consumption type unit height, high frequency type operating frequency is greater than low power consumption type operating frequency, high frequency type power is greater than low power consumption type power The high-frequency type logic standard cell includes a high-frequency type fin, the low-power type logic standard cell includes a low-power type fin, and the effective height of the high-frequency type fin is greater than that of the low-power type fin. The performance of the semiconductor device is improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com