Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

180 results about "De bonding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

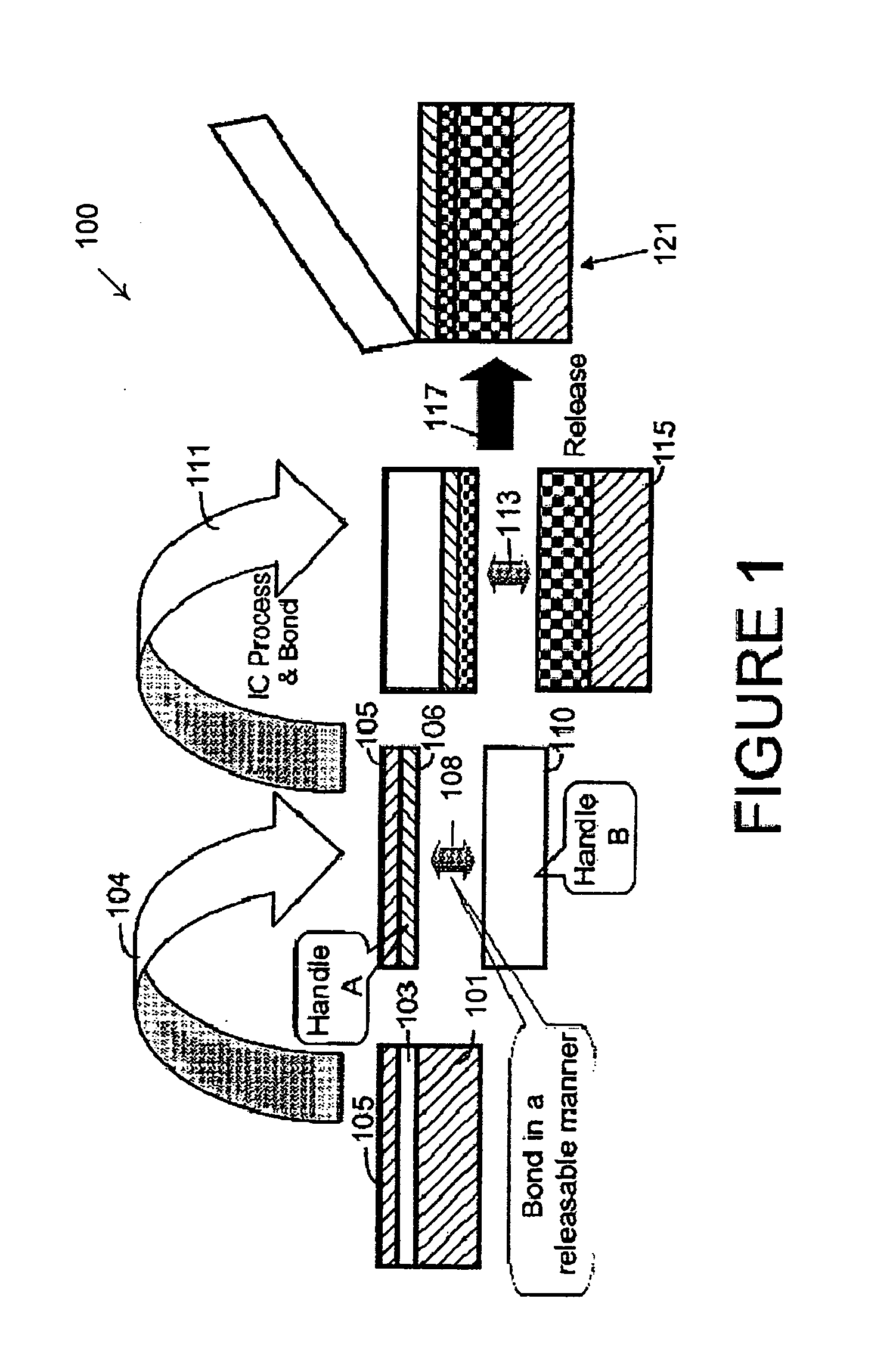

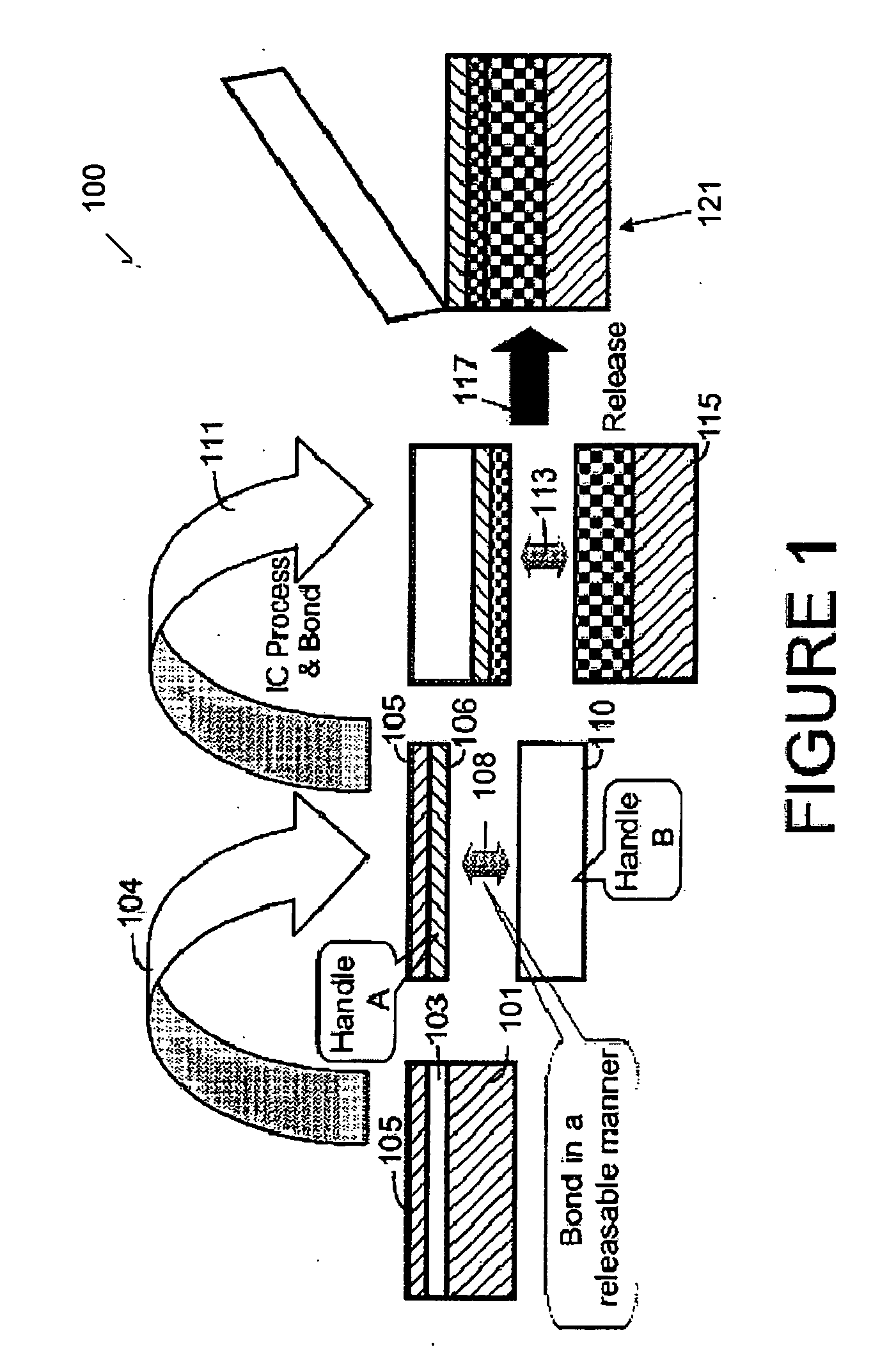

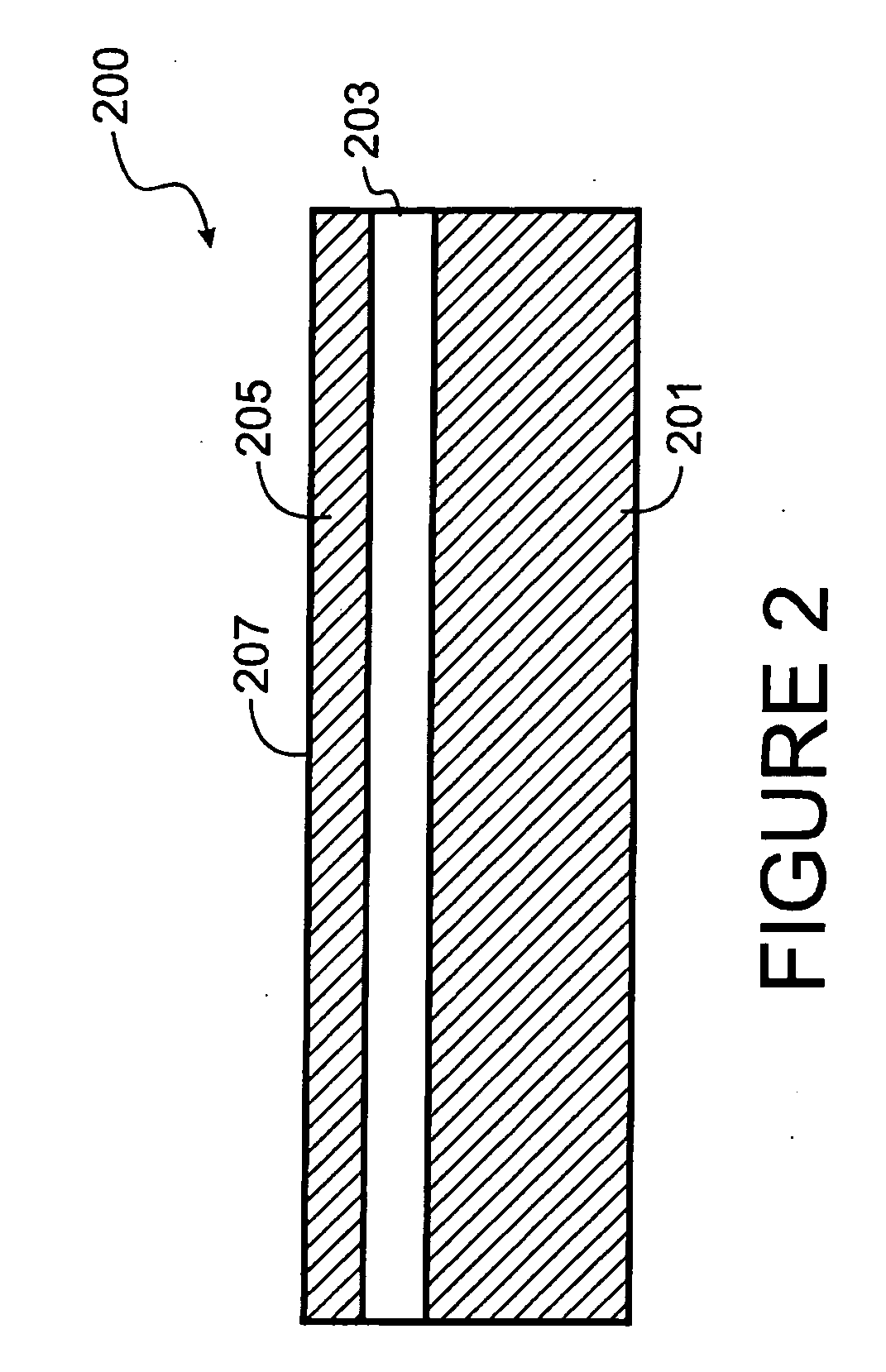

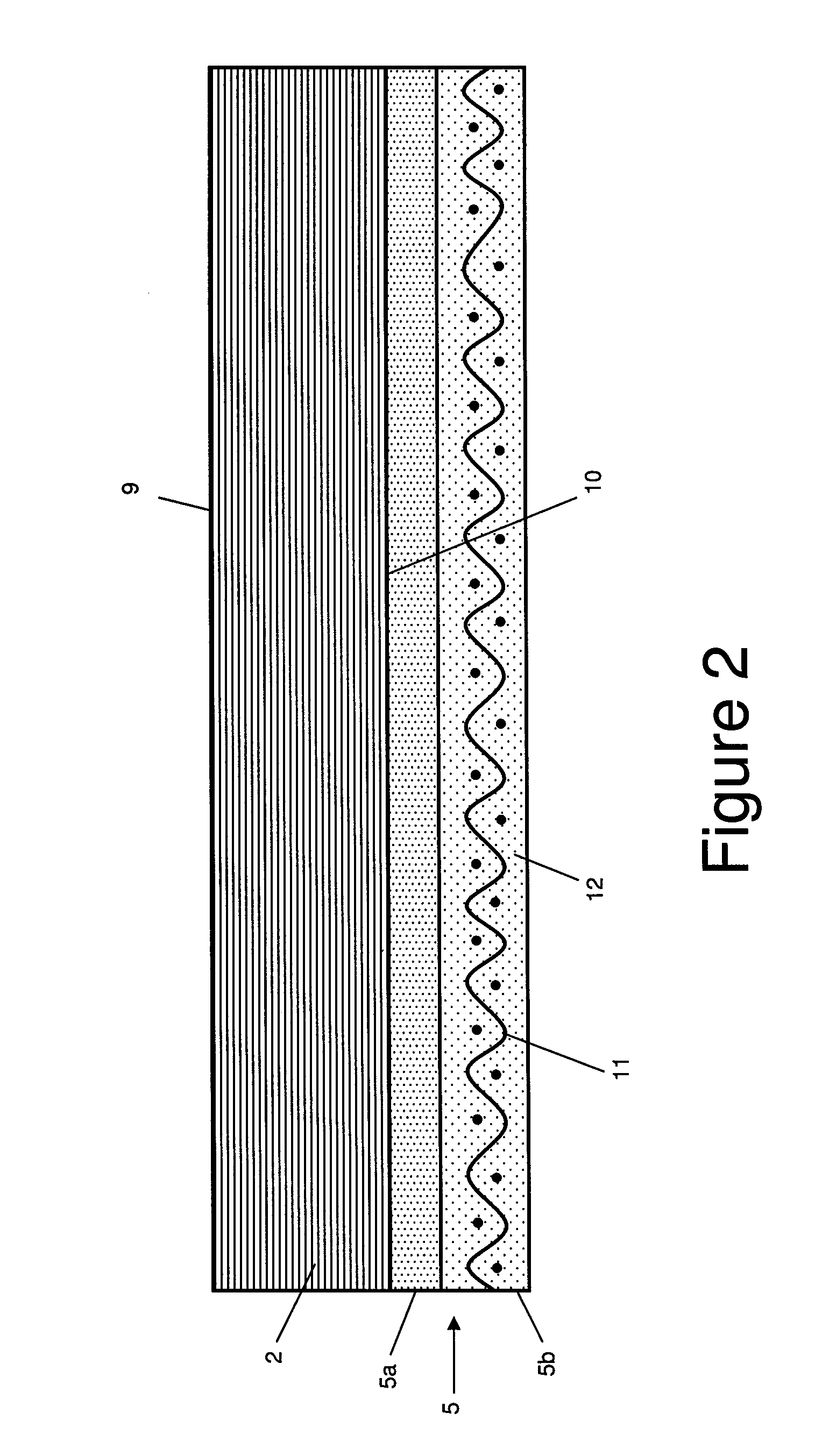

Thin handle substrate method and structure for fabricating devices using one or more films provided by a layer transfer process

ActiveUS7166520B1Avoid the possibility of damageEfficient processingSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor materialsEngineering

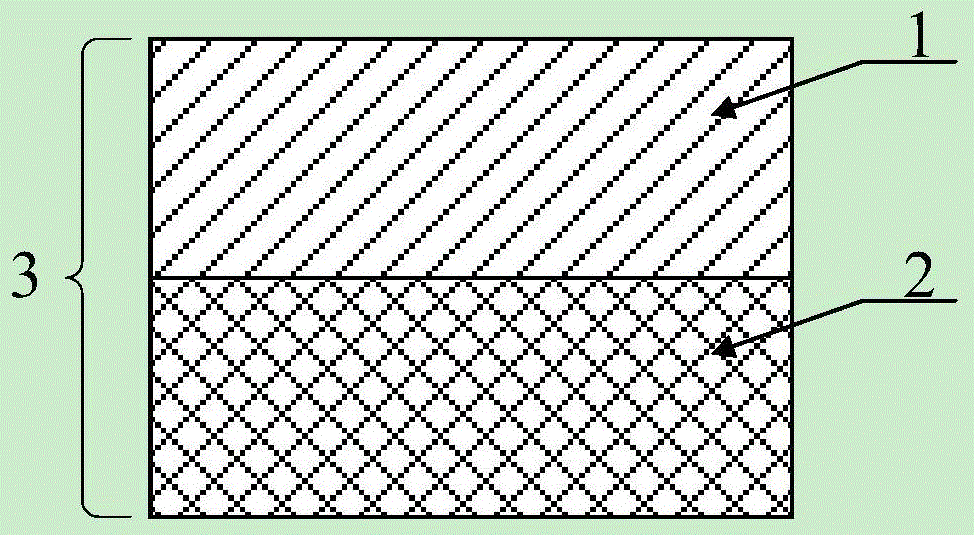

A method for fabricating one or more devices, e.g., integrated circuits. The method includes providing a substrate (e.g., silicon), which has a thickness of semiconductor material and a surface region. The substrate also has a cleave plane provided within the substrate to define the thickness of semiconductor material. The method includes joining the surface region of the substrate to a first handle substrate. In a preferred embodiment, the first handle substrate is termed a “thin” substrate, which provides suitable bonding characteristics, can withstand high temperature processing often desired during the manufacture of semiconductor devices, and has desirable de-bonding characteristics between it and a second handle substrate, which will be described in more detail below. In a preferred embodiment, the first handle substrate is also thick enough and rigid enough to allow for cleaving according to a specific embodiment.

Owner:SILICON GENERAL CORPORATION

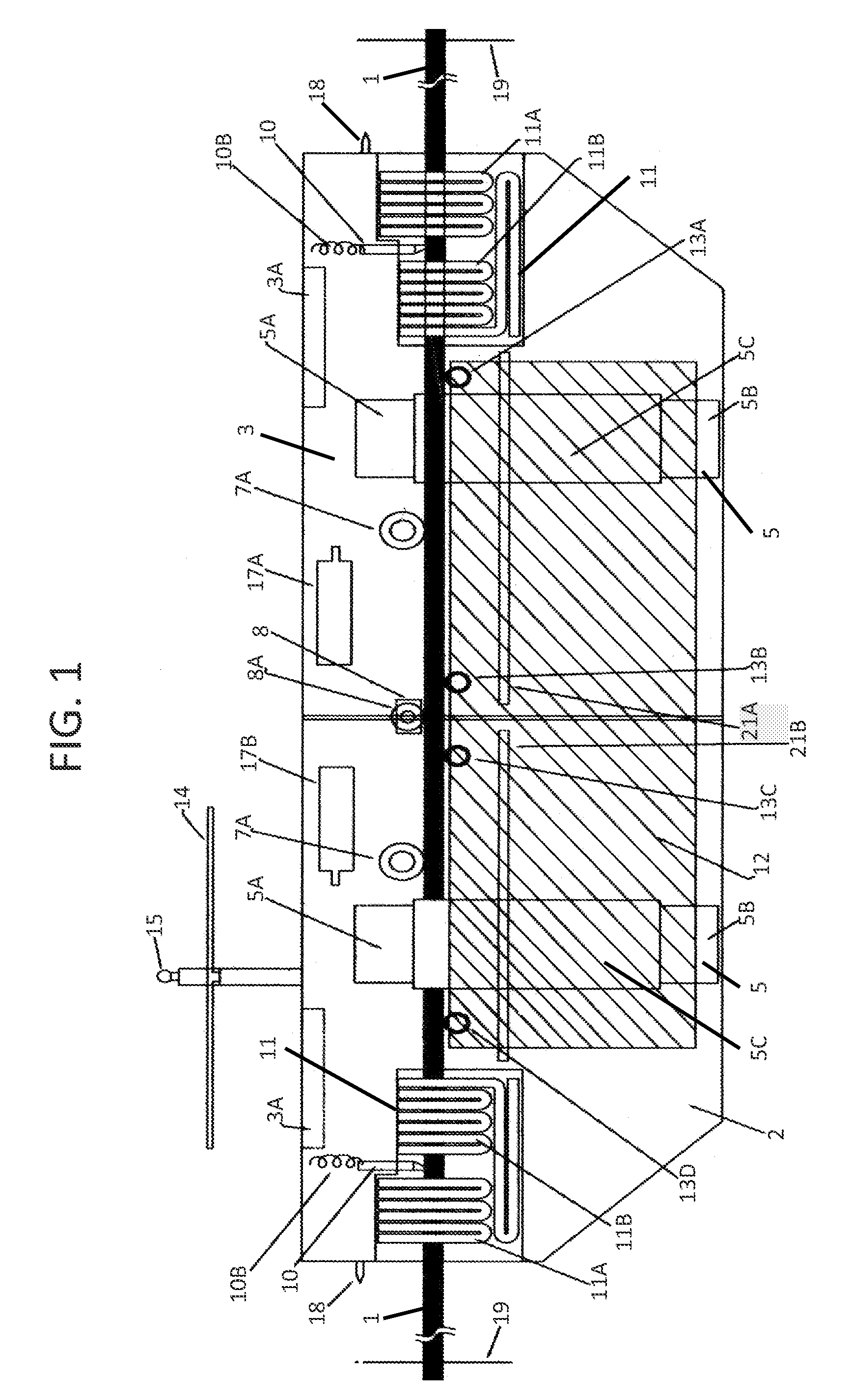

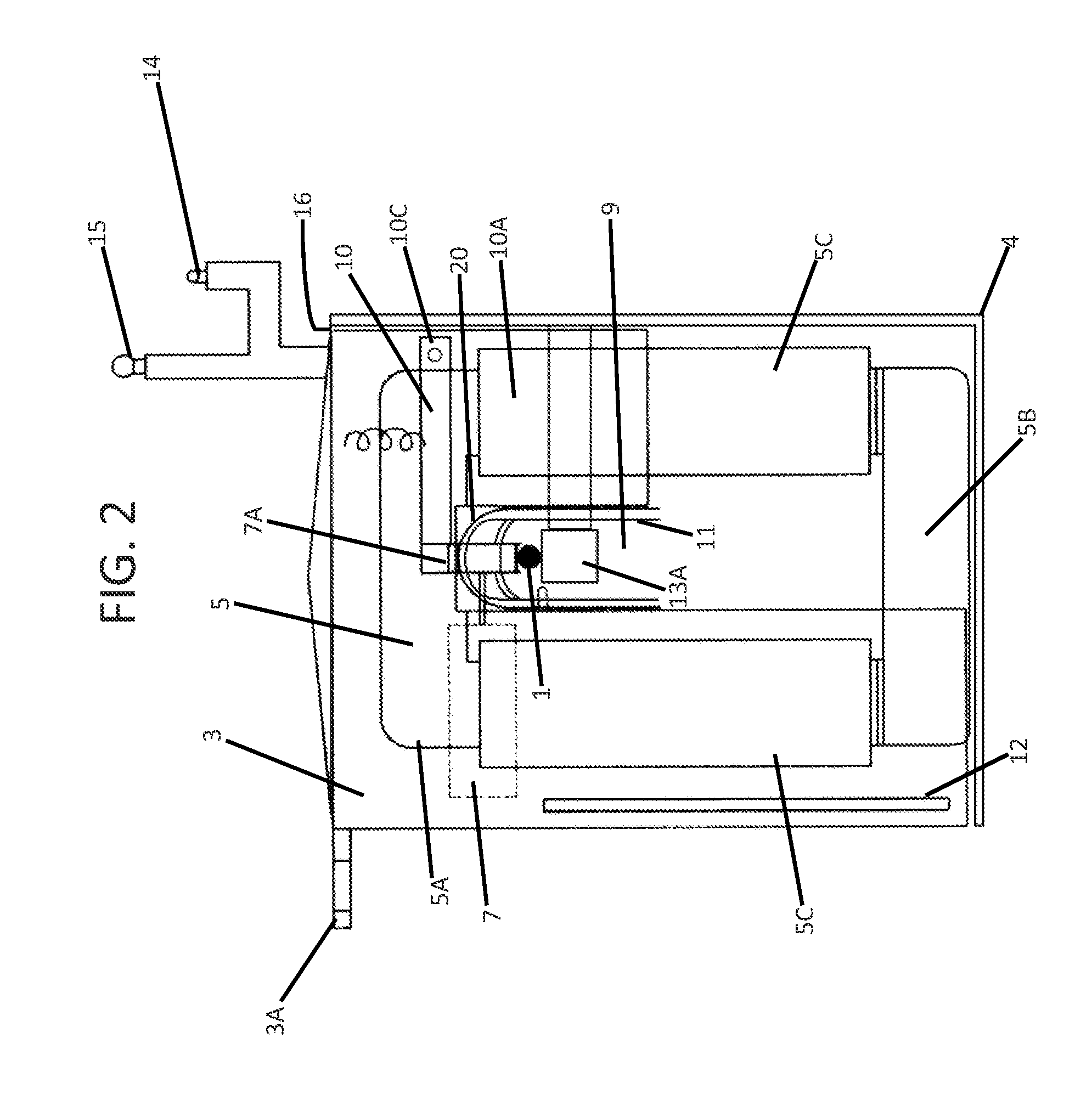

Power Line De-Icing Apparatus

InactiveUS20100243633A1Efficient removalWeaken layerOverhead installationOhmic-resistance heatingChiselEngineering

A power line de-icing apparatus that incorporates both thermal and mechanical means to remove various forms of accumulated ice or wet snow from power lines. The apparatus uses a minimum amount of energy to first de-bond and then break off ice from the power line; using far less power than required to fully melt ice. The apparatus operates autonomously, activating heating and chisel mechanisms, and moving between power line support towers in response to both temperature and ice sensor inputs. This operation is repeated in both directions along the power line as long as icing continues to activate the sensors; removing ice more quickly than it can accumulate and thereby preventing mechanical or electrical damage to the power lines and supporting towers. The apparatus is self contained and powered inductively from the power line. It is installed onto the power line without the need for disconnecting the power line.

Owner:HUYNH TUNG +2

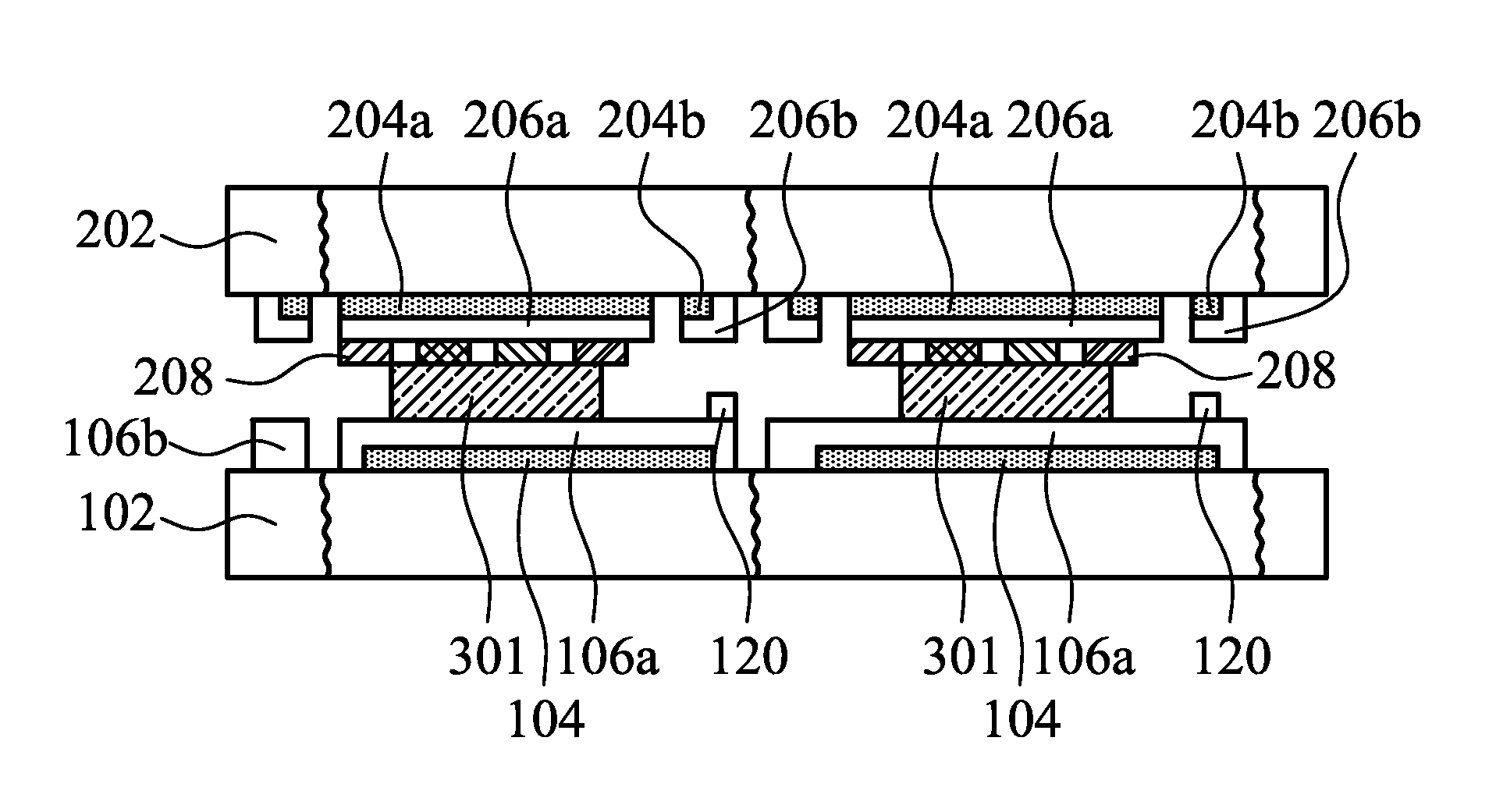

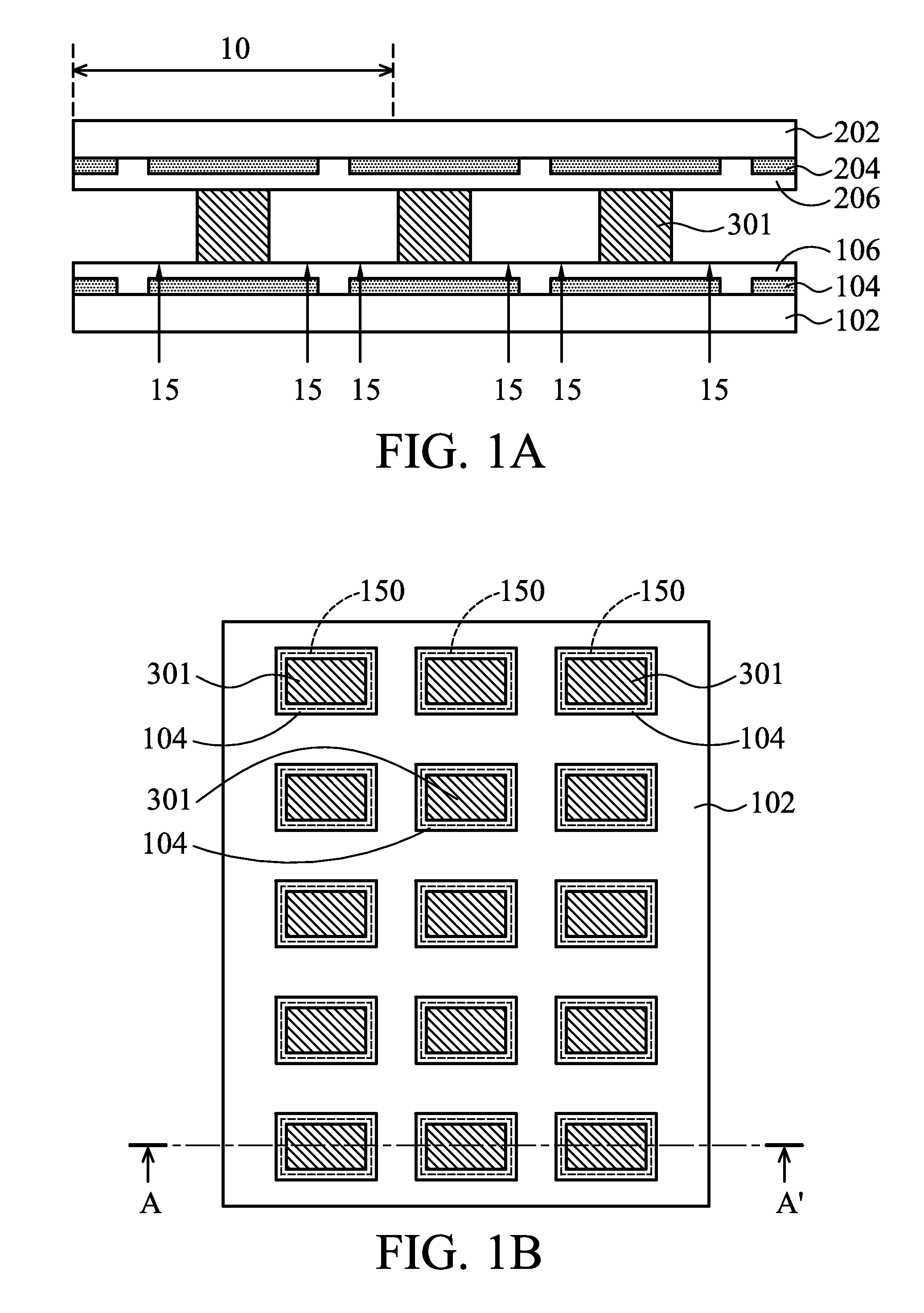

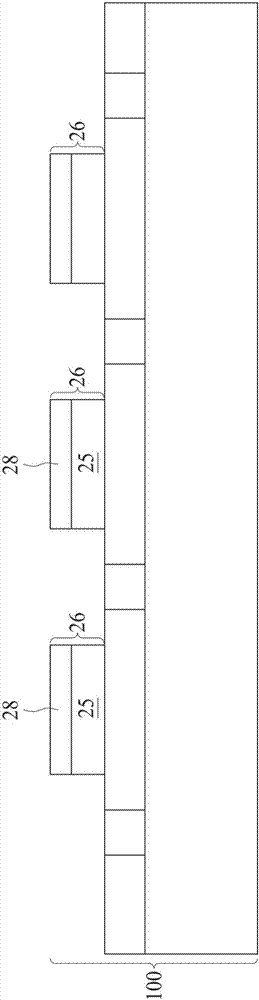

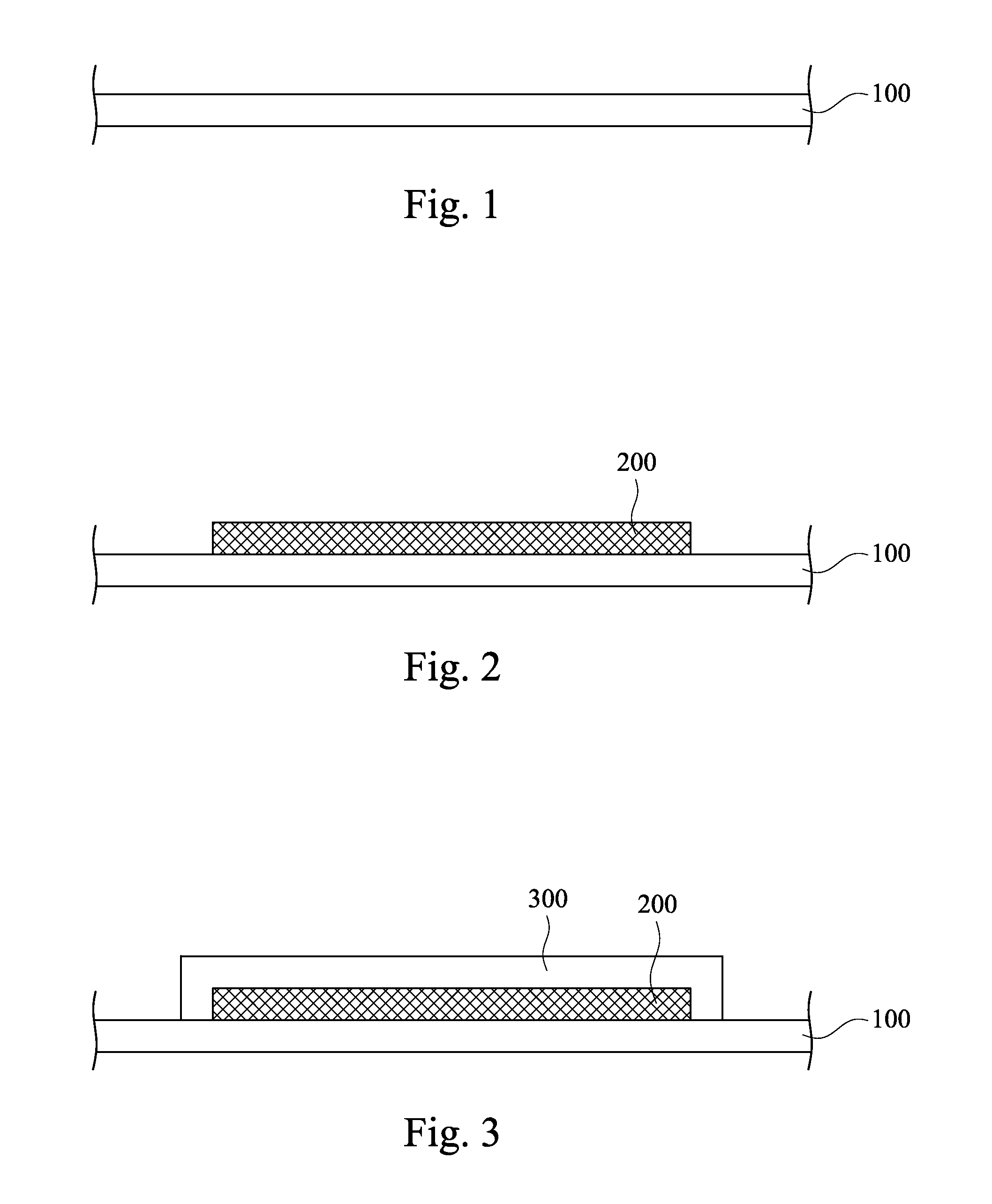

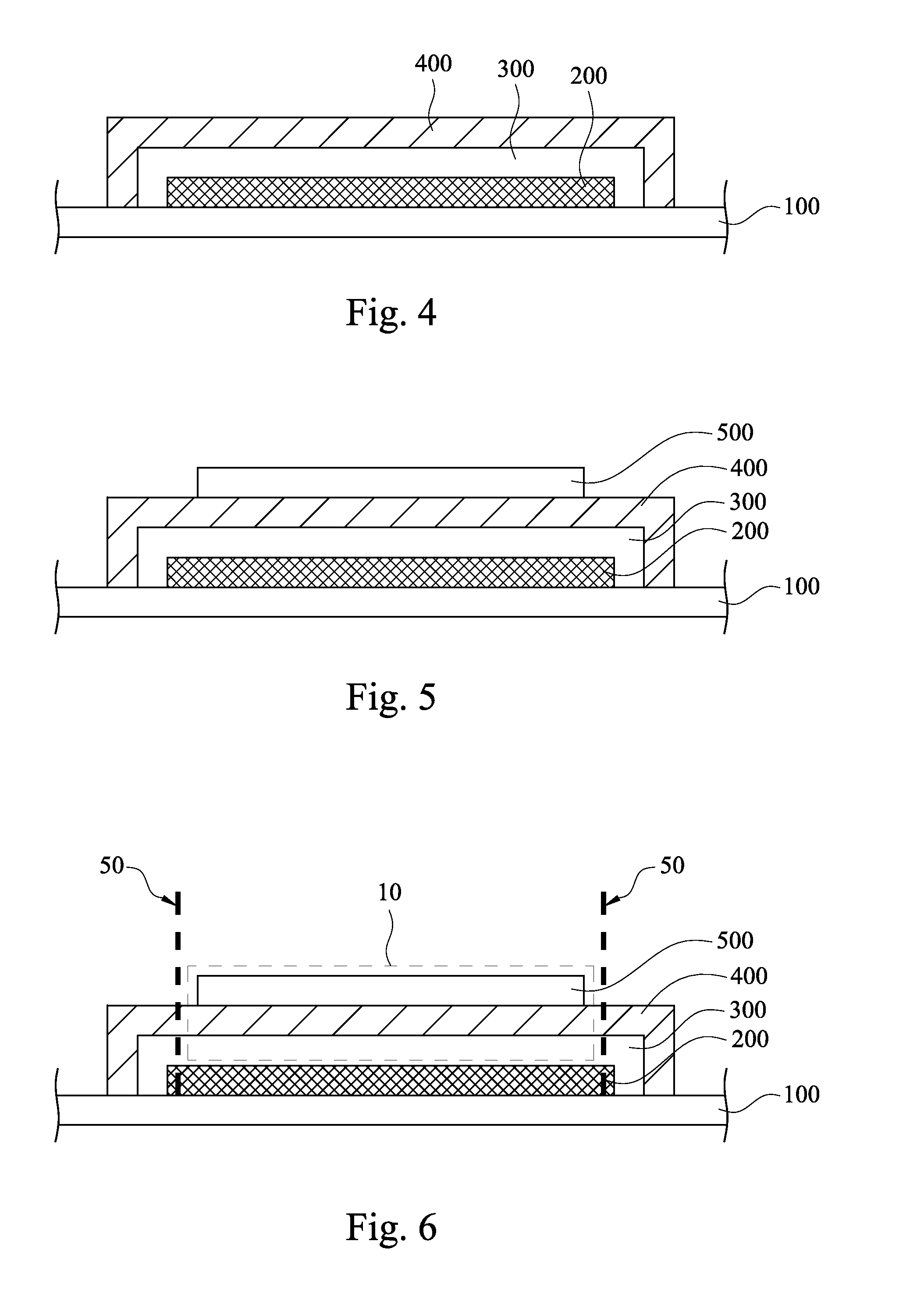

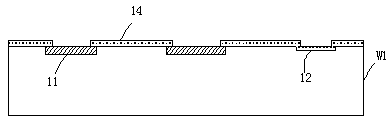

Method for fabricating the flexible electronic device

ActiveUS20130011969A1Solid-state devicesSemiconductor/solid-state device manufacturingEngineeringFlexible electronics

The disclosure provides a method for fabricating the flexible electronic devices, including: providing a first rigid carrier substrate and a second rigid carrier substrate, wherein at least one flexible electronic device is formed between the first rigid carrier substrate and the second rigid carrier substrate, and a plurality of first de-bonding areas, a first flexible substrate, the flexible electronic device, a second flexible substrate, a plurality of second de-bonding areas and the second rigid carrier substrate are formed on the first rigid carrier substrate; performing a first cutting step to cut through the first de-bonding areas; separating the first rigid carrier substrate from the first de-bonding areas; removing the first rigid carrier substrate from the first de-bonding areas; and performing a second cutting step to cut through the second de-bonding areas; separating and removing the second rigid carrier substrate from the second de-bonding areas.

Owner:HANNSTAR DISPLAY CORPORATION

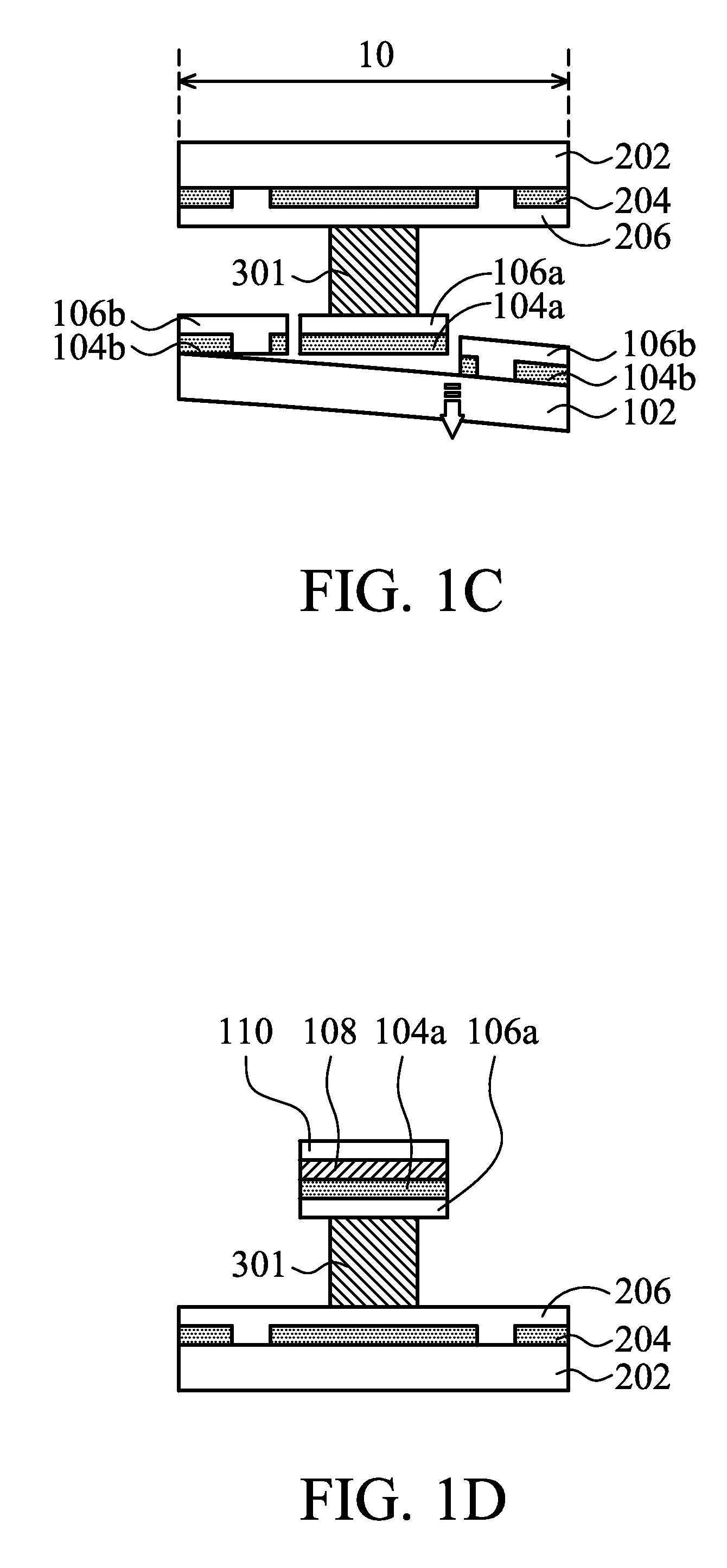

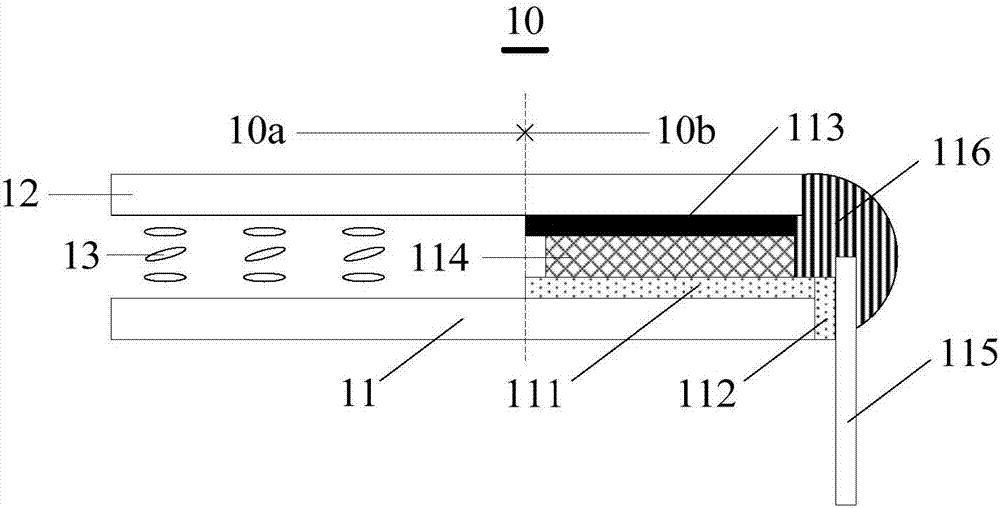

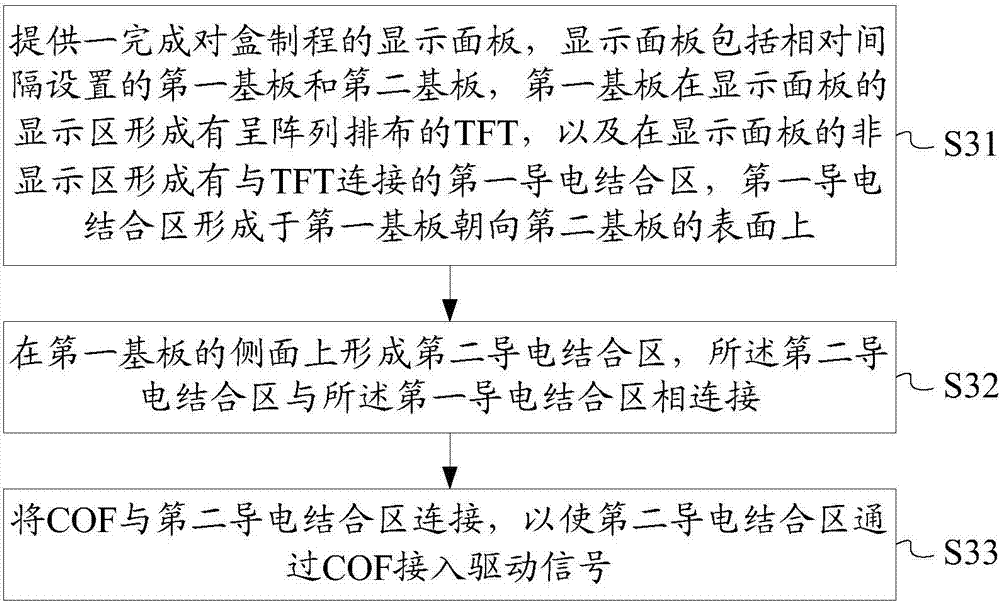

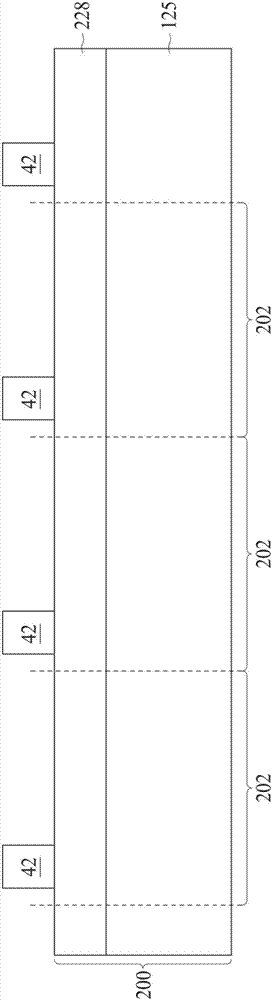

Display panel, manufacturing method thereof and display device

InactiveCN107121854ADoes not increase non-display widthImprove conduction efficiencyNon-linear opticsDisplay deviceEngineering

The invention discloses a display panel, a manufacturing method thereof and a display device. A designed bonding pad comprises a first conductive bonding area and a second conductive bonding area, the first conductive bonding area is arranged on the surface of a first substrate, and the second conductive bonding area is arranged on the side face of the first substrate, that is, a bonding pad connected with a COF is arranged on the side face of an array substrate. On the basis, the conductive efficiency of the bonding pad and the connection stability of the bonding pad and the COF are improved on the premise of being beneficial to narrow-border design and frameless design.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

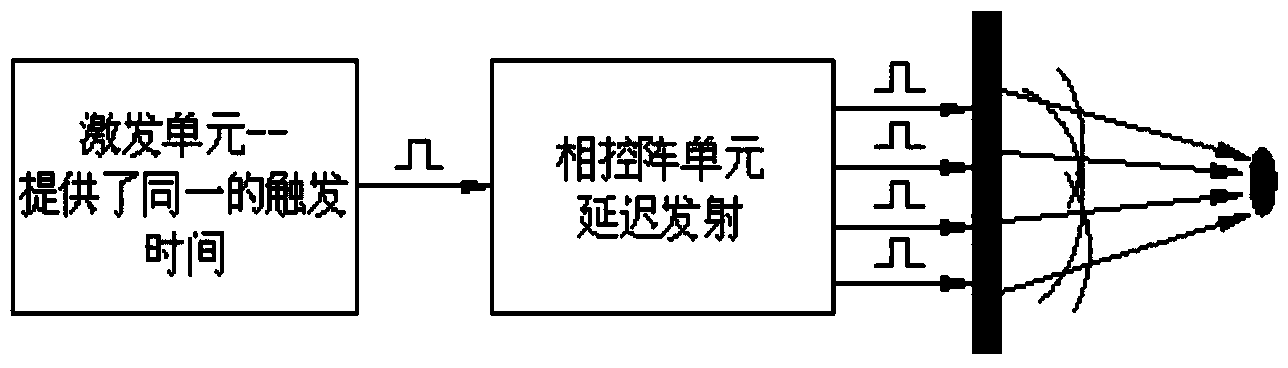

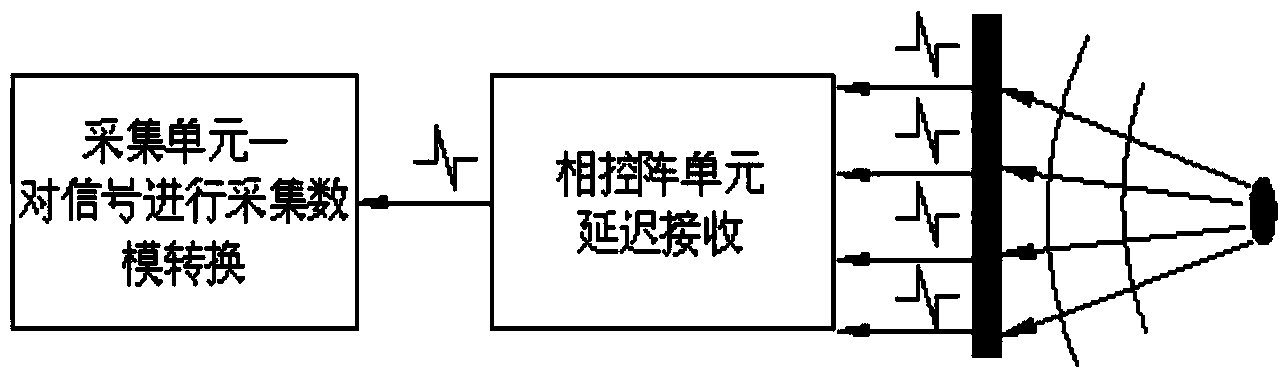

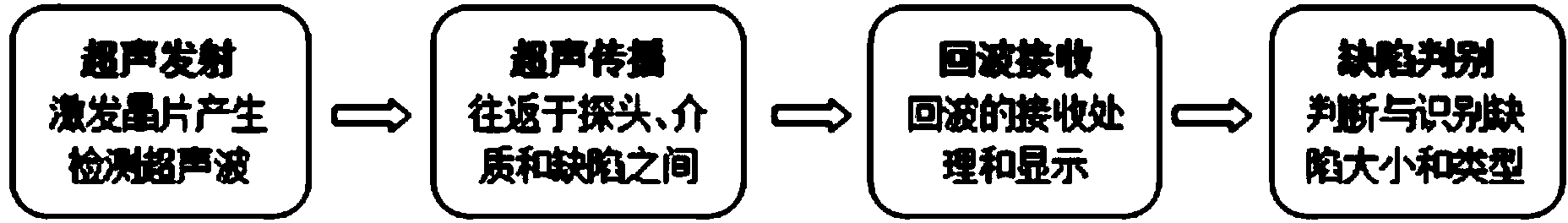

Phased-array ultrasonic detection method for interfacial de-bonding of composite material

InactiveCN103901108AEnables real-time non-destructive testingImprove detection accuracyAnalysing solids using sonic/ultrasonic/infrasonic wavesInterfacial bondingUltrasound

The invention discloses a phased-array ultrasonic detection method for interfacial de-bonding of a composite material. The method comprises the following steps: (1) sequentially triggering each wafer of a phased-array probe to generate ultrasonic signals, superposing the ultrasonic signals, propagating the ultrasonic signals inside the composite material, and reflecting the ultrasonic signals during the interface de-bonding or interfacial de-bonding of the composite material; (2) superposing the reflected ultrasonic signals, receiving the ultrasonic signals by using the phased-array probe, performing data processing, and then outputting a phased-array scanning image through a phased-array display instrument; (3) comparing an ultrasonic detection image during the good interfacial bonding of the composite material with an ultrasonic detection image during the interfacial de-bonding of the composite material to judge whether the composite material has a de-bonding defect. The method has the advantages of high detection accuracy, simple operation process and the like.

Owner:SOUTH CHINA UNIV OF TECH

Cigarette aluminum-foil paper with anti-counterfeiting label

InactiveCN105178107AImprove temperature resistanceImprove aging resistanceFlexible coversWrappersHazardous substanceLaser patterning

The invention provides cigarette aluminum-foil paper with an anti-counterfeiting label. The cigarette aluminum-foil paper comprises liner paper and an aluminum foil layer. An anti-counterfeiting laser film is arranged on the surface of the aluminum foil layer. The manufacturing process comprises the steps that the laser film is manufactured, an aluminum foil body coated with glue is heated and baked, the laser film and the aluminum foil are composited, a BOPP film is stripped from a cured semi-finished product, a BOPP base film on a cooled composited film is removed, a complexing agent for connecting the liner paper and the aluminum foil layer is prepared, and finally the liner paper and the aluminum foil layer are composited. The BOPP base film has the good temperature resistance and ageing resistance, materials are soft, no transparent de-bonding layer needs to coat the materials, and the technological process is simple; the anti-counterfeiting film is transferred onto aluminum foil, laser patterns will not disappear and are not likely to be damaged, and the while film is good in high temperature resistance and will not crack. The complexing agent between the liner paper and the aluminum foil layer is not likely to volatilize to generate hazardous substances, the temperature is high, and adhesive force can be provided for the liner paper and the aluminum foil layer for a long time.

Owner:CHUZHOU CIGARETTE MATERIALS FACTORY

Method for fabricating through substrate vias in semiconductor substrate

ActiveUS8383460B1Solid-state devicesSemiconductor/solid-state device manufacturingAdhesiveEngineering

Methods are provided for fabricating integrated circuit systems that include forming integrated circuits in and on a semiconductor substrate. Via holes are etched into a front surface of the semiconductor substrate and are filled with a conductive material. A carrier wafer having a layer of adhesive thereon is provided and an imprinted pattern is formed in the layer of adhesive. The front surface of the semiconductor substrate is bonded to the carrier wafer with the patterned layer of adhesive. A portion of a back surface of the semiconductor substrate is removed to expose a portion of the conductive material and the thinned back surface is attached to a second substrate. The semiconductor substrate is then de-bonded from the carrier wafer.

Owner:GLOBALFOUNDRIES INC

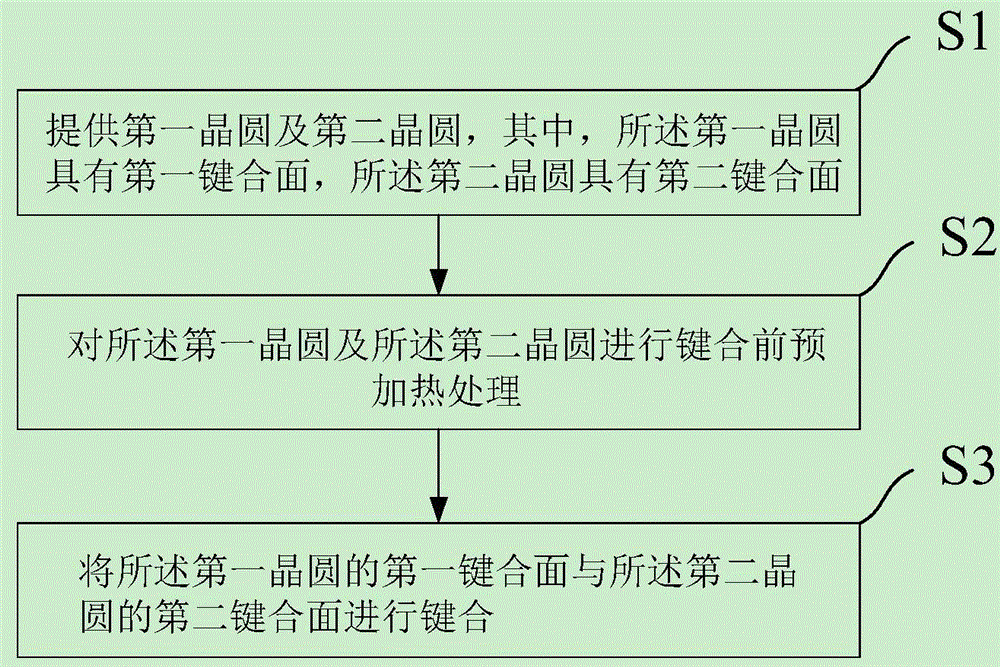

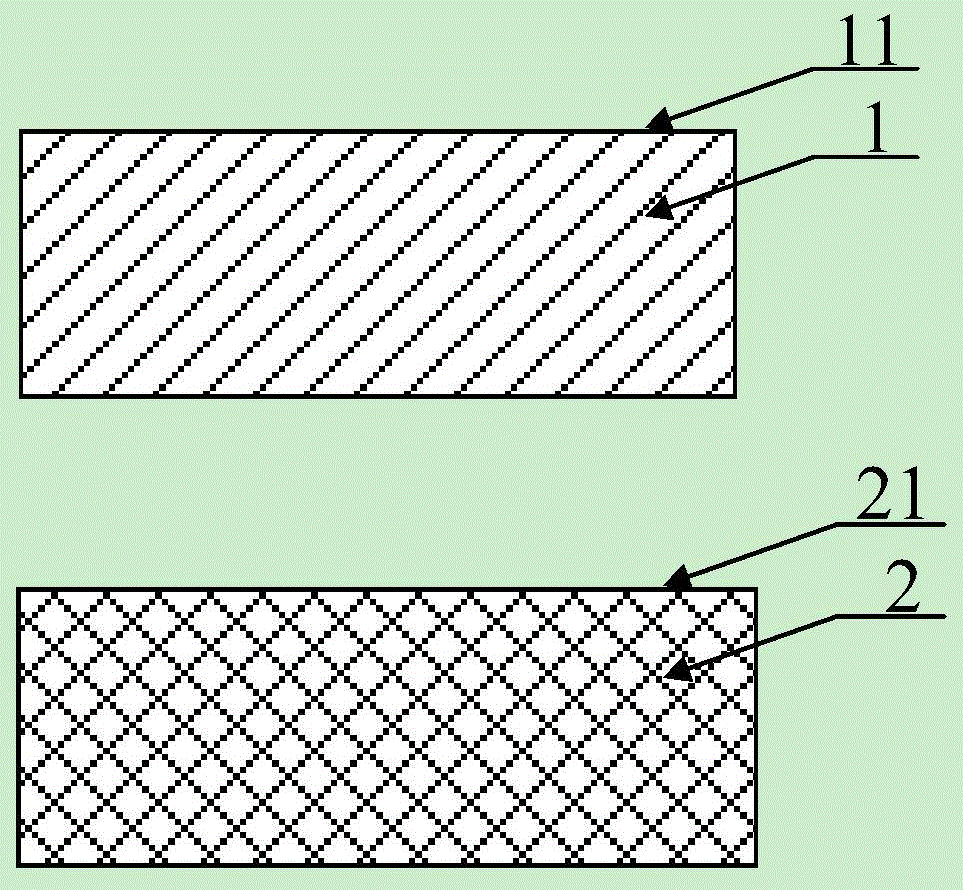

Wafer bonding method and preparation method for foreign substrate

ActiveCN106711027AReduce thermal strainImprove reliabilityPrecision positioning equipmentSoldering apparatusEngineeringWafer bonding

The invention provides a wafer bonding method and a preparation method for a foreign substrate. The wafer bonding method at least comprises the following steps: S1) supplying a first wafer and a second wafer, wherein the first wafer is equipped with a first bonding surface, and the second wafer is equipped with a second bonding surface; S2) preheating before bonding the first wafer and the second wafer; and S3) bonding the first bonding surface of the first wafer with the second bonding surface of the second wafer. According to the scheme, the preheating before the bonding for the wafers is capable of effectively reducing the thermal strain of the foreign bonding structure in a high-temperature post-annealing process, so that the use scope of the foreign bonding can be widened and the reliability of a foreign integrated material can be promoted. Meanwhile, the problems of de-bonding and broken bonding structure caused by thermal strain of the foreign bonding structure in the high-temperature post-annealing process can be solved.

Owner:SHANGHAI NOVEL SI INTEGRATION TECH CO LTD

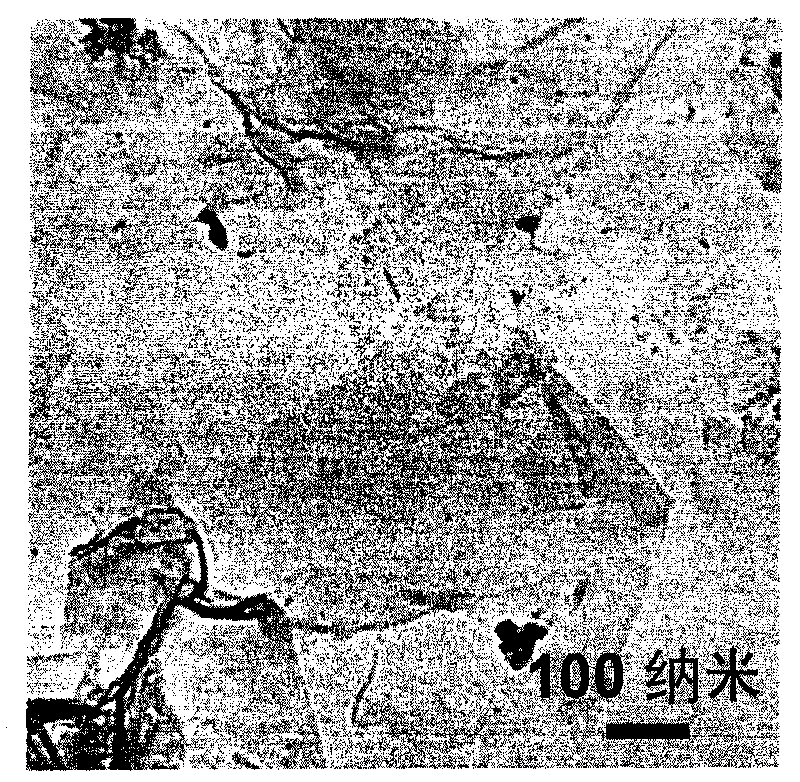

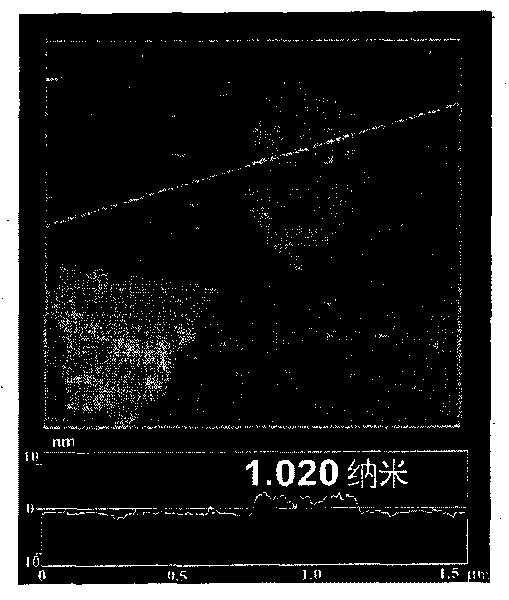

Method for preparing composite material of graphene and graphene poly-p-phenylenediamine

The invention relates to a method for preparing a composite material of graphene and graphene poly-p-phenylenediamine, which comprises the following steps of: dissolving p-phenylenediamine in N,N-dimethylformamide, and then adding the mixture into an oxidized graphite colloid treated by ultrasonic de-bonding; treating the mixture in an oil bath, and filtering an obtained colloid; washing the colloid with acetone, and then dispersing the obtained wet powder into ethanol, glycol, N-methyl pyrrolidone and the N,N-dimethylformamide to obtain a stable graphene colloid; adding a K2S2O8 hydrochloric acid aqueous solution into the unfiltered and unwashed graphene colloid; treating the mixture in an ice bath; and washing the mixture with acetone, hydrochloric acid and water to obtain graphene poly-p-phenylenediamine composite powder. The composite material of the graphene colloid and the graphene poly-p-phenylenediamine prepared by the method has good dispersity and simple preparation process.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

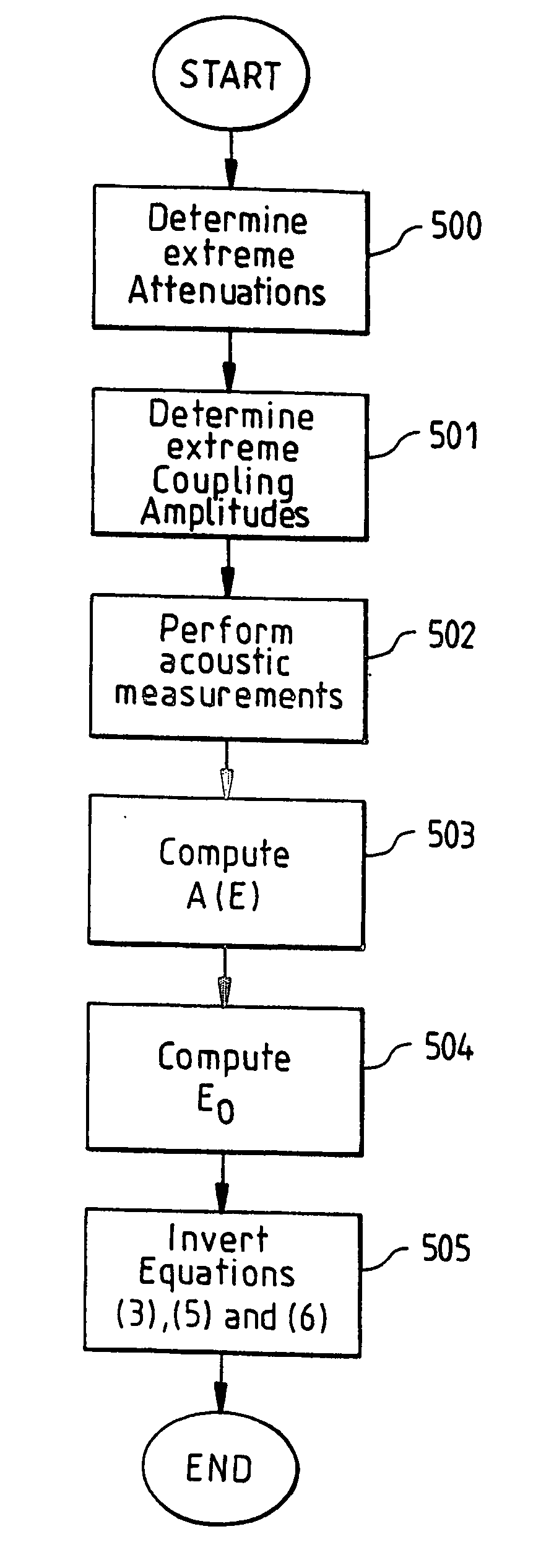

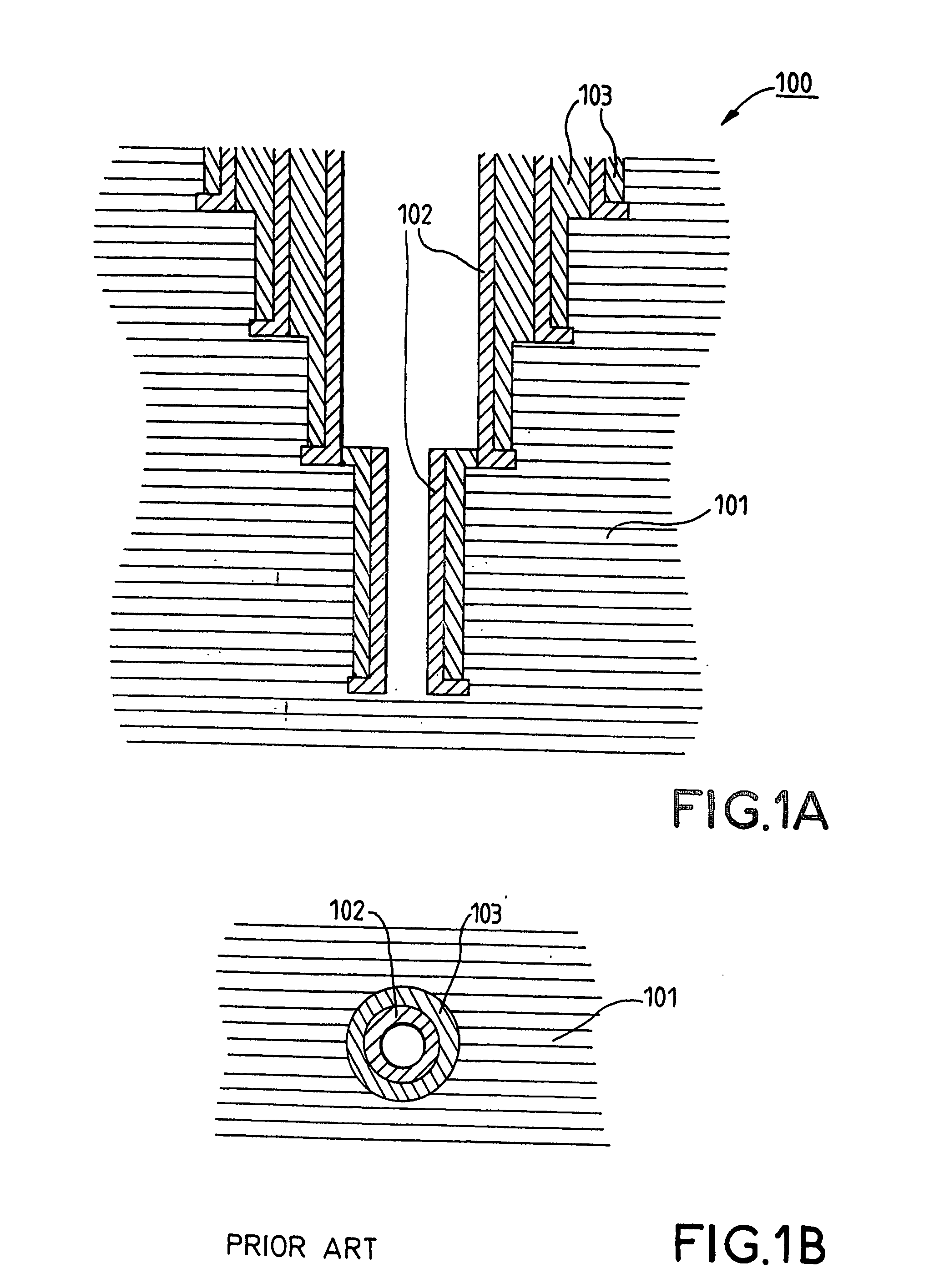

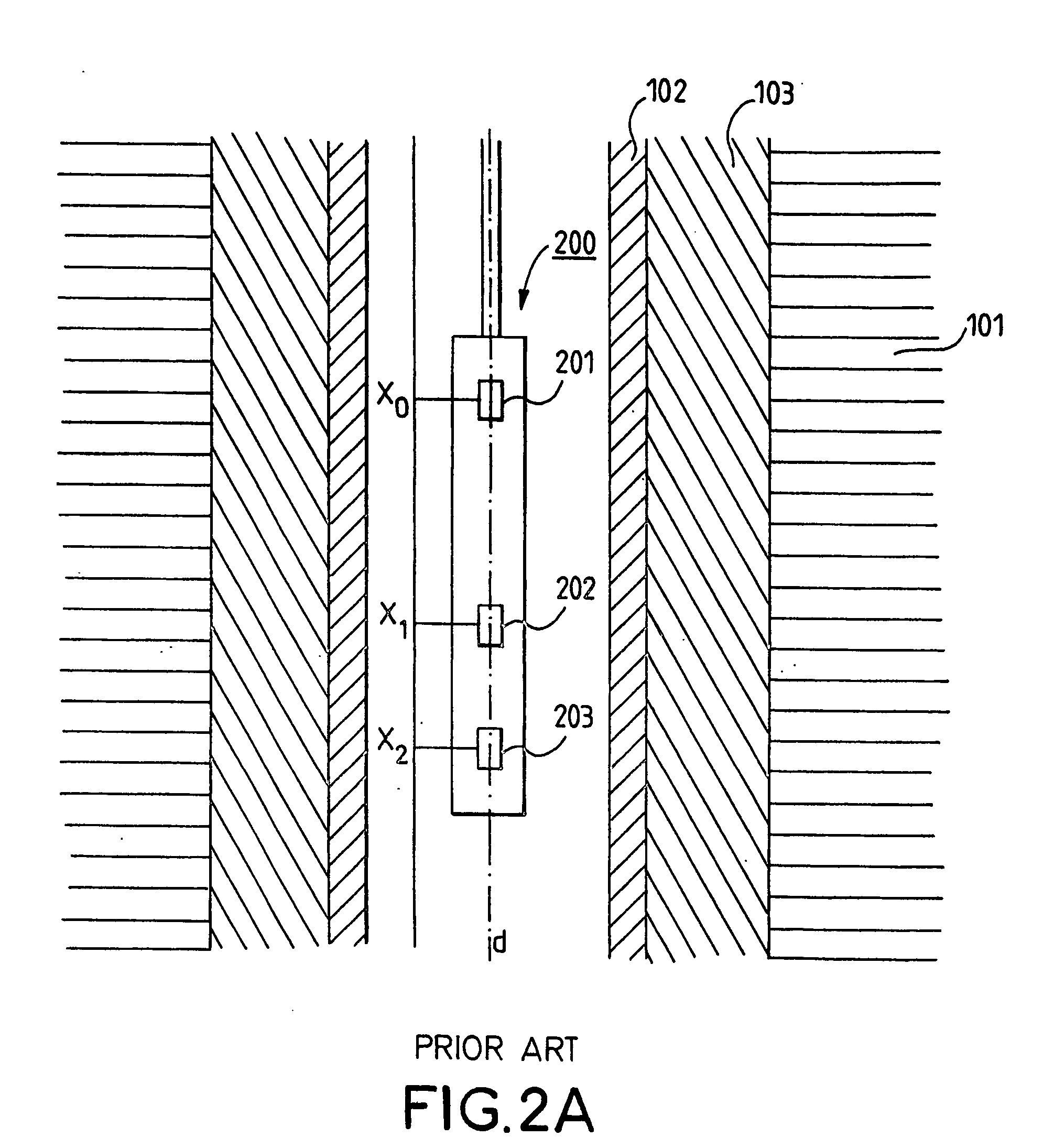

Method for cement bond evaluation in boreholes

InactiveUS20060262644A1Analysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalUltrasound attenuationWavefront

A method for determining components of a tube casing surrounding a tube uses amplitude measurements of an acoustic signal wavefront emitted inside the tube. The acoustic signal wavefront is affected by the components of the tube casing while propagating in the tube. Various parameters such as an attenuation A(E) of the amplitude inside the tube and a coupling amplitude Eo may be determined. Theses parameters may be inserted in equations that are inverted to obtain a percentage of cement bonded φC in the tube casing, a percentage of cement de-bonded φD in the tube casing and a percentage of liquid φW in the tube casing.

Owner:SCHLUMBERGER TECH CORP

Method and structure of three-dimensional chip stacking

ActiveCN106952833ASemiconductor/solid-state device detailsSolid-state devicesEngineeringChip stacking

A method includes placing a first plurality of device dies over a first carrier, with the first plurality of device dies and the first carrier in combination forming a first composite wafer. The first composite wafer is bonded to a second wafer, and the first plurality of device dies is bonded to a second plurality of device dies in the second wafer through hybrid bonding. The method further includes de-bonding the first carrier from the first plurality of device dies, encapsulating the first plurality of device dies in an encapsulating material, and forming an interconnect structure over the first plurality of device dies and the encapsulating material. The embodiment of the invention relates to a package and a manufacturing method thereof.

Owner:TAIWAN SEMICON MFG CO LTD

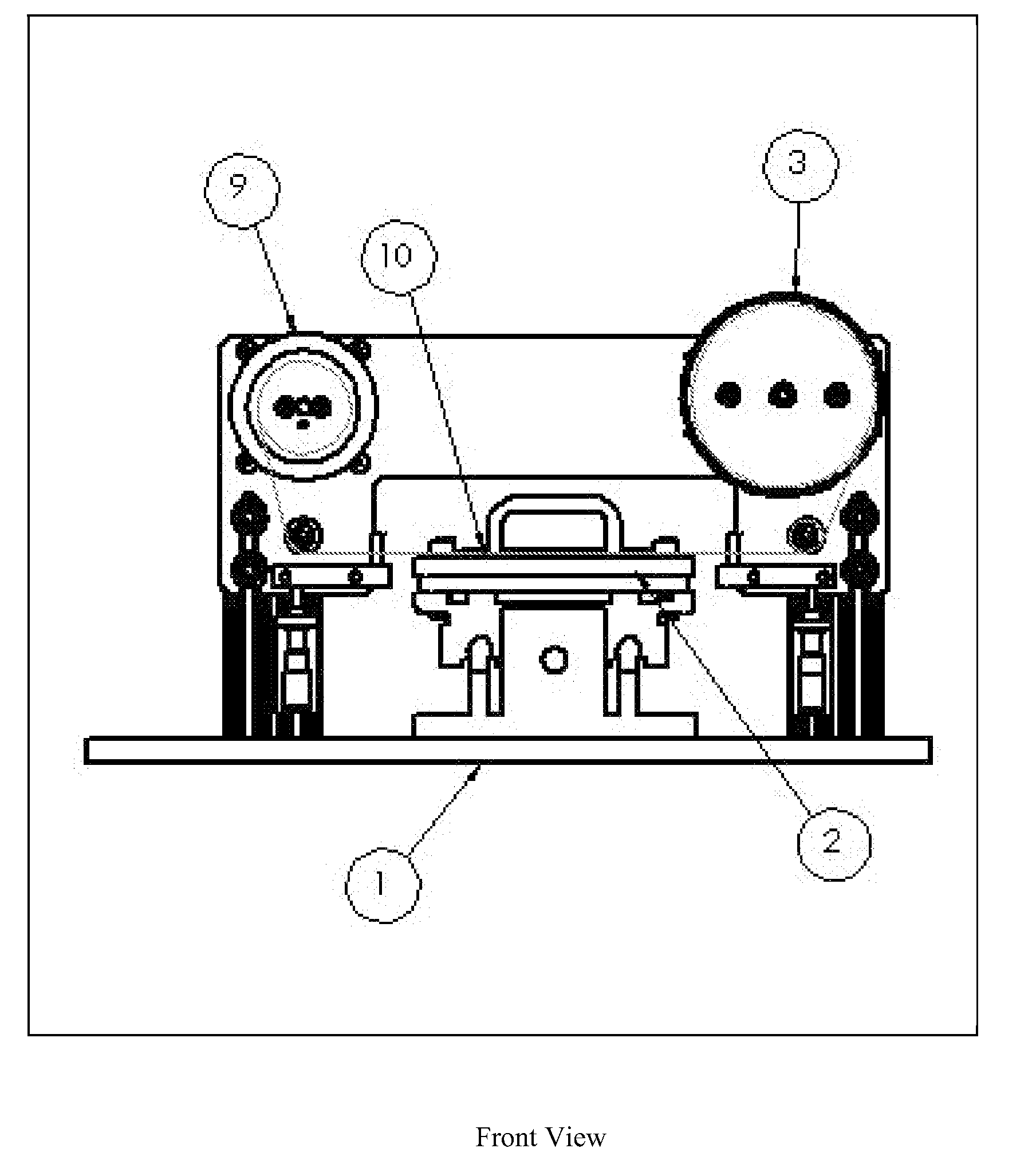

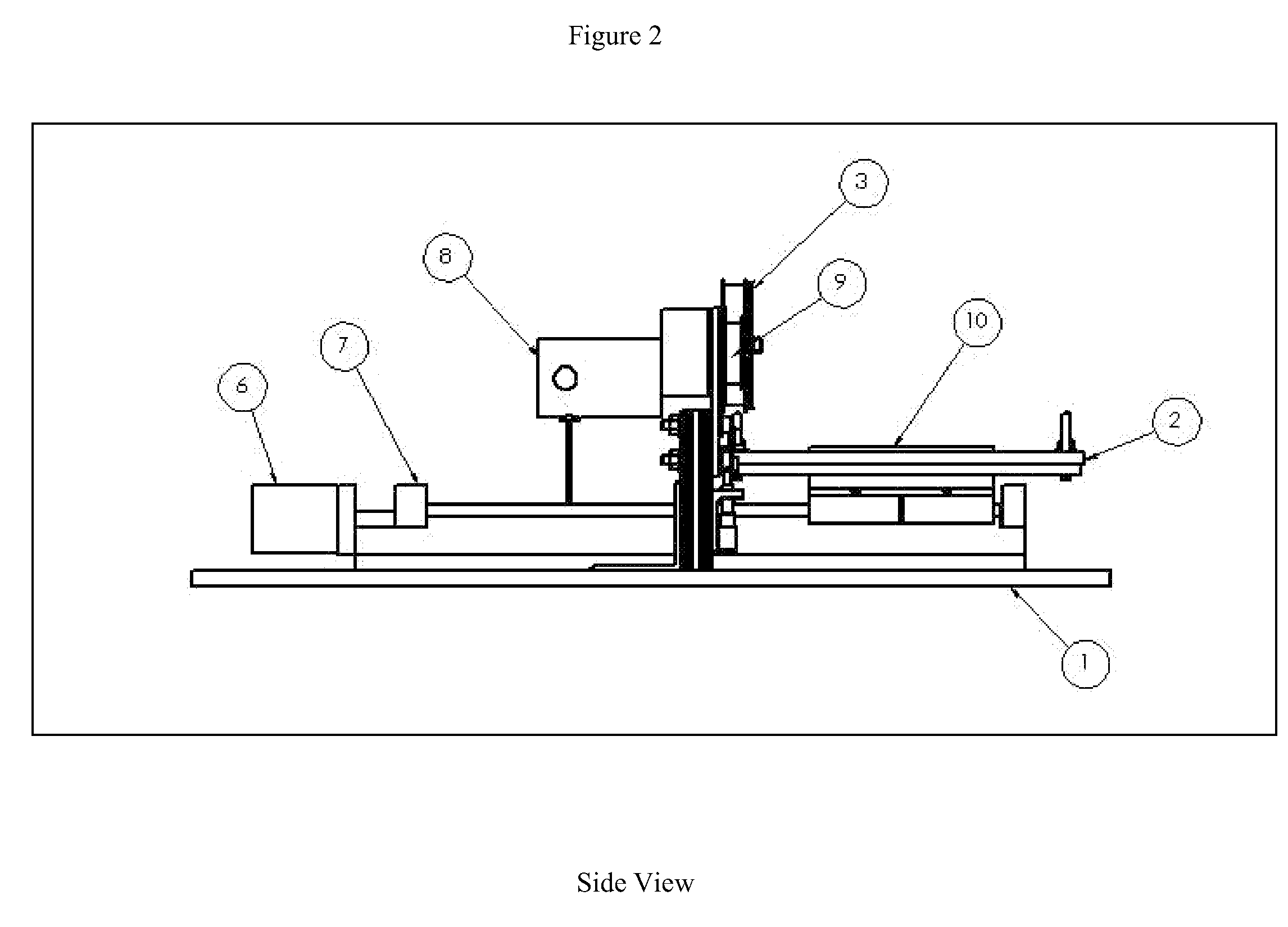

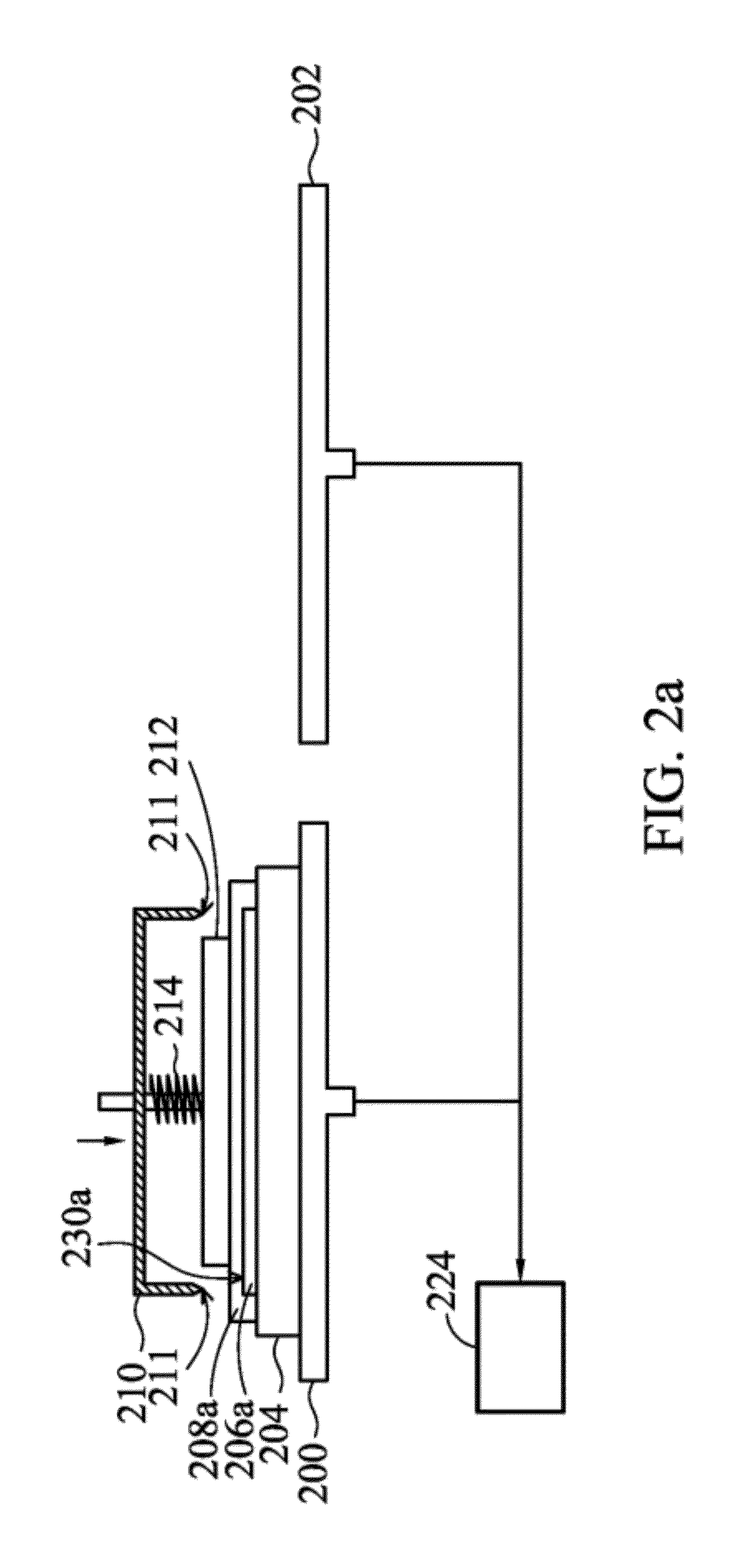

Semi-automated reworkability equipment for de-bonding a display

InactiveUS20110174445A1Semiconductor/solid-state device manufacturingAdhesivesDisplay deviceEngineering

Owner:EI DU PONT DE NEMOURS & CO

Method for bonding carbon fiber/phenolic-nitrile rubber materials

ActiveCN104861884AComplete structureMeet the design requirementsAdhesive processes with surface pretreatmentAdhesive processes with adhesive heatingStructural reliabilityFiber

The invention discloses a method for bonding carbon fiber / phenolic-nitrile rubber materials, and belongs to the field of the manufacturing of a solid rocket engine insulator, and aims at solving the bonding problems of an engine housing, a first EPDM insulation material, a carbon fiber / phenolic-nitrile rubber materials and a second EPDM insulation material and improving the structural reliability. The method mainly comprises the steps of preparation, coating, prefabrication, cleaning, glue coating, setting, thermal pre-pressing, flaw detection, curing and the like. The structural integrity of the engine housing, a first EPDM insulation material, the carbon fiber / phenolic-nitrile rubber materials and the second EPDM insulation material are ensured by using a secondary bonding method, a secondary curing mode, a prefabrication forming method, a stepped temperature rising / dropping mode and other methods; the method has no de-bonding, air-entraining air hole and other quality problems, completely can meet the design requirements, and ensures the safety and reliability of a system.

Owner:HUBEI SANJIANG AEROSPACE JIANGHE CHEM TECH +1

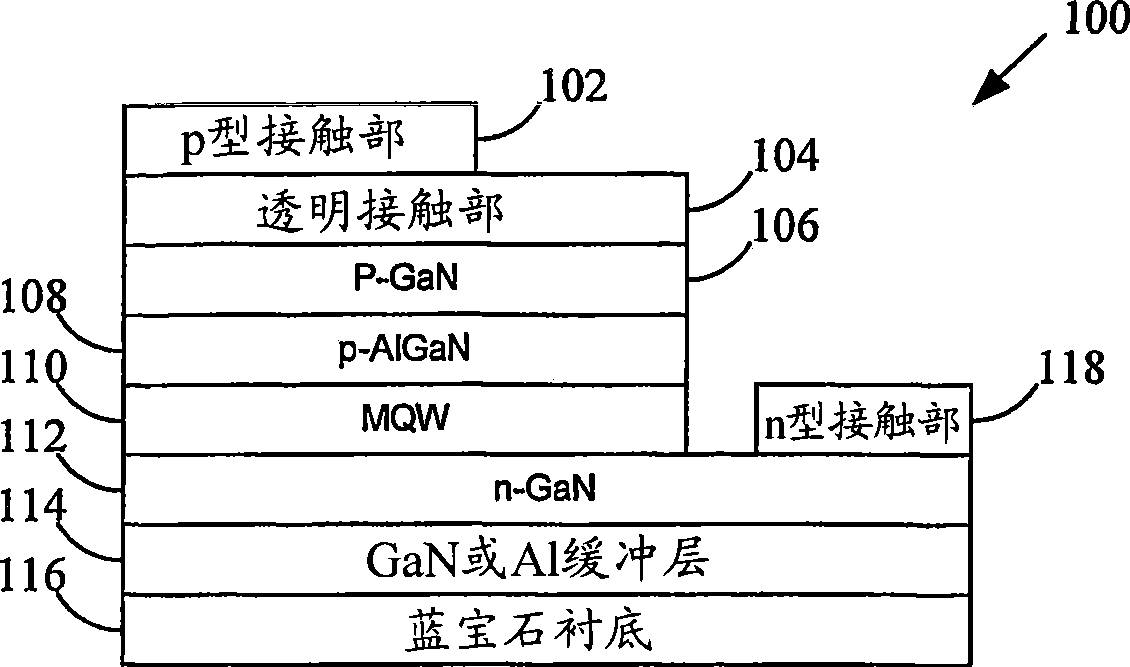

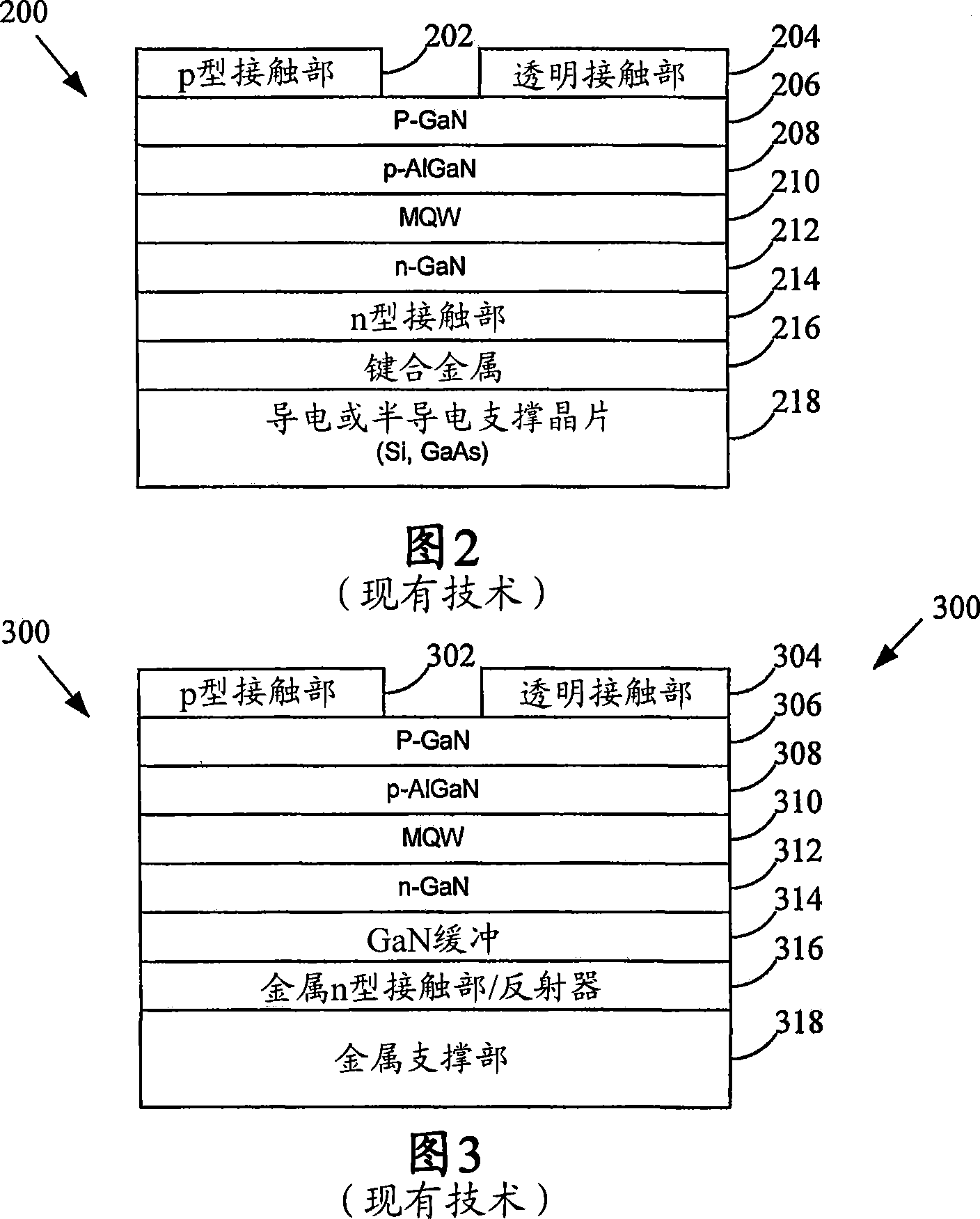

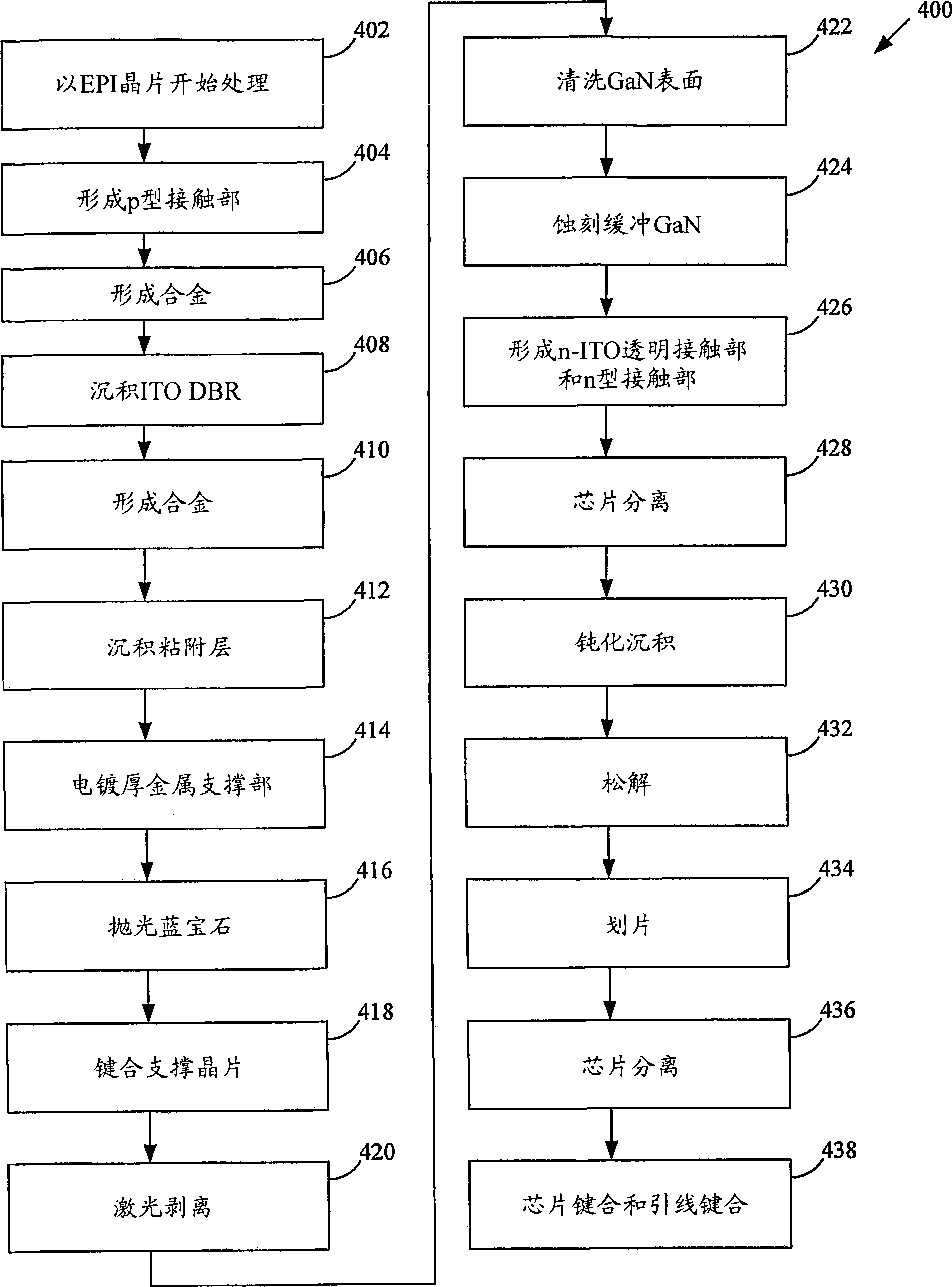

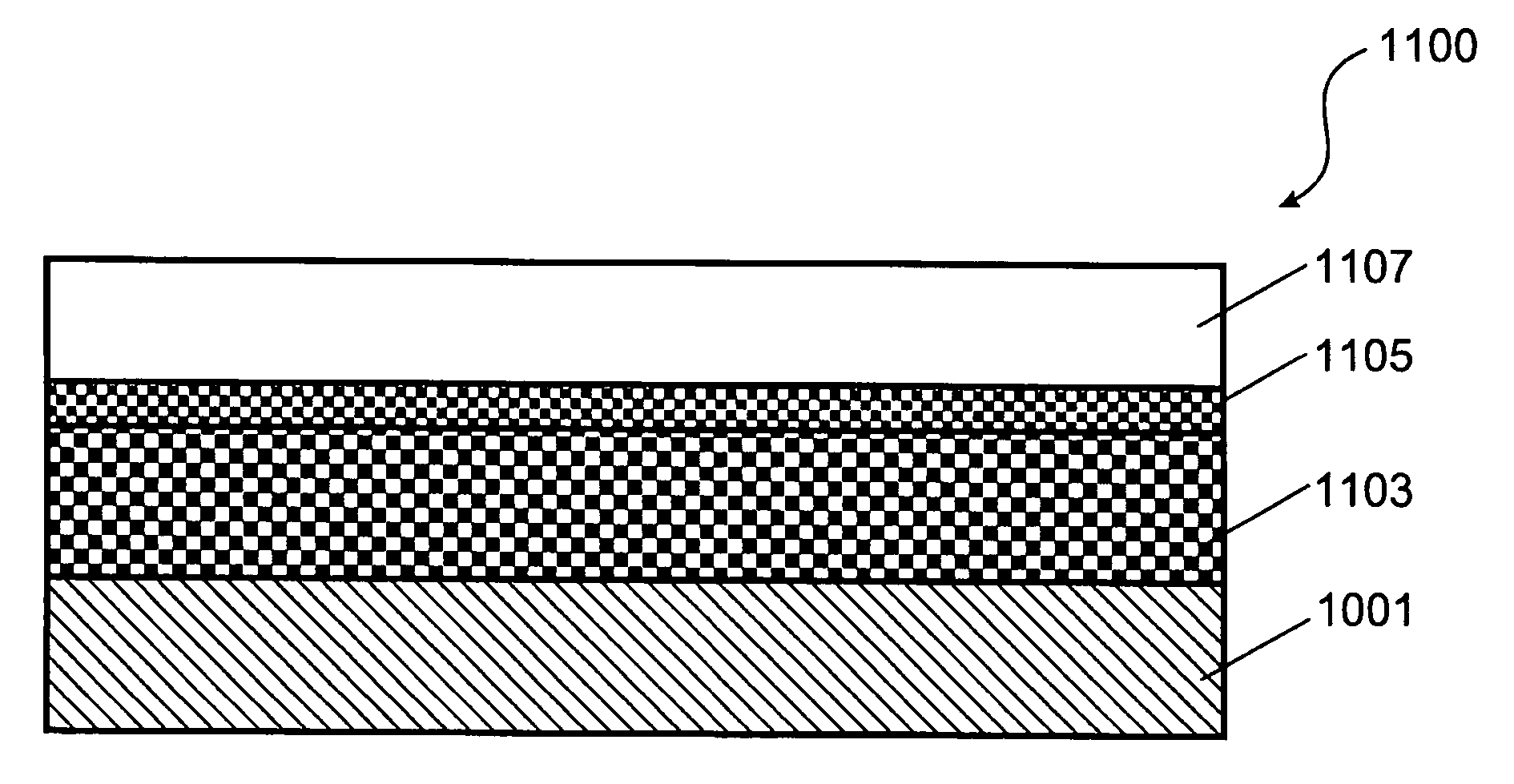

Vertical structure semiconductor devices

InactiveCN101366121AIncrease productionImprove reliabilityLaser detailsSemiconductor laser structural detailsContact layerHigh reflectivity

The invention provides a reliable way to fabricate a new vertical structure compound semiconductor device with improved light output and a laser lift-off processes for mass production of GaN-based compound semiconductor devices. A theme of the invention is employing direct metal support substrate deposition prior to the LLO by an electro-plating method to form an n-side top vertical structure. In addition, an ITO DBR layer is employed right next to a p-contact layer to enhance the light output by higher reflectivity. A perforated metal wafer carrier is also used for wafer bonding for easy handling and de-bonding. A new fabrication process is more reliable compared to the conventional LLO-based vertical device fabrication. Light output of the new vertical device having n-side up structure is increased 2 or 3 times higher than that of the lateral device fabricated with same GaN / InGaN epitaxial films.

Owner:VERTICLE

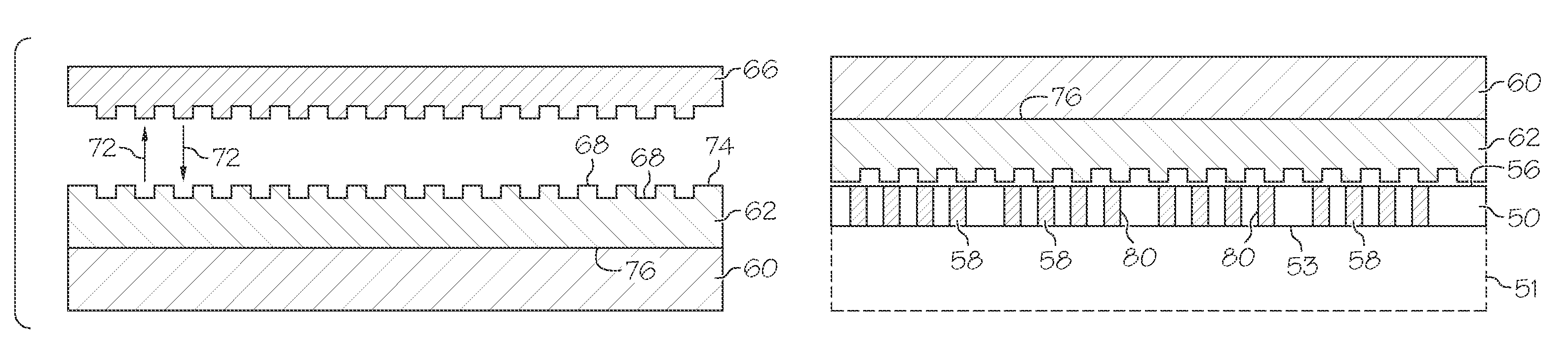

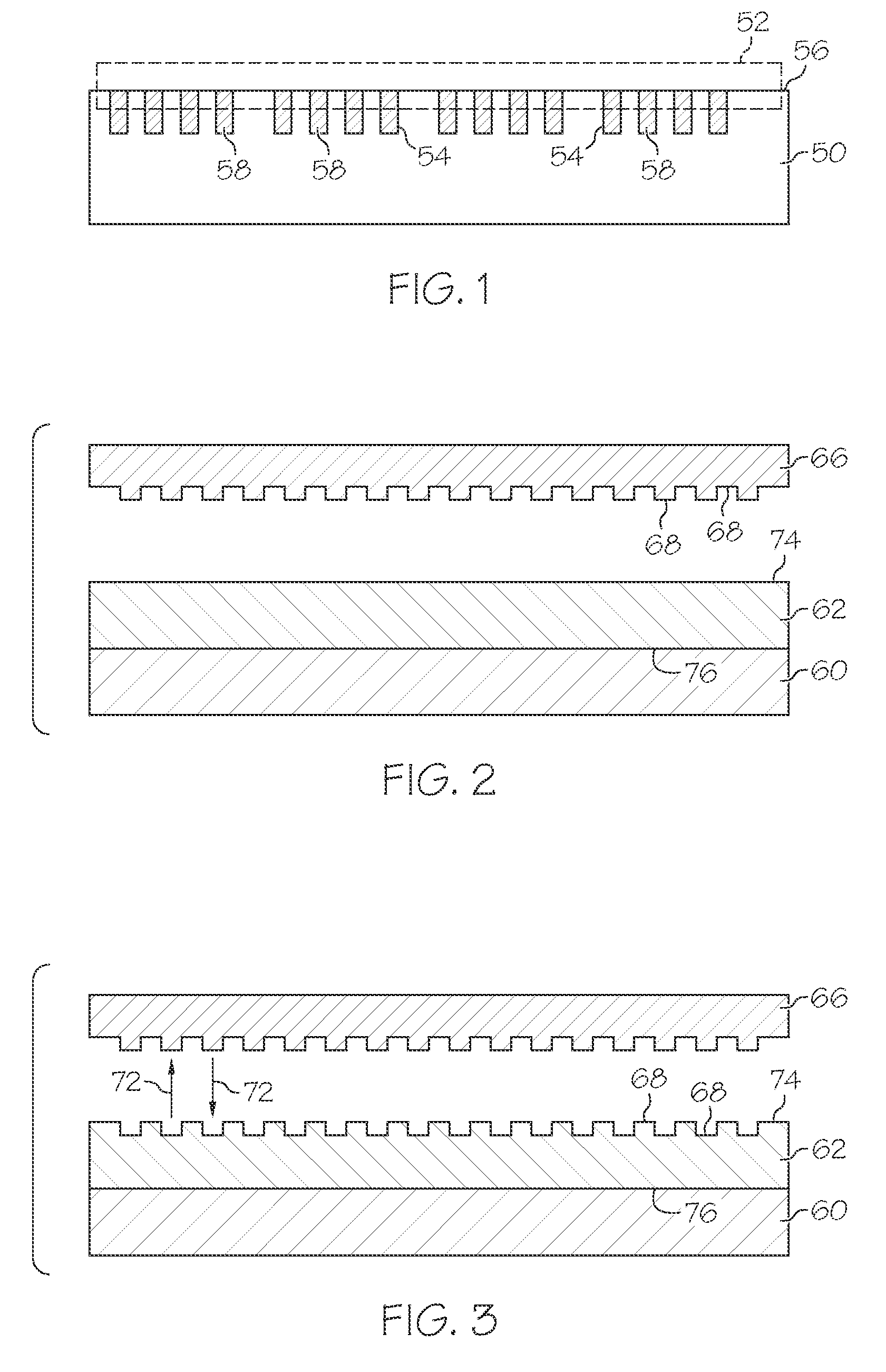

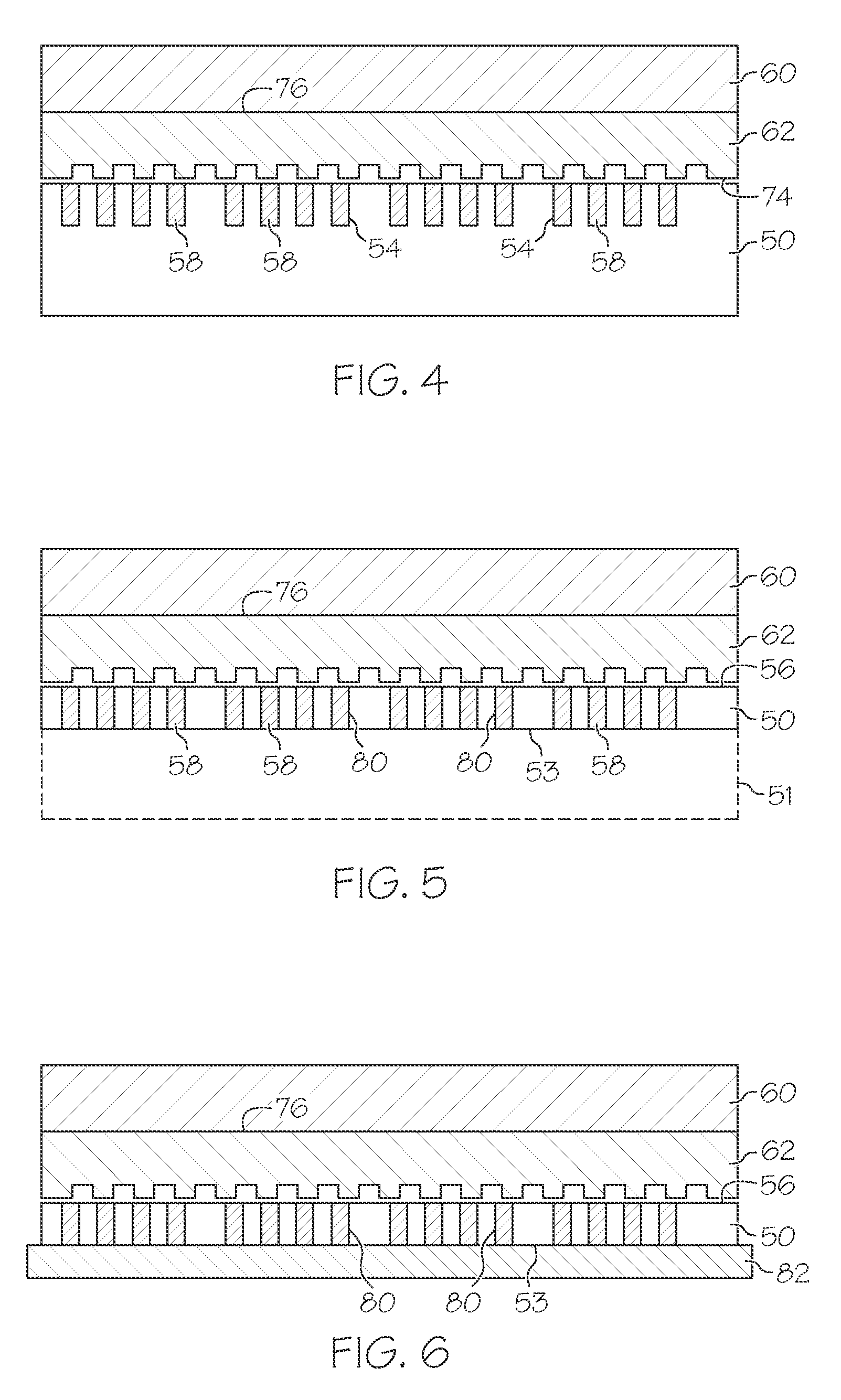

Thin handle substrate method and structure for fabricating devices using one or more films provided by a layer transfer process

InactiveUS20070032084A1Suitable bonding characteristicWithstand high-temperature processingSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor materialsDevice material

A method for fabricating one or more devices, e.g., integrated circuits. The method includes providing a substrate (e.g., silicon), which has a thickness of semiconductor material and a surface region. The substrate also has a cleave plane provided within the substrate to define the thickness of semiconductor material. The method includes joining the surface region of the substrate to a first handle substrate. In a preferred embodiment, the first handle substrate is termed a “thin” substrate, which provides suitable bonding characteristics, can withstand high temperature processing often desired during the manufacture of semiconductor devices, and has desirable de-bonding characteristics between it and a second handle substrate, which will be described in more detail below. In a preferred embodiment, the first handle substrate is also thick enough and rigid enough to allow for cleaving according to a specific embodiment.

Owner:SILICON GENERAL CORPORATION

Method using ultrasonic wave to detect bonding quality

InactiveCN105388214AImprove reliabilityMeet life requirementsAnalysing solids using sonic/ultrasonic/infrasonic wavesAviationSonification

The invention provides a method using ultrasonic wave to detect the bonding quality. The method comprises the following steps: (1) utilizing an ultrasonic wave characteristic scanning technology to find the characteristic waves of rubber, a bonding agent, and a metal member, carrying out ultrasonic tomography in a designated depth range through ultrasonic waves to obtain the de-bonding area or weak-bonding area in any region, automatically recognizing the de-bonding areas and weak-bonding areas by a computer, and then individually calculating the de-bonding area and weak-bonding area; (2) according to the results of characteristic wave imaging, judging the bonding quality. In the step two, simulation software is adopted to calculate the area of each defect and the elastic amplitudes of all defect areas so as to judge the relative bonding strength of each defect area. According to the provided ultrasonic detection method, computer simulation recognition and control technologies are adopted, the artificial uncertain factors in conventional sampling method are reduced, the stability of monitoring technology is improved, thus the reliability of quality of bonded products is improved, and an aviation quality acceptance standard suitable for aviation products is mapped out.

Owner:XIAN AERO ENGINE CONTROLS

Use of carboxylic acid hydrazide for de-bonding polyurethane adhesives

This disclosure relates to the use of carboxylic acid hydrazide for de-bonding (e.g., detaching) polyurethane adhesives. The carboxylic acid hydrazide is present in the polyurethane adhesive as a solid in free form and is thus not incorporated in the polymer. When the adhesive is heated to a temperature of at least 80° C., the polymer is thermally degraded. With such an adhesive, components that are bonded in such a way can be detached in a simple method, by which the repair, the use or the recycling of the components is more easily possible.

Owner:SIKA TECH AG

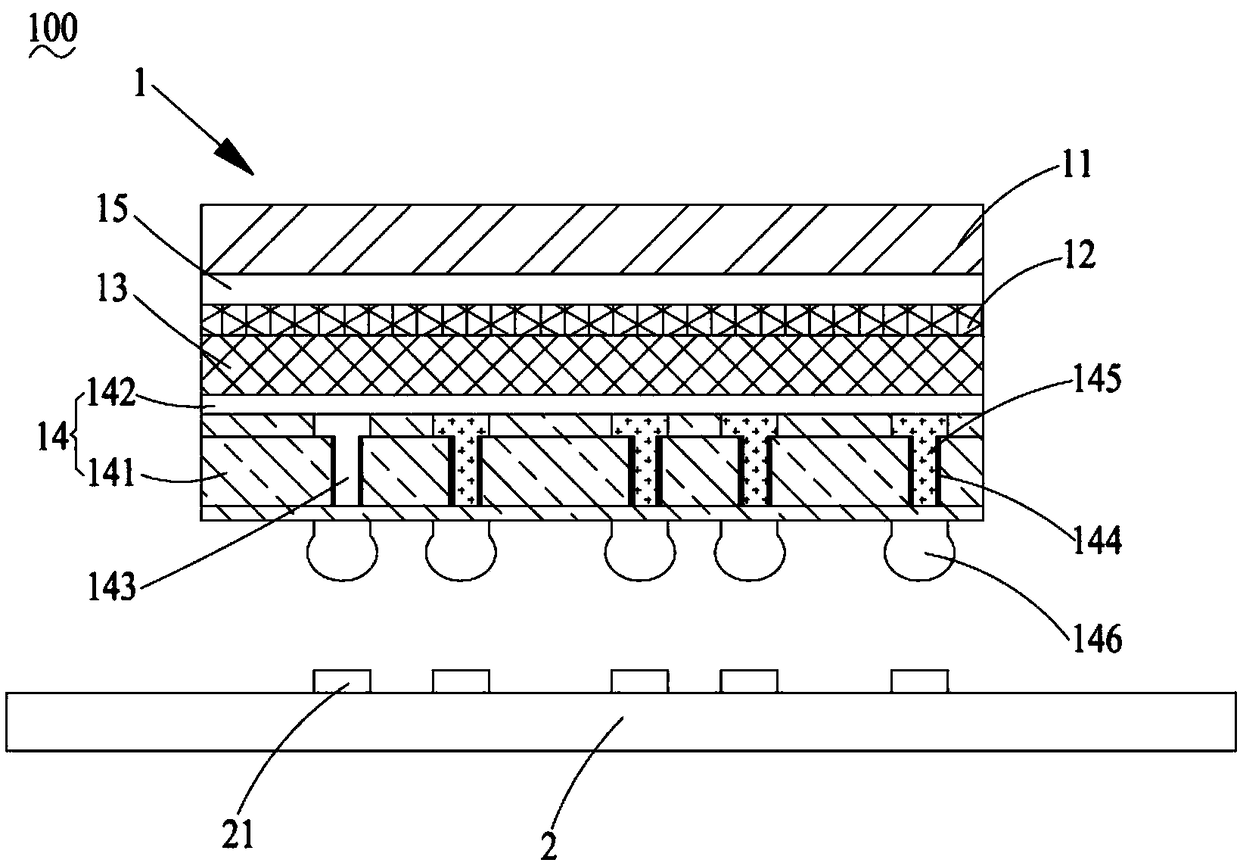

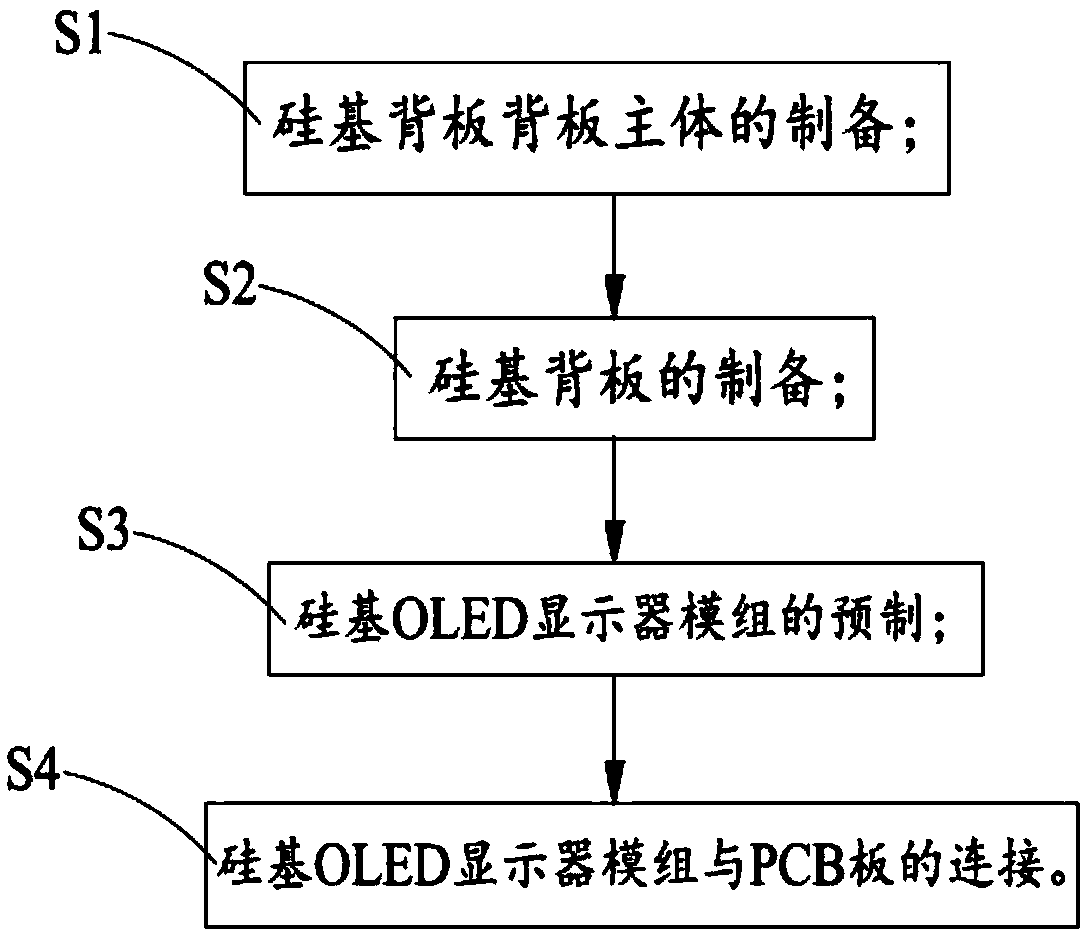

Silicon-based OLED displayer module and its preparation method

InactiveCN108155221AReduce manufacturing costSmall sizeSolid-state devicesSemiconductor devicesInsulation layerEngineering

The invention provides a silicon-based OLED displayer module, which comprises a silicon-based OLED module and a PCB board electrically connected with the silicon-based OLED module; the silicon-based OLED module comprises a transparent packaging layer, a thin film packaging layer, an LED lighting layer and a silicon-based back plate which are orderly distributed from top to bottom; the silicon-based back plate comprises a back plate main body and a driving electrode layer arranged between the OLED lighting layer and the back plate main body; conductive through holes aligned regularly are arranged on the back plate main body, insulation layers are deposited on the surfaces of the conductive through holes, and conductive pillars are arranged in the conductive through holes. The silicon-basedOLED displayer module cancels the Bonding zone of the silicon-based back plate, reduces the dimension of the silicon-based OLED displayer module, improves the composing rate, and further reduces the preparation cost of the silicon-based OLED displayer module.

Owner:KUNSHAN FANTAVIEW ELECTRONICS TECH CO LTD

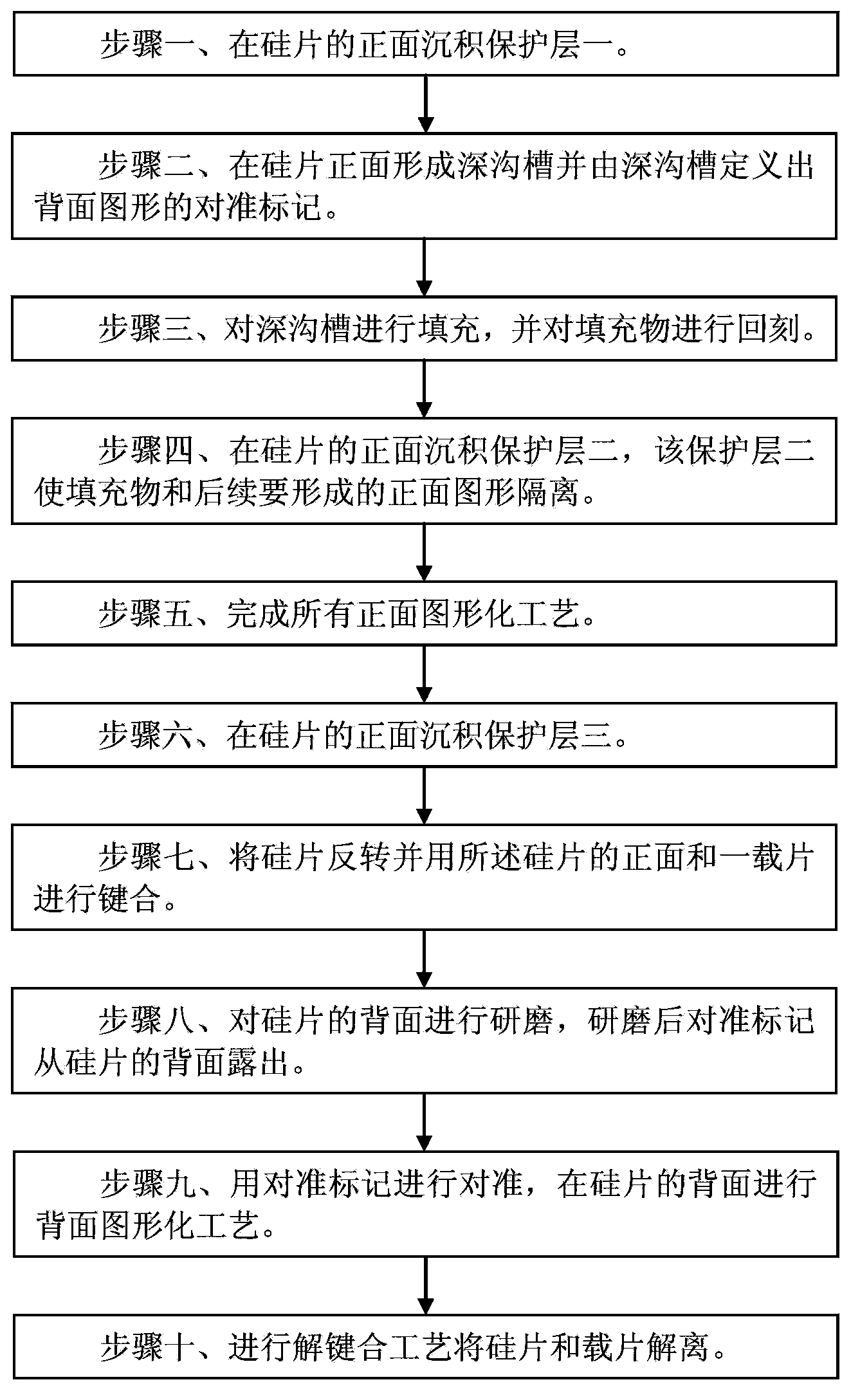

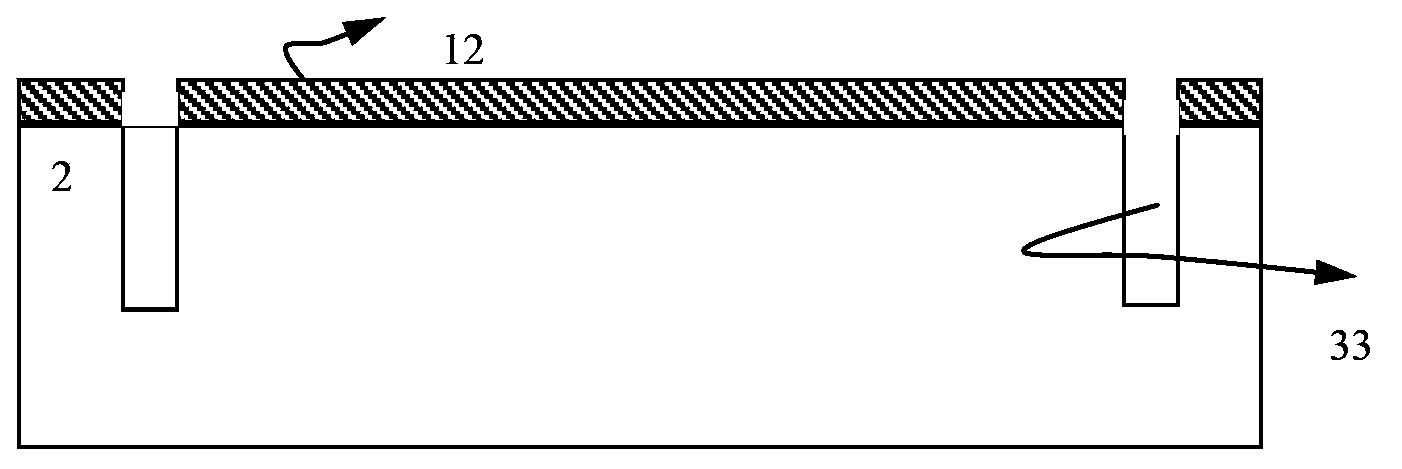

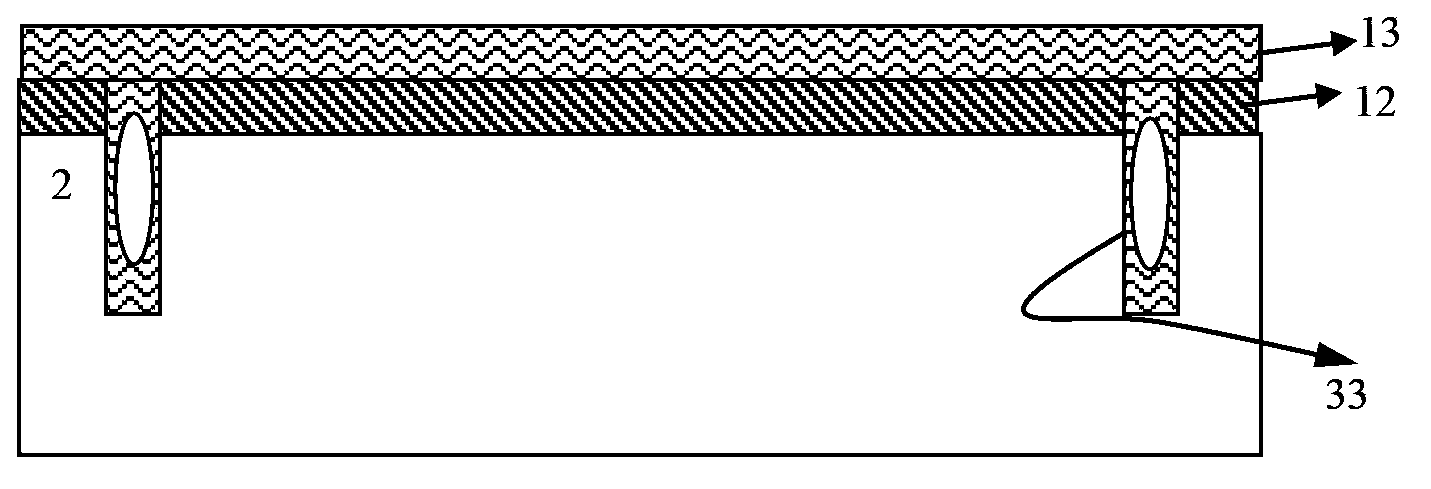

Technique method for patterning back surface of silicon wafer

ActiveCN103811407AReduce manufacturing costProcess compatibleSemiconductor/solid-state device detailsSolid-state devicesSurface patternSilicon chip

The invention discloses a technique method for patterning the back surface of a silicon wafer. The technique method comprises: depositing a protective layer 1; forming a forming a deep trench and defining an aligning mark by using the deep trench; filling the deep trench; depositing a protective layer 2 in order to isolate a filler from a front-surface pattern to be formed subsequently; completing all front-surface patterning techniques; depositing a protective layer 3; reversing the silicon wafer and bonding the front surface of the silicon wafer with a carrier; grinding the back surface of the silicon wafer, wherein the aligning mark is exposed out of the back surface of the silicon wafer after the back surface of the silicon wafer is grinded; aligning by using the aligning mark and performing back surface patterning technique on the back surface of the silicon wafer; and performing a de-bonding technique for separating the silicon wafer from the carrier. According to the method provided by the invention, the aligning mark penetrates through the silicon wafer from the front surface to the back surface; when the back surface patterning technique is performed, an extra photoetching device and technique are not required to be added for achieving the aligning of the back-surface pattern and the front-surface pattern; and the production cost can be greatly decreased. In addition, the method is also compatible with a thin slice technique.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Wafer temporary bonding method

ActiveCN102751207AReduce manufacturing costEasy to operateSemiconductor/solid-state device manufacturingLaser scribingThinning

The invention relates to a wafer temporary bonding method, which comprises the following steps of: a, providing and washing a first wafer; b, providing a carrier wafer, and spin-coating a bond; c, transferring the first wafer and the carrier wafer into a bonding box to form a first bonding body, and thinning the first wafer on the first bonding body according to demands; d, scribing the thinned first wafer on the first bonding body by utilizing a laser scribing machine; e, transferring the first bonding body into the bonding box, and enabling the temperature inside the bonding box to be higher than a softening temperature of the bond; and uniformly applying pressure on the surface of the first wafer by utilizing a flat wafer in the bonding box; f, providing a needed second wafer, and bonding the second wafer with the first wafer according to demands to form a second bonding body; and g, de-bonding the second bonding body. The technique steps are convenient to operate, the production cost is reduced, the tilt curvature influence after the thinning of the wafer can be avoided, permanent bonding can be formed, and safety and reliability can be realized.

Owner:JIANGSU R & D CENTER FOR INTERNET OF THINGS

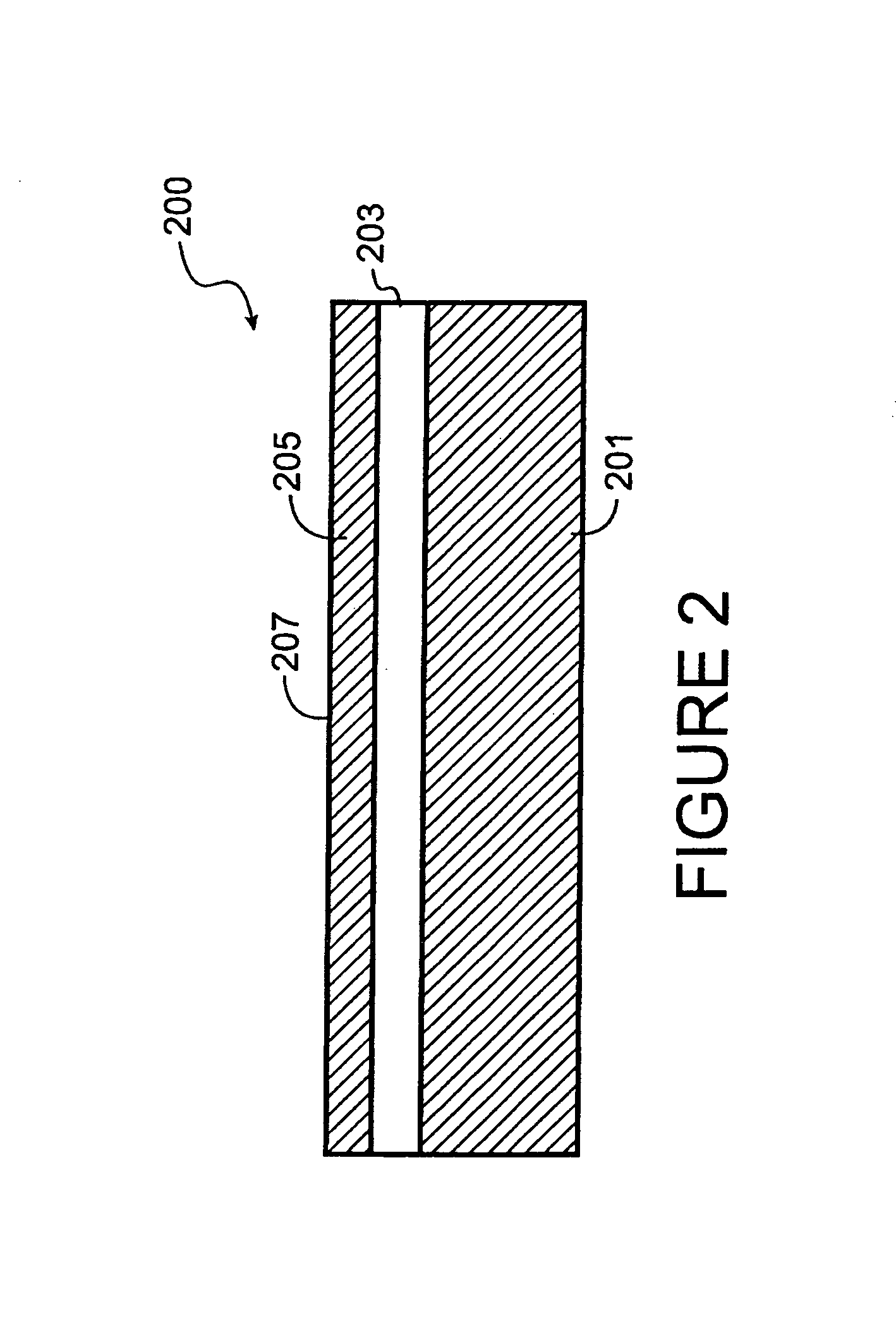

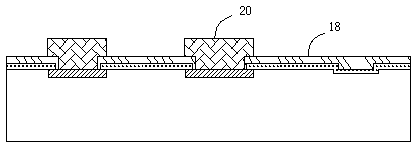

Active Device Substrate and Manufacturing Method Thereof

ActiveUS20140327006A1Improve peeling manufactureEasy to fixFinal product manufacturePrinted circuit aspectsMaterials scienceMetal

An active device substrate includes a flexible substrate, an inorganic de-bonding layer, and at least one active device. The flexible substrate has a first surface and a second surface opposite to the first surface, wherein the first surface is a flat surface. The inorganic de-bonding layer covers the first surface of the flexible substrate, and the material of the inorganic de-bonding layer is metal, metal oxide or combination thereof. The active device is disposed on or above the second surface of the flexible substrate.

Owner:AU OPTRONICS CORP

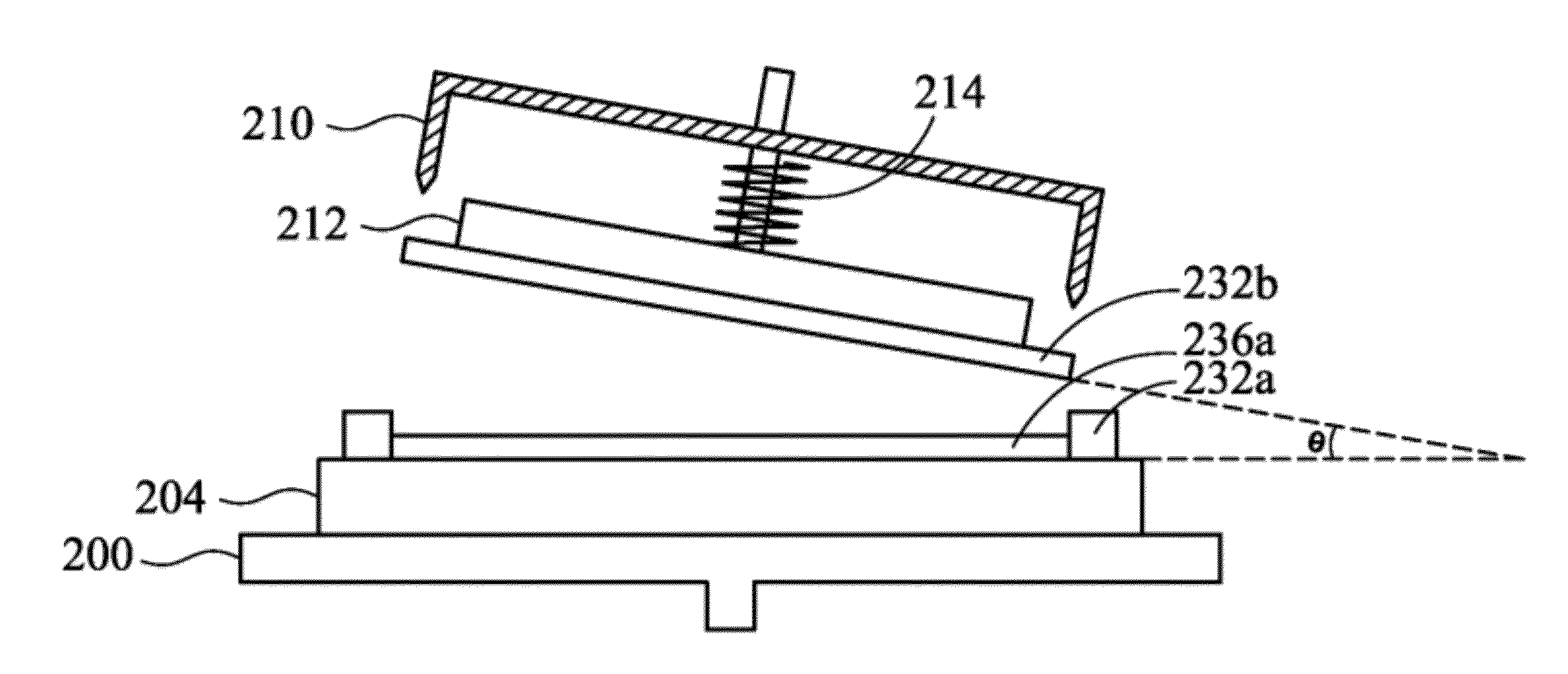

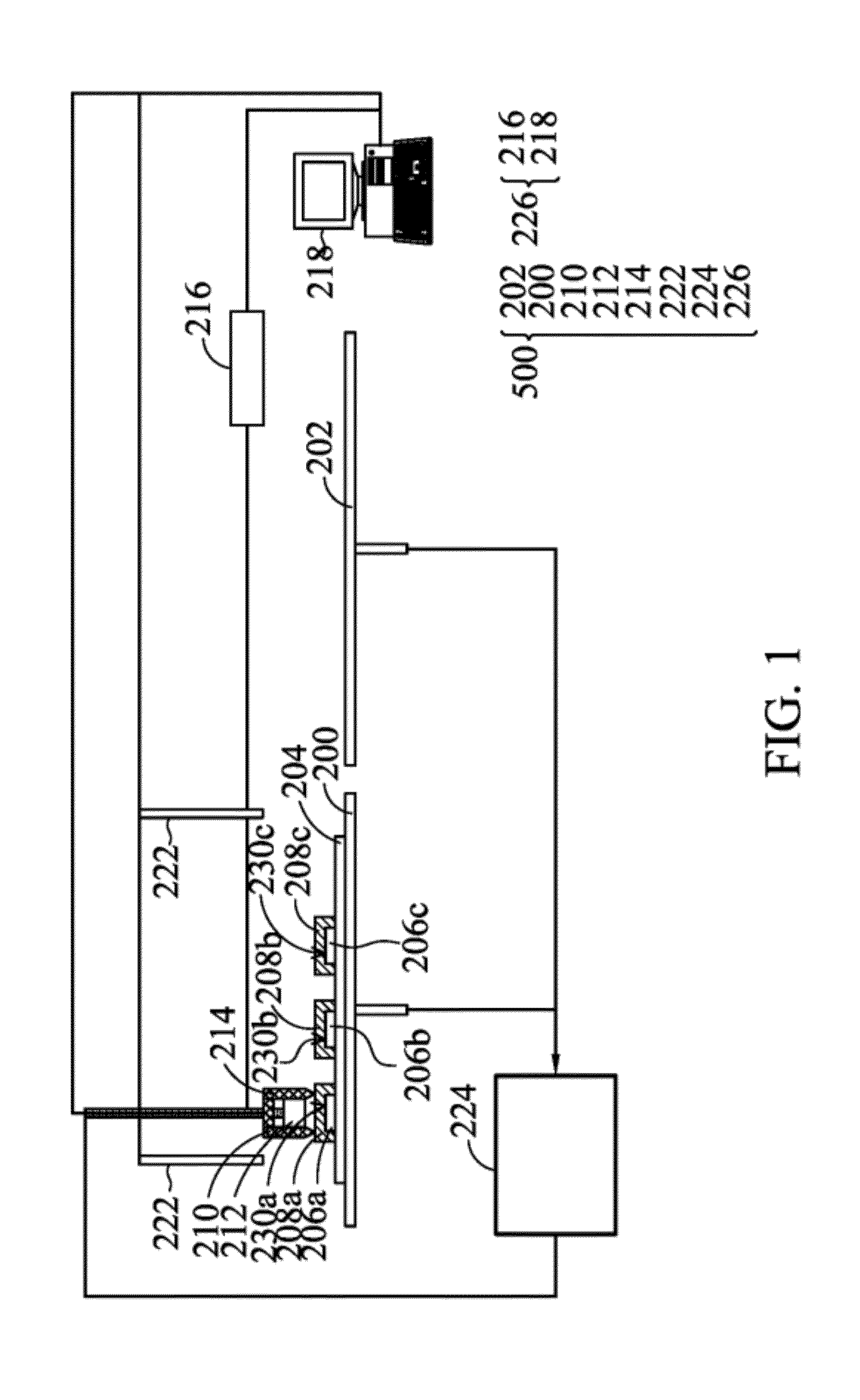

Method for de-bonding flexible device

The disclosure provides a method for de-bonding a flexible device. The method for de-bonding a flexible device includes providing a first carrier to mount a carrier substrate thereon, a release layer thereon and a flexible device covering the release layer and a portion of the carrier substrate. A vacuum suction process is performed to suction the flexible device using a vacuum device. A separation process is performed with air entering into an interface between the flexible device and the release layer to separate a portion of the flexible device from the release layer and the carrier substrate using a separation device. A first release process is performed so that the portion of the flexible device is separated from the vacuum device.

Owner:IND TECH RES INST

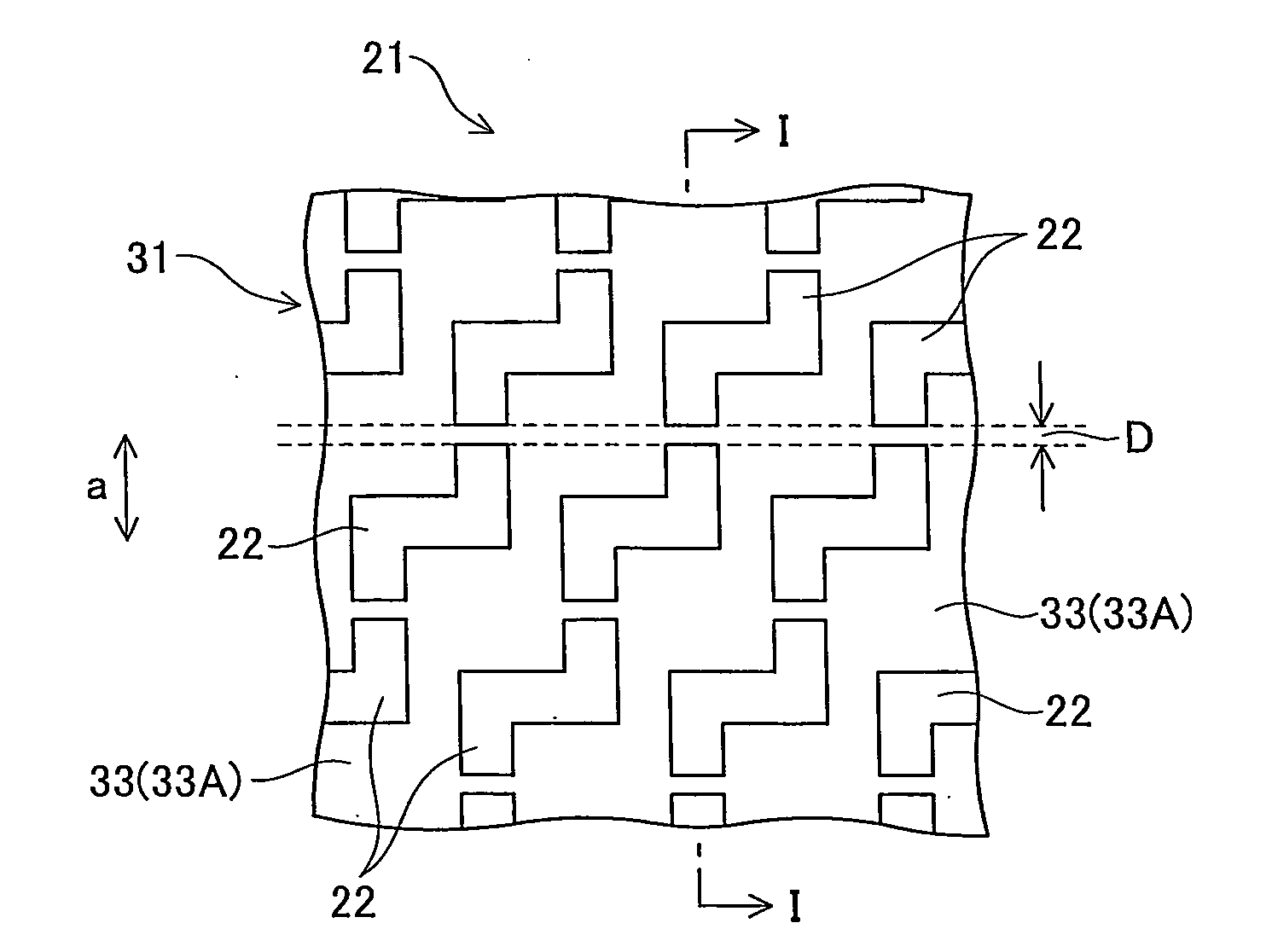

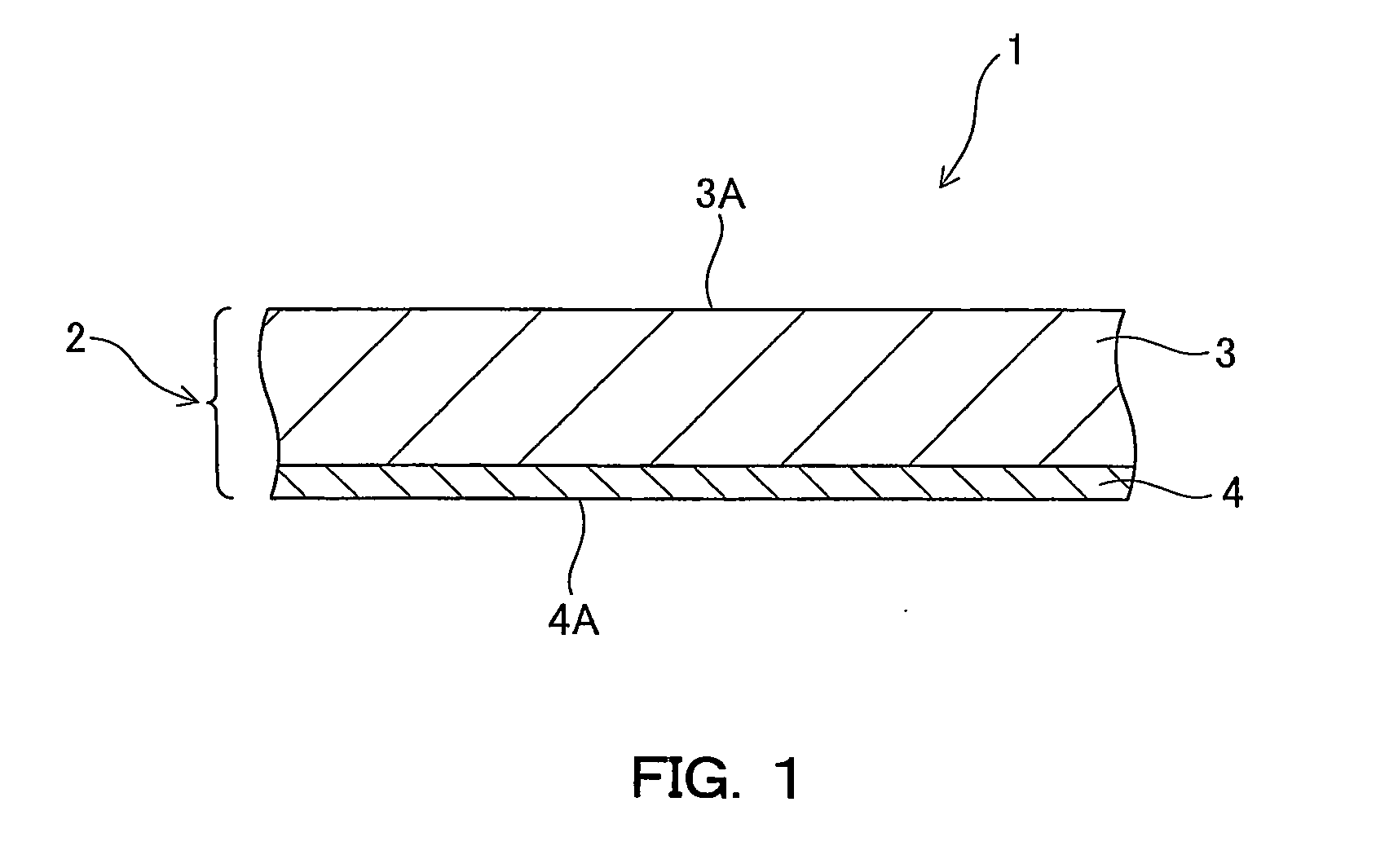

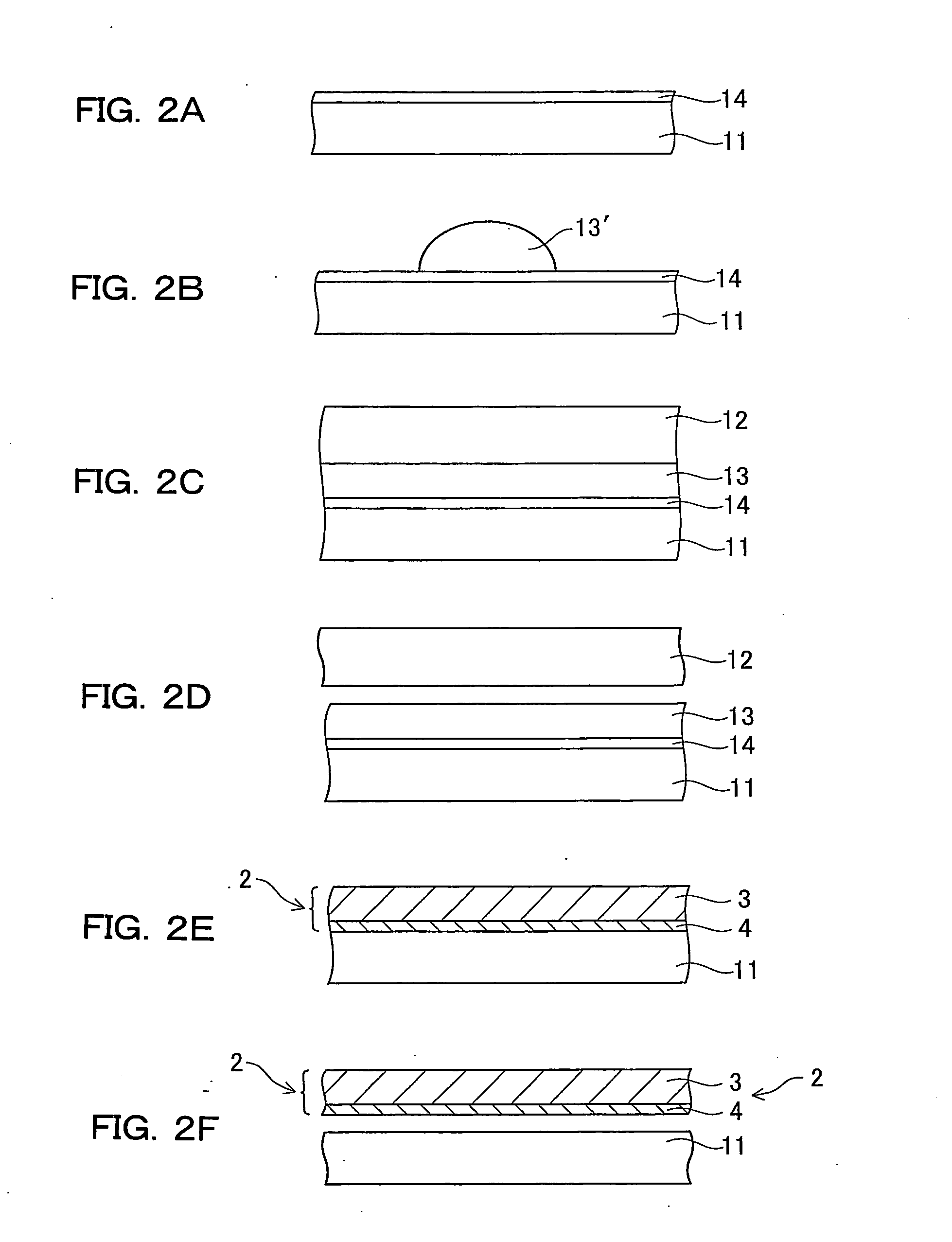

Polydimethylsiloxane sheet, optical element incorporating the same, and manufacturing method thereof

ActiveUS20120224264A1Excellent adhesion to metalFacilitated releaseSynthetic resin layered productsOptical articlesDimethyl siloxanePolydimethylsiloxane

A PDMS sheet that ensures good adhesion, handleability and stability to metal thin films or metal patterns of any desired shape, an optical element that is kept against de-bonding or exfoliation of metal patterns and has high reliability as well as good handleability and stability, and manufacturing methods thereof. The inventive optical element comprises a polydimethyl-siloxane sheet having a pattern-formation surface defined by one surface and a base surface defined by another surface, and a plurality of metal patterns positioned on the pattern-formation surface. Given a low-molecular-weight siloxane of a cyclic structure represented by [—Si(CH3)2O—]k where k is an integer of 3 to 20 inclusive, polydimethylsiloxane sheet comprises a structure where the content of the low-molecular-weight siloxane at the pattern-formation surface is more than that of the low-molecular-weight siloxane at the base surface, and a spacing between the adjacent metal patterns is variable by deformation of the polydimethylsiloxane sheet.

Owner:DAI NIPPON PRINTING CO LTD

Shrink wrap label coating to facilitate recycling

ActiveUS20160200942A1Improve sealingEfficient de-seaming and removalDecorative surface effectsDuplicating/marking methodsEngineeringShrink wrap

The present invention discloses a method of enabling the easy separation of labels, including wrap around labels and sleeve labels, particularly shrink sleeve labels, from containers during recycling through the use of a specially formulated coating to be applied in the seam area. The coatings ensure proper bonding, and shrink properties, of the labels, and have been designed to help de-bonding of the seam in a hot caustic wash step, or a solvent wash step. The method does not rely on floatation separation and therefore may be applied to any container / label material combination regardless of their specific gravity differences.

Owner:SUN CHEM CORP

Heat-conducting copper foil

InactiveCN103879087AEasy to fixEffective coolingSynthetic resin layered productsMetal layered productsInsulation layerHeat conducting

The invention discloses a heat-conducting copper foil which comprises de-bonding layers, an adhesive, a copper foil and an insulation layer, wherein the insulation layer is attached to one side of the copper foil; the other side of the copper foil is coated with the adhesive; the adhesive is arranged on the other side of the insulation layer; the de-bonding layers are arranged on two sides of the adhesive. According to the mode, the heat-conducting copper foil has the advantages of high reliability, good heat conductivity, convenience in adhesion, good insulativity, small thickness, easiness in bending, low price and the like, and is suitable for heat dissipation of chips of small electronic products.

Owner:TAICANG TAIBANG ELECTRONICS TECH

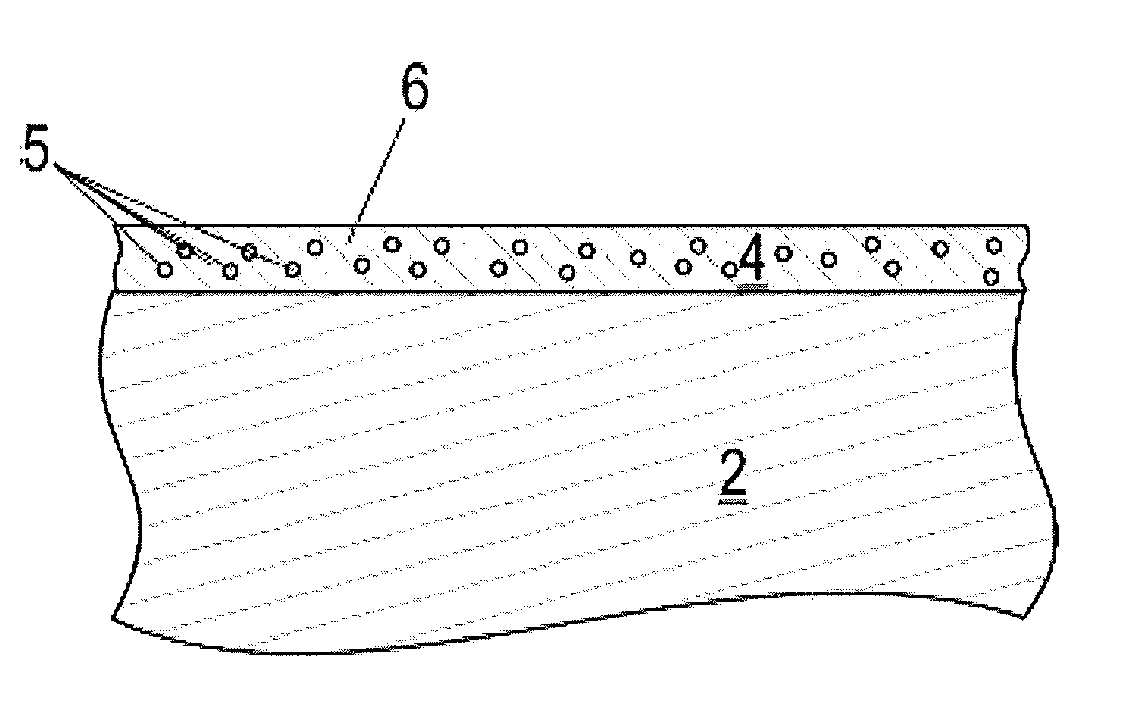

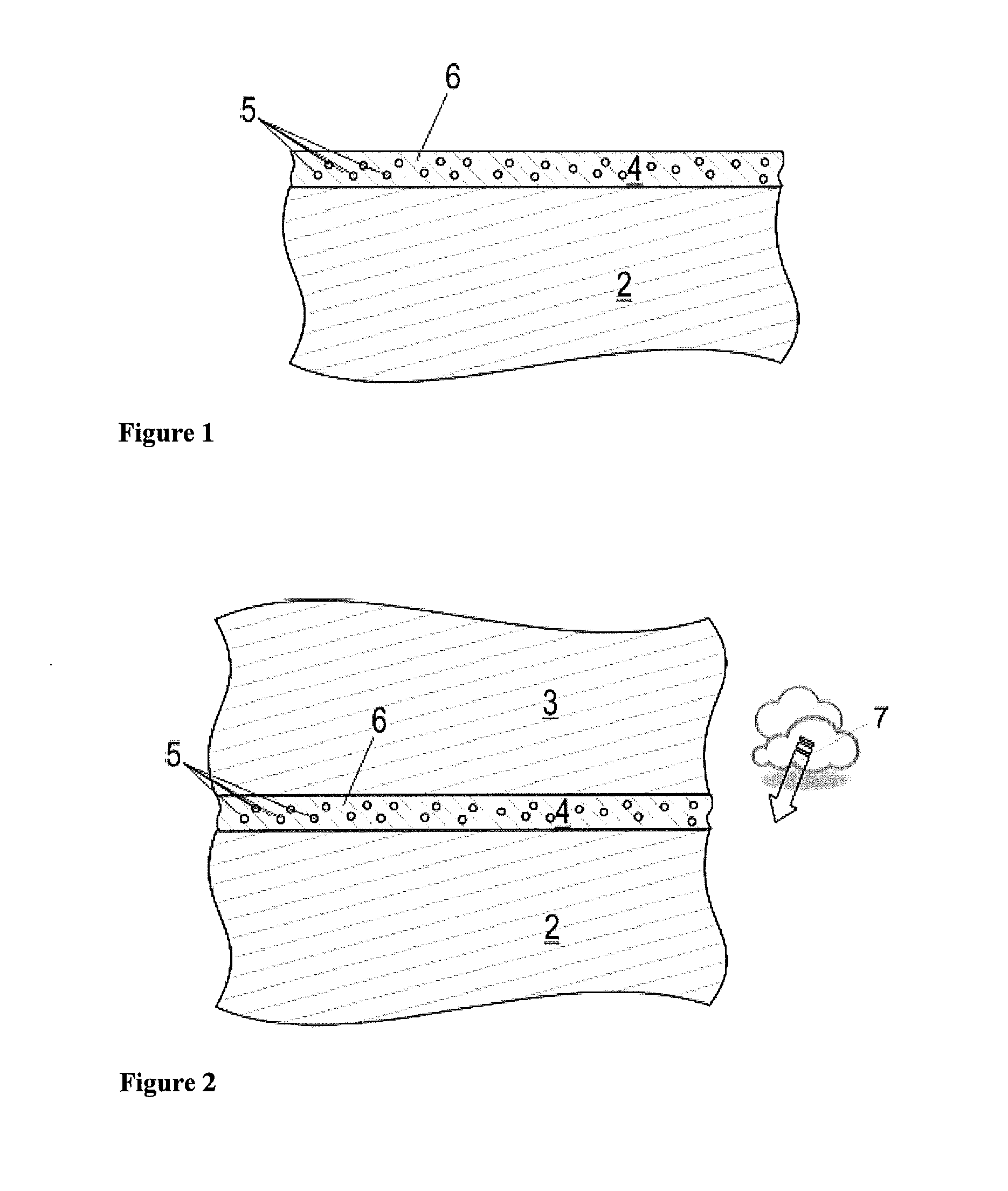

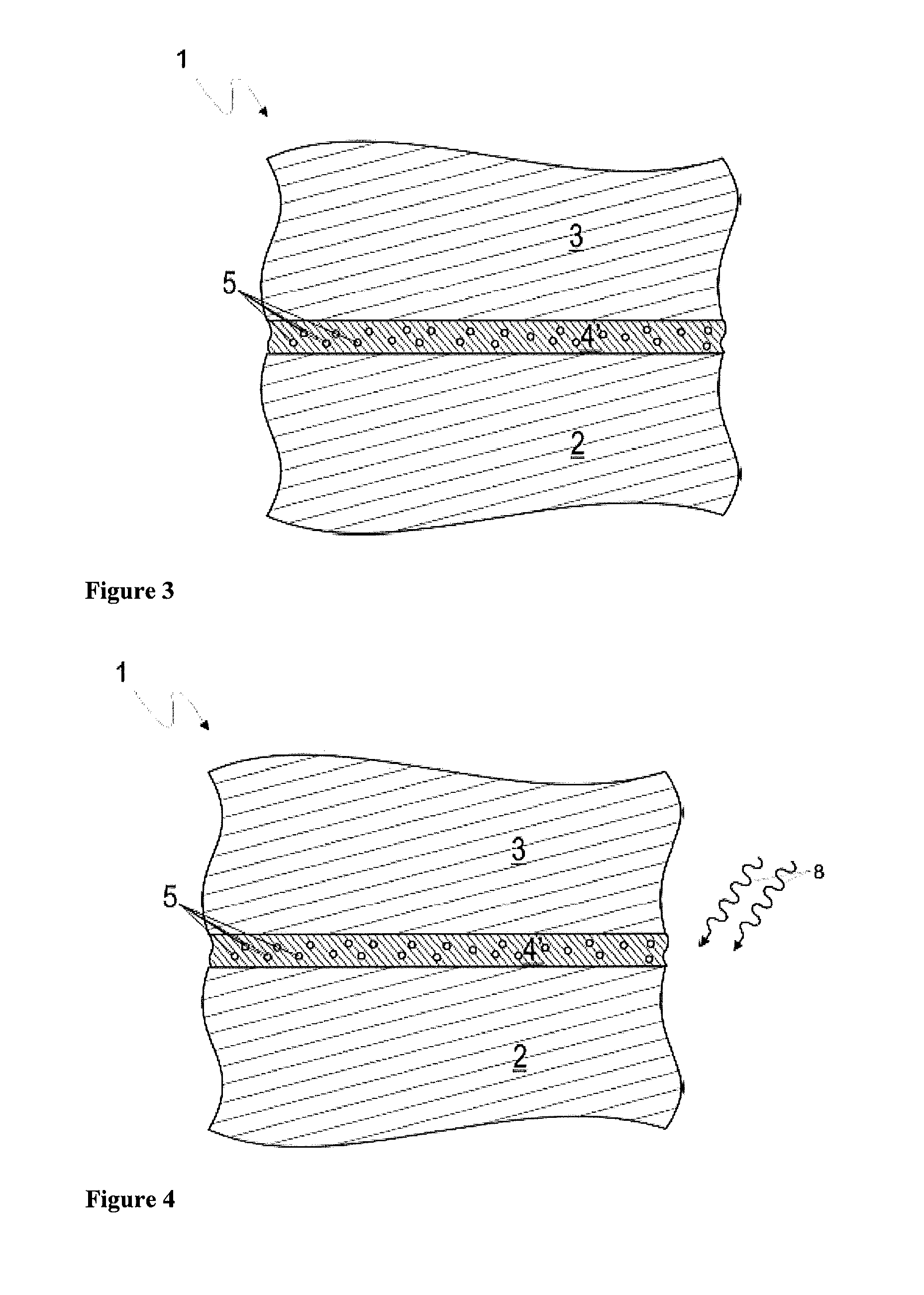

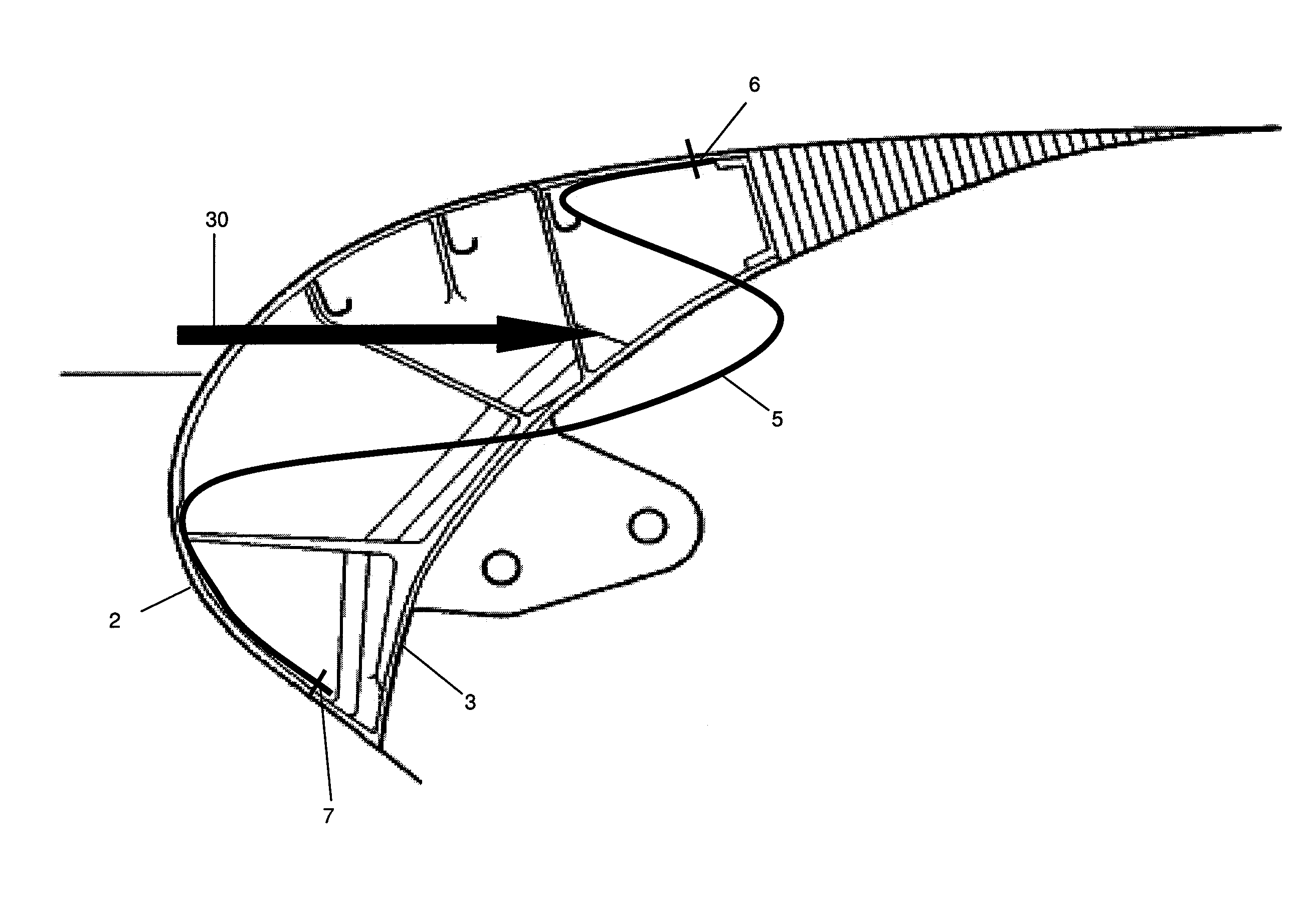

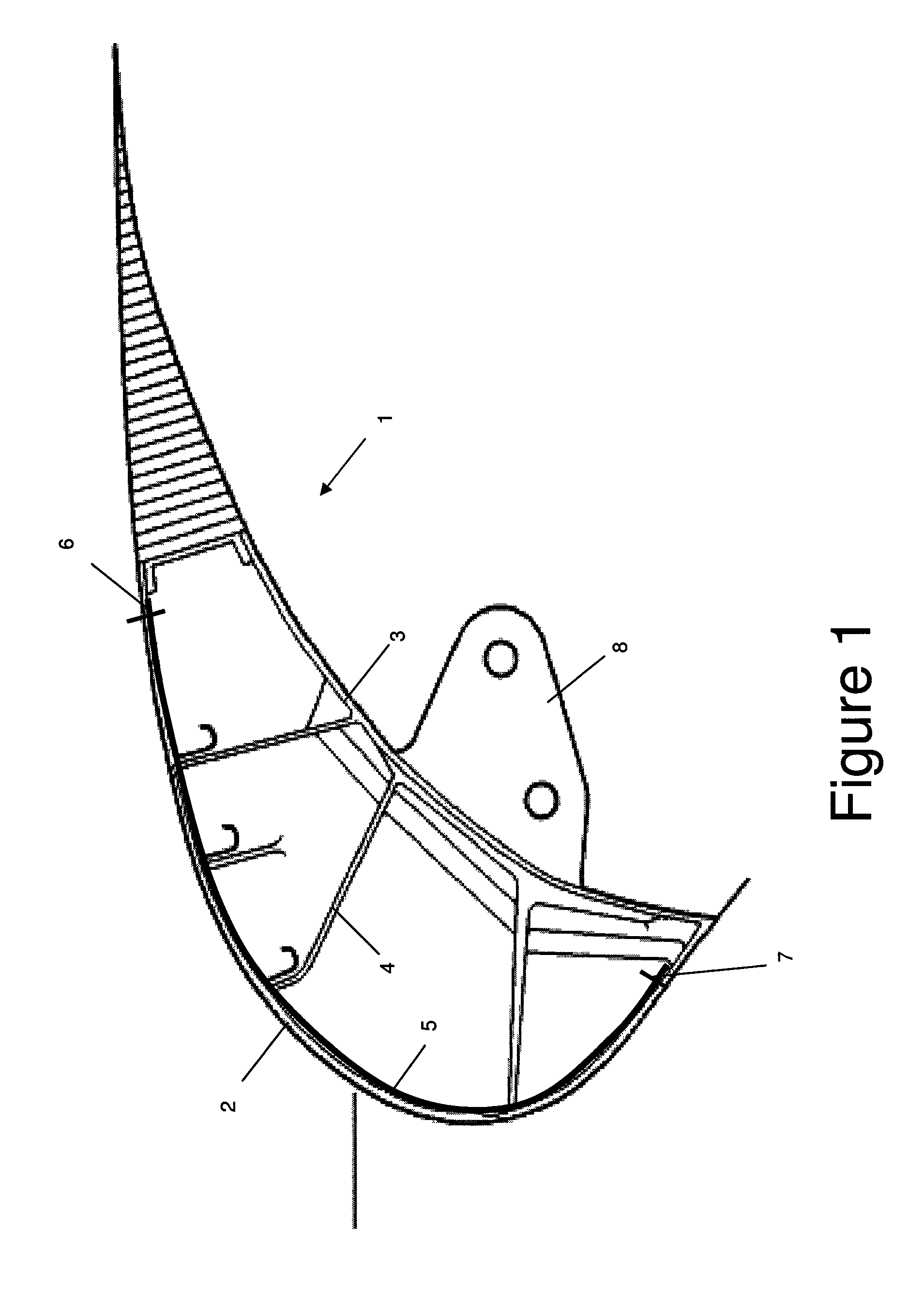

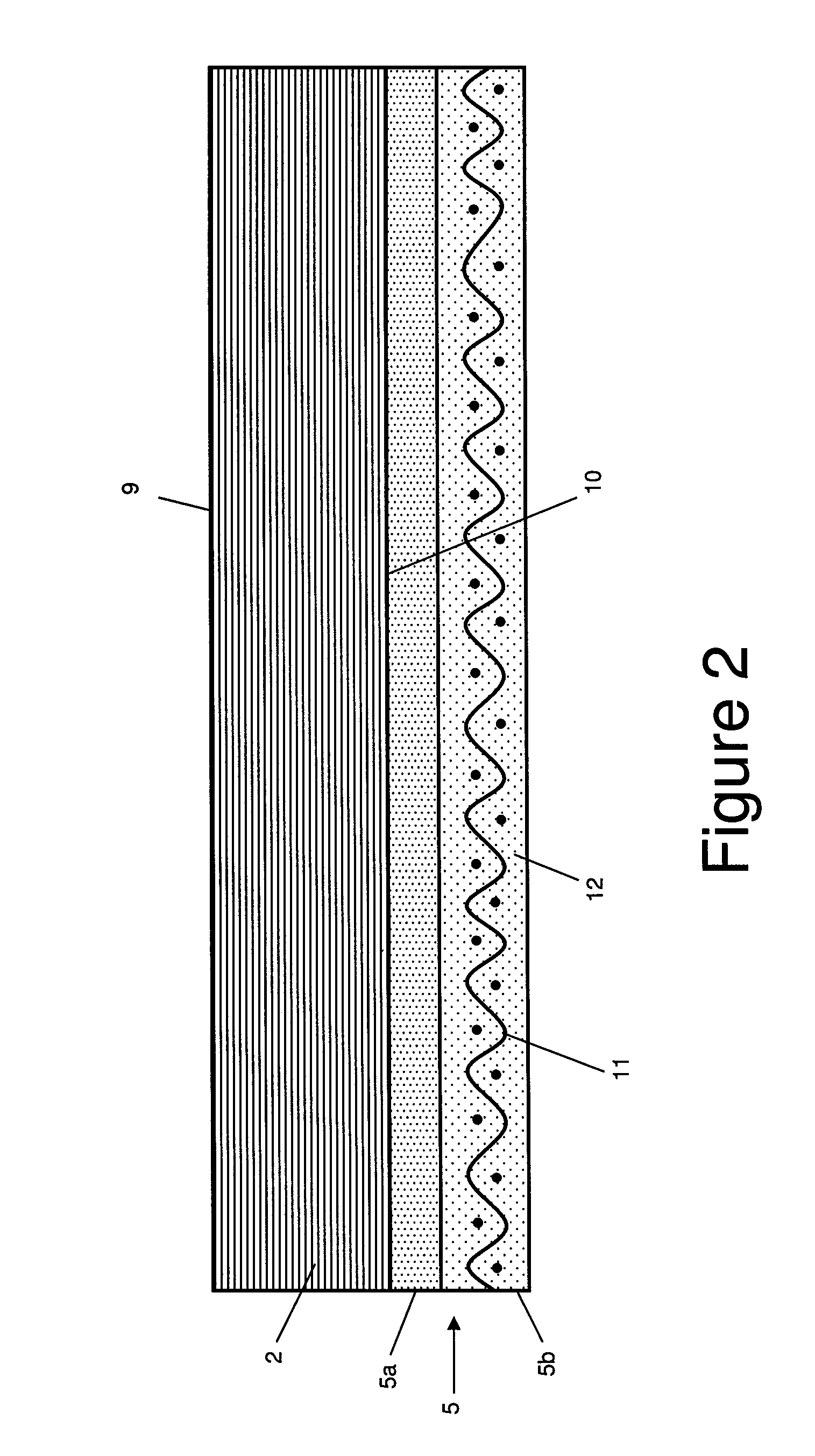

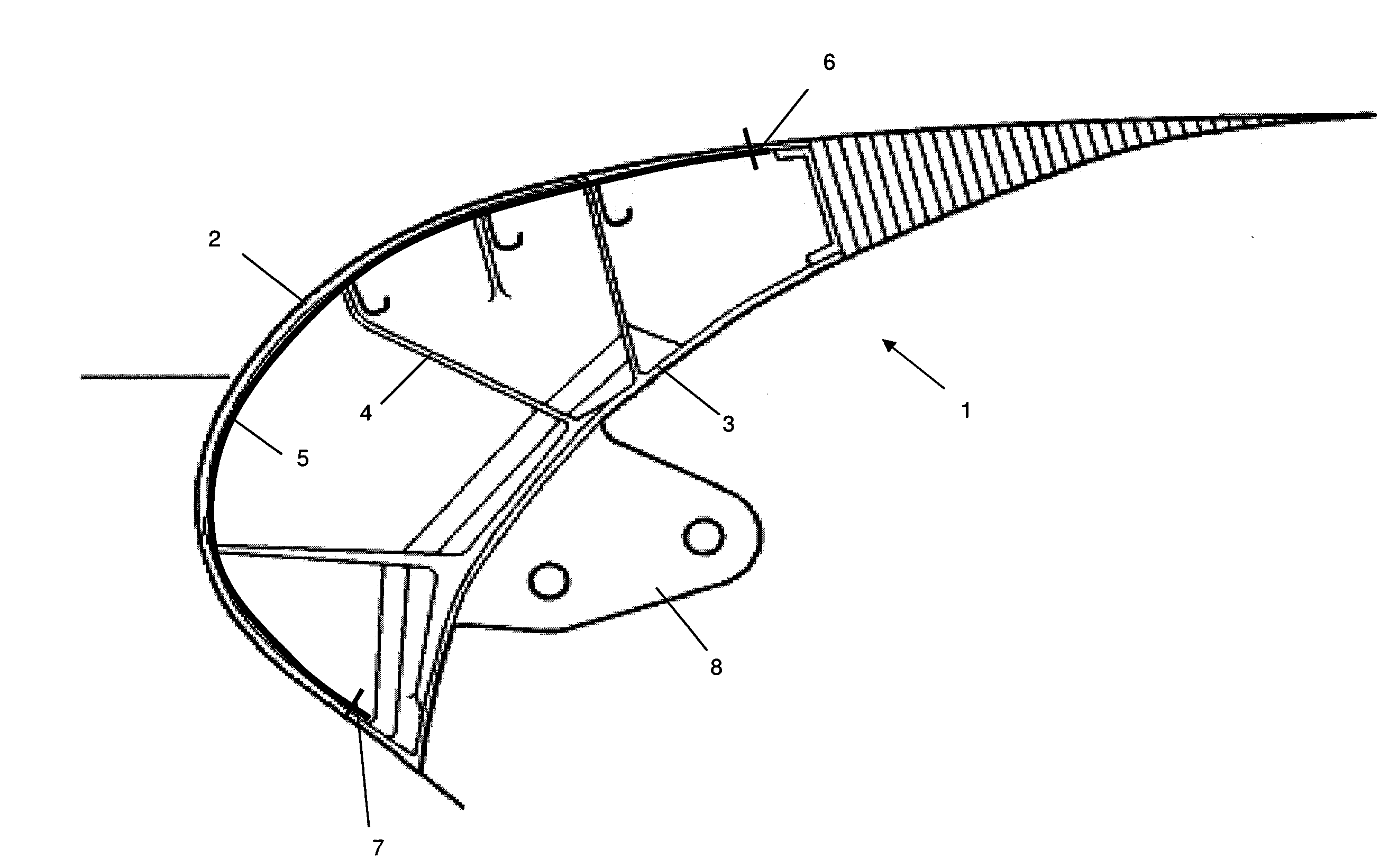

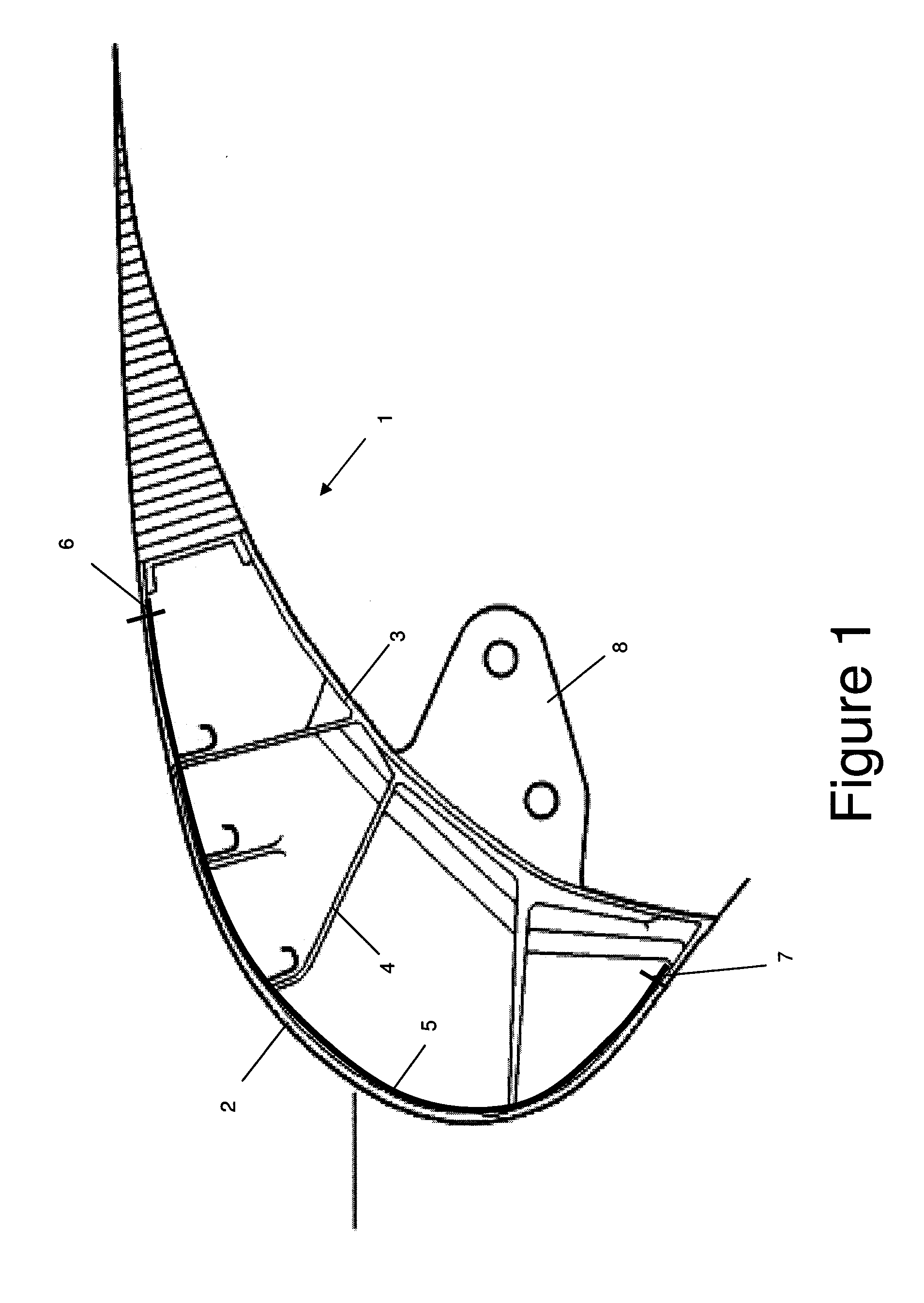

Panel with impact protection membrane

InactiveUS8322657B2Effective protectionLamination ancillary operationsAircraft stabilisationLeading edgeElastomer

An aircraft leading edge panel having an outer aerodynamic surface; and an inner surface carrying the elastomeric impact protection membrane. The membrane comprises a woven or knitted fabric which is impregnated with an elastomeric material. The membrane and the panel may be bonded by an adhesive or co-cured to bond the membrane to the panel. The membrane provides impact protection to the panel by de-bonding from the face of the panel and absorbing at least part of the energy of an object impacting the panel.

Owner:AIRBUS OPERATIONS LTD

Method for holding thin wafer through temporary bonding of porous slide glass

ActiveCN105244308AThe solution cannot be appliedReduce thicknessSolid-state devicesSemiconductor/solid-state device manufacturingChemical solutionEngineering

The present invention discloses a method for holding a thin wafer through temporary bonding of porous slide glass. The temporary slide glass is provided with abdicating slotted holes with the amount not less than the amount of bumps on the wafer, and the abdicating slotted holes are in response to the bumps on the wafer so as to allow the higher bumps at the front wafer surface or all the bumps to insert into the abdicating slotted holes on the temporary slide glass. The thickness of bonding glue may be effectively reduced, the usage amount of the bonding glue may be decreased, and the heat radiation is easy, therefore process problems caused by poor heat radiation of thick glue in the subsequent process may be avoided. Preferably, the abdicating slotted holes are designed to be a through-hole mode, when the abdicating slotted holes are immersed into a chemical solution for bonding removal, the temporary bonding glue may be dissolved through the through holes on the temporary slide glass after completing the wafer back process, and the bonding removal is completed so as to accelerate the de-bonding efficiency.

Owner:HUATIAN TECH KUNSHAN ELECTRONICS

Wafer-level back gold chip packaging structure and packaging method thereof

ActiveCN107910305AIn line with the development directionPackage structure is simpleSemiconductor/solid-state device detailsSolid-state devicesPlastic packagingSemiconductor package

The present invention discloses a back gold chip packaging structure and a packaging method thereof, belonging to the technical field of semiconductor packaging. A plurality of chip electrodes and front protective layers are arranged at the front surface of a silicon-based body, each front protective layer is provided with one front protective layer opening to expose chip electrodes again, and metal bump are arranged at the surfaces of the chip electrodes. The back surface of the silicon-based body is provided with a back gold layer, the back gold layer is in bonding connection with the back surface of the silicon-based body through a back gold bonding layer. A plastic packaging layer packages exposed surfaces of the back gold layer and the silicon-based body, and a plastic packaging layeropening is arranged to expose the exposed surface of the back surface of the back gold layer. The wafer-level back gold chip packaging structure and the packaging method thereof are simple in packaging flow, the silicon face processing technology, the back gold technology, the plastic packaging material ablation and the de-bonding technology are completed on a wafer, and therefore, the wafer-level back gold chip packaging structure and the packaging method thereof accord with future development direction of semiconductor manufacturing.

Owner:JIANGYIN CHANGDIAN ADVANCED PACKAGING CO LTD

Panel with impact protection membrane

InactiveUS20090101759A1Protective structureEffective protectionLamination ancillary operationsAircraft stabilisationElastomerLeading edge

An aircraft leading edge panel having an outer aerodynamic surface; and an inner surface carrying the elastomeric impact protection membrane. The membrane comprises a woven or knitted fabric which is impregnated with an elastomeric material. The membrane and the panel may be bonded by an adhesive or co-cured to bond the membrane to the panel. The membrane provides impact protection to the panel by de-bonding from the face of the panel and absorbing at least part of the energy of an object impacting the panel.

Owner:AIRBUS OPERATIONS LTD

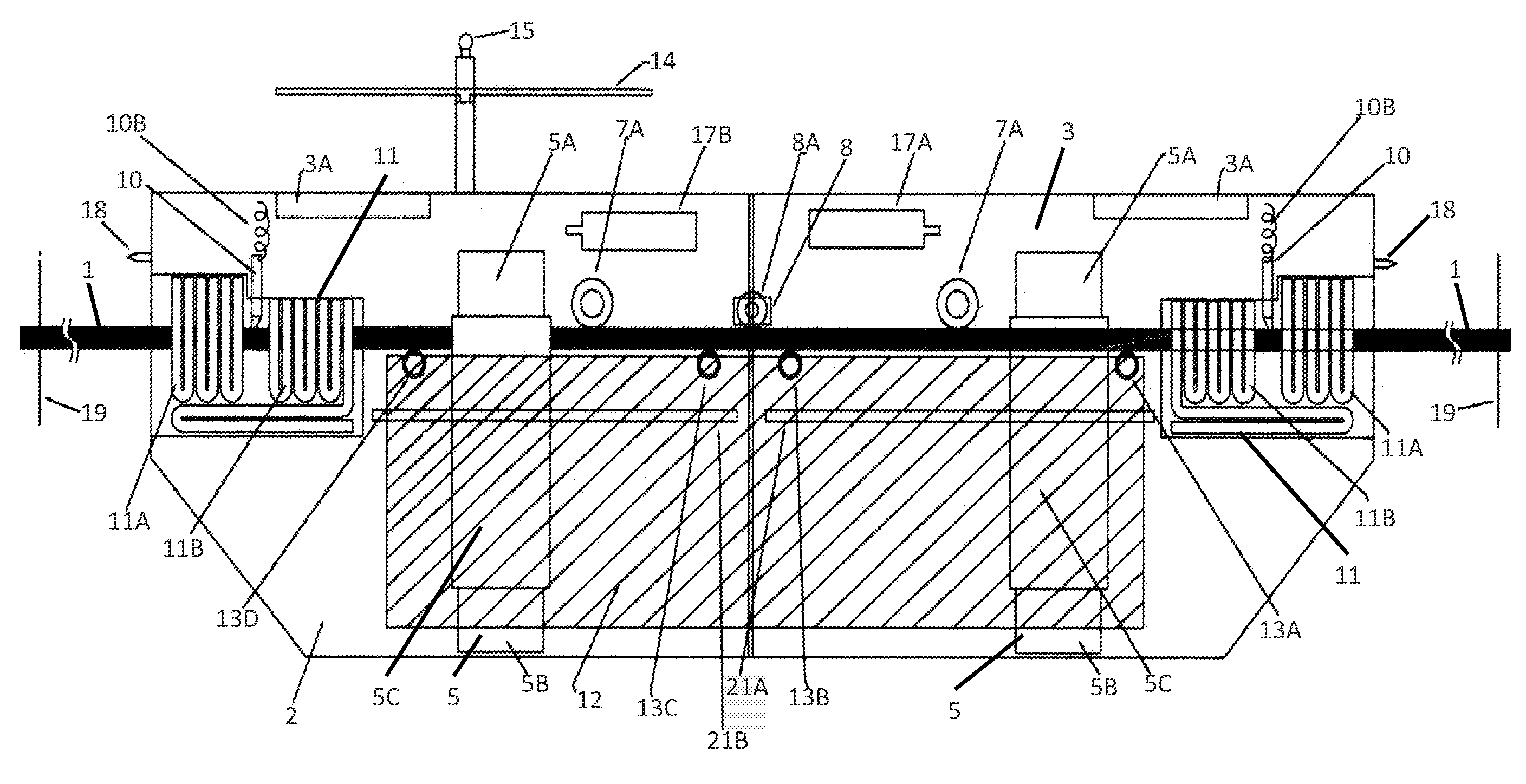

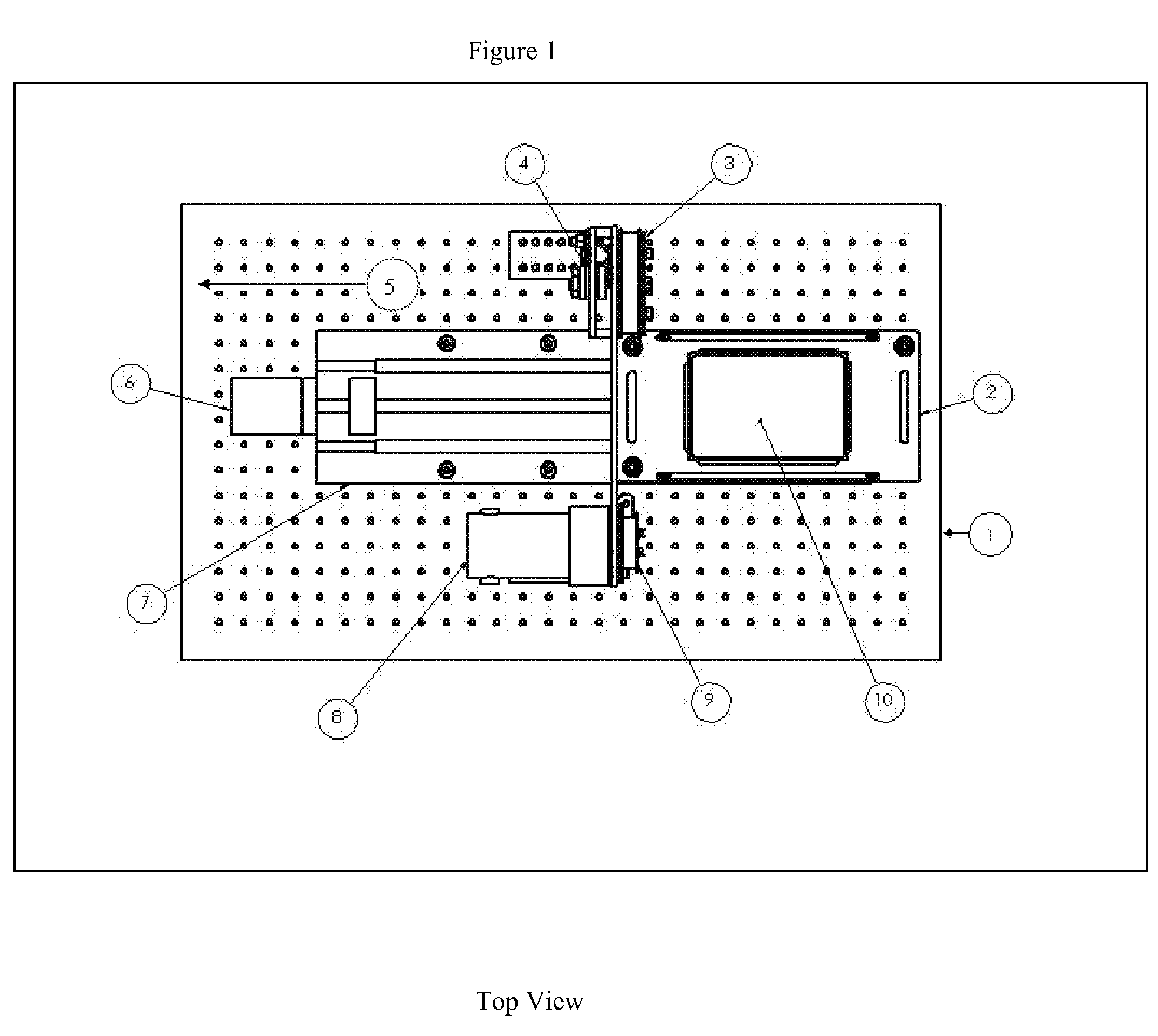

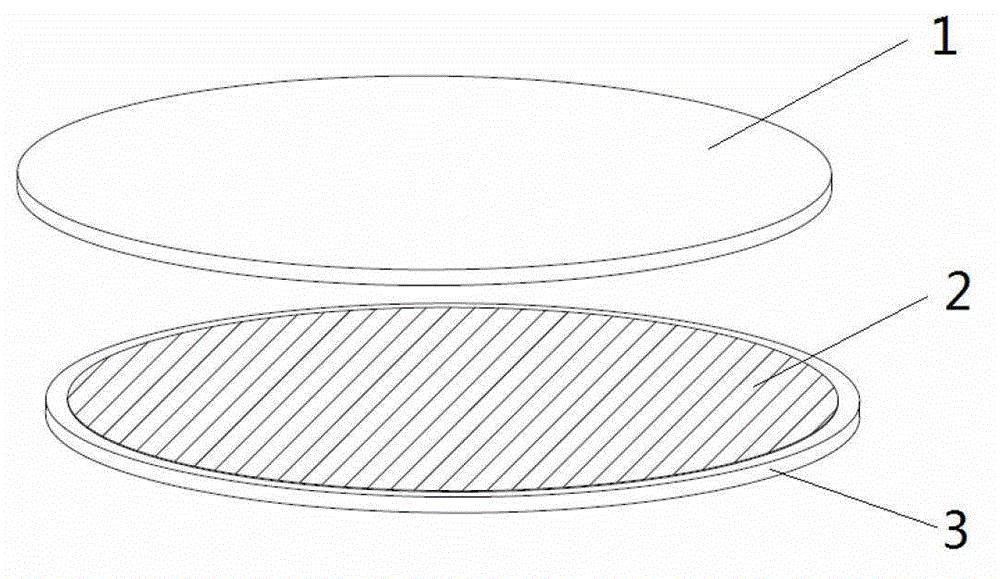

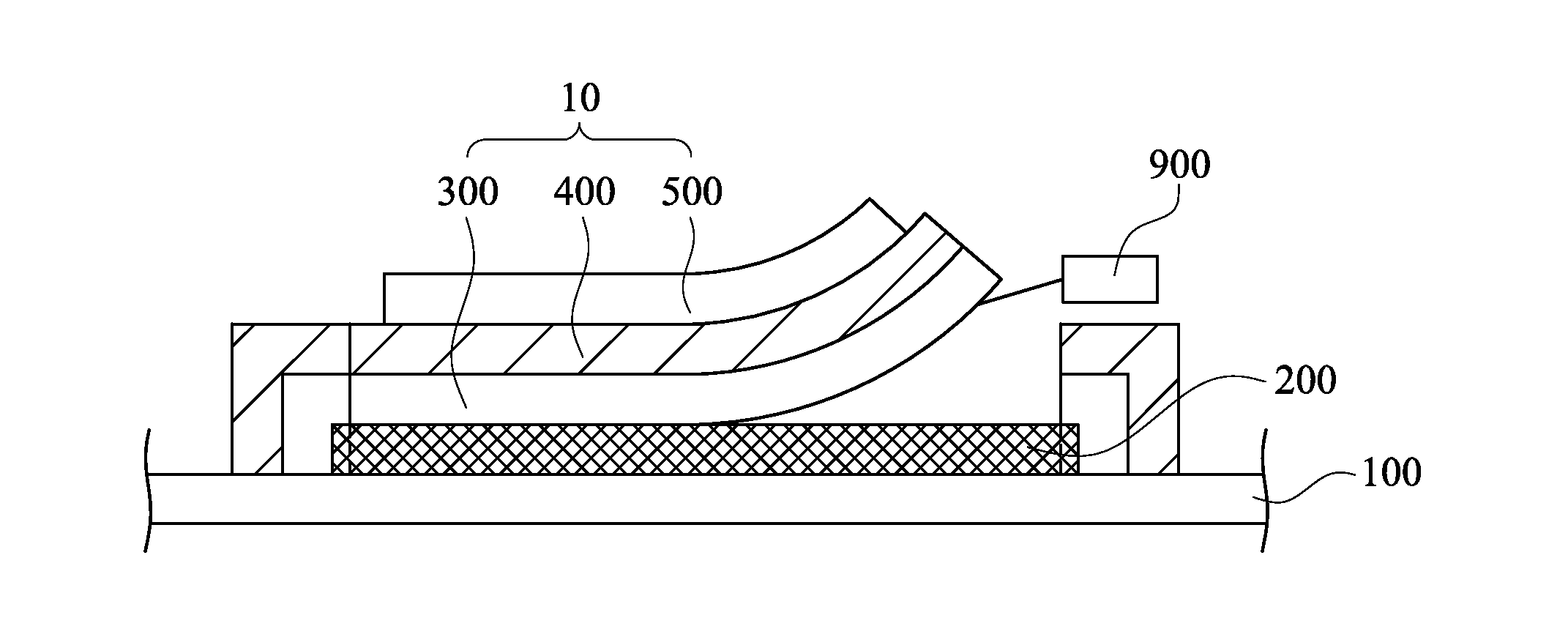

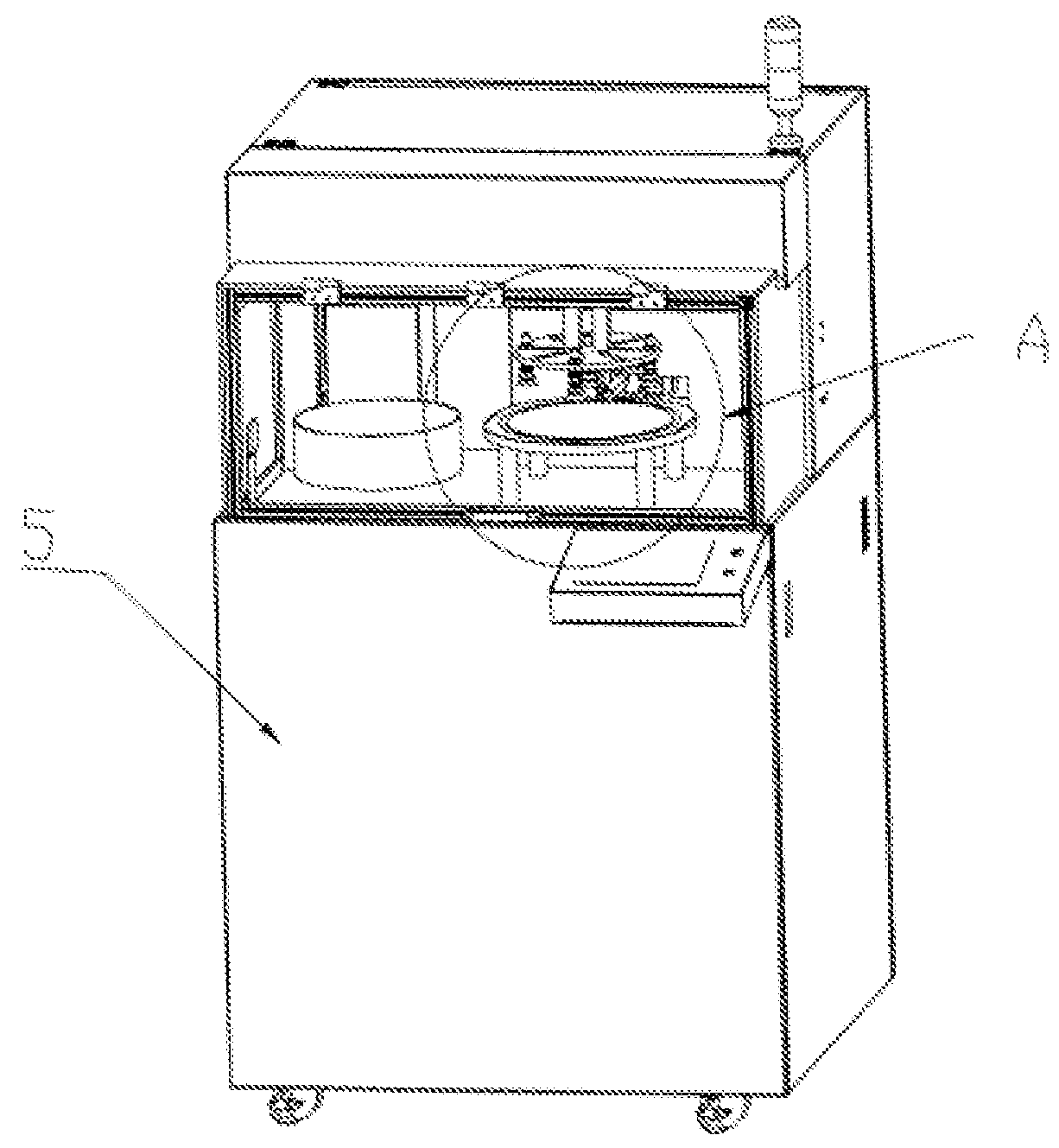

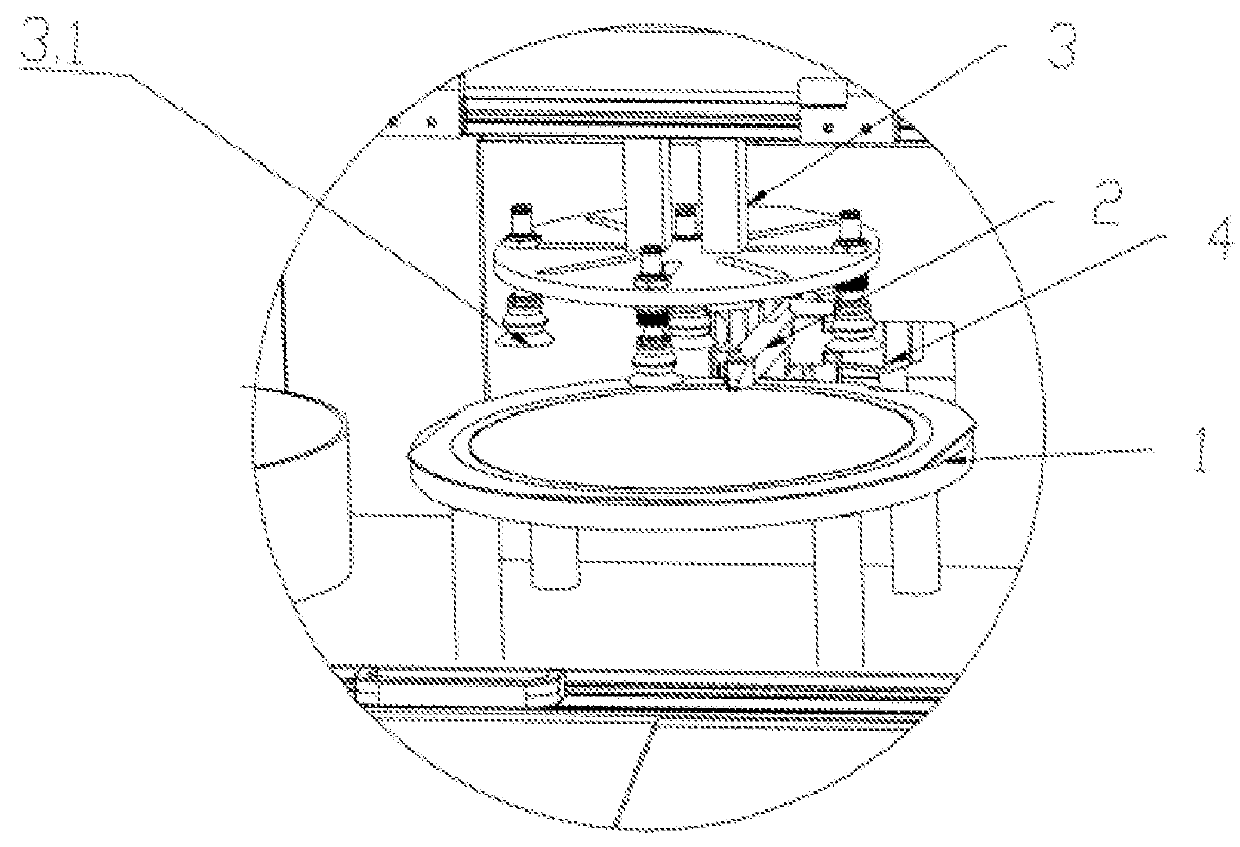

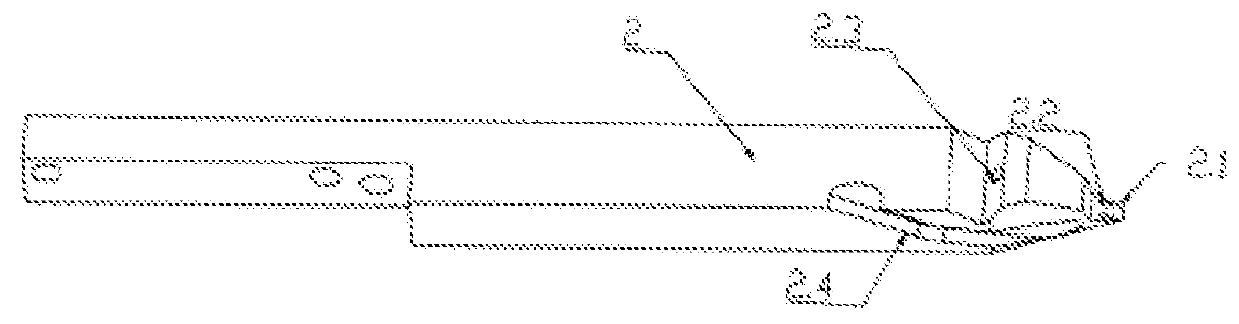

Wafer de-bonding device

InactiveUS20180108558A1Easy to operateHigh degree of automationLamination ancillary operationsSolid-state devicesWafer bondingElectrical and Electronics engineering

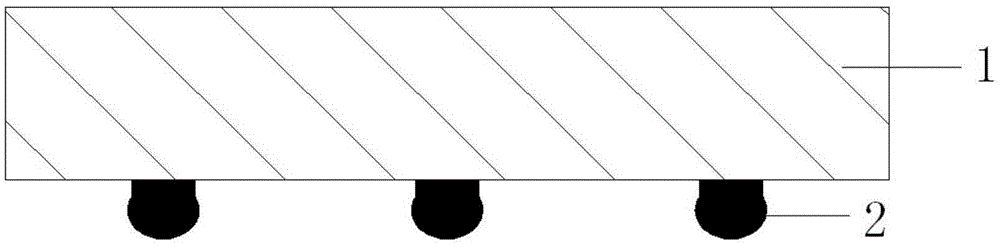

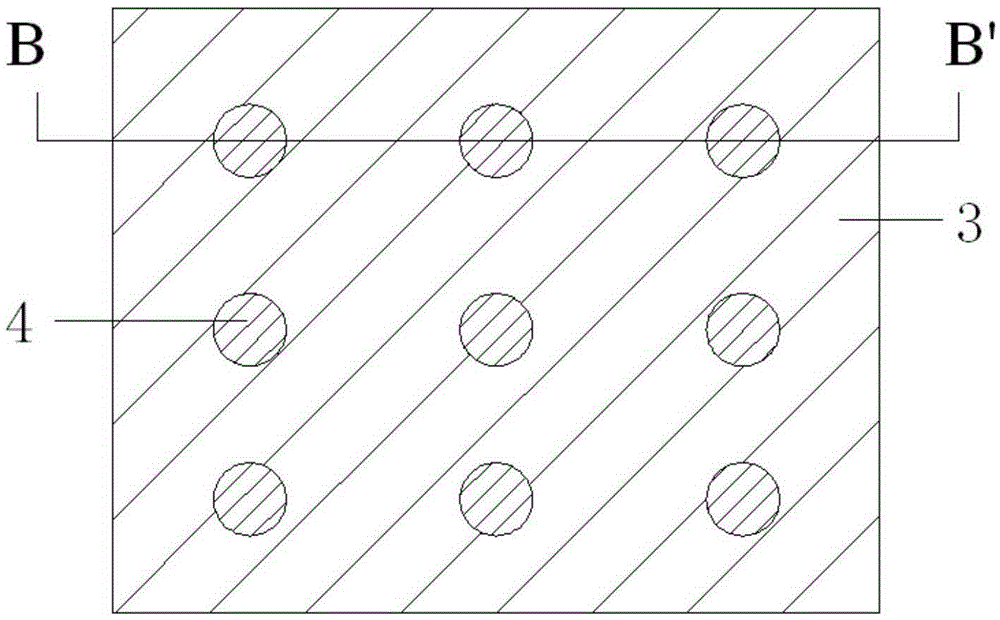

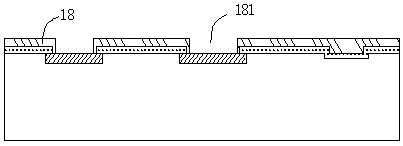

A wafer de-bonding device comprises a stage (1) for holding a device wafer and a carrier wafer bonded together, and a tool (2) with a gas outlet (2.2) disposed in proximity to the stage (1) through an adjustment device for control the tool (2) to move towards or away from the stage (1), the tool (2) being provided with a bit (2.1) to cut a notch into a film or an adhesive layer at a junction of the bonded wafers, the gas outlet (2.2) being provided on the tool bit (2.1), the tool (2) being further provided with a gas inlet (2.3) in communication with the gas outlet (2.2), the gas inlet (2.3) being connected to a gas jet generator so as to direct a gas jet towards the junction of the bonded wafers on the stage (2). The wafer de-bonding device has a high degree of automation and simple operations.

Owner:MICRO MATERIALS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com