Vertical structure semiconductor devices

A semiconductor and device technology, applied in the field of GaN-based vertical structure semiconductor devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

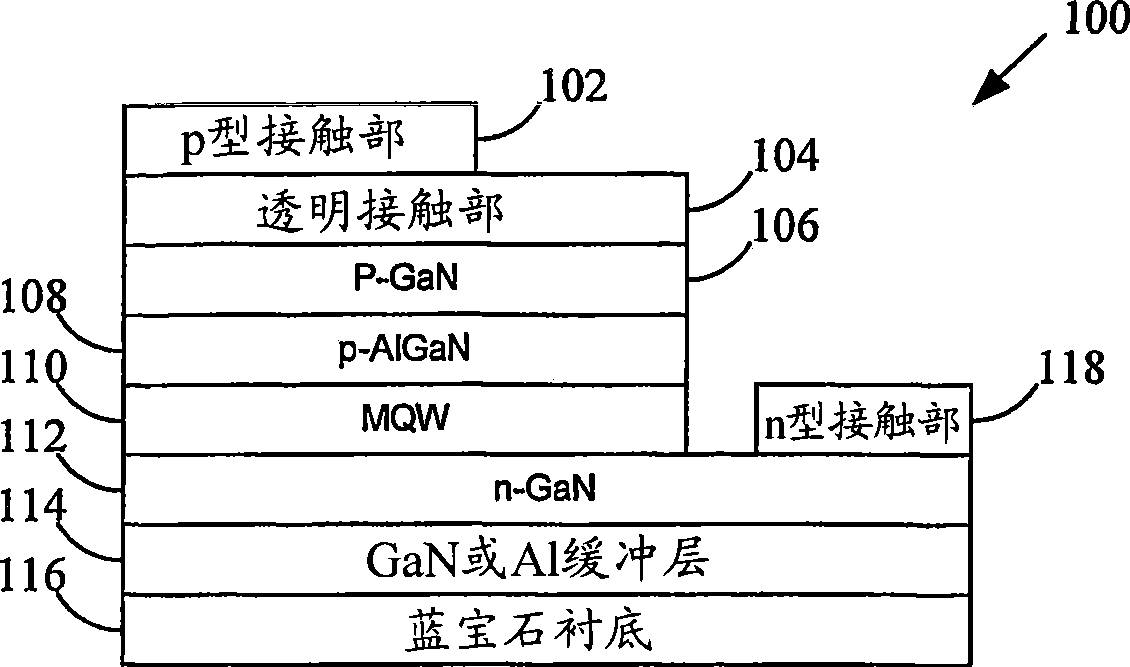

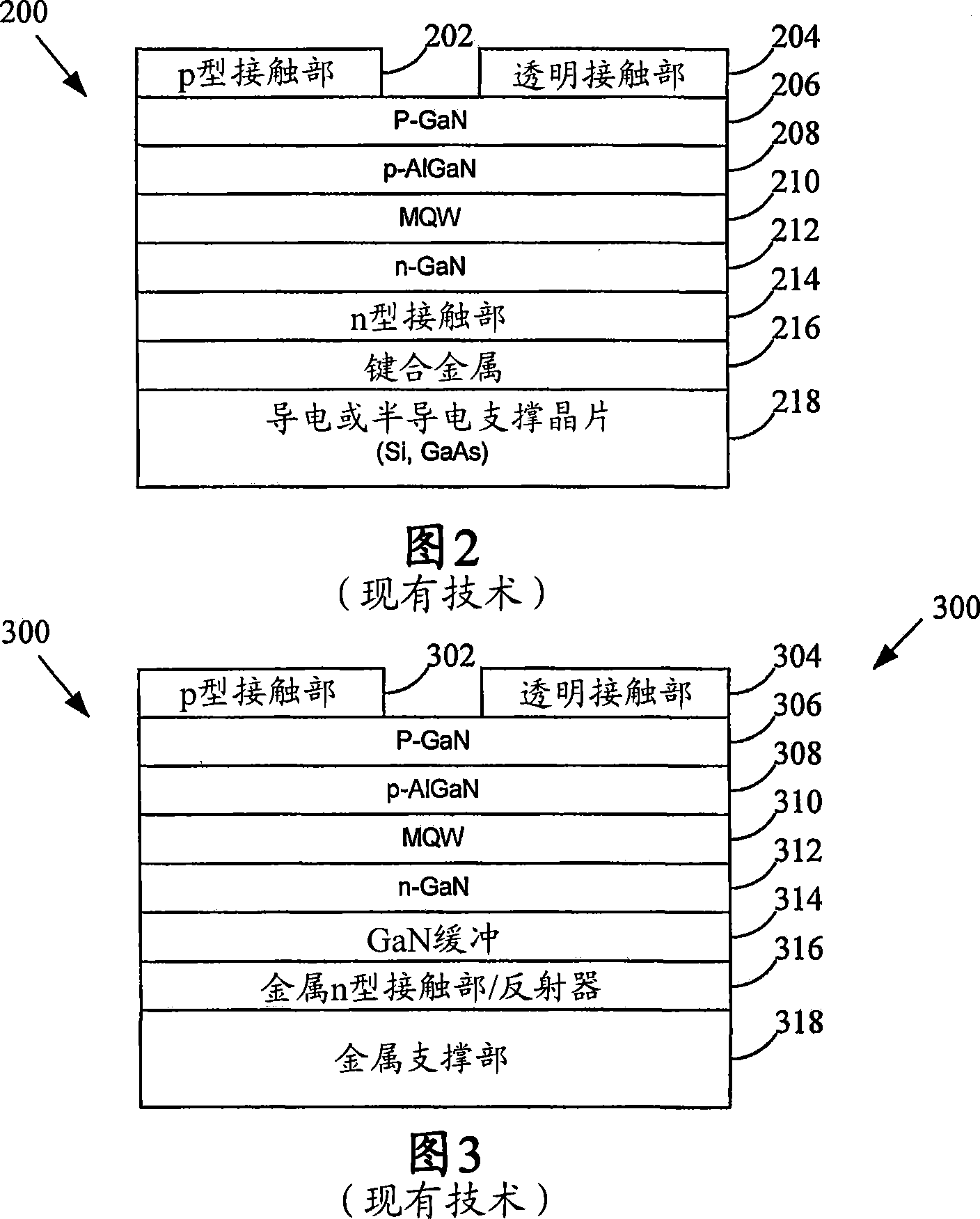

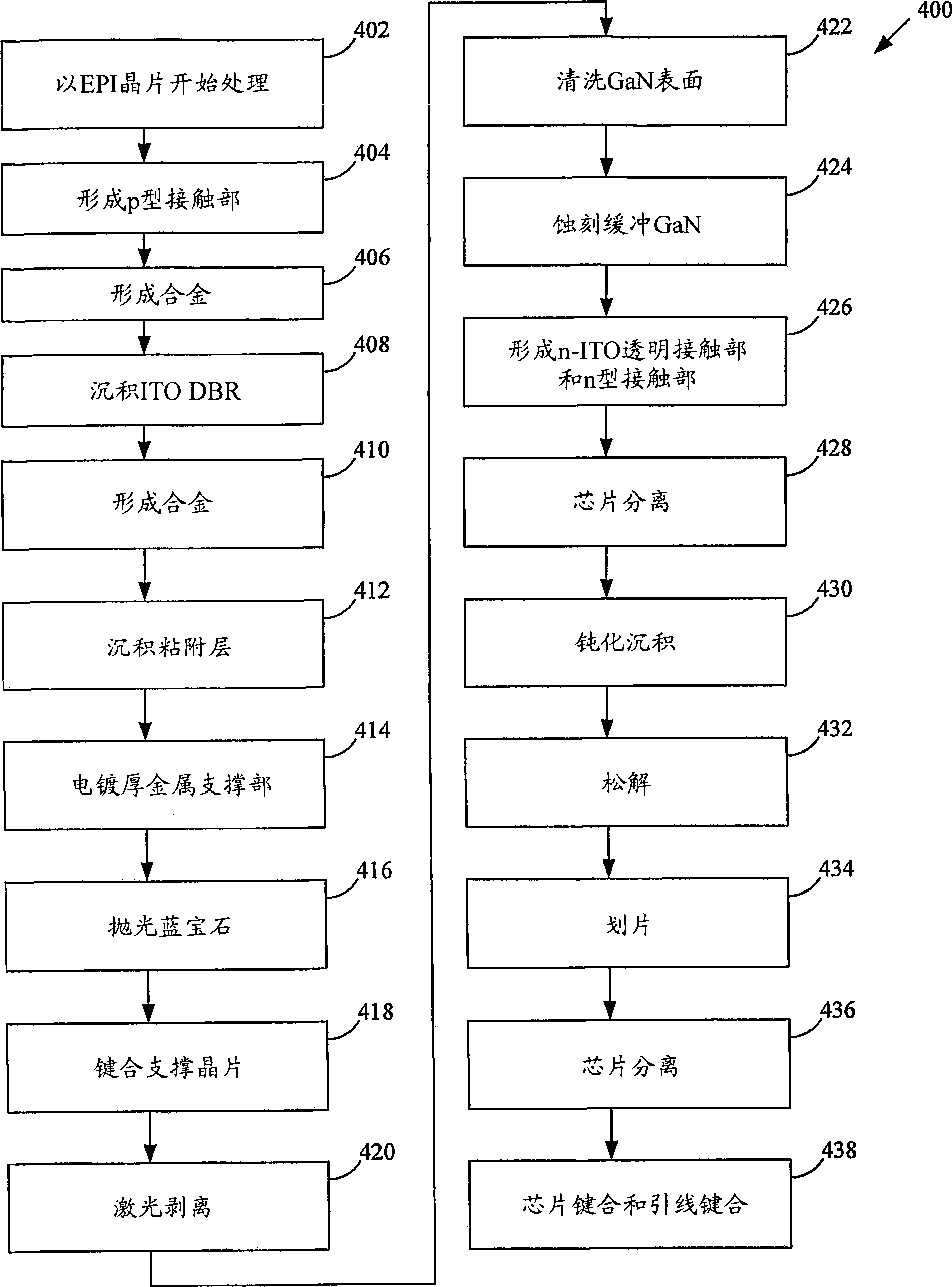

[0033] The invention is described with reference to specific device structures and embodiments. Those skilled in the art should understand that the description is illustrative and provides the best mode for carrying out the invention. The present invention includes a number of formation and deposition steps for fabricating a semiconductor device according to the present invention. This disclosure relates to depositing materials on or over other materials, which are illustrated and described as representing any box with reference, as explained and understood by a person skilled in the art in conjunction with the description, and this disclosure is intended to describe and overlay on top of other materials Techniques for depositing material over, over, or under. For example, some parts of this disclosure describe semiconductor layers constructed from above and other parts describe semiconductor layers constructed from below, and in both cases, as illustrated and shown, the depo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com