Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41 results about "Carbon oxysulfide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

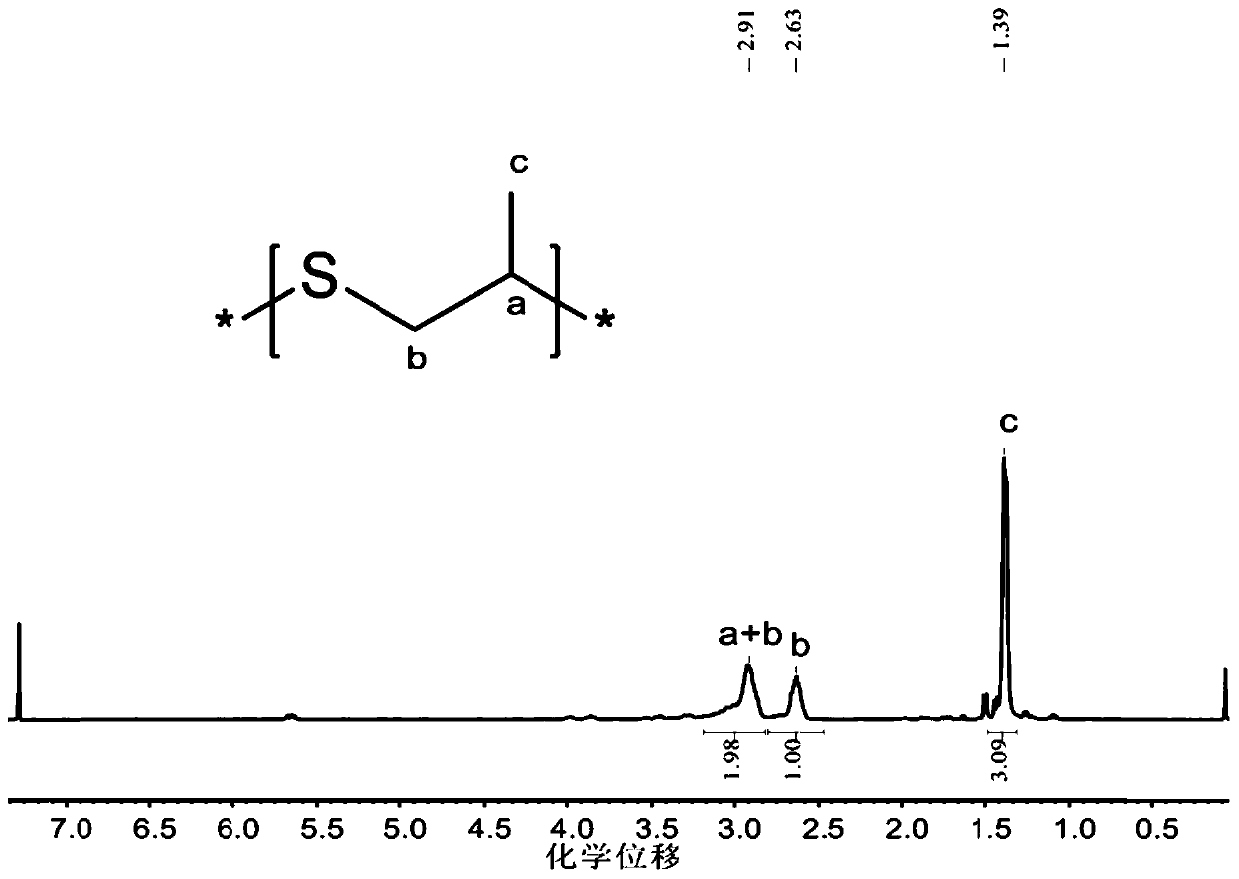

Polythiocarbonate and preparation method thereof

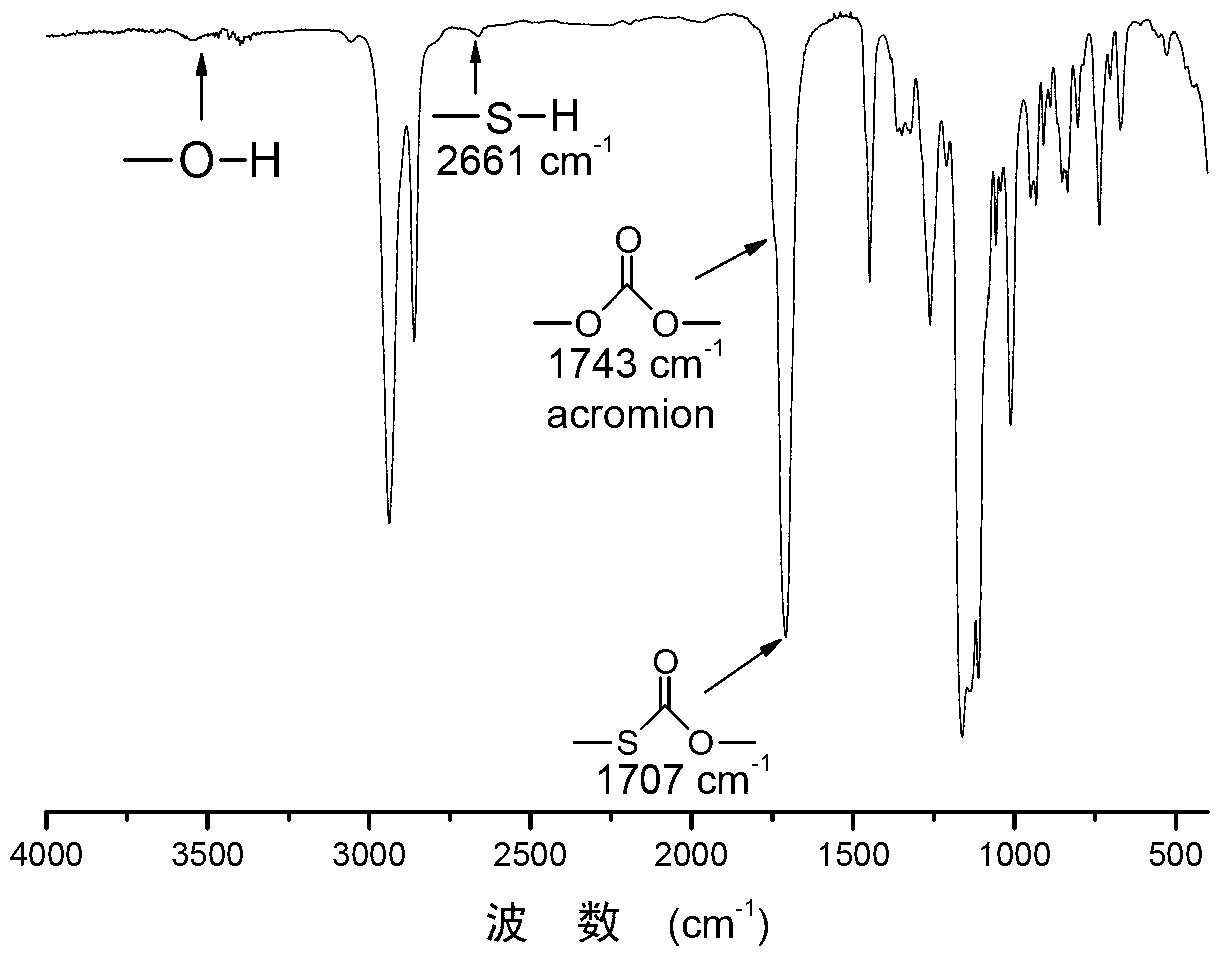

The invention relates to the field of high molecular material synthesis and aims at providing polythiocarbonate and a preparation method thereof. The preparation method comprises the following steps of: adding an epoxide, carbon oxysulfide and a catalyst into a dry high-pressure reaction kettle, carrying out reaction for 1-12 hours at 20-150 DEG C and self-generated pressure, purifying the generated product and drying the generated product to obtain a polythiocarbonate product, wherein the catalyst is a zinc-cobalt double-metal cyanide complex or a silicon dioxide loaded zinc-cobalt double-metal cyanide complex. The polythiocarbonate provided by the invention has wide purposes, the refractive index of the polymerized product is obviously higher than that of a general polymer, such as a COS (Carbon Oxysulfide)-cyclohexene oxide copolymer, and is 1.66, and therefore the polythiocarbonate has potential use in the aspect of a light-guide fiber.

Owner:ZHEJIANG UNIV

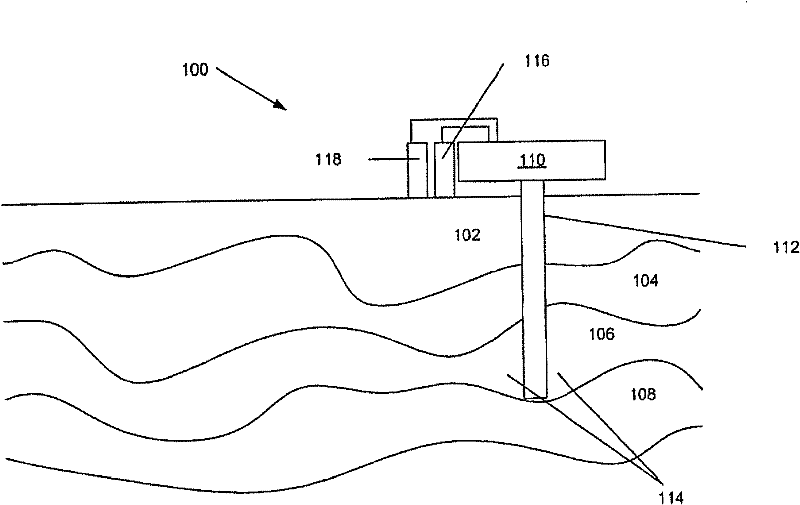

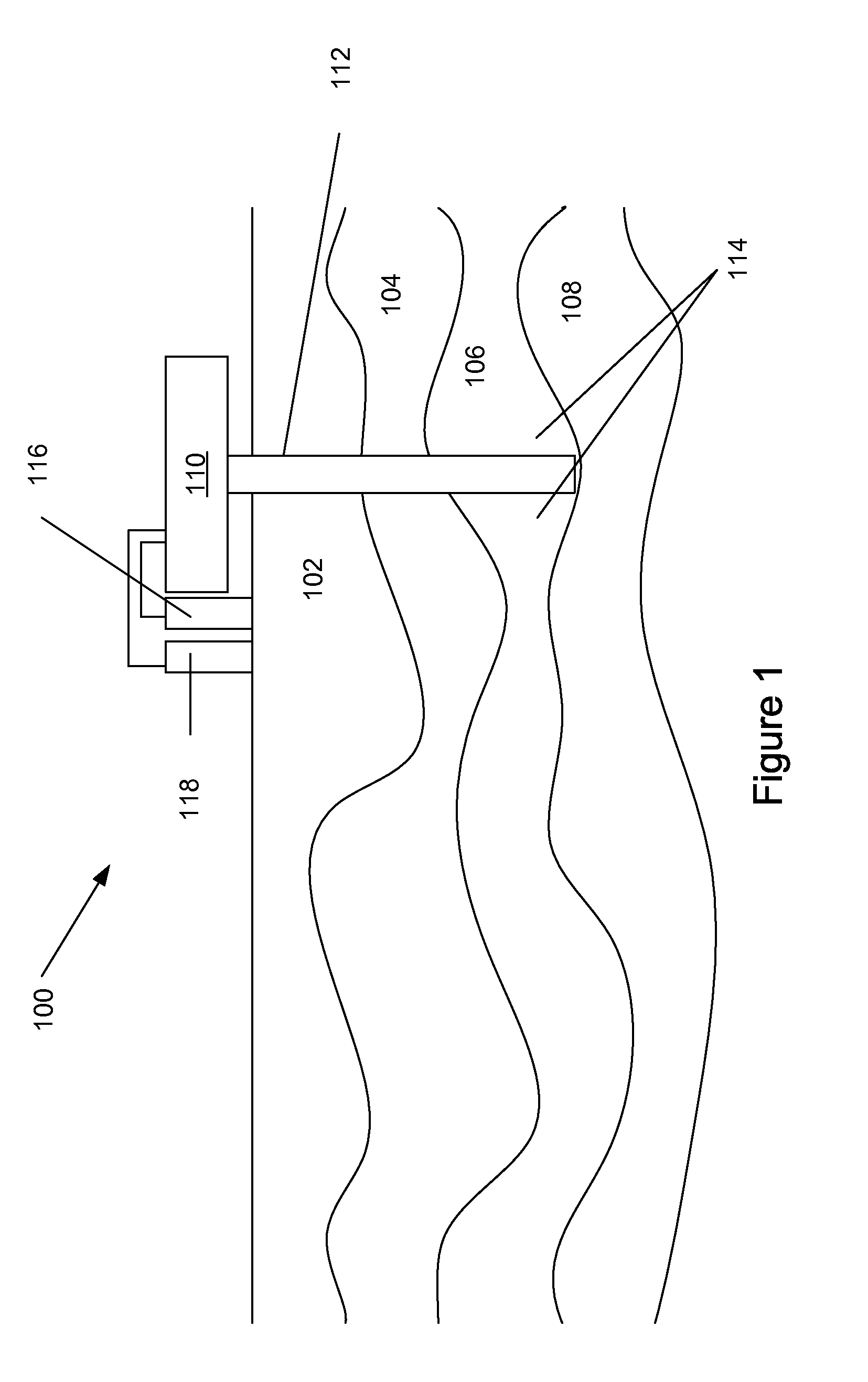

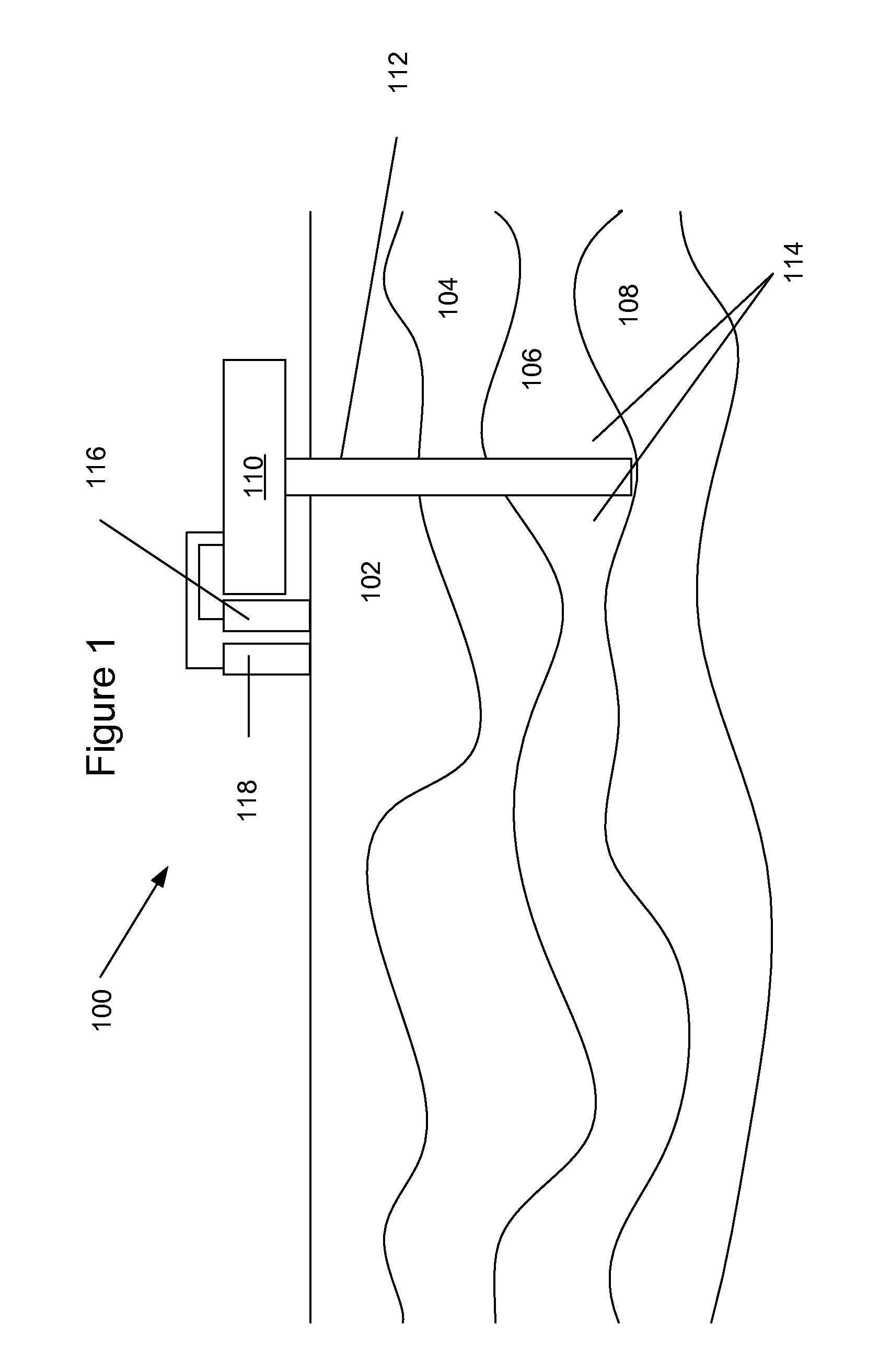

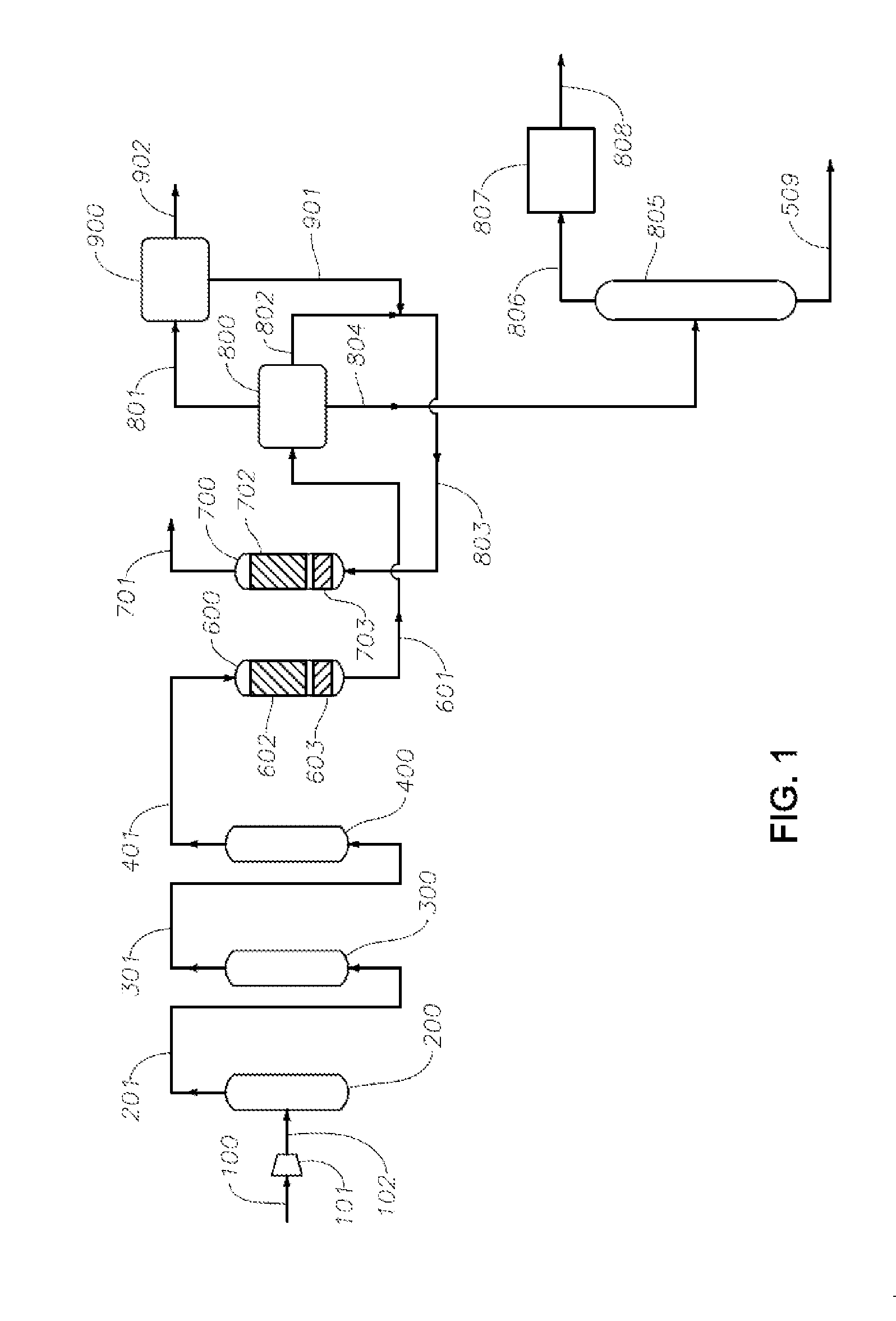

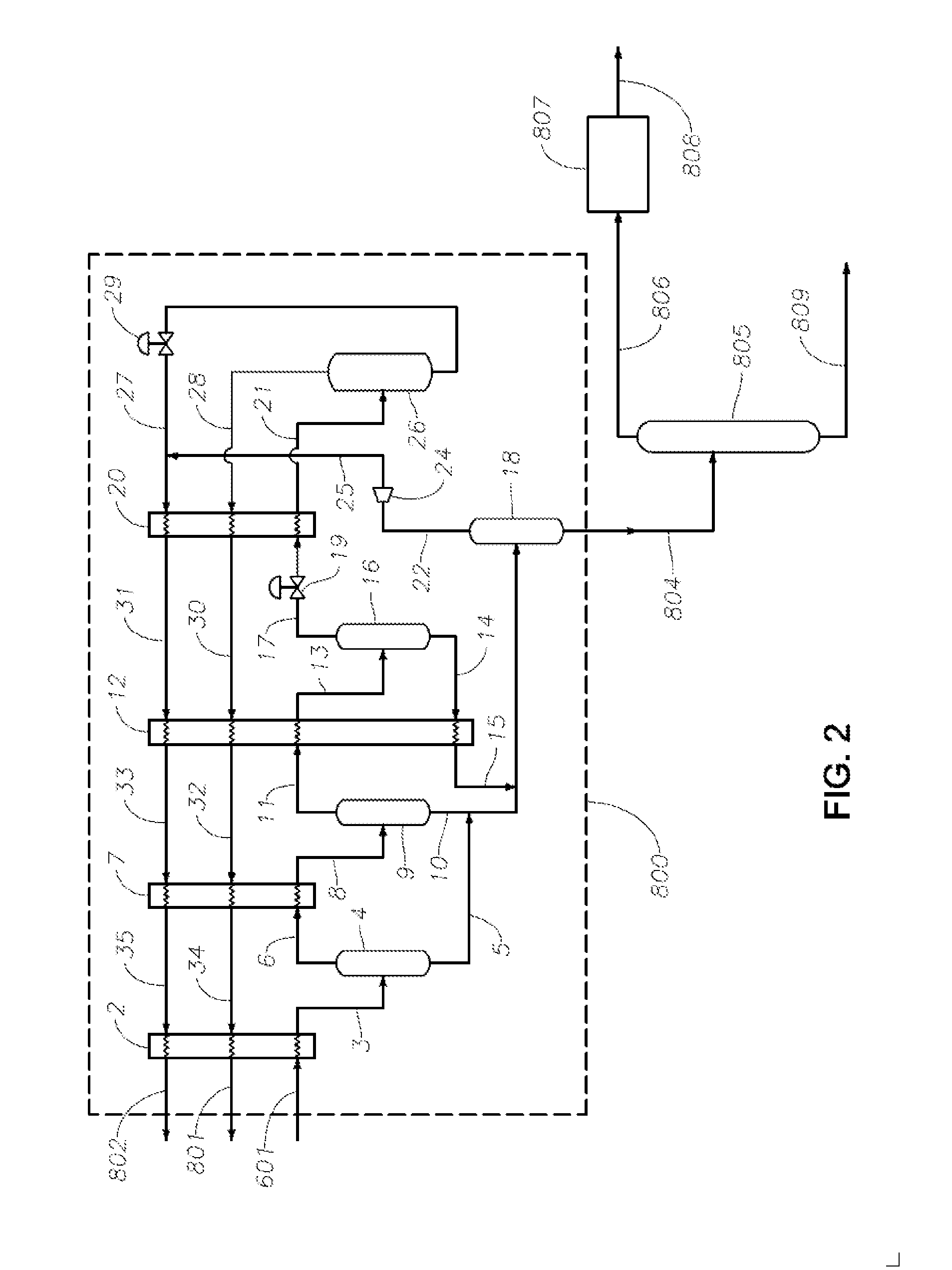

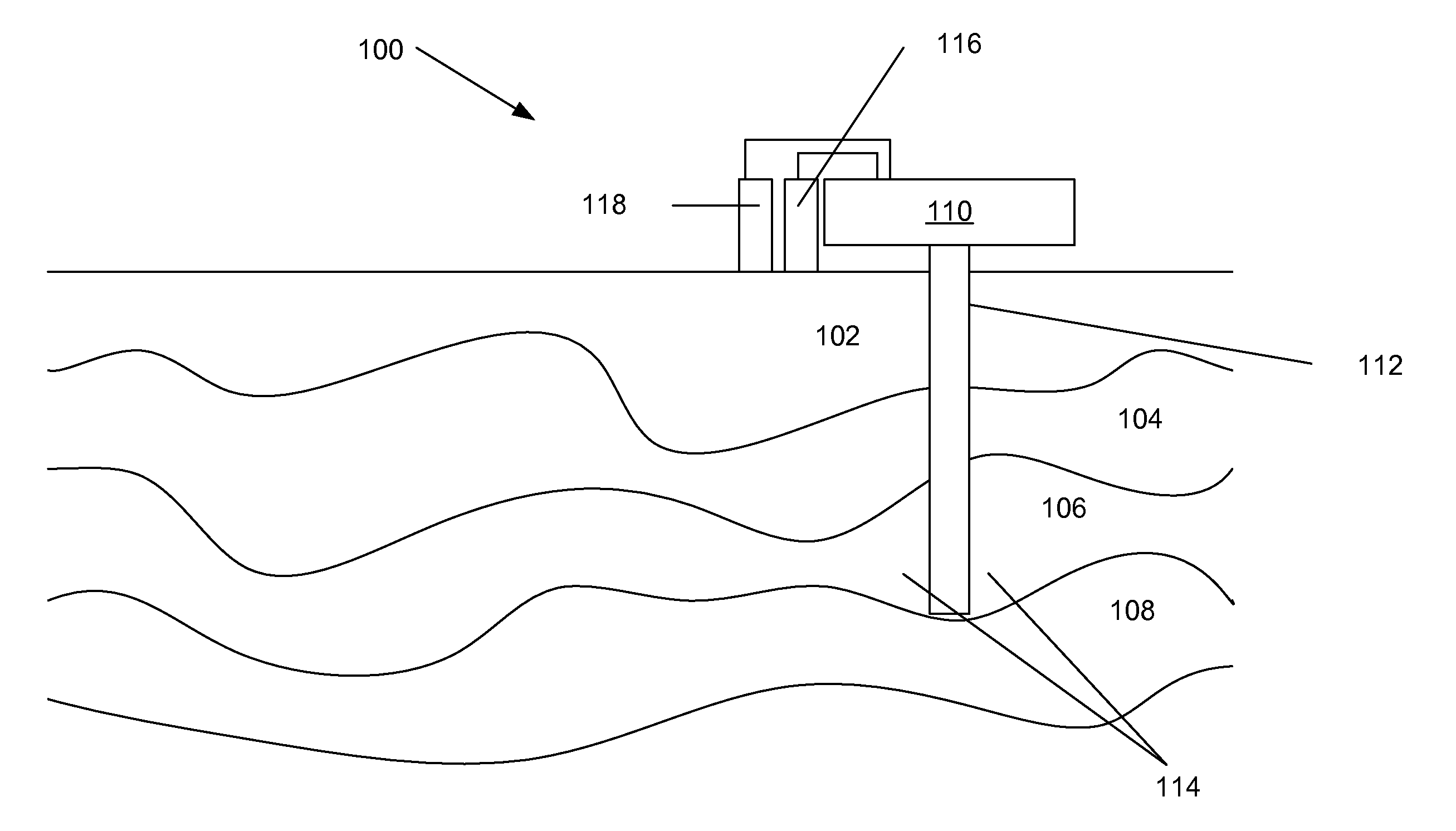

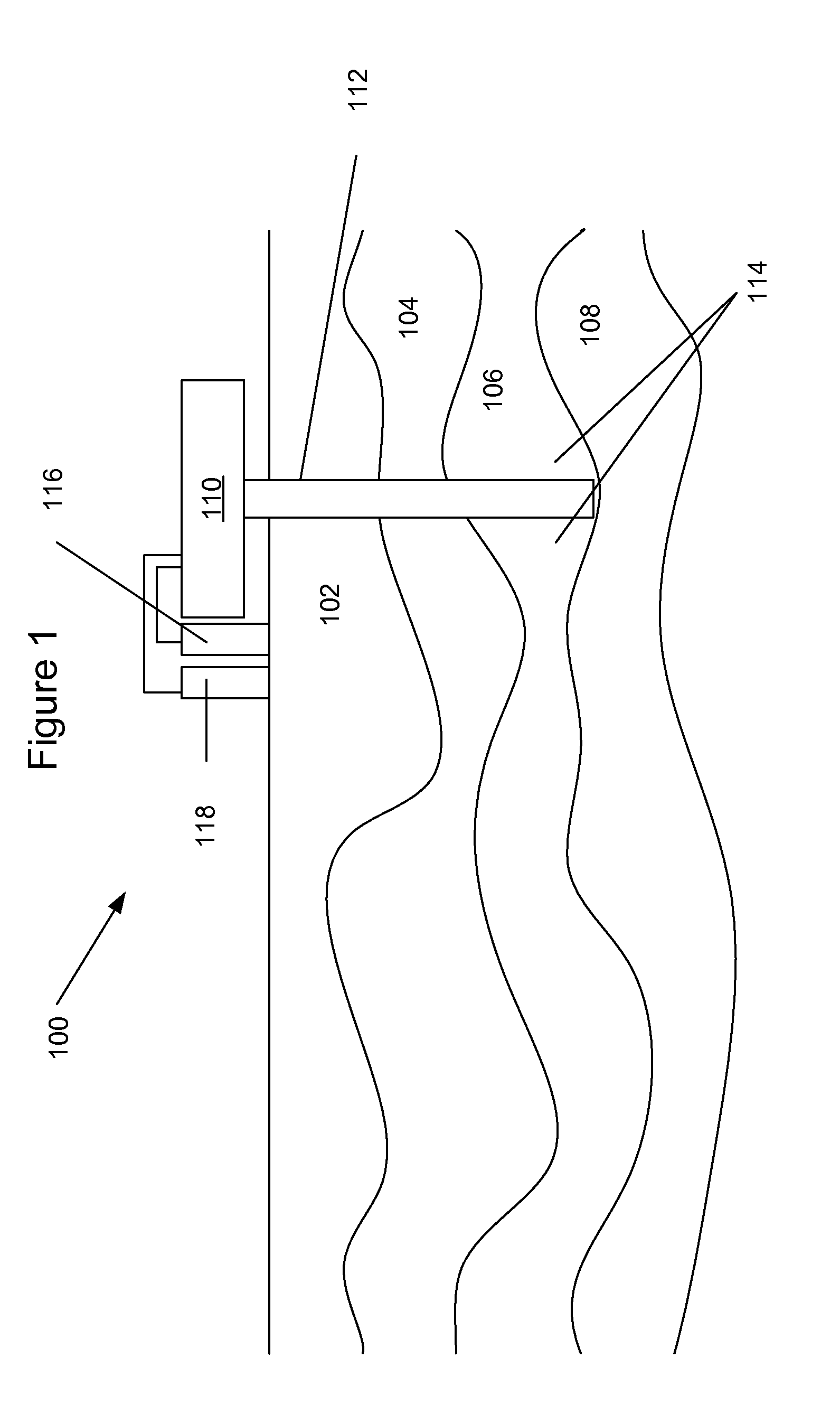

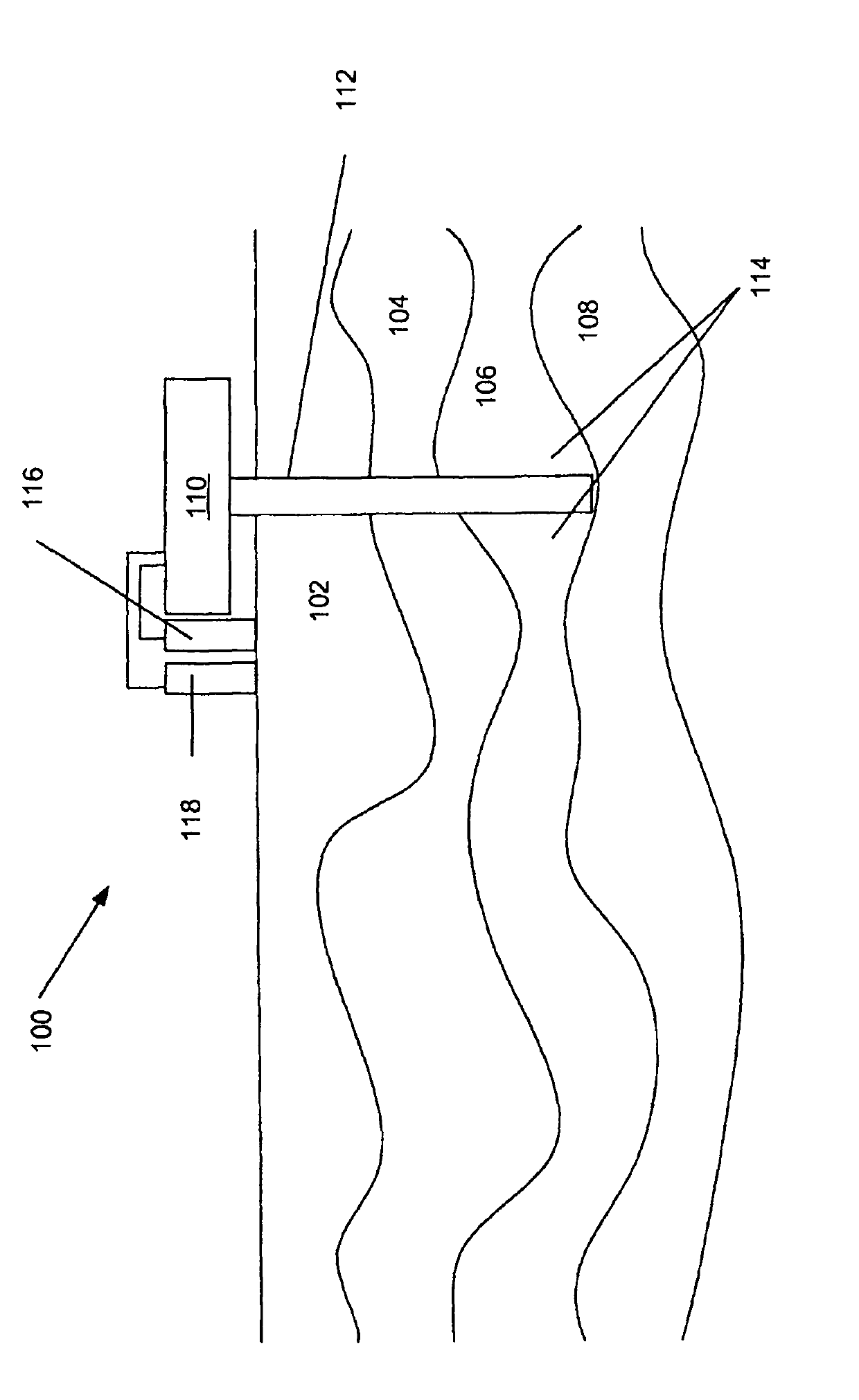

Systems and methods for producing oil and/or gas

InactiveCN102132003AIncrease auto-ignition temperatureFluid removalDrilling compositionCarbon oxysulfideCarbon disulfide

A system for producing oil and / or gas comprises a formation comprising a mixture of oil and / or gas and an enhanced oil recovery mixture comprising an additive to increase an auto-ignition temperature of the mixture and a carbon disulfide formulation and / or a carbon oxysulfide formulation; and a mechanism for recovering at least a portion of the oil and / or gas.

Owner:SHELL INT RES MAATSCHAPPIJ BV

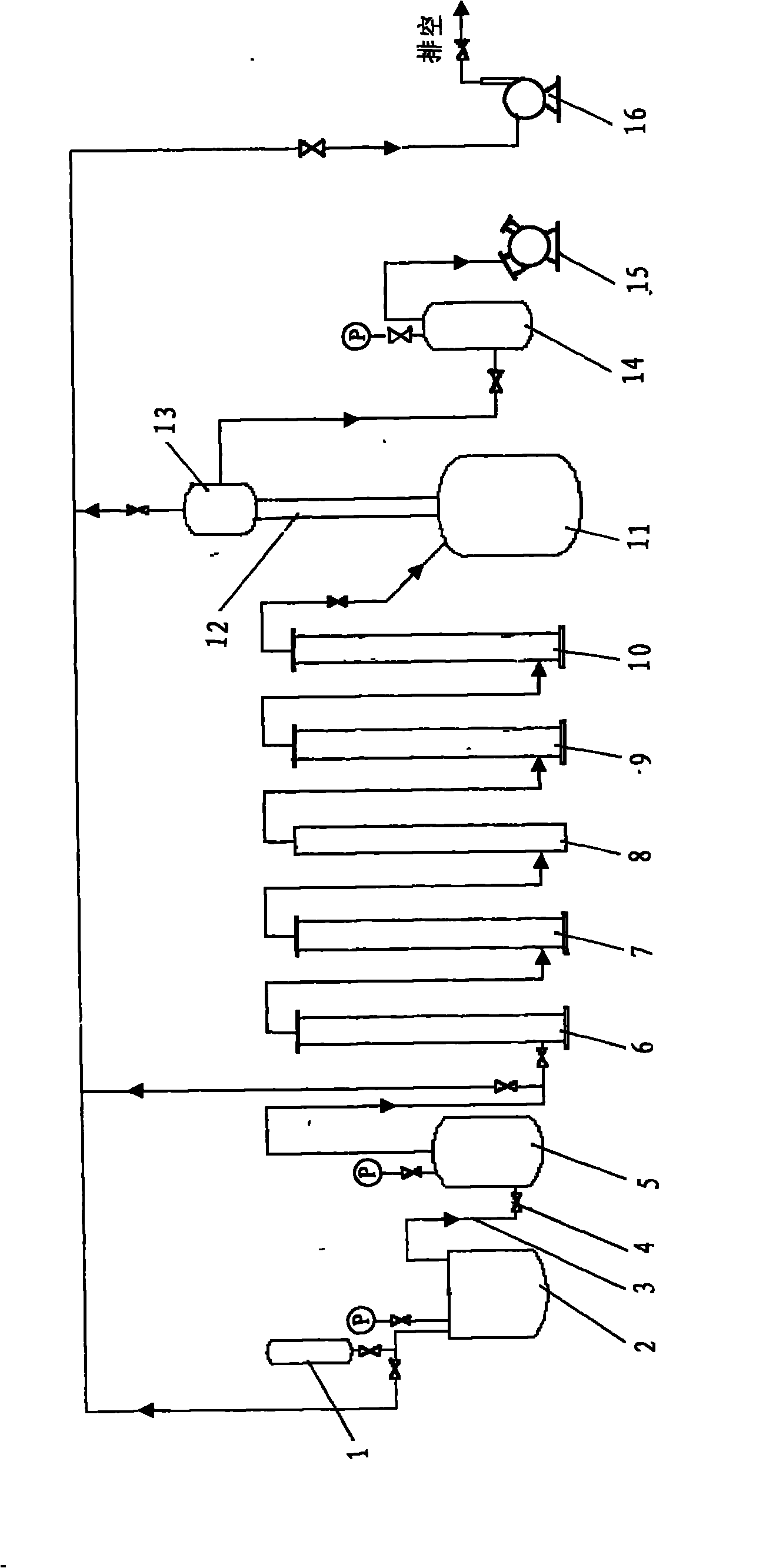

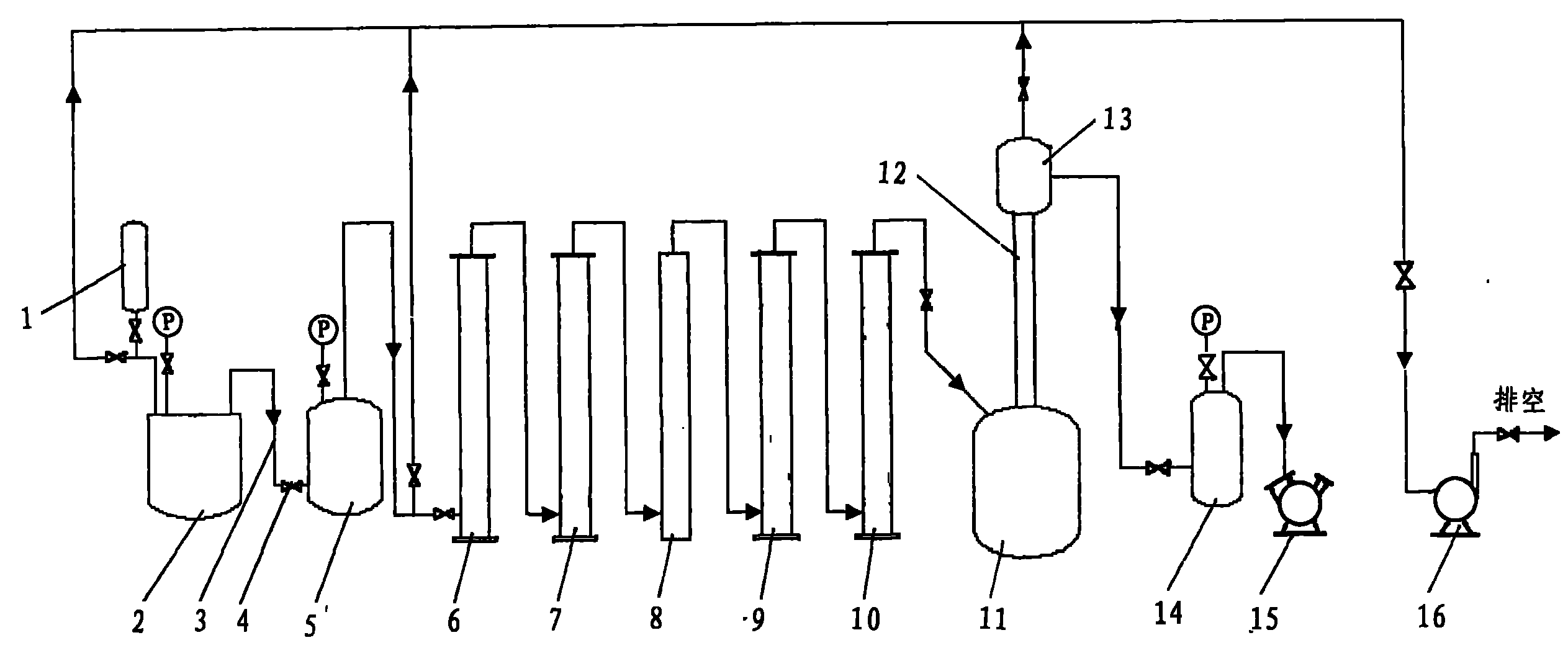

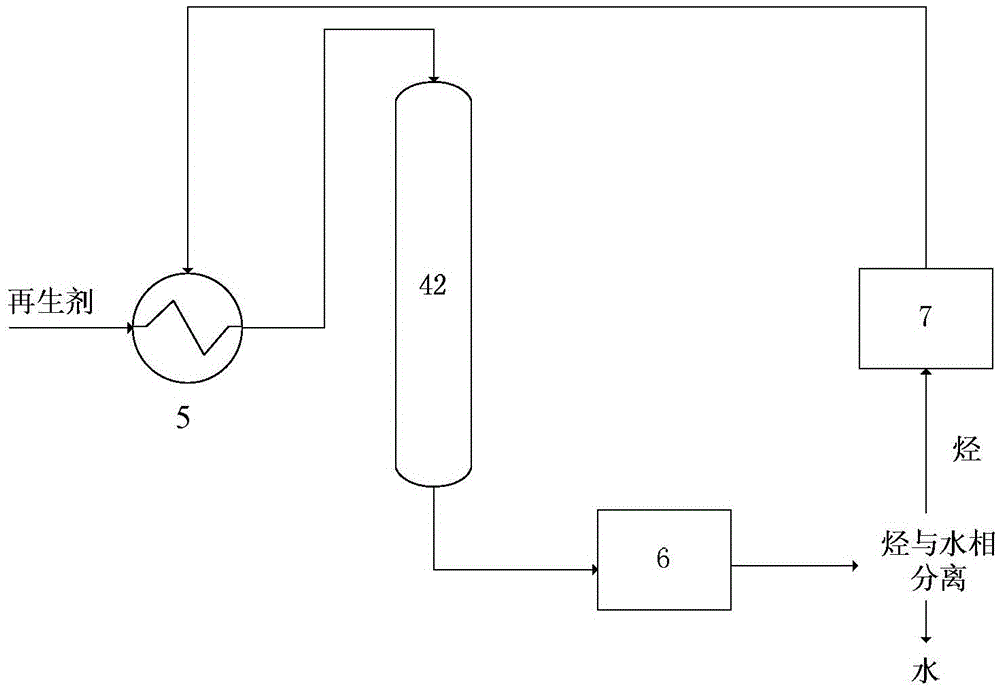

Device and method for simultaneously producing ultra-high-purity carbon oxysulfide and high-purity carbon disulfide

PendingCN107986277AEasy to integrateEasy to recycleCarbon disulfideCarbon oxysulideGas phaseBuffer tank

The invention belongs to a device and a method for simultaneously producing ultra-high-purity carbon oxysulfide and high-purity carbon disulfide. The device comprises a carbon monoxide raw material gas pipeline provided with a first regulating valve, a sulphur raw material pipeline, a carbon disulfide product tank and a carbon oxysulfide product tank, wherein the carbon monoxide raw material gas pipeline and the sulphur raw material pipeline are respectively connected with a first raw material inlet and a second raw material inlet of a reactor; an outlet of the reactor is connected with a buffer tank; a gas outlet formed in the top of the buffer tank is connected with an entrance of a first rectifying tower, a liquid phase outlet of the first rectifying tower is connected with an entranceof a third rectifying tower, and a liquid phase outlet of the third rectifying tower is connected with the carbon disulfide product tank; a gas phase outlet of the first rectifying tower is connectedwith a raw material inlet of a second rectifying tower, and a liquid phase outlet of the second rectifying tower is connected with the carbon oxysulfide product tank; the device and the method have the advantages that a three-tower type complex distillation process is used for extracting the carbon oxysulfide with the purity of not lower than 99.999%, and the purity of the carbon disulfide is improved to 99.99%.

Owner:HENAN XINLIANXIN SHENLENG ENERGY

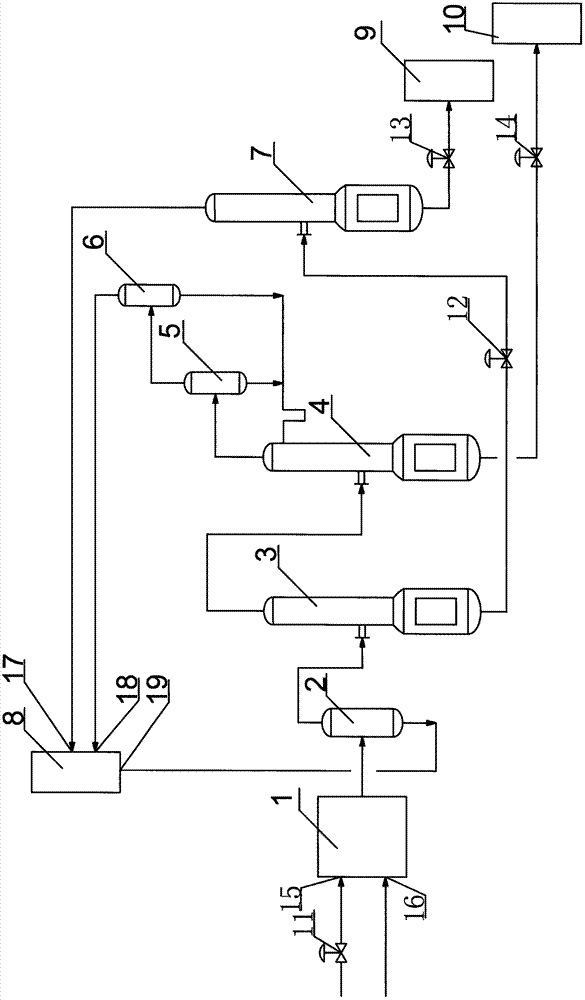

Method for preparing high-purity carbon oxysulfide gas

The invention discloses a method for preparing high-purity carbon oxysulfide gas. The method comprises the following steps of: (i) synthetic reaction: allowing saturated ammonium thiocyanate solution to react with sulfuric acid in a reactor to generate the carbon oxysulfide gas containing impurities; (ii) alkaline washing: continuously introducing the carbon oxysulfide gas containing impurities into a primary alkaline washing tower and a secondary washing tower to remove trace acidic impurities; (iii) primary drying; (vi) secondary drying; and (v) rectification. The method has the advantages of simple equipment, convenience of operation, safe equipment operation, high yield and the like.

Owner:HUAHE NEW TECH DEV COMPANY RES INST OF PHYSICAL & CHEM ENG OF NUCLEAR IND

Detection method of trace volatile sulfide in gypsum board

InactiveCN102253137ASolve the problem of selectivityResolve accuracyComponent separationSorbentCapillary column

The invention relates to a detection method of trace volatile sulfides in a gypsum board. The detection method solves the problems of poor selectivity and difficulty for accurate analysis of volatile sulfides with a low concentration in present detection methods. The detection method realizes the qualitative and quantitative analysis of an object to be detected by placing a gypsum board in a climate box, keeping a constant temperature and humidity, and performing trapping by a solid adsorbent, thermal desorption, separation by a capillary column of gas chromatography, and detection by a flamephotometric detector. The detection method has the advantages of high selectivity, and high sensitivity, is especially applicable to the analysis and determination of trace volatile sulfides (hydrogen sulfide, sulfur dioxide, carbon oxysulfide, carbon disulfide) with a low concentration and multiple components, has accurate and reliable determination, and has good application prospects.

Owner:CHEM MINERALS & METALLIC MATERIALS INSPECTION CENT OF TIANJIN ENTRY EXIT INSPECTION & QUARANTINE BUREAU

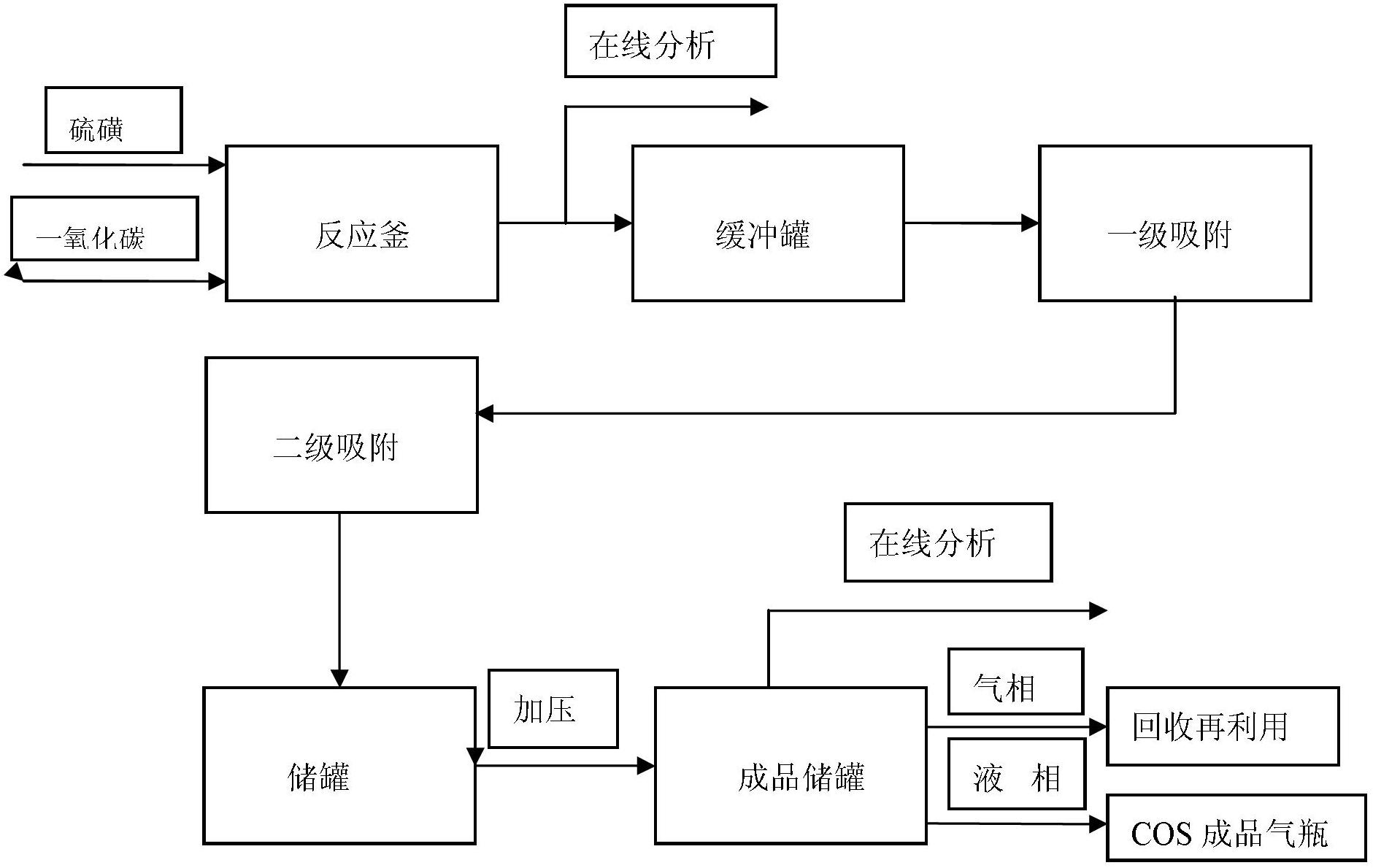

Production method of high-purity carbon oxysulfide

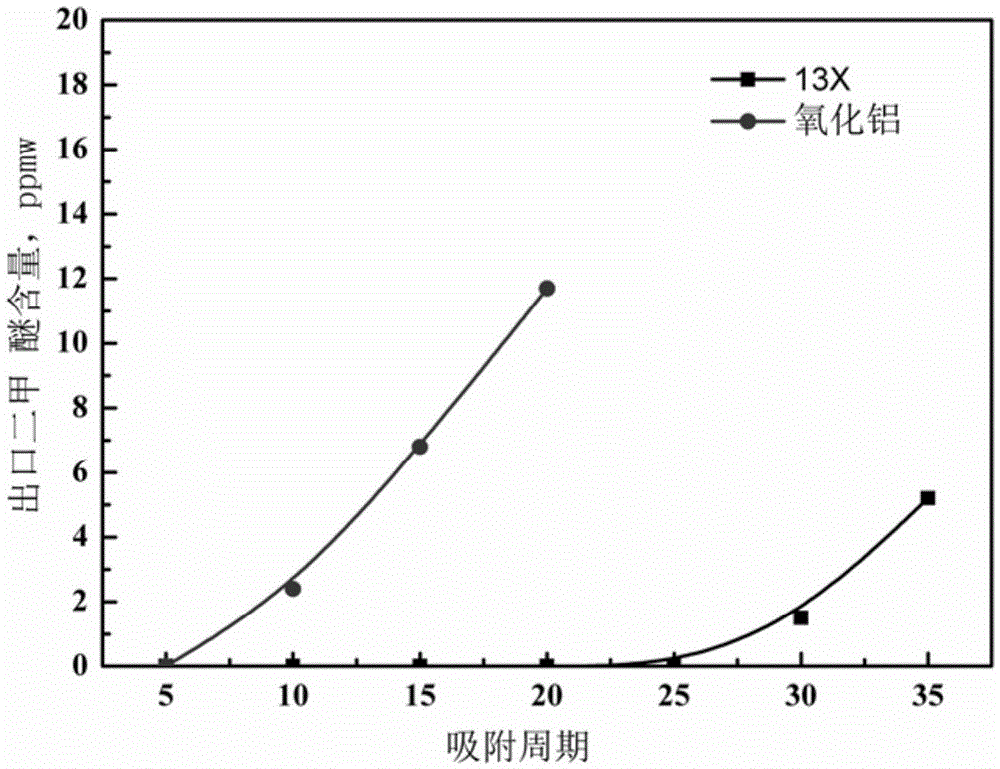

The invention discloses a production method of high-purity carbon oxysulfide. The production method comprises the following steps of: introducing carbon oxide into molten sulfur in a reaction kettle; reacting the carbon oxide with the sulfur to generate carbon oxysulfide by taking calcium chloride as a catalyst; and getting the carbon oxysulfide through calcium chloride and molecular sieve two stage adsorption columns to remove impurities and moisture successively, thereby preparing the high-purity carbon oxysulfide. According to the production method of the high-purity carbon oxysulfide, excess carbon oxide gas and the sulfur are subjected to chemical reaction under the condition of taking the calcium chloride as the catalyst to generate the carbon oxysulfide, the impurities and moisture in the carbon oxysulfide are effectively removed by utilizing the calcium chloride and the molecular sieve as adsorbents in sequence; and thus, the high-purity carbon oxysulfide with purity of reaching up to 98 percent can be prepared. Since the catalyst is properly selected and the process steps are rationally arranged, the reaction speed can be greatly increased, the yield can be improved, and the purity of a product is high; and thus, industrial production can be realized to meet the current market requirements.

Owner:绿菱电子材料(天津)有限公司

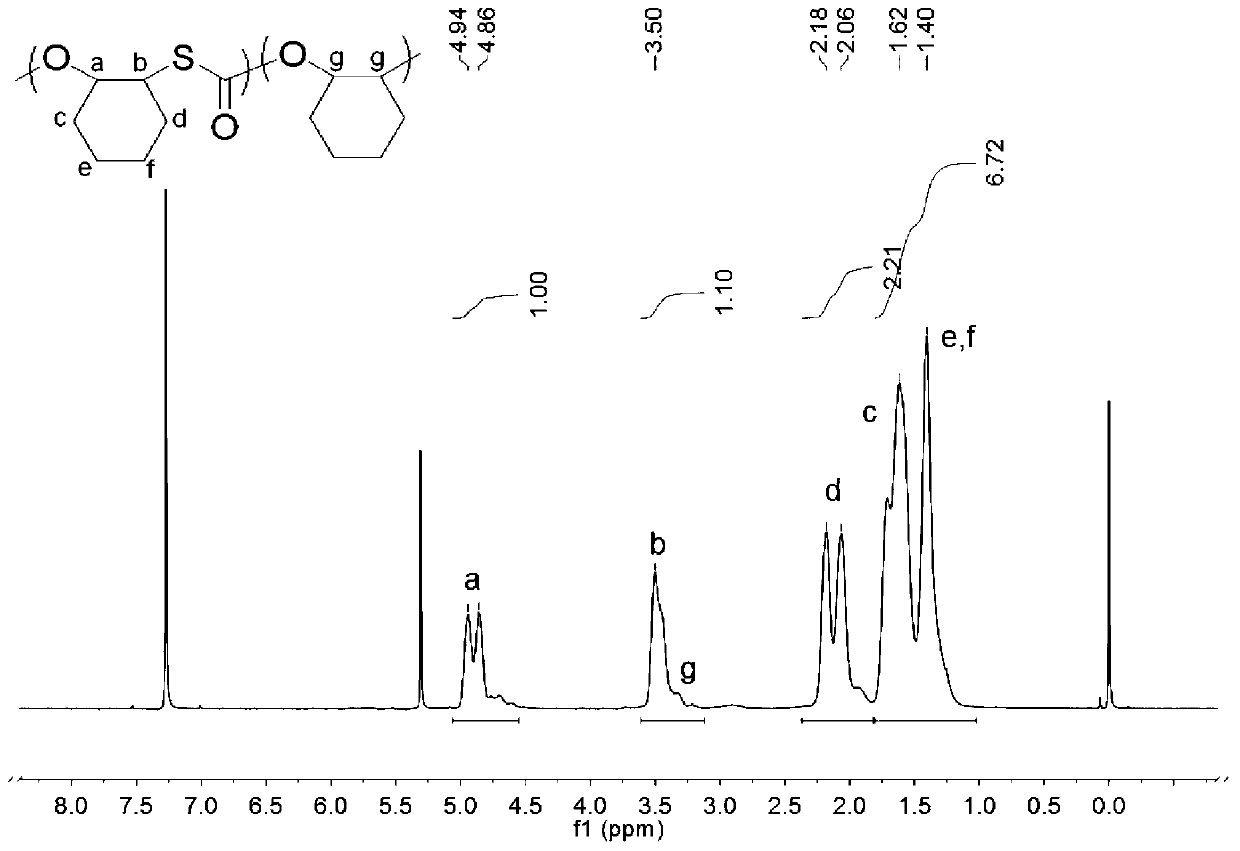

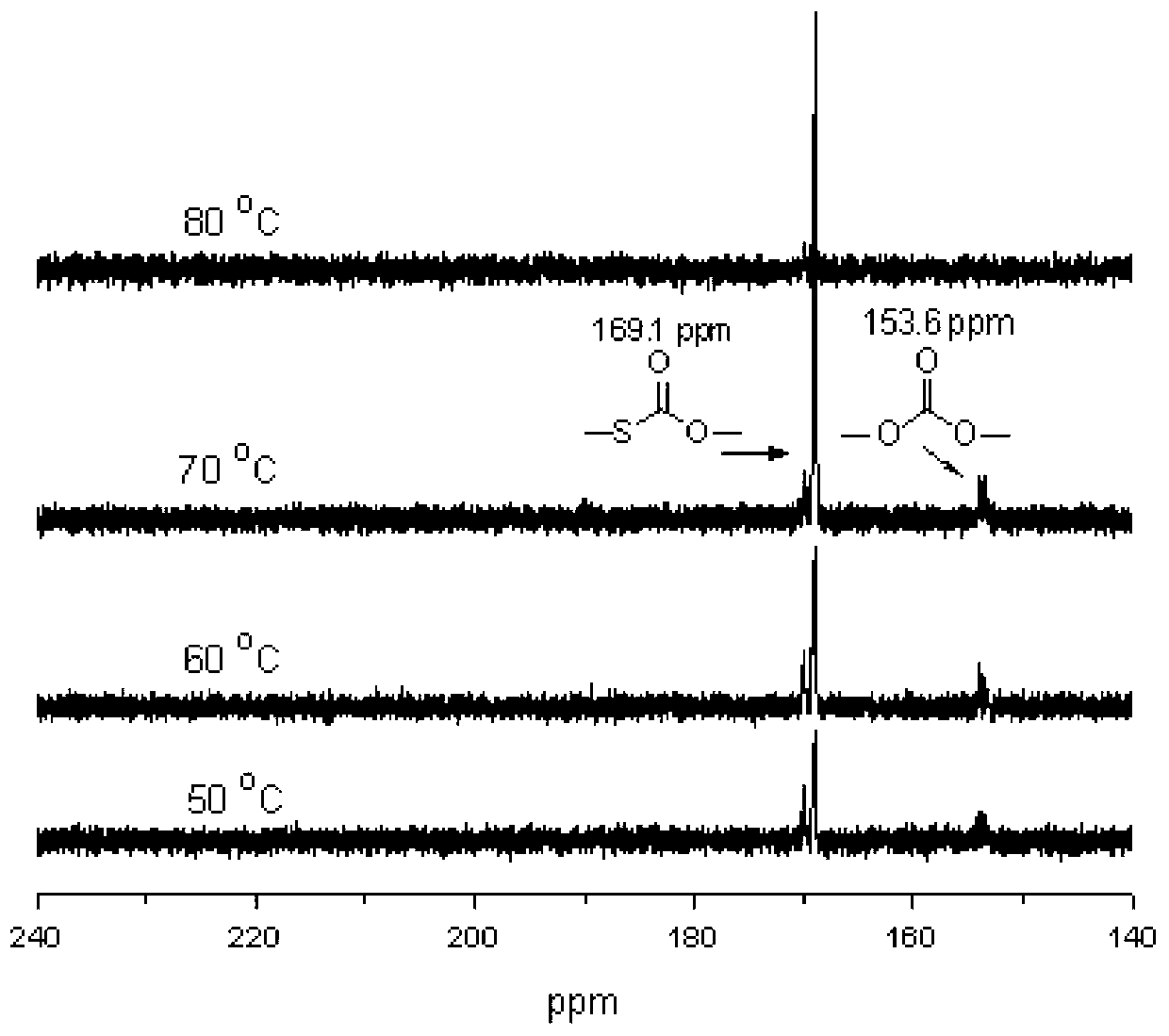

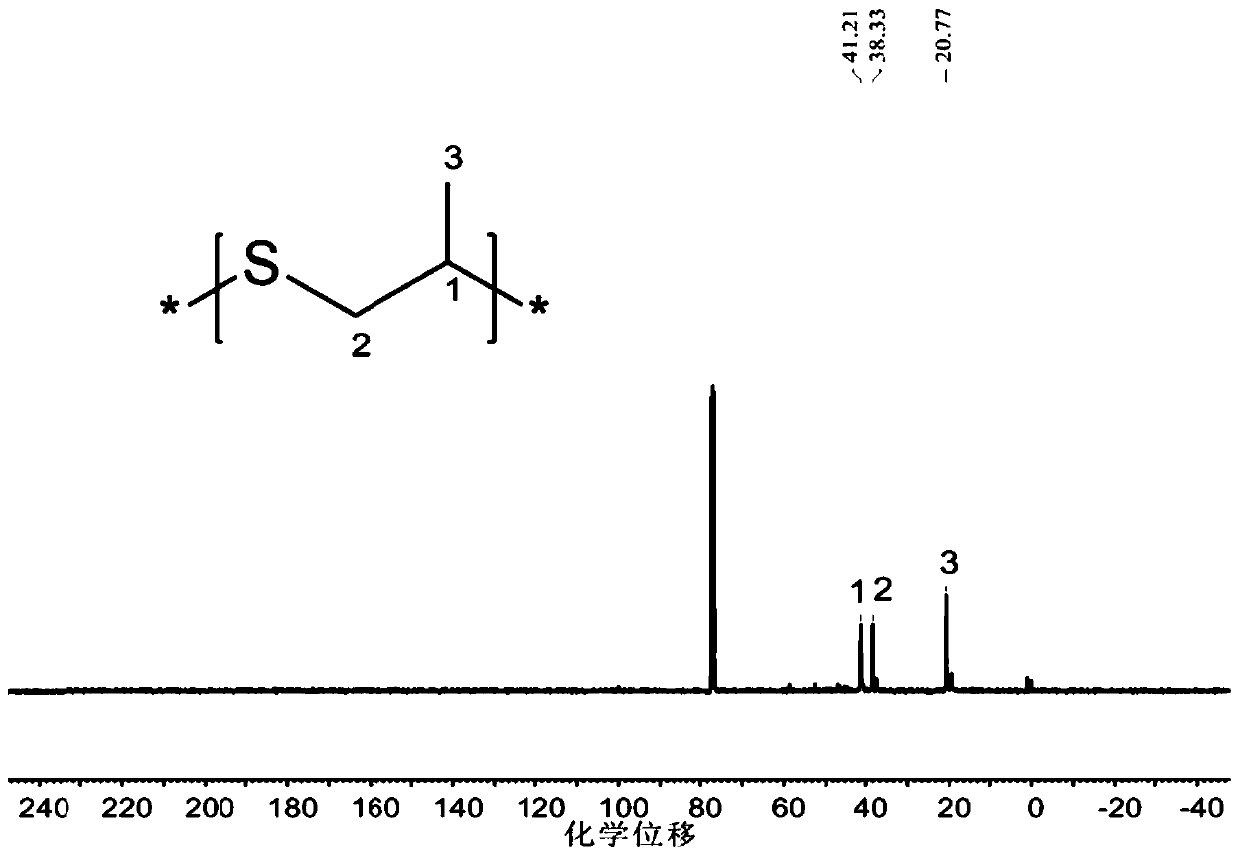

Method for preparing carbon oxysulfide and co-producing sulfur-containing polymer

InactiveCN110204724AExtensive source of monomerNo metal residue issuesCarbon oxysulideReaction temperatureLewis acid catalysis

The invention discloses a method for preparing carbon oxysulfide and co-producing a sulfur-containing polymer. The method includes the following steps: using carbon disulfide and an oxygen-containingmonomer A as raw materials, under the catalysis and initiation effects of Lewis base M, obtaining COS by an oxygen-sulfur exchange reaction and generating an aliphatic polythioether, wherein the reaction temperature is 60-180 DEG C; and reacting the generated COS with an oxygen-containing monomer B under the catalysis effect of Lewis base N and / or Lewis acid to obtain poly(mono thiocarbonate), wherein the reaction temperature is 0-100 DEG C. The method uses an oxygen-sulfur exchange reaction between carbon disulfide and the oxygen-containing oxide to prepare carbon oxysulfide and a plurality of sulfur-containing polymers. The used catalysts can be purchased. No problems of metal residue and color residue exist. The method has good universality and is suitable for large-scale industrial production. Three products with high added value are obtained from two products. Therefore, the prepared aliphatic polythioethers and poly(mono thiocarbonate) are abundant in variety, and the types and applications of sulfur-containing polymers are expanded.

Owner:ZHEJIANG UNIV

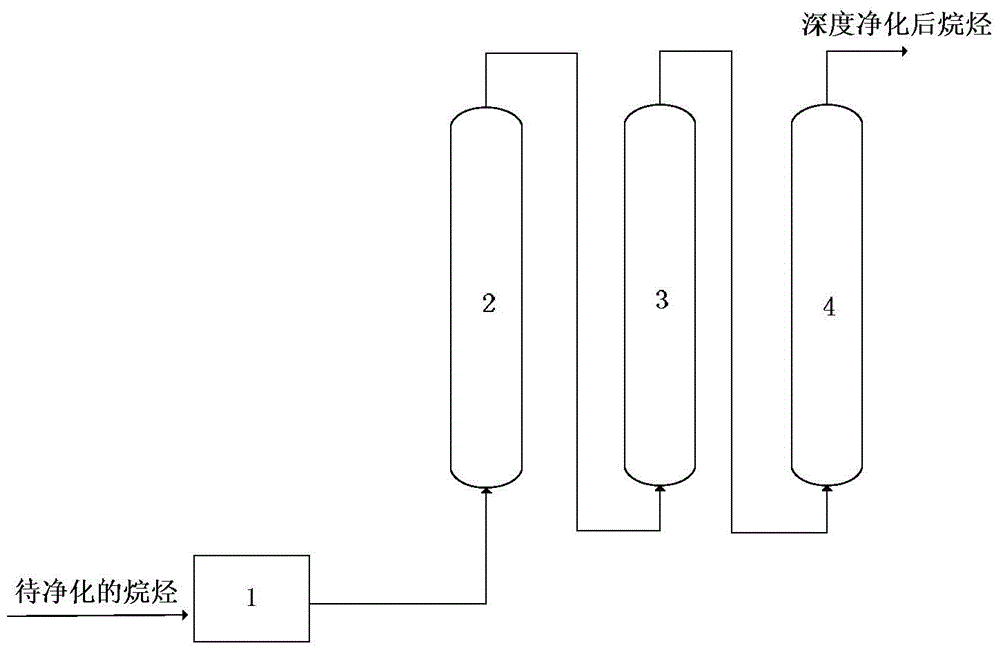

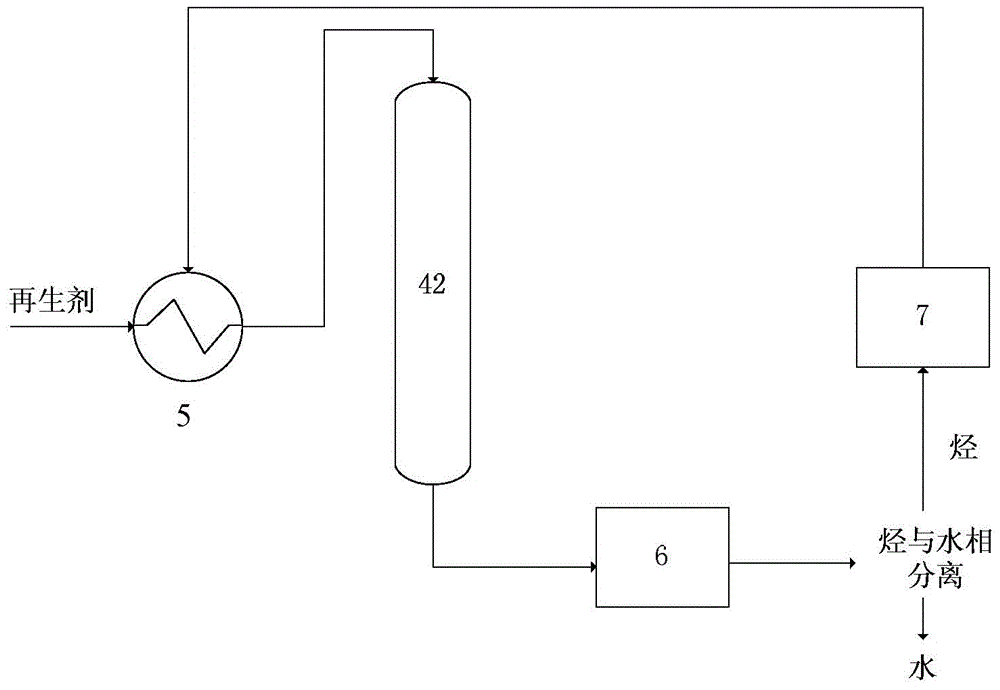

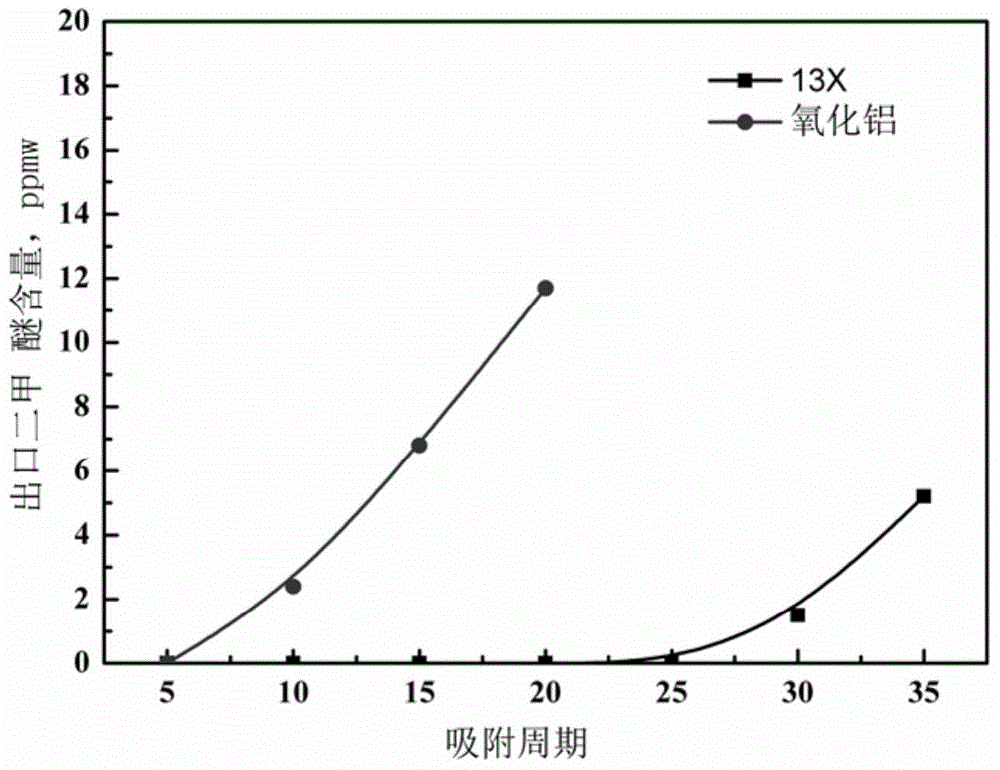

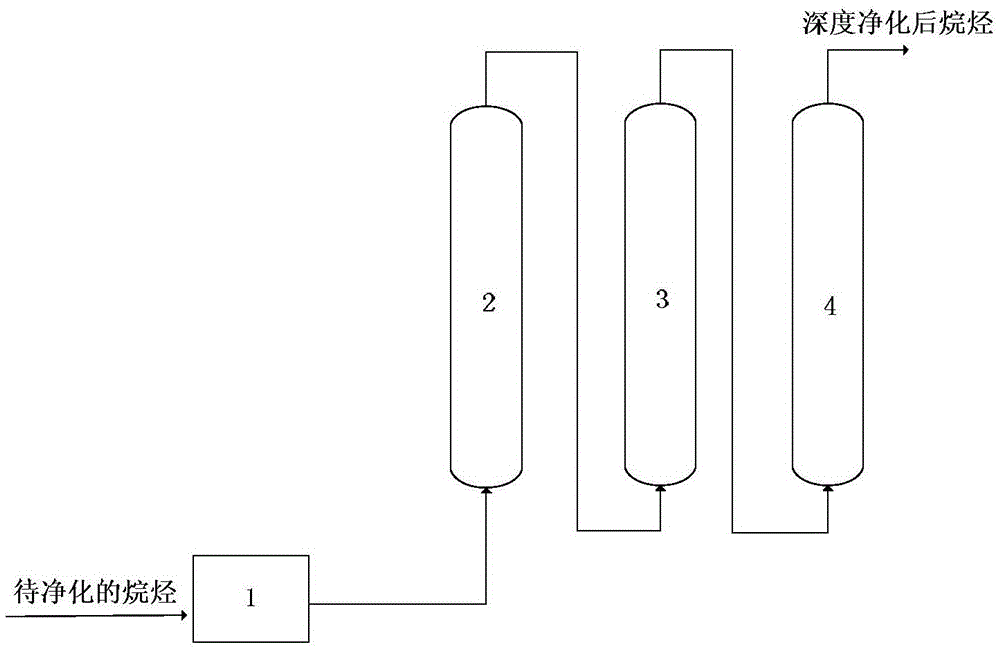

Advanced alkane purifying method for removing impurities

ActiveCN104402663AExtend your lifeEasy to operateHydrocarbonsAdsorption purification/separationDehydrogenationEconomic benefits

The invention provides an advanced alkane purifying method for removing impurities. The method comprises the following steps: 1, alkane to be purified contacts with an alkali solution; 2, the alkane contacts with a copper adsorbent; and 3, the alkane contacts with an adsorbent for selectively adsorbing polar compounds to obtain advanced purified alkane. The advanced alkane purifying method for removing impurities can be used for advanced purification of a C3-C5 alkane fraction generated through FCC; and an alkali washing processing unit, a fine desulphurization unit and a polar compound adsorption unit are used to remove hydrogen sulfide, mercaptan, carbon oxysulfide and other sulfides, and a small content of methanol, dimethyl ether and / or acetone and other impurities, so the C3-C5 alkane fraction generated through the FCC is suitable for being converted to propylene, isobutene or pentene, so the output of olefins is improved, the life of an alkane dehydrogenation catalyst is prolonged, the unit consumption is reduced, the economic benefit is improved, and the operation of a downstream dehydrogenation method is improved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

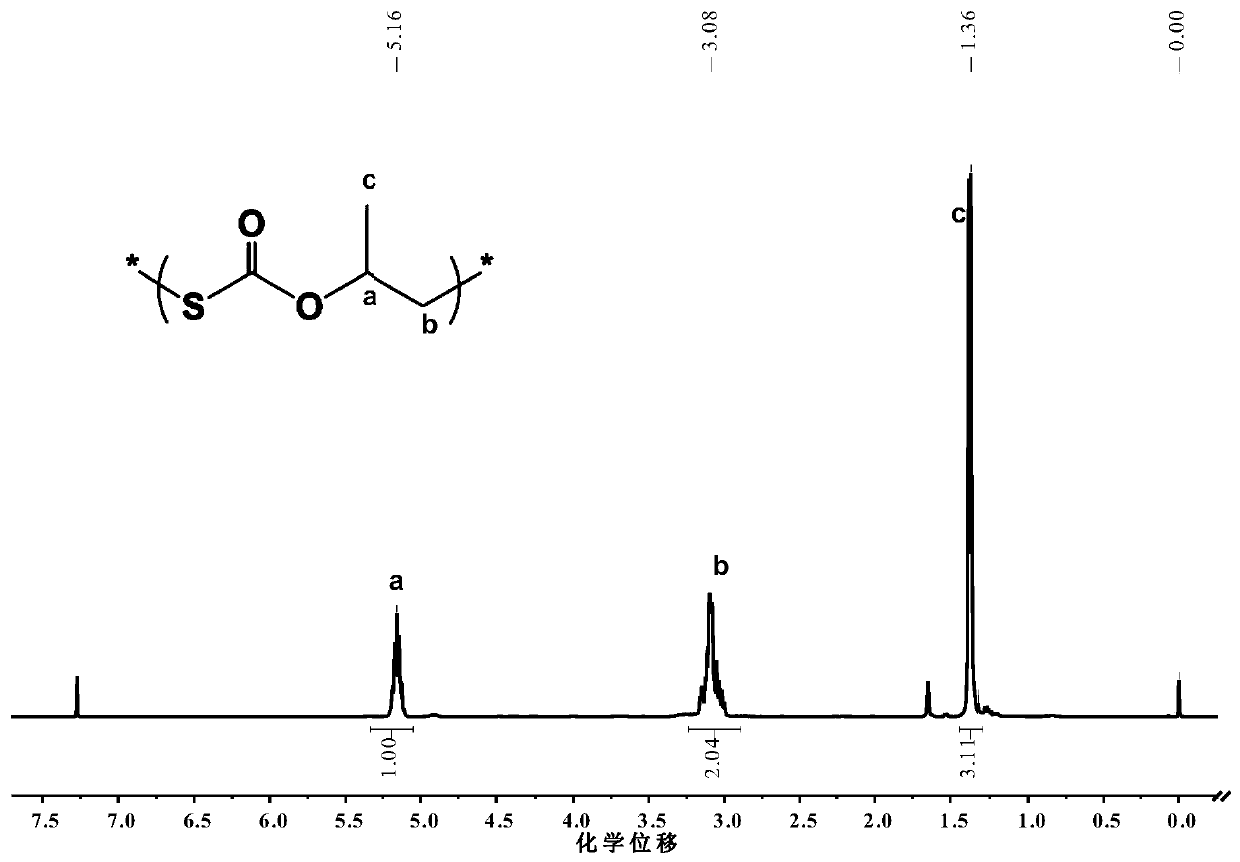

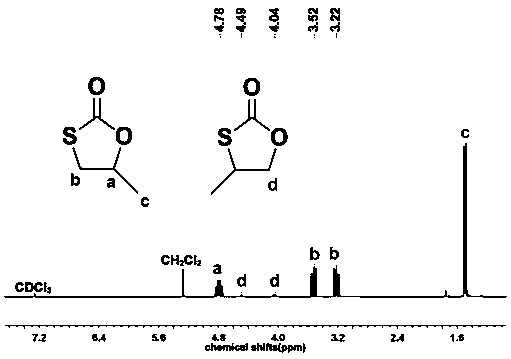

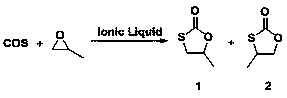

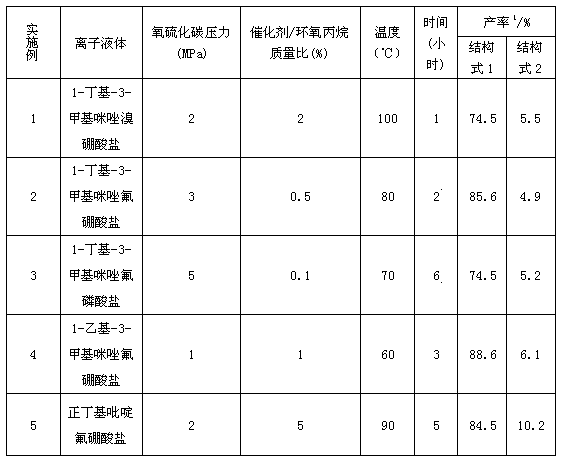

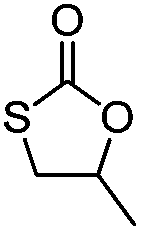

Method for catalytically preparing propylene monothio-carbonate by ionic liquid

The invention discloses a method for catalytically preparing propylene monothio-carbonate by ionic liquid. The method comprises the following steps: using carbon oxysulfide and epoxypropane as raw materials, and using the ionic liquid as a catalyst, reacting in a high-pressure reaction kettle, to obtain the propylene monothio-carbonate. The ionic liquid catalyst developed by the method has the advantages of high activity and high selectivity, and is capable of improving the selectivity and conversion rate of the carbon oxysulfide. The catalyst after vacuum distillation purification can be repeatedly used for a reaction of synthesizing the propylene monothio-carbonate by the carbon oxysulfide and the epoxypropane. A process of preparing the propylene monothio-carbonate is simple, the operation is simple and convenient, the reaction condition is gentle, a reaction rate is rapid, and the reaction process is environment-friendly.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

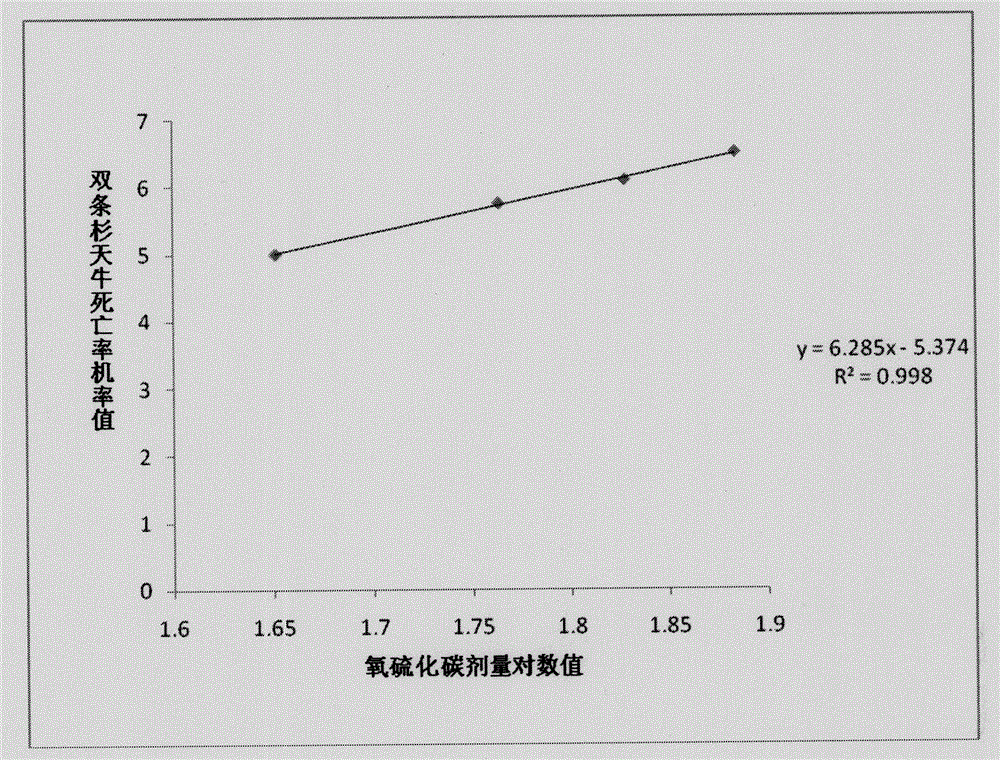

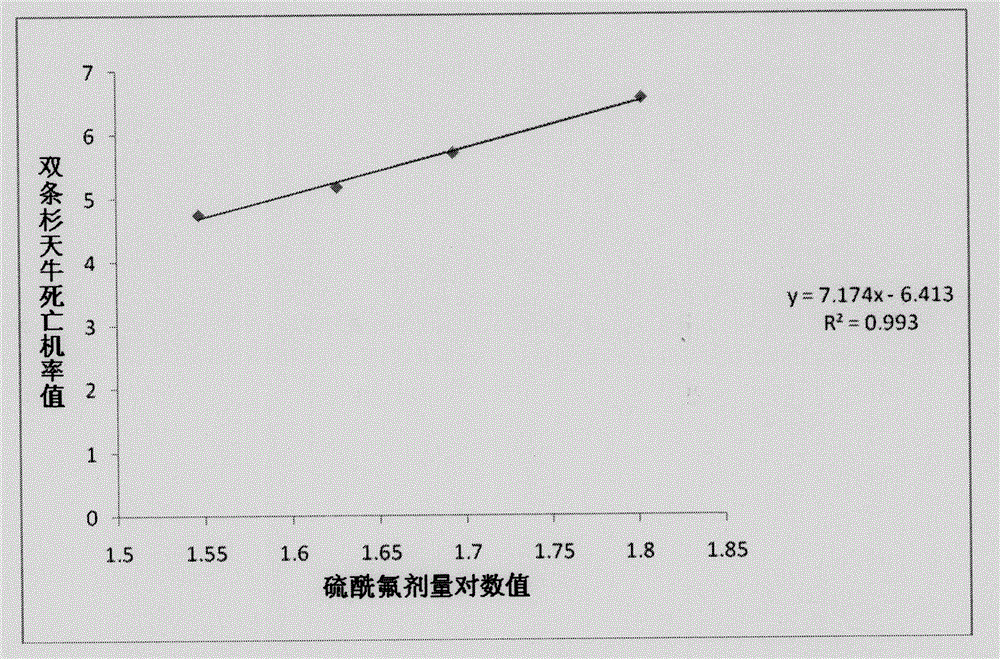

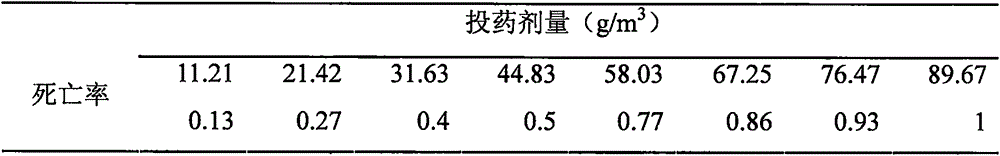

Mixed fumigation agent and method for fumigating semanotus bifasciatus

The invention relates to a mixed fumigation agent and a method for fumigating semanotus bifasciatus. The mixed fumigation agent comprises in parts by weight, 10-100 parts of carbon oxysulfide and 1-100 parts of sulfuryl fluoride. The mixed fumigation agent acts on plant pests or living conditions of the plant pests, and the semanotus bifasciatus can be effectively fumigated once. The mixed fumigation agent is applied to fumigation disinfection treatment of plant quarantine, raw wood, containers, soil, scraping steel vessels, commodity maintenance, animal and plant herbariums, stored wheat and the like and has great social benefits and economic benefits.

Owner:BEIJING ENTRY EXIT INSPECTION & QUARANTINE BUREAU INSPECTION & QUARANTINE TECH CENT

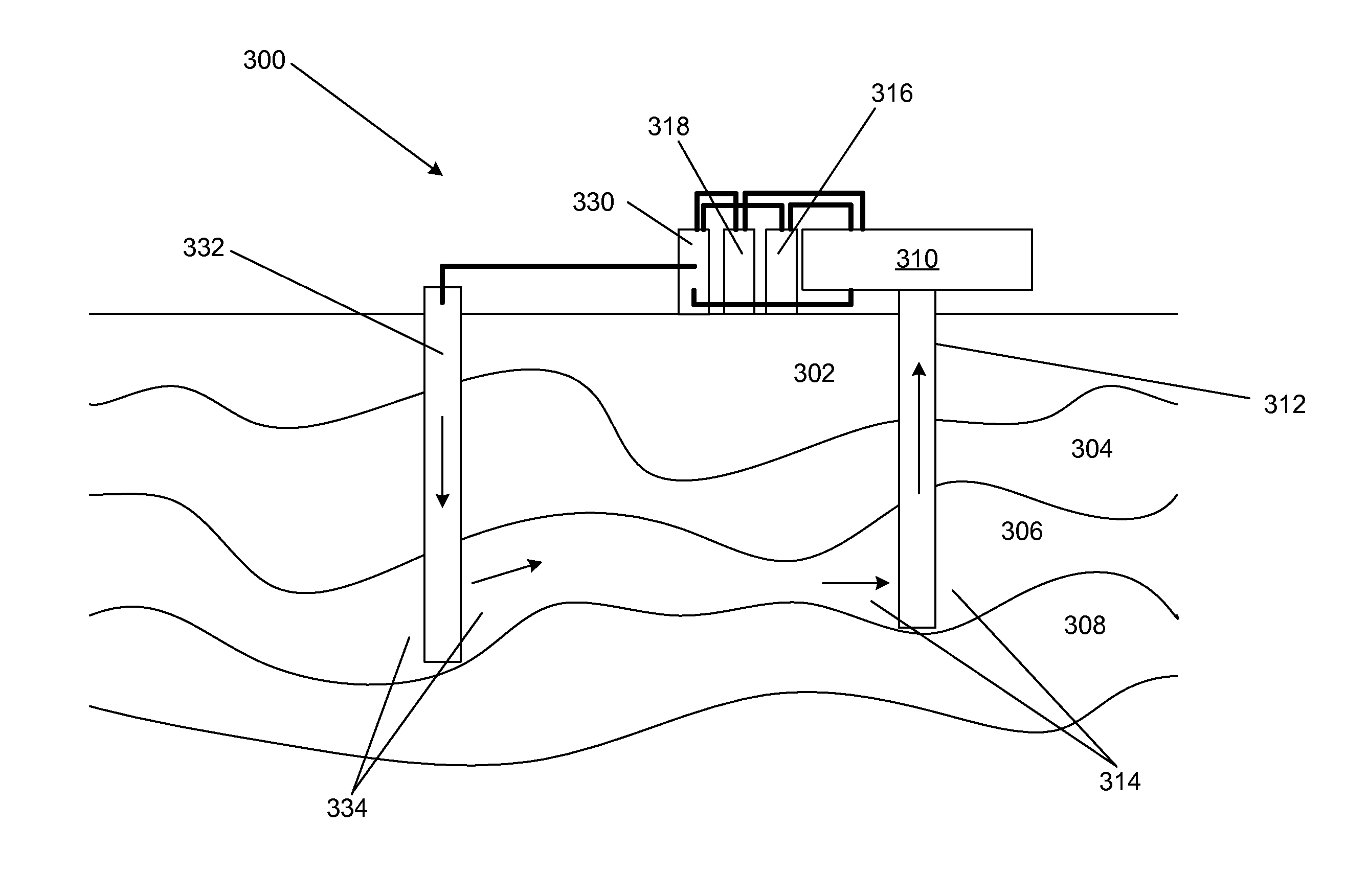

Systems and methods for producing oil and/or gas

A system for producing oil and / or gas comprising a formation comprising a mixture of oil and / or gas and an enhanced oil recovery mixture comprising an additive to increase an auto-ignition temperature of the mixture and a carbon disulfide formulation and / or a carbon oxysulfide formulation; and a mechanism for recovering at least a portion of the oil and / or gas.

Owner:SHELL OIL CO

Systems and methods for producing oil and/or gas

A system including a mechanism for recovering oil and / or gas from an underground formation, the oil and / or gas comprising one or more sulfur compounds; a mechanism for converting at least a portion of the sulfur compounds from the recovered oil and / or gas into a carbon oxysulfide formulation; and a mechanism for releasing at least a portion of the carbon oxysulfide formulation into a formation.

Owner:SHELL OIL CO

Method for preparing monothiocarbonate

InactiveCN107721973AAtom utilization is highSimple processOrganic chemistryMolecular sieve catalystsMolecular sieveCycloaddition

The invention provides a method for preparing monothiocarbonate. The method is characterized in that epoxypropane and carbon oxysulfide are in contact with a catalyst under cycloaddition reaction conditions, wherein the catalyst comprises a template removed titanium silicalite molecular sieve and a template-containing titanium silicalite molecular sieve. The method has the advantages of mild reaction conditions, high epoxypropane conversion rate and high monothiocarbonate selectivity. The method is a green synthesis technology, and also has the advantages of no special production requirements,simplicity and easiness in control of the process, and facilitation of industrial production and application.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

Carbon oxysulfide detection reagent and preparation method thereof

InactiveCN104931432AIncrease contentRapid responseColor/spectral properties measurementsPotassiumZinc nitrate

The invention discloses a carbon oxysulfide detection reagent and a preparation method thereof and belongs to the technical field of gas detection. The carbon oxysulfide detection reagent is composed of, by mass, 5-10 parts of zinc nitrate, 2-6 parts of zinc oxide, 3-8 parts of sodium borate, 12-22 parts of potassium hypermanganate, 1-4 parts of calcium alkyl salicylate, 2-5 parts of triphenylmethanol and 12-20 parts of deionized water. The preparation method includes the following steps: (1), preparing a premixed solution; (2), obtaining a clear mixed solution; (3), sealing after vacuum standing for 4-8h to obtain the carbon oxysulfide detection reagent. A carbon oxysulfide colorimetric method has the advantages of sensitivity in reaction, high detection accuracy and easiness in operation, and low-concentration carbon oxysulfide in environment can be detected quickly and quite conveniently.

Owner:DONGCHEN LEADER TESTING

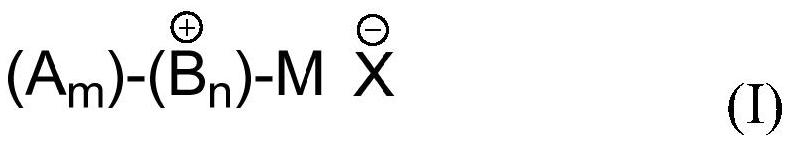

Catalytic supported polymer, and preparation method and application thereof

ActiveCN112812230AHigh catalytic activityImprove catalytic selectivityOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsPolymer scienceThiourea

The invention discloses a catalytic supported polymer. The structural formula is any one of a formula (I) or a formula (II). In the formulas, A is a urea or thiourea group, B is onium salt with positive charges, M is a comonomer, and X is a corresponding negative charge balance ion; and m represents the number of A and is any integer between 1 and 100000, and n represents the number of onium salt groups and is any integer between 1 and 100000. The invention also discloses a preparation method of the catalytic supported polymer, and application in catalysis of polymerization of one or more cyclic monomer bodies for obtaining amacromolecular polymer or a reaction of one or more cyclic monomers with carbon dioxide, carbon disulfide, carbon oxysulfide and carbon monoxide to obtain small molecular compounds and macromolecular polymers of cyclic carbonate cyclic lactone, and cyclic thiocarbonate. The catalytic supported polymer has relatively high catalytic activity and selectivity when applied to catalytic preparation of organic micromolecule and macromolecular polymers.

Owner:ZHEJIANG UNIV

Hydrocarbon Upgrading

The invention relates to hydrocarbon streams containing impurities such as carbon oxysulfides, to processes for upgrading the hydrocarbons by removing at least a portion of the impurities therefrom, to equipment useful in such processes, and to the use of upgraded hydrocarbons for, e.g., chemical manufacturing.

Owner:EXXONMOBIL CHEM PAT INC

Systems and methods for producing oil and/or gas

A system for producing oil and / or gas comprising a mechanism for releasing at least a portion of a sulfur containing compound into a formation; a first mechanism for converting at least a portion of the sulfur containing compound into a carbon disulfide formulation and / or a carbon oxysulfide formulation, the first mechanism for converting within the formation; and a second mechanism for converting at least a portion of the carbon disulfide formulation and / or a carbon oxysulfide formulation into another compound, the second mechanism for converting within the formation.

Owner:SHELL OIL CO

Preparation method of modified graphite electrode material

ActiveCN112599741AImprove charge and discharge performanceImprove cycle performanceSecondary cellsNegative electrodesIonic liquidCarbon oxysulfide

The invention discloses a preparation method of a modified graphite electrode material. The method comprises the following steps: adding a nitric acid solution into graphite, adding a cationic polymer, and carrying out constant-temperature water bath stirring reaction to obtain a first reactant; sequentially introducing ionic liquid and carbon oxysulfide into the first reactant to obtain a secondreactant; washing the second reactant with deionized water, then putting the second reactant into a drying box for curing treatment, then carrying out ball milling with a ball mill, then putting the ball-milled powder into a high-temperature heating furnace, and carrying out carbonization treatment to obtain a third reactant; mixing the third reactant and a conductive agent, performing grinding, performing dispersing in absolute ethyl alcohol, adding an adhesive and potassium oxalate, uniformly performing stirring, drying and tabletting to obtain the modified graphite electrode material. The obtained modified graphite electrode material has good charging and discharging performance and cycle performance.

Owner:DONGGUAN KAIJIN NEW ENERGY TECH

Systems and methods for producing oil and/or gas

Owner:SHELL INT RES MAATSCHAPPIJ BV

Systems and methods for producing oil and/or gas

InactiveUS20110139463A1Promote recoveryFluid removalDrilling compositionCompound (substance)Sulfur containing

A system including a mechanism for releasing at least a portion of a sulfur containing compound into a formation; and a mechanism for converting at least a portion of the sulfur containing compound into a carbon disulfide formulation and / or a carbon oxysulfide formulation, the mechanism within the formation.

Owner:SHELL OIL CO

Detection method of trace volatile sulfide in gypsum board

Owner:CHEM MINERALS & METALLIC MATERIALS INSPECTION CENT OF TIANJIN ENTRY EXIT INSPECTION & QUARANTINE BUREAU

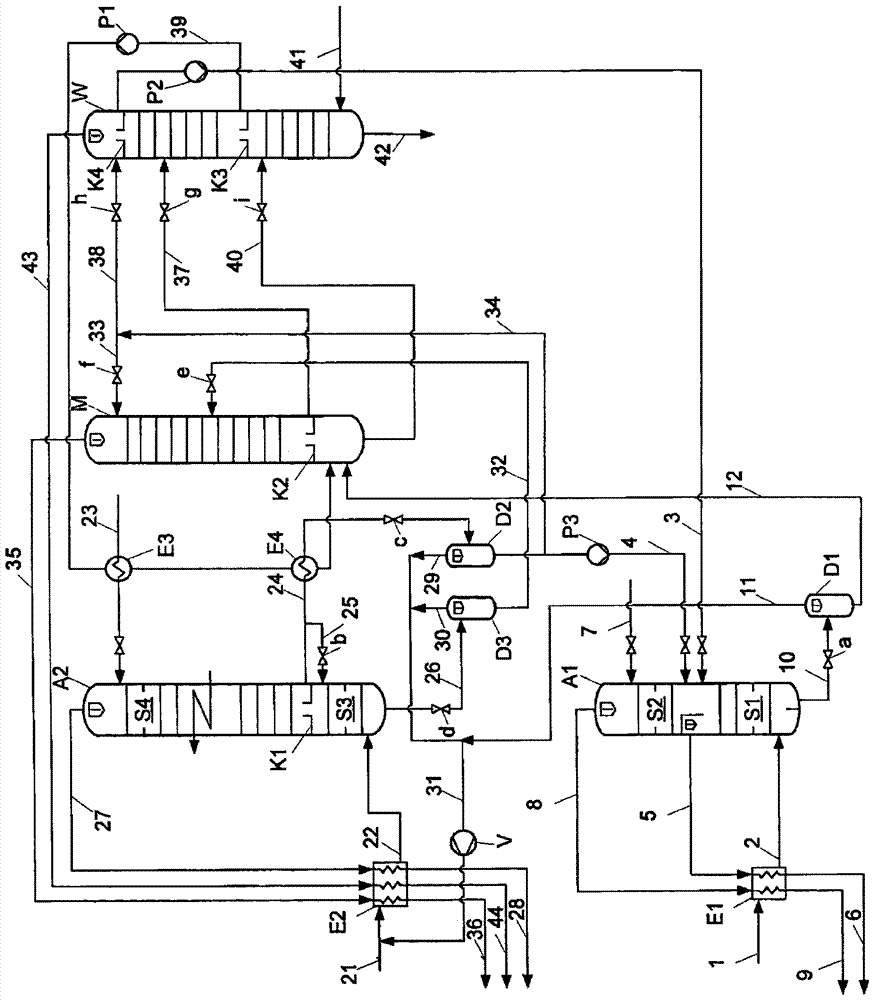

Method for Selective Desulfurization of Synthetic Raw Gas

ActiveCN103571545BReduce partial pressureGas treatmentDispersed particle separationHydrogenCarbon oxysulfide

The invention relates to a method for operating a gas scrubber in which a feed gas containing hydrogen, carbon monoxide, carbon dioxide and carbon oxysulfide and / or hydrogen sulfide is scrubbed in a scrubber (A1) with a scrubbing agent (3, 4) preloaded with carbon dioxide (1), thereby substantially selectively separating sulfur components from the feed gas and producing a desulfurized gas stream (5, 9). The invention is characterized in that sulfur-free scrubbing agents (3, 4) are used whose partial pressure of carbon dioxide is equal to or greater than the partial pressure of carbon dioxide in the feed gas (1) to be desulfurized when it is introduced into the scrubber (A1) pressure.

Owner:LINDE AG

A method for deep purification of alkane impurities

ActiveCN104402663BExtend your lifeEasy to operateHydrocarbonsAdsorption purification/separationAlkaneSorbent

The invention provides an advanced alkane purifying method for removing impurities. The method comprises the following steps: 1, alkane to be purified contacts with an alkali solution; 2, the alkane contacts with a copper adsorbent; and 3, the alkane contacts with an adsorbent for selectively adsorbing polar compounds to obtain advanced purified alkane. The advanced alkane purifying method for removing impurities can be used for advanced purification of a C3-C5 alkane fraction generated through FCC; and an alkali washing processing unit, a fine desulphurization unit and a polar compound adsorption unit are used to remove hydrogen sulfide, mercaptan, carbon oxysulfide and other sulfides, and a small content of methanol, dimethyl ether and / or acetone and other impurities, so the C3-C5 alkane fraction generated through the FCC is suitable for being converted to propylene, isobutene or pentene, so the output of olefins is improved, the life of an alkane dehydrogenation catalyst is prolonged, the unit consumption is reduced, the economic benefit is improved, and the operation of a downstream dehydrogenation method is improved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

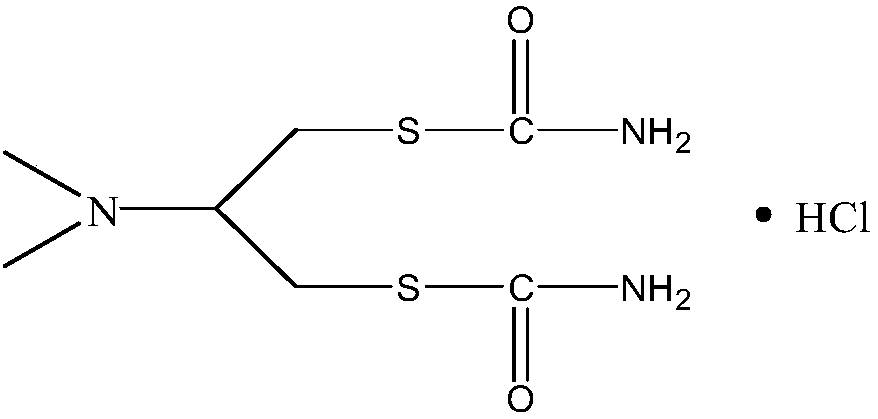

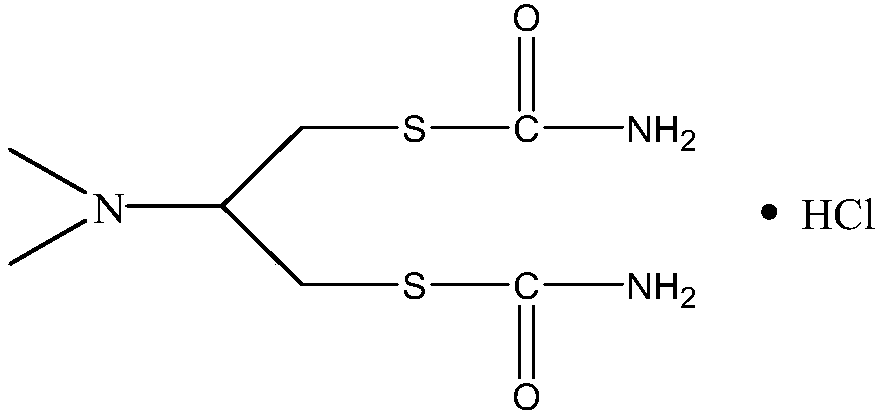

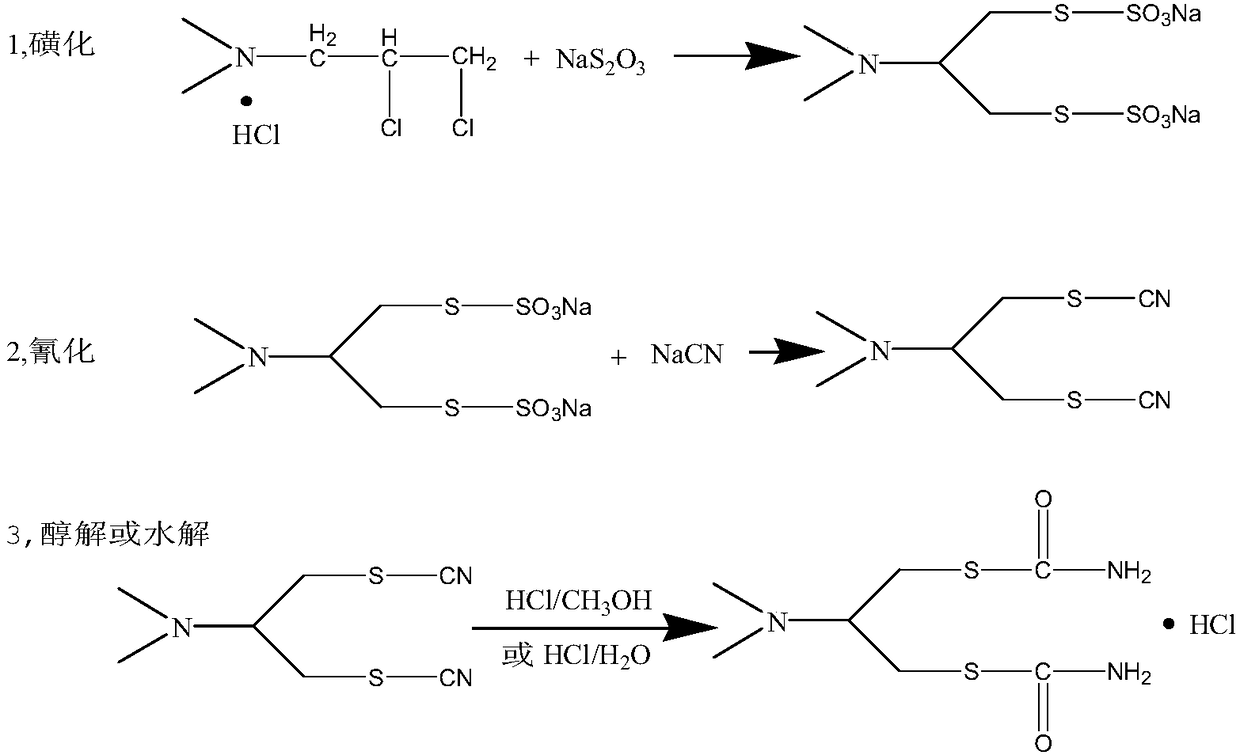

The synthetic method of cartap

ActiveCN106748937BReduce utilizationReduce capacity requirementsOrganic chemistrySulfite saltSynthesis methods

The invention provides a synthesis method of cartap, and relates to a synthesis method of 1,3-bis(carbamyl sulfonium)-2-(N,N-dimethylamino) propane hydrochloride. An original medicine of cartap is prepared from carbon oxysulfide, ammonia and 1-(N,N-dimethylamino)-2,3-propylene dichloride (chloride for short) through a one-pot method in an alkaline solution. By the adoption of the one-pot method for reaction step by step to prepare the cartap, the synthesis method has the advantages of low equipment investment, low energy consumption, easiness and convenience for operation and substantial improvement of the conversion rate. According to the synthesis method, the use of organic raw materials such as sodium thiosulfate (sodium thiosulfate) and sodium cyanide is avoided, so that generation of a large amount of sewage containing sodium sulfite and sodium cyanide is avoided. The synthesis method substantially increases the selectivity and the conversion rate in a reaction process, thus improving the production efficiency and greatly reducing the production cost.

Owner:仪征市海帆化工有限公司

A kind of method for preparing polymonothiocarbonate

ActiveCN106866952BAlternate CopolymerizationClear structurePolycarbonate coatingsPhosphoniumPhosphonium salt

The invention discloses a method for preparing poly(monothiocarbonate). According to the method, carbon oxysulfide and oxygen-containing monomers are used as raw materials; a catalysis system consisting of initiators and Lewis acid is used; after the bulk polymerization or solution polymerization, poly(monothiocarbonate) is obtained; the oxygen-containing monomers are selected from at least one kind of materials of epoxy compounds, oxetane and 3-substituted oxetane; the initiators are selected from quaternary ammonium salt, quaternary phosphonium salts or organic alkali. The preparation method of synthesizing the poly(monothiocarbonate) through anion ring-opening polymerization by using a catalytic system formed by at least one kind of materials from quaternary ammonium salt, quaternary phosphonium salts or organic alkali, and the Lewis acid; the poly(monothiocarbonate) with the specific chain structures can be obtained through preparation. The catalysis system can be obtained only through compounding; the metal residue and color residue problems do not exist.

Owner:ZHEJIANG UNIV

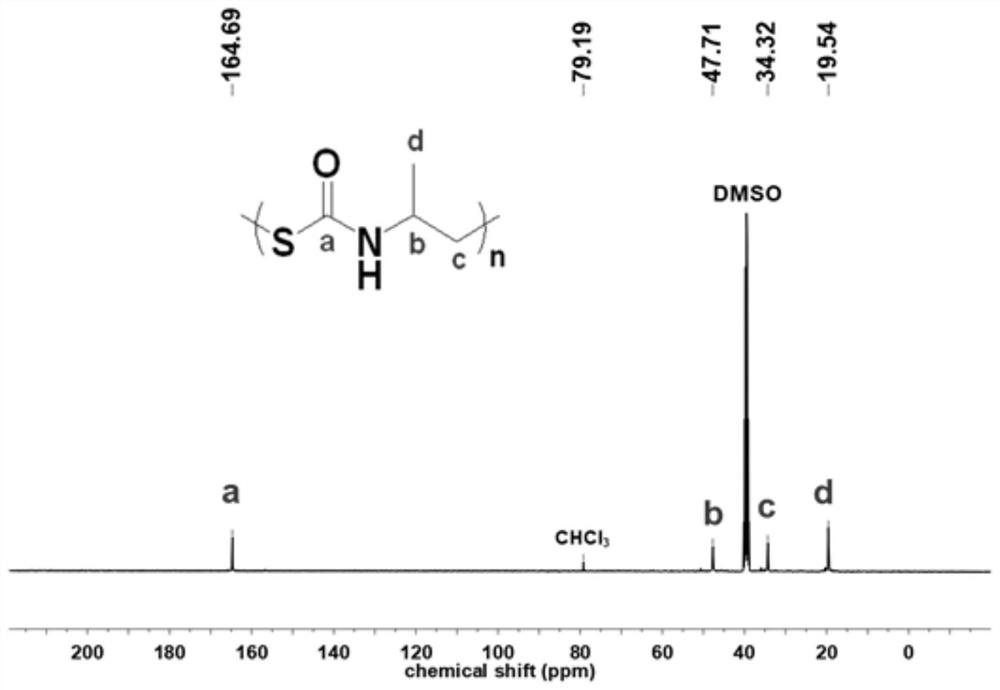

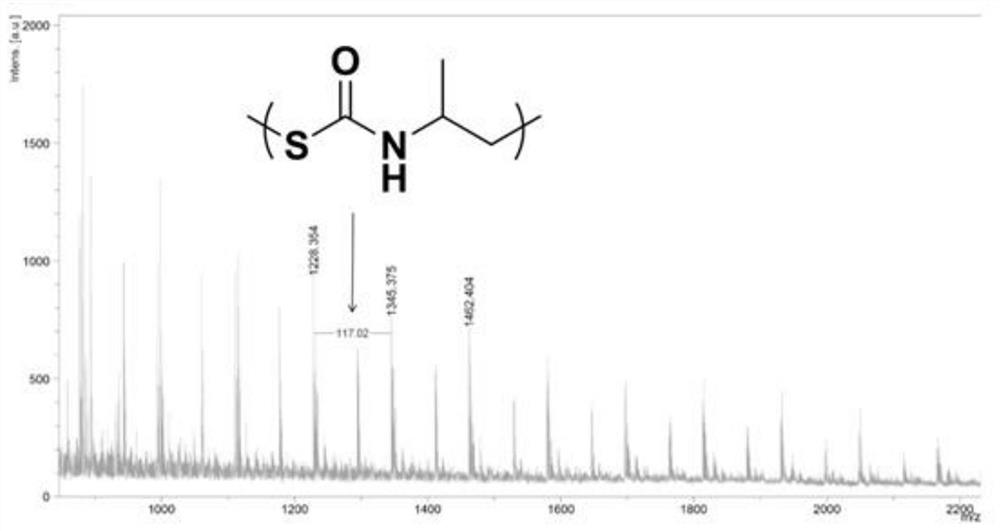

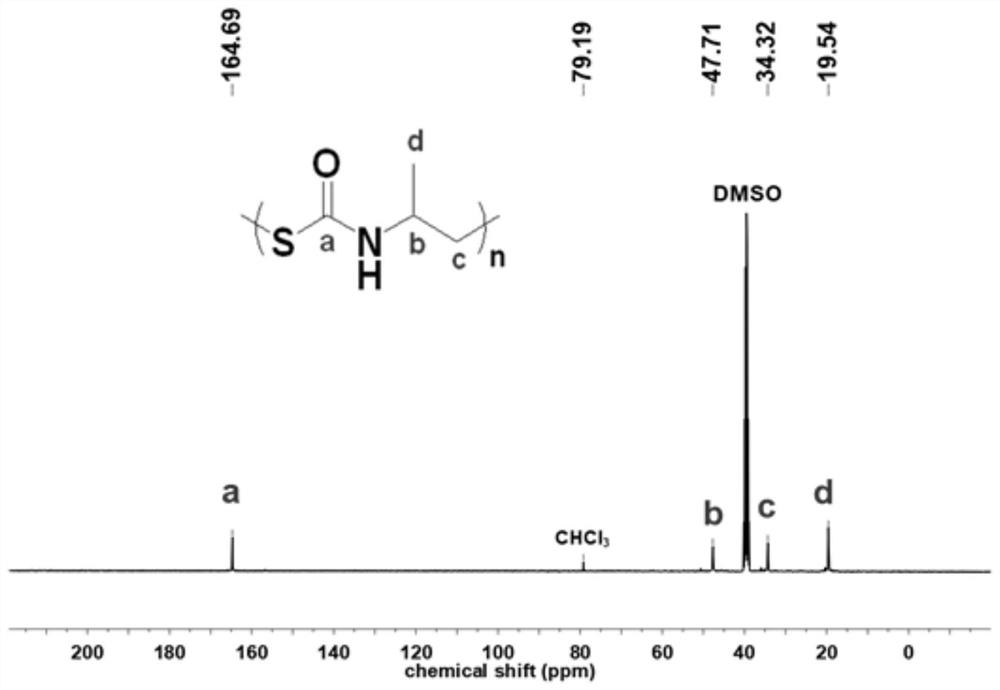

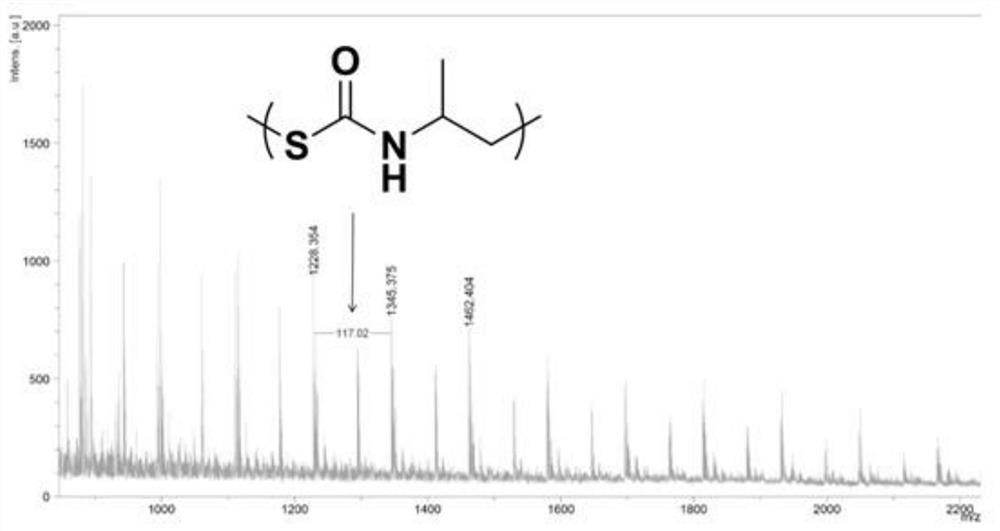

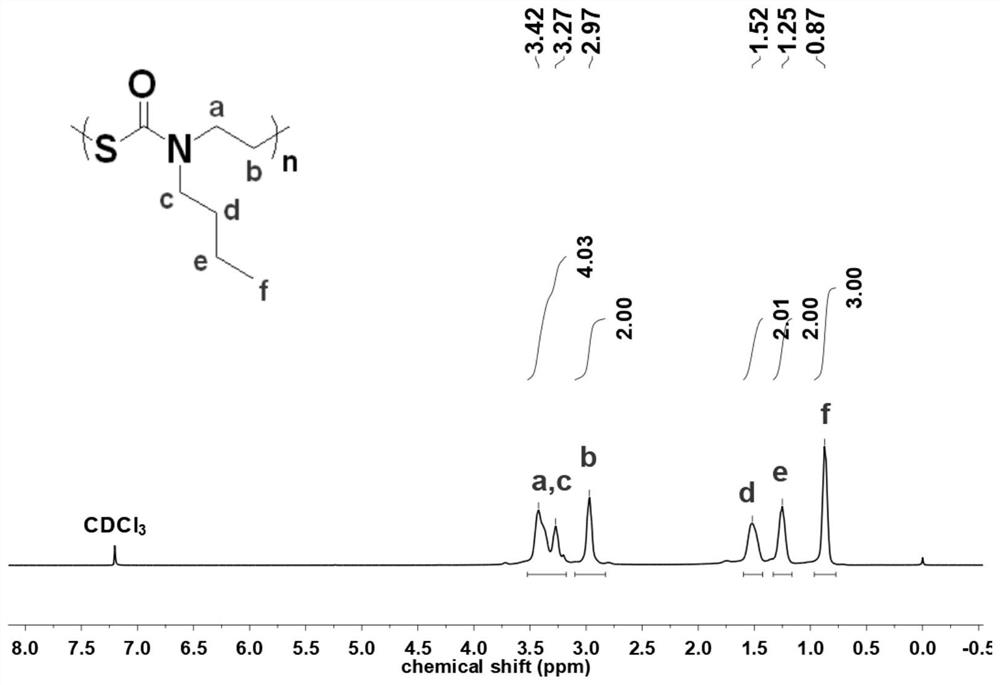

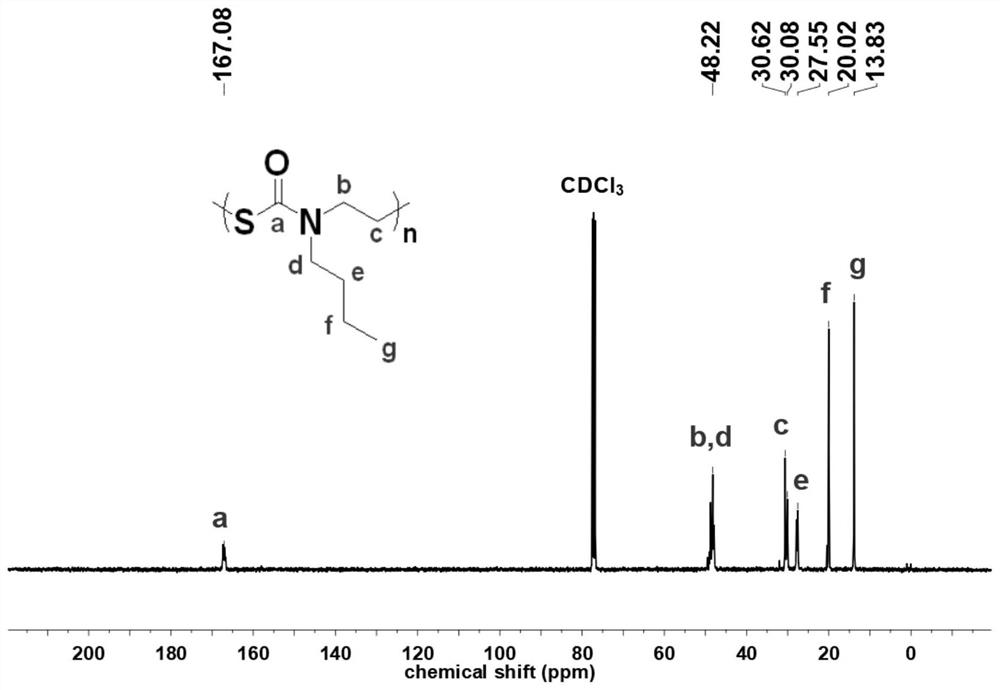

A kind of polythiourethane and preparation method thereof

The invention belongs to the technical field of polymer materials, in particular to a polythiocarbamate and a preparation method thereof. The method provided by the invention uses carbon oxysulfide and 2-methylaziridine as raw materials, without using a catalyst, and can obtain polythiocarbamate by copolymerization under bulk or solvent conditions, and the reaction is preferably in the range of 0- carried out at a temperature of 120°C. The method developed by the invention has the following advantages: it can react by itself without a catalyst; the raw materials are cheap and easy to obtain, the synthesis is simple, and the toxic mercapto compounds and isocyanate compounds in the traditional system are not used; the prepared polythiocarbamate main chain The structure is clear and has a fully alternating structure; there are strong hydrogen bonds between molecules, excellent thermal properties, no metal residues and colorless; the synthesis process is simple and easy to operate, the reaction conditions are mild, the reaction rate is fast, and the reaction process is environmentally friendly. The material has a strong adsorption effect on heavy metal mercury ions, and can be used to adsorb mercury ions in water systems.

Owner:HANGZHOU POLY MATERIAL SCI & TECH CO LTD

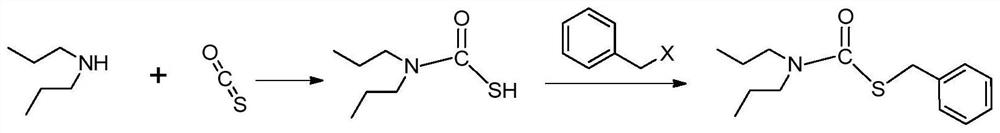

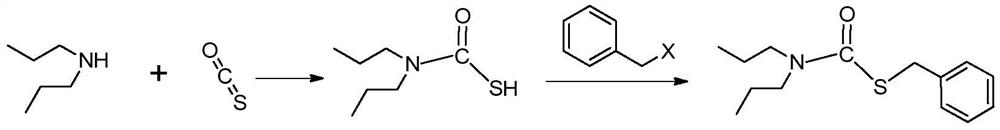

Preparation method of prothiocarb

PendingCN114685334ALow content of impurity dibenzyl disulfideImprove product qualityOrganic chemistryOrganic solventPropylamine

The invention provides a preparation method of prothiocarb, which comprises the following steps: introducing carbon oxysulfide into a di-n-propylamine solution, adding benzyl halide after the introduction is finished, carrying out heat preservation reaction after the addition is finished, adding water into the system after the reaction is finished, heating, acidifying, stirring, standing, separating liquid, washing an organic phase with water twice, and distilling to obtain the product prothiocarb with the purity of more than 98%, the yield is greater than 92%, and the content of impurity dibenzyl disulfide is lower than 0.04%. According to the preparation method disclosed by the invention, water or other organic solvents are not used during preparation reaction, the operation is simple, safe and controllable, the reaction time is short, the preparation yield is high, the product purity is high, and the content of impurity dibenzyl disulfide in the product is low; and the unreacted raw material di-n-propylamine can be recycled, so that less organic waste liquid is generated, and the three-waste treatment capacity and cost are reduced.

Owner:CAC NANTONG CHEM

Polythiocarbamate and preparation method thereof

The invention belongs to the technical field of high polymer materials, and particularly relates to polythiocarbamate and a preparation method thereof. According to the method provided by the invention, carbon oxysulfide and 2-methyl aziridine are used as raw materials without use of a catalyst, so that polythiocarbamate can be obtained through copolymerization under the condition of a body or a solvent, and the reaction is preferably carried out at the temperature of 0-120 DEG C. The method developed by the invention has the advantages that the reaction can be carried out without a catalyst;raw materials are cheap and easy to obtain, synthesis is easy and convenient, and toxic sulfhydryl compounds and isocyanate compounds in a traditional system are not used; the prepared polythiocarbamate has a clear main chain structure and has a fully alternating structure; strong hydrogen-bond interaction exists between molecules, so that the polythiocarbamate has great thermal performance, is free of metal residue and is colorless; the synthesis process is simple and convenient to operate, mild in reaction condition, high in reaction rate and environment-friendly. The material has a strong adsorption effect on heavy metal mercury ions, and can be used for adsorbing mercury ions in a water system.

Owner:HANGZHOU POLY MATERIAL SCI & TECH CO LTD

Systems and methods for producing oil and/or gas

A system including a mechanism for releasing at least a portion of a sulfur containing compound into a formation; and a mechanism for converting at least a portion of the sulfur containing compound into a carbon disulfide formulation and / or a carbon oxysulfide formulation, the mechanism within the formation.

Owner:SHELL OIL CO

A kind of crystalline n-substituted polythiocarbamate and its preparation method

ActiveCN111171315BRaw materials are cheap and easy to getEasy to synthesizeThiocarbamatePolymer science

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com