Method for preparing high-purity carbon oxysulfide gas

A technology of carbon oxysulfide and gas, which is applied in the field of preparing high-purity carbon oxysulfide gas, which can solve problems such as high cost, high impurity content, and difficult handling of carbon disulfide, and achieve the effects of safe operation, simple equipment, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

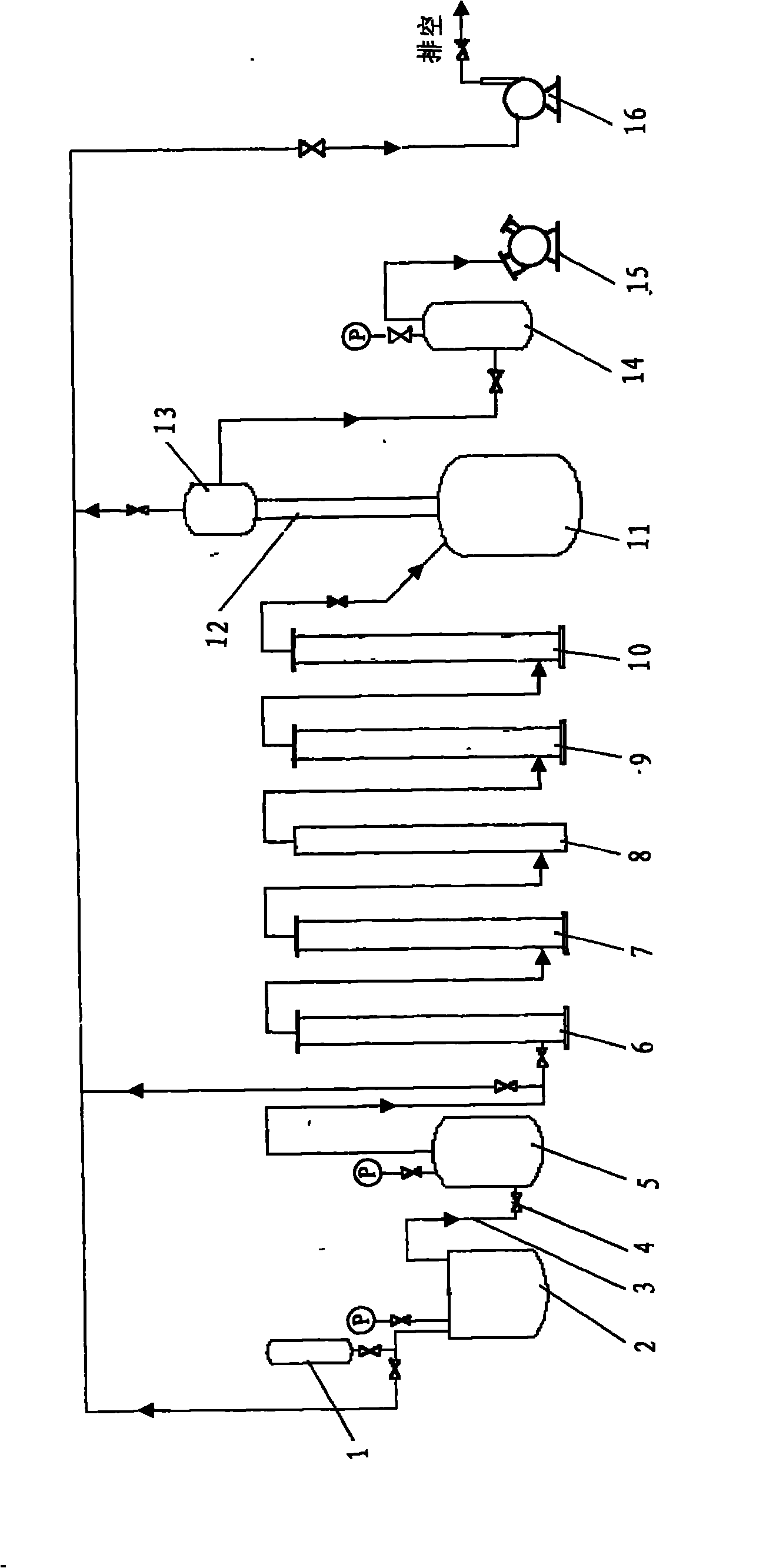

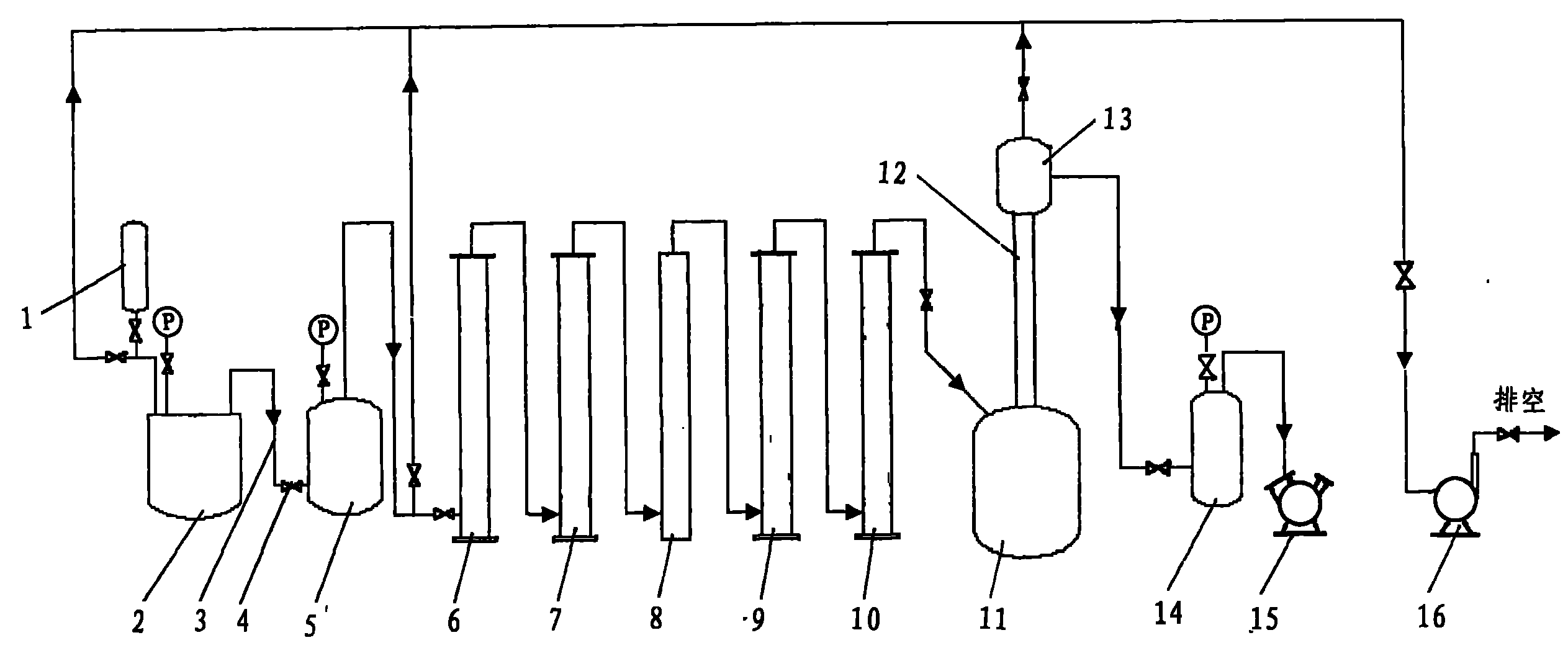

[0058] Add an appropriate amount of sulfuric acid with a concentration of 50% into the reactor 2, and heat the reactor to 70°C after evacuating the reactor 2 to test for leaks. Add the saturated solution prepared with 15 kilograms of ammonium thiocyanate in raw material tank 1. Open the reactor inlet valve 4 and the ammonium thiocyanate saturated solution enters the reactor through the pipeline 3 and starts to react with sulfuric acid. Between 70 and 80°C. The reactant is carbon oxysulfide gas containing impurities.

[0059] Analyzing the reactor to analyze the gas composition at the outlet of the reactor, the gas contains a small amount of oxygen (O 2 ), nitrogen (N 2 ) carbon dioxide (CO 2 ), carbon monoxide (CO), carbon disulfide (CS 2 ), hydrogen sulfide (H 2 S), water (H 2 O), and carbon oxysulfide (COS) gas.

[0060]The carbon oxysulfide gas that contains impurity enters alkali washing tower 6 and alkali washing tower 7 continuously and carries out alkali washing...

Embodiment 2

[0066] Add an appropriate amount of sulfuric acid with a concentration of 65% into the reactor 2, and heat the reactor to 50°C after evacuating the reactor 2 to test for leaks. Add the saturated solution prepared with 15 kilograms of ammonium thiocyanate in raw material tank 1. Open the reactor inlet valve 4 and the ammonium thiocyanate saturated solution enters the reactor through the pipeline 3 and starts to react with sulfuric acid. Between 50 and 60°C. The reactant is carbon oxysulfide gas containing impurities.

[0067] Analyzing the reactor to analyze the gas composition at the outlet of the reactor, the gas contains a small amount of oxygen (O 2 ), nitrogen (N 2 ) carbon dioxide (CO 2 ), carbon monoxide (CO), carbon disulfide (CS 2 ), hydrogen sulfide (H 2 S), water (H 2 O), and carbon oxysulfide (COS) gas.

[0068] The carbon oxysulfide gas that contains impurity enters alkali washing tower 6 and alkali washing tower 7 continuously and carries out alkali washin...

Embodiment 3

[0074] Add an appropriate amount of sulfuric acid with a concentration of 80% into the reactor 2, and heat the reactor to 30°C after evacuating the reactor 2 to test for leaks. Add the saturated solution prepared with 15 kilograms of ammonium thiocyanate in raw material tank 1. Open the reactor inlet valve 4 and the ammonium thiocyanate saturated solution enters the reactor through the pipeline 3 and starts to react with sulfuric acid. Between 30 and 40°C. The reactant is carbon oxysulfide gas containing impurities.

[0075] Analyzing the reactor to analyze the gas composition at the outlet of the reactor, the gas contains a small amount of oxygen (O 2 ), nitrogen (N 2 ) carbon dioxide (CO 2 ), carbon monoxide (CO), carbon disulfide (CS 2 ), hydrogen sulfide (H 2 S), water (H 2 O), and carbon oxysulfide (COS) gas.

[0076] The carbon oxysulfide gas that contains impurity enters alkali washing tower 6 and alkali washing tower 7 continuously and carries out alkali washin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com