Polythiocarbamate and preparation method thereof

A technology of polythiocarbamate and carbon oxysulfide, applied in the field of polythiocarbamate and its preparation, can solve the problem of no regioselective synthesis of polythiocarbamate and the like, and achieve metal-free Residue, clear main chain structure, mild reaction conditions

Active Publication Date: 2020-10-13

HANGZHOU POLY MATERIAL SCI & TECH CO LTD

View PDF14 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0007] So far, there has been no report on the direct copolymerization of carbon oxysulfide and ring nitrogen monomer 2-methylaziridine to generate polythiocarbamate with asymmetric chain structure, and there is no regioselective synthesis of polythiocarbamate Ester reports

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1-16

[0047] The parameters are shown in Table 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Initial thermal decomposition temperature | aaaaa | aaaaa |

Login to View More

Abstract

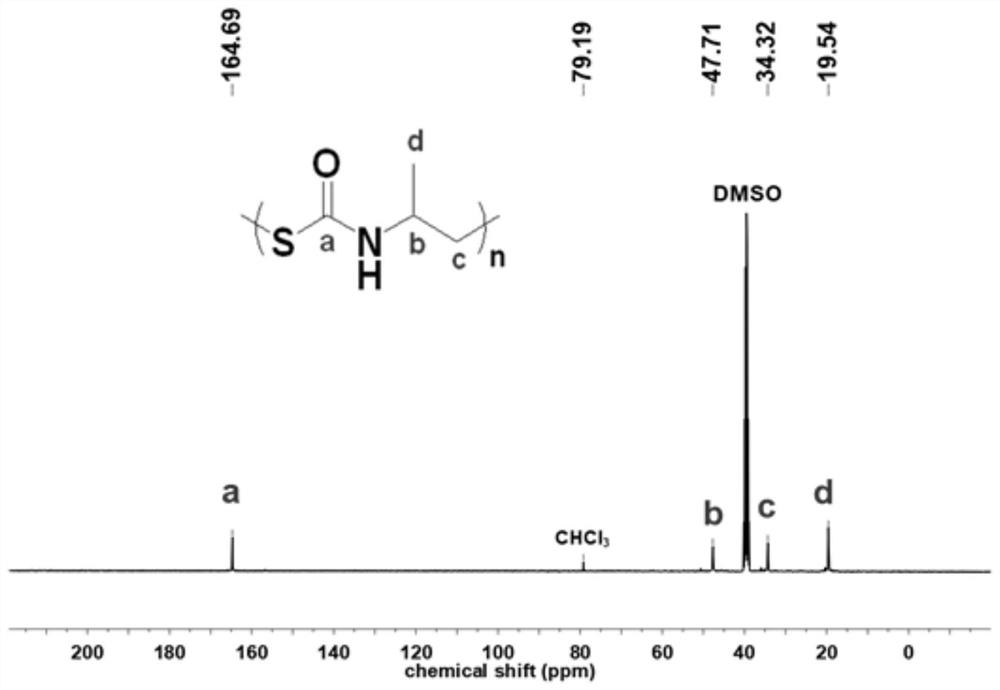

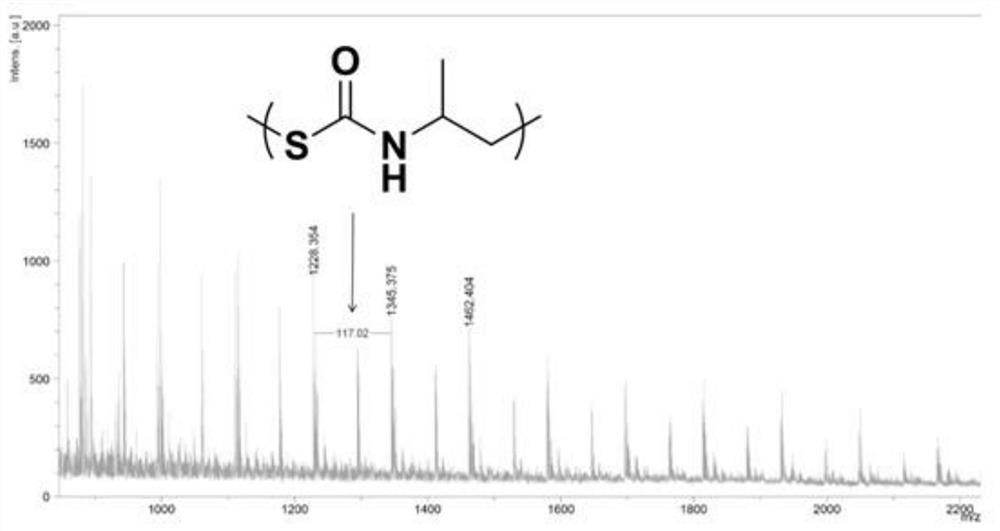

The invention belongs to the technical field of high polymer materials, and particularly relates to polythiocarbamate and a preparation method thereof. According to the method provided by the invention, carbon oxysulfide and 2-methyl aziridine are used as raw materials without use of a catalyst, so that polythiocarbamate can be obtained through copolymerization under the condition of a body or a solvent, and the reaction is preferably carried out at the temperature of 0-120 DEG C. The method developed by the invention has the advantages that the reaction can be carried out without a catalyst;raw materials are cheap and easy to obtain, synthesis is easy and convenient, and toxic sulfhydryl compounds and isocyanate compounds in a traditional system are not used; the prepared polythiocarbamate has a clear main chain structure and has a fully alternating structure; strong hydrogen-bond interaction exists between molecules, so that the polythiocarbamate has great thermal performance, is free of metal residue and is colorless; the synthesis process is simple and convenient to operate, mild in reaction condition, high in reaction rate and environment-friendly. The material has a strong adsorption effect on heavy metal mercury ions, and can be used for adsorbing mercury ions in a water system.

Description

technical field [0001] The invention belongs to the field of polymer material synthesis, and in particular relates to a polythiourethane and a preparation method thereof. Background technique [0002] Polythiourethane is a sulfur-containing nitrogen-containing polymer with excellent optical properties, chemical stability and thermal stability, and has broad potential application value in optical materials, high-performance fibers, adhesives and engineering plastics. Usually, polythiourethane is prepared by reacting dibasic or polythiol with dibasic or polyisocyanate. Due to the complex and cumbersome synthesis method of raw material dibasic thiol or polythiol, and the high toxicity of isocyanate, this synthetic route has great limitations. [0003] Carbon oxysulfide (COS) is an atmospheric pollutant released from the combustion of fossil fuels, coal gas, many chemical processes, volcanic eruptions, and the decay of plants or proteins. Carbon oxysulfide in the troposphere c...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08G71/04

CPCC08G71/04

Inventor 罗铭卞丛盛姚雨桦吴双左晓兵胡昕

Owner HANGZHOU POLY MATERIAL SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com