Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about How to "Waste of material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

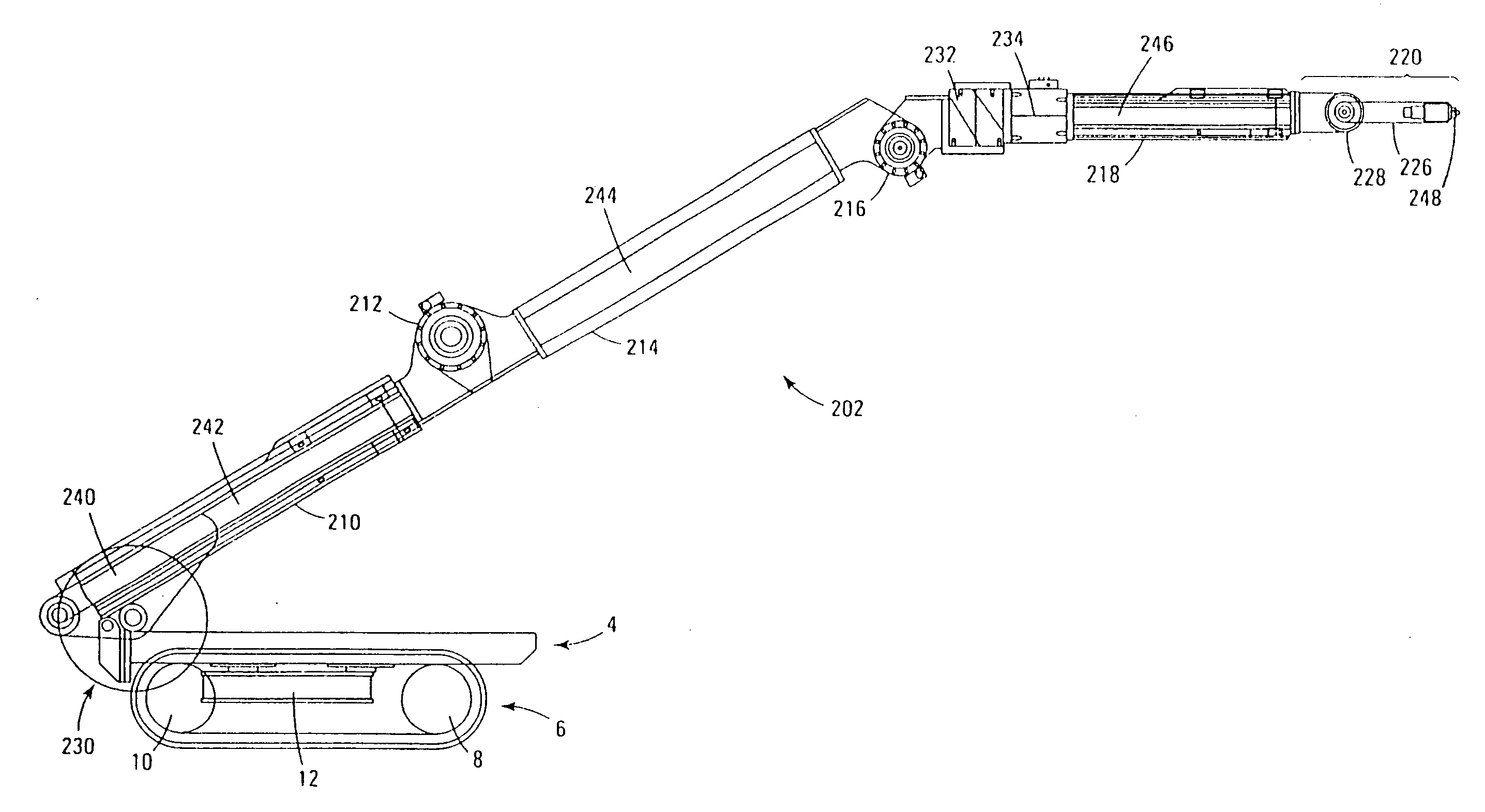

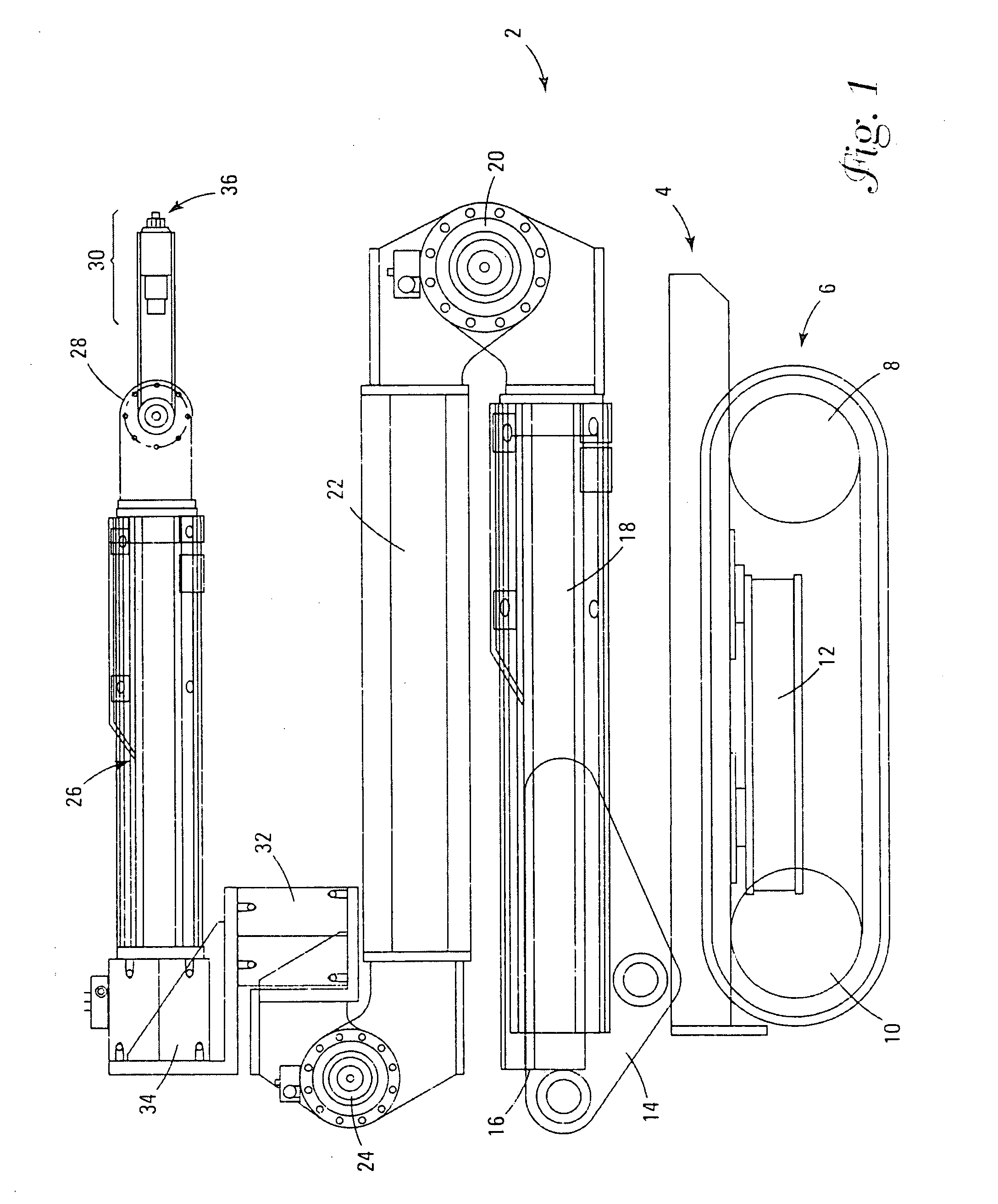

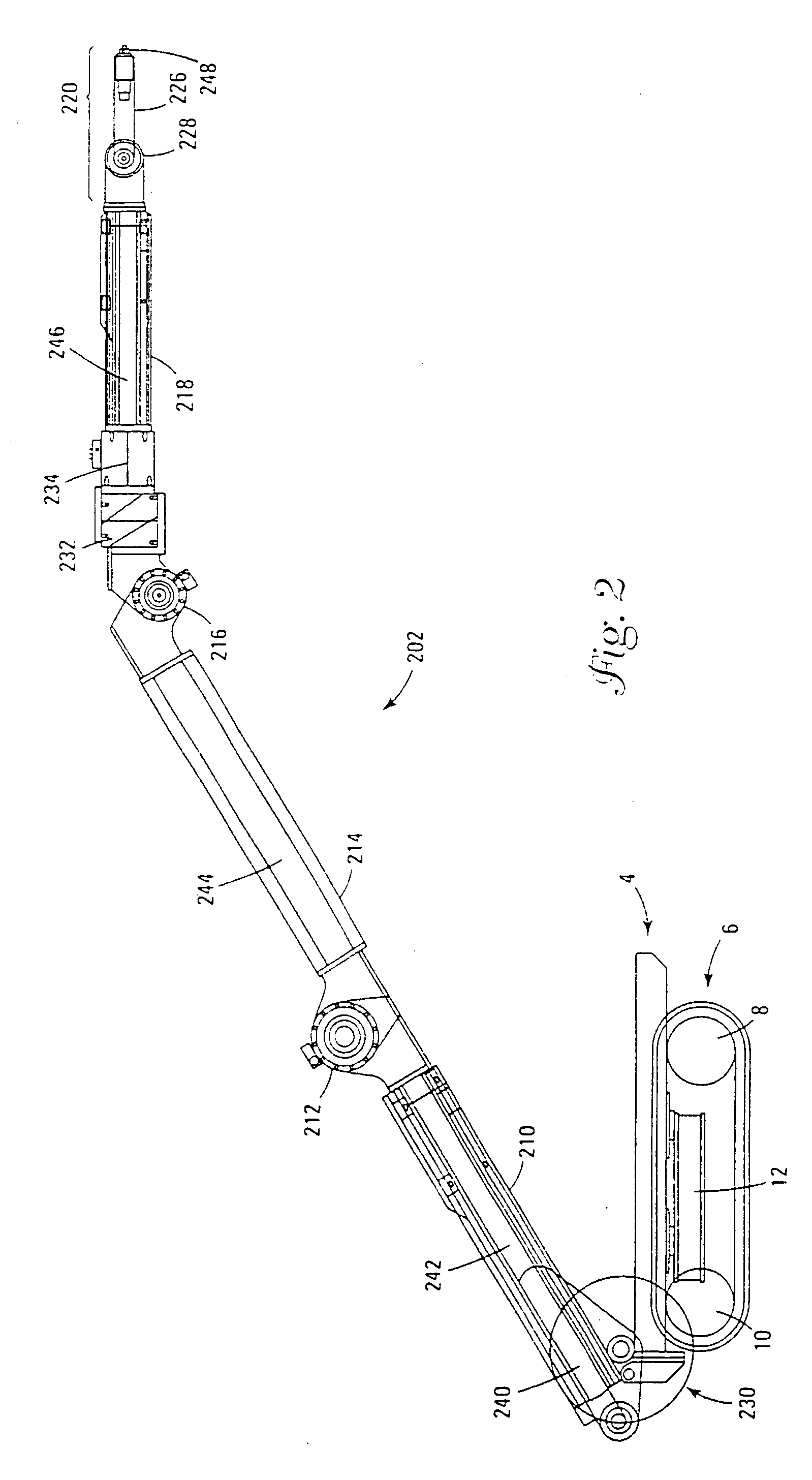

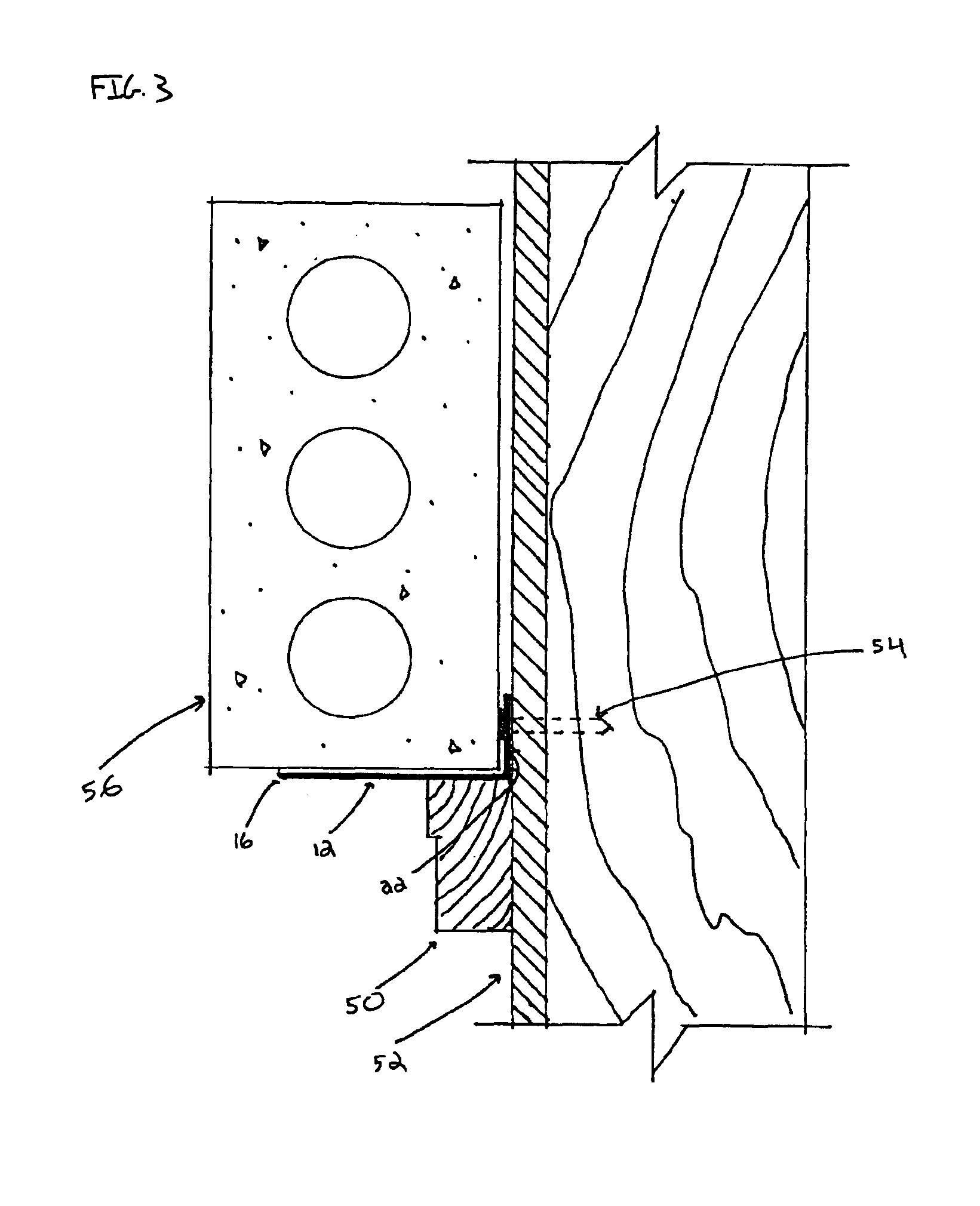

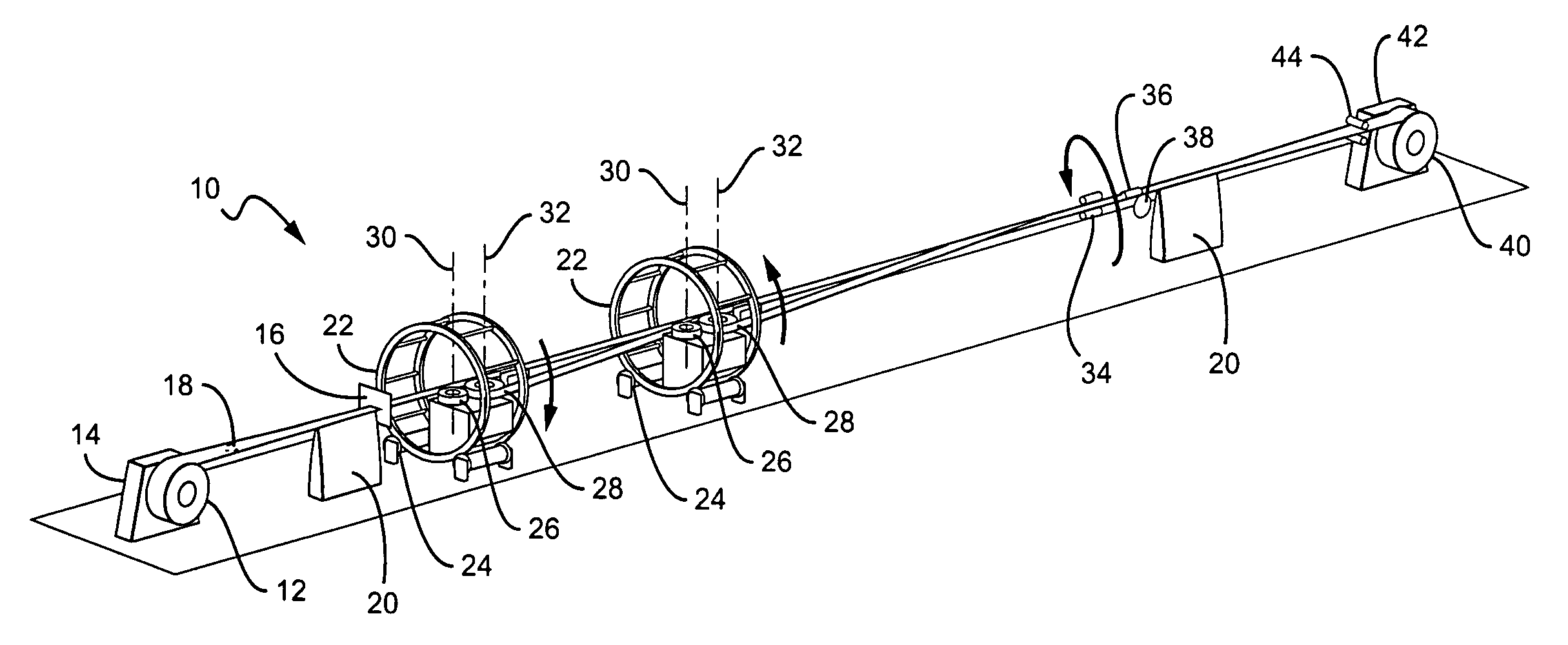

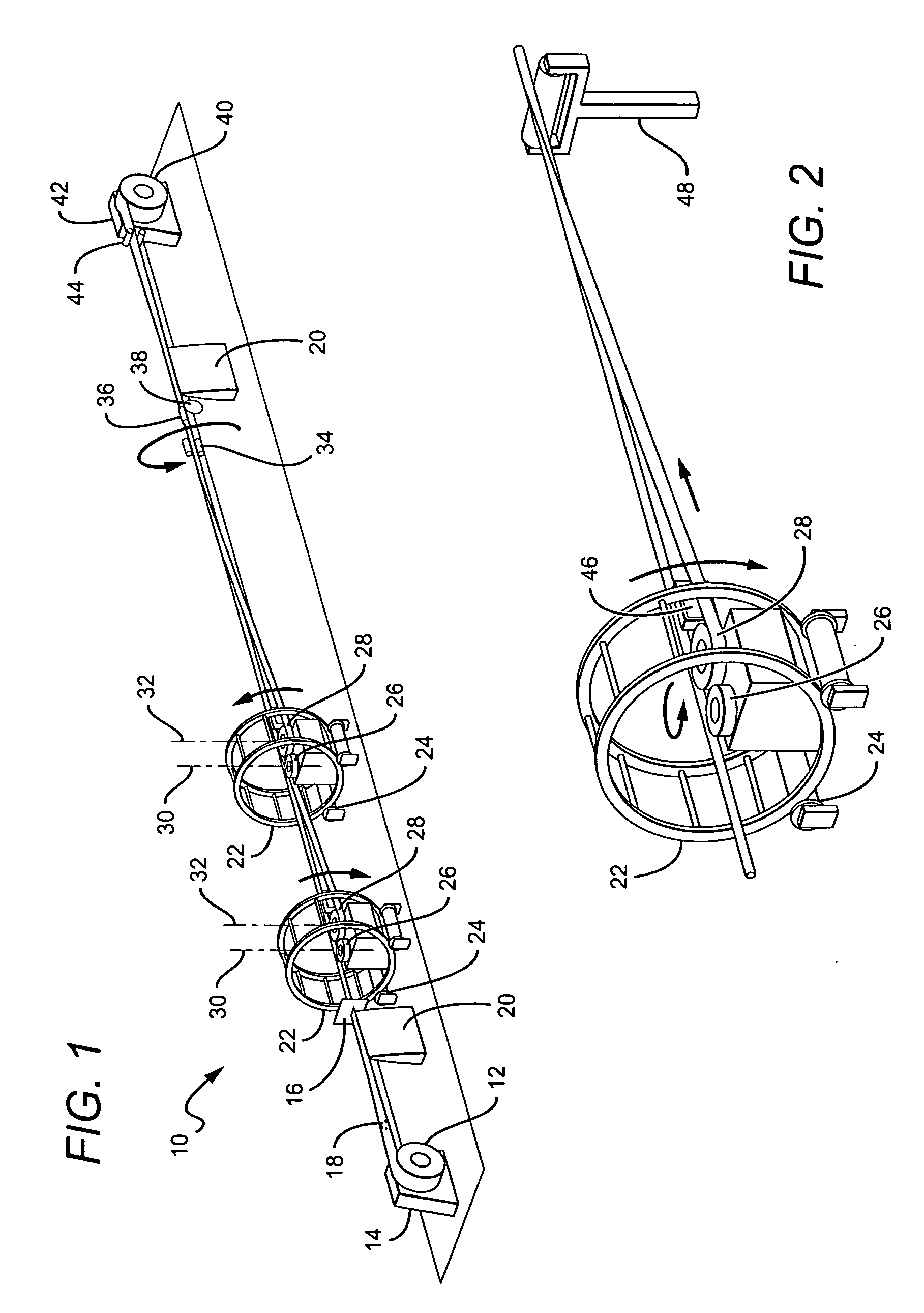

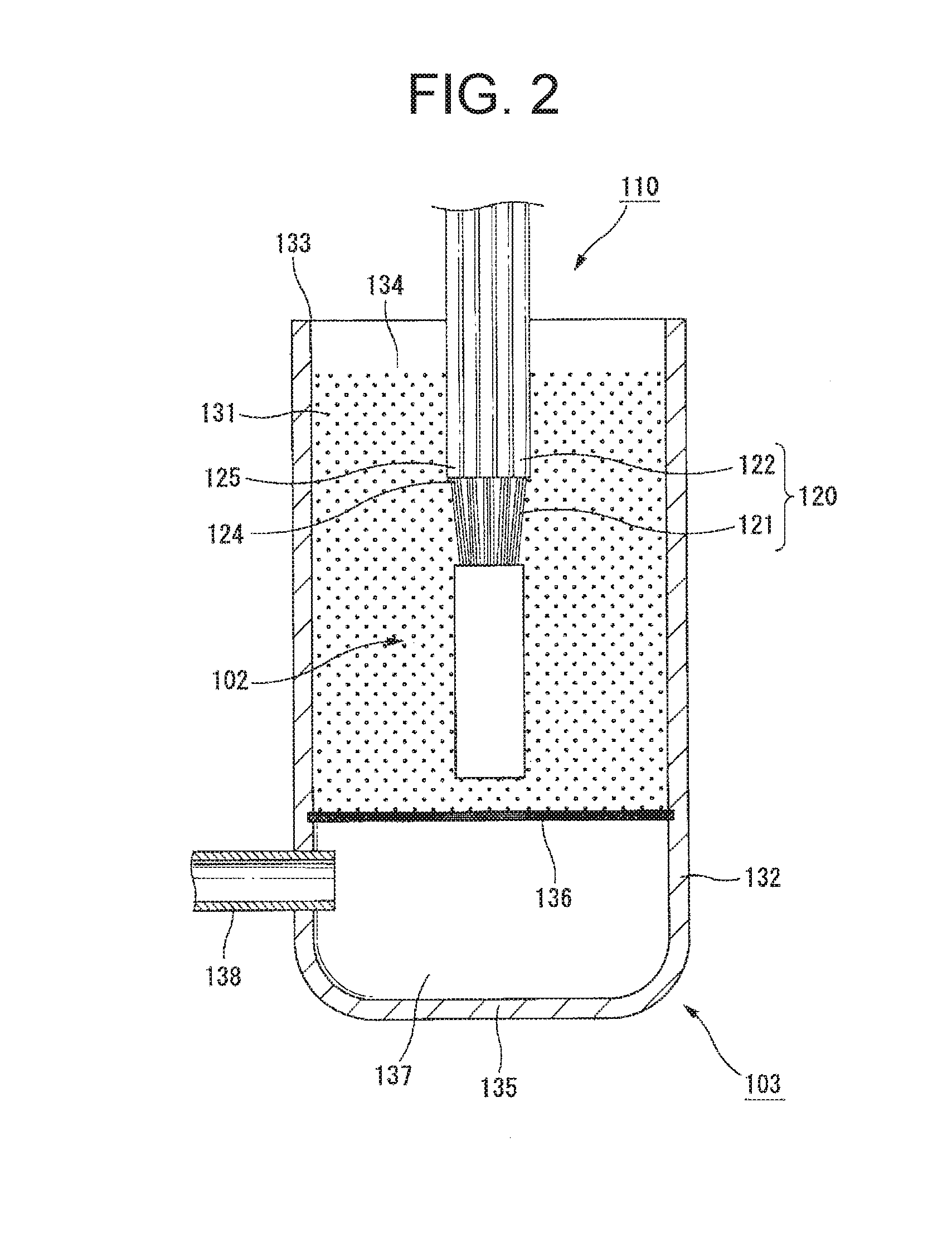

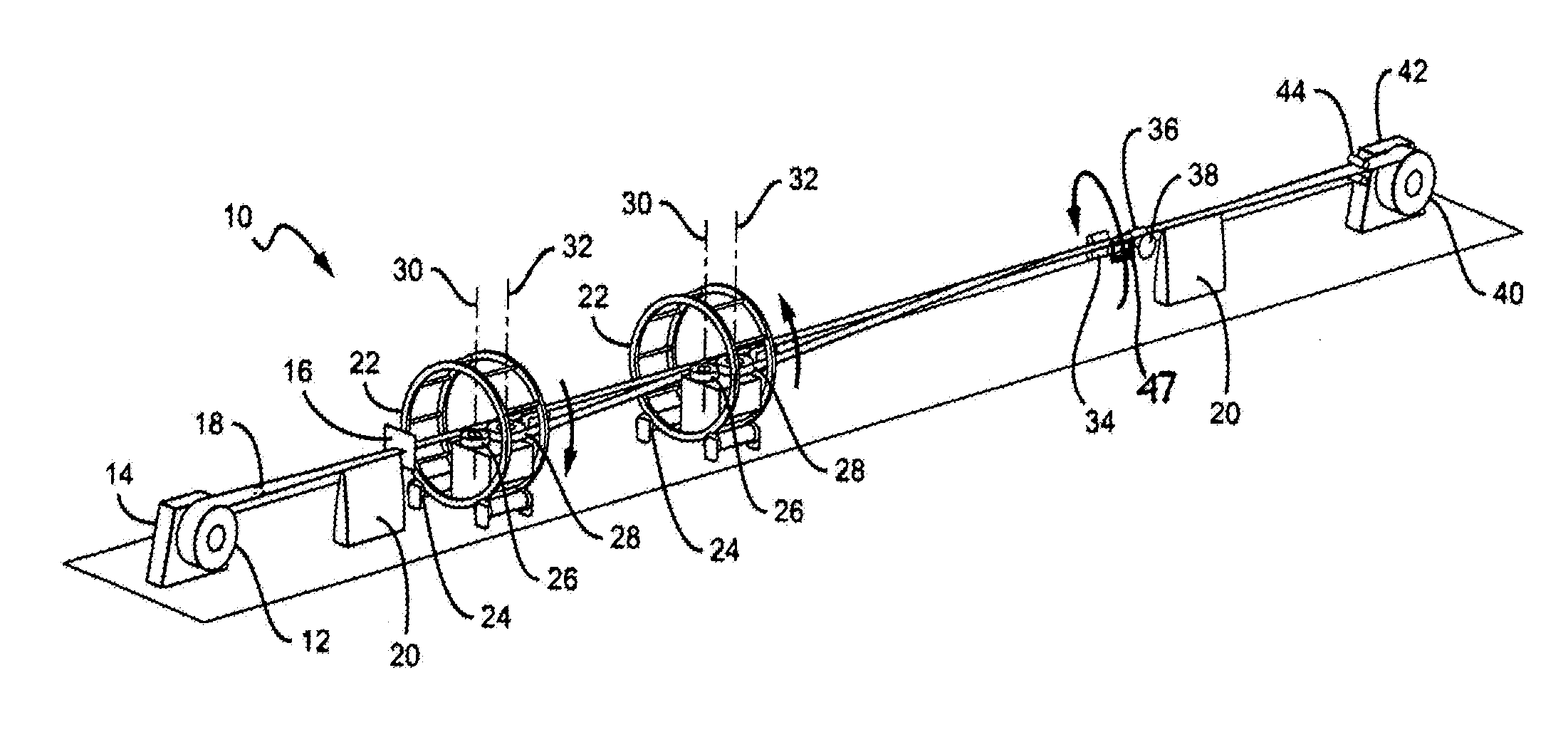

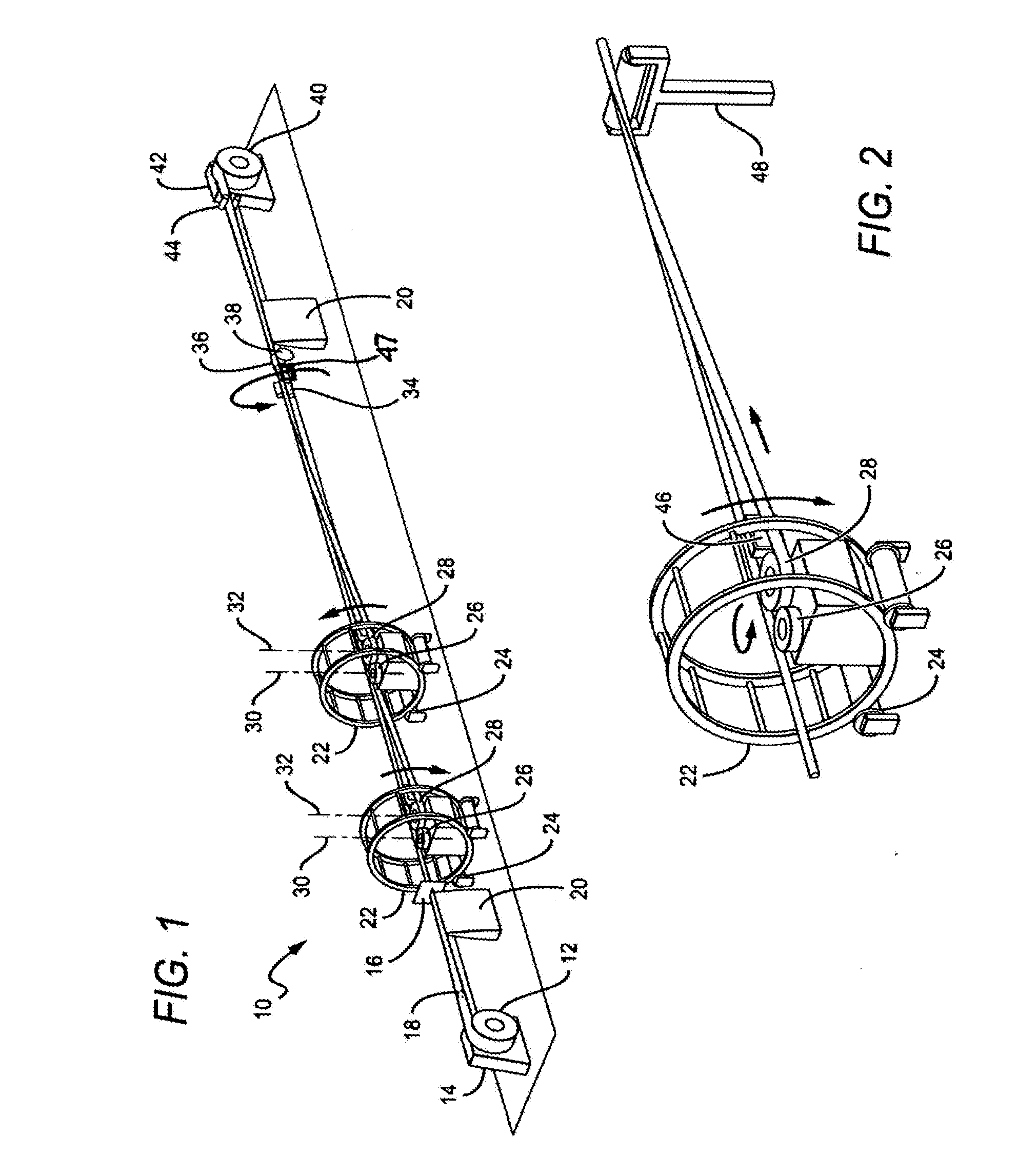

On-site land mine removal system

InactiveUS20090223355A1Reduced effectivenessReduce eliminateDefensive equipmentDefence devicesLiquid jetDetonation

A method of deactivating land mines buried in ground comprises projecting high-pressure water jets into ground, cutting through ground with the high-pressure water jets, and making at least one cut through a land mine or cutting through at least one land mine that had been under the ground, the cutting of the land mine reducing the performance of the land mine. The method may reduce the performance of the land mine by rendering the land mine inactive to normal detonation procedures for the land mine. To reach as many surface areas on the buried landmines, it is preferable that at least two high-pressure water jets are spaced apart are used to cut through the ground. The method may be practiced with the high-pressure water jet being carried on a vehicle and cutting is done in a line that is formed at least in part by movement of the vehicle over the ground while the high-pressure water jet is cutting ground. An apparatus for the reduction in effectiveness of land mines buried in ground may comprise a self-contained push-cart unit or a unit attached or attachable to a vehicle. A complete system could comprise a vehicle having a source of liquid, a high-pressure pump to move the liquid under high pressure, a nozzle directing a liquid jet path for the liquid, a support for the nozzle, abrasive delivery system, and nozzle being controllable to direct the liquid towards the ground while the nozzle is fixed relative to the vehicle.

Owner:MANDERS STEPHEN M

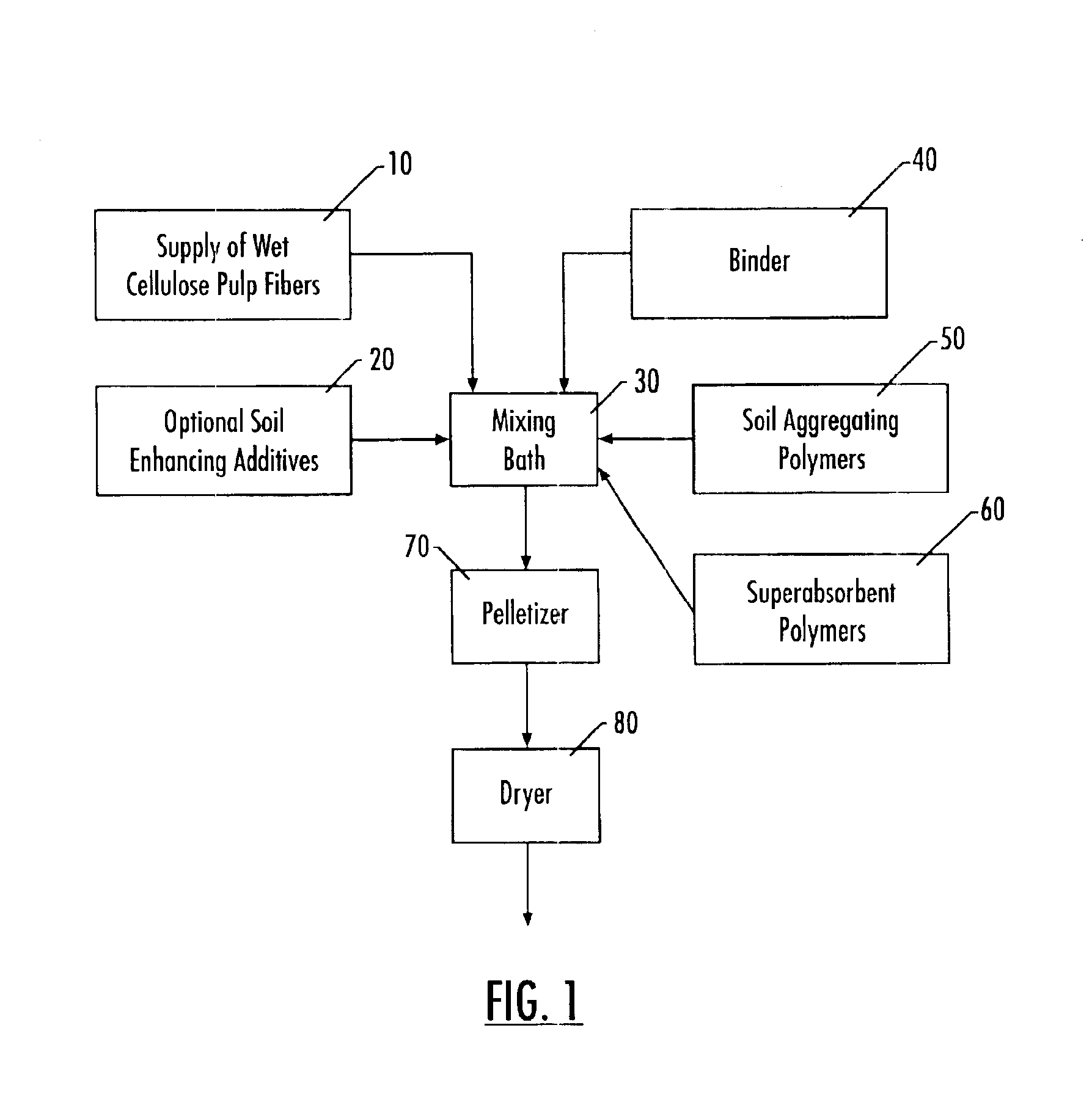

Lignocellulose fiber composite with soil conditioners

InactiveUS6855182B2Conveniently applyEasily disperseAmmonium nitratesOrganic fertilisersFiber matrixFertilizer

A pellet for use in conditioning soil made of a lignocellulose fiber matrix having up to 20% by weight of a soil conditioning material incorporated therein. The soil conditioning material comprises one or more synthetic soil conditioning polymers and, optionally, additional soil enhancing additives such as fertilizers, gypsum, and calcium salts. The preferred lignocellulose materials are pulp fibers with an alpha-cellulose purity of greater than about 75% by weight, with preferred lignin content of no higher than 10%. The soil conditioning polymers are preferably polyacrylamides (PAMs) or modified PAMs, but may be a combination of other soil conditioning polymers. The pellet is produced by dispersing the polymers into a bath of lignocellulose fibers. The dispersion is then formed into pellets with a pelletizing machine such that the polymer and other soil conditioning material is interspersed within the matrix formed by the pelletized lignocellulose.

Owner:RAYONIER PERFORMANCE FIBERS

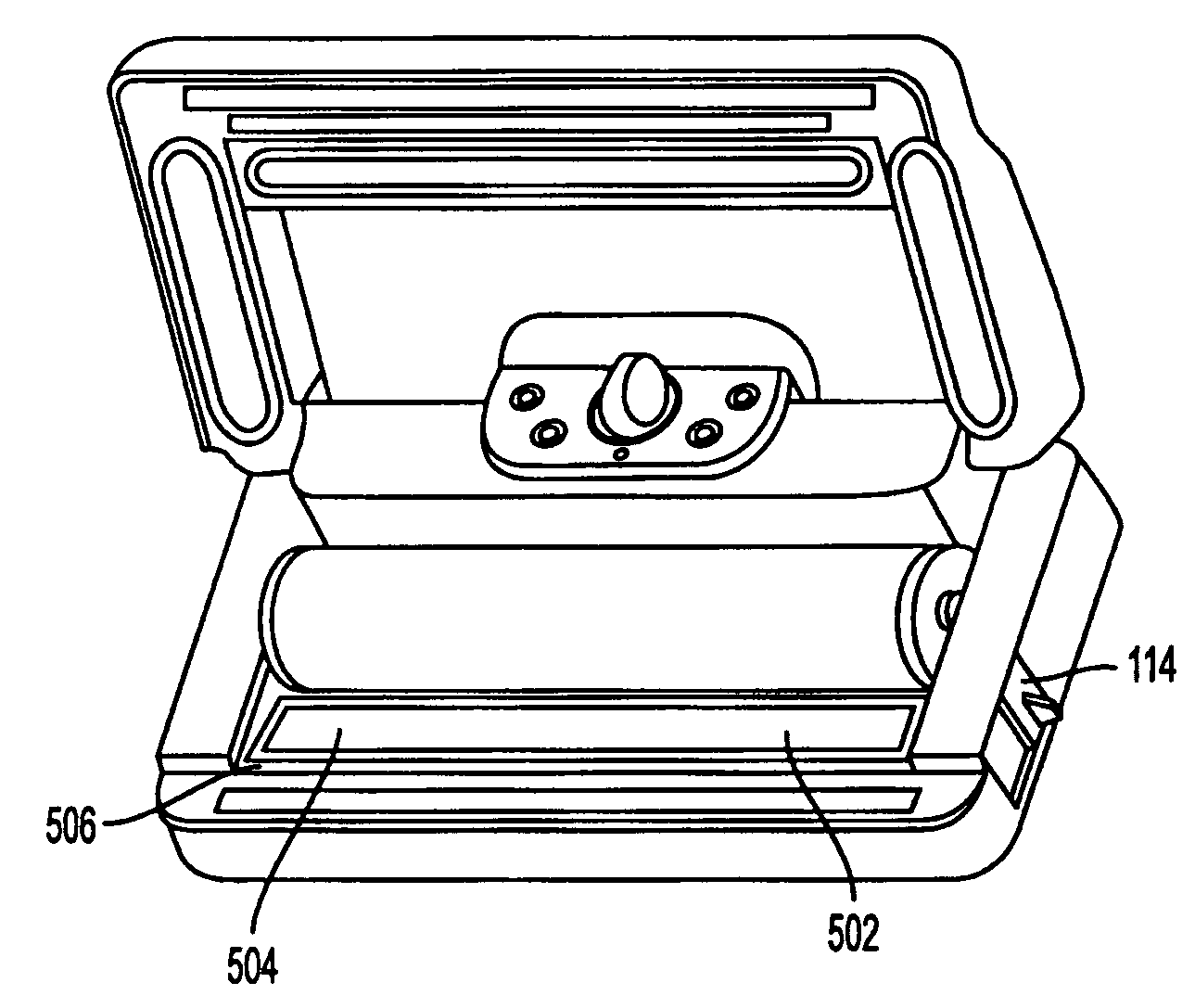

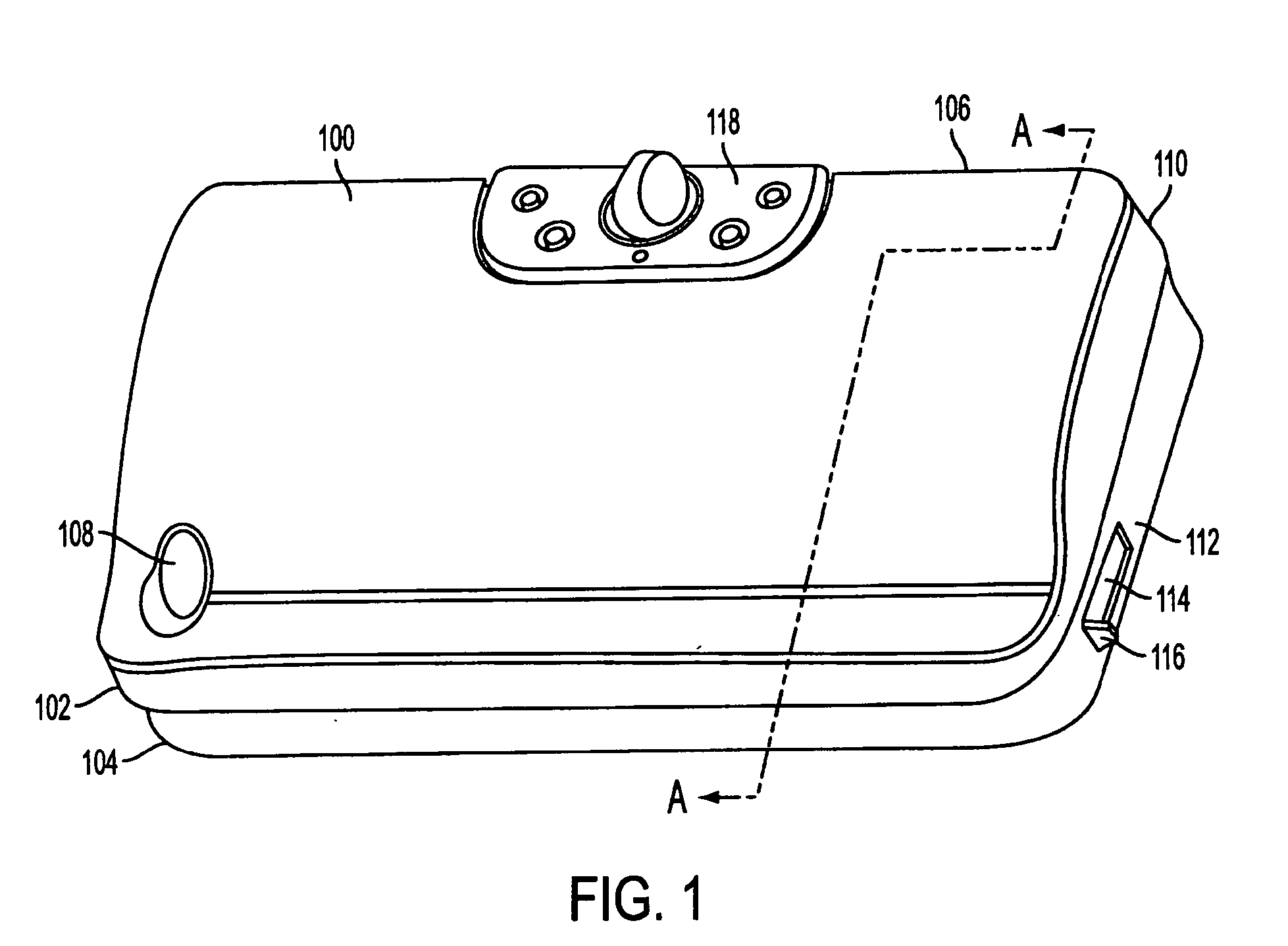

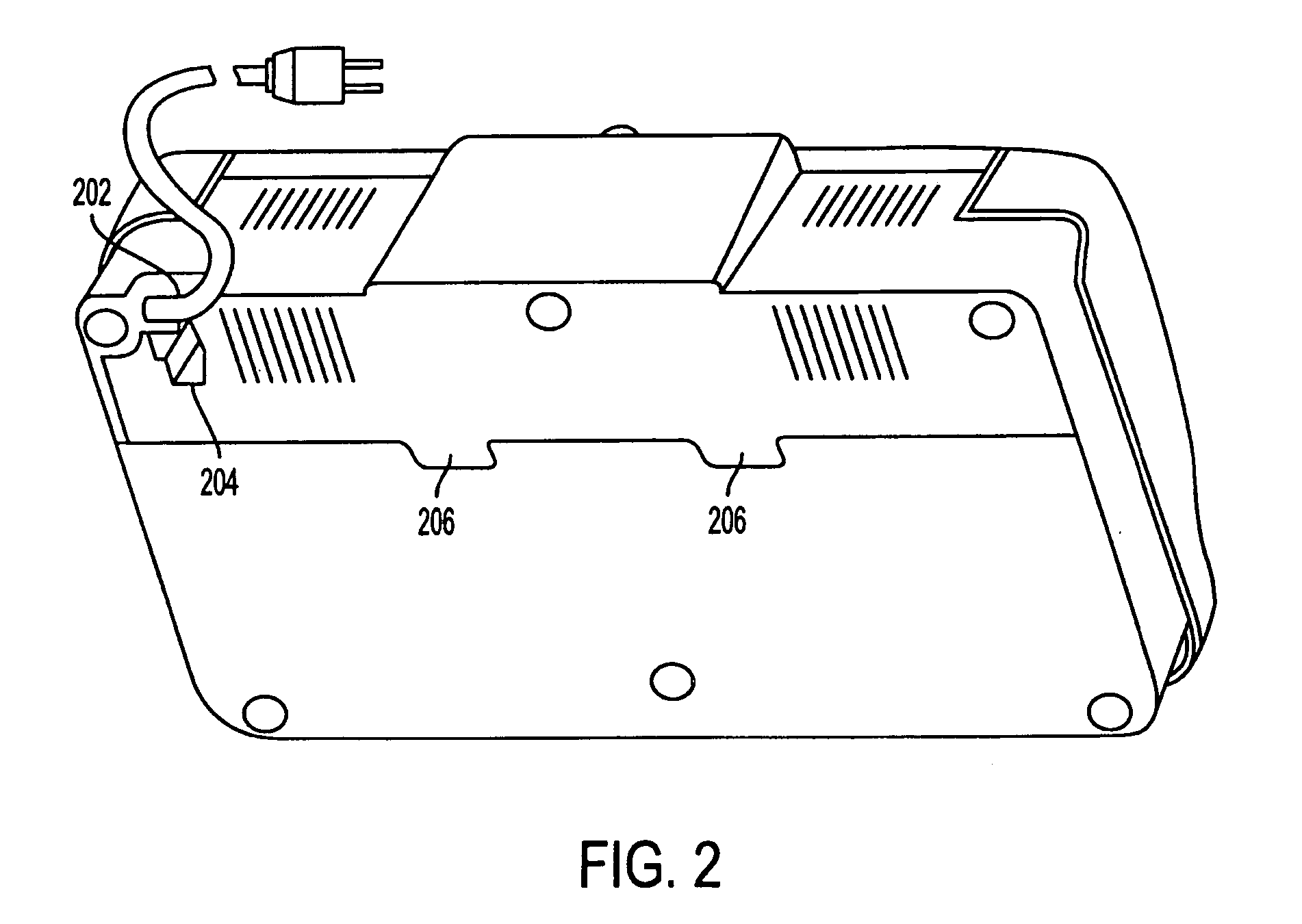

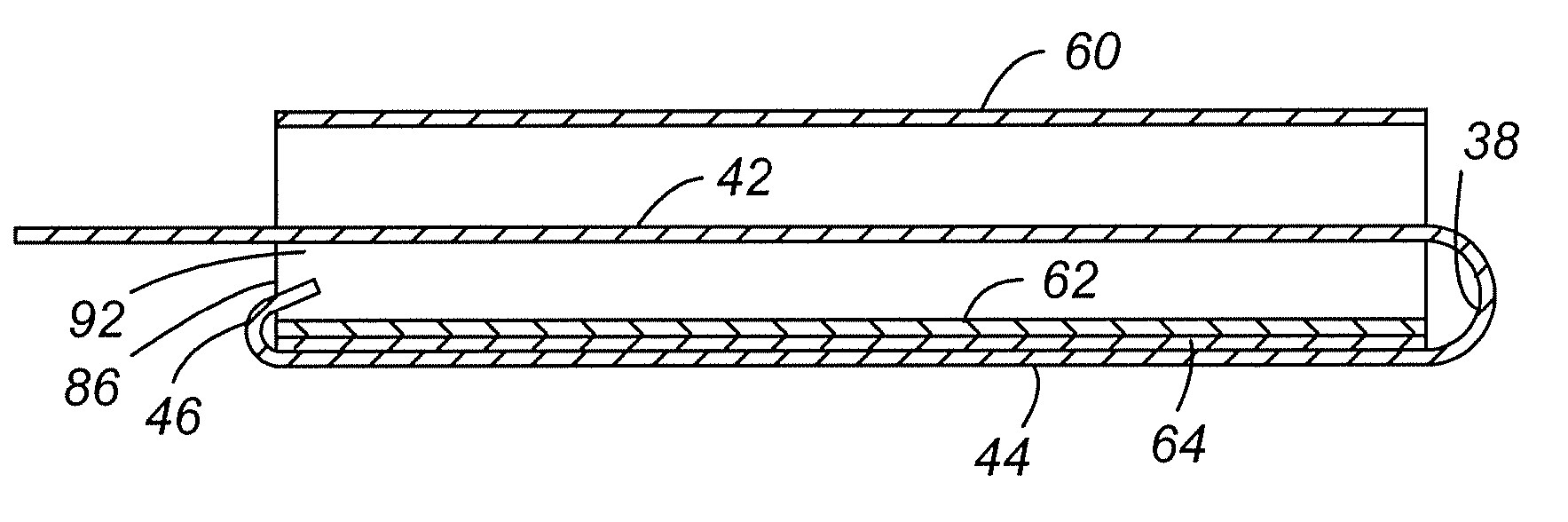

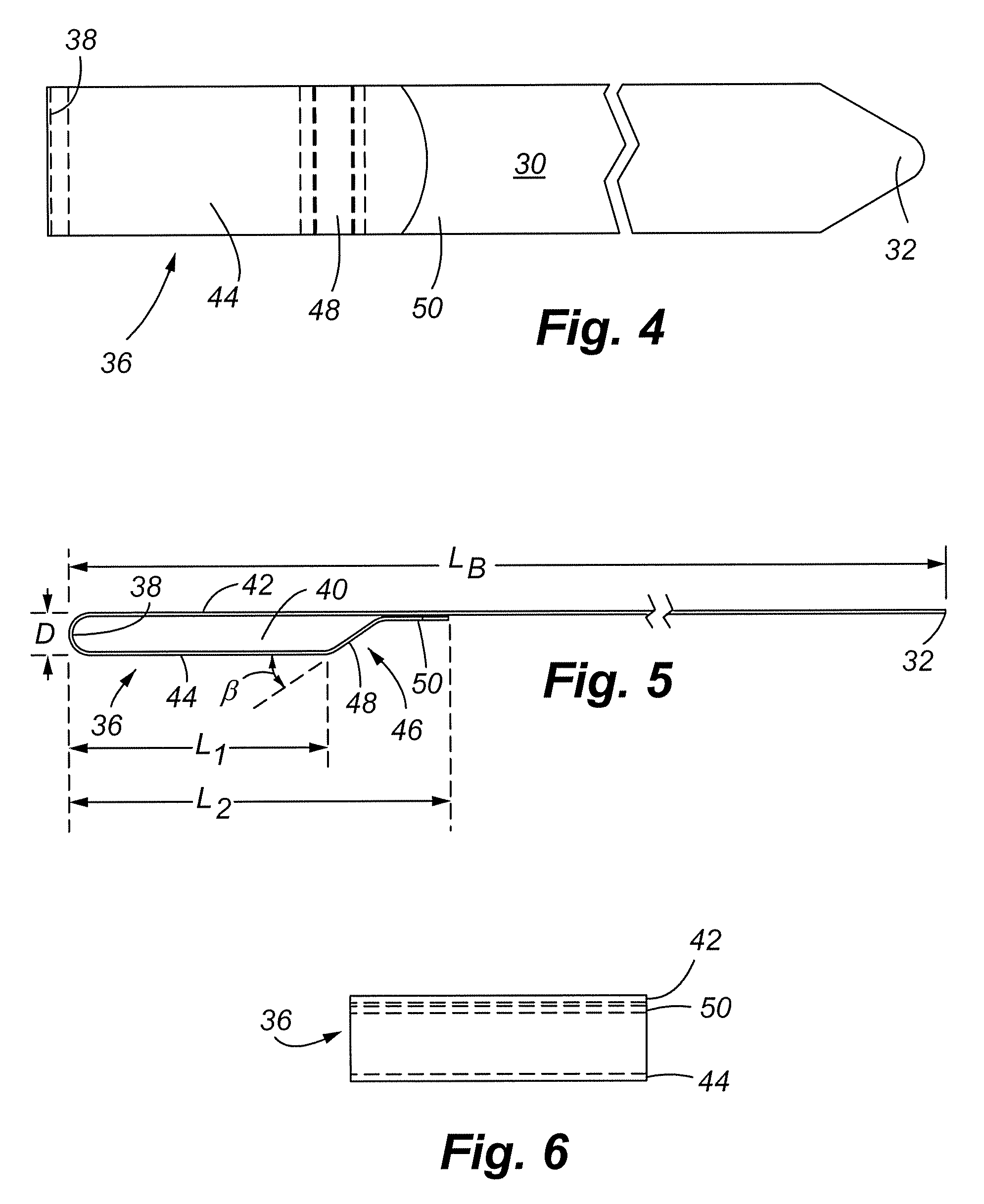

Heat sealing element and control of same

InactiveUS20050022474A1Waste of materialAvoid sealing effectWrapper twisting/gatheringPackaging under vacuum/special atmosphereTemperature controlVacuum pack

A vacuum packaging appliance for heat sealing items in a vacuum packaging plastic bag is disclosed. The appliance comprises a lid adapted to define a vacuum chamber when it is moved to a closed position relative to a trough in the base of the device. Adjacent to a trough in the lower portion of the device, a heat sealing element is placed in order to seal the contents of the bag once the vacuum packaging is complete. In another embodiment, the heat sealing element is mounted on the lid of the device and comes into contact with the vacuum bag when the lid is in a closed position. The heat sealing elements are controlled by a controller that allows operator selections of seals and sealing time adjustments based on inputs from a plurality of sensors. The controller is further able to energize one or two of the heating elements based on predetermined conditions. The methods and structures described control both heating and cooling of the heat sealing elements. The vacuum pump exhaust may also be directed below the heat sealing elements in order to cool the elements. The control and placement of the heat sealing elements allows for precise feedback and temperature control of the elements and therefore ensuring proper vacuum sealing of the containers.

Owner:TILIA INT INC

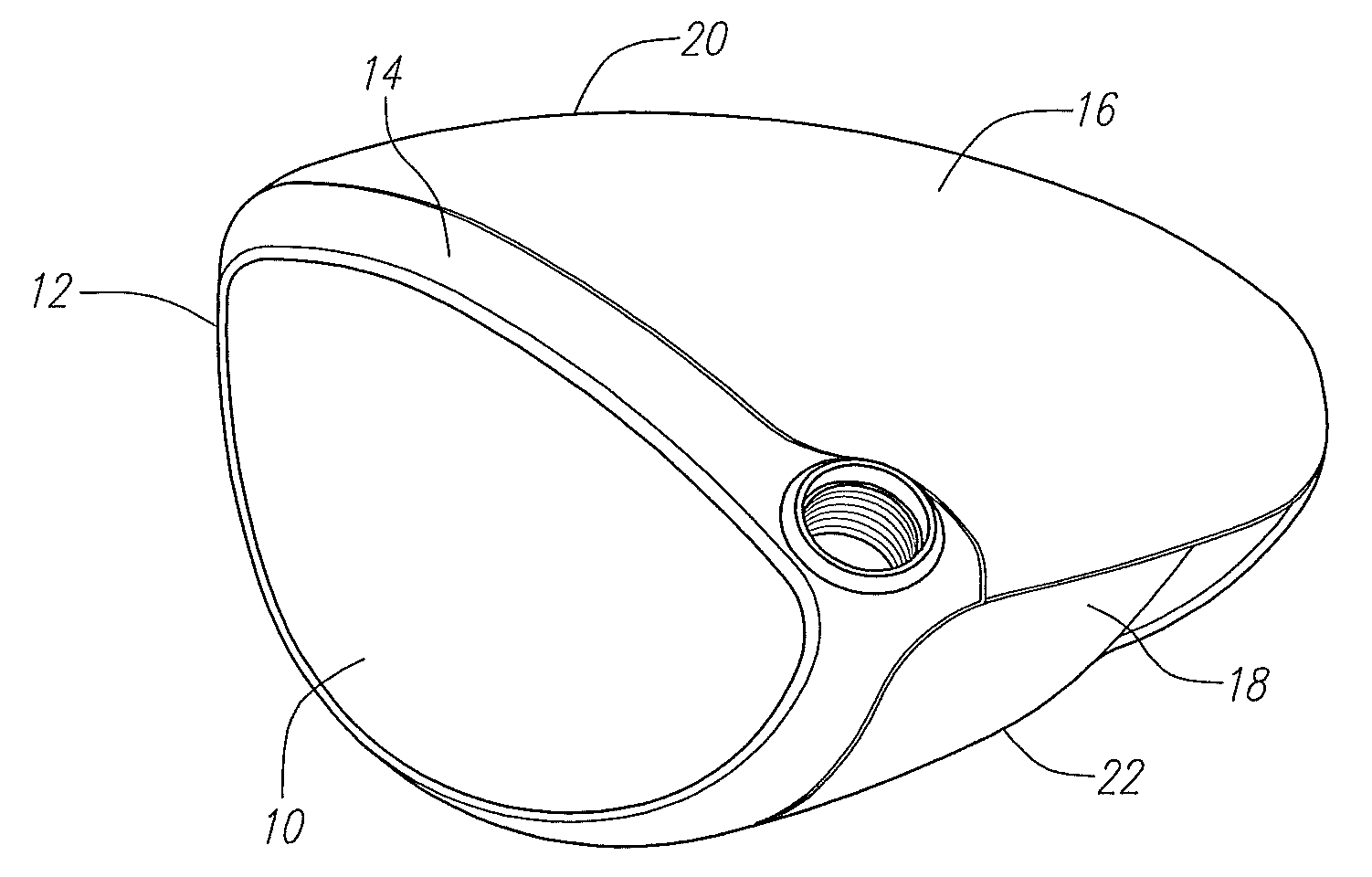

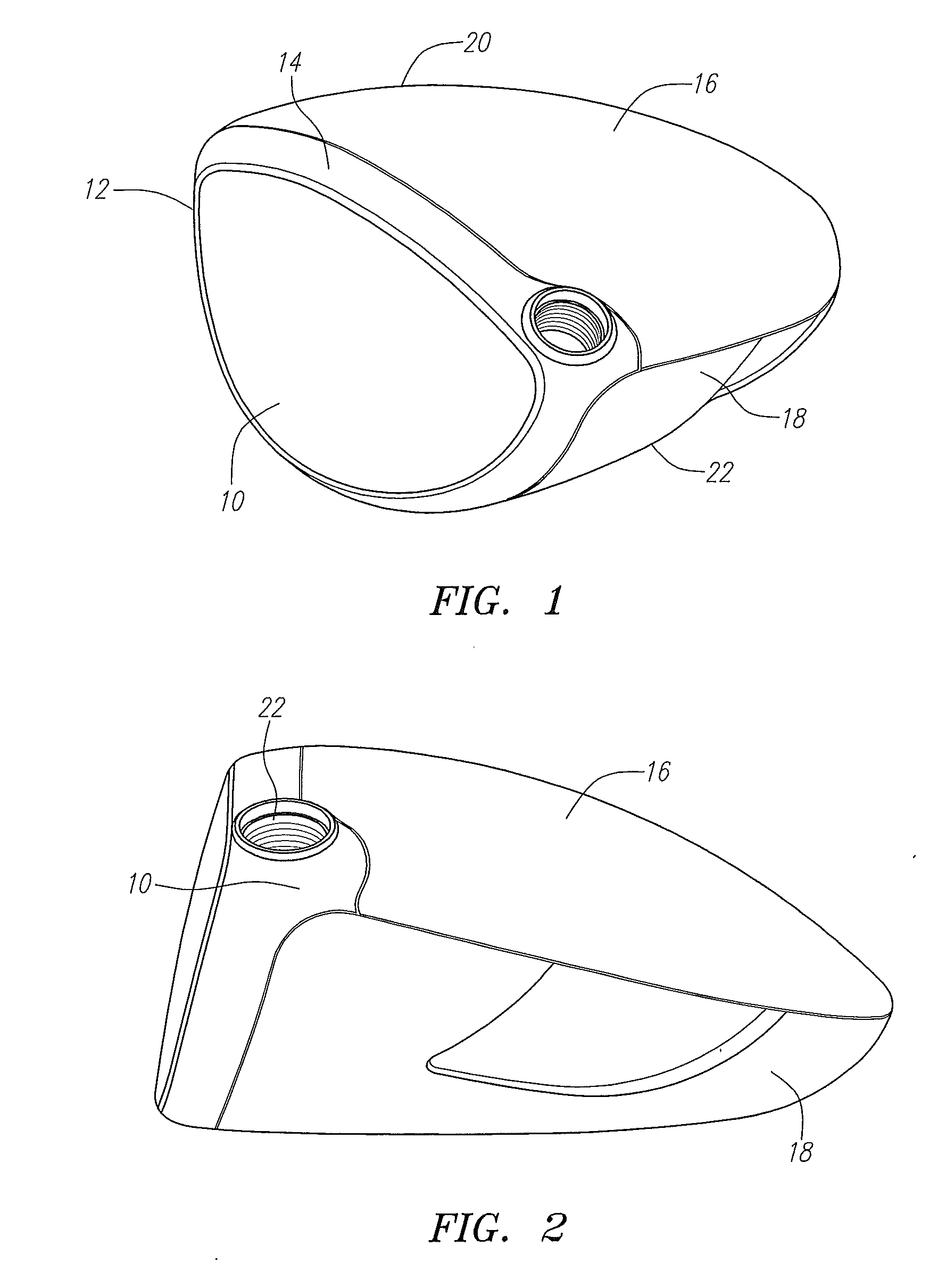

Method for forming a multiple material golf club head

InactiveUS20100139079A1Additional costWaste of materialMetal rolling stand detailsMetal working apparatusEngineeringGolf club

Owner:CALLAWAY GOLF CO

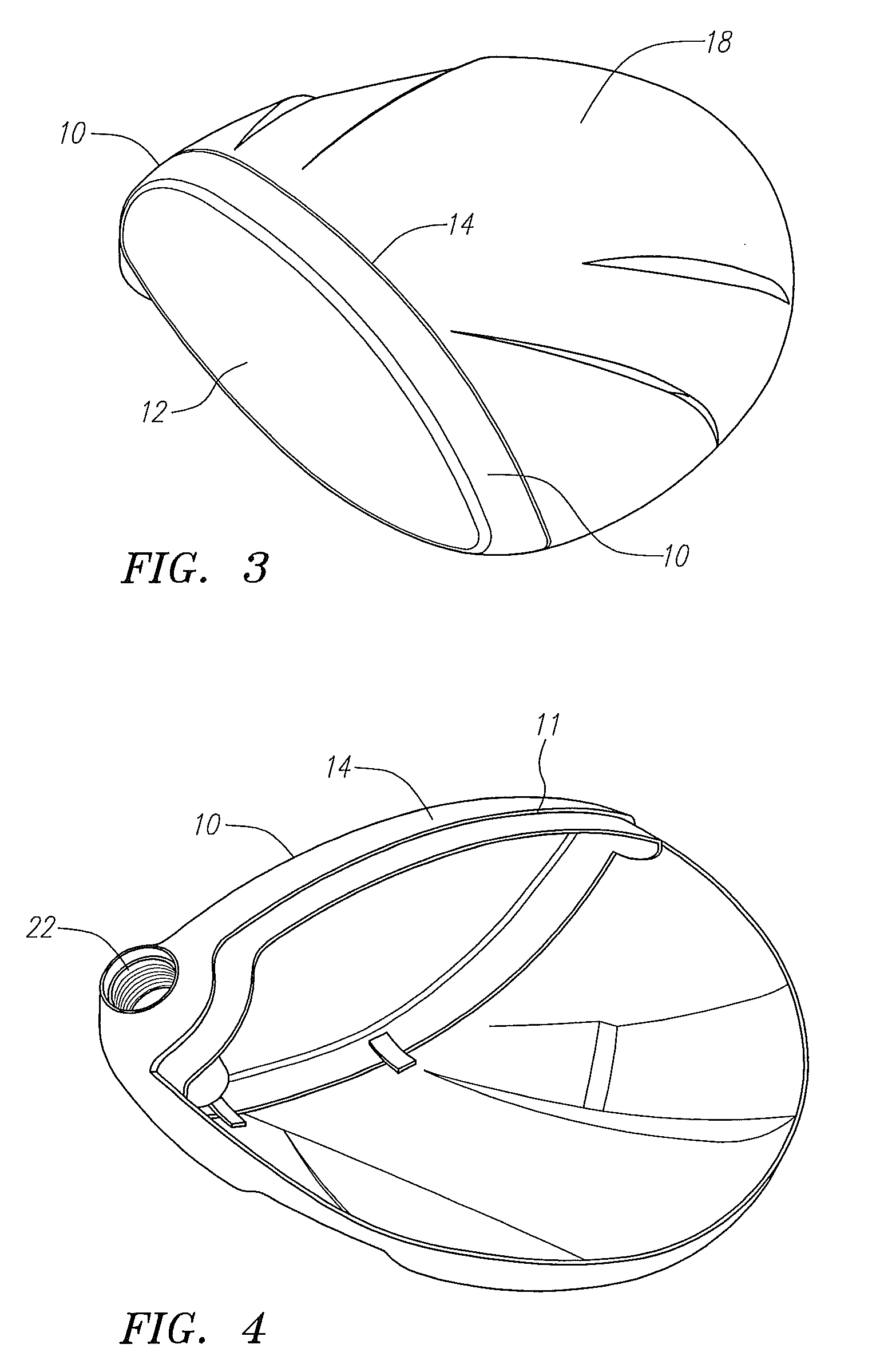

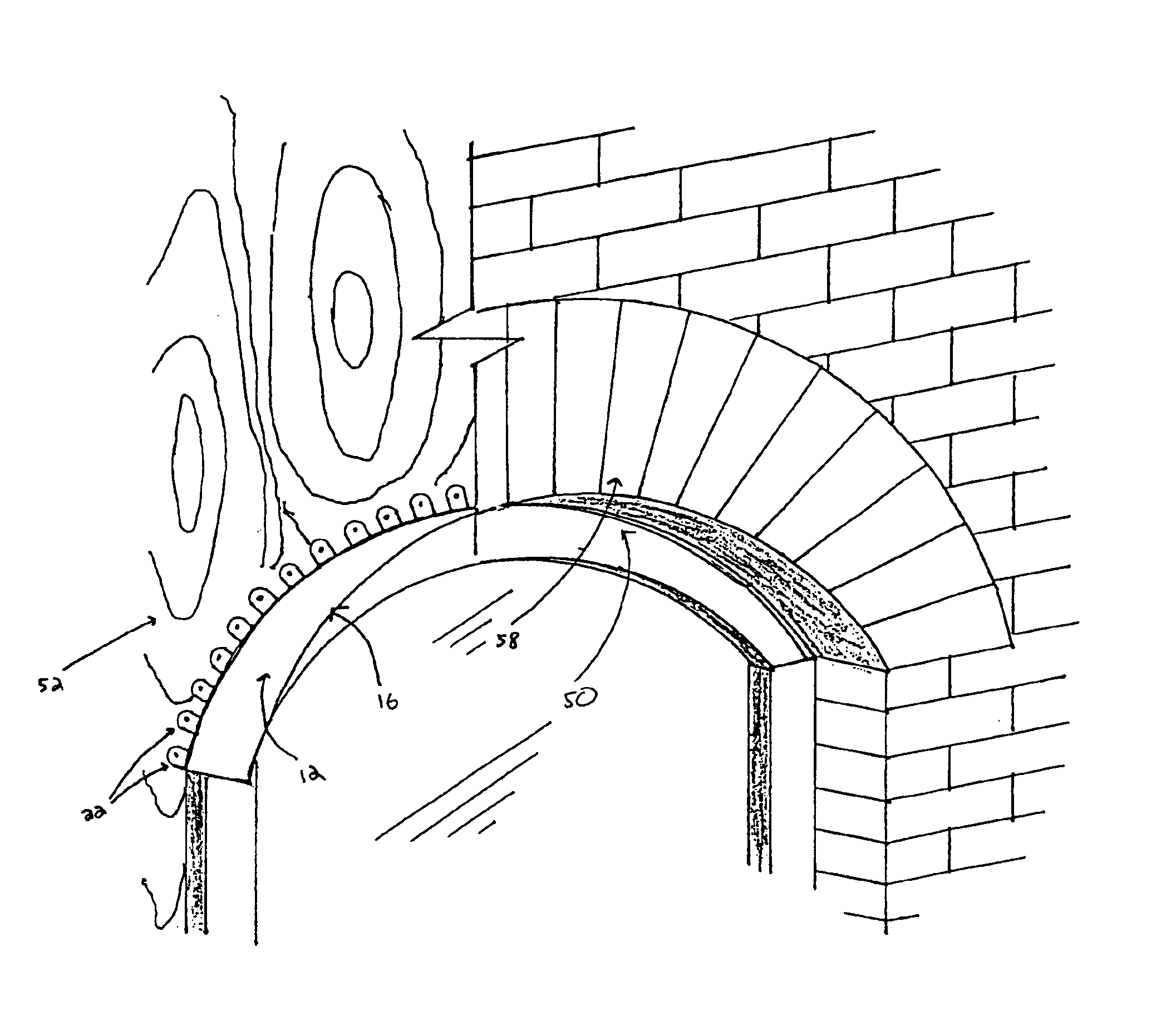

Adjustable masonry arch form

An adjustable masonry arch form is disclosed. The adjustable masonry arch form has a planar base section to support the masonry elements which will form the masonry arch, and a plurality of attachment elements secured to the planar base for securing the form to a structure. The adjustable masonry arch form is constructed from material rigid enough to support the masonry elements, but flexible enough to be bent to conform to any given arched construction without unwanted buckling of the form. The masonry elements which form the masonry arch are placed directly on the planar base of the form in the desired configuration and secured in the masonry arch by mortar. The form is left in position permanently, obviating the need to build a temporary arch support saving time and expense and obviating waste of materials.

Owner:BAILEY MICHAEL EUGENE

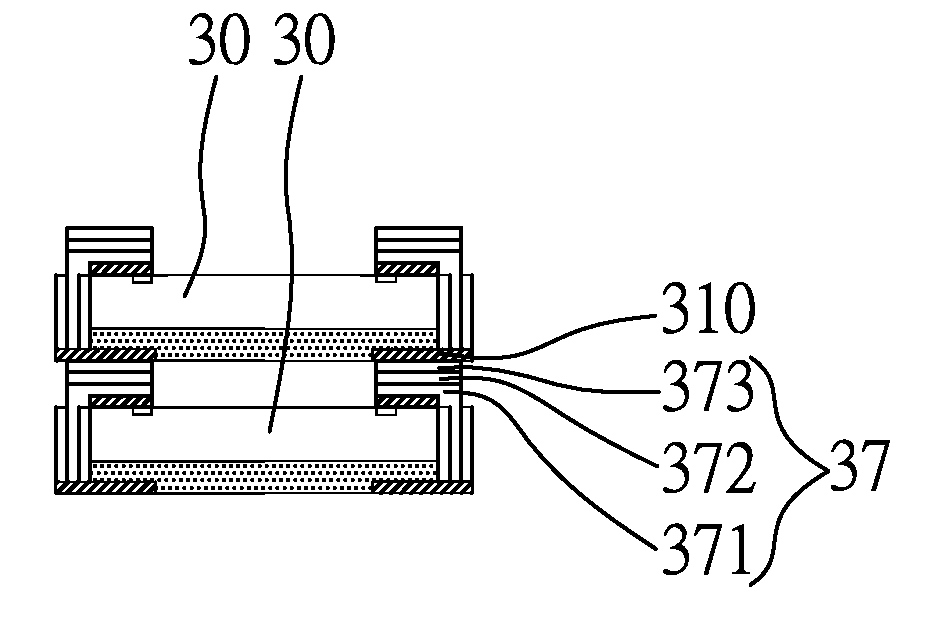

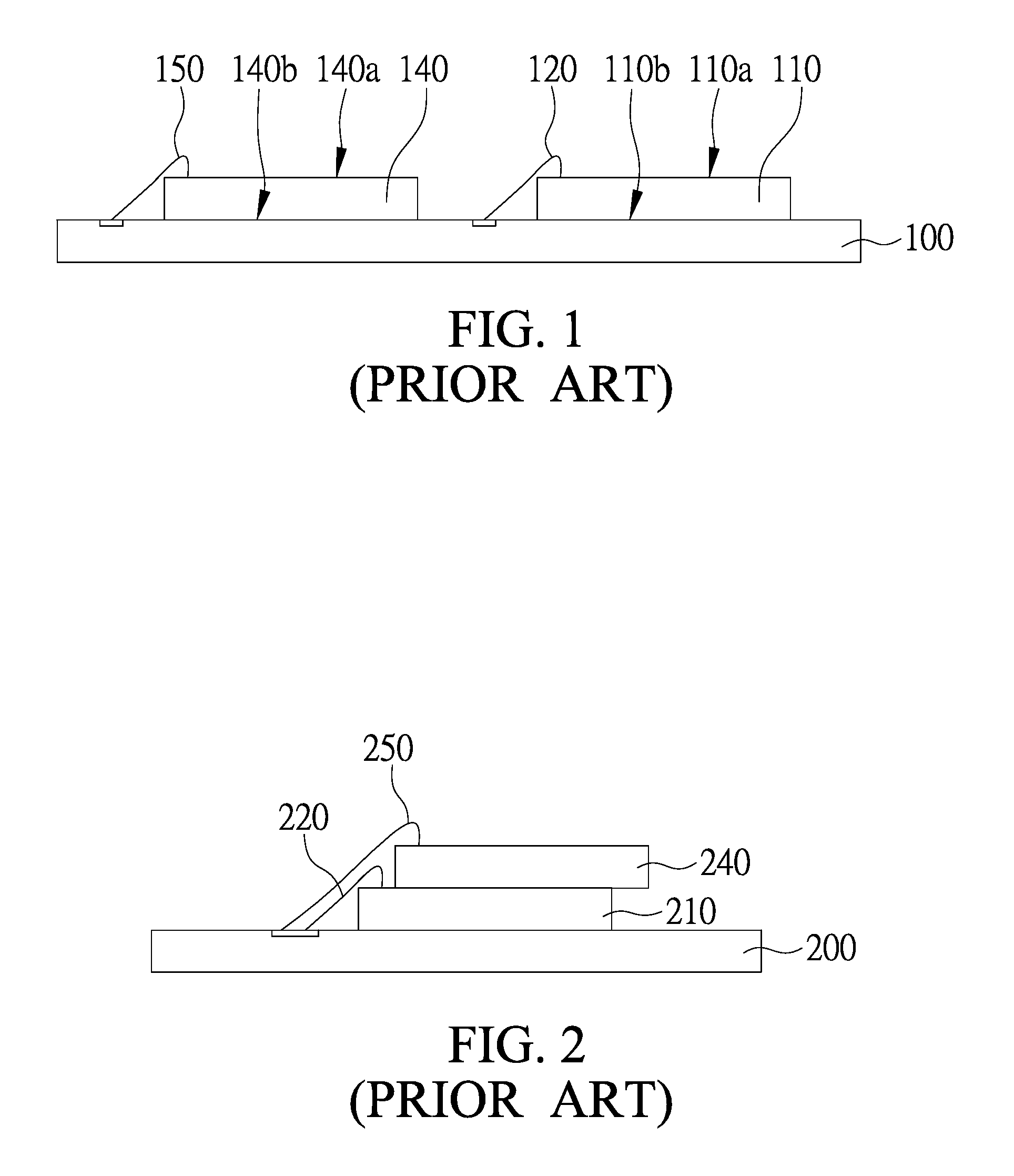

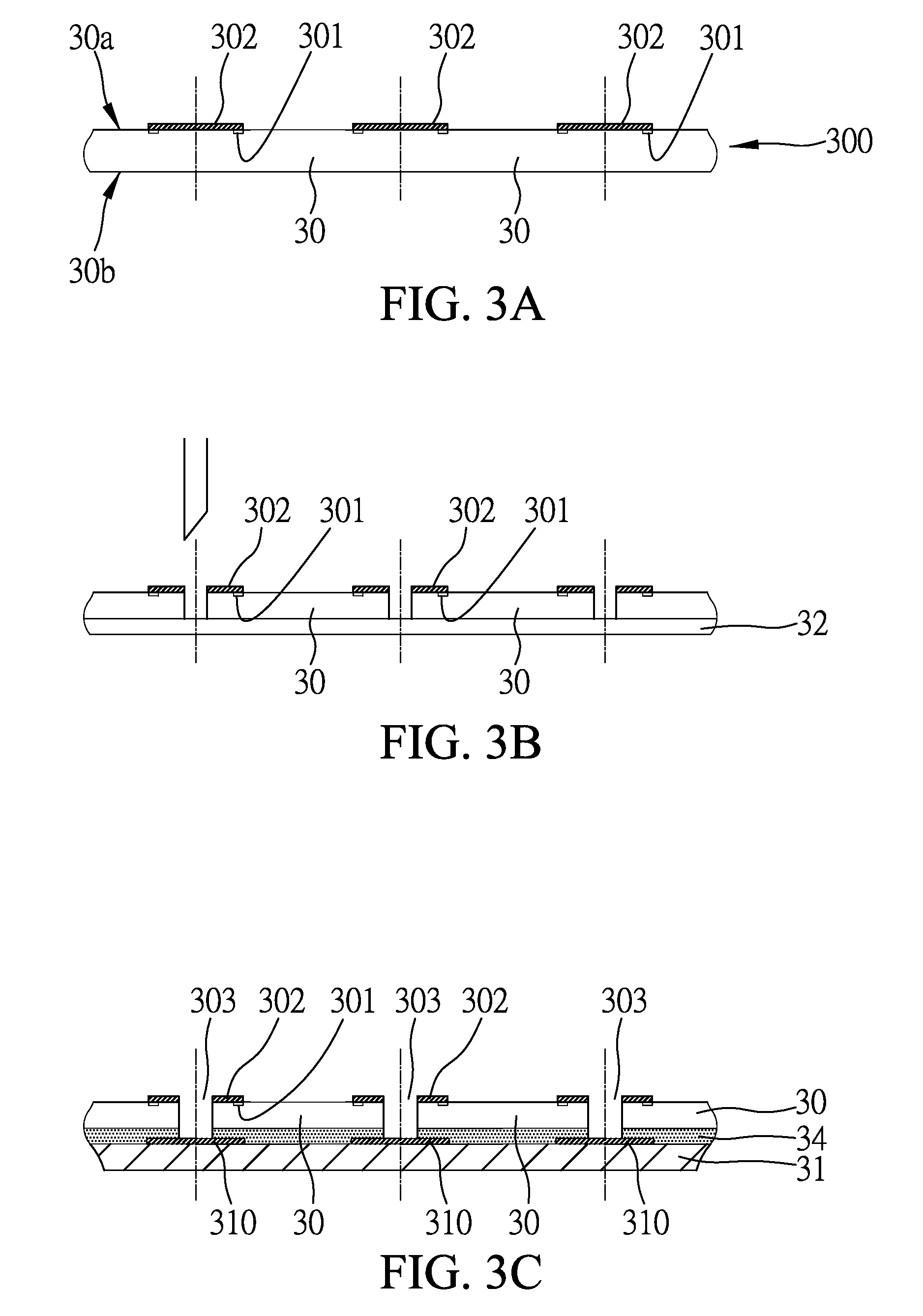

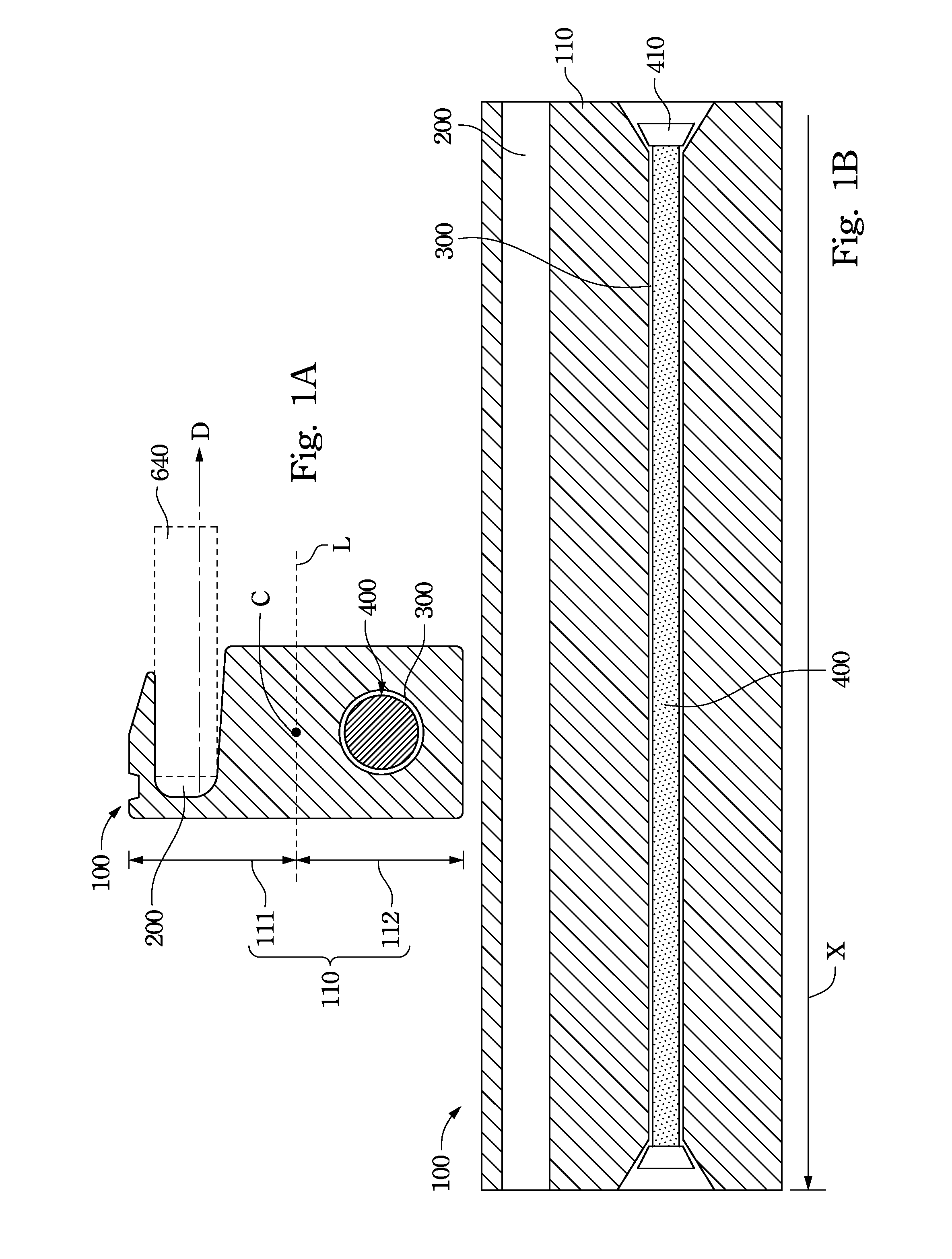

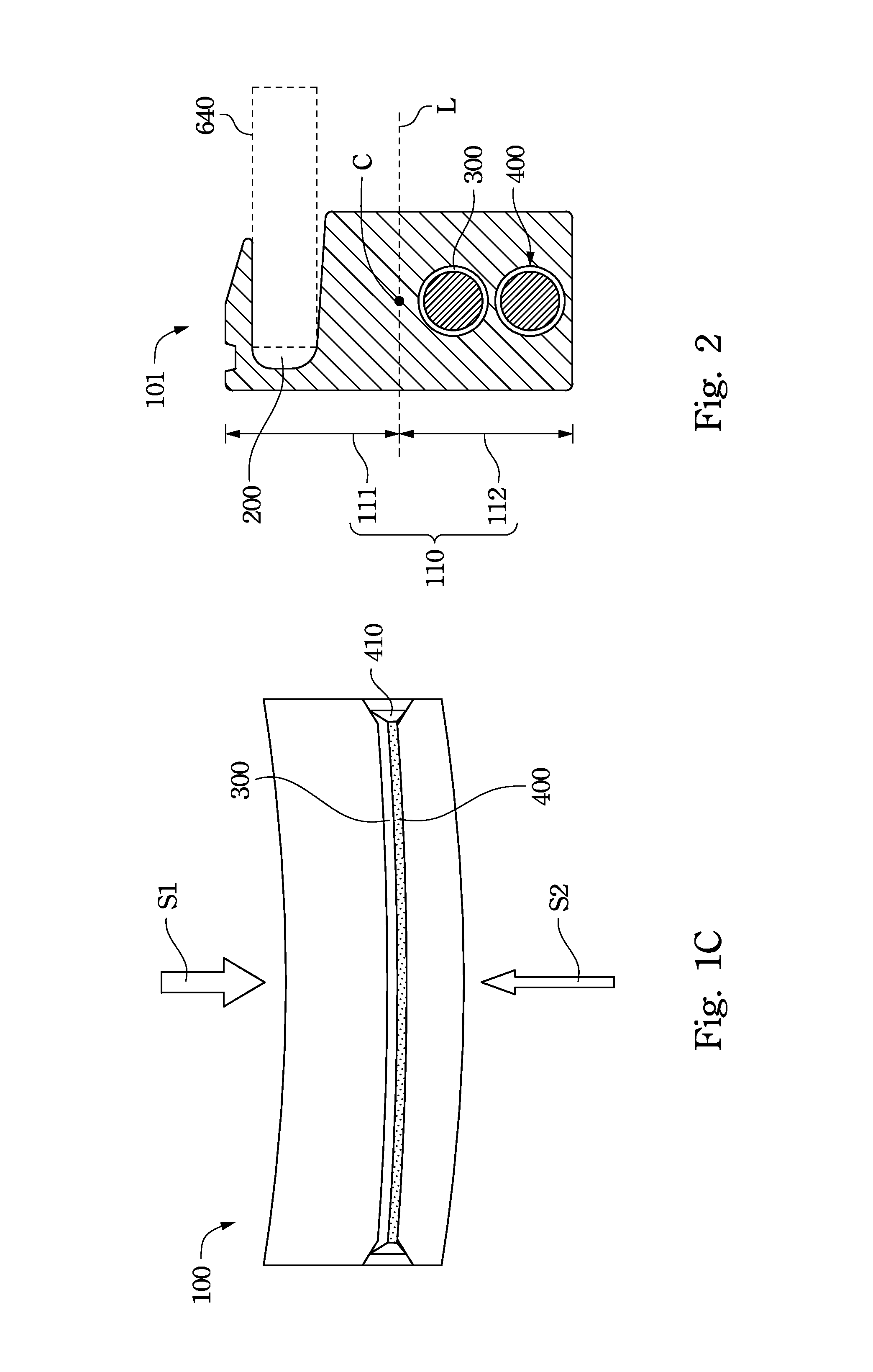

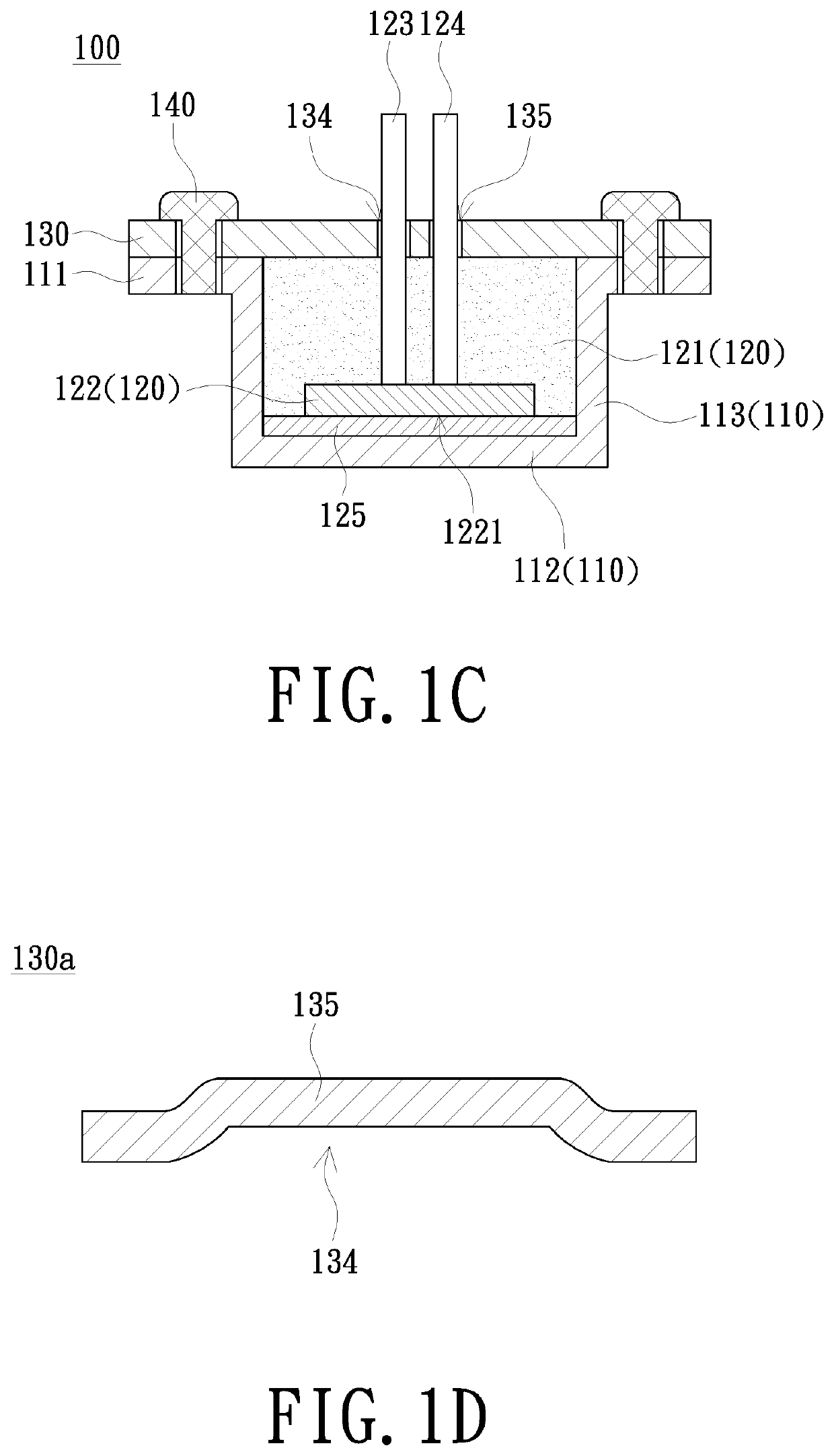

Semiconductor Device and Method for Fabricating the Same

InactiveUS20080258306A1Waste of materialIncrease in costSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsEngineeringSemiconductor

The present invention provides a semiconductor device and a method for fabricating the same. The semiconductor device includes a chip having an active surface and an opposing non-active surface, wherein a plurality of bond pads are formed on the active surface, and first metal layers are formed on the bond pads and to edges of the non-active surface; conductive traces disposed on the non-active surface of the chip; a dielectric layer covering sides of the chip and formed with a plurality of openings therein to expose a portion of the conductive traces; and a plurality of second metal layers formed in the openings of the dielectric layer and on the first metal layers, such that the bond pads are electrically connected to the conductive traces via the first and second metal layers.

Owner:SILICONWARE PRECISION IND CO LTD

Nanopolymetalic reducing agent filler

InactiveUS20120285899A1Reduce processingShort agglomerationWater contaminantsTreatment involving filtrationPyrolusiteIron powder

The present invention provides a nanopolymetallic reducing agent filler comprising 20%-70% iron powder, 10%-30% tourmaline power, 2%-15% copper power, 3%-10% bamboo charcoal powder, 2%-15% kaoline, 2%-15% magnesite powder, 2%-15% pyrolusite powder, and 10%-30% zeolite powder. All percentages described above are by weight. A process of forming the nanopolymetallic reducing agent filler is also provided, including grinding and ball milling raw materials of each component respectively into powder particles of 10 nm-100 μm, which are then mixed uniformly by weight percentage and granulated to form a granular mixture, and sintering the granular mixture at high temperature or cold pressing it into a granular filler.

Owner:T & H USA GROUP

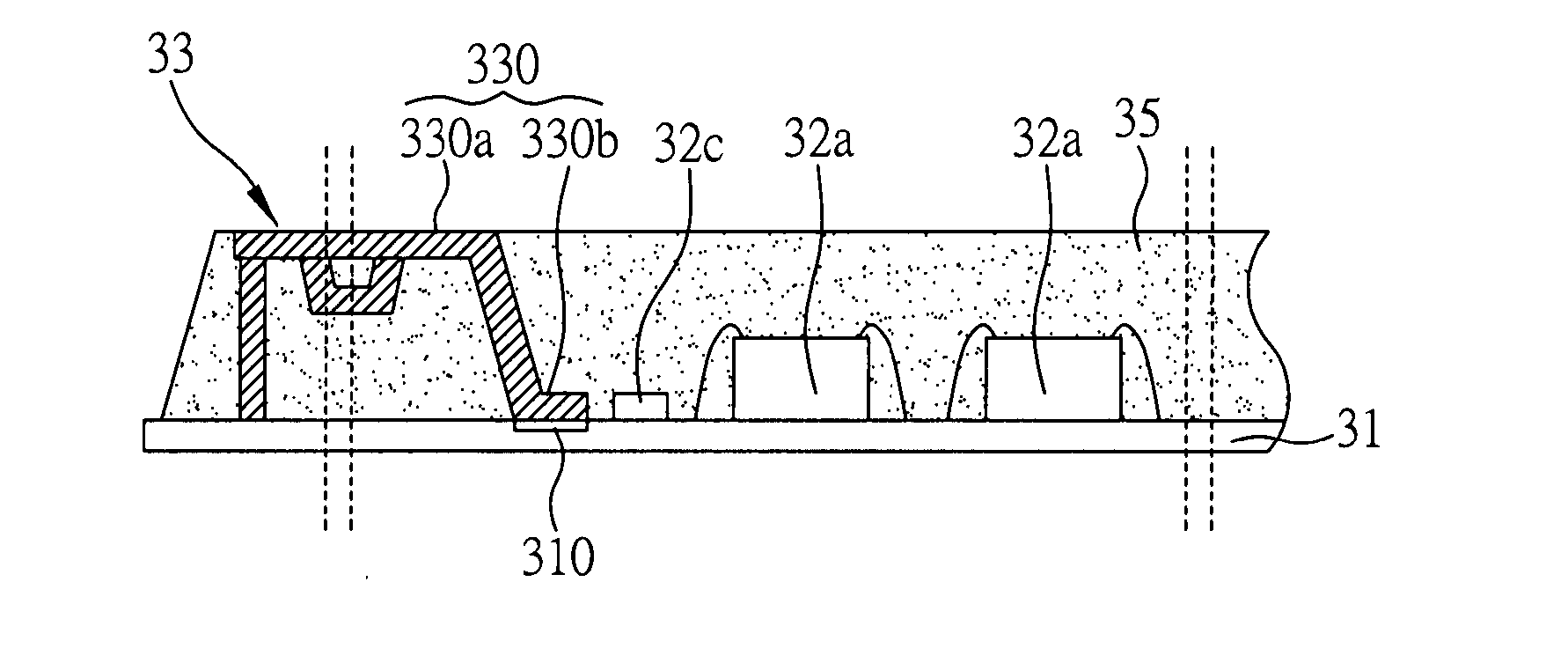

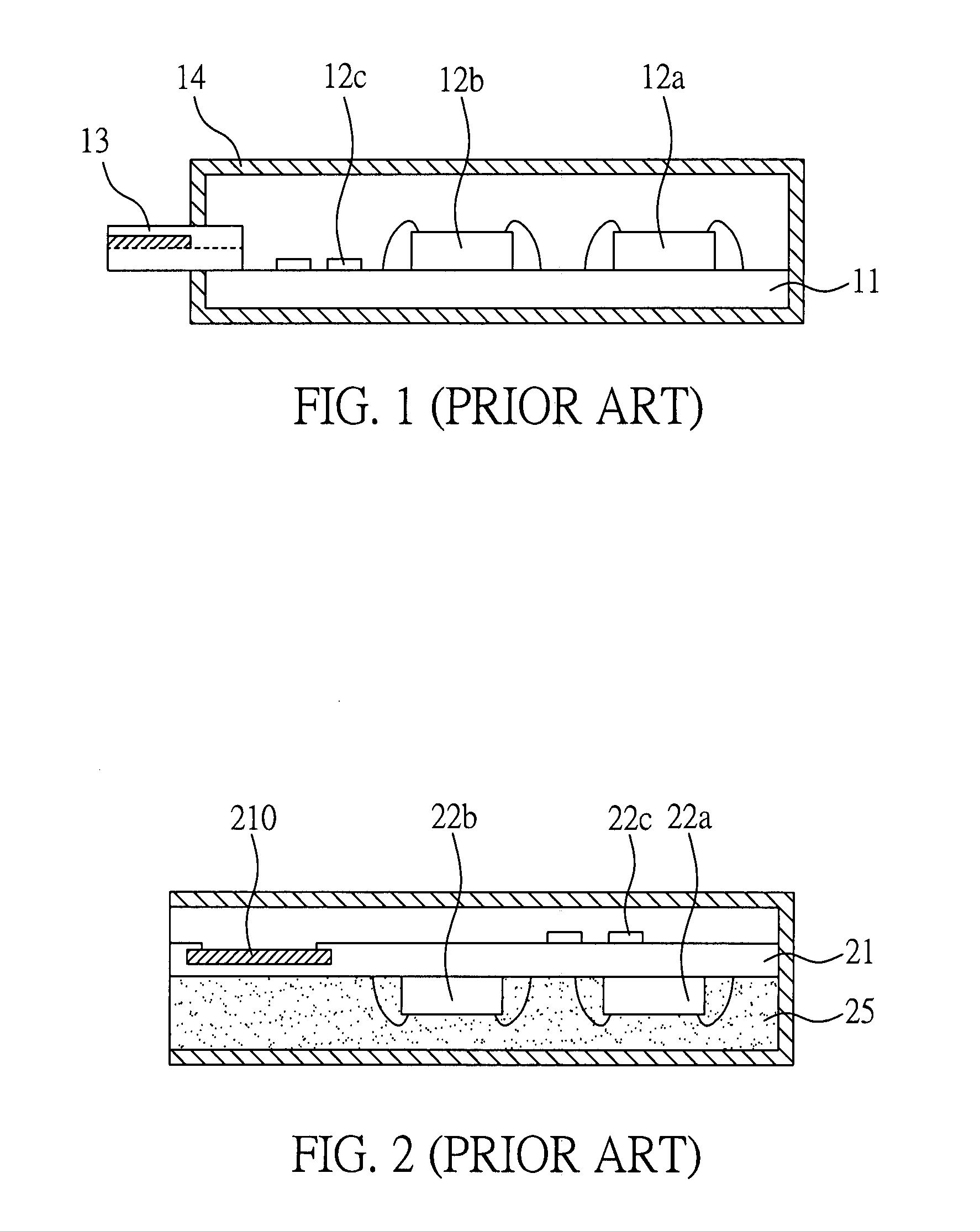

Semiconductor package and method of making the same

InactiveUS20080009153A1Minimized in sizeAvoid problemsElectrically conductive connectionsSemiconductor/solid-state device detailsSemiconductor packageElectrical connection

A semiconductor package and its fabrication method are disclosed. The fabrication method has the steps of: providing at least a lead frame having a plurality of terminal leads formed with flat portions and contacting portions, providing at least a circuit board having a plurality of electrical connection pads, mounting the contacting portions on and electrically connecting to the electrical connection pads, attaching and electrically connecting electronic elements to the circuit board, forming an encapsulant for encapsulating the lead frames and the electronic elements but uncovering the flat portions of the terminal leads, and cutting around the circuit board along a cutting path that crosses through each of the terminal leads so as to allow each of the terminal leads to be electrically independent, wherein the terminal leads are employed to act as the electrical terminals of USB memory cards for storing or retrieving data.

Owner:SILICONWARE PRECISION IND CO LTD

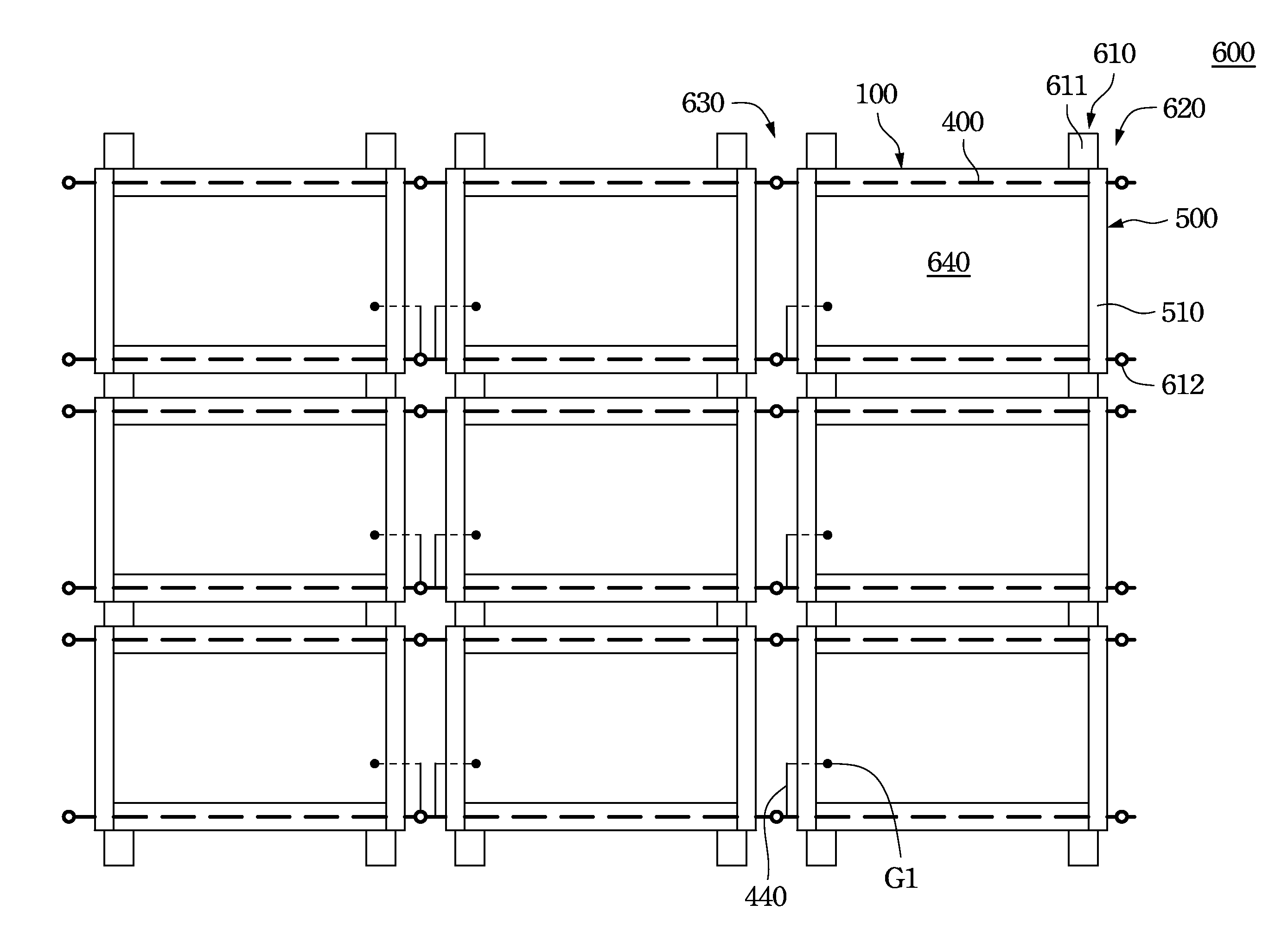

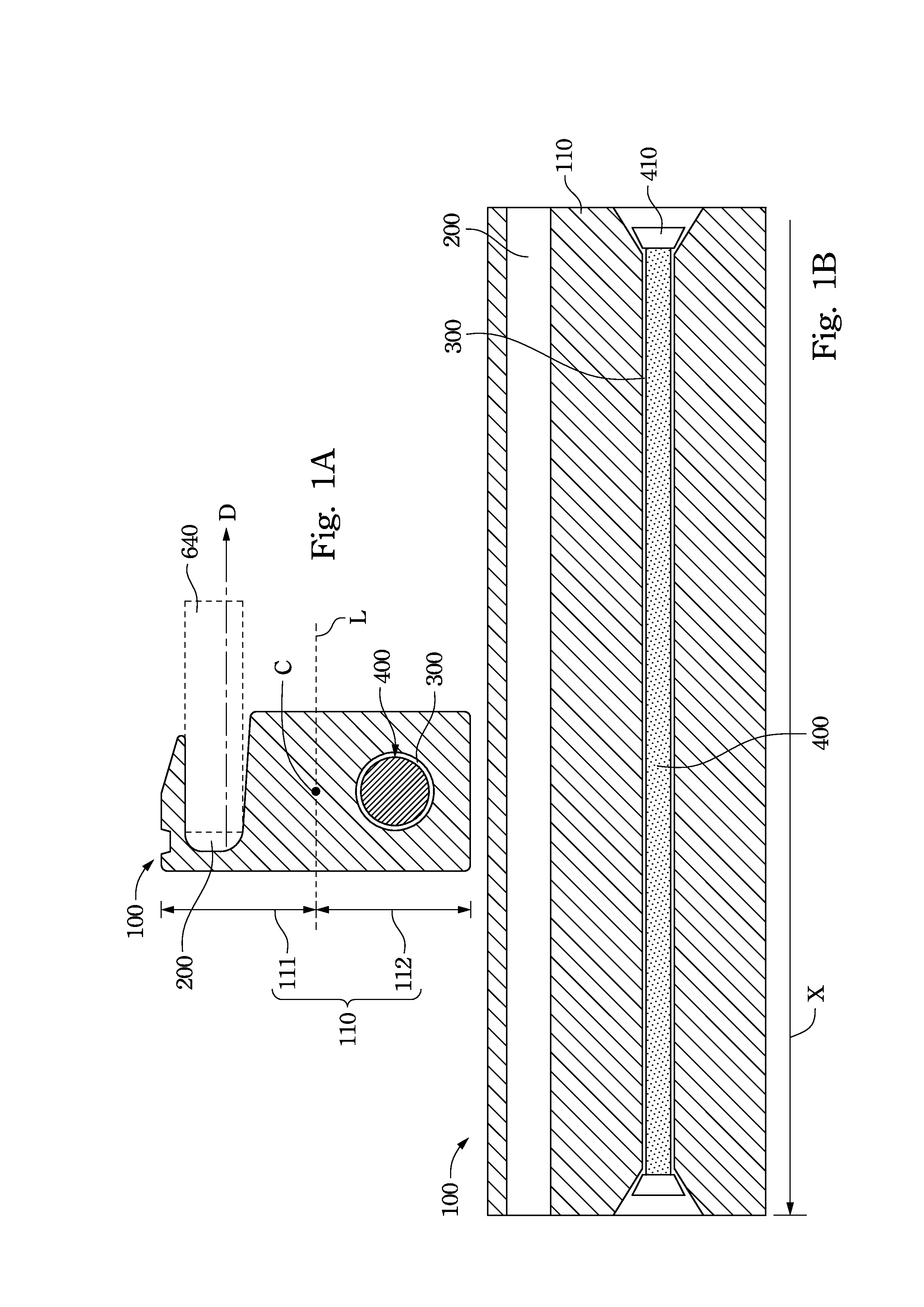

Photovoltaic array system, photovoltaic device thereof, and frame element of photovoltaic device thereof

ActiveUS20130174891A1Easy be bentAvoid deformationSolar heating energySolar heat devicesEngineeringPhotovoltaics

The disclosure provides a photovoltaic array system, a photovoltaic device of the photovoltaic array system, and a frame element of the photovoltaic device of the photovoltaic array system. The frame element includes a groove, a receiving hole and a metal wire. The groove extends along a longitudinal axial direction of the frame element for holding one lateral side of a photovoltaic panel. The receiving hole extends along the longitudinal axial direction for receiving the metal wire therein, and is parallel to the longitudinal axial direction.

Owner:AU OPTRONICS CORP

High-speed automatic dispensing device with replaceable dispensing head and dispensing station

ActiveUS8697012B2Waste of materialContinuous operationAnalysis using chemical indicatorsWithdrawing sample devicesProduction ratePipette

Owner:MUSASHI ENG INC

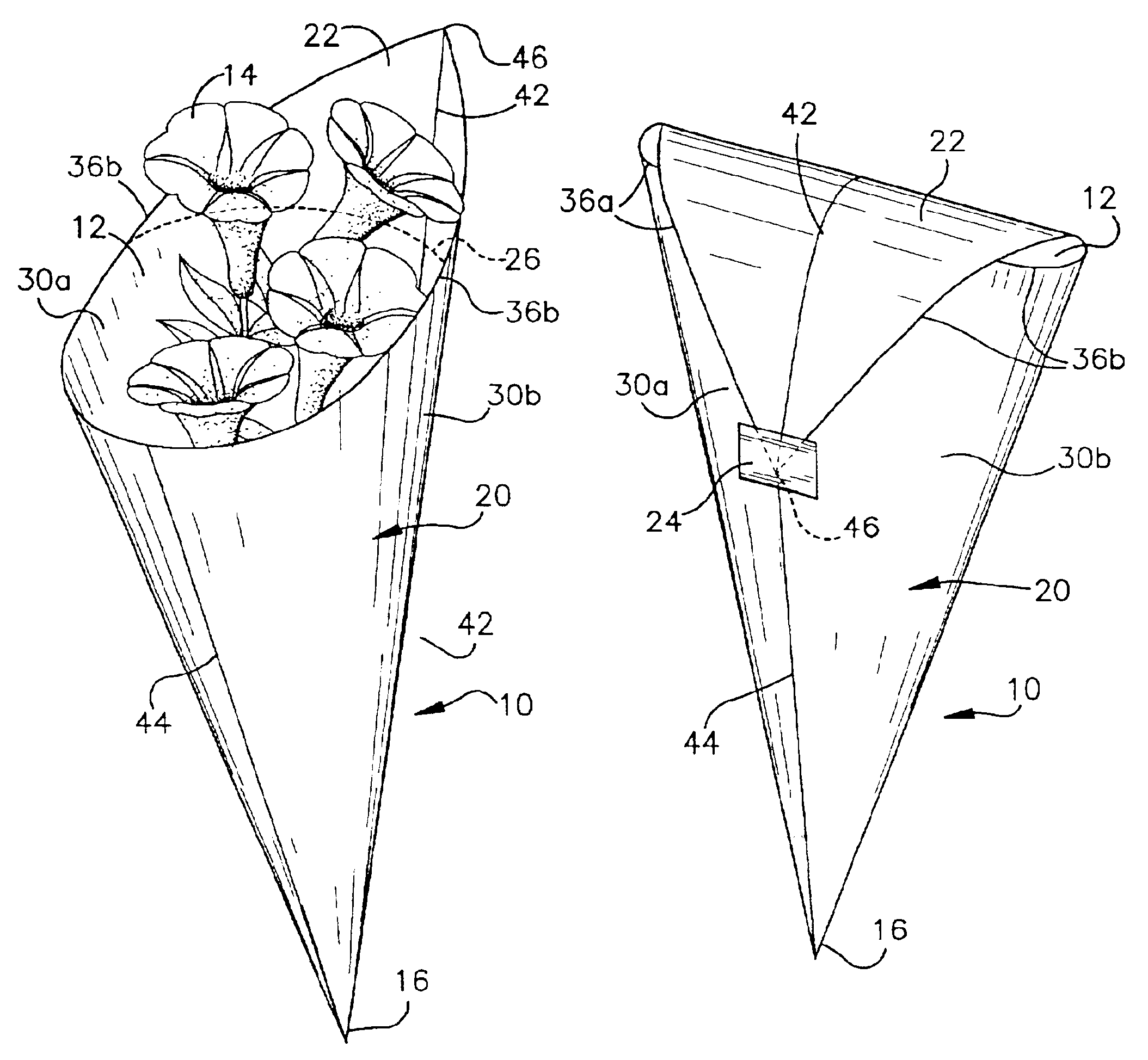

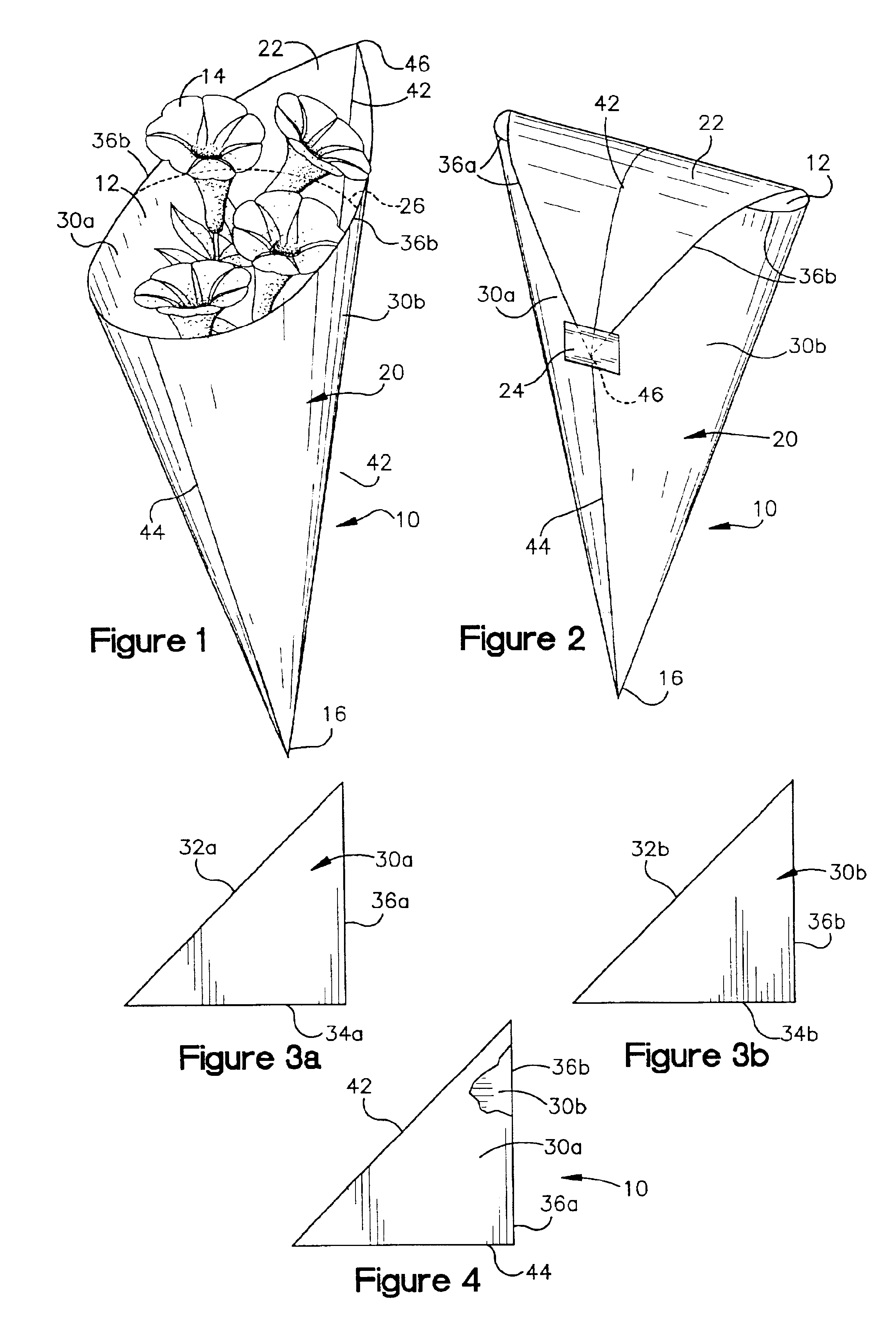

Bouquet container

InactiveUS6944988B2Easy accessSufficient dimensionLiving organism packagingFloral handlingRight triangleEngineering

A plant container including a receptacle having a top opening for insertion of a plant therein and a top flap for selective folding over the top opening to cover the receptacle. A stack of these containers may be compactly stored in a collapsed flat state and then individual containers expanded upon purchase of plant. The containers may be made from panels having a right triangular shape so that may be mass produced in such a manner that wasted web material is minimized.

Owner:PROFESSIONAL PACKAGE

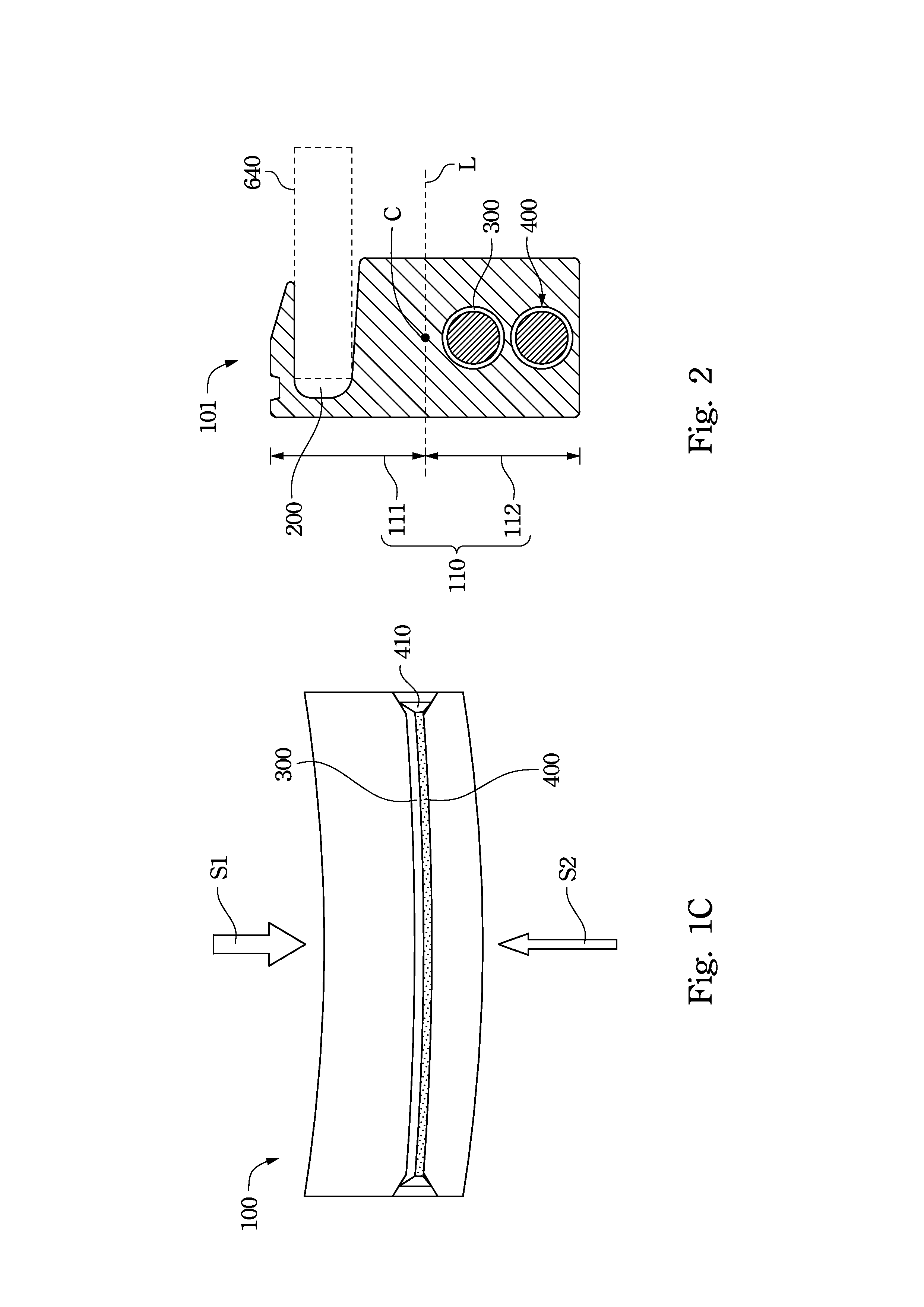

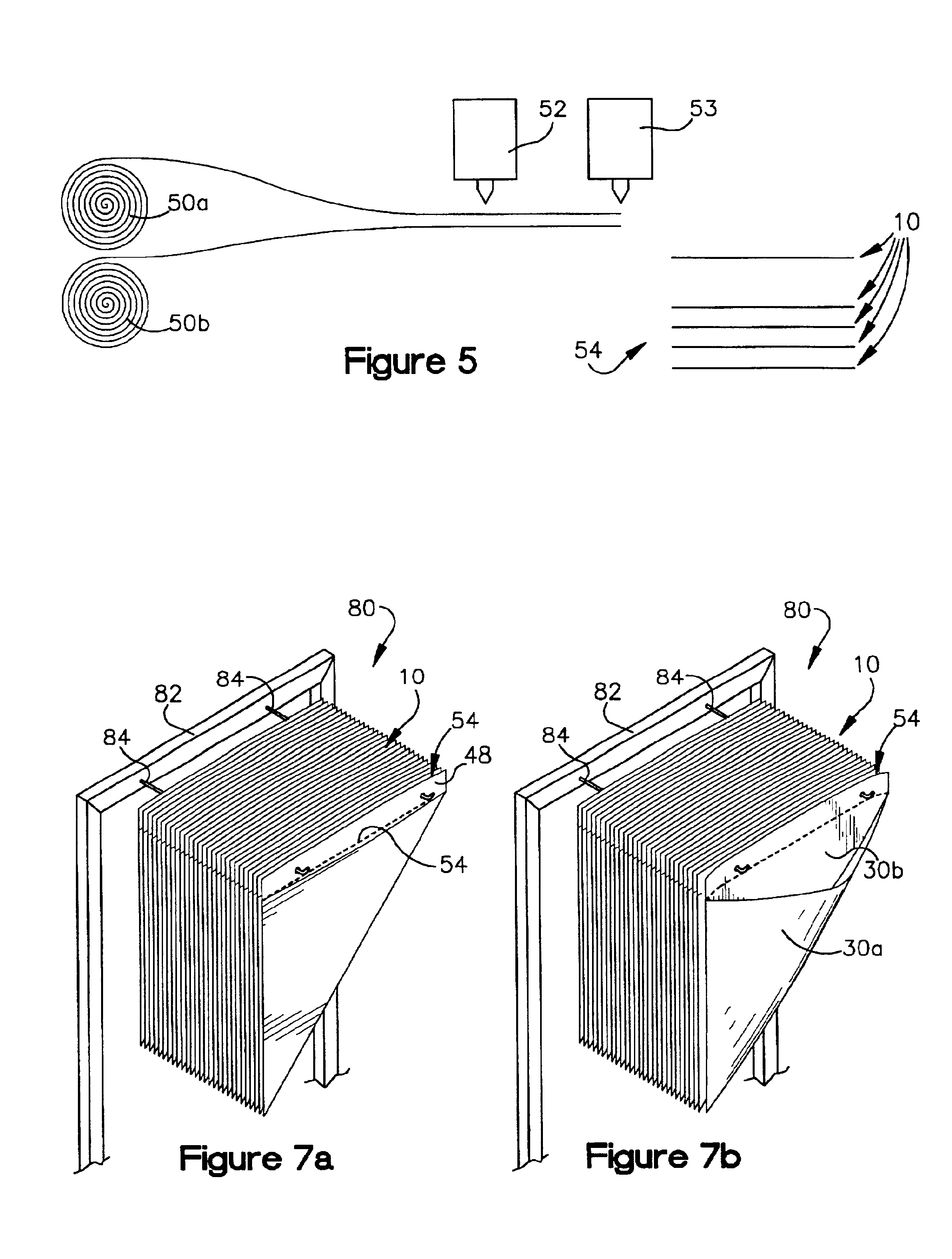

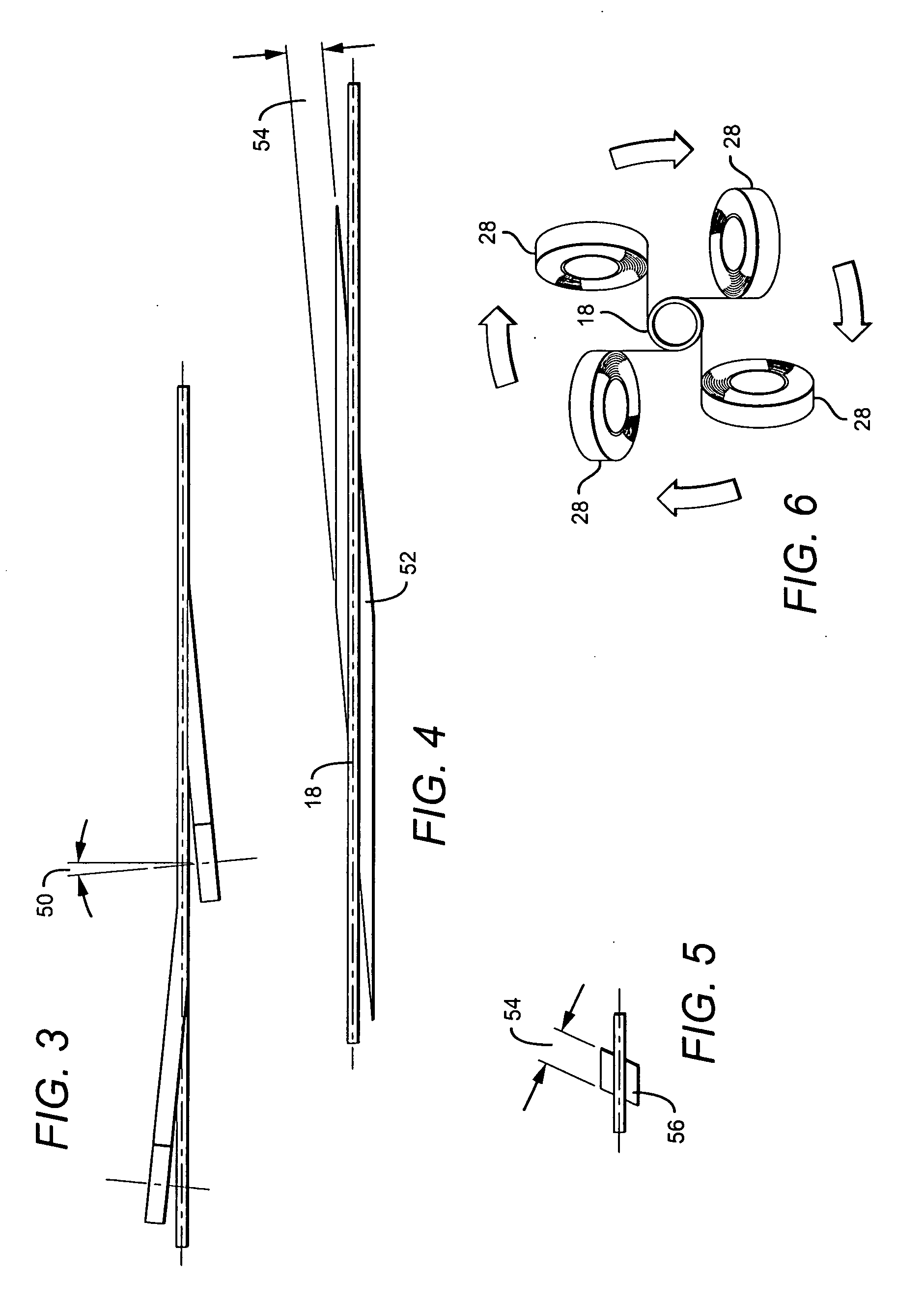

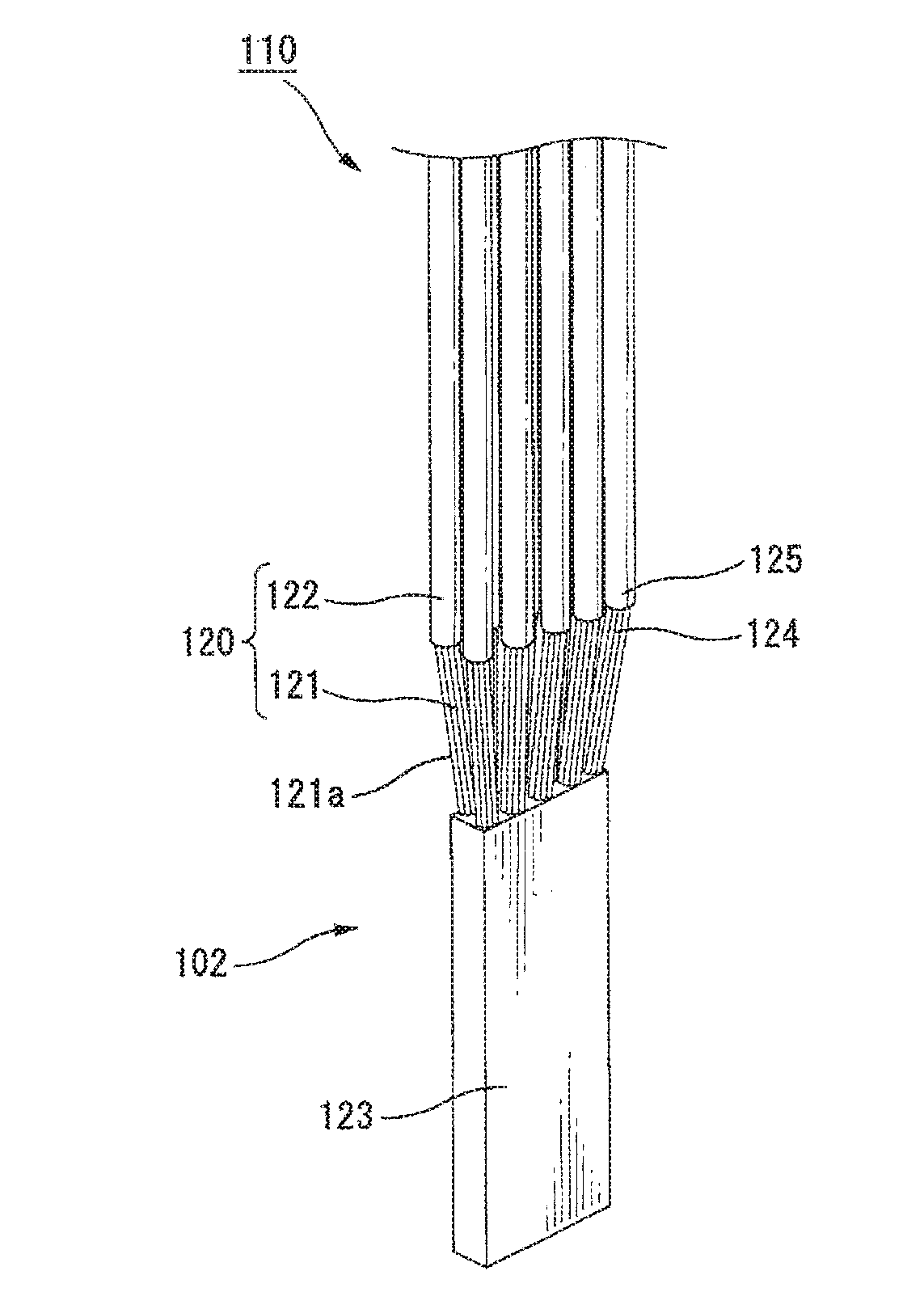

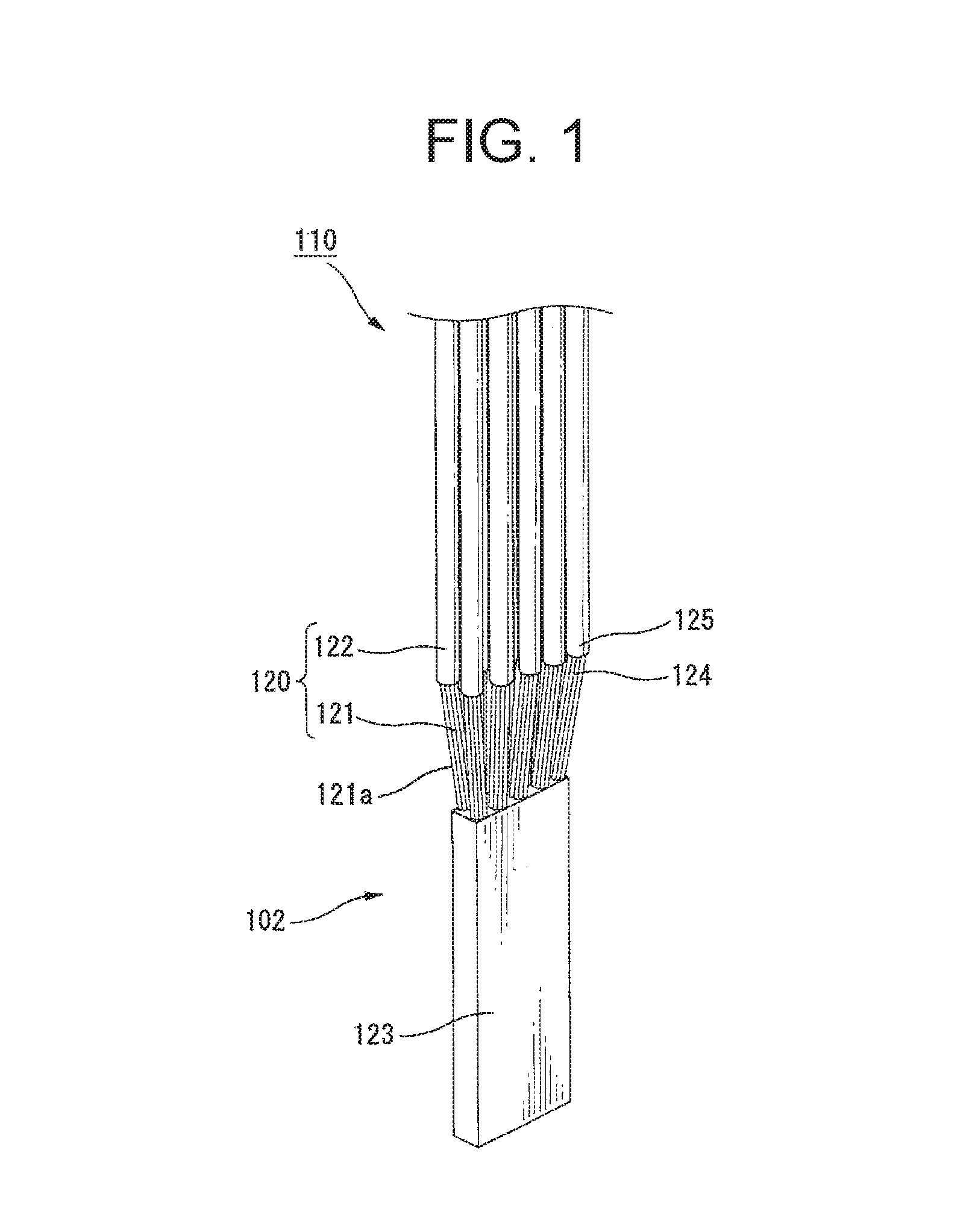

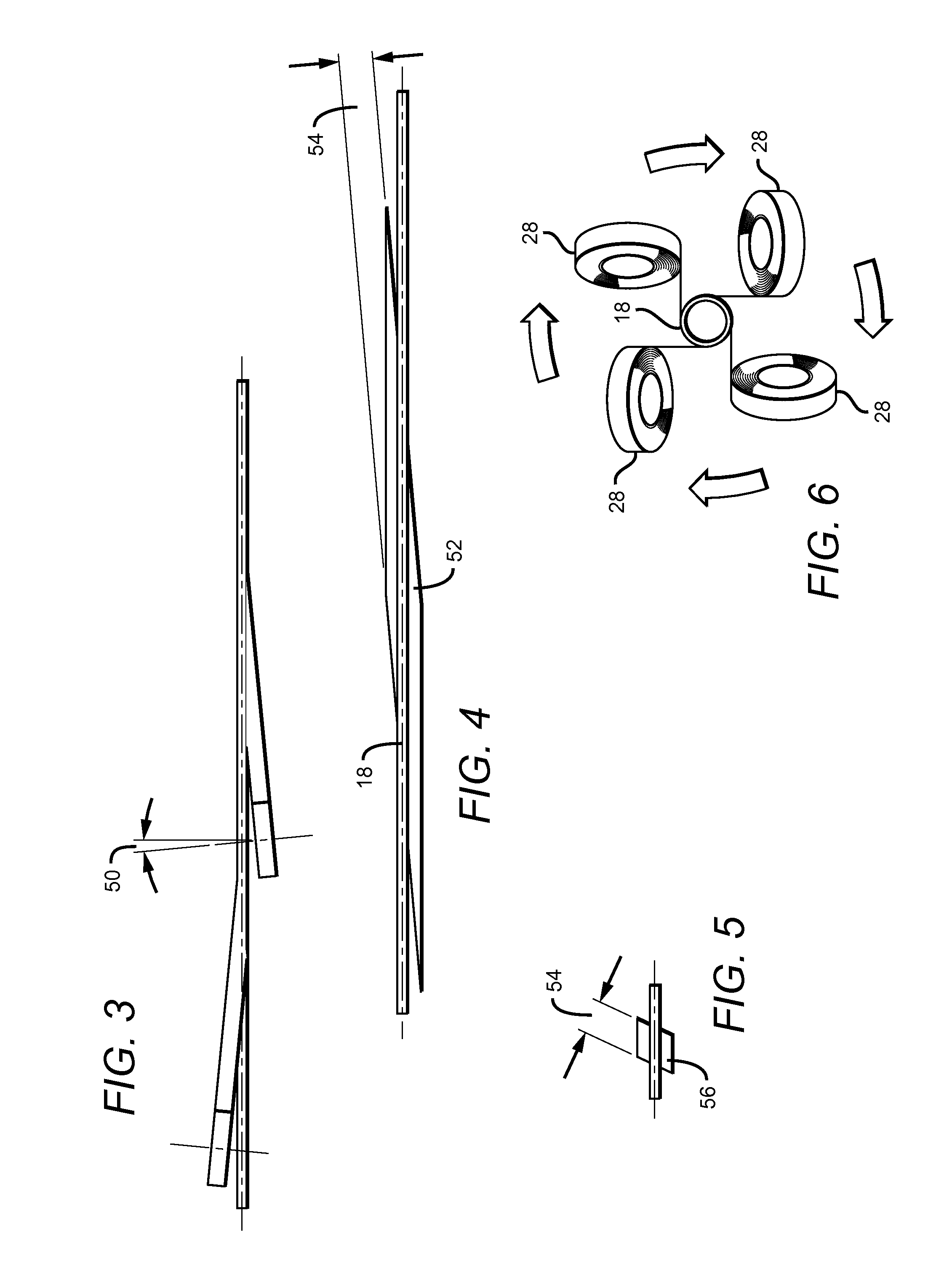

Method and apparatus for producing off-axis composite prepreg material

InactiveUS20070289700A1Simplifies lay-up machineryEfficiently and cheaply producesAdhesivesBand shapeFiber orientation

The invention is directed to a method and apparatus for preferably producing a two layer off-axis composite prepreg material in tape form that has fiber direction at angles such as plus or minus five degrees to the longitudinal direction of the backing paper. The use of such off-axis prepreg composite material tape is primarily for fabricating high length-to-width ration parts such as composite wing stringers or spars for aircraft.

Owner:THE BOEING CO

Free end band and seal

ActiveUS20060272133A1Avoid wasting materialReduce labor costsStaplesFlexible elementsClosed loopEngineering

A pre-cut and preformed free end band and seal of a predetermined length, and method of making and using the same is disclosed. The band is preformed with a substantially closed loop of band material to capture a seal to provide a preassembled band and seal wherein the seal is generally inhibited from being dislodged during packing, shipment, handling and installation. The band and seal are also formed in a manner to facilitate relative positioning of the band and seal as well as placement of a crimping tool relative to the band and seal for optimized crimping of the band and seal.

Owner:BAND IT IDEX

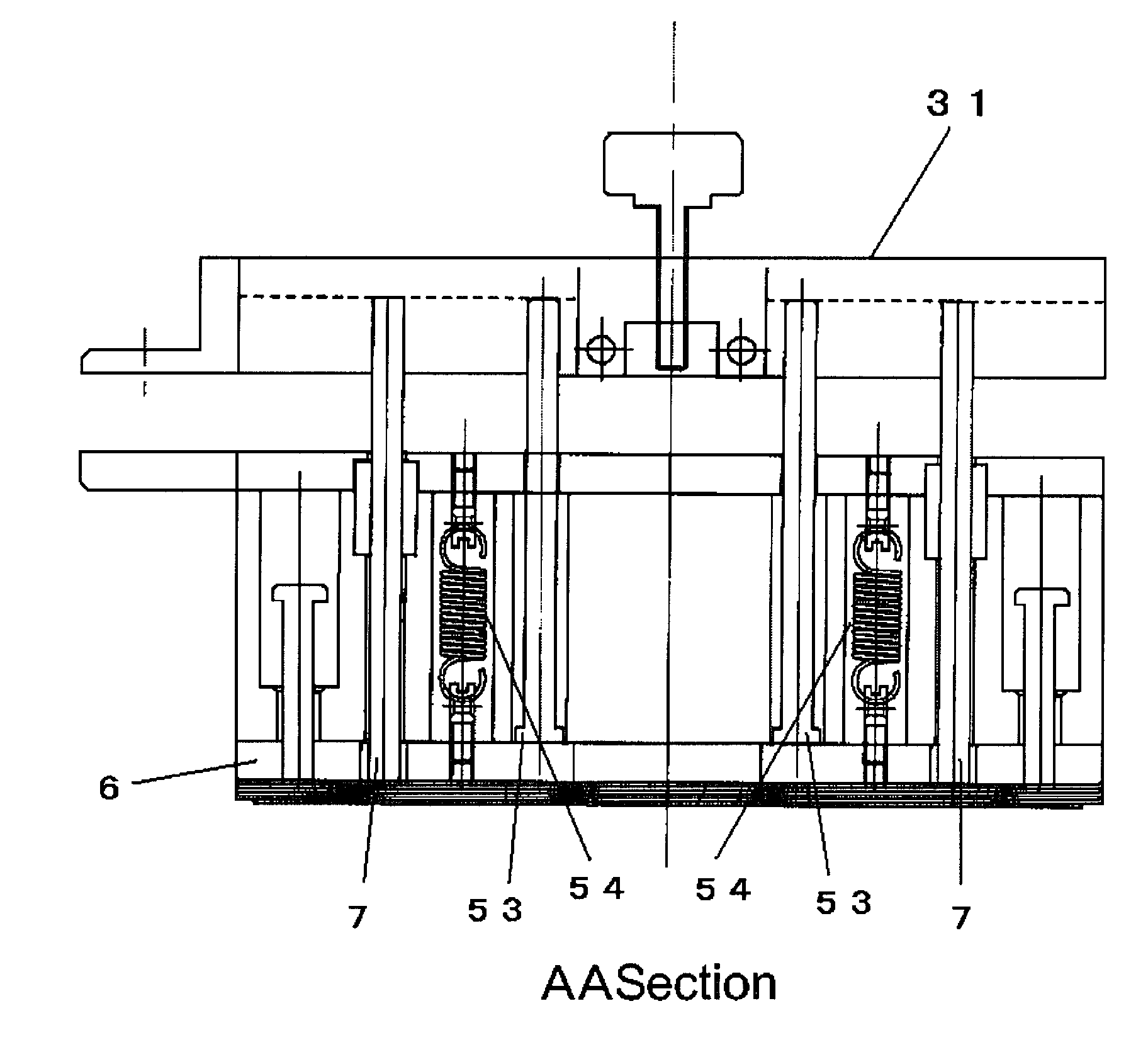

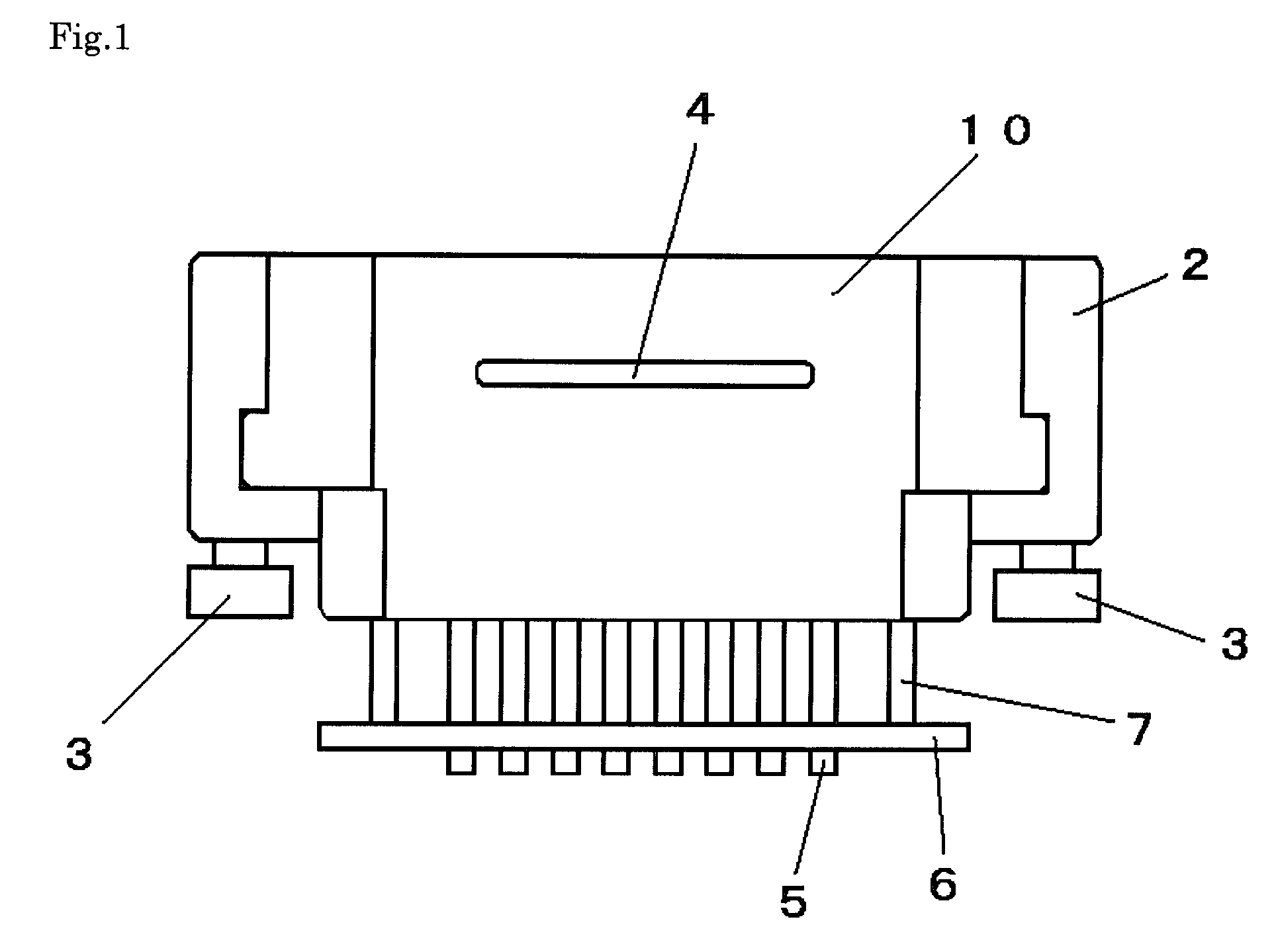

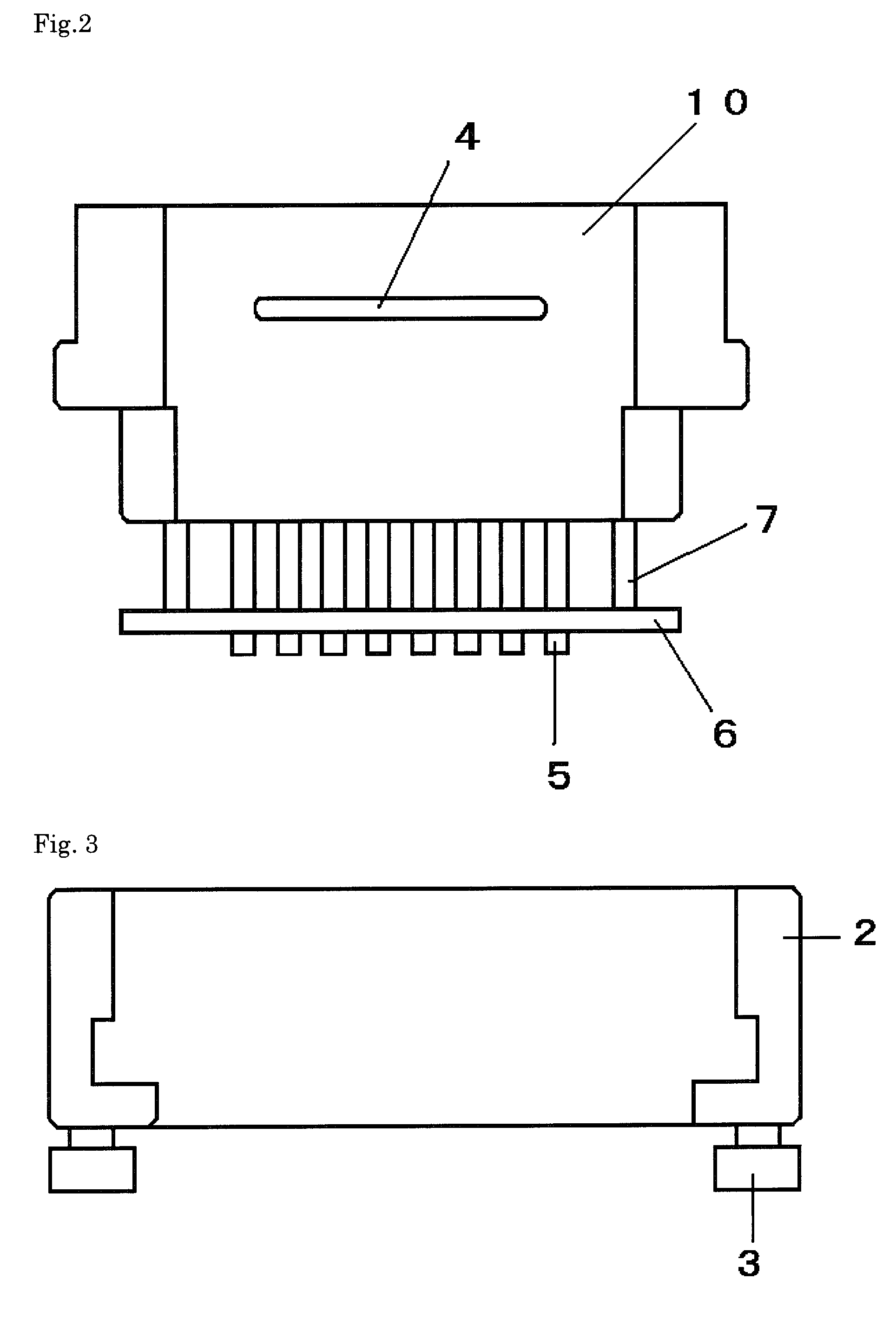

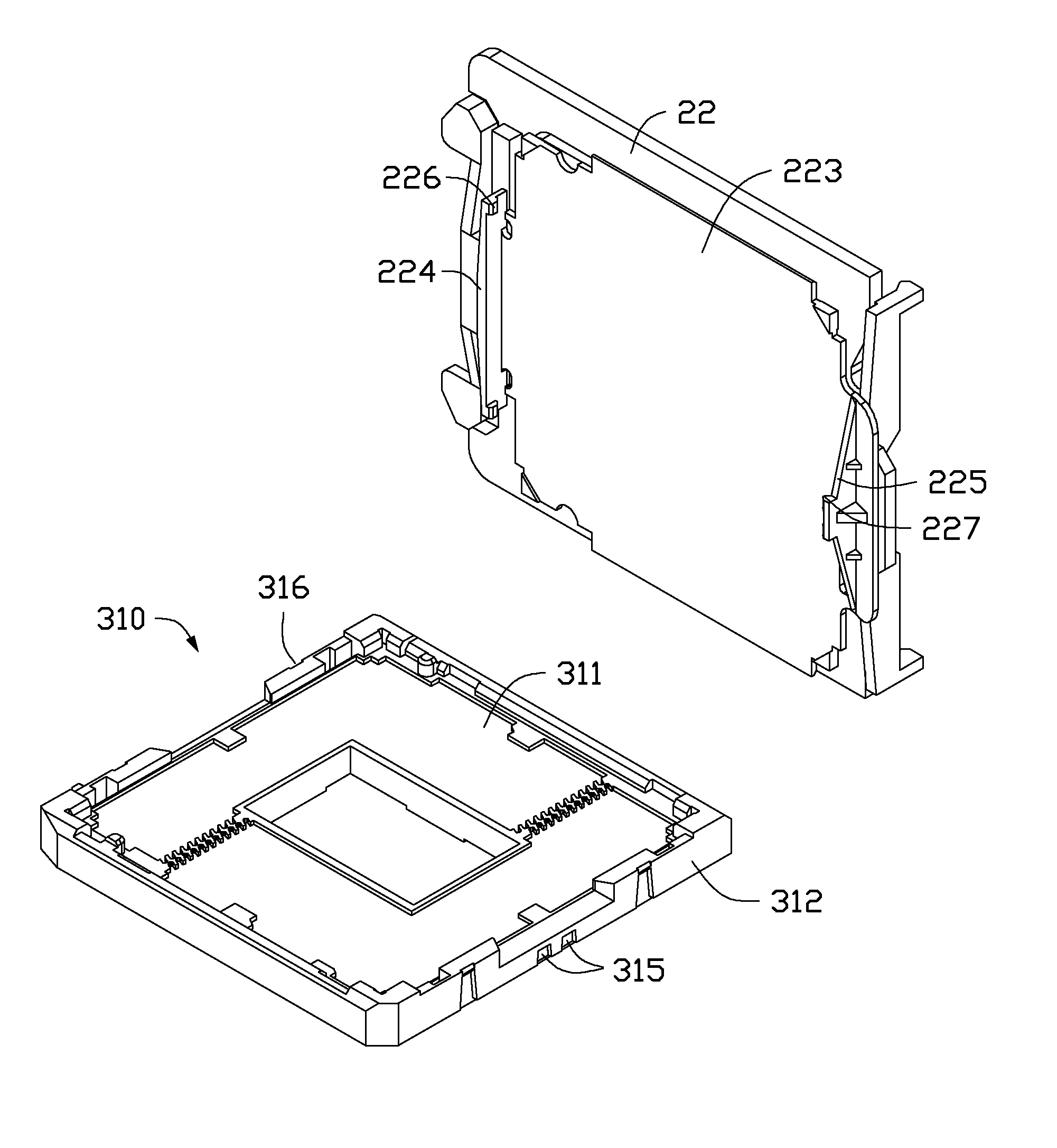

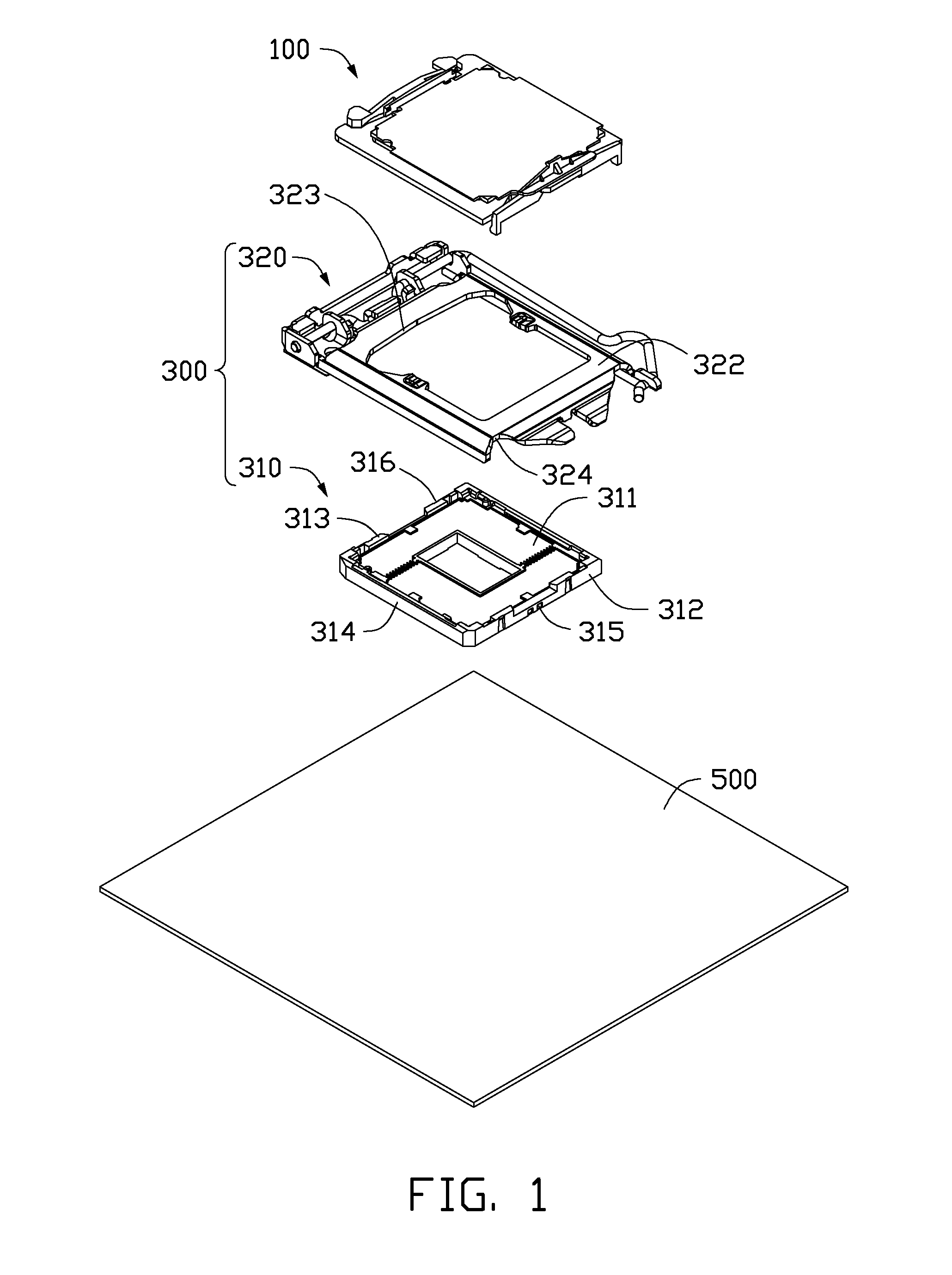

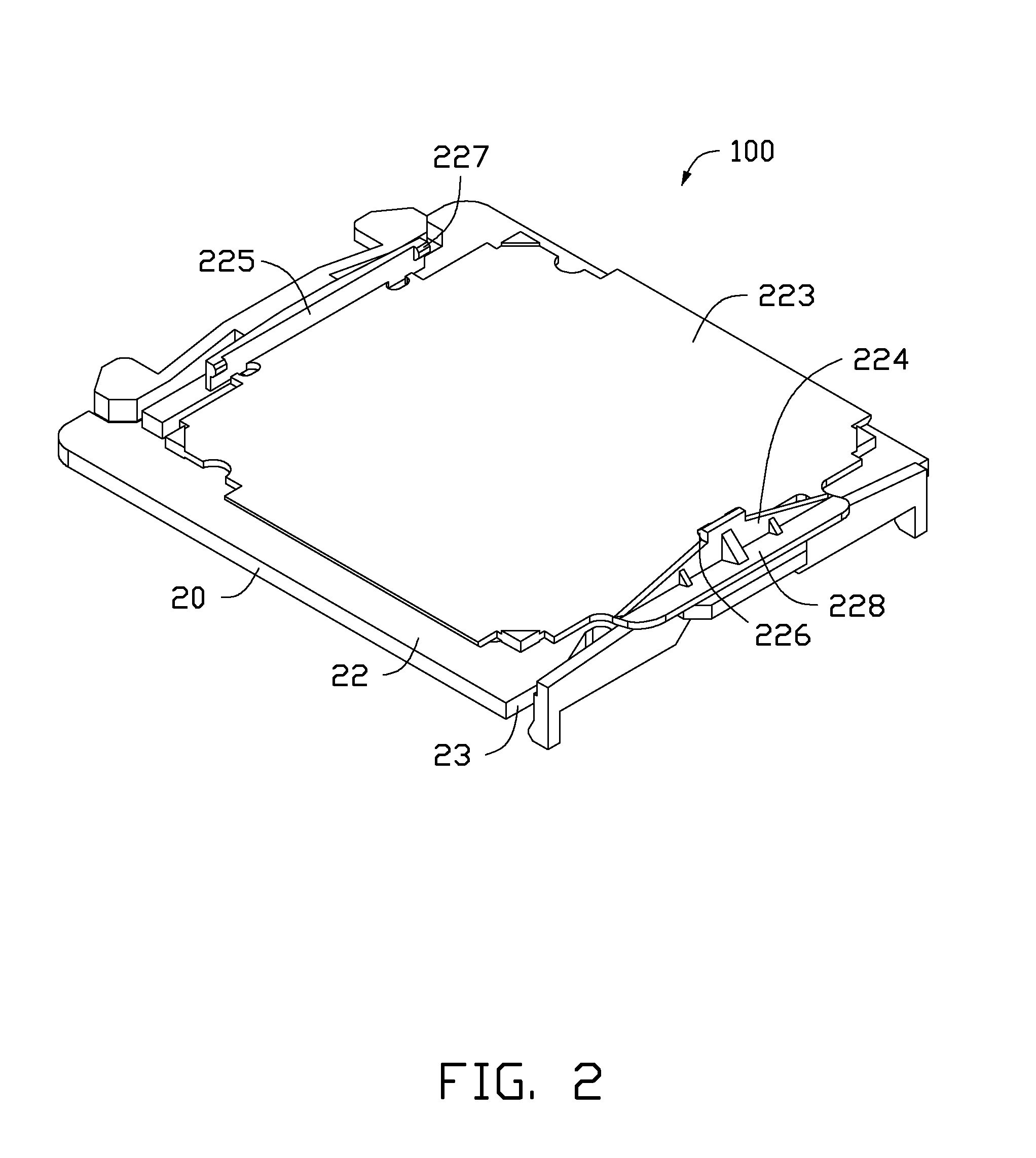

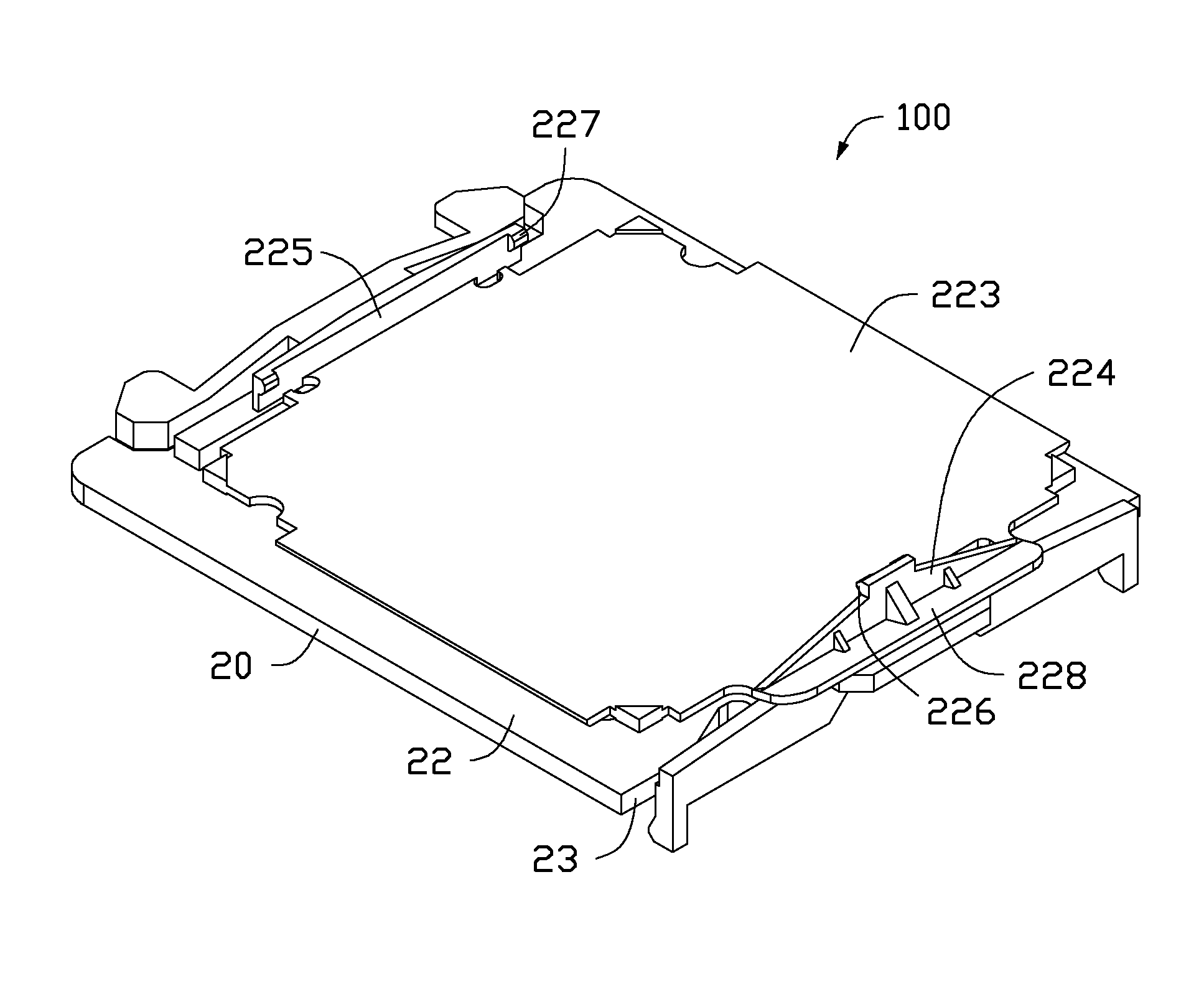

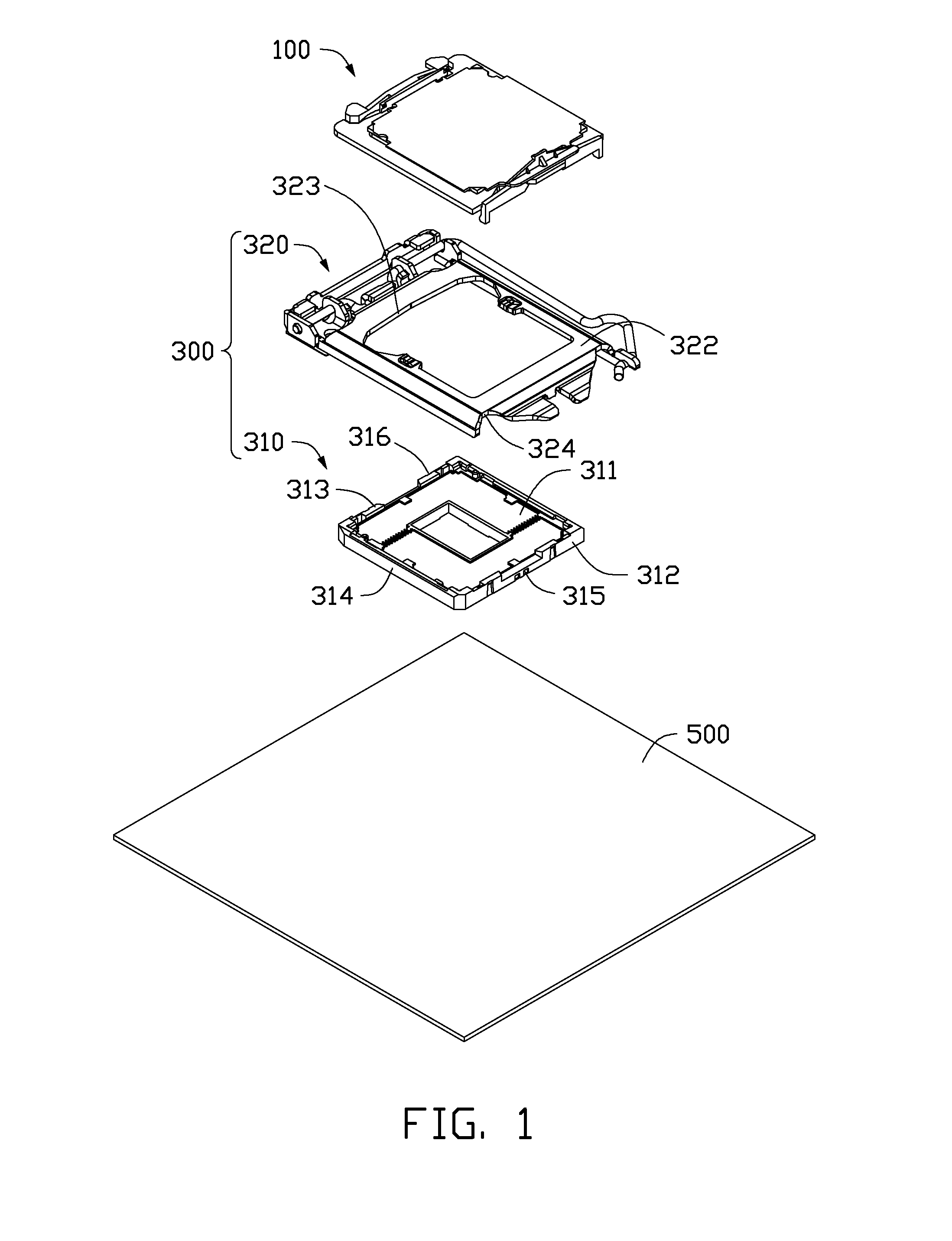

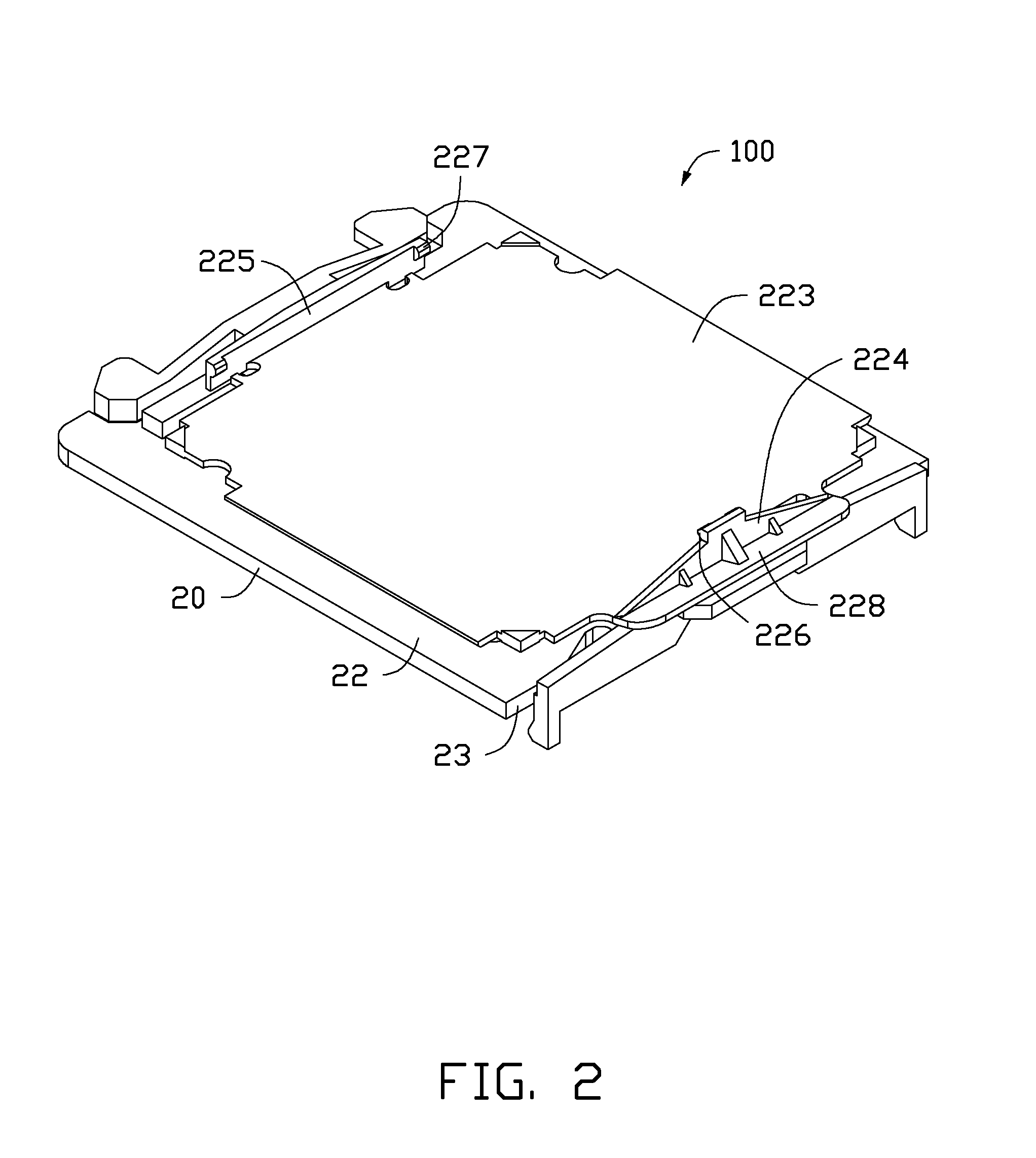

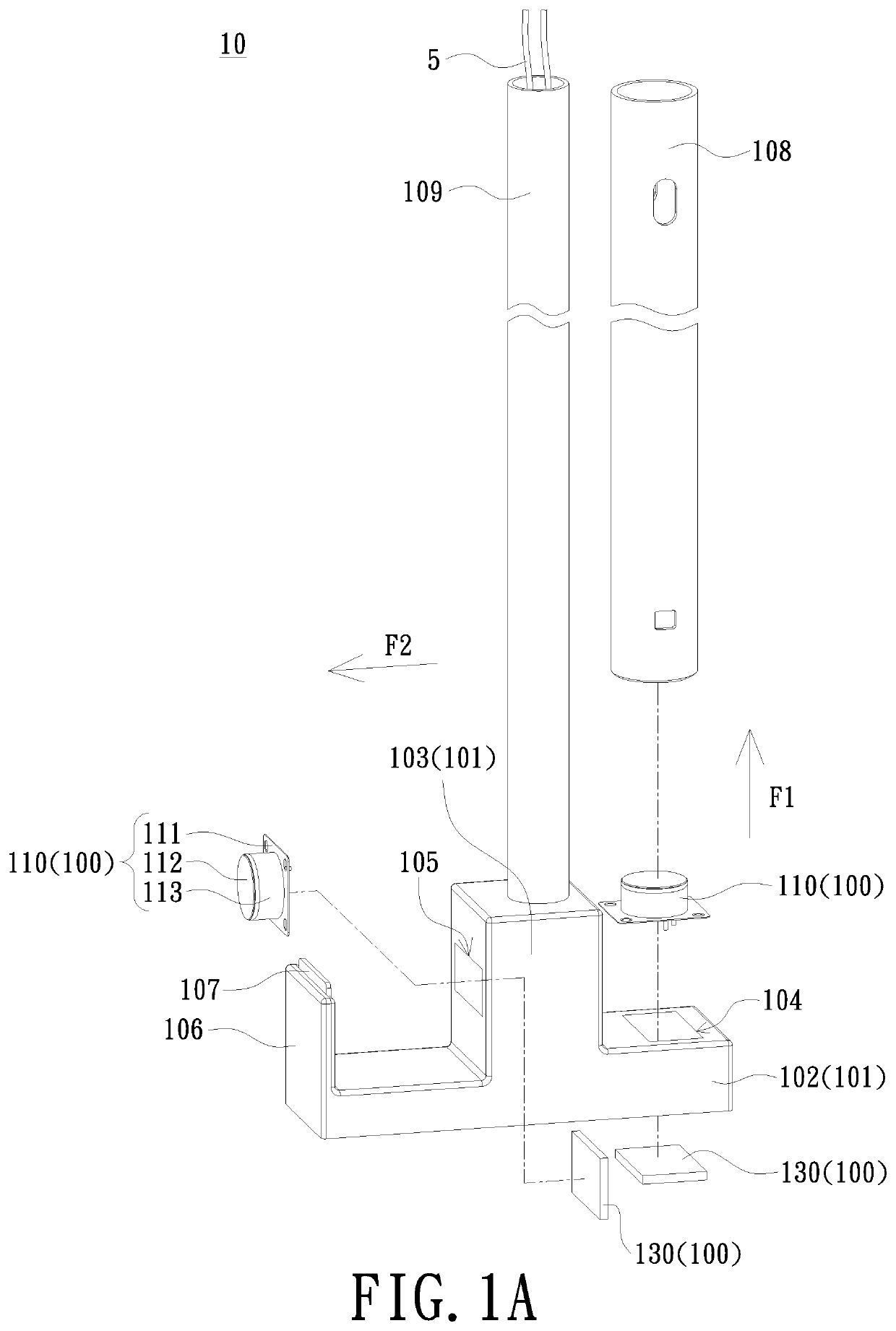

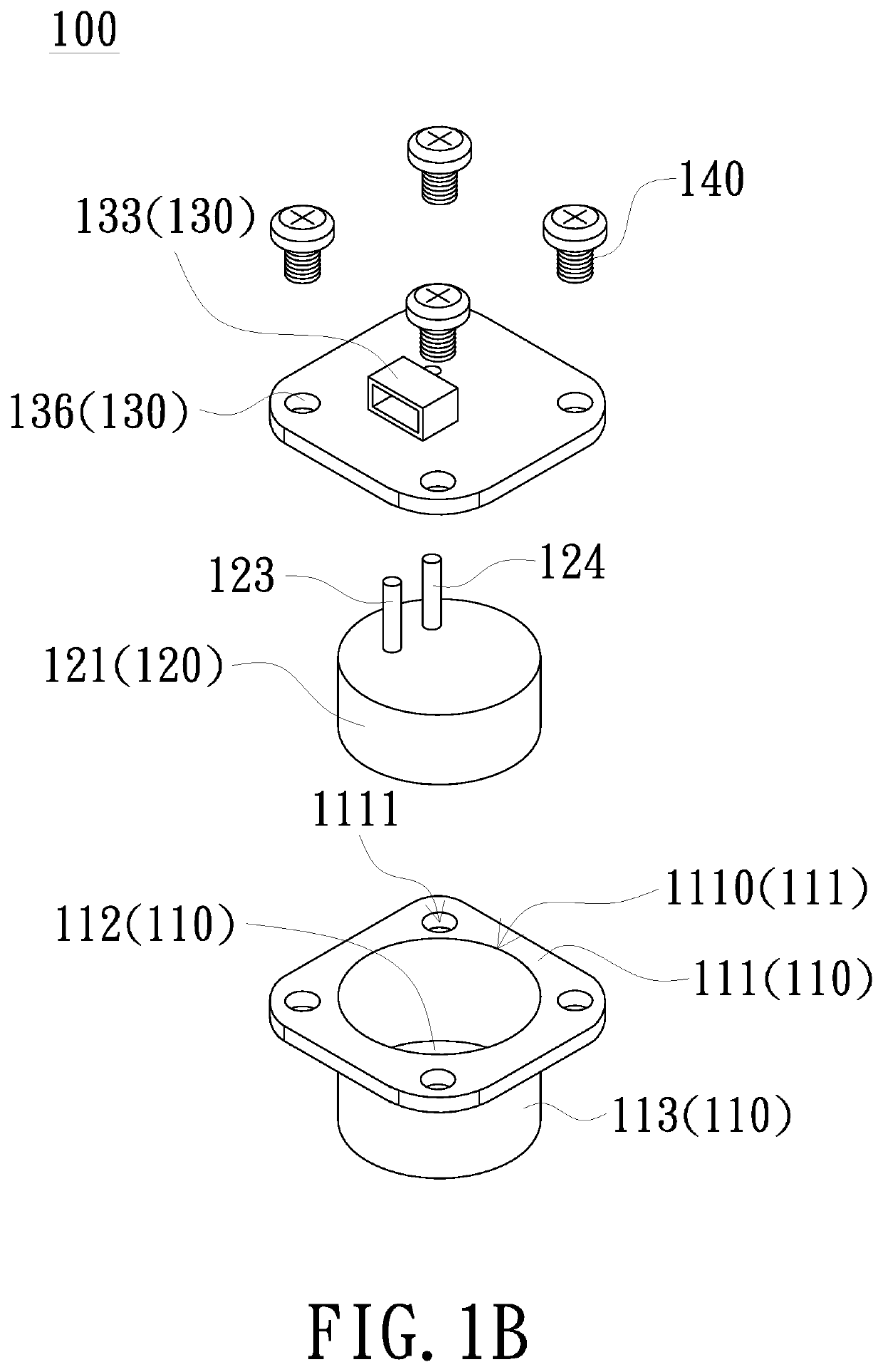

Central processing unit socket assembly

InactiveUS8939776B2Waste of materialComponent plug-in assemblagesPrinted circuitsEngineeringMechanical engineering

A central processing unit socket assembly includes a socket mounted on a circuit board, a locking apparatus, and a cover. The cover includes a main plate, a resilient first locking portion formed on a first end of a first surface of the main plate, a second locking portion formed on a second end of the first surface of the main plate opposite to the first locking portion, and a number of connecting pins protruding out from a second surface of the main plate opposite to the first surface of the main plate. The first and second locking portion of the first surface of the cover can be detachably latched to the socket. The connecting pins can be connected on the locking apparatus.

Owner:SCIENBIZIP CONSULTINGSHENZHENCO

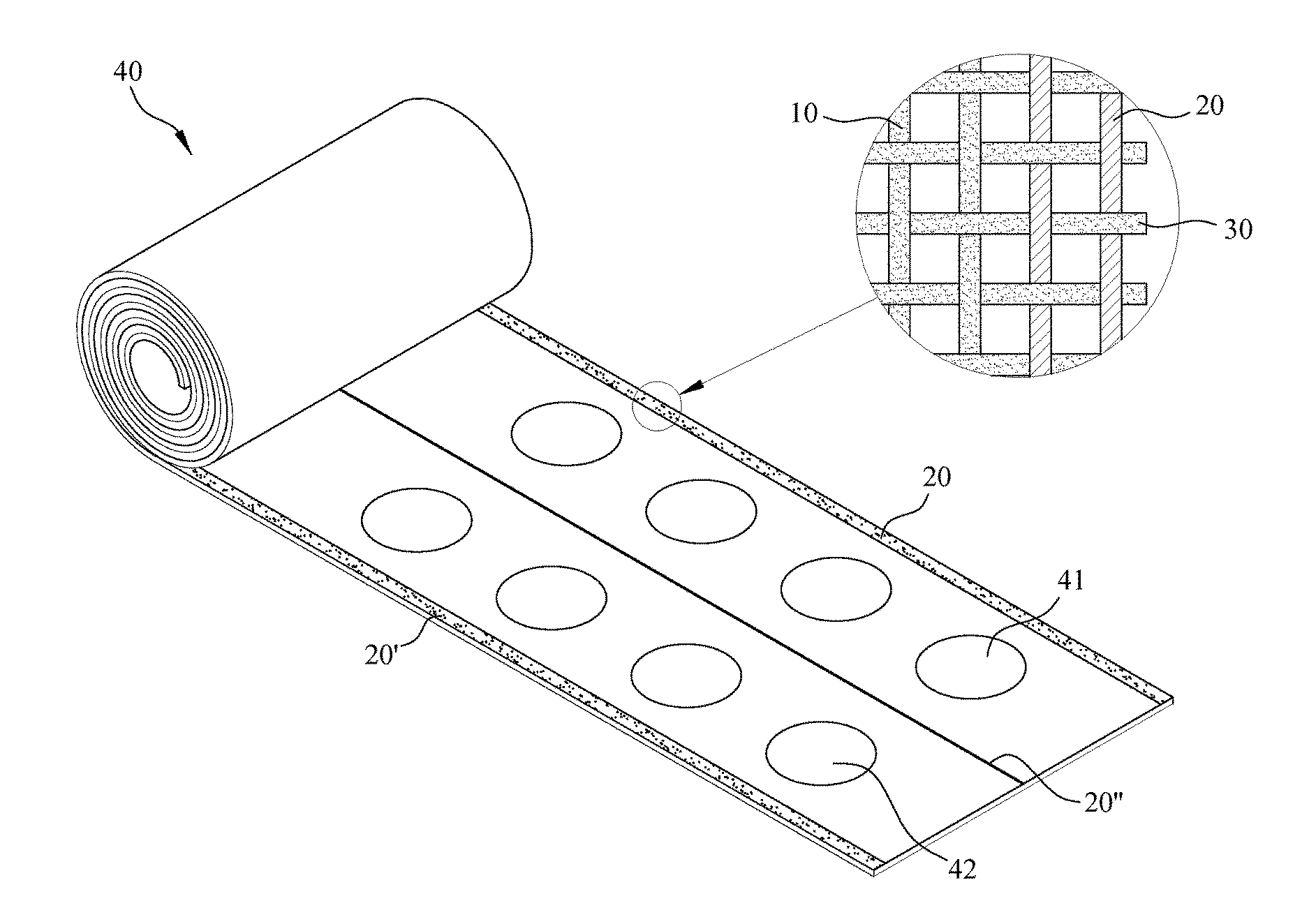

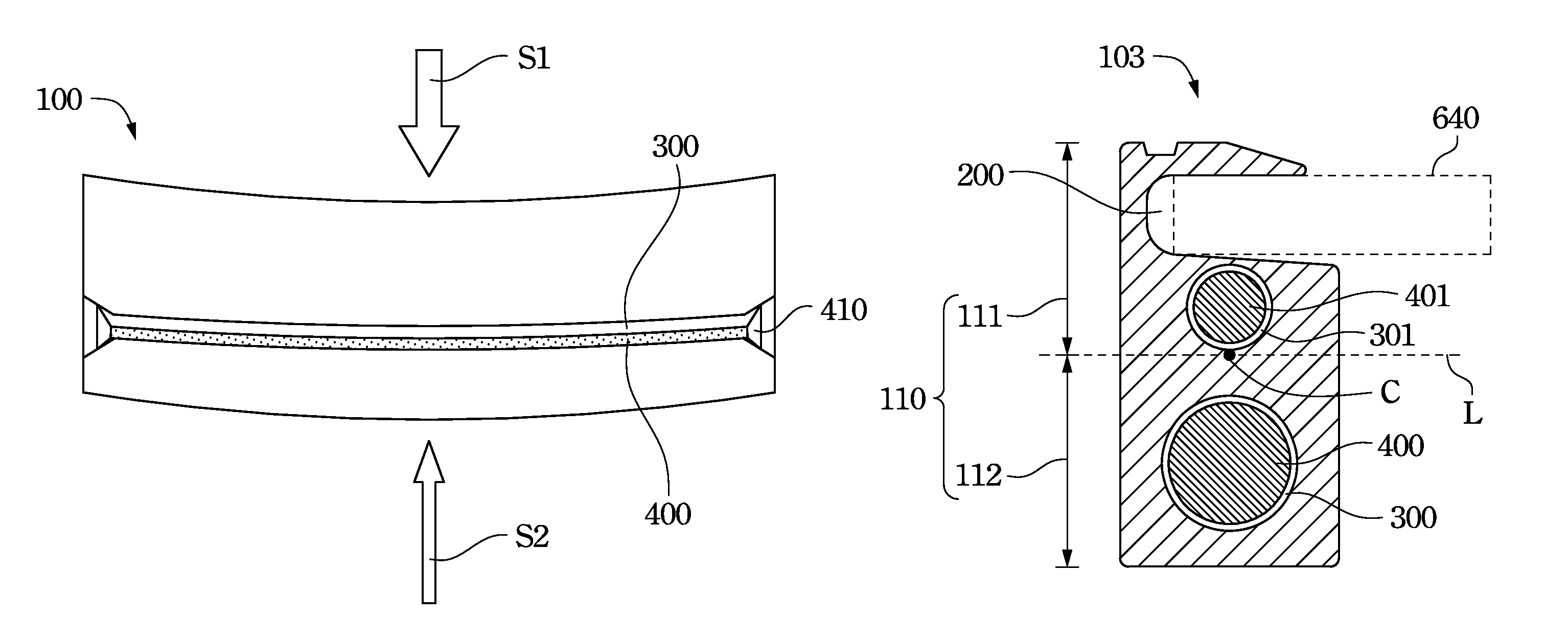

Speaker diaphragm fabric and manufacturing method thereof

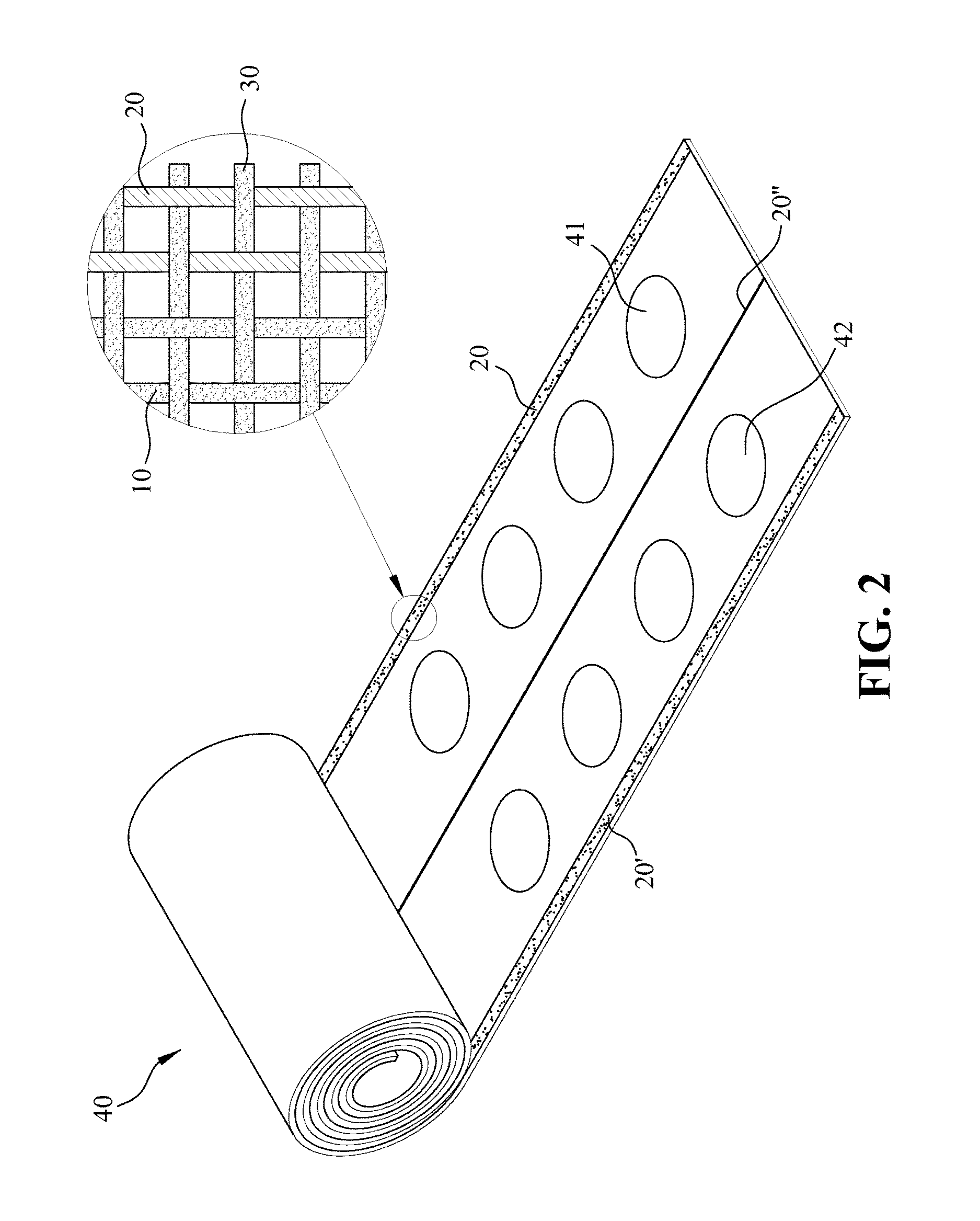

ActiveUS20170037547A1Reduce waste costsEasy to identifyFibre diaphragmsWoven fabricsEngineeringLoudspeaker

A method of manufacturing a speaker diaphragm fabric for a loudspeaker, includes: a preparation step, a plurality of first warps, at least one second warp and a plurality of wefts are prepared, wherein the second warp has characteristics different from the first warps; and a weaving step: the plurality of the first warps and the second warps are aligned and the wefts transversely cross and pass alternately over and under each of the first warps and the second warps in order to form the speaker diaphragm fabric having at least one formation region and a non-formation region exterior to the formation region. The second warps made from an inferior material are provided at the non-formation region, thereby reducing the waste cost and facilitating the differentiation of the formation region and the non-formation region.

Owner:OHARA HIROSHI

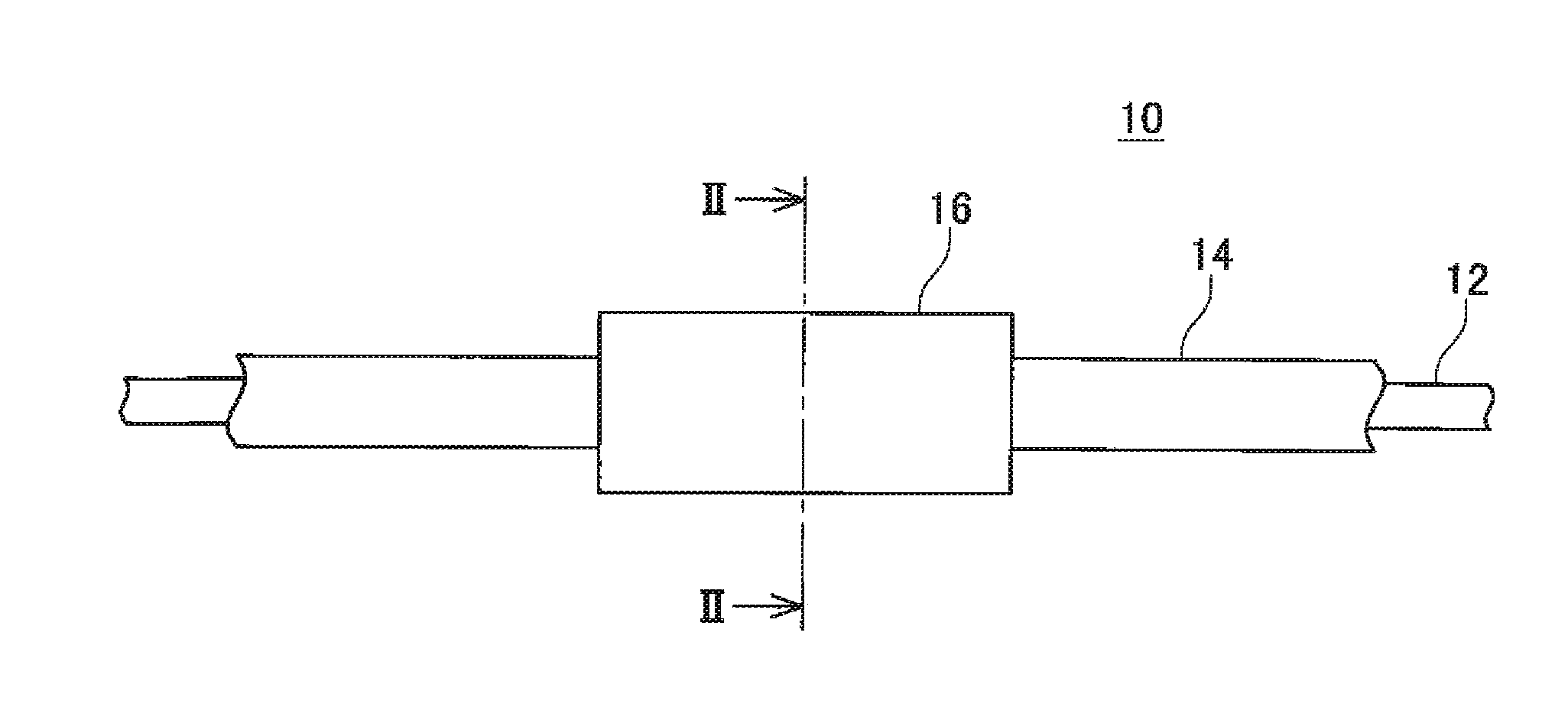

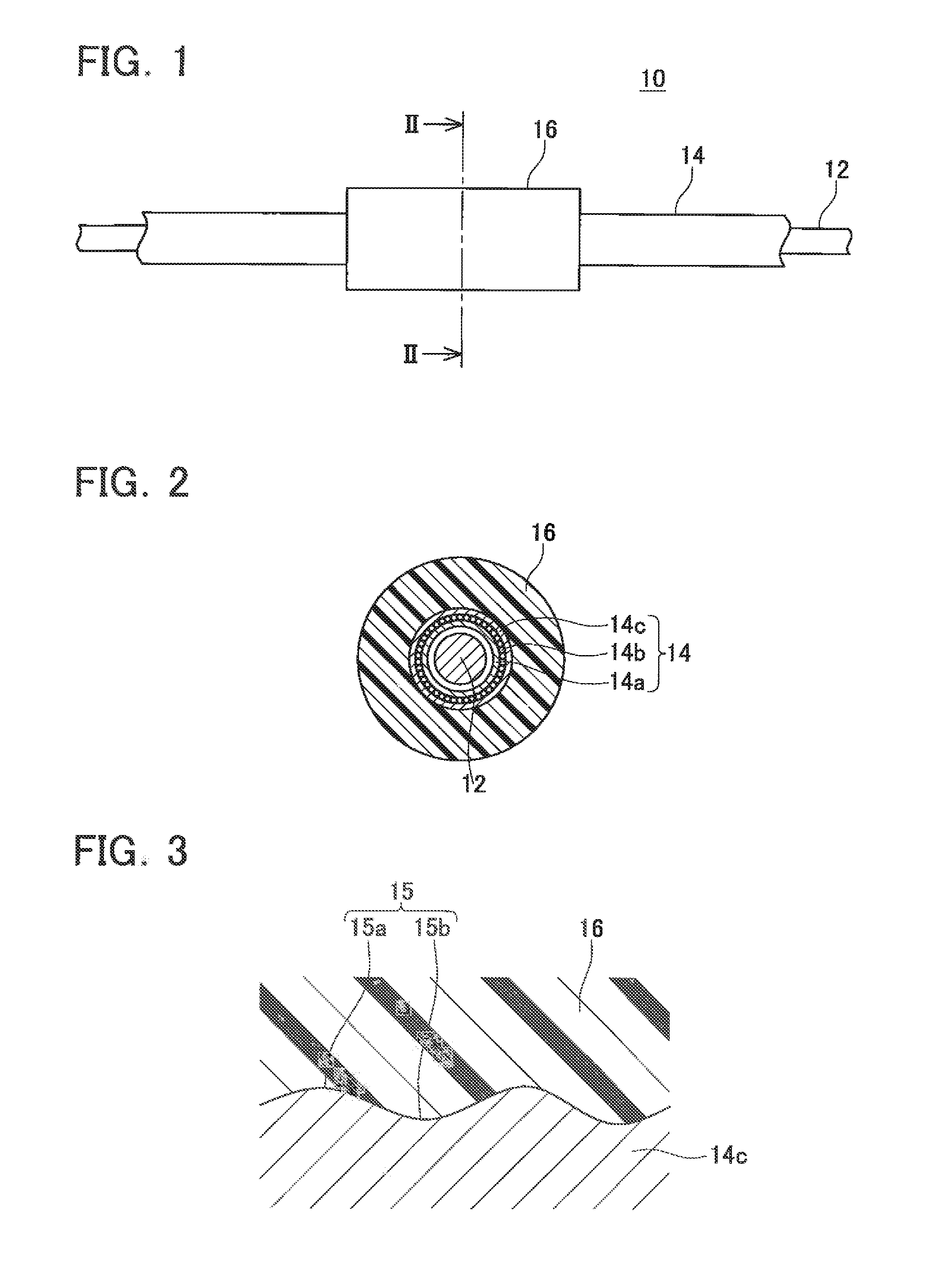

Method of manufacturing cable and method of manufacturing composite electric wire

InactiveUS20160203891A1Improve machinabilityEasy to operateLiquid surface applicatorsApparatus for heat treatmentMelt temperatureMelting temperature

To provide a method of manufacturing a cable when the cable is obtained by coating a core wire and a method of manufacturing a composite electric wire. To coat an outer circumferential side of a core wire or a plurality of bundled core wires with a coating portion made of an insulating polymeric material, first any exposure target region of the core wire is held below a melting temperature of the insulating polymeric material and a coating target region of the core wire positioned outside the exposure target region is heated to the melting temperature of a powder material (insulating polymeric material in a powder state). Then, the coating portion is formed by immersing the core wire of the coating target region having been heated in the powder material inside an immersion container to allow the insulating polymeric material to adhere to the core wire of the coating target region.

Owner:YAZAKI CORP

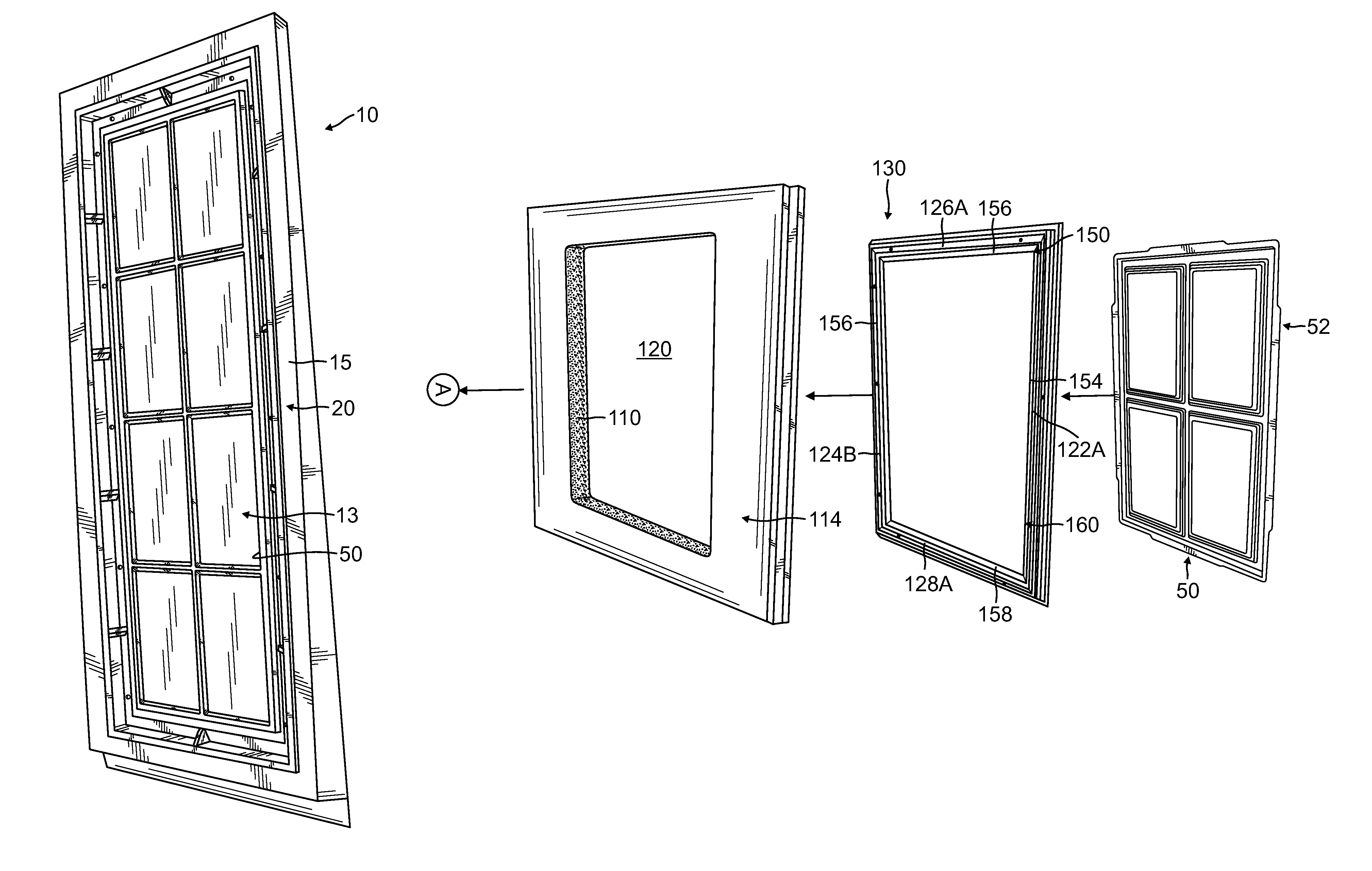

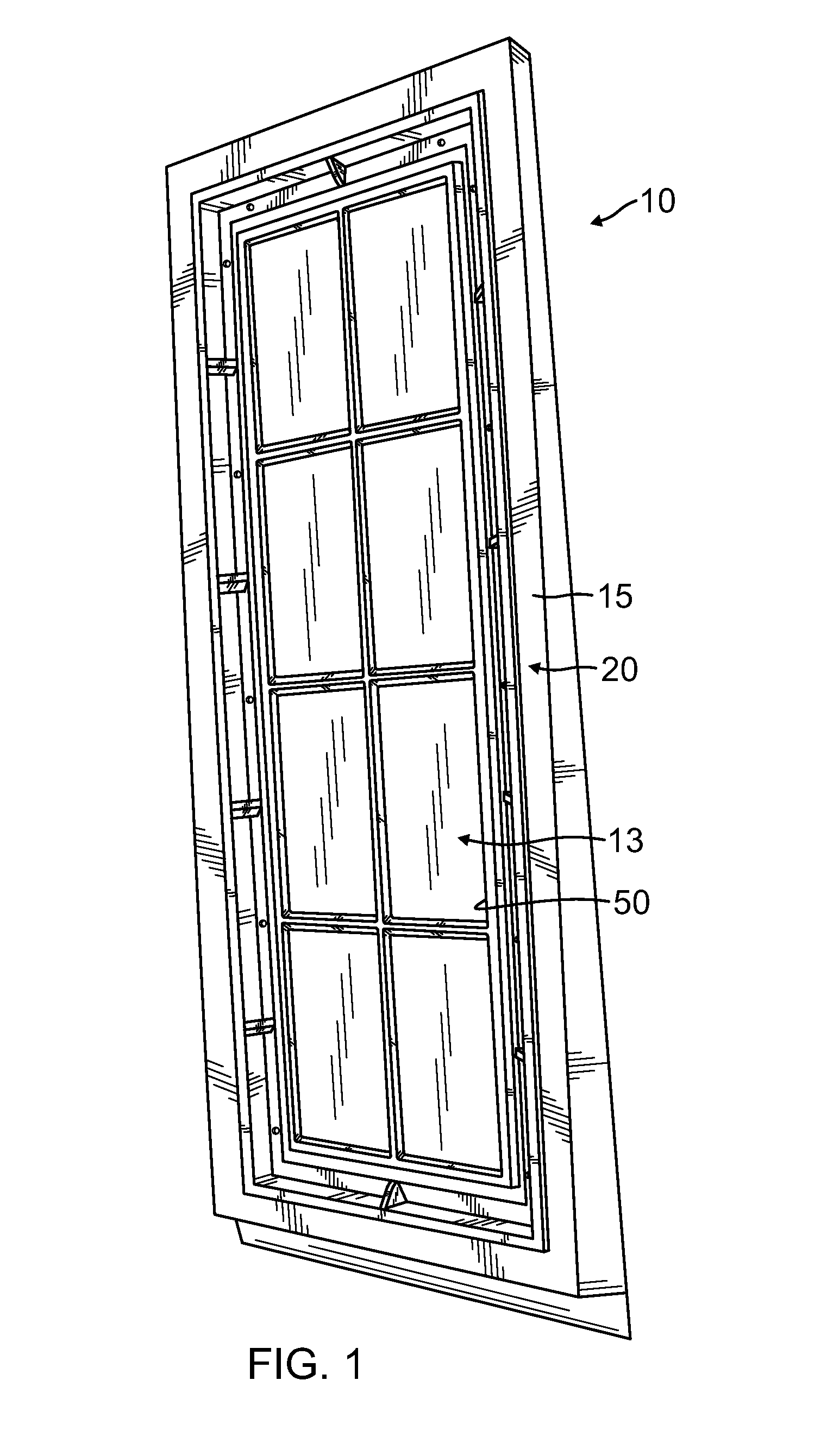

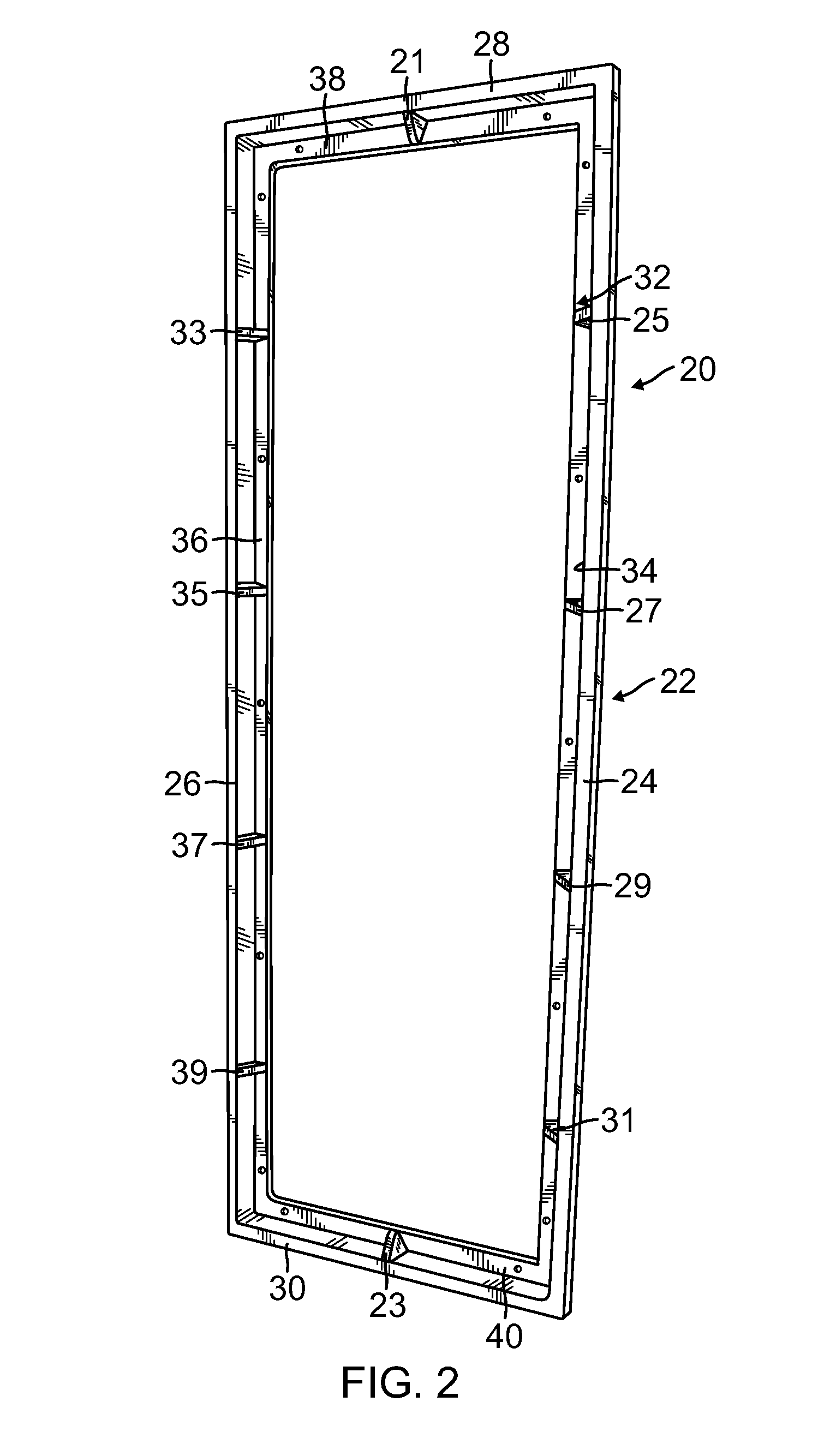

Cost effective method for manufacturing retainers and inserts incorporated into a garage door panel

InactiveUS8756897B1Saving wasting interior vacuum formed materialWaste of materialBuilding repairsBuilding material handlingGlass sheetForming processes

A method for forming garage door components, the method including: (a) vacuum forming a combination of a retainer combined with the formation of a decorative insert vacuum formed within the retainer, the decorative insert removed from the retainer to provide a separate retainer and a separate decorative insert, by forming them together, the interior of the vacuum formed piece is used as the decorative insert instead of being thrown away as in prior art vacuum forming processes thereby saving wasting the interior vacuum formed material. There is also a garage door panel including an interior retainer retaining a glass plate on its rear surface, and inserted into an opening in a garage door panel and a window frame inserted into the garage door panel on its opposite side to retain the glass plate by its front surface. A decorative insert is retained between the glass plate and the window frame.

Owner:KELLEY ROBERT A

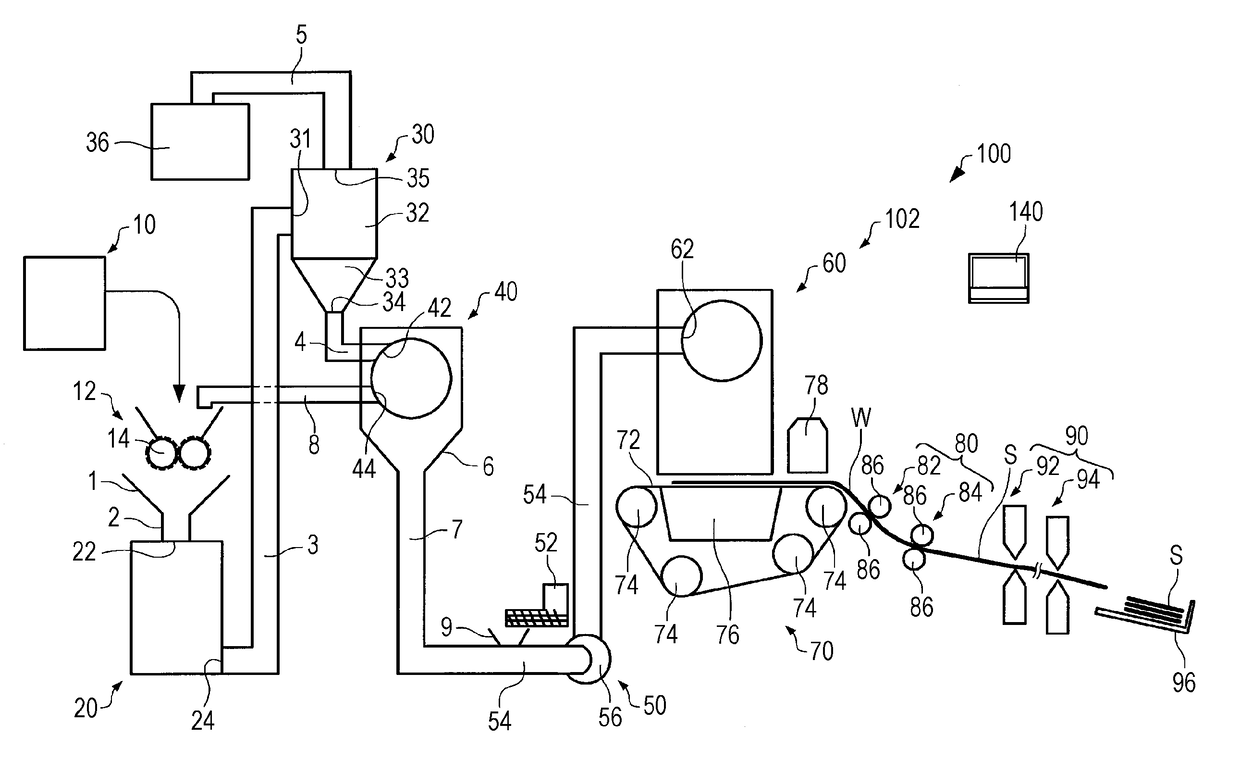

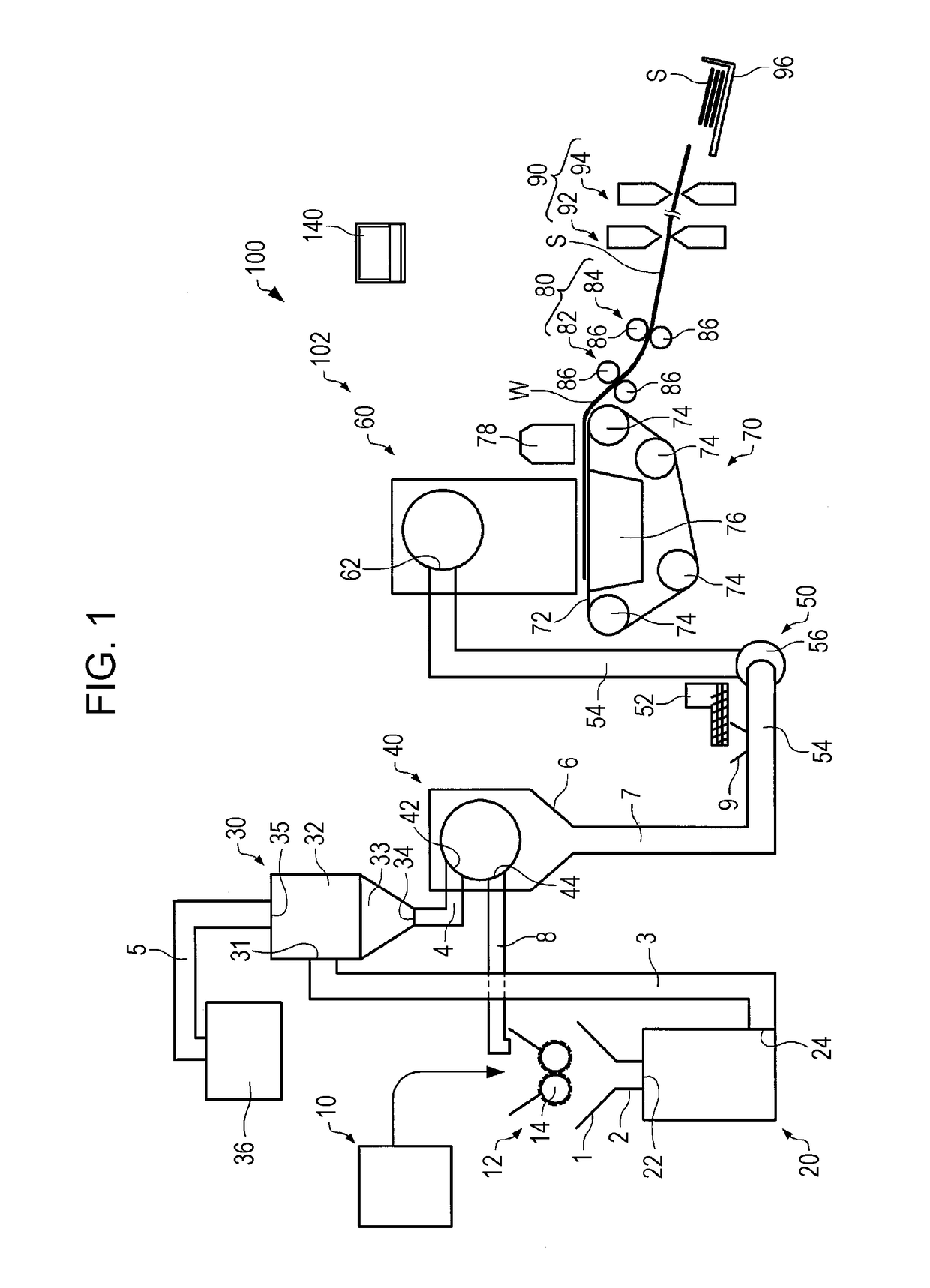

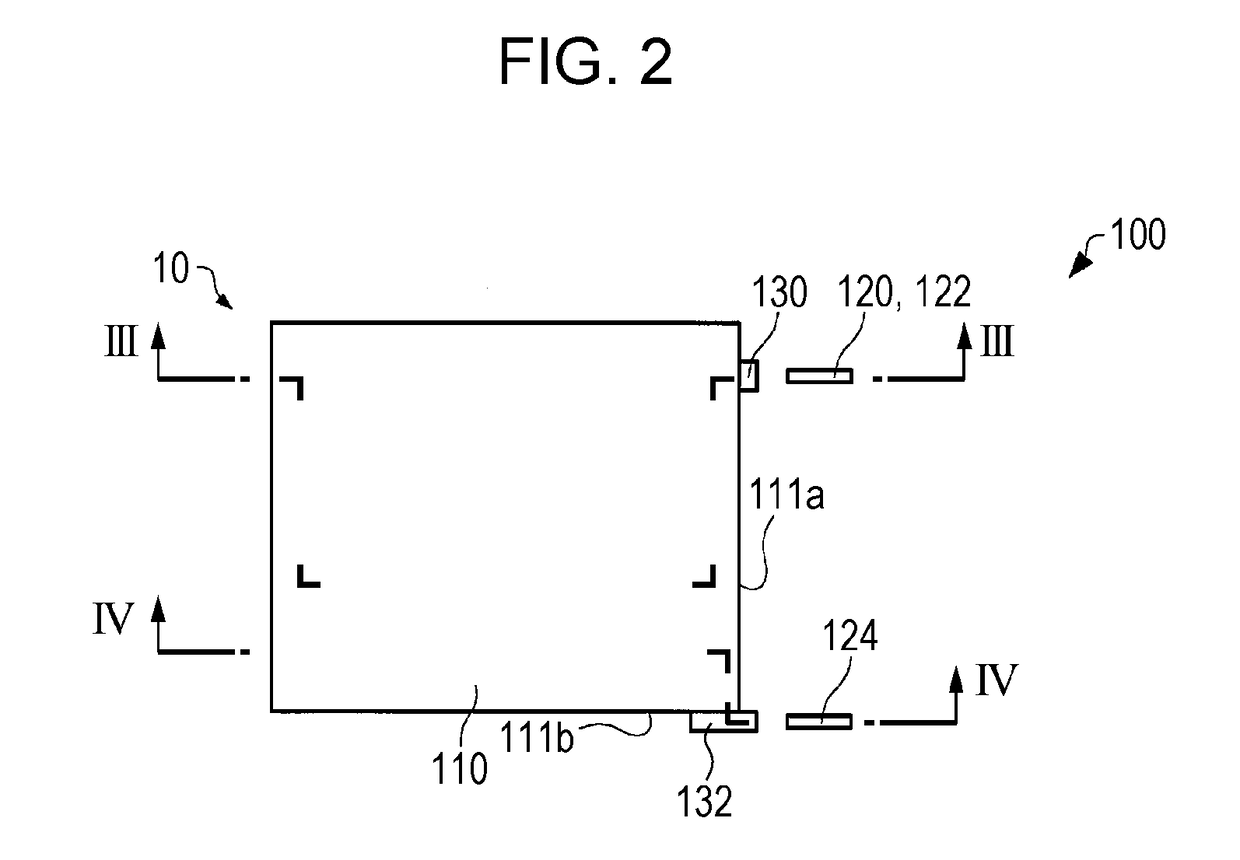

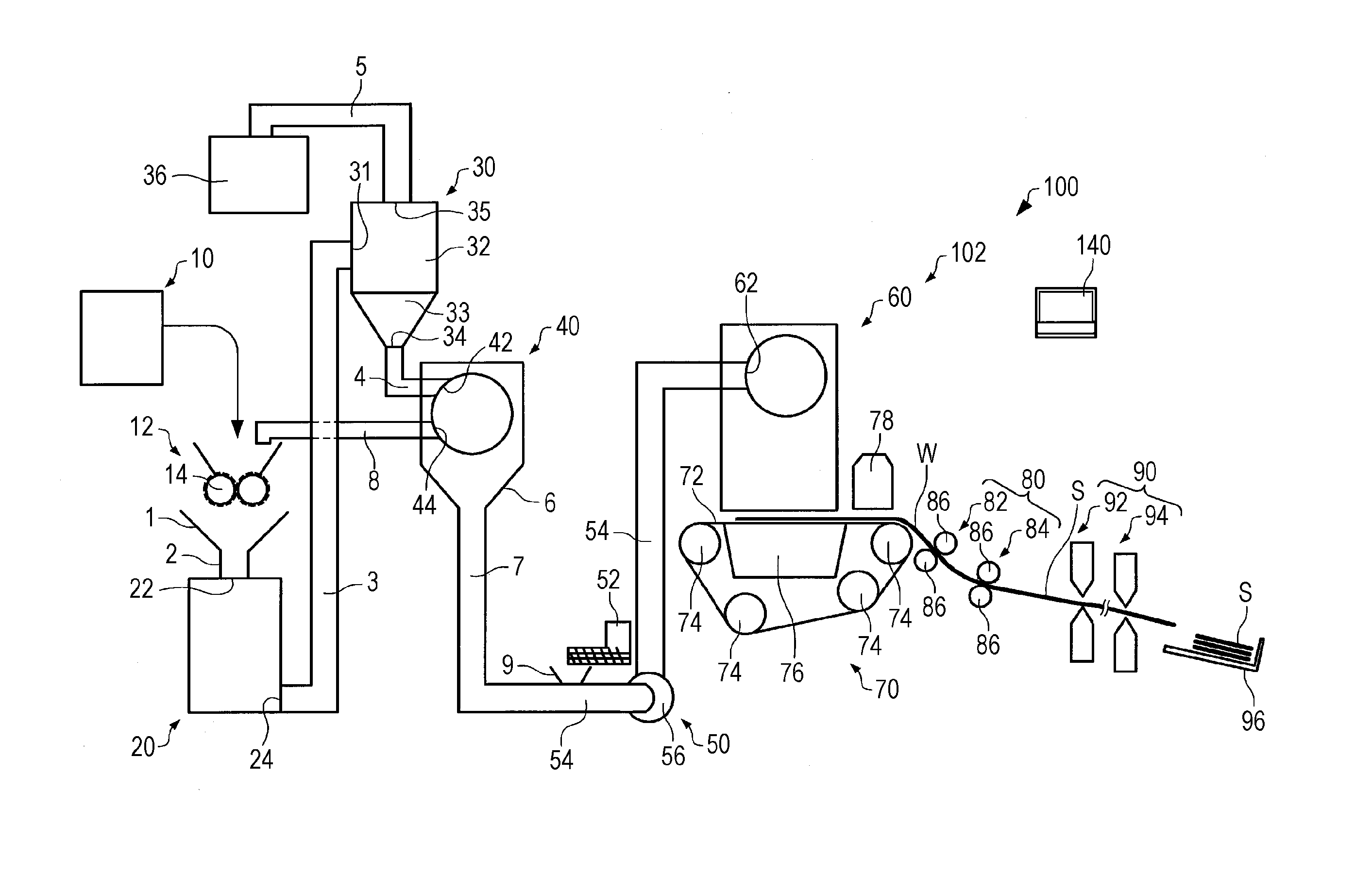

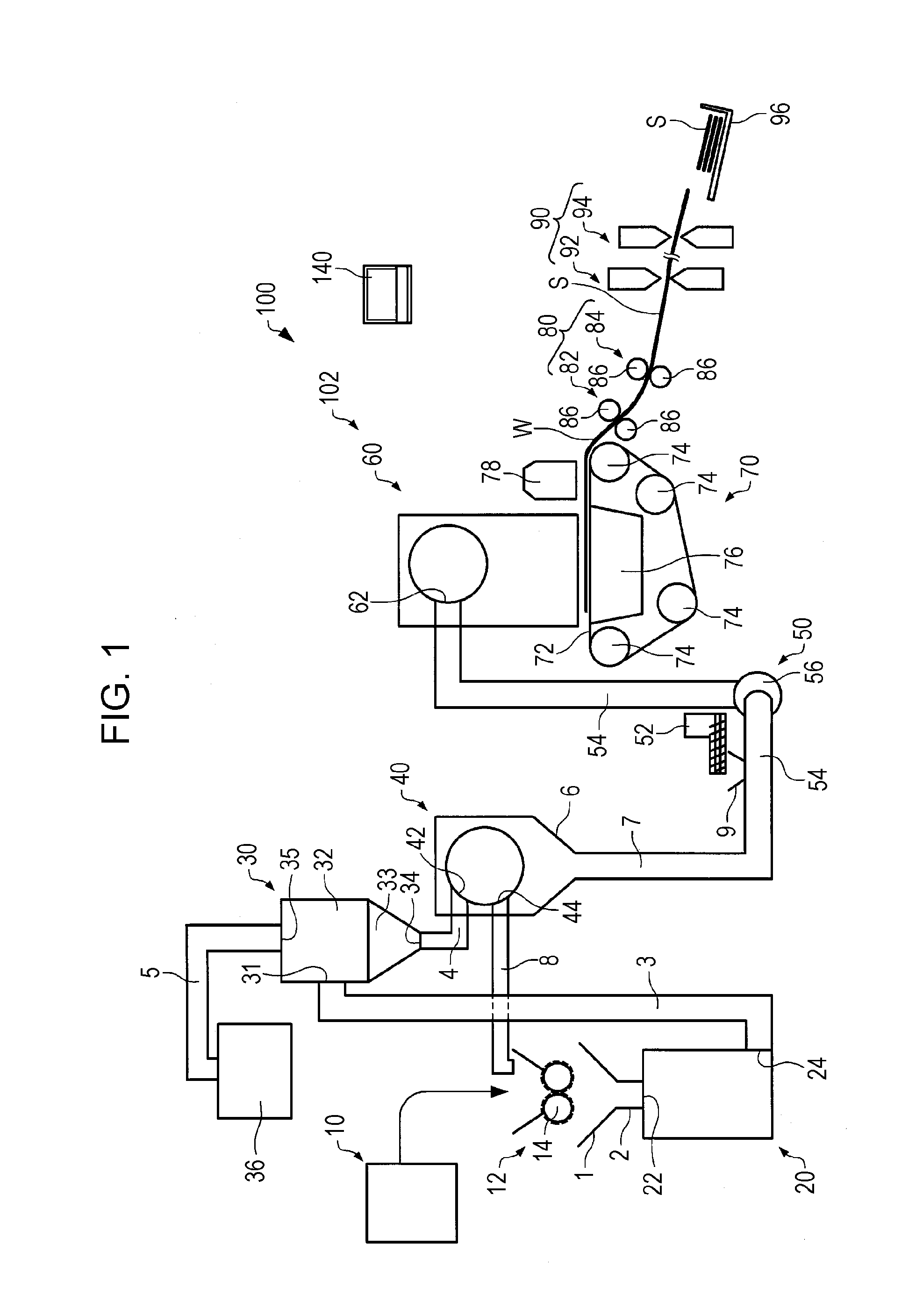

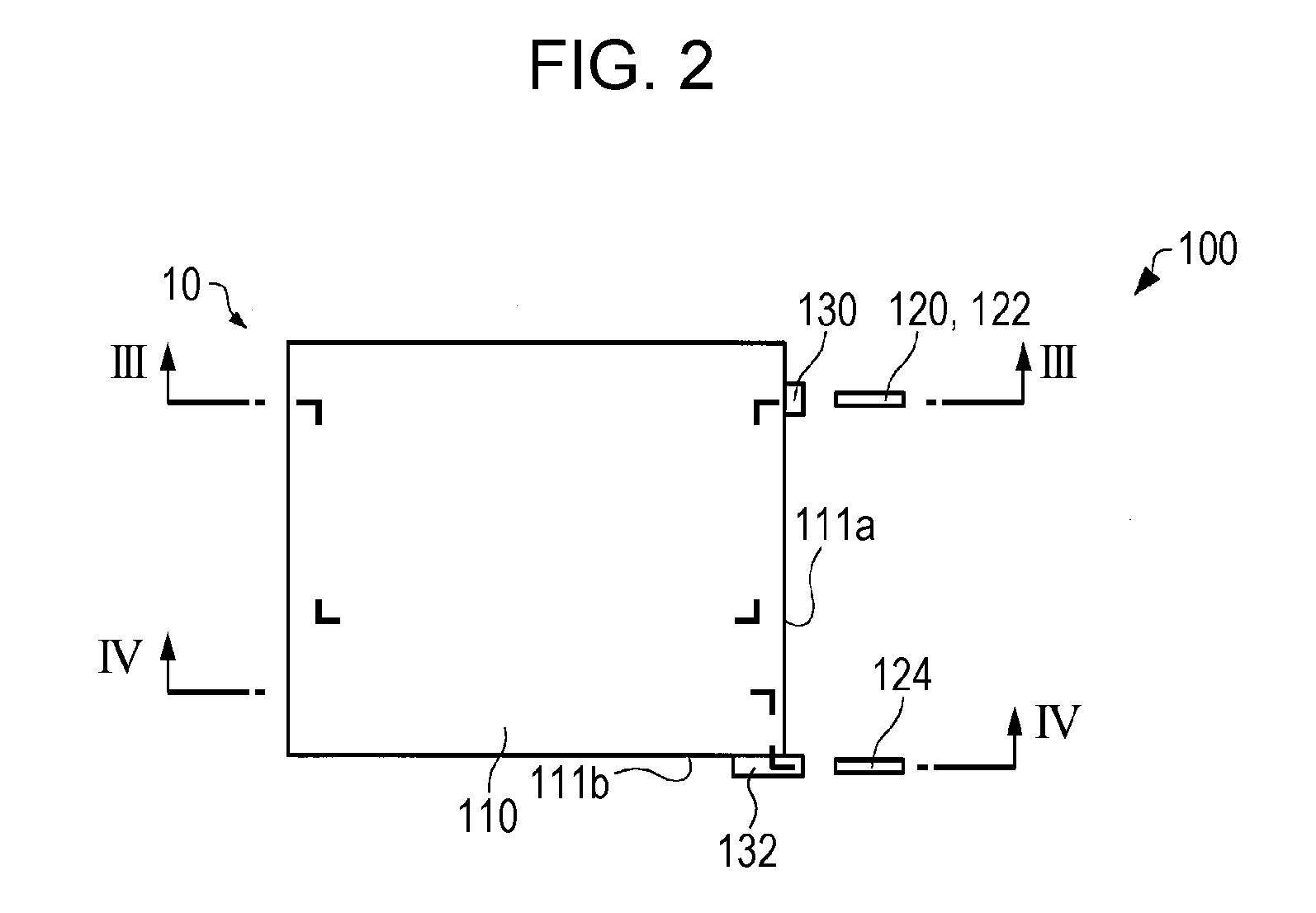

Sheet manufacturing apparatus and sheet manufacturing method

ActiveUS9920478B2Desired characteristicWaste of materialNon-woven fabricsPaper-making machinesManufactured apparatusManufacturing cell

Owner:SEIKO EPSON CORP

Central processing unit socket assembly

InactiveUS20140199860A1Waste of materialLive contact access preventionComponent plug-in assemblagesEngineeringMechanical engineering

A central processing unit socket assembly includes a socket mounted on a circuit board, a locking apparatus, and a cover. The cover includes a main plate, a resilient first locking portion formed on a first end of a first surface of the main plate, a second locking portion formed on a second end of the first surface of the main plate opposite to the first locking portion, and a number of connecting pins protruding out from a second surface of the main plate opposite to the first surface of the main plate. The first and second locking portion of the first surface of the cover can be detachably latched to the socket. The connecting pins can be connected on the locking apparatus.

Owner:SCIENBIZIP CONSULTINGSHENZHENCO

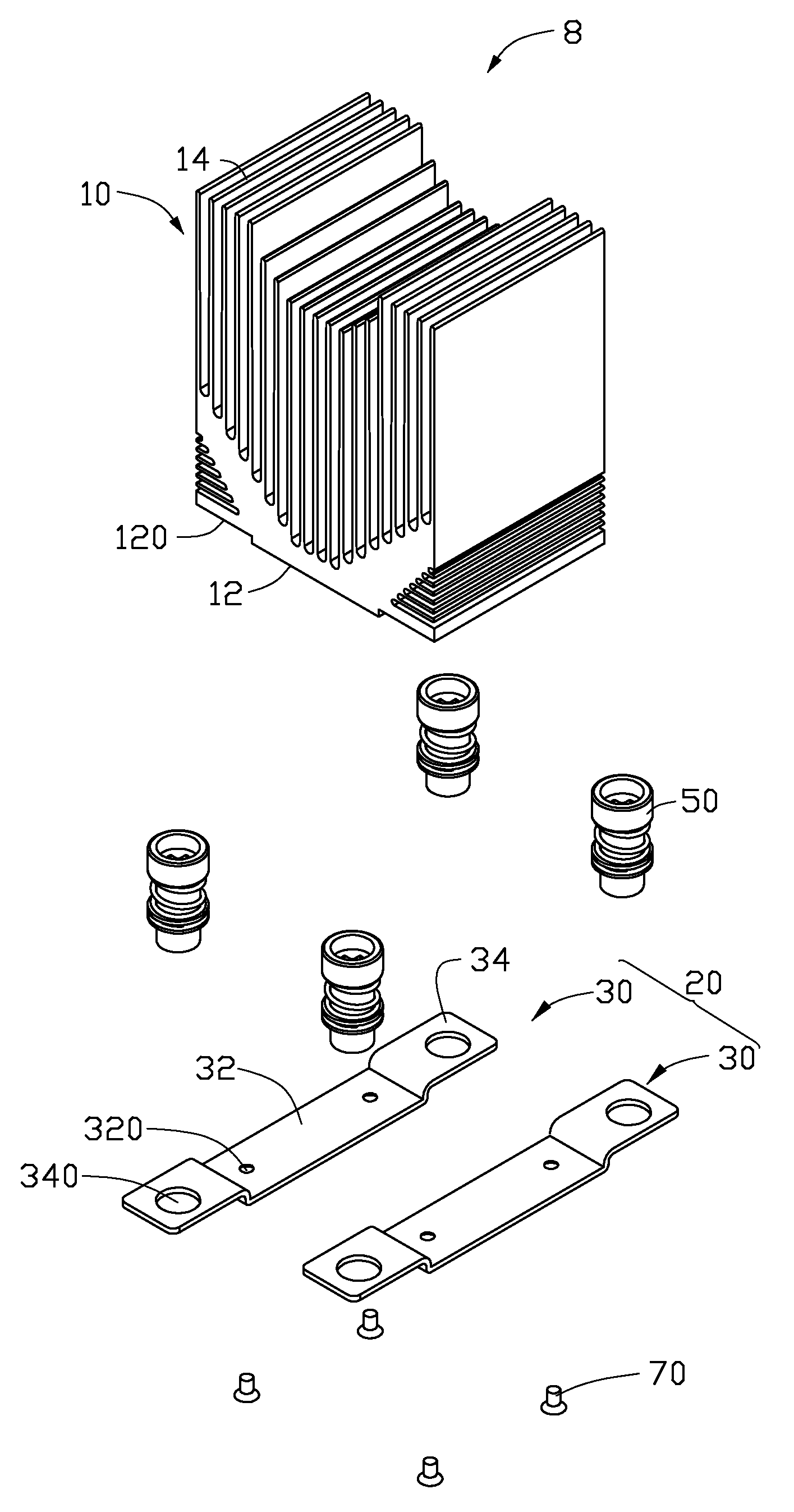

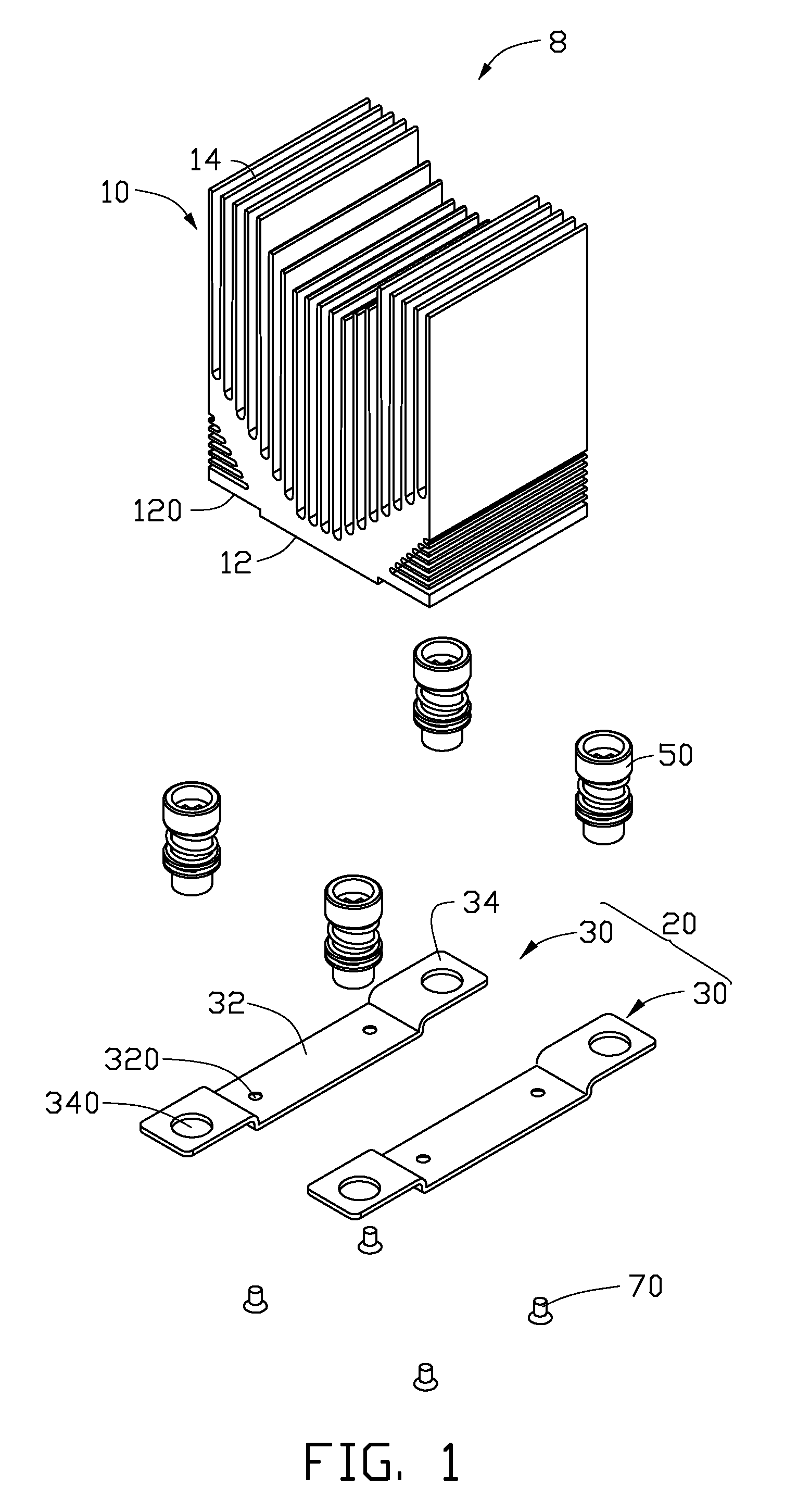

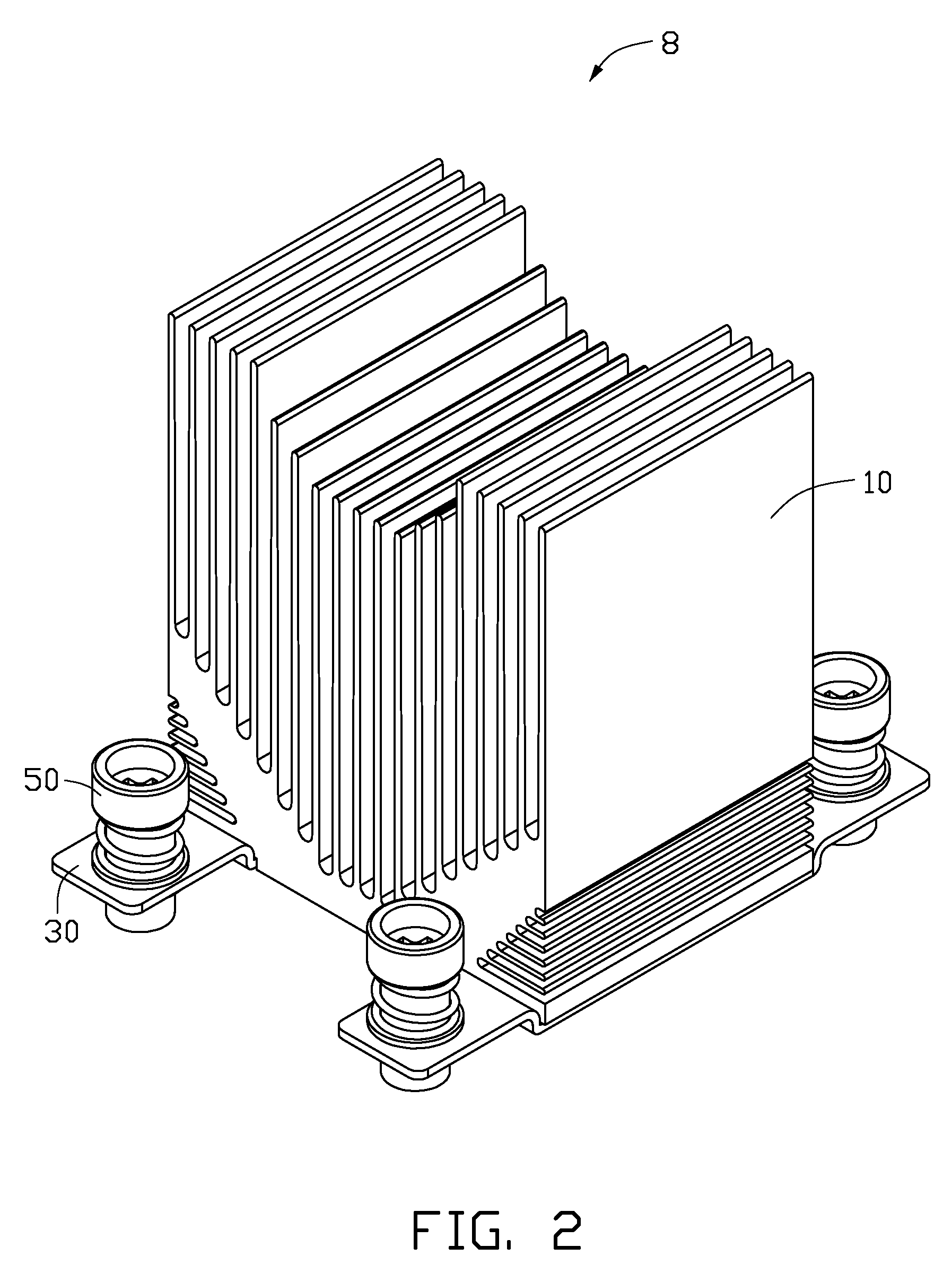

Heat sink

InactiveUS20100259900A1Waste of materialSnap fastenersDigital data processing detailsHeat spreaderFastener

A heat sink includes a cooling member to dissipate heat, and a fixing member for mounting fasteners. The cooling member includes a base and a number of fins extending from the base. The cooling member and the fixing member are independently formed, and the fixing member is fixed to a bottom of the base of the cooling member via fixing means.

Owner:HON HAI PRECISION IND CO LTD

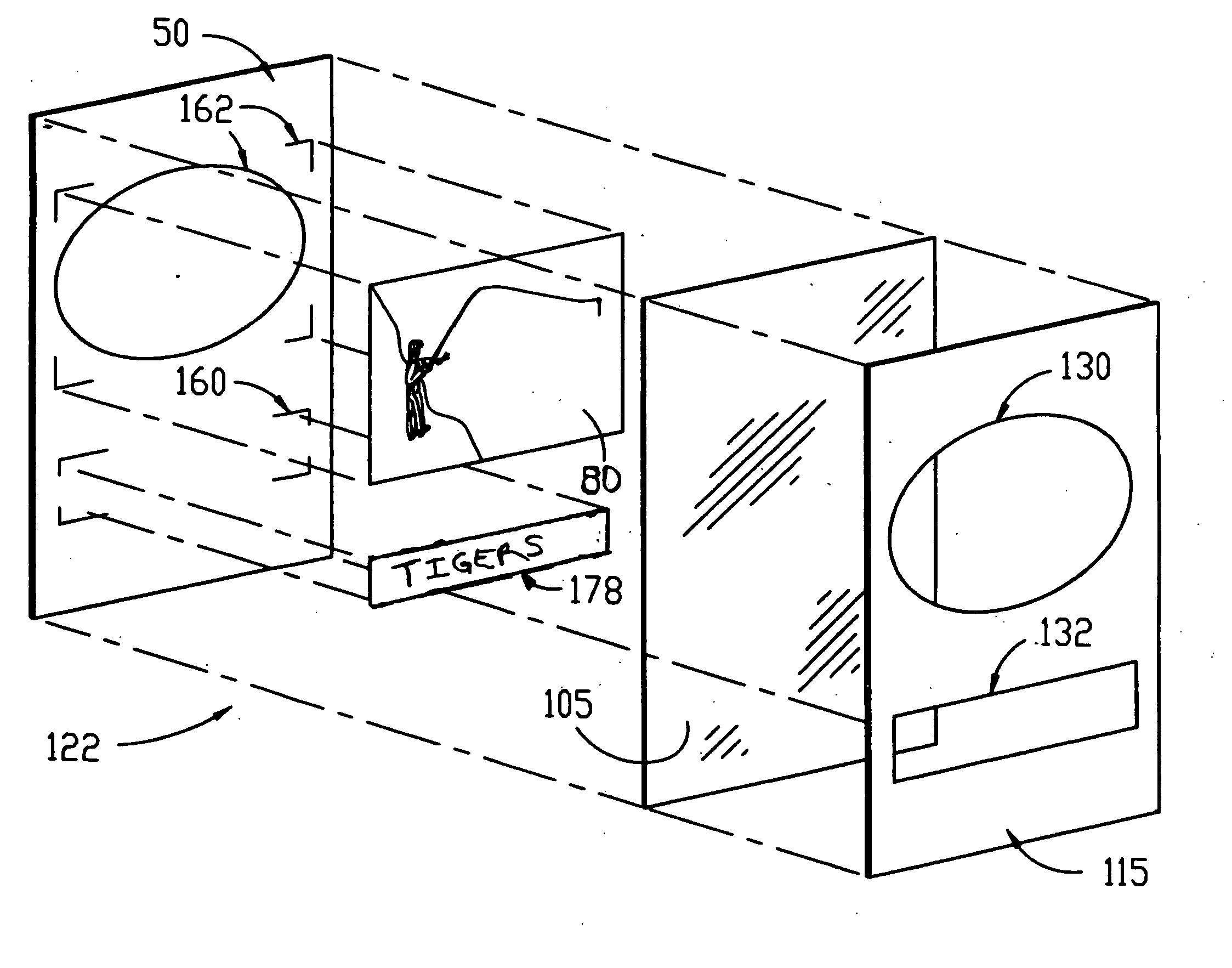

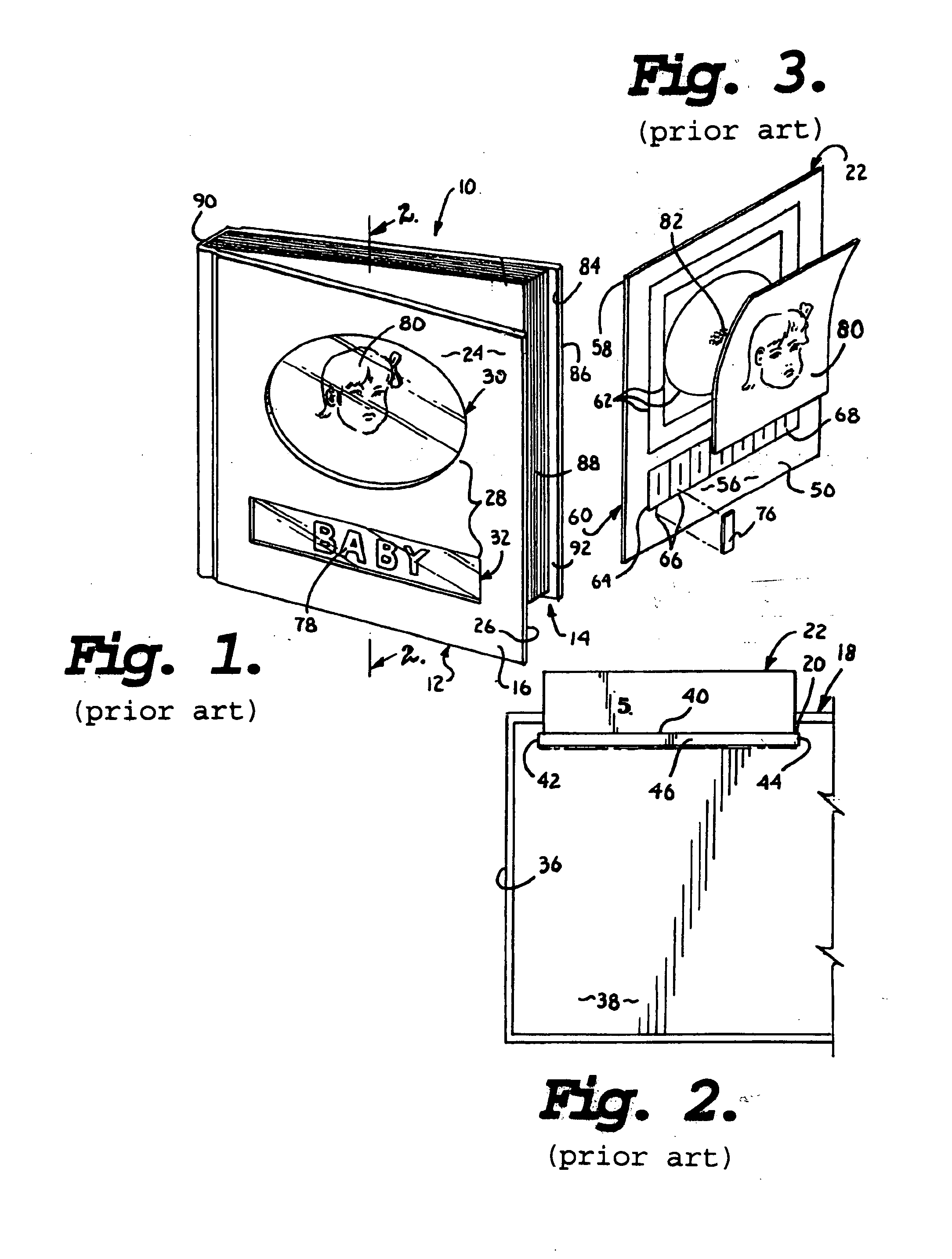

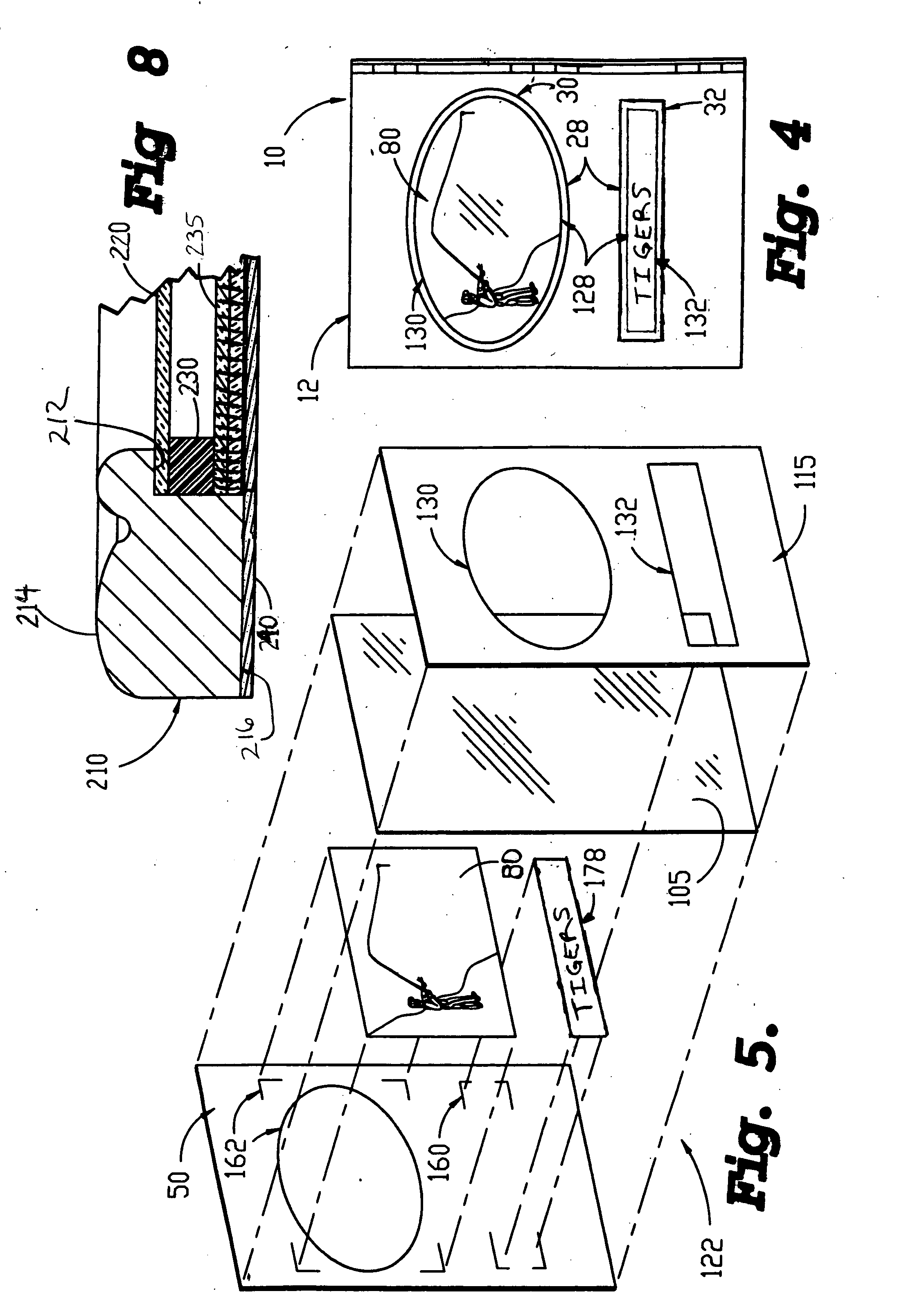

Customizable storage and display systems

InactiveUS20050000137A1Eliminates any wasted materialShorten assembly timePicture framesDomestic mirrorsGraphicsDisplay device

A custom display storage system includes storage and display assemblies. One embodiment of the storage assembly includes an album or scrapbook containing pages for mounting graphic works and other generally planar objects. An embodiment of the display assembly includes a display unit joined at the edges with a backing to form a pocket. The display unit includes openings for display of character strings and / or graphic images. The backing includes a slot, hinge, or some other opening system to provide access to the pocket. A customizable insert assembly for insertion into the pocket includes a base sheet having guidelines for mounting images and / or character strings; a clear synthetic resin sheet; and a mat including cut outs aligned with the guidelines of the base sheet. An alternative embodiment of the system includes a container for storing three dimensional items as well as graphic works. The custom display storage system may also comprise a kit with a selection of character units, multiple variations of mats (i.e. color, thickness, cut-out sizes, etc.) and an album or storage container with a variety of display units. Another embodiment of the display system of the instant invention is provided that allows for the display of a either three dimensional or two dimensional items, or combinations of the same. The display system includes a frame, a display glass, an injection molded spacer, and a backing. The spacer provides spacing between the display glass and the backing to accommodate three dimensional items and / or to provide a three dimensional look to the display.

Owner:THE BANK OF NEW YORK MELLON AS ADMINISTATIVE AGENT +1

Sheet manufacturing apparatus and sheet manufacturing method

ActiveUS20160069023A1Desired characteristicWaste of materialLamination ancillary operationsLaminationManufactured apparatusManufacturing cell

Owner:SEIKO EPSON CORP

Photovoltaic array system, photovoltaic device thereof, and frame element of photovoltaic device thereof

ActiveUS8806814B2Easy be bentAvoid deformationPhotovoltaic supportsSolar heating energyPhotovoltaics

Owner:AU OPTRONICS CORP

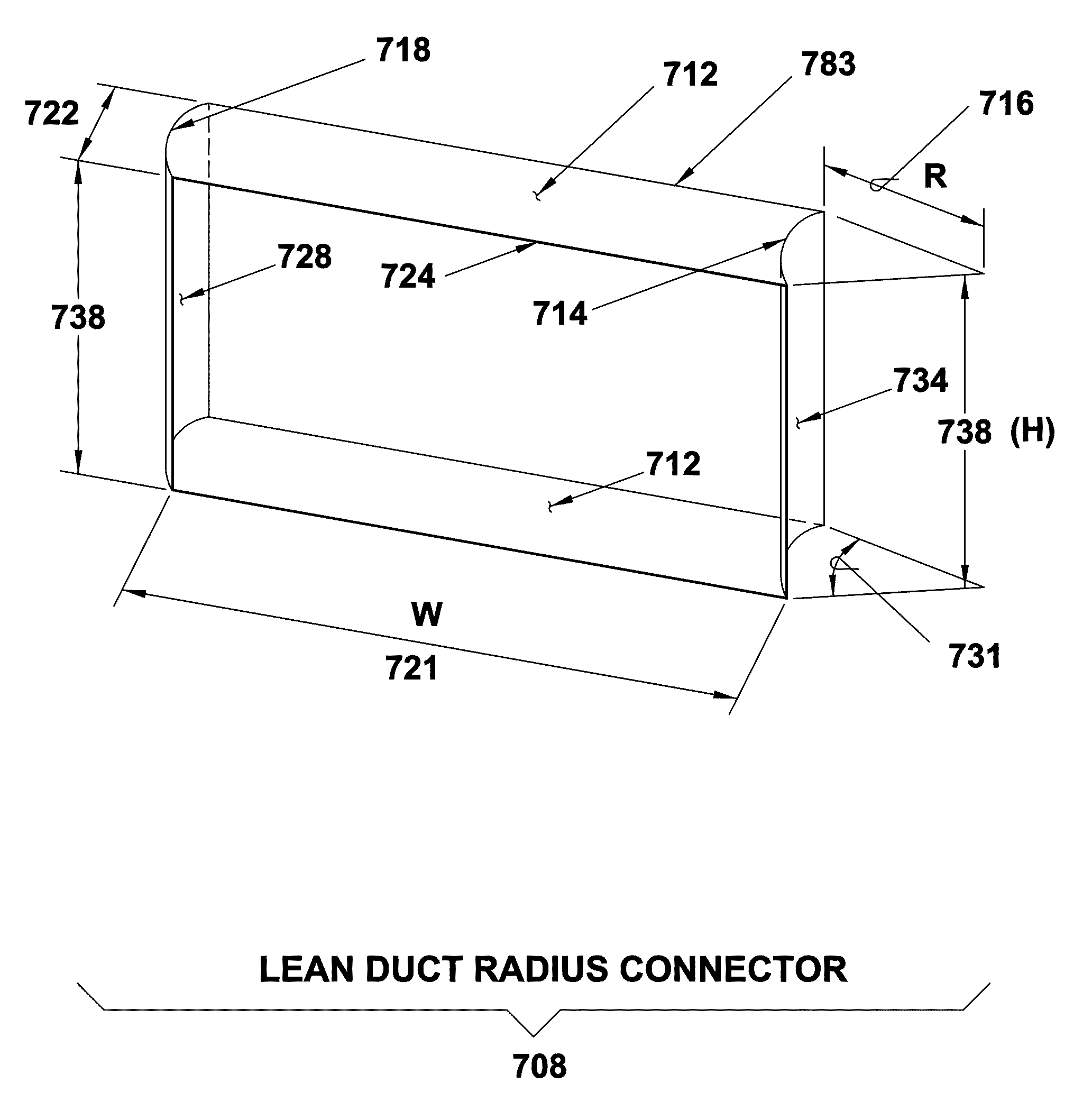

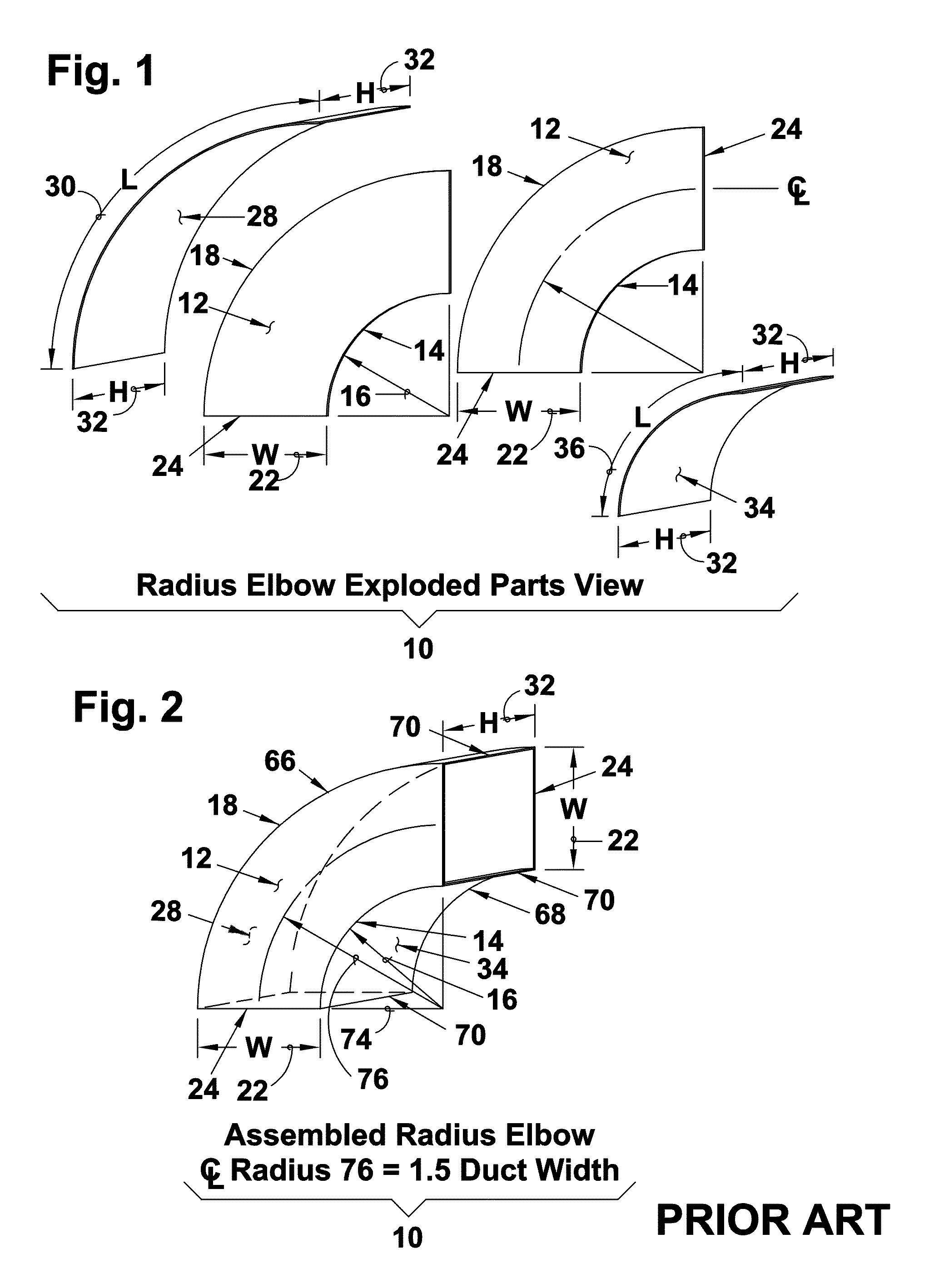

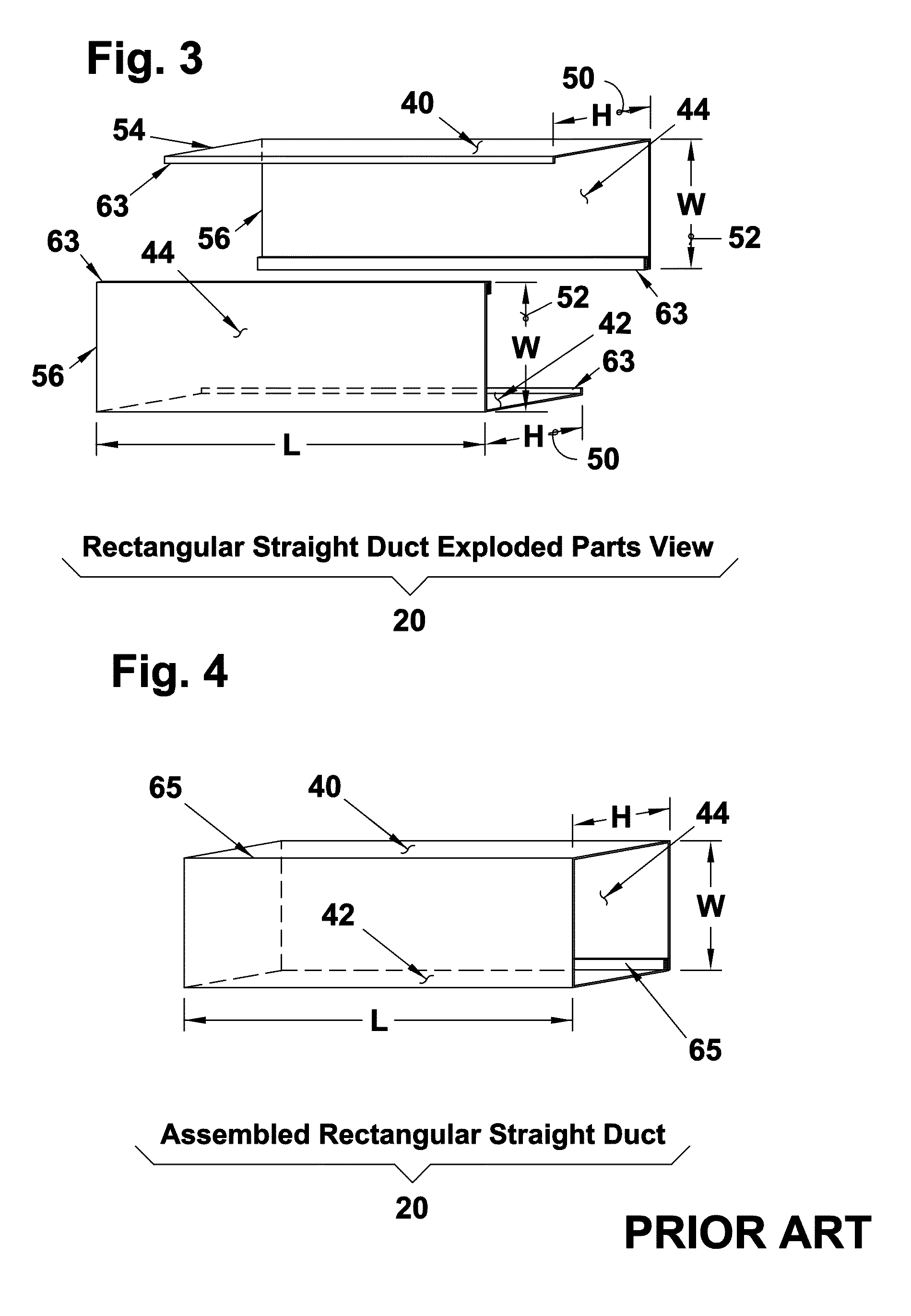

Lean duct fabrication

Segmented ductwork fittings shaped to minimize waste and labor while retaining the performance characteristics of traditional radius fittings. Lean Duct fittings utilize both curved sections and straight tubular sections at an angle to one another to provide a predetermined change in the direction or location of fluid flow through the finished duct system.

Owner:SANTELER LESLIE EDWARD

Control cable

InactiveUS20110226081A1Degree of freedom of shape of be improveWaste of materialShaft for linear movementElectrical and Electronics engineering

Owner:CHUO SPRING

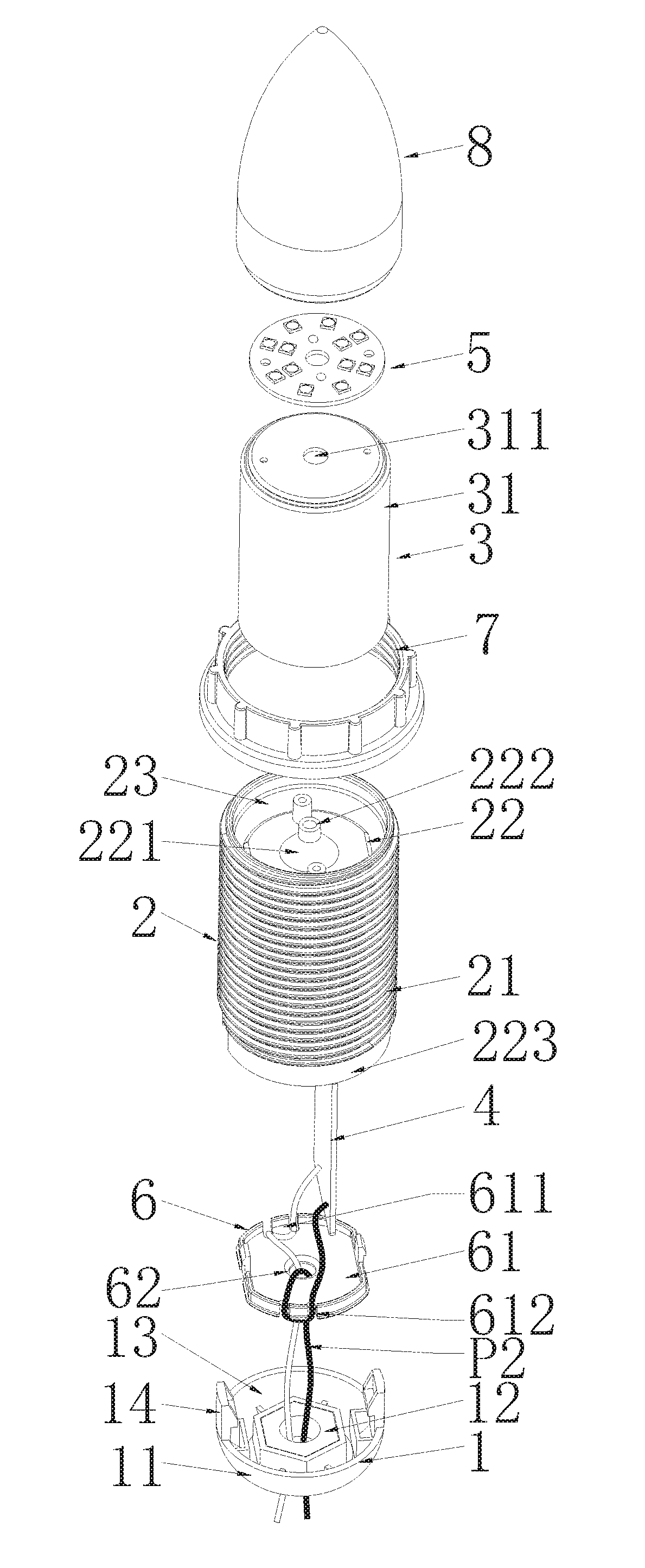

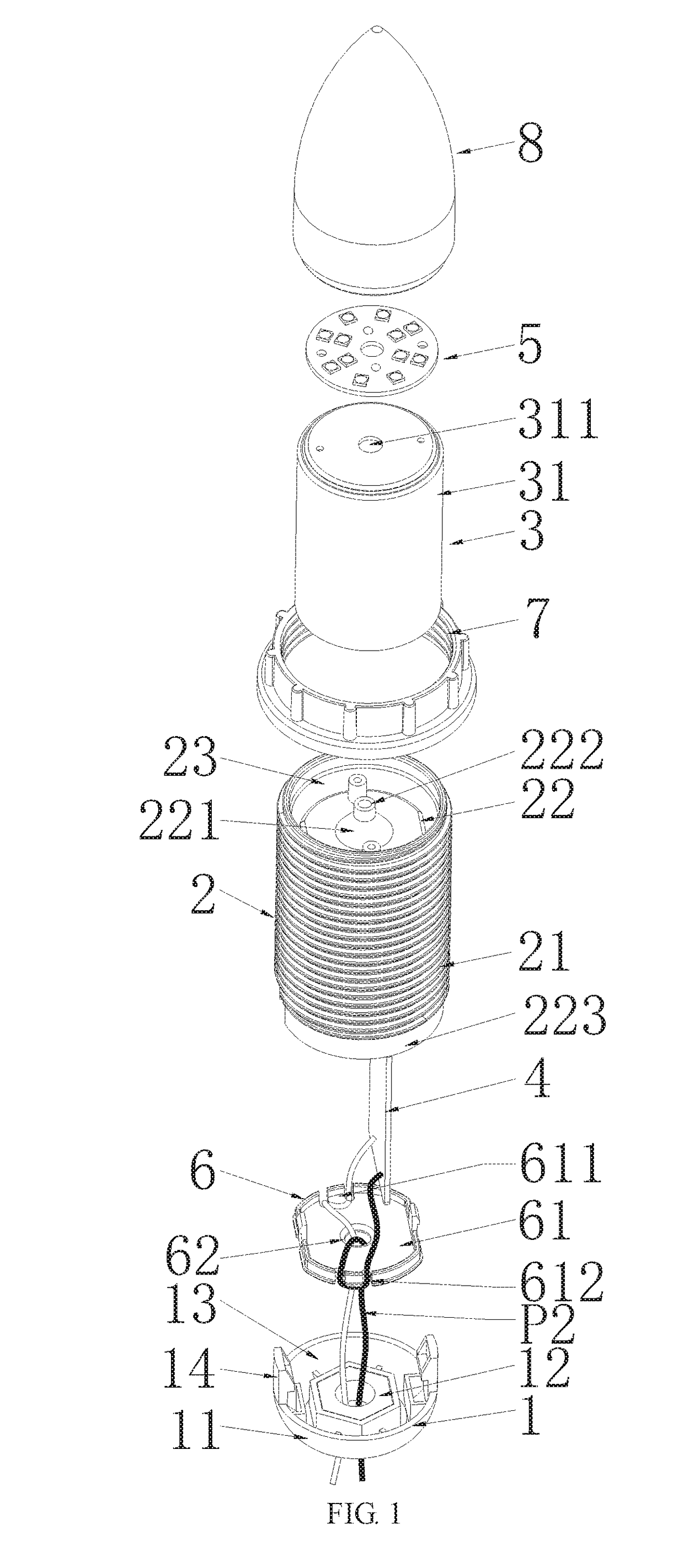

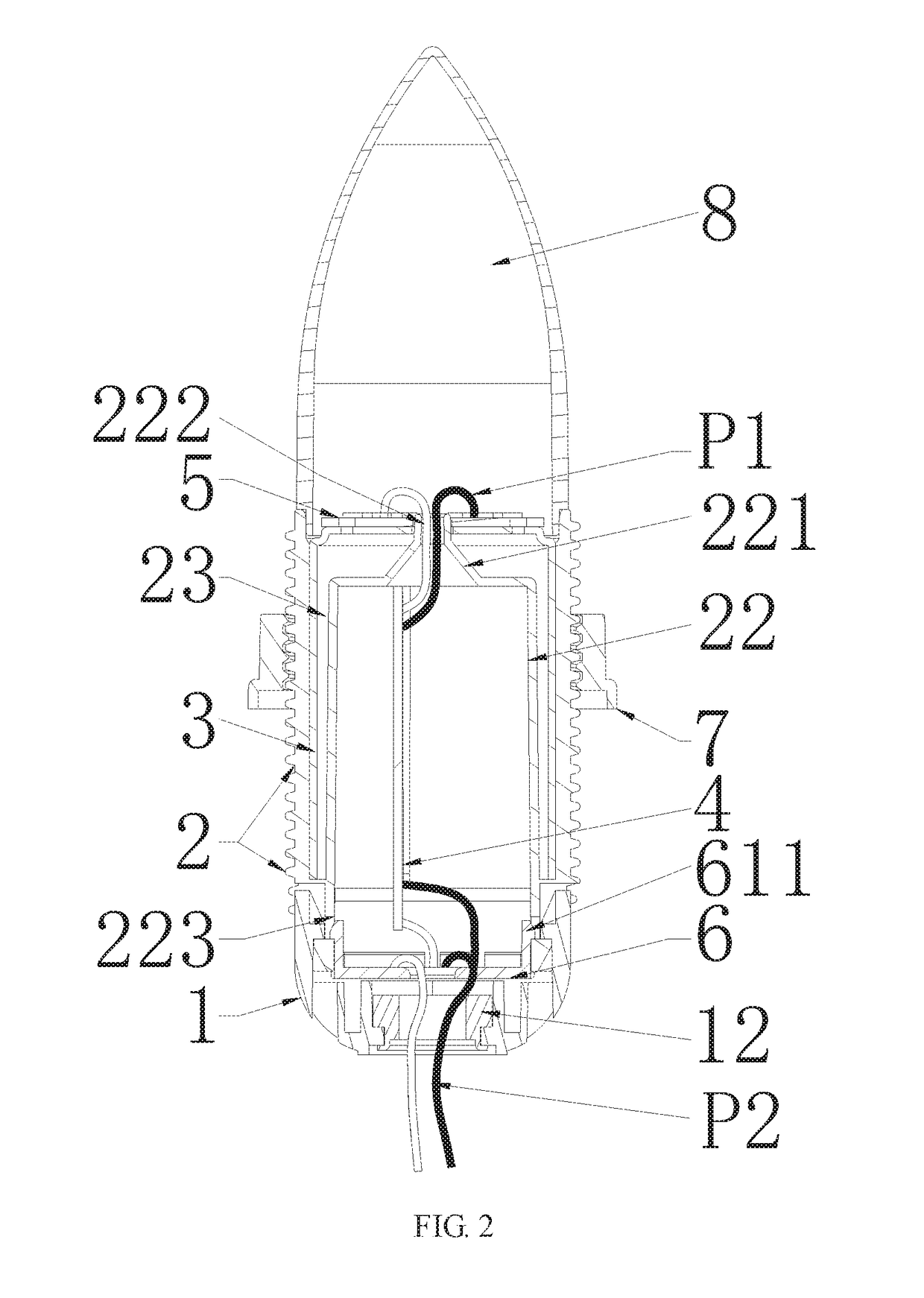

Decorative glass light and assembly method thereof

ActiveUS20180128473A1High light efficiencyLow light efficiencyCoupling device connectionsPlanar light sourcesEngineering

Owner:MOON SANG PIL

Method and Apparatus for Producing Off-Axis Composite Prepreg Material

InactiveUS20110041988A1Improve productivityEfficiently and cheaply producesLamination ancillary operationsLaminationEngineeringFiber orientation

The embodiments are directed to a method and apparatus for preferably producing a two layer off-axis composite prepreg material in tape form that has fiber direction at angles such as plus or minus five degrees to the longitudinal direction of the backing paper. The use of such off-axis prepreg composite material tape is primarily for fabricating high length-to-width ration parts such as composite wing stringers or spars for aircraft.

Owner:THE BOEING CO

Ultrasonic sensing apparatus

ActiveUS20200393413A1Convenient be detachedConvenient be changedAnalysing fluids using sonic/ultrasonic/infrasonic wavesMachines/enginesEngineeringMechanical engineering

An ultrasonic sensing apparatus includes an accommodating shell and at least one detection device. The accommodating shell includes a base and a convex portion connected to the base. A side of the base has a first detection opening toward a first direction, and a side of the convex portion has a second detection opening toward a second direction. Each of the at least one detection device is disposed in the base or the convex portion of the accommodating shell and includes a board, a piezoelectric assembly, a housing and a plurality of fixing members. The plurality of fixing members are configured to fix the board on the top wall of the housing to press the board to the encapsulating body of the piezoelectric assembly, thereby pressing the piezoelectric sheet to the bottom wall.

Owner:QIAN JUN TECH LTD

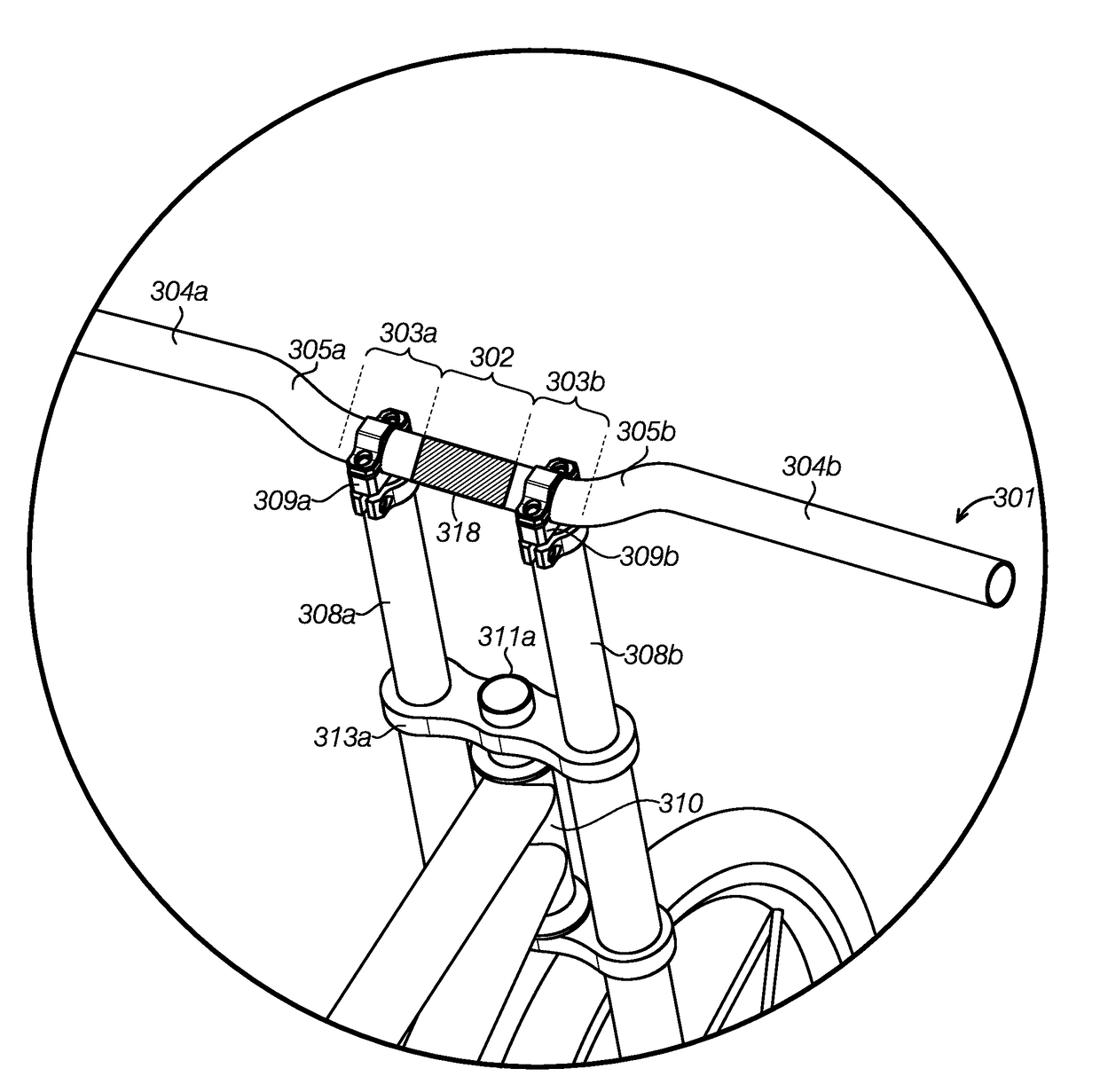

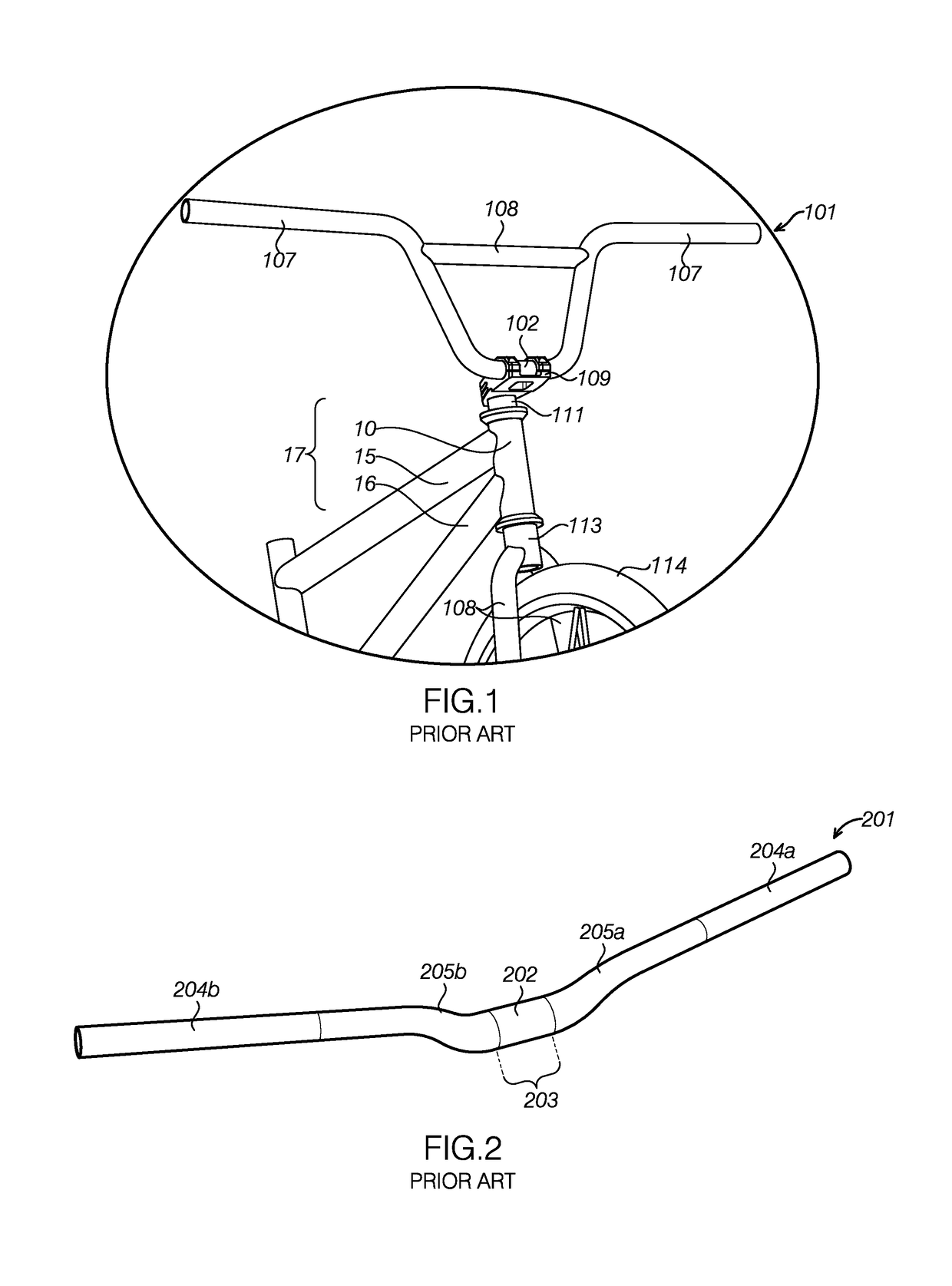

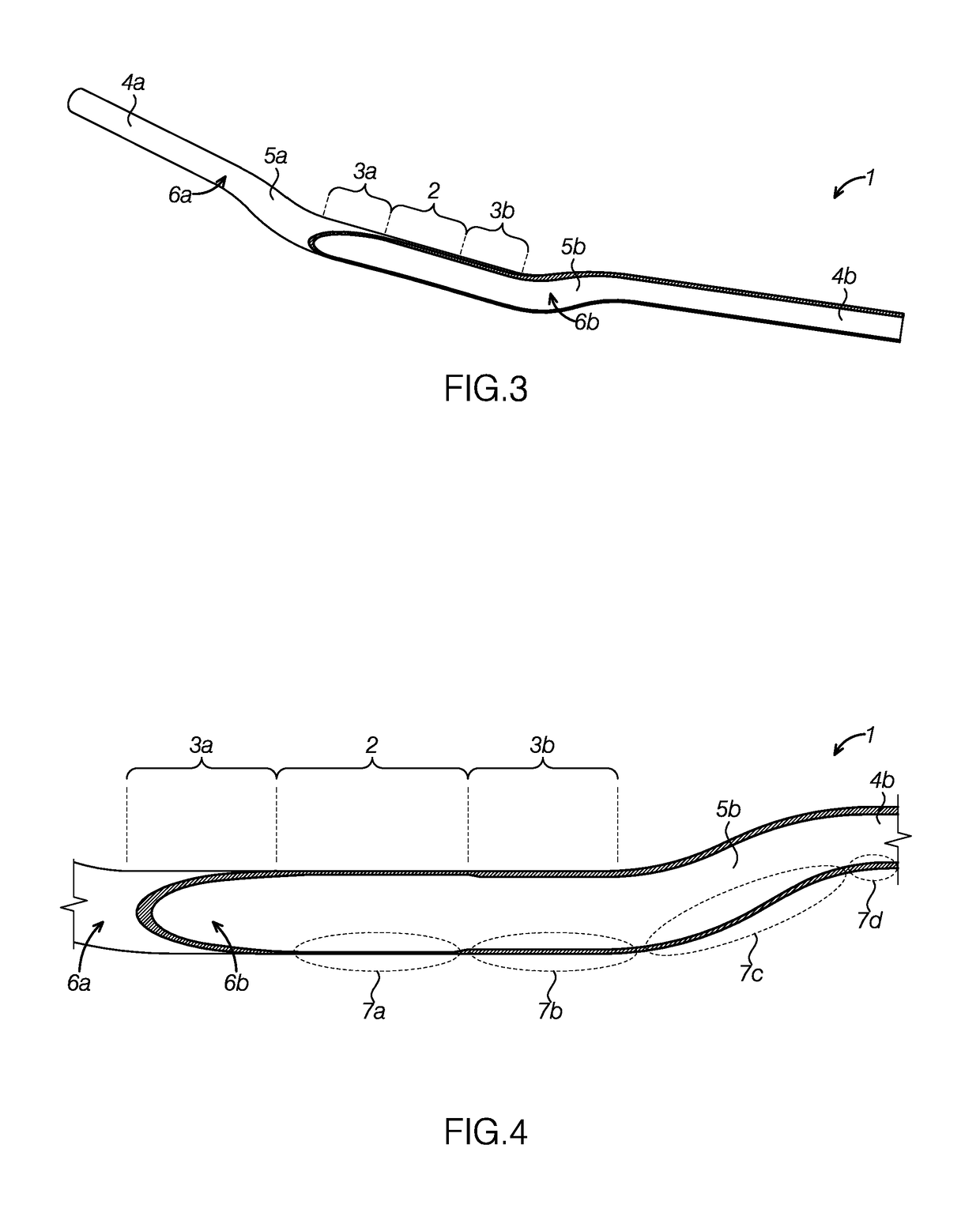

Bicycle handlebar

ActiveUS20170106933A1Reduce weightPreserving rigiditySteering deviceEngineeringUltimate tensile strength

Owner:MARUI SHINJI

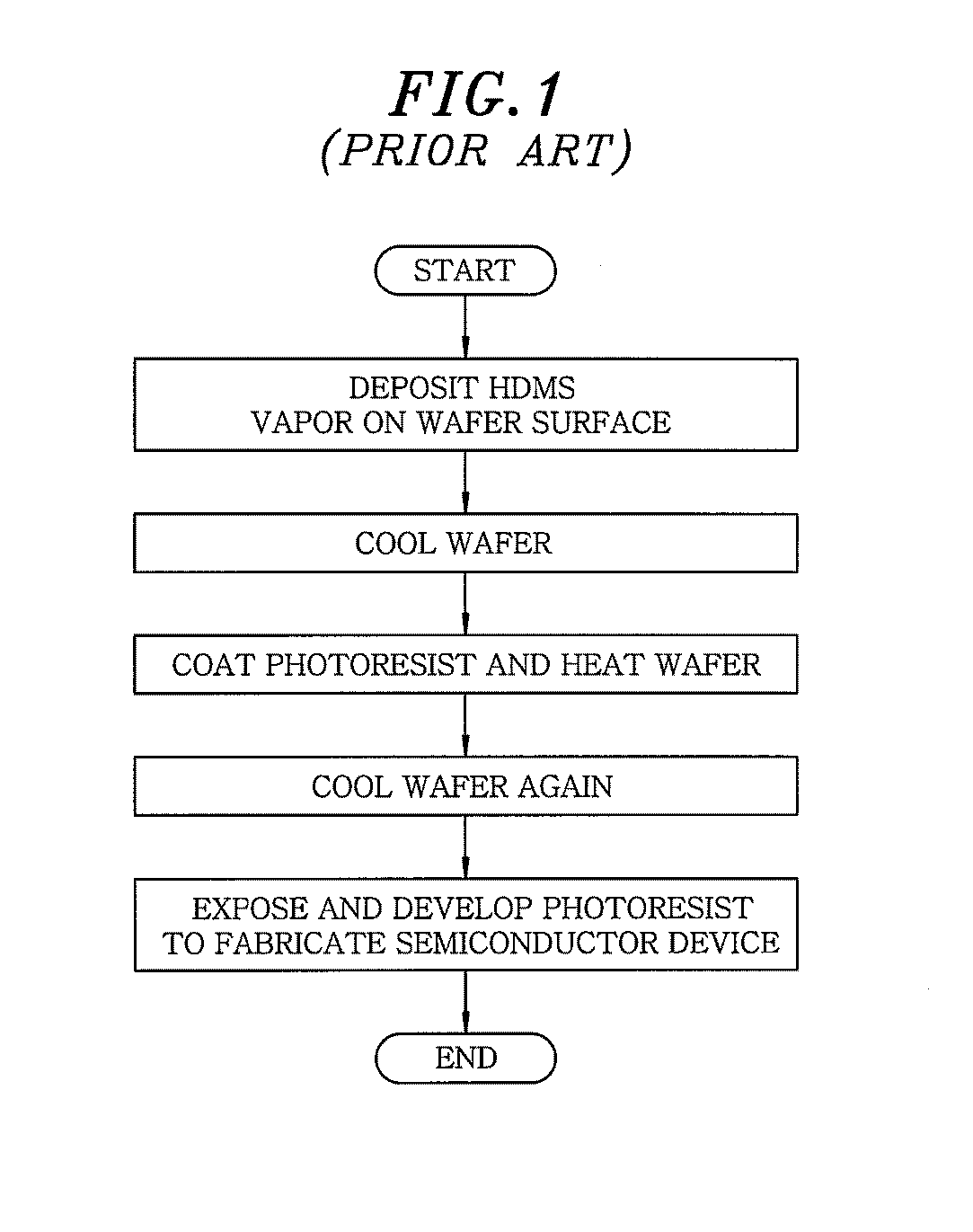

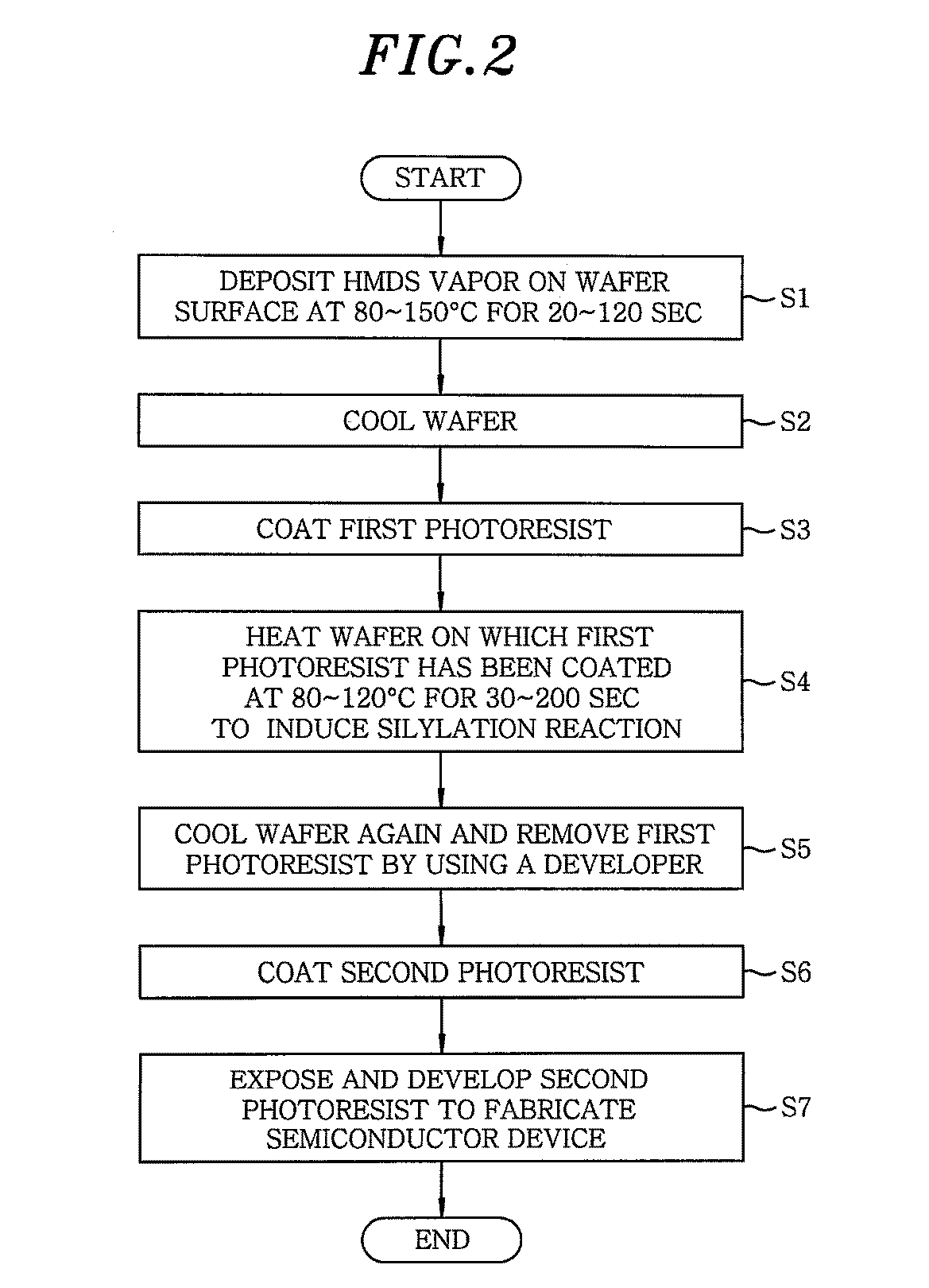

Method of fabricating semiconductor device

InactiveUS20080090180A1Shorten the timeImprove productivitySemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusProduction rateDevice material

A semiconductor fabrication method may include depositing hexamethyldisilazane (HMDS) on a wafer surface, cooling the wafer and coating the wafer surface with a first photoresist, heating the wafer on which the first photoresist has been coated to induce a silylation reaction, cooling the wafer, and developing and removing the first photoresist. Adhesion between the wafer's surface and a subsequently applied photoresist may thus be enhanced. Accordingly, manufacturing time can be saved and productivity can be improved by simplifying the fabrication process and preventing waste of materials.

Owner:DONGBU HITEK CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com